check engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 755 of 1449

ENGINE ELECTRICAL -Starting System16-23

REASSEMBLY SERVICE POINT

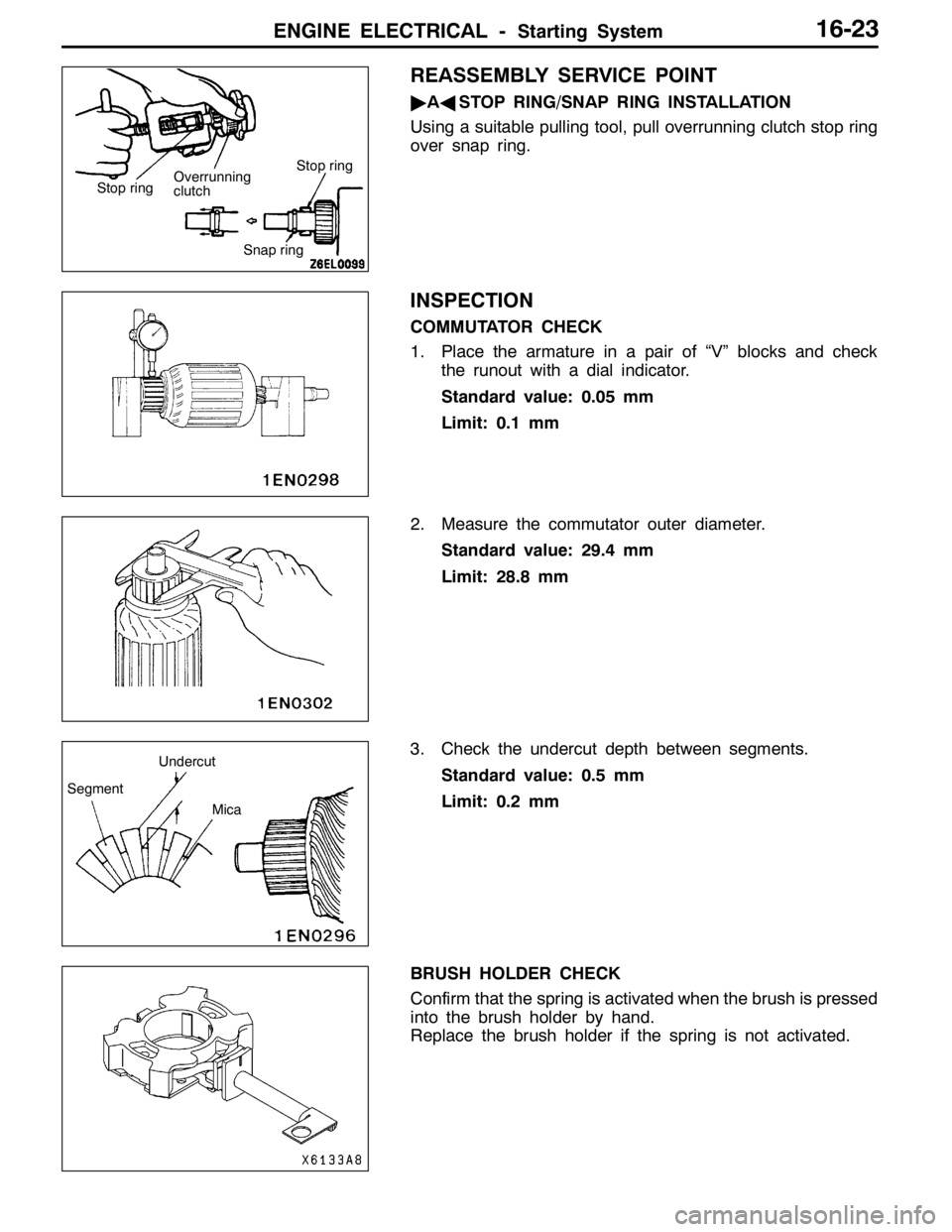

"AASTOP RING/SNAP RING INSTALLATION

Using a suitable pulling tool, pull overrunning clutch stop ring

over snap ring.

INSPECTION

COMMUTATOR CHECK

1. Place the armature in a pair of “V” blocks and check

the runout with a dial indicator.

Standard value: 0.05 mm

Limit: 0.1 mm

2. Measure the commutator outer diameter.

Standard value: 29.4 mm

Limit: 28.8 mm

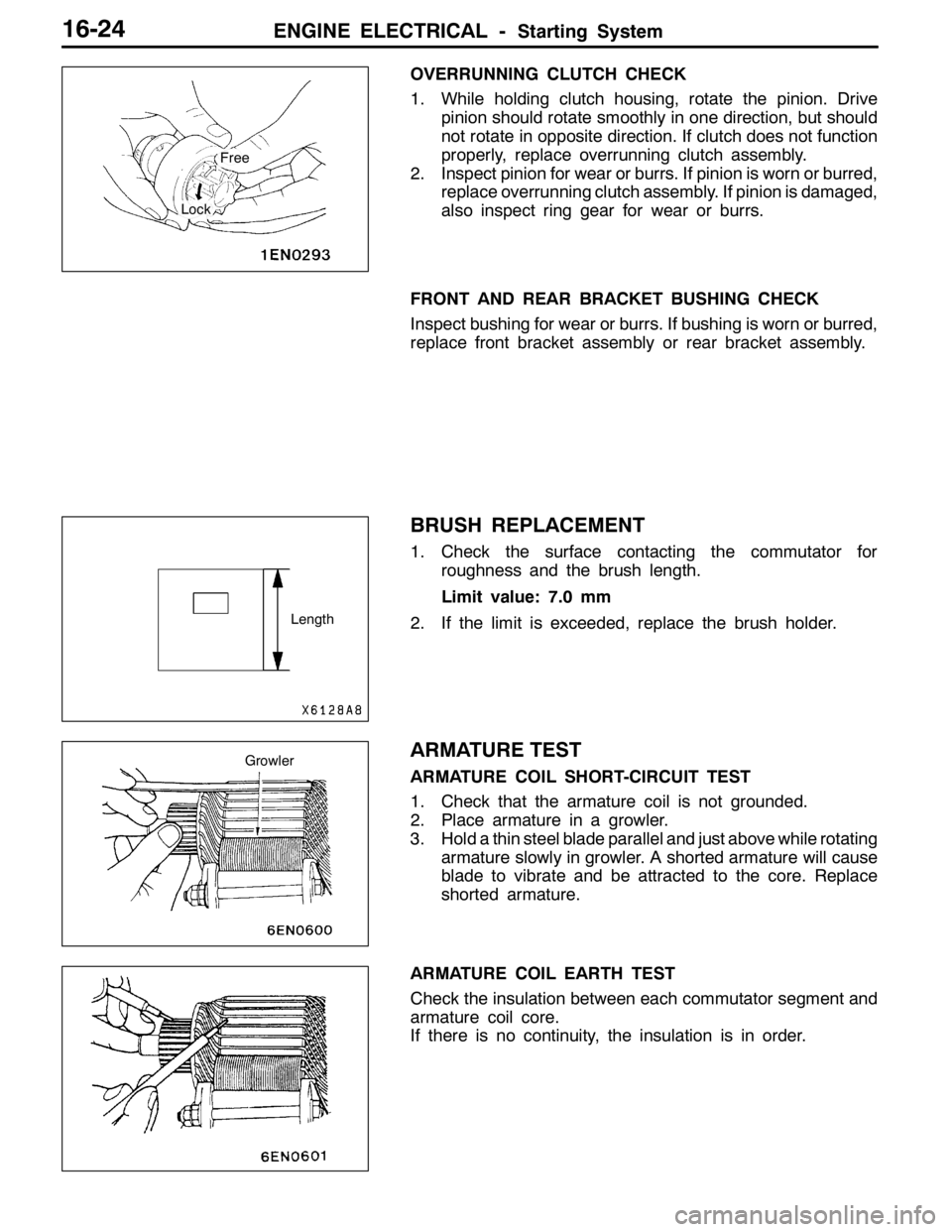

3. Check the undercut depth between segments.

Standard value: 0.5 mm

Limit: 0.2 mm

BRUSH HOLDER CHECK

Confirm that the spring is activated when the brush is pressed

into the brush holder by hand.

Replace the brush holder if the spring is not activated.

Stop ringOverrunning

clutchStop ring

Snap ring

Undercut

Segment

Mica

Page 756 of 1449

ENGINE ELECTRICAL -Starting System16-24

OVERRUNNING CLUTCH CHECK

1. While holding clutch housing, rotate the pinion. Drive

pinion should rotate smoothly in one direction, but should

not rotate in opposite direction. If clutch does not function

properly, replace overrunning clutch assembly.

2. Inspect pinion for wear or burrs. If pinion is worn or burred,

replace overrunning clutch assembly. If pinion is damaged,

also inspect ring gear for wear or burrs.

FRONT AND REAR BRACKET BUSHING CHECK

Inspect bushing for wear or burrs. If bushing is worn or burred,

replace front bracket assembly or rear bracket assembly.

BRUSH REPLACEMENT

1. Check the surface contacting the commutator for

roughness and the brush length.

Limit value: 7.0 mm

2. If the limit is exceeded, replace the brush holder.

ARMATURE TEST

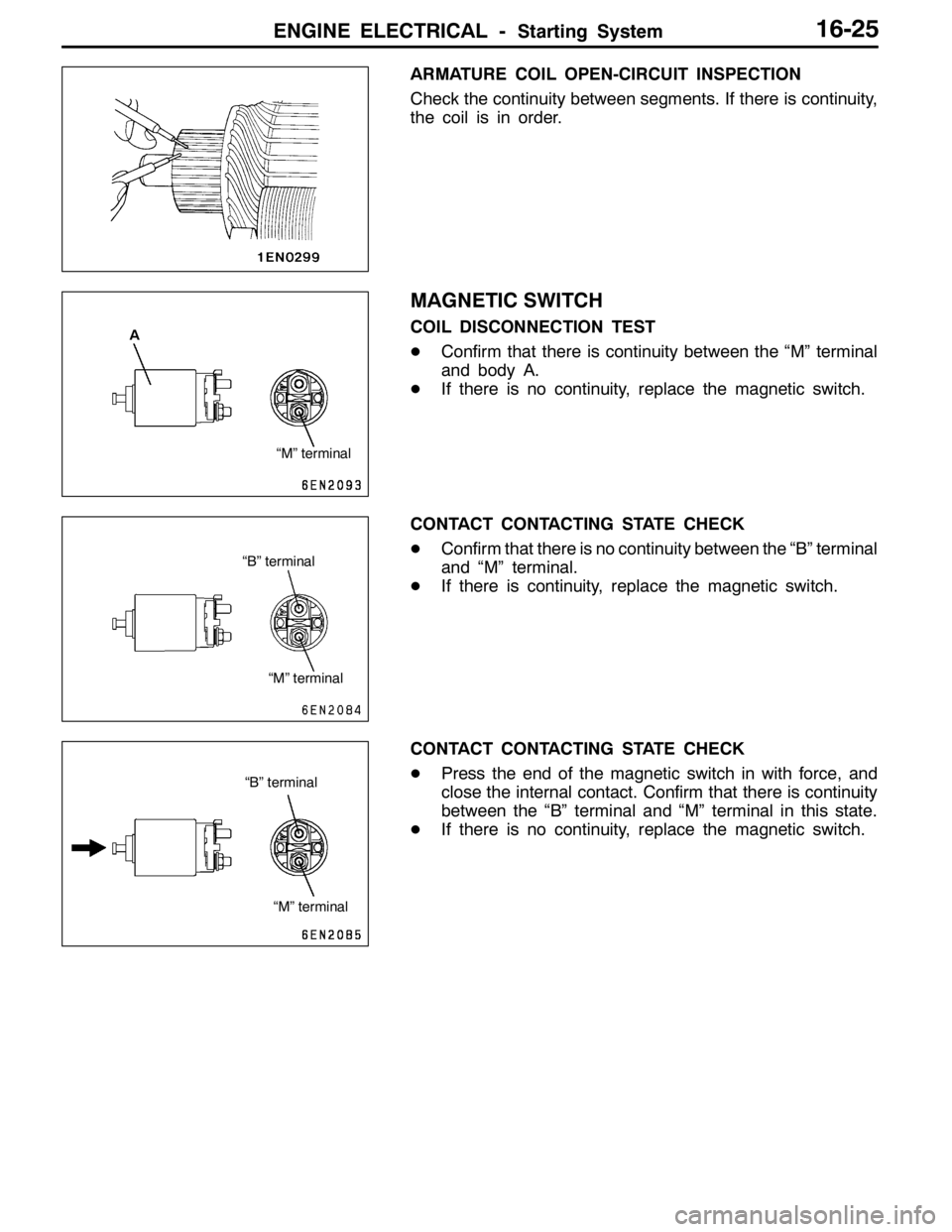

ARMATURE COIL SHORT-CIRCUIT TEST

1. Check that the armature coil is not grounded.

2. Place armature in a growler.

3. Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will cause

blade to vibrate and be attracted to the core. Replace

shorted armature.

ARMATURE COIL EARTH TEST

Check the insulation between each commutator segment and

armature coil core.

If there is no continuity, the insulation is in order.

Free

Lock

Length

Growler

Page 757 of 1449

ENGINE ELECTRICAL -Starting System16-25

ARMATURE COIL OPEN-CIRCUIT INSPECTION

Check the continuity between segments. If there is continuity,

the coil is in order.

MAGNETIC SWITCH

COIL DISCONNECTION TEST

DConfirm that there is continuity between the “M” terminal

and body A.

DIf there is no continuity, replace the magnetic switch.

CONTACT CONTACTING STATE CHECK

DConfirm that there is no continuity between the “B” terminal

and “M” terminal.

DIf there is continuity, replace the magnetic switch.

CONTACT CONTACTING STATE CHECK

DPress the end of the magnetic switch in with force, and

close the internal contact. Confirm that there is continuity

between the “B” terminal and “M” terminal in this state.

DIf there is no continuity, replace the magnetic switch.

“M” terminal A

“M” terminal “B” terminal

“M” terminal “B” terminal

Page 760 of 1449

ENGINE ELECTRICAL -Ignition System16-28

ON-VEHICLE SERVICE

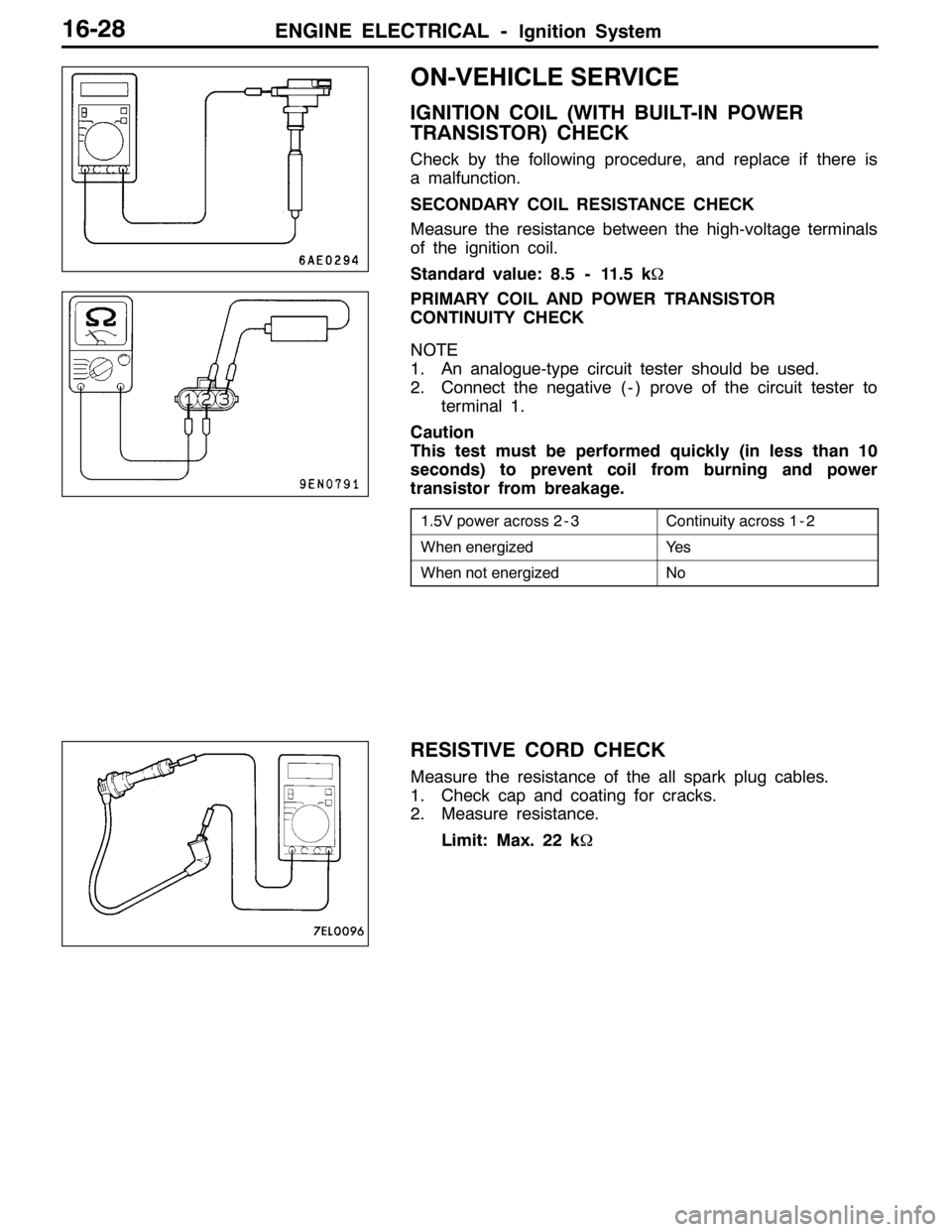

IGNITION COIL (WITH BUILT-IN POWER

TRANSISTOR) CHECK

Check by the following procedure, and replace if there is

a malfunction.

SECONDARY COIL RESISTANCE CHECK

Measure the resistance between the high-voltage terminals

of the ignition coil.

Standard value: 8.5 - 11.5 kΩ

PRIMARY COIL AND POWER TRANSISTOR

CONTINUITY CHECK

NOTE

1. An analogue-type circuit tester should be used.

2. Connect the negative ( - ) prove of the circuit tester to

terminal 1.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning and power

transistor from breakage.

1.5V power across 2 - 3Continuity across 1 - 2

When energizedYe s

When not energizedNo

RESISTIVE CORD CHECK

Measure the resistance of the all spark plug cables.

1. Check cap and coating for cracks.

2. Measure resistance.

Limit: Max. 22 kΩ

Page 761 of 1449

ENGINE ELECTRICAL -Ignition System16-29

SPARK PLUG CHECK, CLEANING AND REPLACEMENT

SPARK PLUG GAP CHECK

Caution

1. Do not adjust the gap of the iridium plug.

2. Cleaning of the iridium plug could damage the tip of the electrode. Thus, if the plug must

be cleaned because of soot, etc., use a plug cleaner and clean within a short time of 20 seconds

or less to protect the electrode. Do not use a wire brush, etc.

3. Even when the functions of the iridium plug are normal, the electrode section may be blackened.

However, the adhered carbon has properties that easily burned off compared to the conventional

type, so there is no problem. Check the quality of the spark plug by checking the insulation

resistance.

Check the plug gap, and replace if the checked value is more than the limit value.

Standard value, limit value:

MakerModelStandard value (mm)Limit value (mm)

NGKIGR7A-G0.6 - 0.70.75

DENSOVW22PR-DA70.6 - 0.70.75

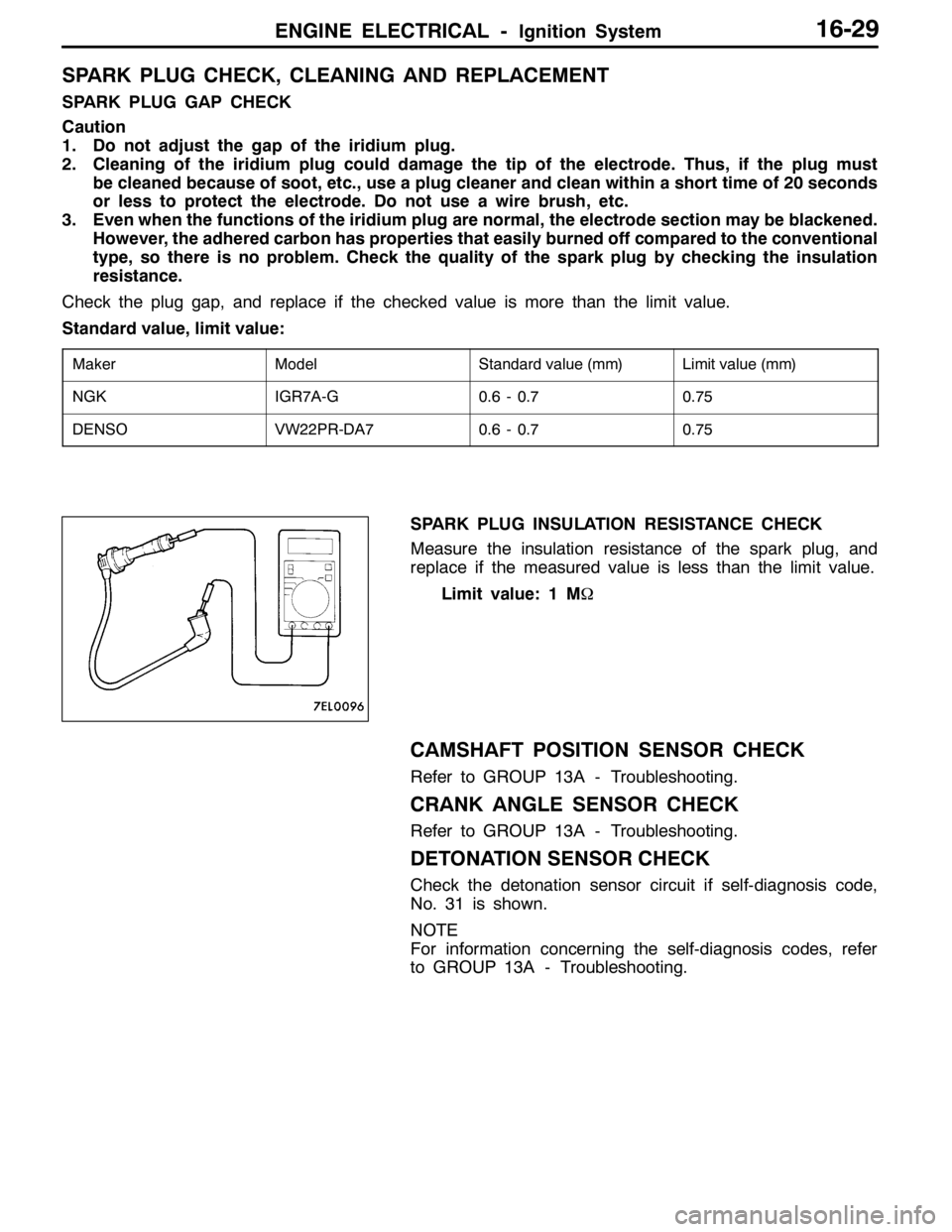

SPARK PLUG INSULATION RESISTANCE CHECK

Measure the insulation resistance of the spark plug, and

replace if the measured value is less than the limit value.

Limit value: 1 MΩ

CAMSHAFT POSITION SENSOR CHECK

Refer to GROUP 13A - Troubleshooting.

CRANK ANGLE SENSOR CHECK

Refer to GROUP 13A - Troubleshooting.

DETONATION SENSOR CHECK

Check the detonation sensor circuit if self-diagnosis code,

No. 31 is shown.

NOTE

For information concerning the self-diagnosis codes, refer

to GROUP 13A - Troubleshooting.

Page 762 of 1449

ENGINE ELECTRICAL -Ignition System16-30

WAVEFORM CHECK USING AN ANALYZER

Ignition Secondary Voltage Waveform Check

MEASUREMENT METHOD

1. Clamp the secondary pickup around the spark plug cable.

NOTE

(1) The peak ignition voltage will be reversed when the

spark cables No. 2 and No. 4, or No. 1 and No.

3 cylinders are clamped.

(2) Because of the two-cylinder simultaneous ignition

system, the waveforms for two cylinders in each group

appear during waveform observation (No. 1 cylinder

- No. 4 cylinder, No. 2 cylinder - No. 3 cylinder).

However, waveform observation is only applicable

for the cylinder with the spark plug cable clamped

by the secondary pickup.

(3) Identifying which cylinder waveform is displayed can

be difficult. For reference, remember that the

waveform of the cylinder attached to the secondary

pickup will be displayed as stable.

2. Clamp the spark plug cable with the trigger pickup.

NOTE

Clamp the trigger pickup to the same spark plug cable

clamped by the secondary pickup.

Page 771 of 1449

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 2.........

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2...............

ON-VEHICLE SERVICE 2...................

Accelerator Cable Check and

Adjustment 2................................

ACCELERATOR CABLE AND PEDAL 3......

EMISSION CONTROL SYSTEM 4......

GENERAL INFORMATION 4................

Emission Control Device Reference

Table 4.....................................

SERVICE SPECIFICATIONS 5..............

VACUUM HOSE 5..........................

Vacuum Hose Piping Diagram 5..............

Vacuum Circuit Diagram 6....................

Vacuum Hose Check 7......................

Vacuum Hose Installation 7..................

CRANKCASE EMISSION CONTROL

SYSTEM 8................................

General Information 8........................

System Diagram 8..........................

Component Location 9.......................

Positive Crankcase Ventilation System Check 9....

PCV Valve Check 9.........................

EVAPORATIVE EMISSION CONTROL

SYSTEM 10...............................

General Information 10.......................

System Diagram 10..........................

Component Location 10......................

Purge Control System Check 11...............

Purge Port Vacuum Check 11.................

Purge Control Solenoid Valve Check 12.........

Check Valve Check 12.......................

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 13...............................

General Information 13.......................

Operation 13................................

System Diagram 13..........................

Component Location 14......................

Exhaust Gas Recirculation (EGR) Control System

Check 14...................................

EGR Valve Check 15.........................

EGR Port Vacuum Check 15..................

EGR Control Solenoid Valve Check 16..........

EGR VALVE 17............................

CANISTER 18.............................

CATALYTIC CONVERTER 19................

General Information 19.......................

Page 772 of 1449

ENGINE AND EMISSION CONTROL -Engine Control System17-2

ENGINE CONTROL SYSTEM

GENERAL INFORMATION

A cable-type accelerator mechanism and a

suspended-type pedal have been adopted.

SERVICE SPECIFICATIONS

ItemsStandard value

Accelerator cable play mm1-2

Engineidlespeedr/min850±50Engineidle speed±/min850±50

ON-VEHICLE SERVICE

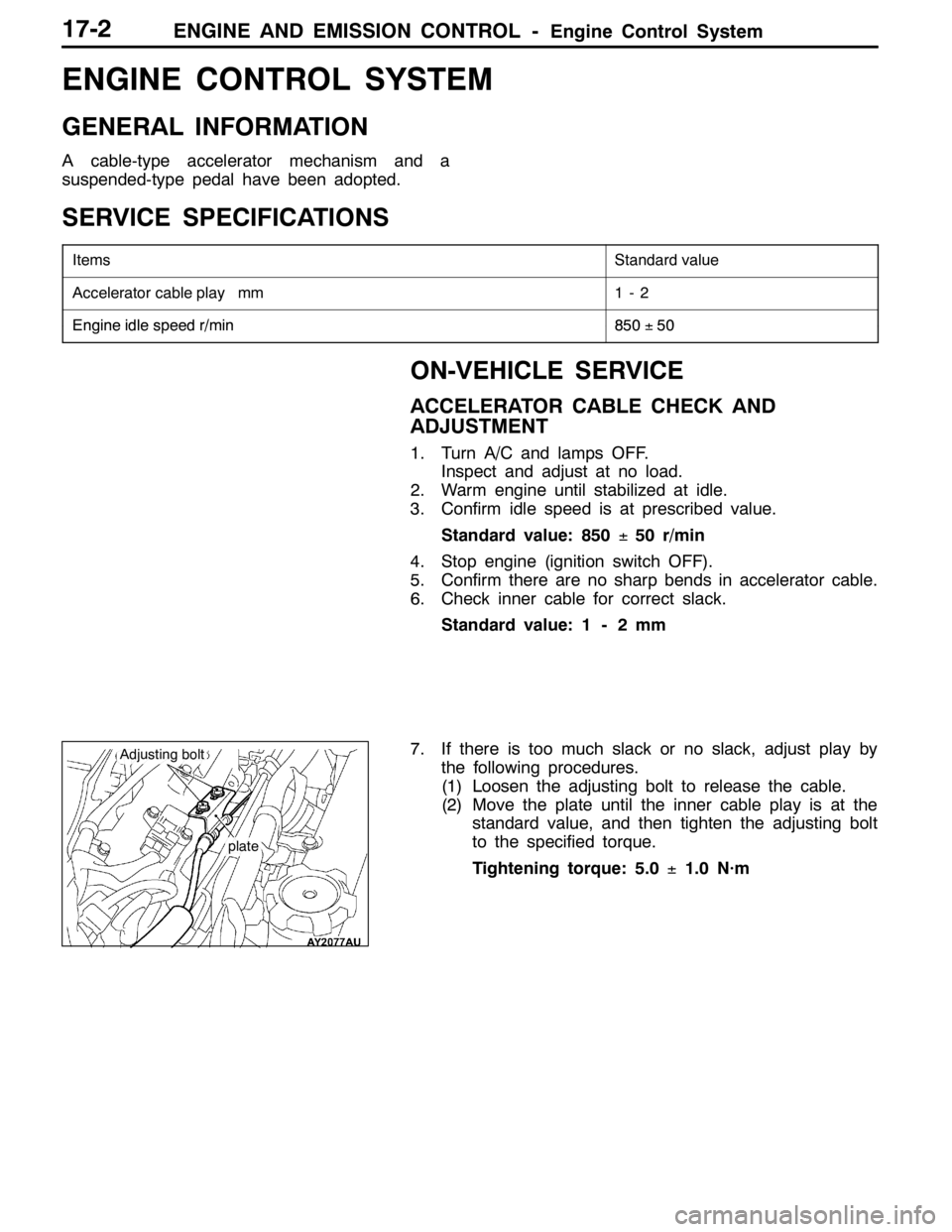

ACCELERATOR CABLE CHECK AND

ADJUSTMENT

1. Turn A/C and lamps OFF.

Inspect and adjust at no load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at prescribed value.

Standard value: 850±50 r/min

4. Stop engine (ignition switch OFF).

5. Confirm there are no sharp bends in accelerator cable.

6. Check inner cable for correct slack.

Standard value: 1 - 2 mm

7. If there is too much slack or no slack, adjust play by

the following procedures.

(1) Loosen the adjusting bolt to release the cable.

(2) Move the plate until the inner cable play is at the

standard value, and then tighten the adjusting bolt

to the specified torque.

Tightening torque: 5.0±1.0 N·m

plate

Adjusting bolt

Page 774 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-4

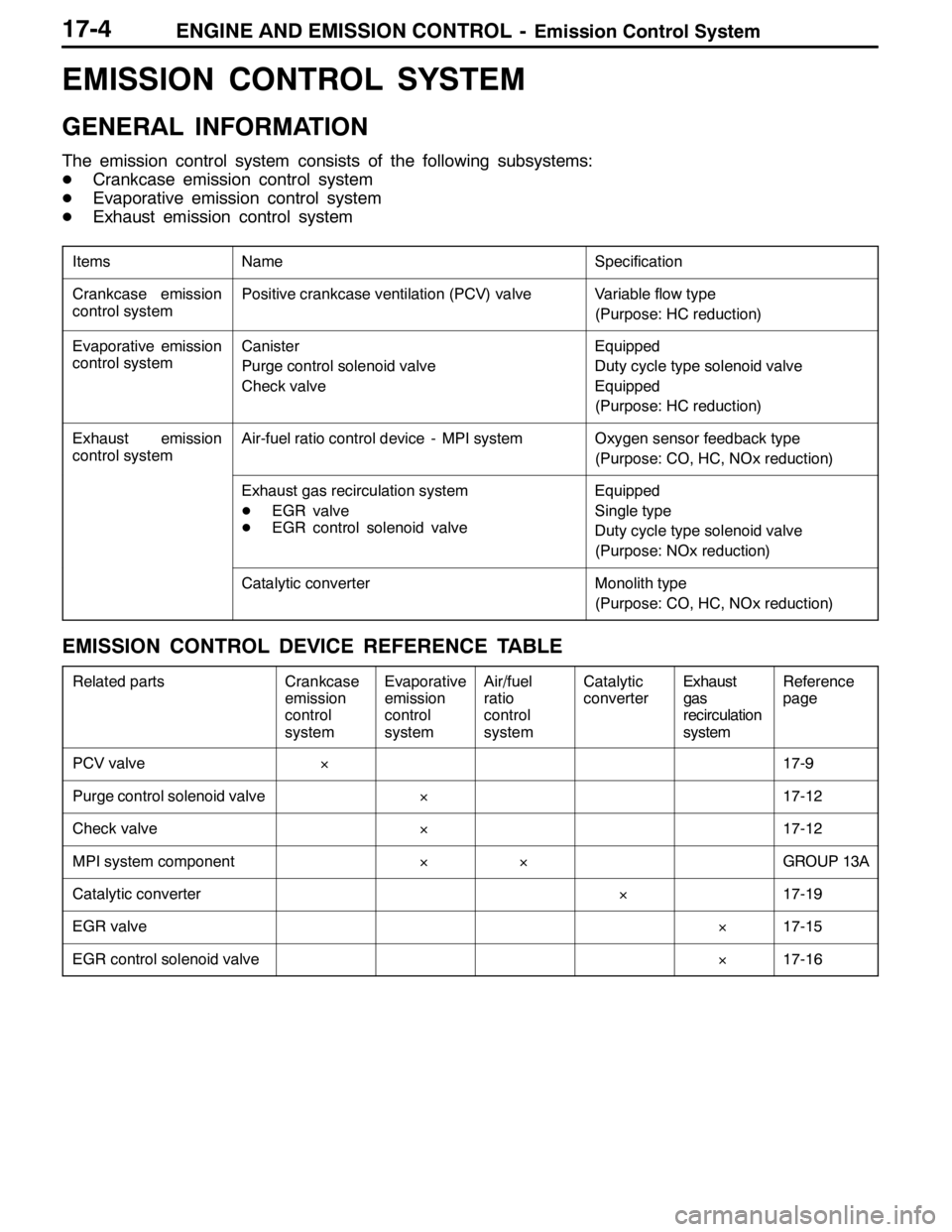

EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The emission control system consists of the following subsystems:

DCrankcase emission control system

DEvaporative emission control system

DExhaust emission control system

ItemsNameSpecification

Crankcase emission

control systemPositive crankcase ventilation (PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission

control systemCanister

Purge control solenoid valve

Check valveEquipped

Duty cycle type solenoid valve

Equipped

(Purpose: HC reduction)

Exhaust emission

control systemAir-fuel ratio control device - MPI systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

DEGR valve

DEGR control solenoid valveEquipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE REFERENCE TABLE

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel

ratio

control

systemCatalytic

converterExhaust

gas

recirculation

systemReference

page

PCV valve×17-9

Purge control solenoid valve×17-12

Check valve×17-12

MPI system component××GROUP 13A

Catalytic converter×17-19

EGR valve×17-15

EGR control solenoid valve×17-16

Page 775 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-5

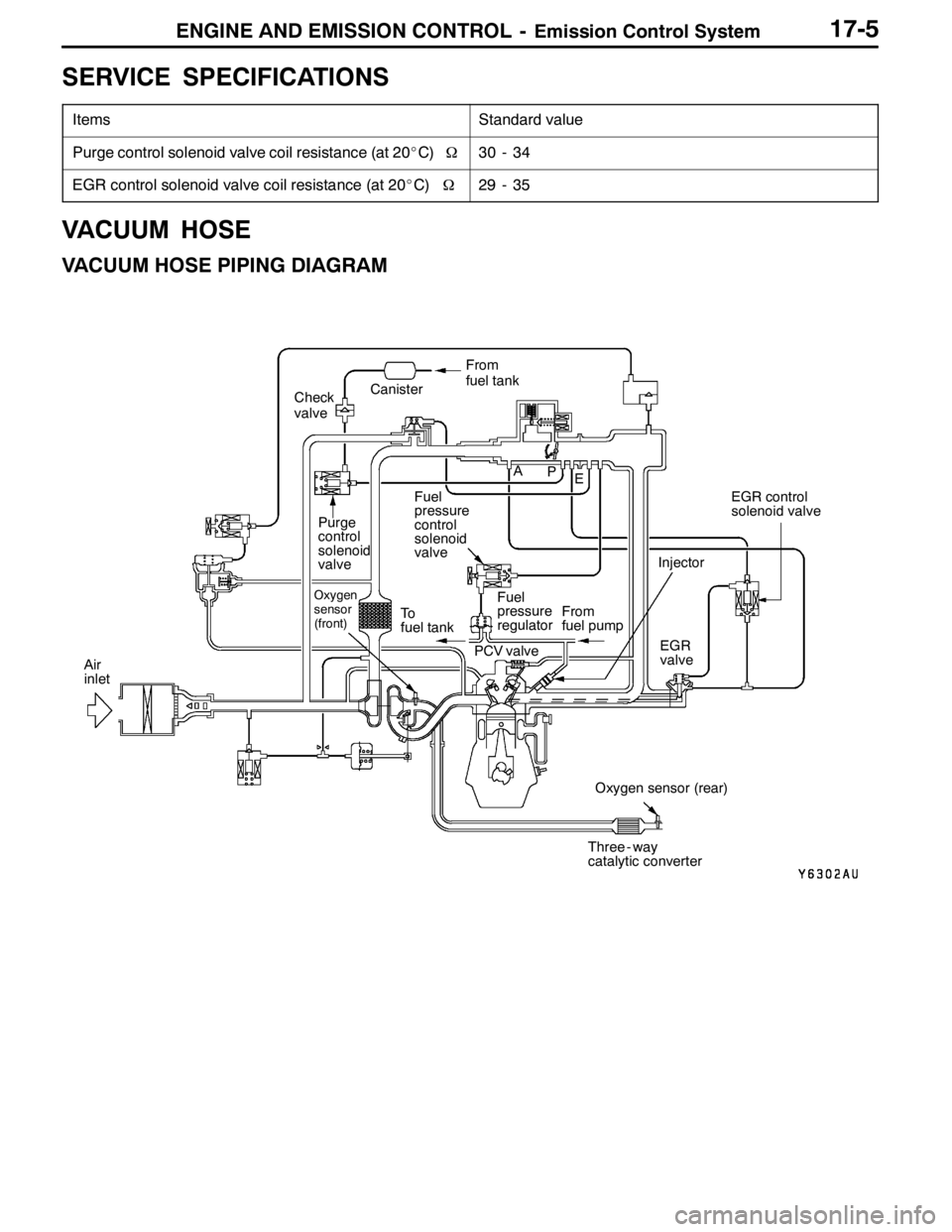

SERVICE SPECIFICATIONS

ItemsStandard value

Purge control solenoid valve coil resistance (at 20_C)Ω30 - 34

EGR control solenoid valve coil resistance (at 20_C)Ω29 - 35

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAM

Fuel

pressure

control

solenoid

valve

Oxygen

sensor

(front)

Check

valve

Fuel

pressure

regulator

PCV valve To

fuel tank

Oxygen sensor (rear) From

fuel pump

Air

inletEGR control

solenoid valve

Purge

control

solenoid

valveCanisterFrom

fuel tank

EGR

valve Injector

Three - way

catalytic converter A

P

E