check engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 776 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-6

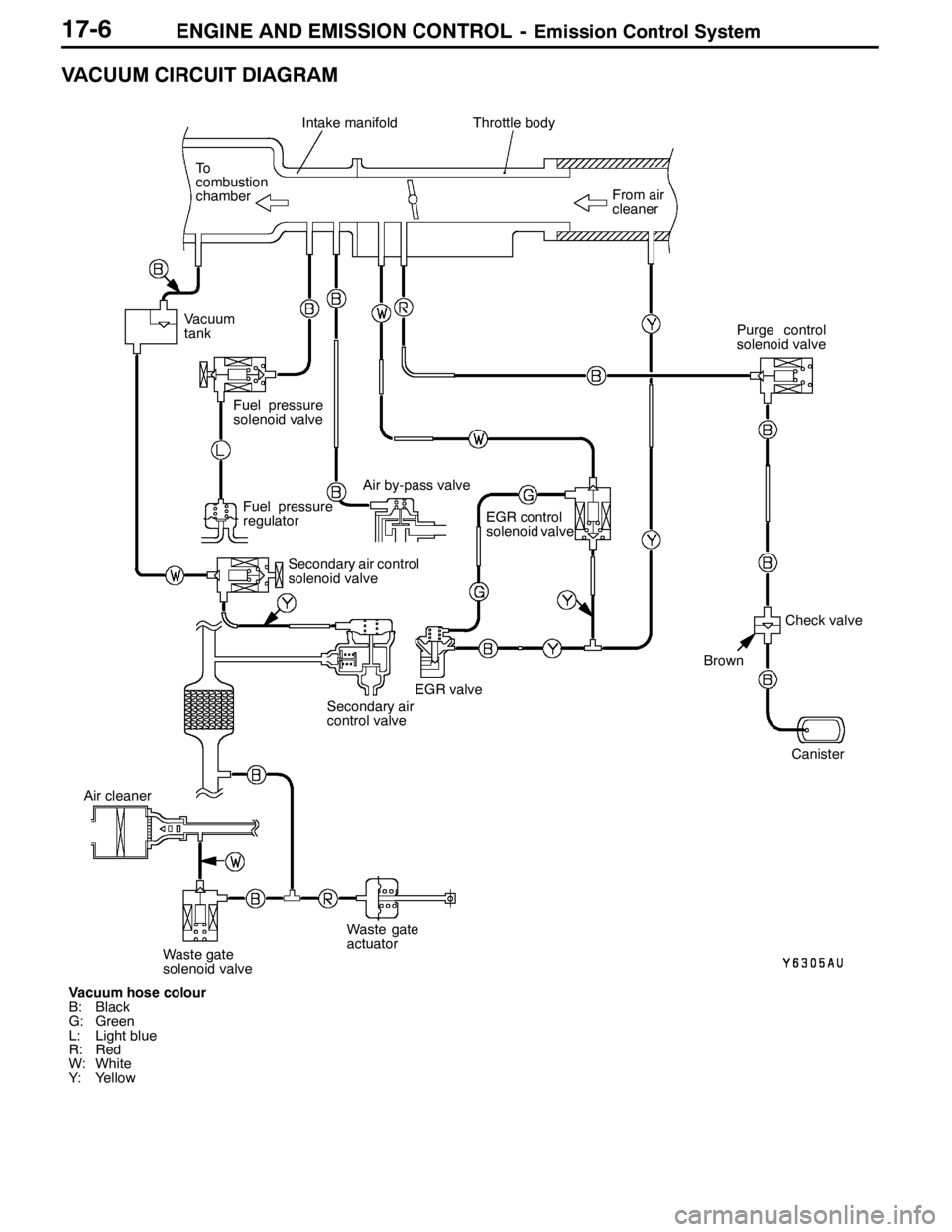

VACUUM CIRCUIT DIAGRAM

Vacuum hose colour

B: Black

G: Green

L: Light blue

R: Red

W: White

Y: YellowFrom air

cleaner

Intake manifoldThrottle body

To

combustion

chamber

Fuel pressure

regulator

EGR control

solenoid valve

Canister

EGR valve

Brown

Check valve Vacuum

tank

Fuel pressure

solenoid valve

Air by-pass valve

Secondary air control

solenoid valve

Secondary air

control valvePurge control

solenoid valve

Air cleaner

Waste gate

solenoid valveWaste gate

actuator

Page 777 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-7

VACUUM HOSE CHECK

1. Using the piping diagram as a guide, check to be sure

that the vacuum hoses are correctly connected.

2. Check the connection condition of the vacuum hoses,

(removed, loose, etc.) and check to be sure that there

are no bends or damage.

VACUUM HOSE INSTALLATION

1. When connecting the vacuum hoses, they should be

securely inserted onto the nipples.

2. Connect the hoses correctly, using the vacuum hose piping

diagram as a guide.

Page 779 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System

PCV valve

17-9

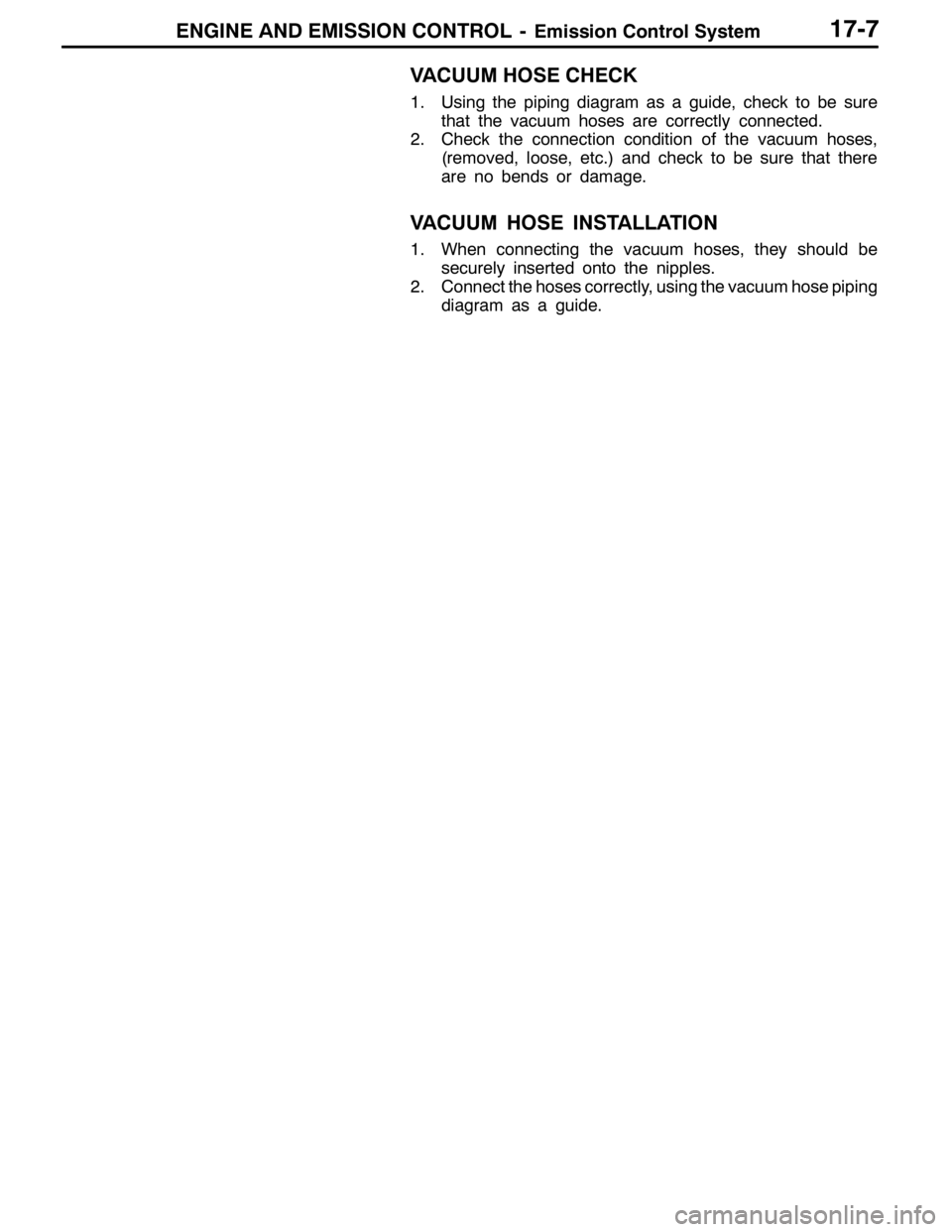

COMPONENT LOCATION

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK

1. Remove the ventilation hose from the PCV valve.

2. Remove the PCV valve from the rocker cover.

3. Reinstall the PCV valve at the ventilation hose.

4. Start the engine and run at idle.

5. Place a finger at the opening of the PCV valve and check

that vacuum of the intake manifold is felt.

NOTE

At this moment, the plunger in the PCV valve moves

back and forth.

6. If vacuum is not felt, clean the PCV valve or replace

it.

PCV VALVE CHECK

1. Insert a thin rod into the PCV valve from the side shown

in the illustration (rocker cover installation side), and move

the rod back and forth to check that the plunger moves.

2. If the plunger does not move, there is a clogging in the

PCV valve. In this case, clean or replace the PCV valve.

PCV valve

PCV valve

Page 780 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System

Vacuum tank

Alternator

Purge control solenoid valve

17-10

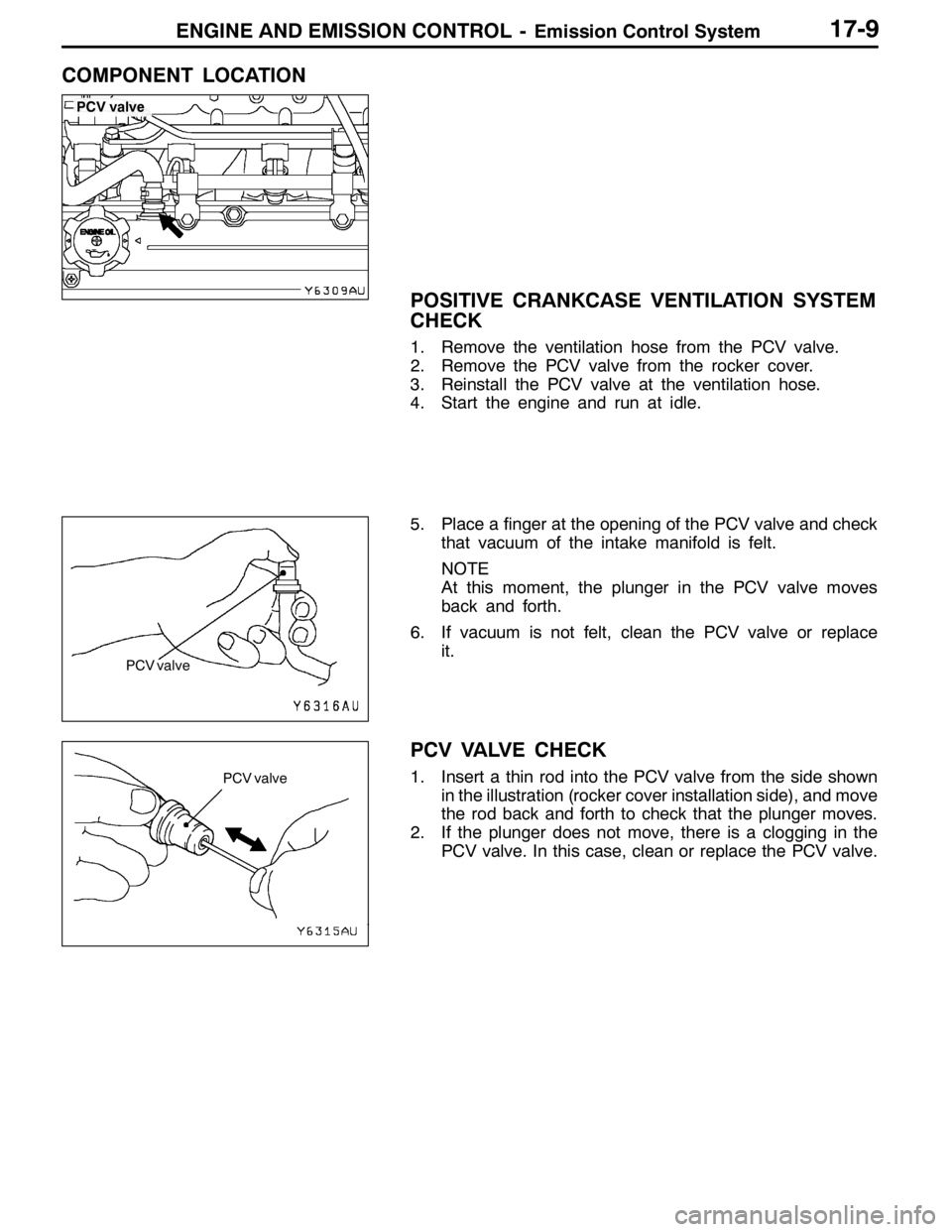

EVAPORATIVE EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The evaporative emission control system prevents

fuel vapours generated in the fuel tank from

escaping into the atmosphere.

Fuel vapours from the fuel tank flow through the

fuel tank pressure control valve and vapour

pipe/hose to be stored temporarily in the canister.

When driving the vehicle, fuel vapours stored in

the canister flow through the purge solenoid and

purge port and go into the intake manifold to be

sent to the combustion chamber.When the engine coolant temperature is low or

when the intake air quantity is small (when the

engine is at idle, for example), the engine control

unit turns the purge solenoid off to shut off the

fuel vapour flow to the intake manifold.

This does not only insure the driveability when the

engine is cold or running under low load but also

stabilize the emission level.

SYSTEM DIAGRAM

BatteryIntake air

temperature sensor

Barometric pressure

sensor

Check

valve

Canister

Control

relay

Purge control

solenoid valve

(ON: Open)

Engine-ECUEngine coolant

temperature sensor Air flow sensor

COMPONENT LOCATION

Page 781 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-11

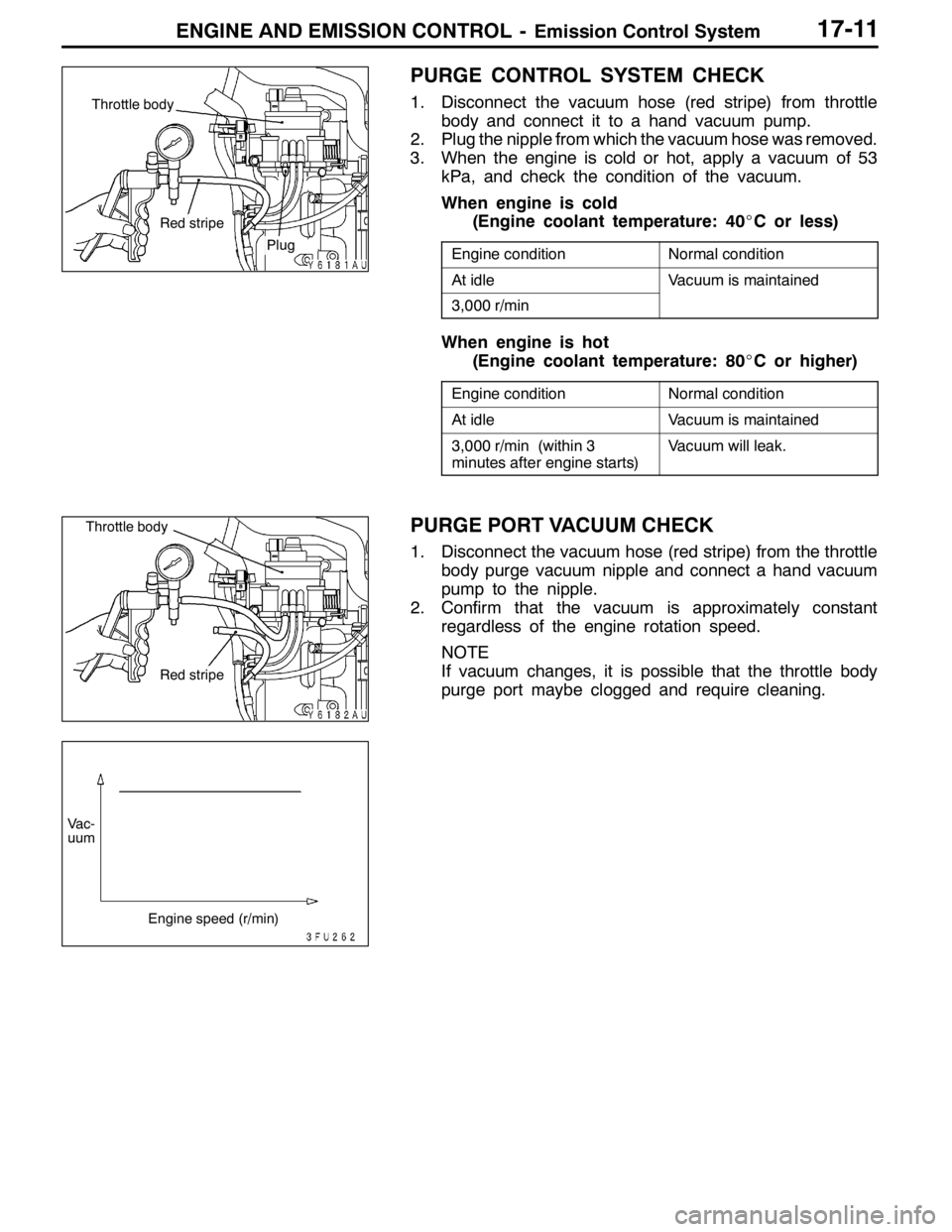

PURGE CONTROL SYSTEM CHECK

1. Disconnect the vacuum hose (red stripe) from throttle

body and connect it to a hand vacuum pump.

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53

kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40_C or less)

Engine conditionNormal condition

At idleVacuum is maintained

3,000 r/min

When engine is hot

(Engine coolant temperature: 80_C or higher)

Engine conditionNormal condition

At idleVacuum is maintained

3,000 r/min (within 3

minutes after engine starts)Vacuum will leak.

PURGE PORT VACUUM CHECK

1. Disconnect the vacuum hose (red stripe) from the throttle

body purge vacuum nipple and connect a hand vacuum

pump to the nipple.

2. Confirm that the vacuum is approximately constant

regardless of the engine rotation speed.

NOTE

If vacuum changes, it is possible that the throttle body

purge port maybe clogged and require cleaning.

Red stripe

Plug

Throttle body

Red stripe

Throttle body

Vac-

uum

Engine speed (r/min)

Page 782 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-12

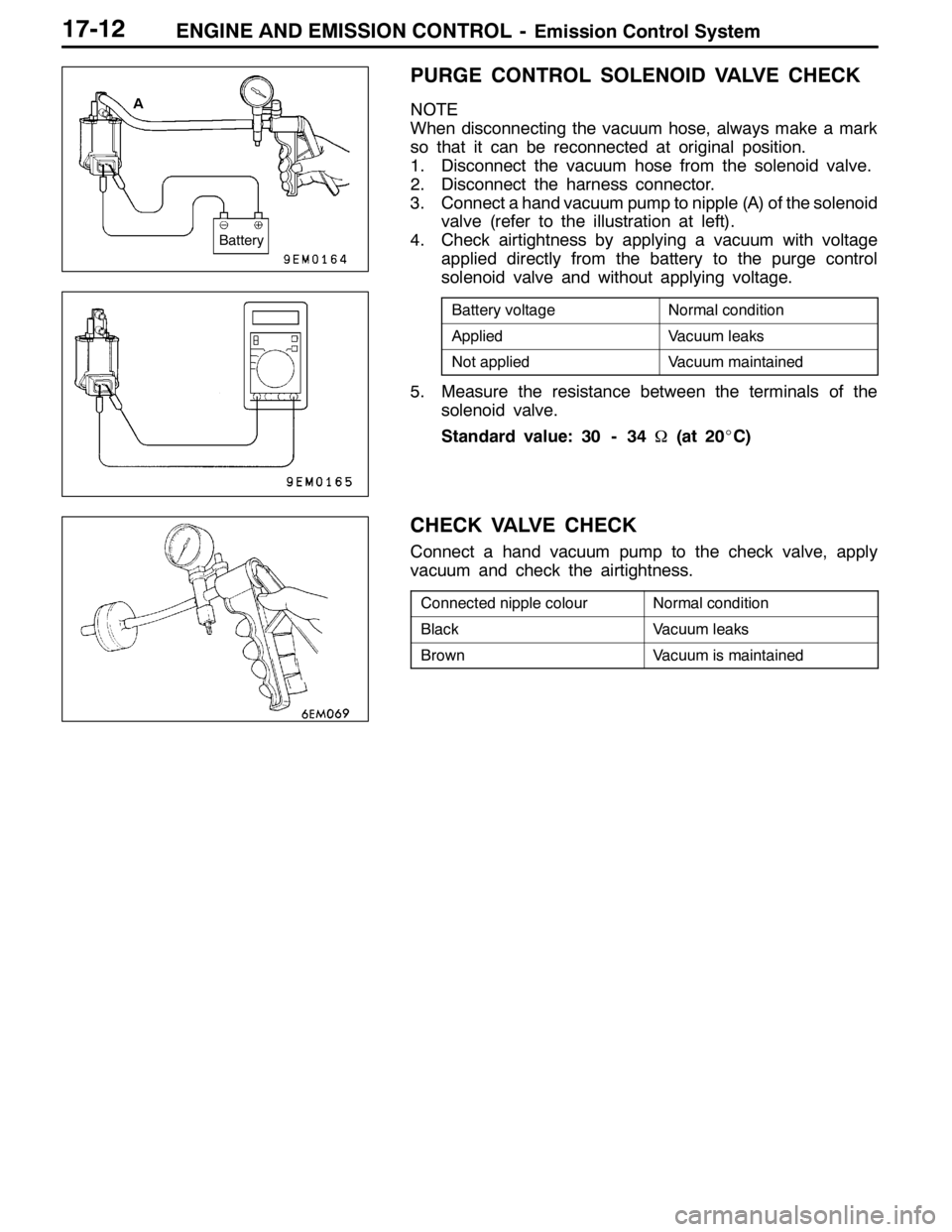

PURGE CONTROL SOLENOID VALVE CHECK

NOTE

When disconnecting the vacuum hose, always make a mark

so that it can be reconnected at original position.

1. Disconnect the vacuum hose from the solenoid valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the solenoid

valve (refer to the illustration at left).

4. Check airtightness by applying a vacuum with voltage

applied directly from the battery to the purge control

solenoid valve and without applying voltage.

Battery voltageNormal condition

AppliedVacuum leaks

Not appliedVacuum maintained

5. Measure the resistance between the terminals of the

solenoid valve.

Standard value: 30 - 34Ω(at 20_C)

CHECK VALVE CHECK

Connect a hand vacuum pump to the check valve, apply

vacuum and check the airtightness.

Connected nipple colourNormal condition

BlackVacuum leaks

BrownVacuum is maintained

Battery A

Page 784 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System

EGR control solenoid valve

Vacuum tank

Alternator

EGR valve

Throttle body

17-14

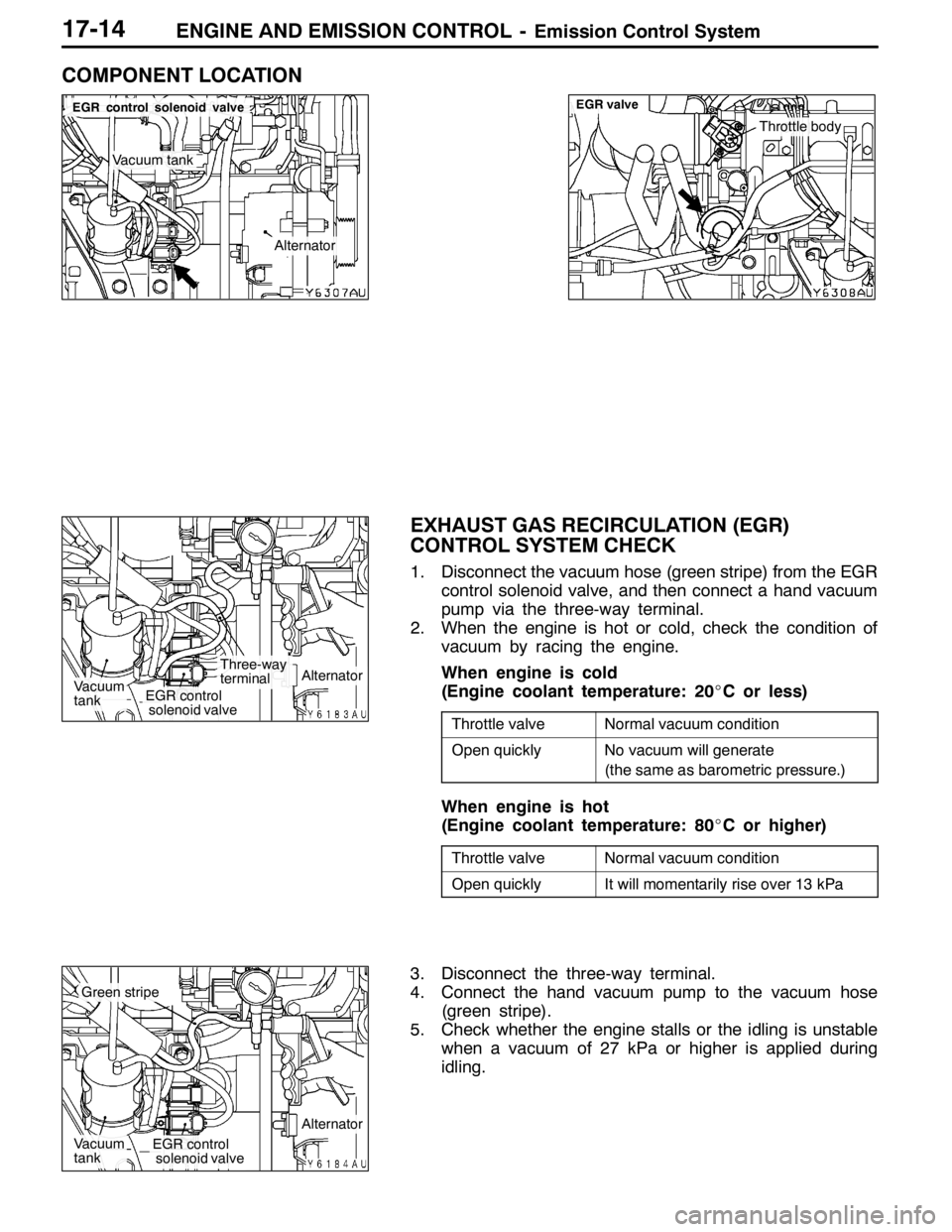

COMPONENT LOCATION

EXHAUST GAS RECIRCULATION (EGR)

CONTROL SYSTEM CHECK

1. Disconnect the vacuum hose (green stripe) from the EGR

control solenoid valve, and then connect a hand vacuum

pump via the three-way terminal.

2. When the engine is hot or cold, check the condition of

vacuum by racing the engine.

When engine is cold

(Engine coolant temperature: 20_C or less)

Throttle valveNormal vacuum condition

Open quicklyNo vacuum will generate

(the same as barometric pressure.)

When engine is hot

(Engine coolant temperature: 80_C or higher)

Throttle valveNormal vacuum condition

Open quicklyIt will momentarily rise over 13 kPa

3. Disconnect the three-way terminal.

4. Connect the hand vacuum pump to the vacuum hose

(green stripe).

5. Check whether the engine stalls or the idling is unstable

when a vacuum of 27 kPa or higher is applied during

idling.

Three-way

terminal

EGR control

solenoid valveVacuum

tankAlternator

EGR control

solenoid valveVacuum

tank

Alternator

Green stripe

Page 785 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-15

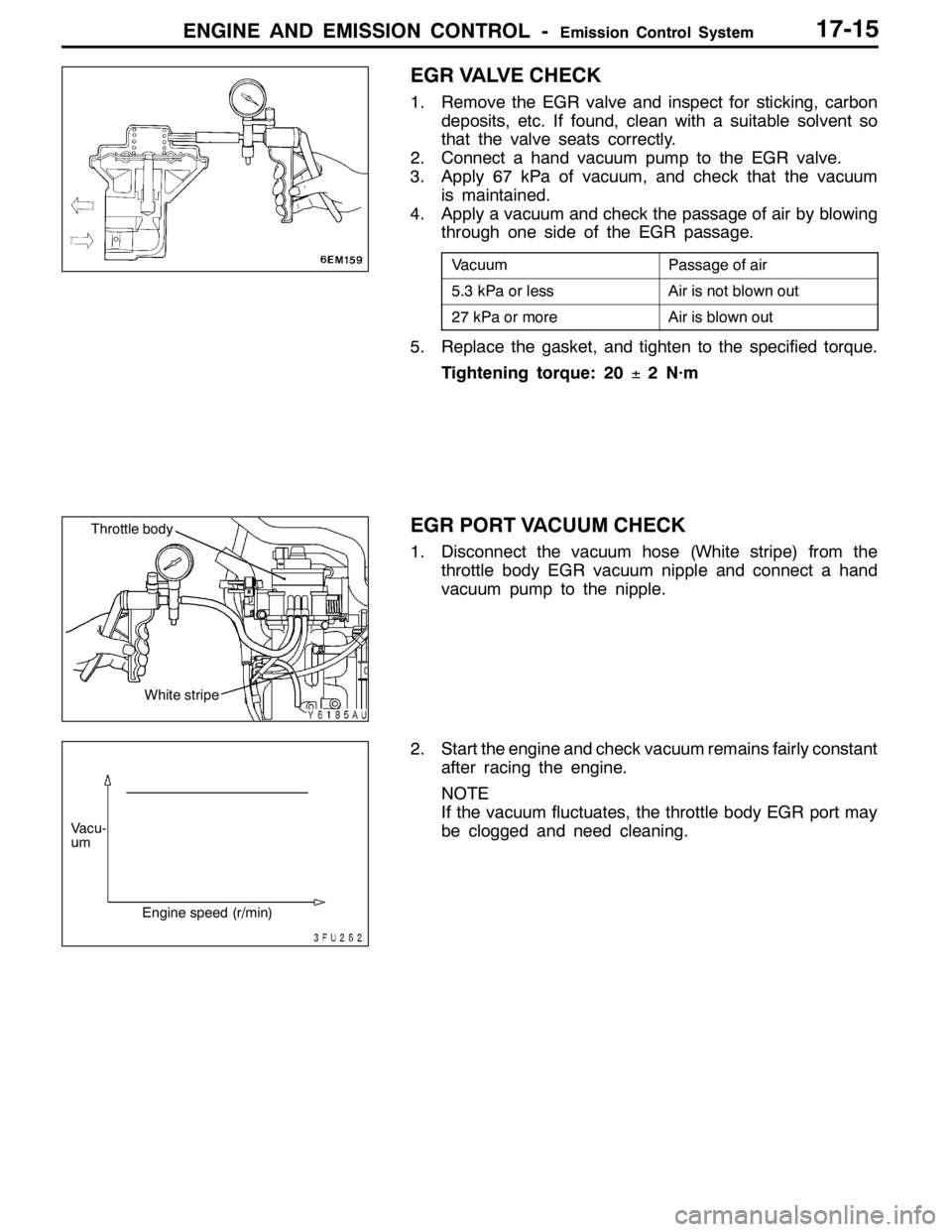

EGR VALVE CHECK

1. Remove the EGR valve and inspect for sticking, carbon

deposits, etc. If found, clean with a suitable solvent so

that the valve seats correctly.

2. Connect a hand vacuum pump to the EGR valve.

3. Apply 67 kPa of vacuum, and check that the vacuum

is maintained.

4. Apply a vacuum and check the passage of air by blowing

through one side of the EGR passage.

VacuumPassage of air

5.3 kPa or lessAir is not blown out

27 kPa or moreAir is blown out

5. Replace the gasket, and tighten to the specified torque.

Tightening torque: 20±2 N·m

EGR PORT VACUUM CHECK

1. Disconnect the vacuum hose (White stripe) from the

throttle body EGR vacuum nipple and connect a hand

vacuum pump to the nipple.

2. Start the engine and check vacuum remains fairly constant

after racing the engine.

NOTE

If the vacuum fluctuates, the throttle body EGR port may

be clogged and need cleaning.

White stripe

Throttle body

Vacu-

um

Engine speed (r/min)

Page 786 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-16

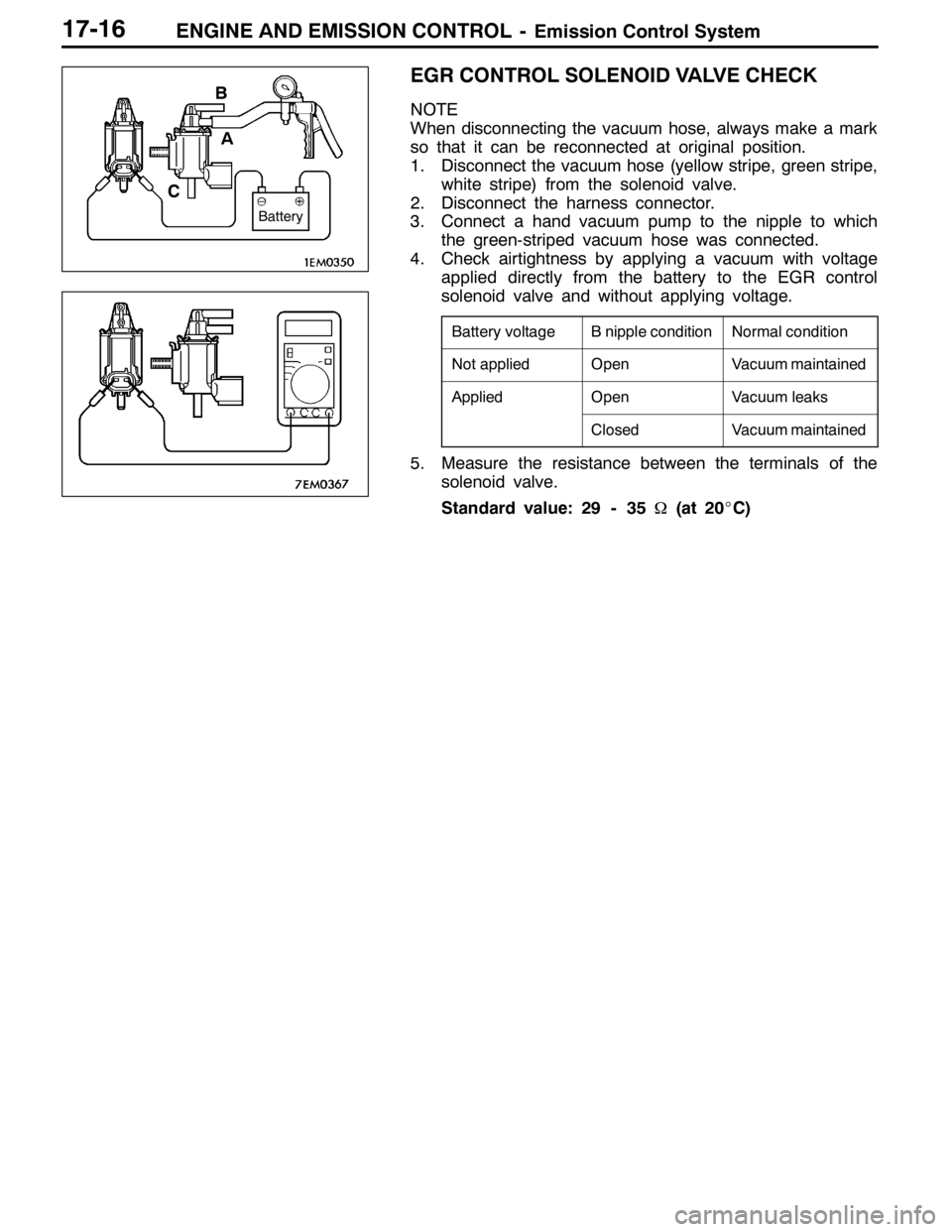

EGR CONTROL SOLENOID VALVE CHECK

NOTE

When disconnecting the vacuum hose, always make a mark

so that it can be reconnected at original position.

1. Disconnect the vacuum hose (yellow stripe, green stripe,

white stripe) from the solenoid valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to the nipple to which

the green-striped vacuum hose was connected.

4. Check airtightness by applying a vacuum with voltage

applied directly from the battery to the EGR control

solenoid valve and without applying voltage.

Battery voltageB nipple conditionNormal condition

Not appliedOpenVacuum maintained

AppliedOpenVacuum leaks

ClosedVacuum maintained

5. Measure the resistance between the terminals of the

solenoid valve.

Standard value: 29 - 35Ω(at 20_C)

Battery

A B

C

Page 788 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-18

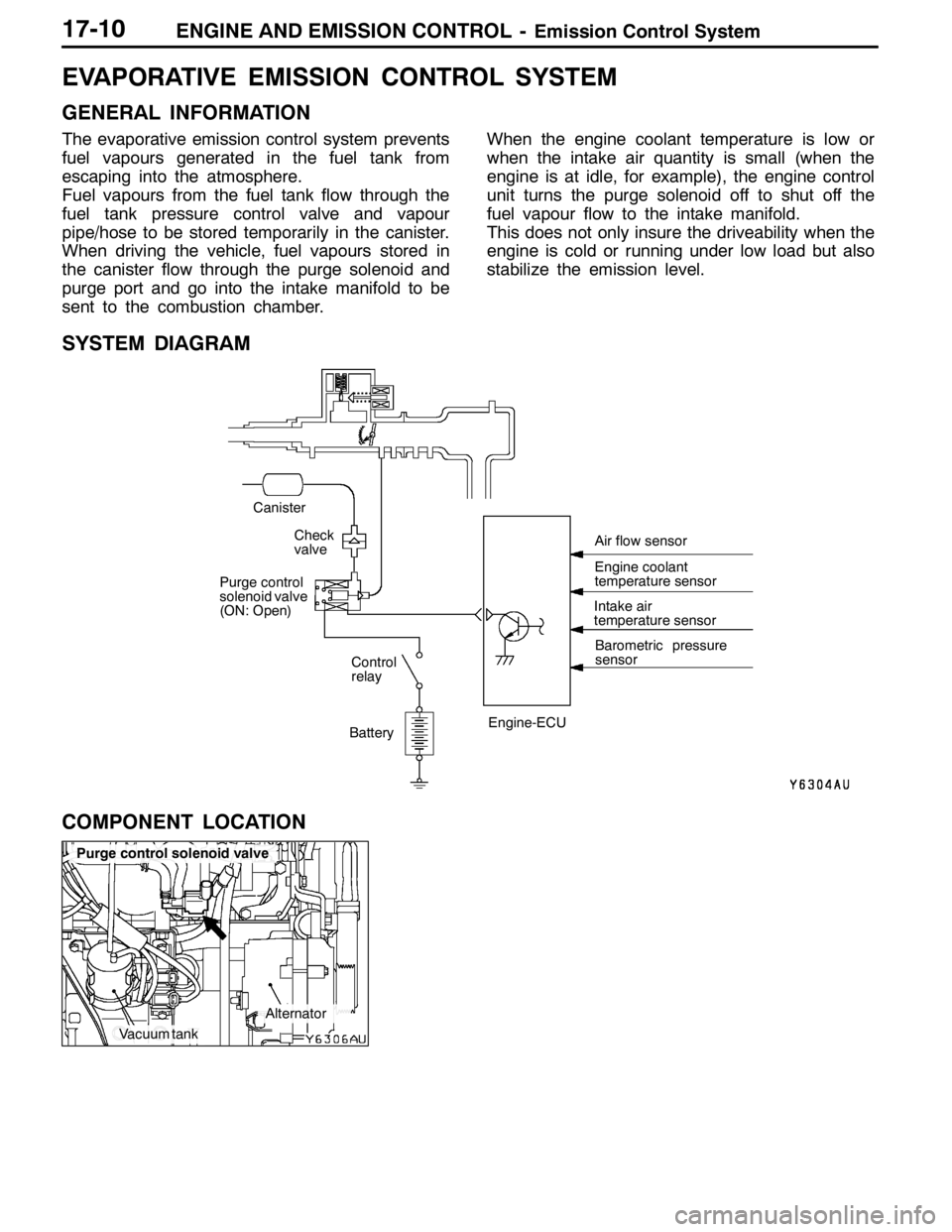

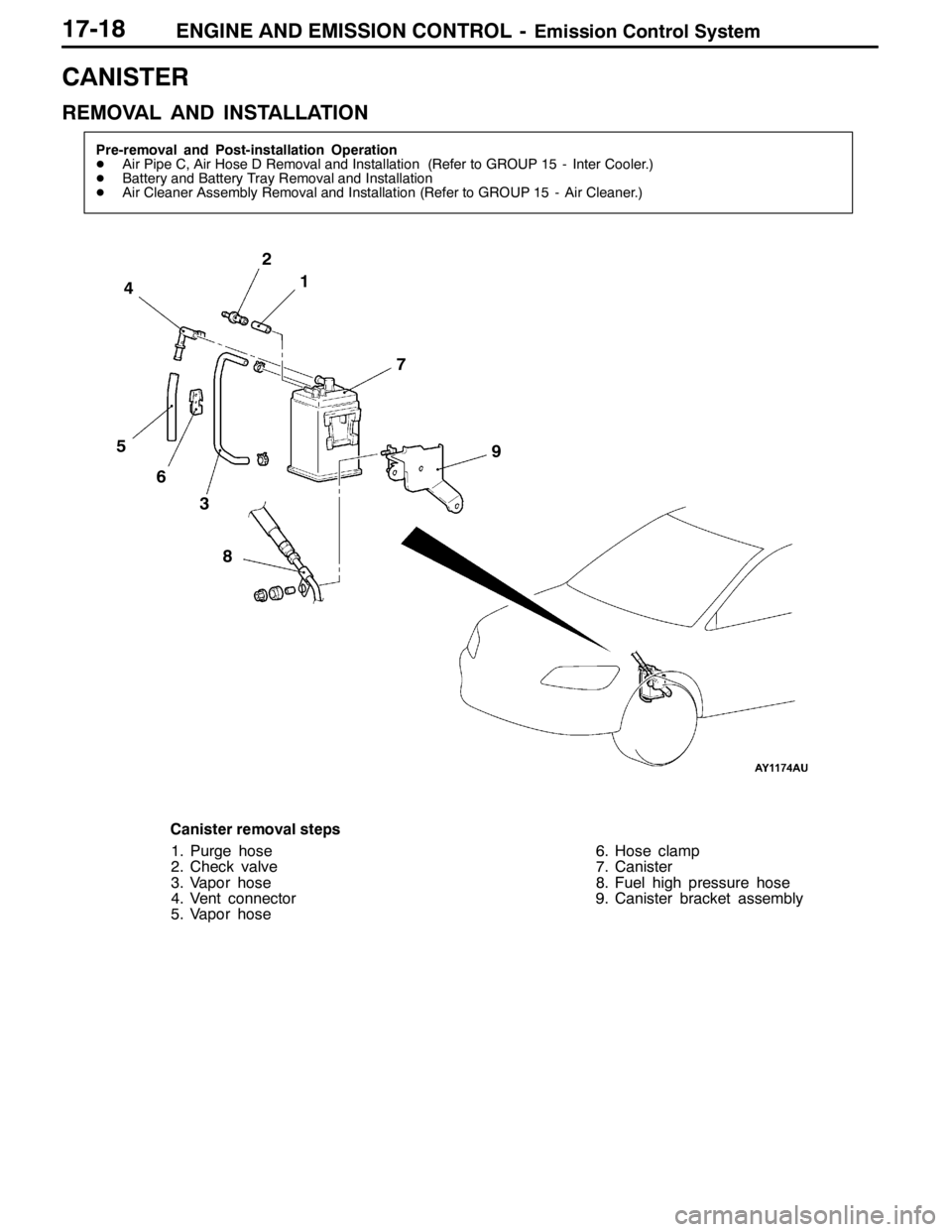

CANISTER

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DAir Pipe C, Air Hose D Removal and Installation (Refer to GROUP 15 - Inter Cooler.)

DBattery and Battery Tray Removal and Installation

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15 - Air Cleaner.)

1 2

3 4

5

67

89

Canister removal steps

1. Purge hose

2. Check valve

3. Vapor hose

4. Vent connector

5. Vapor hose6. Hose clamp

7. Canister

8. Fuel high pressure hose

9. Canister bracket assembly