check engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 795 of 1449

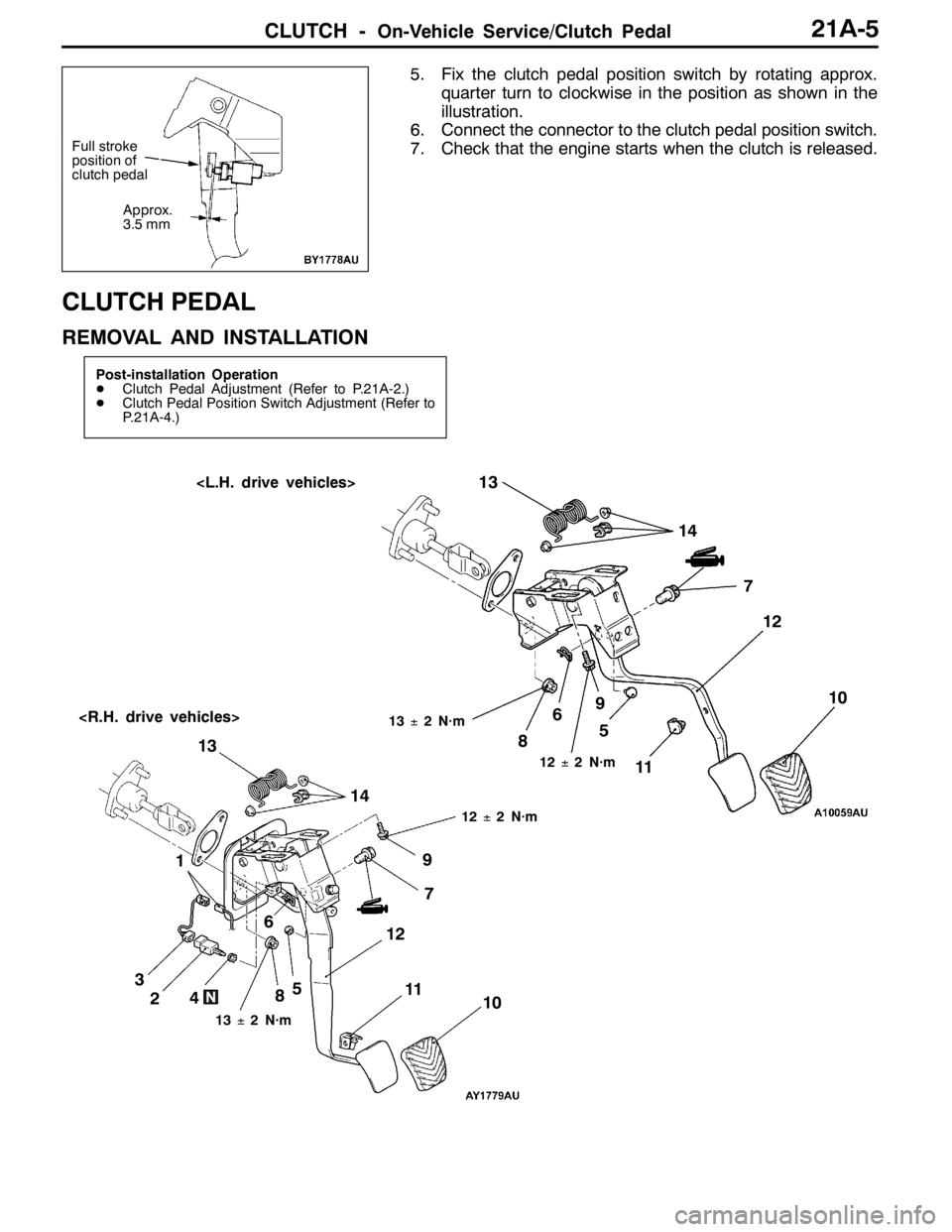

CLUTCH -On-Vehicle Service/Clutch Pedal21A-5

5. Fix the clutch pedal position switch by rotating approx.

quarter turn to clockwise in the position as shown in the

illustration.

6. Connect the connector to the clutch pedal position switch.

7. Check that the engine starts when the clutch is released.

CLUTCH PEDAL

REMOVAL AND INSTALLATION

Post-installation Operation

DClutch Pedal Adjustment (Refer to P.21A-2.)

DClutch Pedal Position Switch Adjustment (Refer to

P.21A-4.)

6713±2 N·m

1

12±2 N·m

8

11

2459

12±2 N·m

67

13±2 N·m

10 8

12 13

3145 910

1112 13

14

Full stroke

position of

clutch pedal

Approx.

3.5 mm

Page 812 of 1449

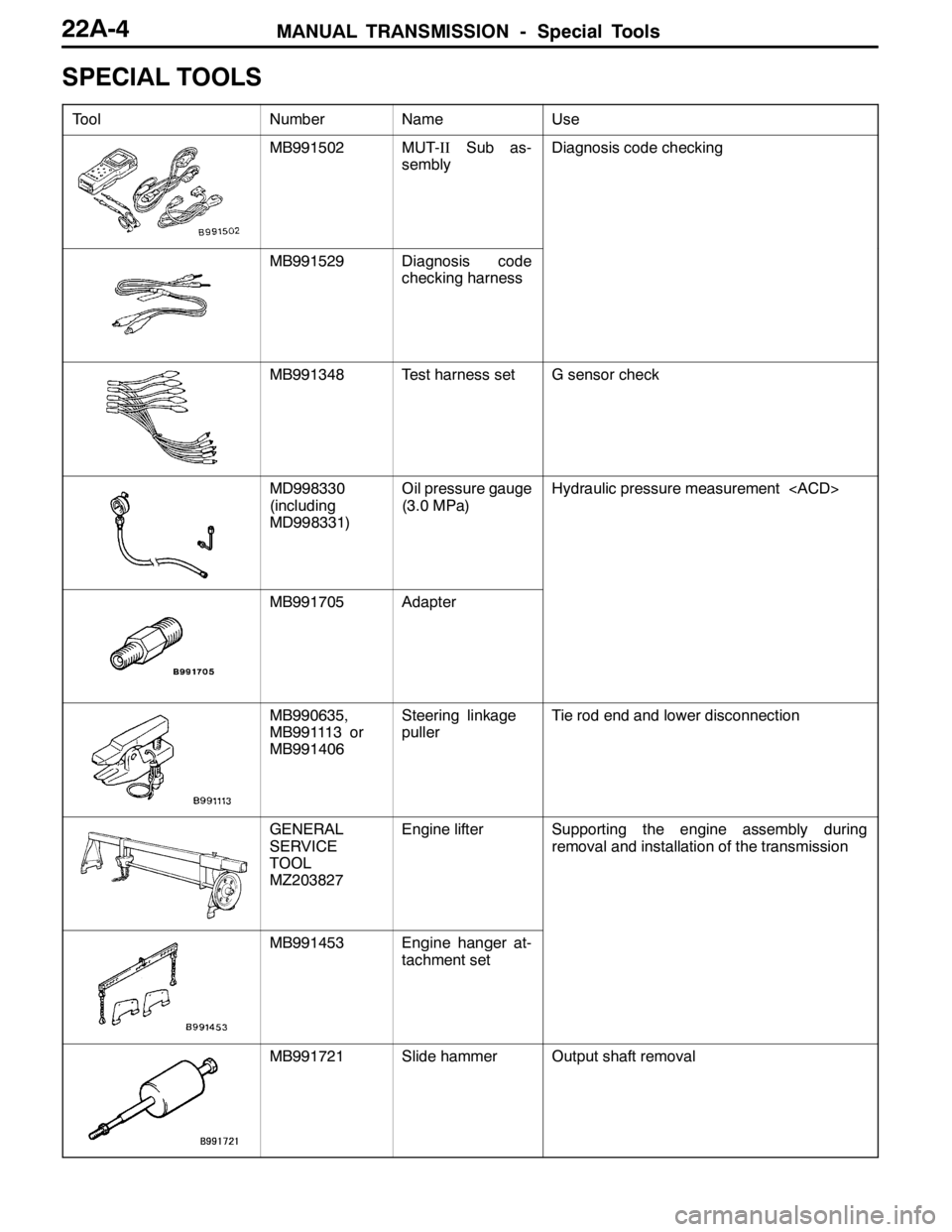

MANUAL TRANSMISSION - Special Tools22A-4

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IISub as-

semblyDiagnosis code checking

MB991529Diagnosis code

checking harness

MB991348Test harness setGsensor check

MD998330

(including

MD998331)Oil pressure gauge

(3.0 MPa)Hydraulic pressure measurement

MB991705Adapter

MB990635,

MB991113 or

MB991406

Steering linkage

pullerTie rod end and lower disconnection

GENERAL

SERVICE

TOOL

MZ203827Engine lifterSupporting the engine assembly during

removal and installation of the transmission

MB991453Engine hangerat-

tachment set

MB991721Slide hammerOutput shaft removal

Page 813 of 1449

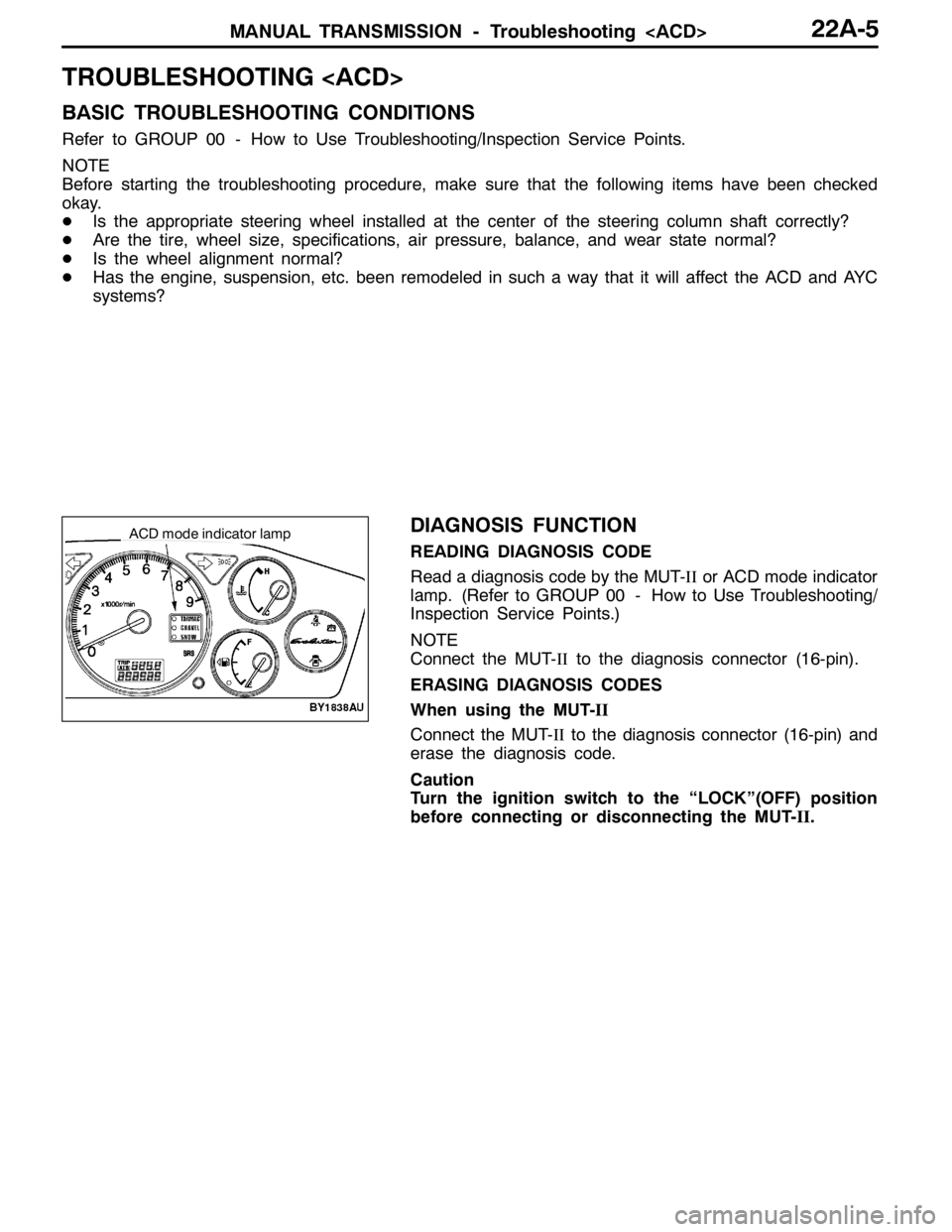

MANUAL TRANSMISSION - Troubleshooting

TROUBLESHOOTING

BASIC TROUBLESHOOTING CONDITIONS

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

NOTE

Before starting the troubleshooting procedure, make sure that the following items have been checked

okay.

DIs the appropriate steering wheel installed at the center of the steering column shaft correctly?

DAre the tire, wheel size, specifications, air pressure, balance, and wear state normal?

DIs the wheel alignment normal?

DHas the engine, suspension, etc. been remodeled in such a way that it will affect the ACD and AYC

systems?

DIAGNOSIS FUNCTION

READING DIAGNOSIS CODE

Read a diagnosis code by the MUT-IIor ACD mode indicator

lamp. (Refer to GROUP 00 - How to Use Troubleshooting/

Inspection Service Points.)

NOTE

Connect the MUT-IIto the diagnosis connector (16-pin).

ERASING DIAGNOSIS CODES

When using the MUT-II

Connect the MUT-IIto the diagnosis connector (16-pin) and

erase the diagnosis code.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

ACDmode indicator lamp

Page 839 of 1449

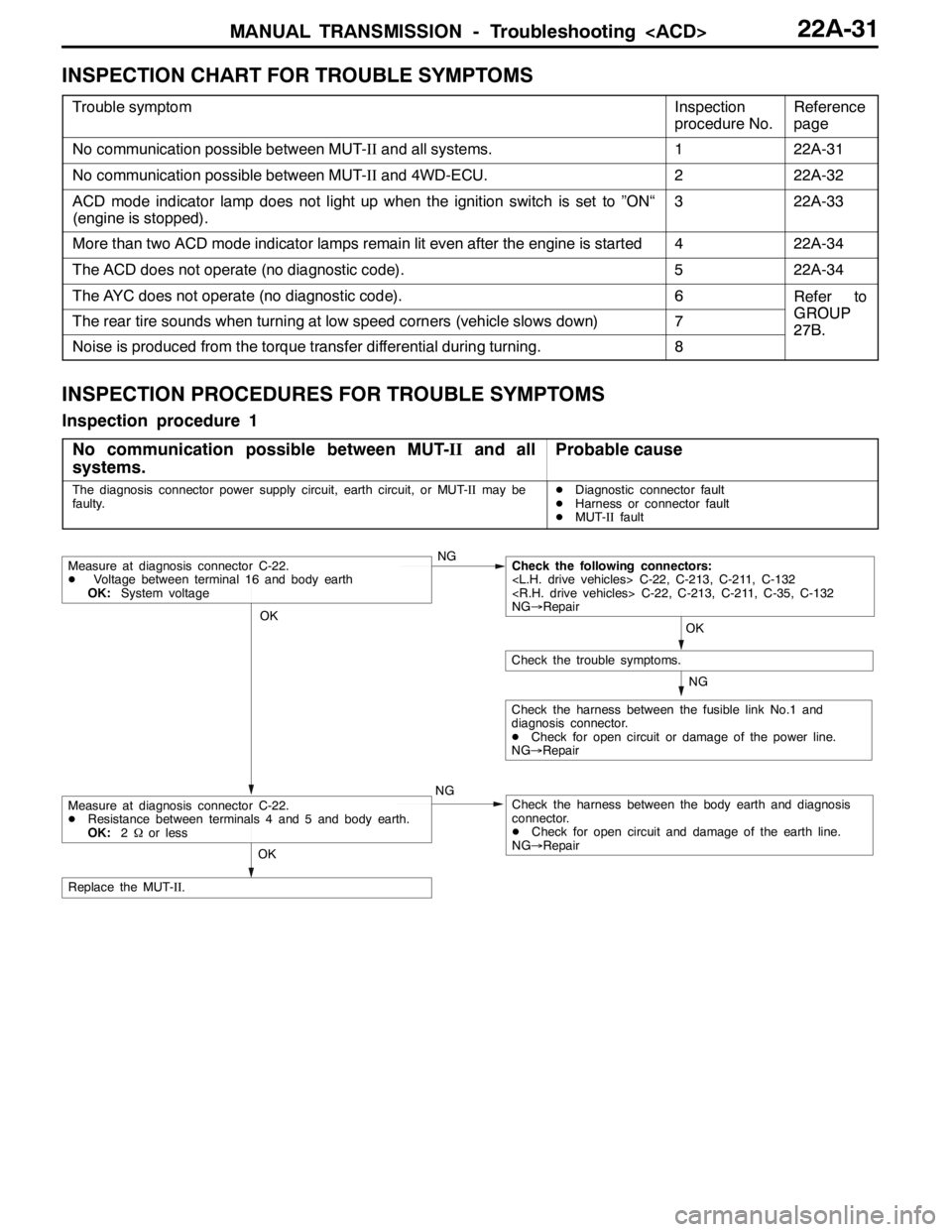

MANUAL TRANSMISSION - Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

No communication possible between MUT-IIand all systems.122A-31

No communication possible between MUT-IIand 4WD-ECU.222A-32

ACD mode indicator lamp does not light up when the ignition switch is set to ”ON“

(engine is stopped).322A-33

More than two ACD mode indicator lamps remain lit even after the engine is started422A-34

The ACD does not operate (no diagnostic code).522A-34

The AYC does not operate (no diagnostic code).6Refer to

GROUPThe rear tire sounds when turning at low speed corners (vehicle slows down)7GROUP

27B.

Noise is produced from the torque transfer differential during turning.8

27B.

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

No communication possible between MUT-IIand all

systems.

Probable cause

The diagnosis connector power supply circuit, earth circuit, or MUT-IImay be

faulty.DDiagnostic connector fault

DHarness or connector fault

DMUT-IIfault

OK

NG

NG

Check the harness between the fusible link No.1 and

diagnosis connector.

DCheck for open circuit or damage of the power line.

NG→Repair

OK

Check the trouble symptoms.

Measure at diagnosis connector C-22.

DVoltage between terminal 16 and body earth

OK:System voltageNGCheck the following connectors:

NG→Repair

Check the harness between the body earth and diagnosis

connector.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Replace the MUT-II.

Measure at diagnosis connector C-22.

DResistance between terminals 4 and 5 and body earth.

OK:2Ωor less

Page 841 of 1449

MANUAL TRANSMISSION - Troubleshooting

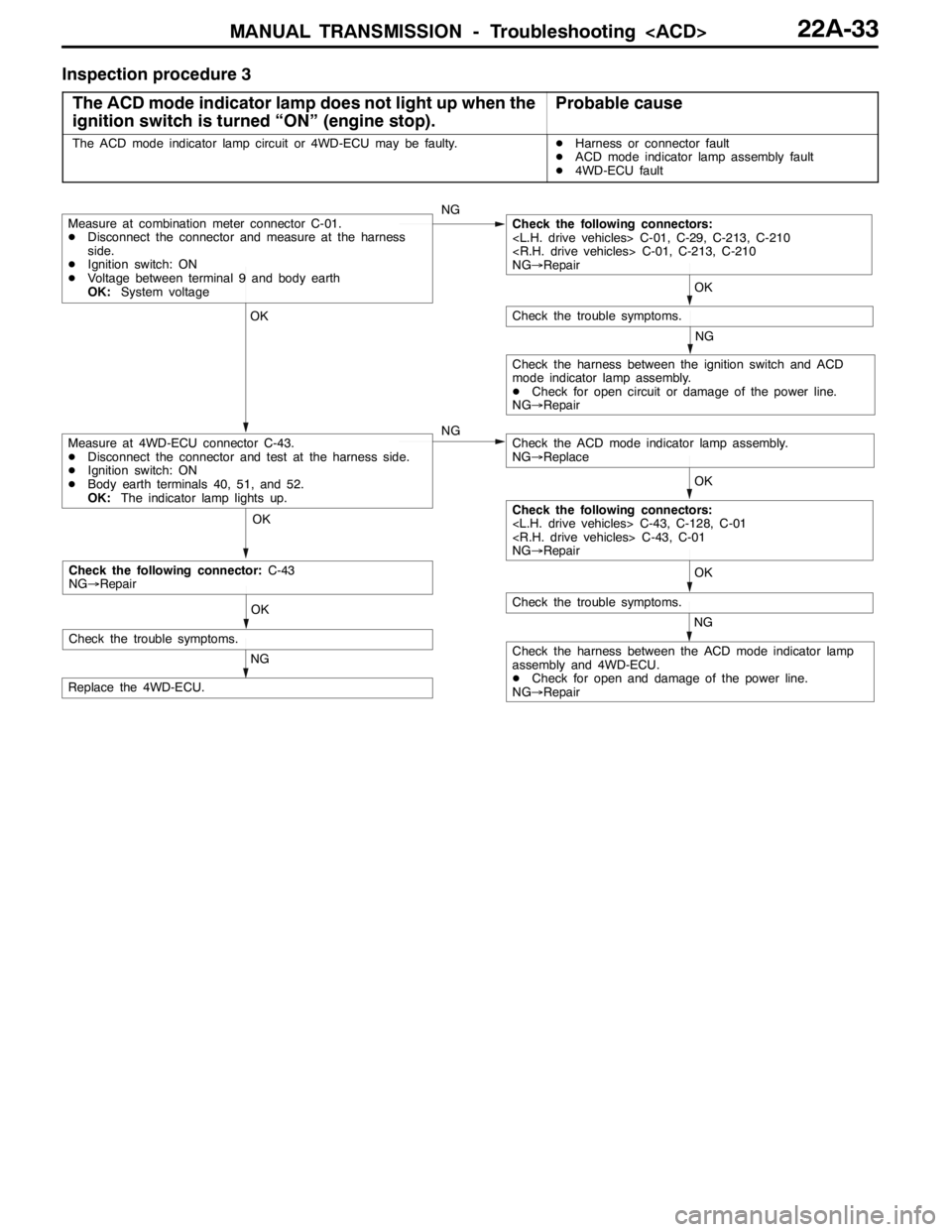

Inspection procedure 3

The ACD mode indicator lamp does not light up when the

ignition switch is turned “ON” (engine stop).

Probable cause

The ACD mode indicator lamp circuit or 4WD-ECU may be faulty.DHarness or connector fault

DACD mode indicator lamp assembly fault

D4WD-ECU fault

OK OK OKOK

NG

OK

NG

NG

NG

Check the harness between the ACD mode indicator lamp

assembly and 4WD-ECU.

DCheck for open and damage of the power line.

NG→Repair

Replace the 4WD-ECU.

Measure at 4WD-ECU connector C-43.

DDisconnect the connector and test at the harness side.

DIgnition switch: ON

DBody earth terminals 40, 51, and 52.

OK:The indicator lamp lights up.

Check the trouble symptoms.

Measure at combination meter connector C-01.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 9 and body earth

OK:System voltageCheck the following connectors:

NG→Repair

Check the trouble symptoms.

Check the ACD mode indicator lamp assembly.

NG→Replace

Check the harness between the ignition switch and ACD

mode indicator lamp assembly.

DCheck for open circuit or damage of the power line.

NG→Repair

Check the following connectors:

NG→Repair

OK

NG

Check the trouble symptoms.

Check the following connector:C-43

NG→Repair

Page 842 of 1449

MANUAL TRANSMISSION - Troubleshooting

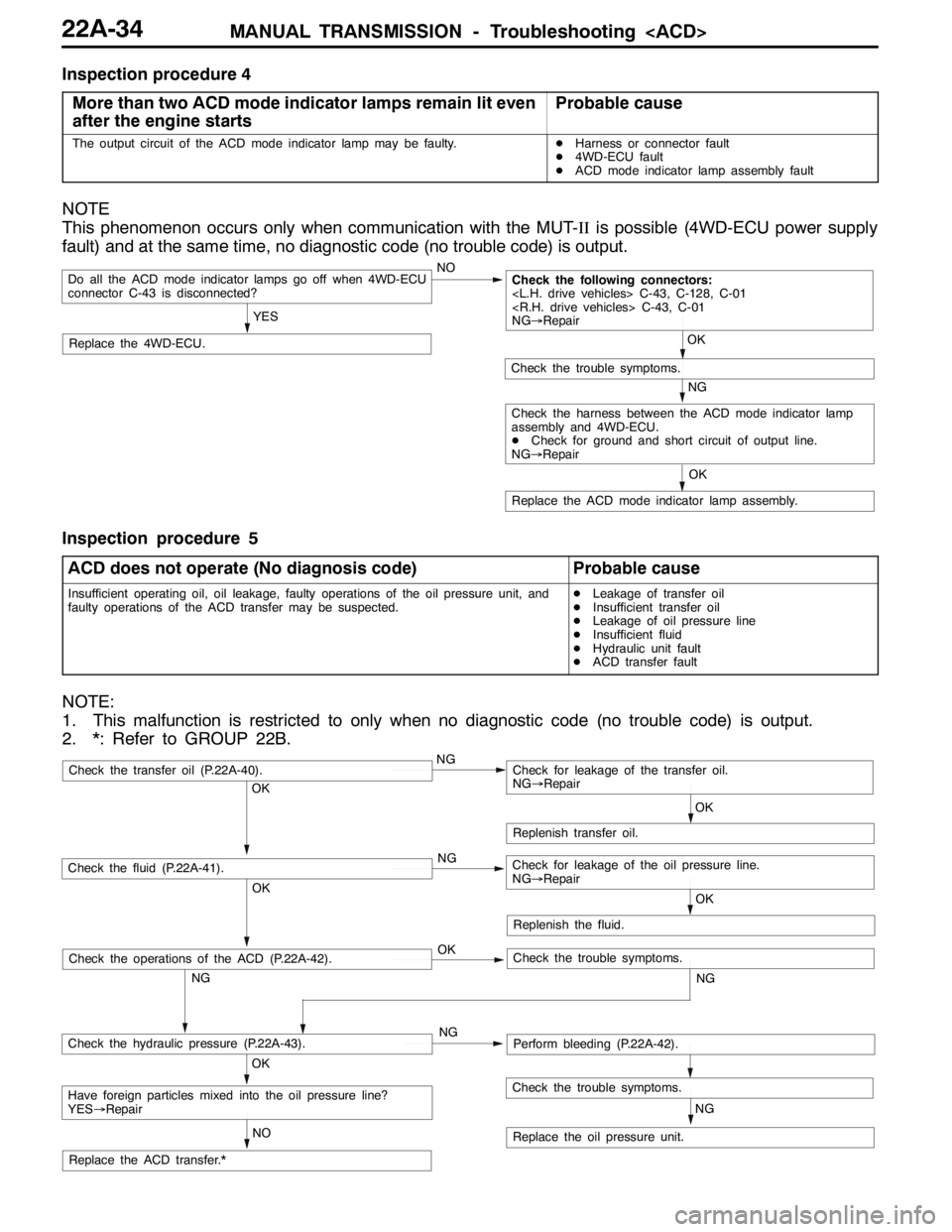

Inspection procedure 4

More than two ACD mode indicator lamps remain lit even

after the engine starts

Probable cause

The output circuit of the ACD mode indicator lamp may be faulty.DHarness or connector fault

D4WD-ECU fault

DACD mode indicator lamp assembly fault

NOTE

This phenomenon occurs only when communication with the MUT-IIis possible (4WD-ECU power supply

fault) and at the same time, no diagnostic code (no trouble code) is output.

NO

Replace the 4WD-ECU.

Do all the ACD mode indicator lamps go off when 4WD-ECU

connector C-43 is disconnected?

YES

Replace the ACD mode indicator lamp assembly.OK

NG

Check the trouble symptoms.

Check the following connectors:

NG→Repair

OK

Check the harness between the ACD mode indicator lamp

assembly and 4WD-ECU.

DCheck for ground and short circuit of output line.

NG→Repair

Inspection procedure 5

ACD does not operate (No diagnosis code)

Probable cause

Insufficient operating oil, oil leakage, faulty operations of the oil pressure unit, and

faulty operations of the ACD transfer may be suspected.DLeakage of transfer oil

DInsufficient transfer oil

DLeakage of oil pressure line

DInsufficient fluid

DHydraulic unit fault

DACD transfer fault

NOTE:

1. This malfunction is restricted to only when no diagnostic code (no trouble code) is output.

2. *: Refer to GROUP 22B.

OK

NG OKNG OKNG

NG

NO

NG

OK

Replenish transfer oil.

Replace the oil pressure unit.

Have foreign particles mixed into the oil pressure line?

YES→Repair

Check the hydraulic pressure (P.22A-43).Perform bleeding (P.22A-42).

Check the fluid (P.22A-41).Check for leakage of the oil pressure line.

NG→Repair

Check the transfer oil (P.22A-40).Check for leakage of the transfer oil.

NG→Repair

Check the trouble symptoms.

Replace the ACD transfer.*OK

Replenish the fluid.

OK

NG

Check the operations of the ACD (P.22A-42).Check the trouble symptoms.

Page 843 of 1449

MANUAL TRANSMISSION - Troubleshooting

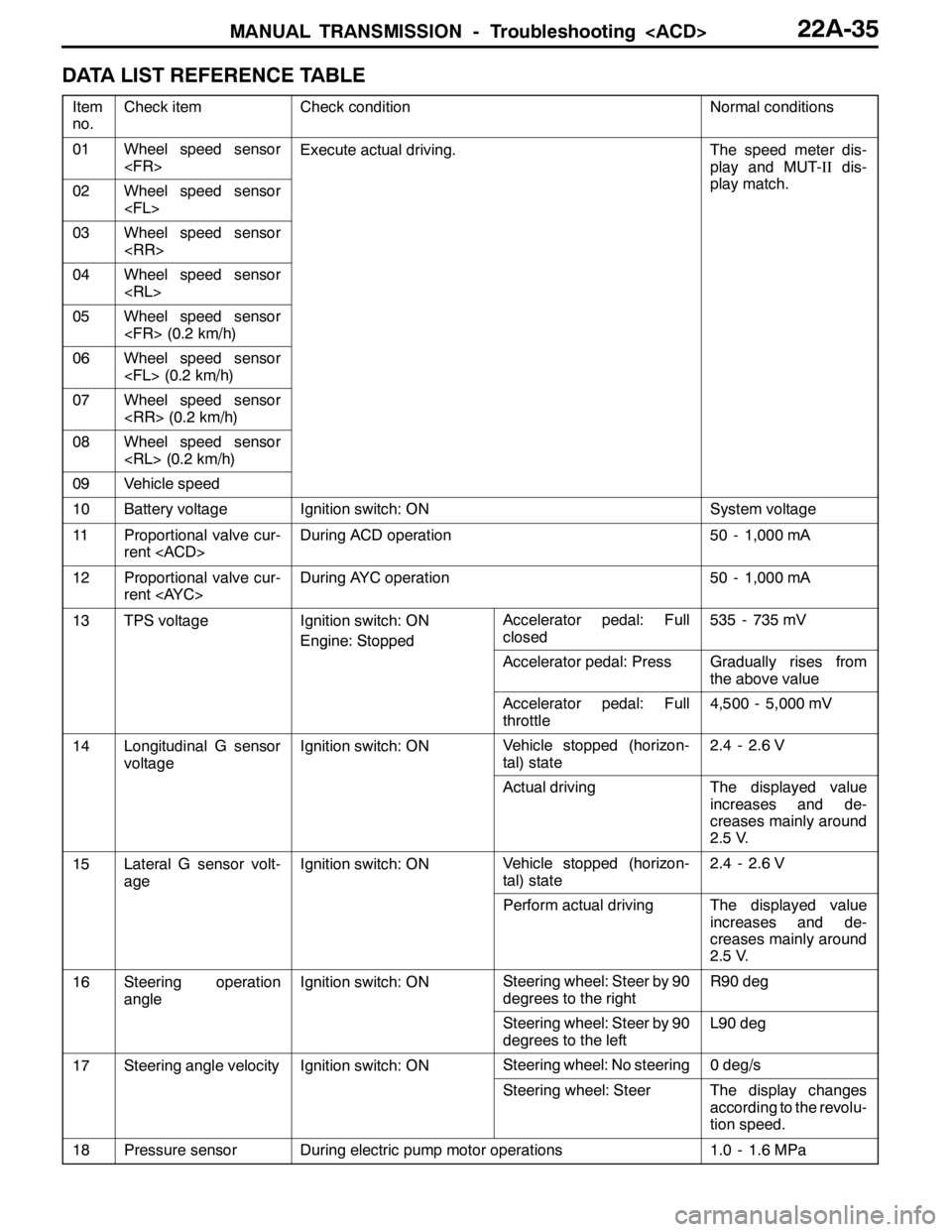

DATA LIST REFERENCE TABLE

Item

no.Check itemCheck conditionNormal conditions

01Wheel speed sensor

play and MUT-IIdis-

lth02Wheel speed sensor

py

play match.

03Wheel speed sensor

04Wheel speed sensor

05Wheel speed sensor

06Wheel speed sensor

07Wheel speed sensor

08Wheel speed sensor

09Vehicle speed

10Battery voltageIgnition switch: ONSystem voltage

11Proportional valve cur-

rent

12Proportional valve cur-

rent

13TPS voltageIgnition switch: ON

Engine: StoppedAccelerator pedal: Full

closed535 - 735 mV

Engine:Stopped

Accelerator pedal: PressGradually rises from

the above value

Accelerator pedal: Full

throttle4,500 - 5,000 mV

14Longitudinal G sensor

voltageIgnition switch: ONVehicle stopped (horizon-

tal) state2.4 - 2.6 V

g

Actual drivingThe displayed value

increases and de-

creases mainly around

2.5 V.

15Lateral G sensor volt-

ageIgnition switch: ONVehicle stopped (horizon-

tal) state2.4 - 2.6 V

g

Perform actual drivingThe displayed value

increases and de-

creases mainly around

2.5 V.

16Steering operation

angleIgnition switch: ONSteering wheel: Steer by 90

degrees to the rightR90 deg

g

Steering wheel: Steer by 90

degrees to the leftL90 deg

17Steering angle velocityIgnition switch: ONSteering wheel: No steering0 deg/sggyg

Steering wheel: SteerThe display changes

according to the revolu-

tion speed.

18Pressure sensorDuring electric pump motor operations1.0 - 1.6 MPa

Page 844 of 1449

MANUAL TRANSMISSION - Troubleshooting

Item

no.Normal conditions Check condition Check item

19Pressure sensor power

supplyIgnition switch: ONApprox.5 V

20Valve power supplyIgnition switch: ONSystem voltage

21Steering wheel sensor

voltage

are displayed alter-

nately.

22Steering wheel sensor

voltage

are displayed alter-

nately.

23Steering wheel sensor

ltSTN

Ignition switch: ONSteering wheel: Neutral1-2Vg

voltage

g

Steering wheel: Turn2.5 - 4.5 V

51Idle switchIgnition switch: ONAccelerator pedal: Full

closedON

Accelerator pedal: PressOFF

52Steering wheel sensor

STN

Ignition switch: ONsteering wheel: NeutralONg

g

Steering wheel: Turn from

the neutral positionOFF

53Steering wheel sensor

played alternaltely.

54Steering wheel sensor

played alternately

55Steering wheel sensor

learning

tral position learning exe-

cutedON

Steering wheel sensor neu-

tral position learning unex-

ecutedOFF

56Stop lamp switchIgnition switch: ONBrake pedal: DepressONppg

Engine: StoppedBrake pedal: ReleaseOFF

57Motor monitorElectric pump motor is currently operatingON

Electric pump motor is currently not operatingOFF

58Oil pressure stateElectric pump motor is currently operatingLOWp

Electric pump motor is currently not operatingHIGH

59Directional valve

Ri ht

AYC clutch right side is currently operatingON

60Directional valve

Lft

AYC clutch left side is currently operatingON

61ABS monitorABS is currently operatingON

ABS is currently not operatingOFF

62Parking brake switchIgnition switch: ONParking brake lever: PullONgg

Engine:StoppedParking brake lever: Re-

leaseOFF

63ACD mode switchIgnition switch: ONACD mode switch: PressONg

Engine:StoppedACD mode switch: ReleaseOFF

Page 850 of 1449

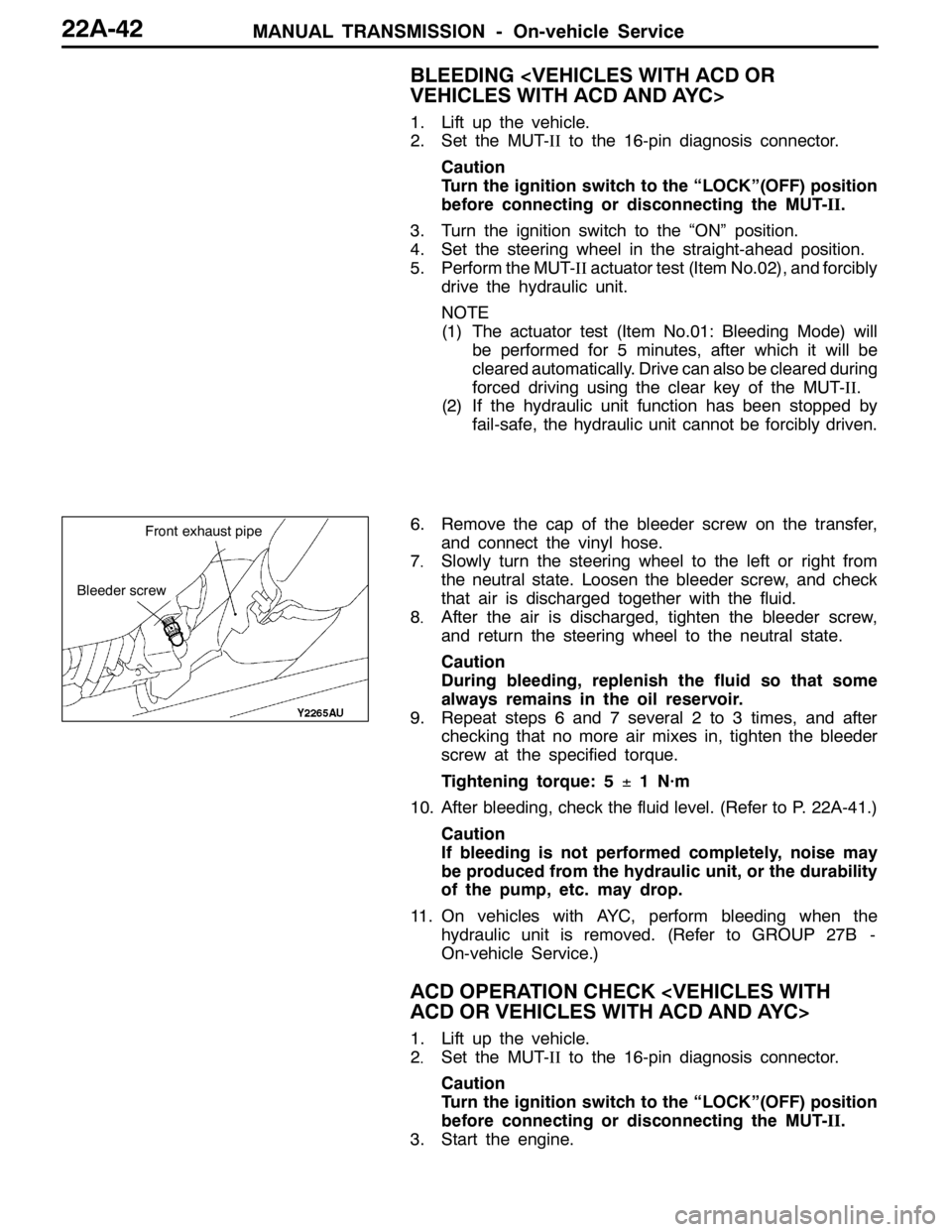

MANUAL TRANSMISSION - On-vehicle Service22A-42

BLEEDING

1. Lift up the vehicle.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Turn the ignition switch to the “ON” position.

4. Set the steering wheel in the straight-ahead position.

5. Perform the MUT-IIactuator test (Item No.02), and forcibly

drive the hydraulic unit.

NOTE

(1) The actuator test (Item No.01: Bleeding Mode) will

be performed for 5 minutes, after which it will be

cleared automatically. Drive can also be cleared during

forced driving using the clear key of the MUT-II.

(2) If the hydraulic unit function has been stopped by

fail-safe, the hydraulic unit cannot be forcibly driven.

6. Remove the cap of the bleeder screw on the transfer,

and connect the vinyl hose.

7

.Slowly turn the steering wheel to the left or right from

the neutral state. Loosen the bleeder screw, and check

that air is discharged together with the fluid.

8

.After the air is discharged, tighten the bleeder screw,

and return the steering wheel to the neutral state.

Caution

During bleeding, replenish the fluid so that some

always remains in the oil reservoir.

9. Repeat steps 6 and 7 several 2 to 3 times, and after

checking that no more air mixes in, tighten the bleeder

screw at the specified torque.

Tightening torque: 5±1 N·m

10. After bleeding, check the fluid level. (Refer to P. 22A-41.)

Caution

If bleeding is not performed completely, noise may

be produced from the hydraulic unit, or the durability

of the pump, etc. may drop.

11. On vehicles with AYC, perform bleeding when the

hydraulic unit is removed. (Refer to GROUP 27B -

On-vehicle Service.)

ACD OPERATION CHECK

1. Lift up the vehicle.

2

.Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Start the engine.

Bleeder screw

Front exhaust pipe

Page 851 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-43

4. Set the gear to the 2nd gear or above, operate the MUT-II,

and check from the service data (Item No.09) that the

wheel speed is within 10 km/h to 20 km/h.

NOTE

(1) Set the steering wheel to the neutral position

(2) The ACD may continue operating (operation sounds

can be heard) when the steering wheel is steered,

this is not a system fault. In this case, set the steering

wheel to the neutral position, and perform the following

operations to stop the ACD.

DRelease the clutch.

DSet the gear to “N”.

DStop the engine

5. Perform the MUT-IIactuator test (Item No.05), and forcibly

drive the transfer.

NOTE

(1) The actuator test (Item No. 05: ACD Operation Check

Mode) is performed for 1 minute, after which it will

be cleared automatically. Drive can also be cleared

during forced driving using the clear key of the MUT-II.

(2) If the hydraulic unit function has been stopped by

fail-safe, the transfer cannot be forcibly driven.

6. Check that the front and rear wheel speeds satisfy the

following in the MUT-IIactuator test (Item No.05).

The front wheel will be faster than the back wheels by

more than 2 km/h.

NOTE

If the above are not satisfied, check the oil pressure as

the system may be faulty.

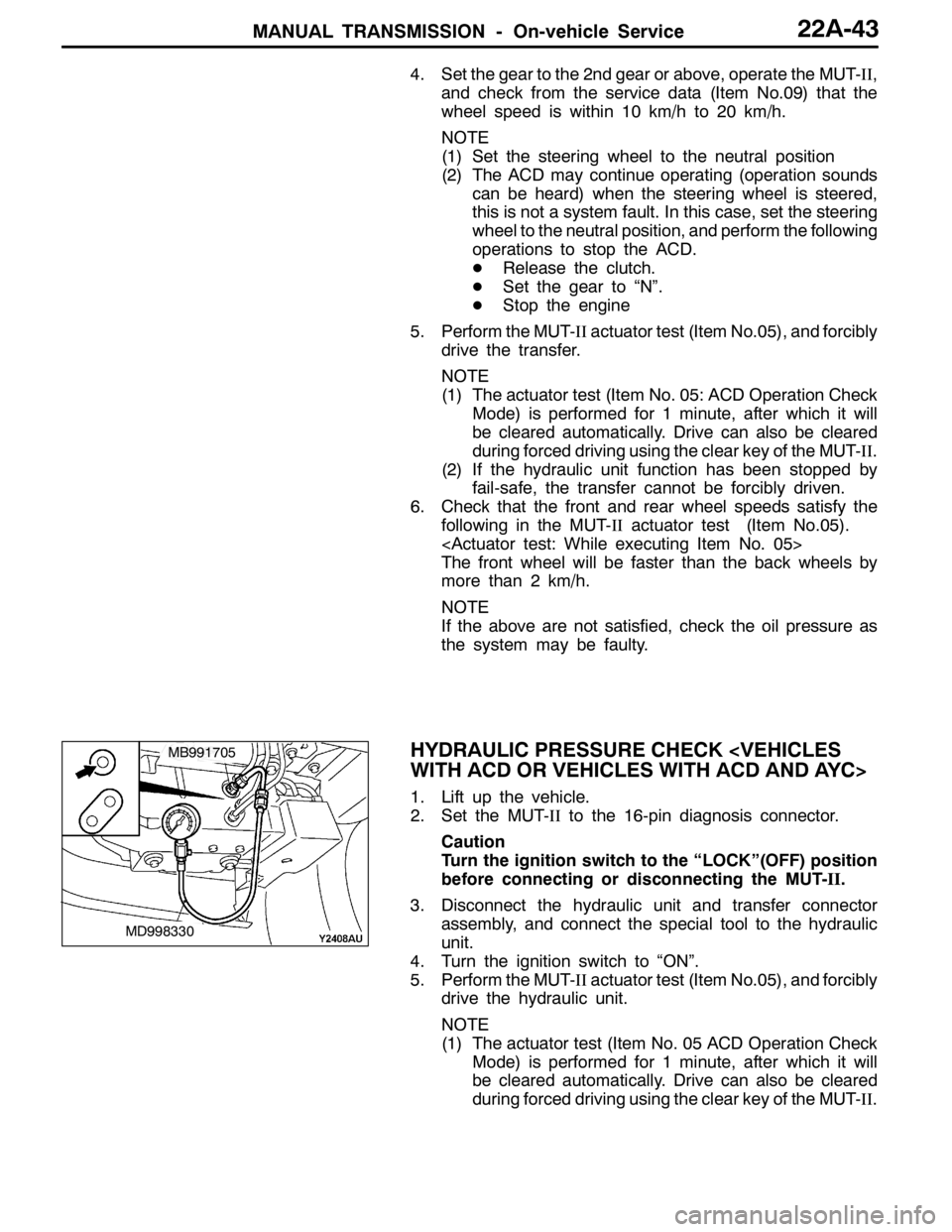

HYDRAULIC PRESSURE CHECK

1. Lift up the vehicle.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Disconnect the hydraulic unit and transfer connector

assembly, and connect the special tool to the hydraulic

unit.

4. Turn the ignition switch to “ON”.

5. Perform the MUT-IIactuator test (Item No.05), and forcibly

drive the hydraulic unit.

NOTE

(1) The actuator test (Item No. 05 ACD Operation Check

Mode) is performed for 1 minute, after which it will

be cleared automatically. Drive can also be cleared

during forced driving using the clear key of the MUT-II.

MD998330

MB991705