check engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1123 of 1449

STEERING -On-vehicle Service37A-9

POWER STEERING FLUID LEVEL CHECK

1. Park the vehicle on a flat, level surface, start the engine,

and then turn the steering wheel several times to raise

the temperature of the fluid to approximately 50 - 60_C.

2. With the engine running, turn the wheel all the way to

the left and right several times.

3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine

is stopped, and while it is running. If the change of the

fluid level is 5 mm or more, air bleeding should be done.

POWER STEERING FLUID REPLACEMENT

1. Raise the front wheels on a jack, and then support them

with rigid racks.

2. Disconnect the return hose connection.

3. Connect a vinyl hose to the return hose, and drain the

oil into a container.

4. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

5. While operating the starting motor intermittently, turn the

steering wheel all the way to the left and right several

times to drain all of the fluid.

6. Connect the return hoses securely, and then secure it

with the clip.

7. Fill the oil reservoir with specified fluid up to the lower

position of the filter, and then bleed air.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

POWER STEERING SYSTEM BLEEDING

1. Jack up the vehicle and support the front wheels with

rigid racks.

2. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

3. Cranking the engine with the starter several times

intermittently (during 15 to 20 seconds), turn the steering

wheel left and right fully five or six times.

Caution

(1) During the bleeding, refill the fluid so that the

level never falls below the lower position of the

filter.

(2) Be sure to bleed air only while cranking. If the

bleeding is done with the engine running, the air

will be broken up and absorbed into the fluid.

4. Connect the ignition coil connectors and idle the engine.

5. Turn the steering wheel left and right fully until no bubbles

comes out in the oil reservoir.

6. See that the fluid is not milky and that the fluid level

is up to the specified position on the level gauge.

7. See that the fluid level changes little when the steering

wheel is turned left and right.

8. Check difference in fluid levels between the engine

stopped and running.

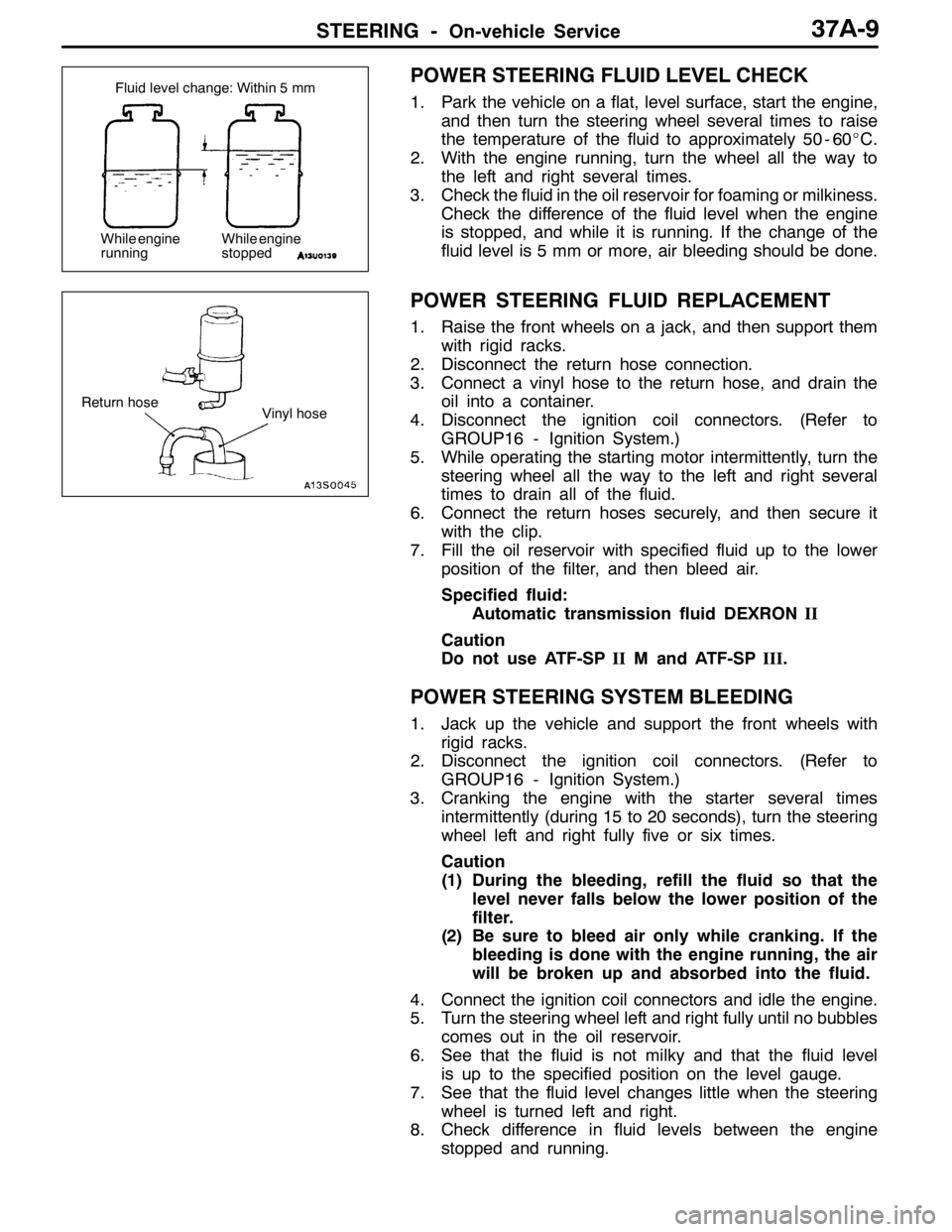

Fluid level change: Within 5 mm

While engine

runningWhile engine

stopped

Return hose

Vinyl hose

Page 1124 of 1449

STEERING -On-vehicle Service37A-10

9. If the level changes more than 5 mm, the air is badly

bled. So, bleed air again.

Caution

(1) If the fluid level rises suddenly after the engine

is stopped, the bleeding is incomplete.

(2) Incomplete bleeding causes abnormal noises

from the pump and the flow-control valve. This

could lessen the life of the pump and the other

parts.

OIL PUMP PRESSURE TEST

1. Disconnect the pressure hose from the oil pump, and

then connect the special tools.

2. Bleed the air, and then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50 - 60_C.

3. Start the engine and idle it at 1,000±100 r/min.

4. Fully close the shut-off valve of the pressure gauge and

measure the oil pump relief pressure to confirm that it

is within the standard value range.

Standard value: 8.4 - 9.0 MPa

5. If the standard value is not met, the oil pump is defective.

So, replace the oil pump. Then, measure oil pressure

again.

6. With the pressure gauge shut - off valve fully open, check

the hydraulic pressure in unladen condition.

Standard value: 0.2 - 0.8 MPa

7. If the standard value is not met, the oil line or steering

gear is probably defective. So, repair and measure oil

pressure again.

8. Turn the steering wheel fully either left or right and check

the retention hydraulic pressure.

Standard value: 8.4 - 9.0 MPa

9. If the pressure is below the standard value, disassemble

and reassemble the steering gear. If above, replace the

oil pump. Then, measure oil pressure again.

10. Remove the special tools, and tighten the pressure hose

to the specified torque.

Tightening torque: 18±3 N·m

11. Bleed the system.

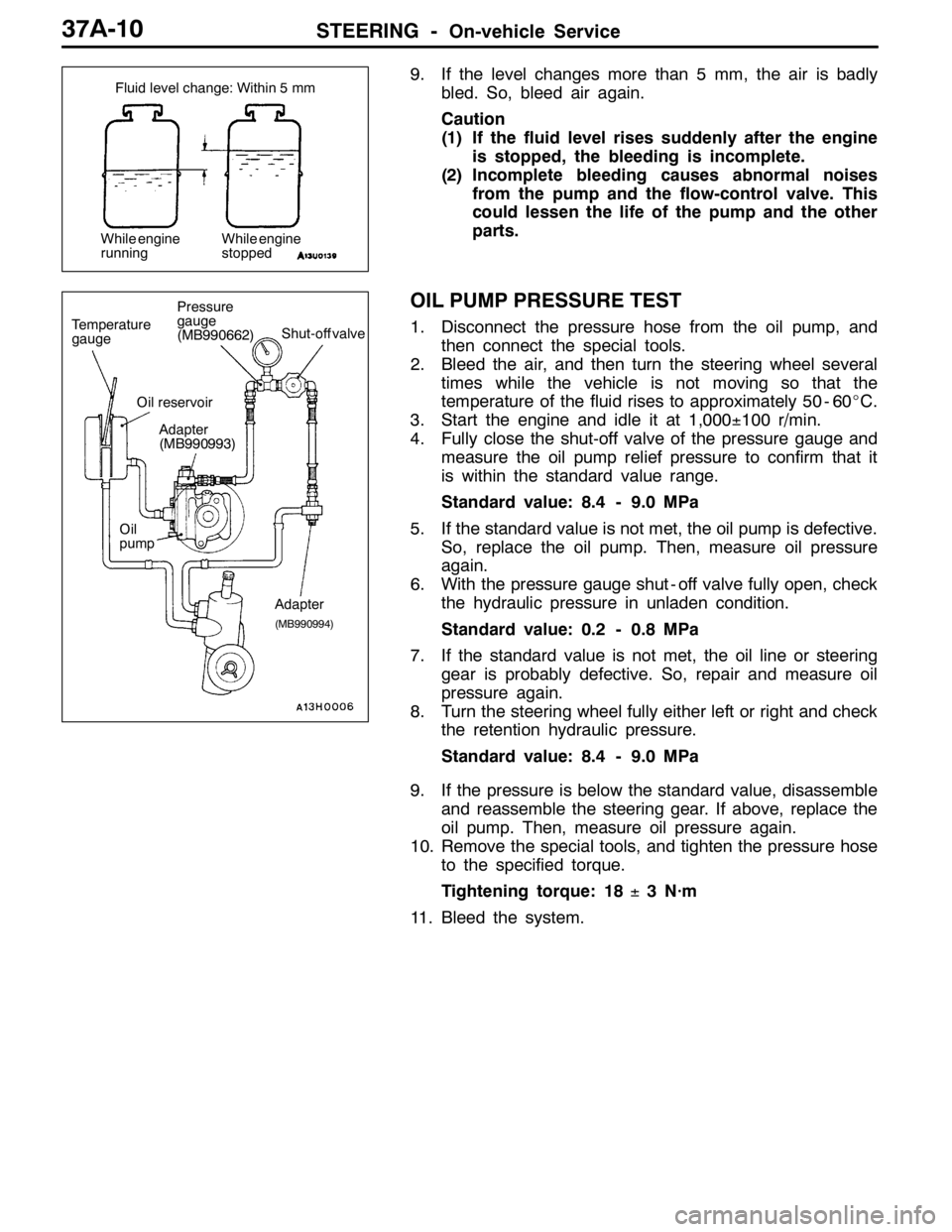

Fluid level change: Within 5 mm

While engine

runningWhile engine

stopped

Temperature

gaugePressure

gauge

(MB990662)Shut-off valve

Oil

pumpOil reservoir

Adapter

(MB990994)

Adapter

(MB990993)

Page 1125 of 1449

STEERING -On-vehicle Service37A-11

POWER STEERING OIL PRESSURE SWITCH

CHECK

1. Disconnect the pressure hose from the oil pump, and

then connect the special tools.

2. Bleed the air, and then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50 - 60_C.

3. The engine should be idling.

4. Disconnect the connection of the connector for the oil

pressure switch, and set an ohmmeter in position.

5. Gradually close the shut-off valve of the pressure gauge

and increase the hydraulic pressure, then check whether

or not the hydraulic pressure that activates the switch

is the standard value.

Standard value: 1.8 - 2.4 MPa

6. Gradually open the shut-off valve and reduce the hydraulic

pressure; then check whether or not the hydraulic pressure

that deactivates the switch is the standard value.

Standard value: 1.0 - 2.4 MPa

7. Remove the special tools, and then tighten the pressure

hose to the specified torque.

Tightening torque: 18±3 N·m

8. Bleed the system.

BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

tie rod end.

NOTE

Cracks or damage of the dust cover may cause damage

of the ball joint.

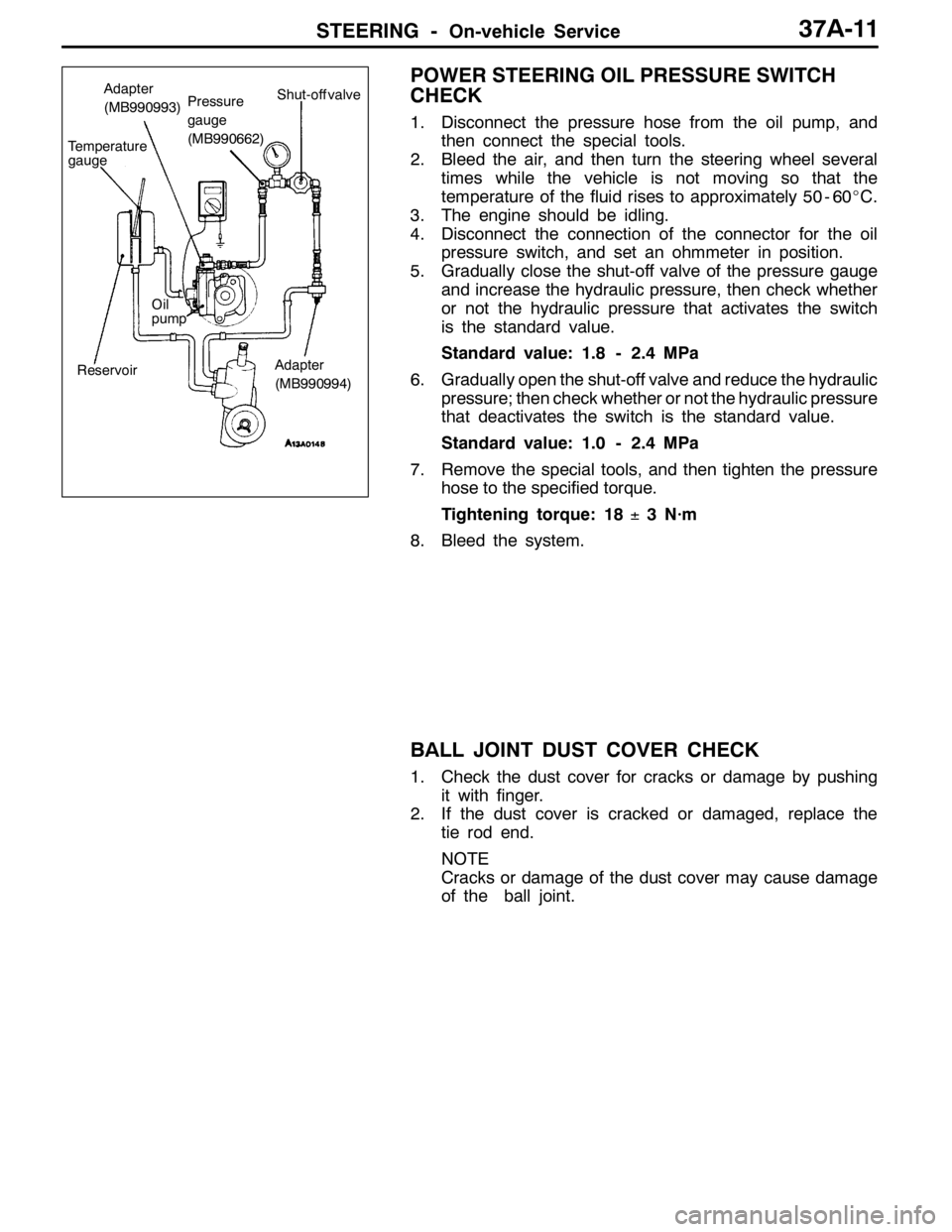

Temperature

gaugeShut-off valve

Oil

pump

ReservoirAdapter

(MB990993)Pressure

gauge

(MB990662)

Adapter

(MB990994)

Page 1322 of 1449

54A-2

CHASSIS

ELECTRICAL

CONTENTS

BATTERY 4..............................

SERVICE SPECIFICATION 4....................

ON-VEHICLE SERVICE 4......................

Fluid Level and Specific Gravity Check 4........

Charging 4.................................

Battery Testing Procedure 5...................

IGNITION SWITCH AND IMMOBILIZER

SYSTEM 6...............................

SPECIAL TOOLS 6............................

TROUBLESHOOTING 6........................

IMMOBILIZER-ECU CHECK 10.................

IGNITION SWITCH 11..........................

COMBINATION METER 14................

SERVICE SPECIFICATIONS 14.................

SEALANT 14..................................

SPECIAL TOOLS 15...........................

TROUBLESHOOTING 15.......................

ON-VEHICLE SERVICE 19.....................Speedometer Check 19......................

Tachometer Check 20........................

Fuel Gauge Unit Check 20....................

Engine Coolant Temperature Gauge

Unit Check 21...............................

COMBINATION METER 22.....................

HEADLAMP ASSEMBLY 24...............

SERVICE SPECIFICATIONS 24.................

TROUBLESHOOTING 24.......................

ON-VEHICLE SERVICE 24.....................

Headlamp Aiming 24.........................

Headlamp Intensity Measurement 28...........

Headlamp Bulb(low beam)Replacement28 ....

Headlamp Bulb(high beam)Replacement29 ...

Position Lamp Bulb Replacement29 ...........

Front Turn Signal Lamp Bulb Replacement29 ...

Headlamp Auto Cut Adjustment Procedure29 ...

HeadlampAuto Cut Function Check 29.........

HEADLAMP ASSEMBLY 30....................

CONTINUED ON NEXT PAGE

Page 1327 of 1449

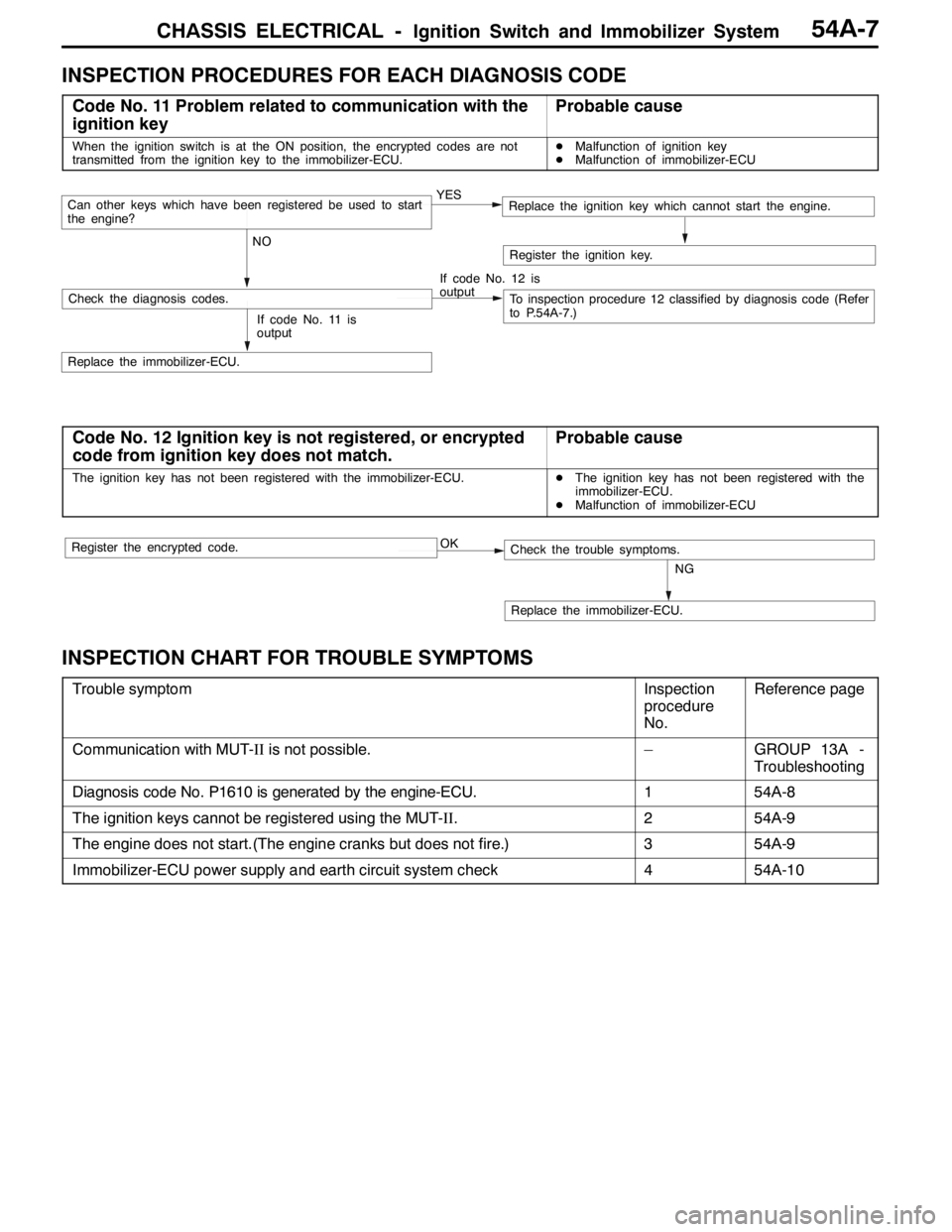

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-7

INSPECTION PROCEDURES FOR EACH DIAGNOSIS CODE

Code No. 11 Problem related to communication with the

ignition keyProbable cause

When the ignition switch is at the ON position, the encrypted codes are not

transmitted from the ignition key to the immobilizer-ECU.DMalfunction of ignition key

DMalfunction of immobilizer-ECU

YES

NOCan other keys which have been registered be used to start

the engine?Replace the ignition key which cannot start the engine.

If code No. 12 is

output

Check the diagnosis codes.To inspection procedure 12 classified by diagnosis code (Refer

to P.54A-7.)

Replace the immobilizer-ECU.

Register the ignition key.

If code No. 11 is

output

Code No. 12 Ignition key is not registered, or encrypted

code from ignition key does not match.Probable cause

The ignition key has not been registered with the immobilizer-ECU.DThe ignition key has not been registered with the

immobilizer-ECU.

DMalfunction of immobilizer-ECU

OK

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.Register the encrypted code.

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure

No.Reference page

Communication with MUT-IIis not possible.–GROUP 13A -

Troubleshooting

Diagnosis code No. P1610 is generated by the engine-ECU.154A-8

The ignition keys cannot be registered using the MUT-II.254A-9

The engine does not start.(The engine cranks but does not fire.)354A-9

Immobilizer-ECU power supply and earth circuit system check454A-10

Page 1328 of 1449

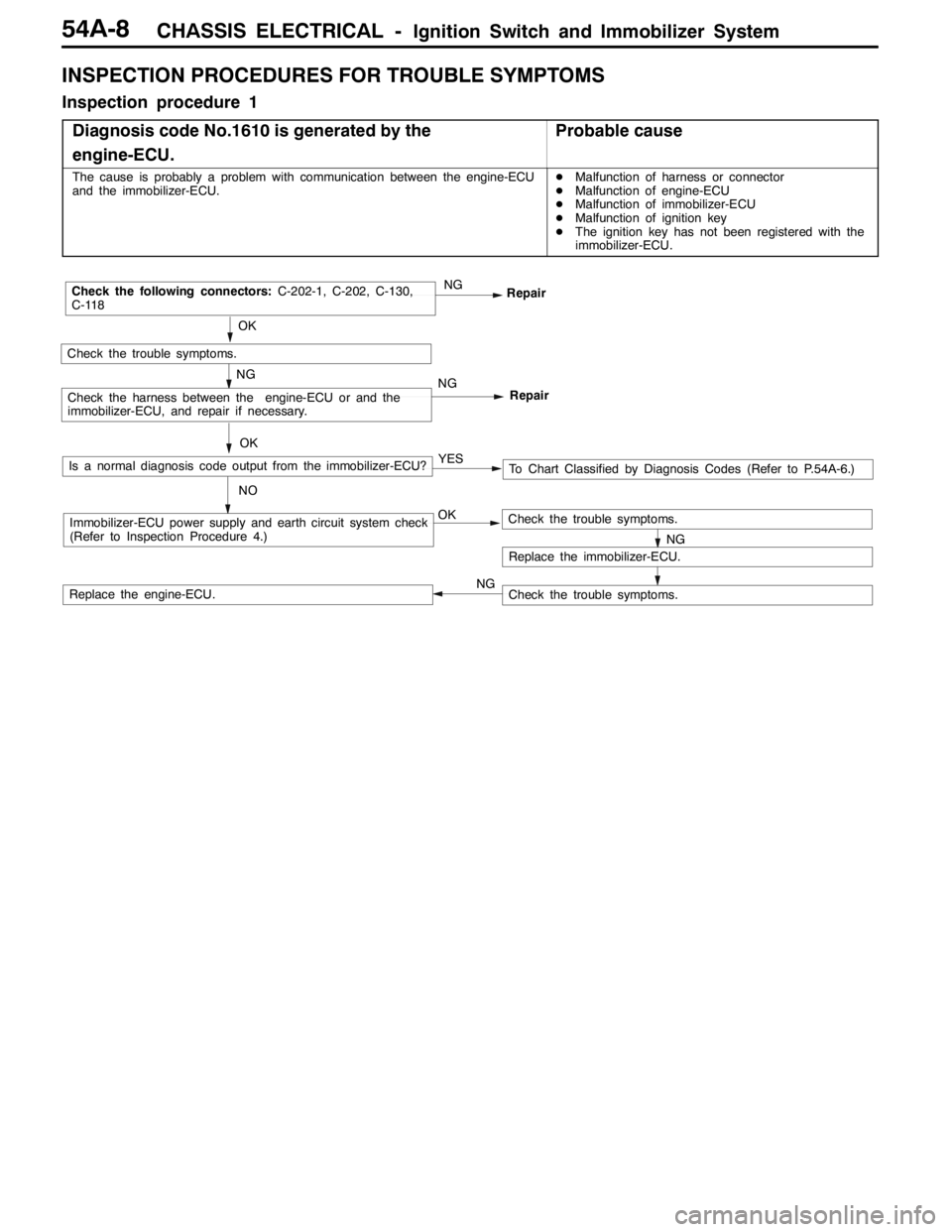

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-8

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

Diagnosis code No.1610 is generated by the

engine-ECU.

Probable cause

The cause is probably a problem with communication between the engine-ECU

and the immobilizer-ECU.DMalfunction of harness or connector

DMalfunction of engine-ECU

DMalfunction of immobilizer-ECU

DMalfunction of ignition key

DThe ignition key has not been registered with the

immobilizer-ECU.

OKImmobilizer-ECU power supply and earth circuit system check

(Refer to Inspection Procedure 4.)

OK

Check the trouble symptoms.

NGRepair

NGCheck the following connectors:C-202-1, C-202, C-130,

C-118

Repair

NGCheck the harness between the engine-ECU or and the

immobilizer-ECU, and repair if necessary.

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

Check the trouble symptoms.Replace the engine-ECU.OK

Is a normal diagnosis code output from the immobilizer-ECU?

NOTo Chart Classified by Diagnosis Codes (Refer to P.54A-6.) YES

NG

Page 1329 of 1449

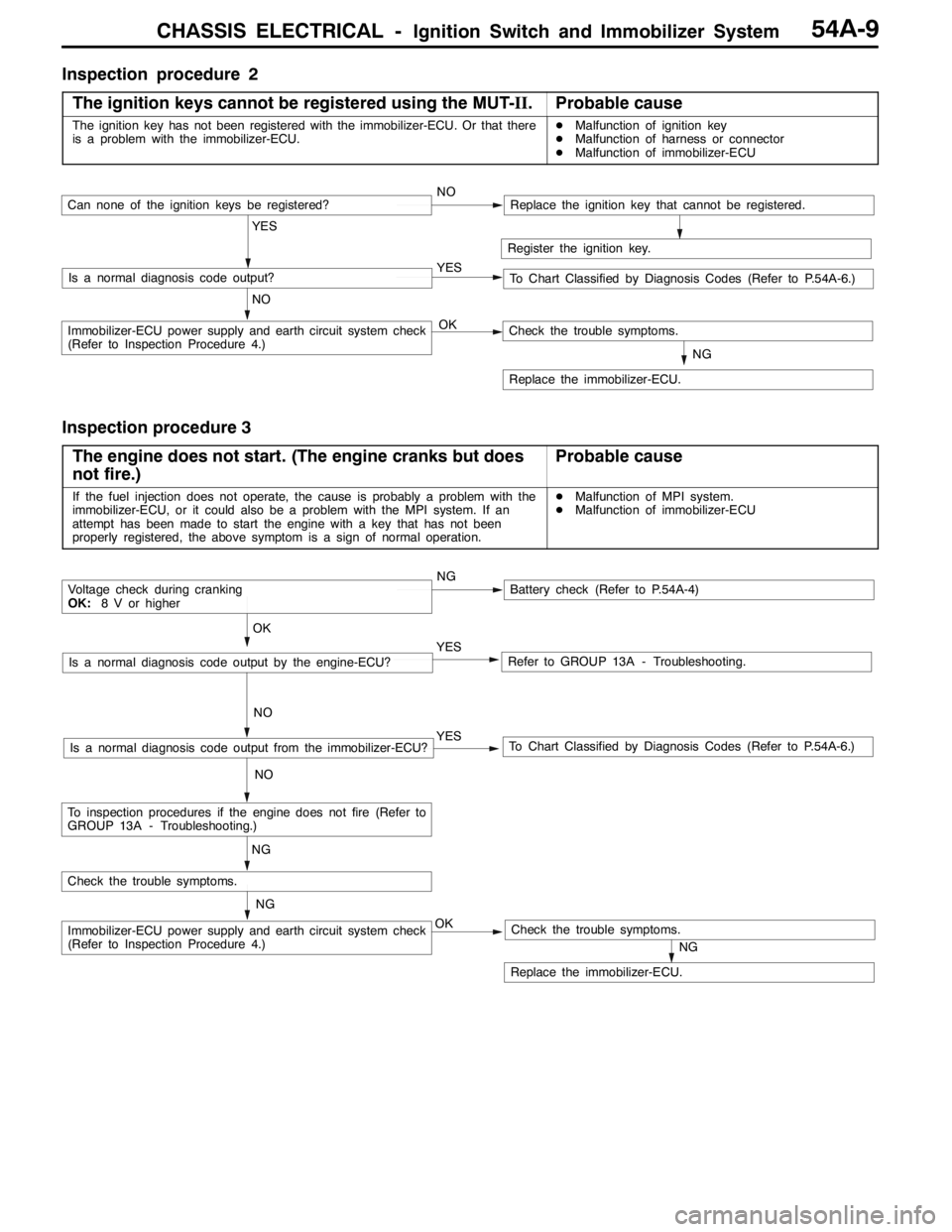

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-9

Inspection procedure 2

The ignition keys cannot be registered using the MUT-II.

Probable cause

The ignition key has not been registered with the immobilizer-ECU. Or that there

is a problem with the immobilizer-ECU.DMalfunction of ignition key

DMalfunction of harness or connector

DMalfunction of immobilizer-ECU

Register the ignition key.

YES

NO YESIs a normal diagnosis code output?

NOCan none of the ignition keys be registered?Replace the ignition key that cannot be registered.

To Chart Classified by Diagnosis Codes (Refer to P.54A-6.)

OKImmobilizer-ECU power supply and earth circuit system check

(Refer to Inspection Procedure 4.)

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

Inspection procedure 3

The engine does not start. (The engine cranks but does

not fire.)

Probable cause

If the fuel injection does not operate, the cause is probably a problem with the

immobilizer-ECU, or it could also be a problem with the MPI system. If an

attempt has been made to start the engine with a key that has not been

properly registered, the above symptom is a sign of normal operation.DMalfunction of MPI system.

DMalfunction of immobilizer-ECU

NGBattery check (Refer to P.54A-4)

YES

NO

Refer to GROUP 13A - Troubleshooting.YES

NO

To Chart Classified by Diagnosis Codes (Refer to P.54A-6.)Is a normal diagnosis code output from the immobilizer-ECU?

OK

Voltage check during cranking

OK:8 V or higher

Is a normal diagnosis code output by the engine-ECU?

NG

OKImmobilizer-ECU power supply and earth circuit system check

(Refer to Inspection Procedure 4.)

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

Check the trouble symptoms.

NG

To inspection procedures if the engine does not fire (Refer to

GROUP 13A - Troubleshooting.)

Page 1330 of 1449

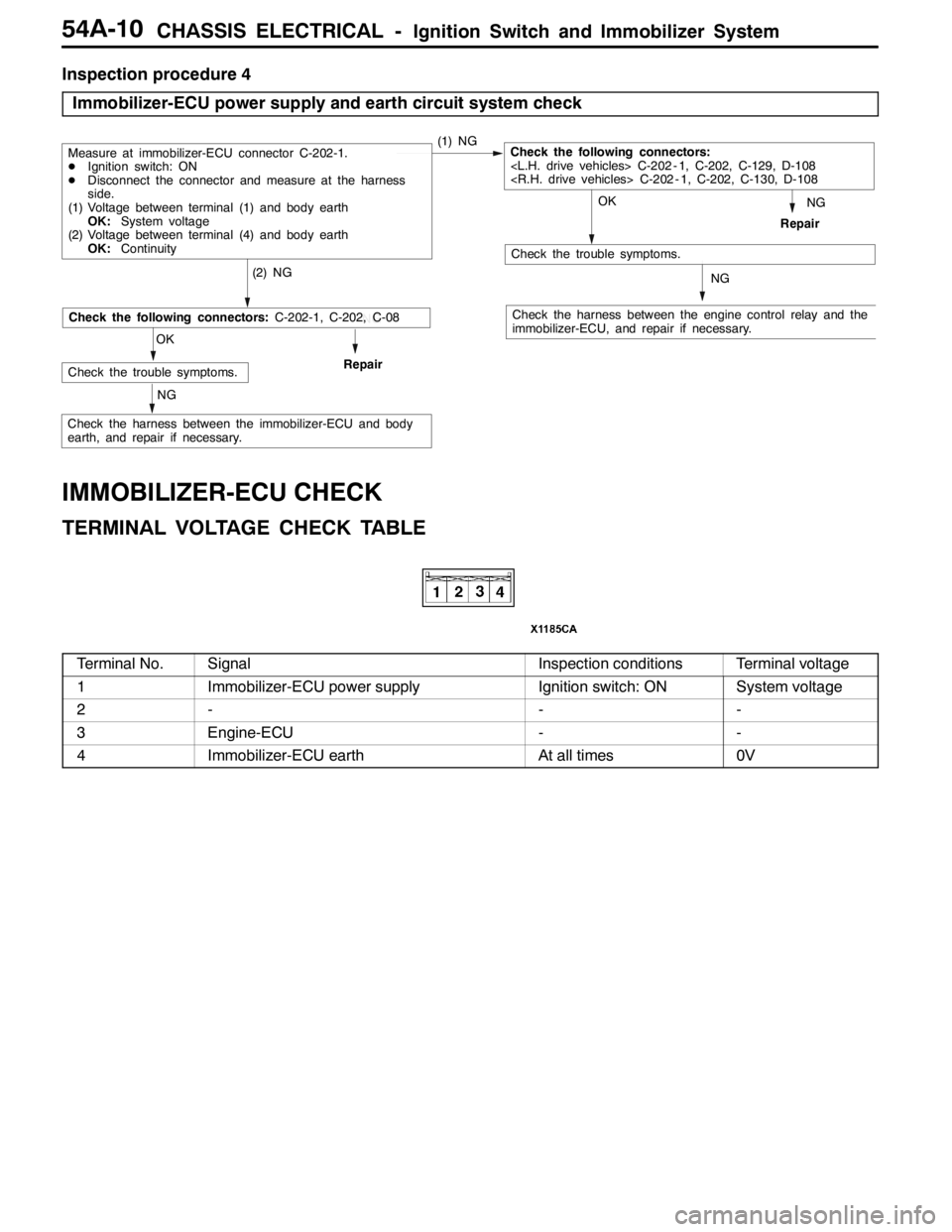

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-10

Inspection procedure 4

Immobilizer-ECU power supply and earth circuit system check

NG

Check the harness between the engine control relay and the

immobilizer-ECU, and repair if necessary.

OK

Check the trouble symptoms.

(2) NG

Repair

Measure at immobilizer-ECU connector C-202-1.

DIgnition switch: ON

DDisconnect the connector and measure at the harness

side.

(1) Voltage between terminal (1) and body earth

OK:System voltage

(2) Voltage between terminal (4) and body earth

OK:Continuity(1) NGCheck the following connectors:

NG

NG

OK

Check the trouble symptoms.Repair

NG

Check the following connectors:C-202-1, C-202, C-08

Check the harness between the immobilizer-ECU and body

earth, and repair if necessary.

IMMOBILIZER-ECU CHECK

TERMINAL VOLTAGE CHECK TABLE

Terminal No.SignalInspection conditionsTerminal voltage

1Immobilizer-ECU power supplyIgnition switch: ONSystem voltage

2---

3Engine-ECU--

4Immobilizer-ECU earthAt all times0V

Page 1332 of 1449

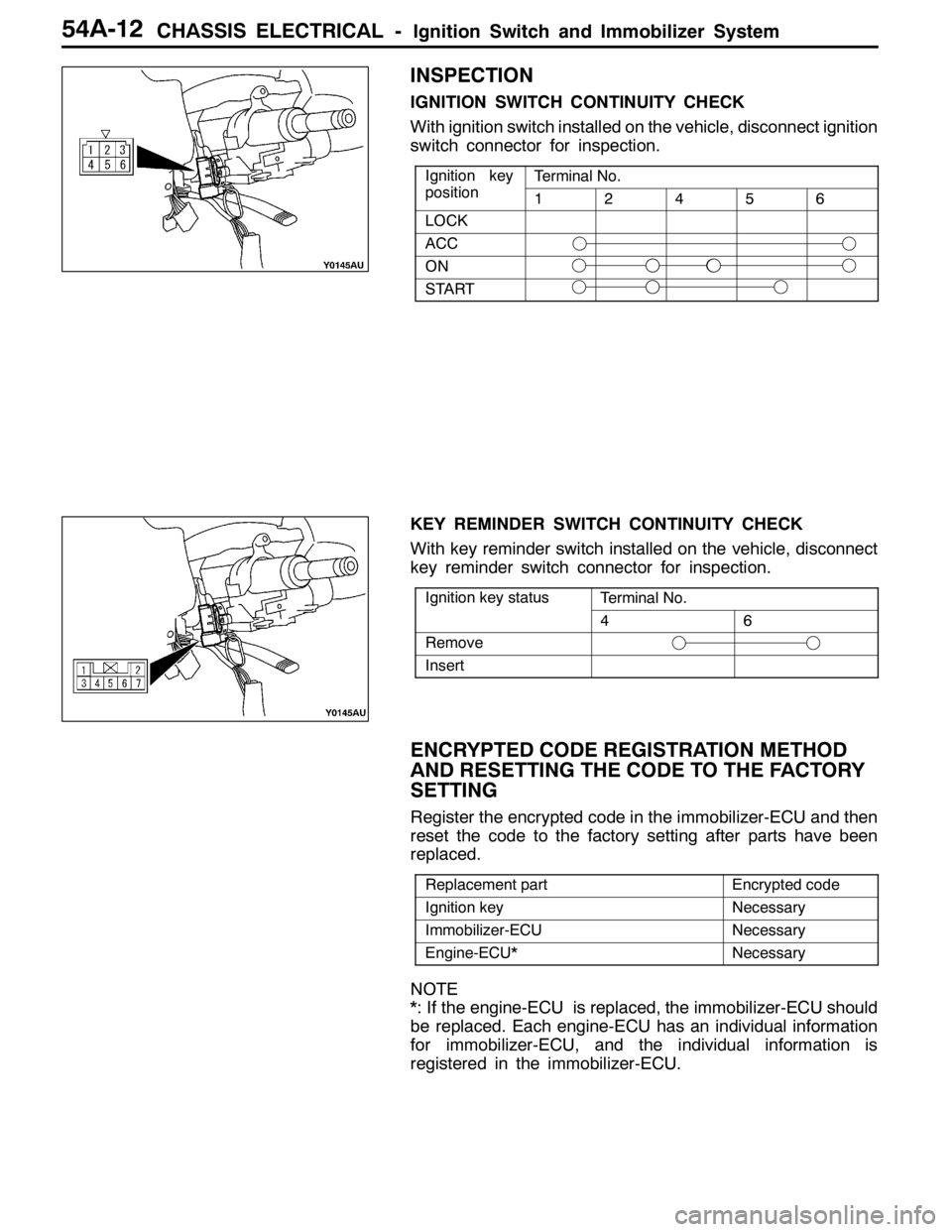

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-12

INSPECTION

IGNITION SWITCH CONTINUITY CHECK

With ignition switch installed on the vehicle, disconnect ignition

switch connector for inspection.

Ignition key

iti

Terminal No.gy

position12456

LOCK

ACC

ON

START

KEY REMINDER SWITCH CONTINUITY CHECK

With key reminder switch installed on the vehicle, disconnect

key reminder switch connector for inspection.

Ignition key statusTerminal No.gy

46

Remove

Insert

ENCRYPTED CODE REGISTRATION METHOD

AND RESETTING THE CODE TO THE FACTORY

SETTING

Register the encrypted code in the immobilizer-ECU and then

reset the code to the factory setting after parts have been

replaced.

Replacement partEncrypted code

Ignition keyNecessary

Immobilizer-ECUNecessary

Engine-ECU*Necessary

NOTE

*: If the engine-ECU is replaced, the immobilizer-ECU should

be replaced. Each engine-ECU has an individual information

for immobilizer-ECU, and the individual information is

registered in the immobilizer-ECU.

Page 1333 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-13

ENCRYPTED CODE REGISTRATION METHOD

If using an ignition key that has just been newly purchased,

or if the immobilizer-ECU has been replaced, you will need

to register the encrypted codes for each ignition key being

used into the immobilizer-ECU. (A maximum of eight different

encrypted codes can be registered.)

Moreover, when the immobilizer-ECU has been replaced, you

will need to use the MUT-IIto register the password that

the user specifies into the immobilizer-ECU. (Refer to the

MUT-IIinstruction manual for instructions on using the MUT-II.)

Caution

Because registering of the encrypted codes is carried

out after all previously-registered codes have been

erased, you should have ready all of the ignition keys

that have already been registered.

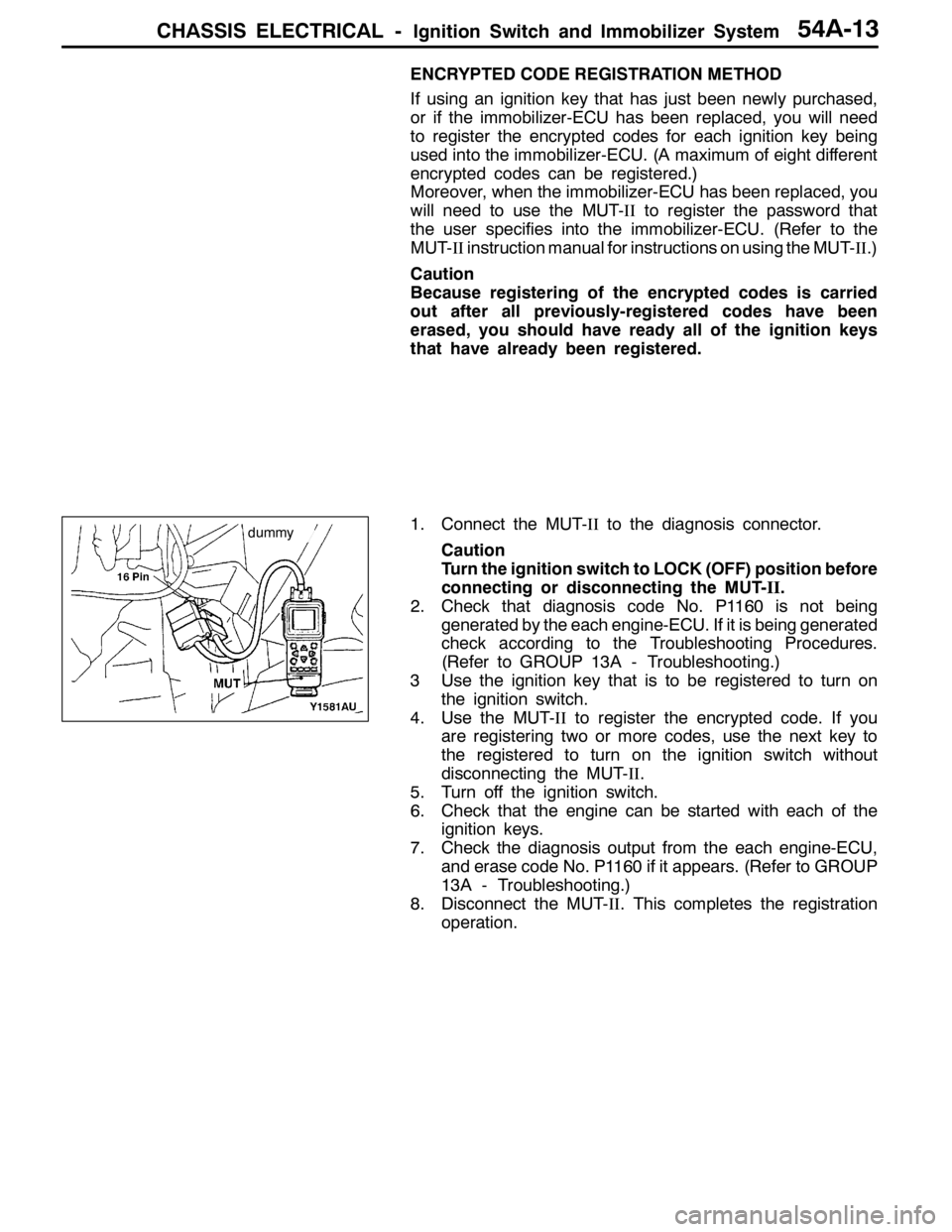

1. Connect the MUT-IIto the diagnosis connector.

Caution

Turn the ignition switch to LOCK (OFF) position before

connecting or disconnecting the MUT-II.

2. Check that diagnosis code No. P1160 is not being

generated by the each engine-ECU. If it is being generated

check according to the Troubleshooting Procedures.

(Refer to GROUP 13A - Troubleshooting.)

3 Use the ignition key that is to be registered to turn on

the ignition switch.

4. Use the MUT-IIto register the encrypted code. If you

are registering two or more codes, use the next key to

the registered to turn on the ignition switch without

disconnecting the MUT-II.

5. Turn off the ignition switch.

6. Check that the engine can be started with each of the

ignition keys.

7. Check the diagnosis output from the each engine-ECU,

and erase code No. P1160 if it appears. (Refer to GROUP

13A - Troubleshooting.)

8. Disconnect the MUT-II. This completes the registration

operation.

dummy