lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1323 of 1449

54A-3

SIDE TURN-SIGNAL LAMP 31............

SPECIAL TOOL 31............................

SIDE TURN-SIGNAL LAMP 31..................

ROOM LAMP 31.........................

TROUBLESHOOTING 31.......................

REAR COMBINATION LAMP 32...........

SPECIAL TOOL 32............................

TROUBLESHOOTING 32.......................

REAR COMBINATION LAMP 32................

HIGH-MOUNTED STOP LAMP 34.........

ON-VEHICLE SERVICE 34......................

High-mounted Stop Lamp Bulb Replacement 34.

HIGH-MOUNTED STOP LAMP 34................

LICENCE PLATE LAMP 35...............

ON-VEHICLE SERVICE 35.....................

License Plate Lamp Replacement 35...........

LICENCE PLATE LAMP 35.....................

HAZARD WARNING LAMP SWITCH 36....

SPECIAL TOOL 36............................

HAZARD WARNING LAMP SWITCH 36.........

HORN 37................................

CIGARETTE LIGHTER 37.................

COLUMN SWITCH 38....................

SPECIAL TOOL 38............................

COLUMN SWITCH 38..........................

CLOCK 40...............................

SPECIAL TOOL 40............................

CLOCK 40....................................

POLE ANTENNA 41......................

ROOF ANTENNA 42......................

DEFOGGER 42...........................

TROUBLESHOOTING 42......................

ON-VEHICLE SERVICE 43.....................

Printed Heater Check 43......................

Defogger Relay Continuity Check 43...........

DEFOGGER SWITCH 43.......................

Page 1331 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-11

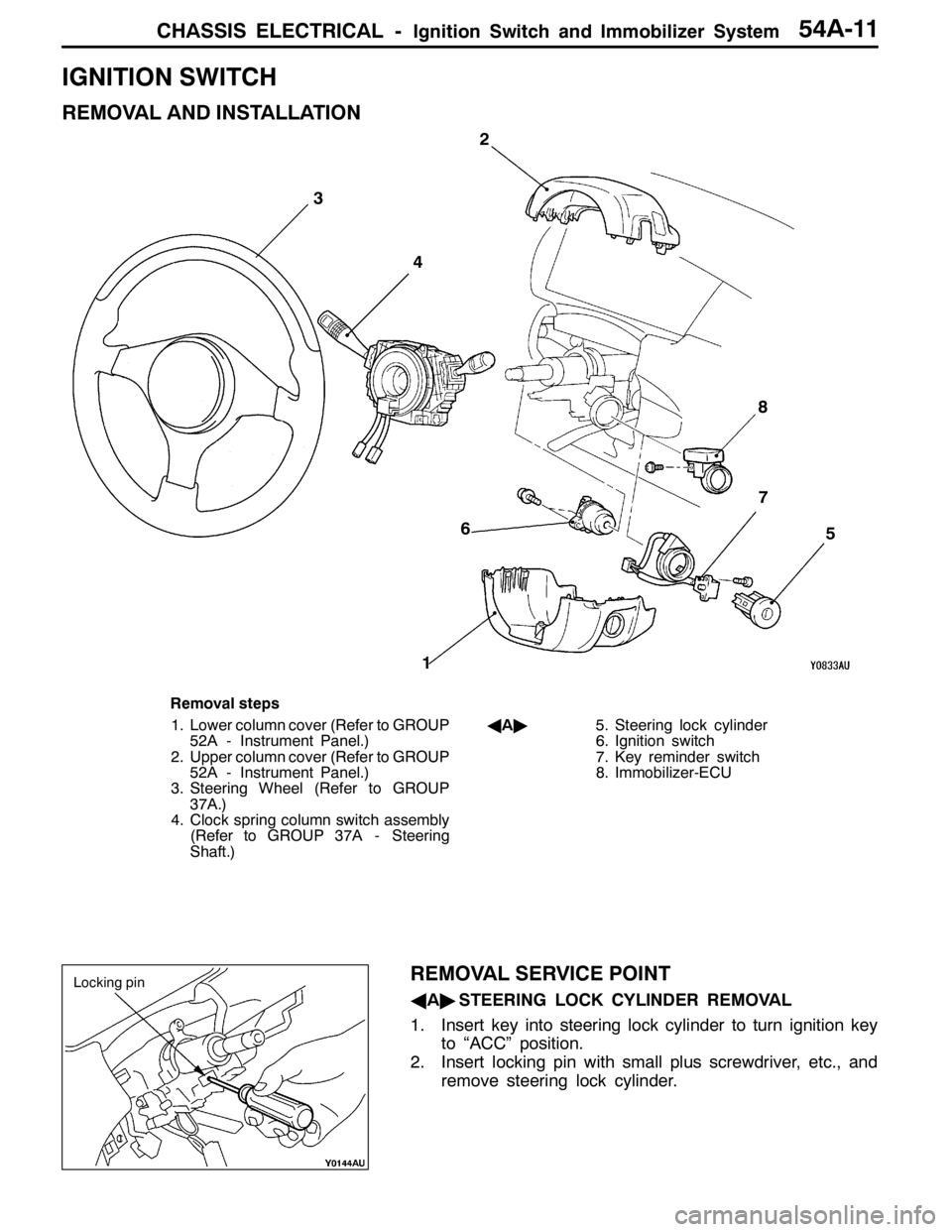

IGNITION SWITCH

REMOVAL AND INSTALLATION

7

6

15 32

4

8

Removal steps

1. Lower column cover (Refer to GROUP

52A - Instrument Panel.)

2. Upper column cover (Refer to GROUP

52A - Instrument Panel.)

3. Steering Wheel (Refer to GROUP

37A.)

4. Clock spring column switch assembly

(Refer to GROUP 37A - Steering

Shaft.)AA"5. Steering lock cylinder

6. Ignition switch

7. Key reminder switch

8. Immobilizer-ECU

REMOVAL SERVICE POINT

AA"STEERING LOCK CYLINDER REMOVAL

1. Insert key into steering lock cylinder to turn ignition key

to “ACC” position.

2. Insert locking pin with small plus screwdriver, etc., and

remove steering lock cylinder.

Locking pin

Page 1332 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-12

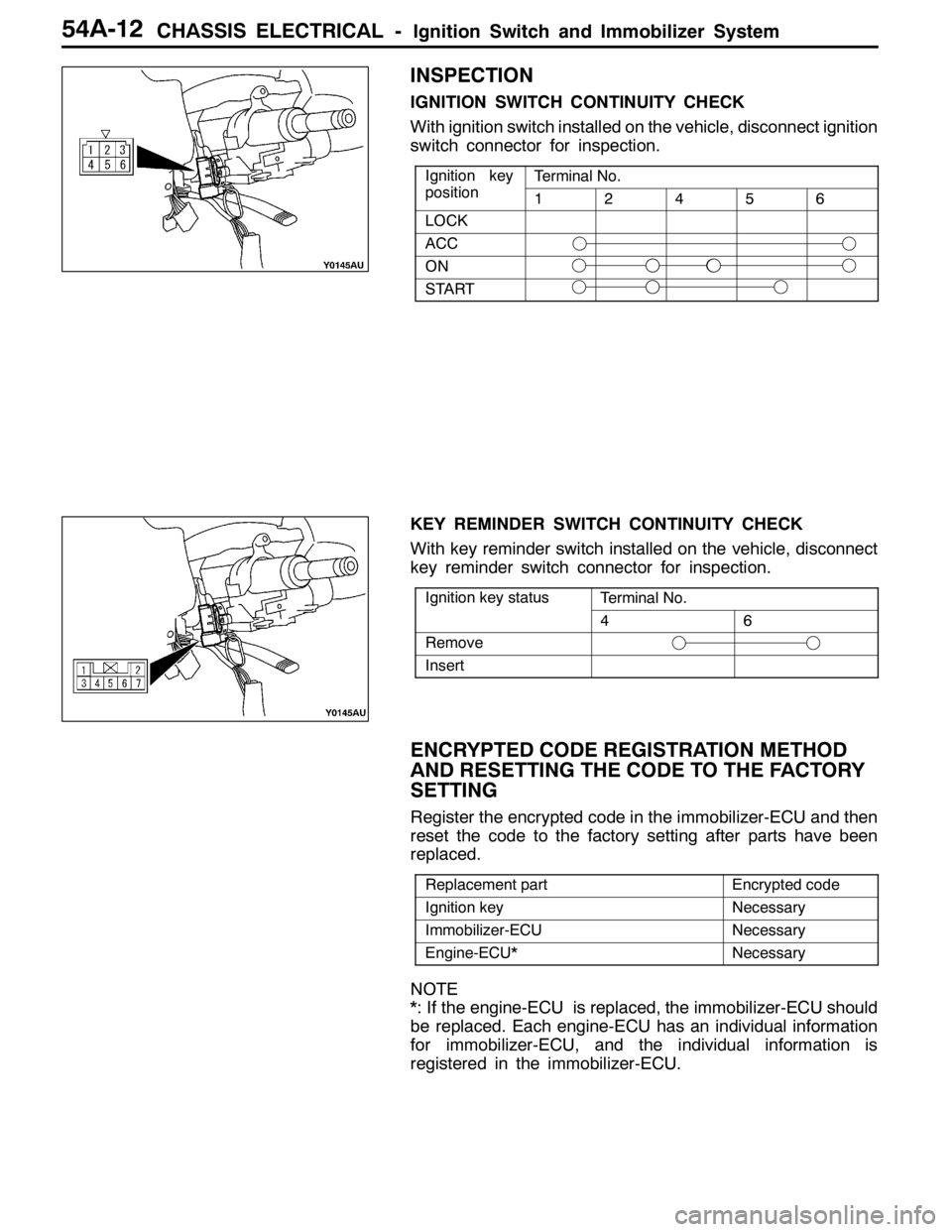

INSPECTION

IGNITION SWITCH CONTINUITY CHECK

With ignition switch installed on the vehicle, disconnect ignition

switch connector for inspection.

Ignition key

iti

Terminal No.gy

position12456

LOCK

ACC

ON

START

KEY REMINDER SWITCH CONTINUITY CHECK

With key reminder switch installed on the vehicle, disconnect

key reminder switch connector for inspection.

Ignition key statusTerminal No.gy

46

Remove

Insert

ENCRYPTED CODE REGISTRATION METHOD

AND RESETTING THE CODE TO THE FACTORY

SETTING

Register the encrypted code in the immobilizer-ECU and then

reset the code to the factory setting after parts have been

replaced.

Replacement partEncrypted code

Ignition keyNecessary

Immobilizer-ECUNecessary

Engine-ECU*Necessary

NOTE

*: If the engine-ECU is replaced, the immobilizer-ECU should

be replaced. Each engine-ECU has an individual information

for immobilizer-ECU, and the individual information is

registered in the immobilizer-ECU.

Page 1333 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-13

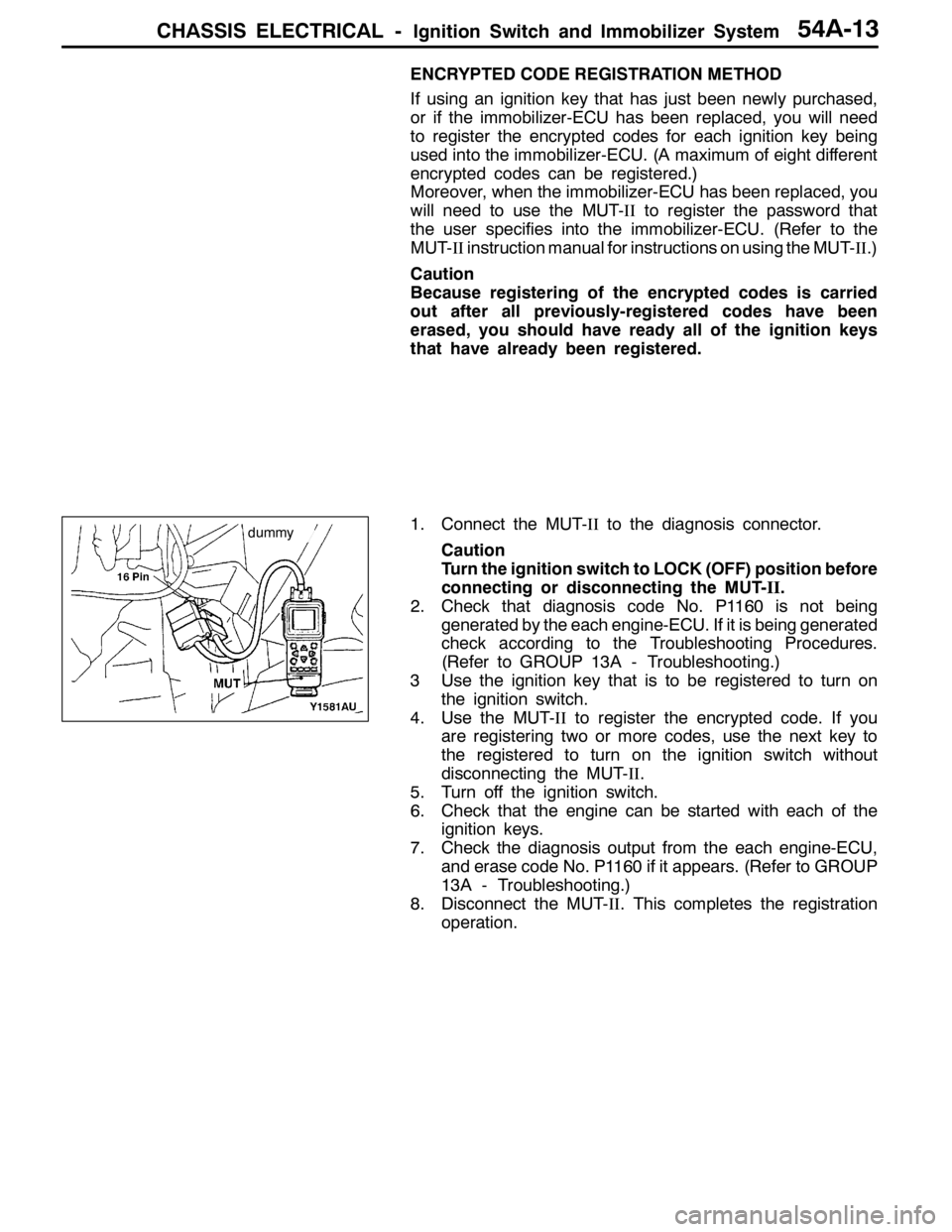

ENCRYPTED CODE REGISTRATION METHOD

If using an ignition key that has just been newly purchased,

or if the immobilizer-ECU has been replaced, you will need

to register the encrypted codes for each ignition key being

used into the immobilizer-ECU. (A maximum of eight different

encrypted codes can be registered.)

Moreover, when the immobilizer-ECU has been replaced, you

will need to use the MUT-IIto register the password that

the user specifies into the immobilizer-ECU. (Refer to the

MUT-IIinstruction manual for instructions on using the MUT-II.)

Caution

Because registering of the encrypted codes is carried

out after all previously-registered codes have been

erased, you should have ready all of the ignition keys

that have already been registered.

1. Connect the MUT-IIto the diagnosis connector.

Caution

Turn the ignition switch to LOCK (OFF) position before

connecting or disconnecting the MUT-II.

2. Check that diagnosis code No. P1160 is not being

generated by the each engine-ECU. If it is being generated

check according to the Troubleshooting Procedures.

(Refer to GROUP 13A - Troubleshooting.)

3 Use the ignition key that is to be registered to turn on

the ignition switch.

4. Use the MUT-IIto register the encrypted code. If you

are registering two or more codes, use the next key to

the registered to turn on the ignition switch without

disconnecting the MUT-II.

5. Turn off the ignition switch.

6. Check that the engine can be started with each of the

ignition keys.

7. Check the diagnosis output from the each engine-ECU,

and erase code No. P1160 if it appears. (Refer to GROUP

13A - Troubleshooting.)

8. Disconnect the MUT-II. This completes the registration

operation.

dummy

Page 1360 of 1449

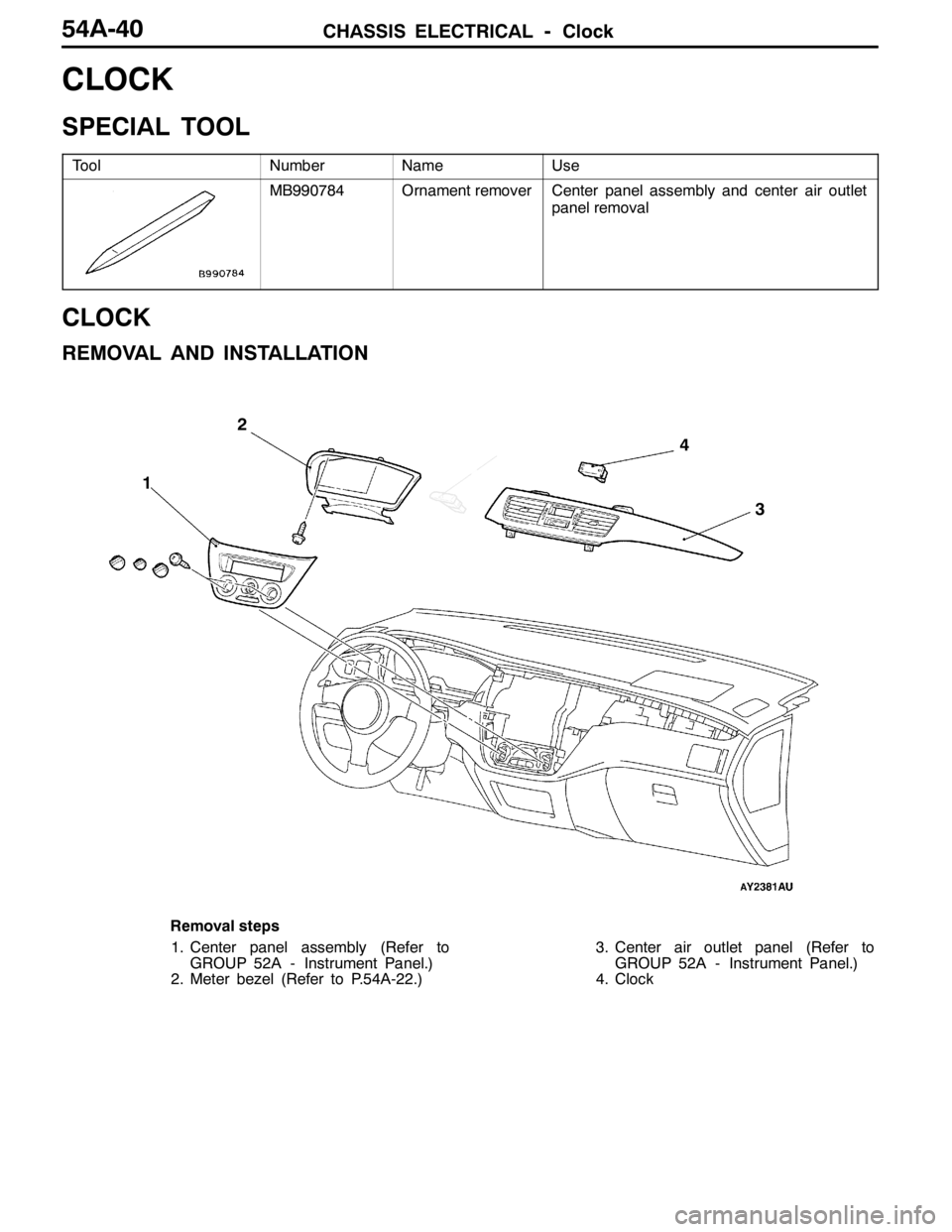

CHASSIS ELECTRICAL-Clock54A-40

CLOCK

SPECIAL TOOL

ToolNumberNameUse

MB990784Ornament removerCenter panel assembly and center air outlet

panel removal

CLOCK

REMOVAL AND INSTALLATION

2

3 4

1

Removal steps

1. Center panel assembly (Refer to

GROUP 52A - Instrument Panel.)

2. Meter bezel (Refer to P.54A-22.)3. Center air outlet panel (Refer to

GROUP 52A - Instrument Panel.)

4. Clock

Page 1361 of 1449

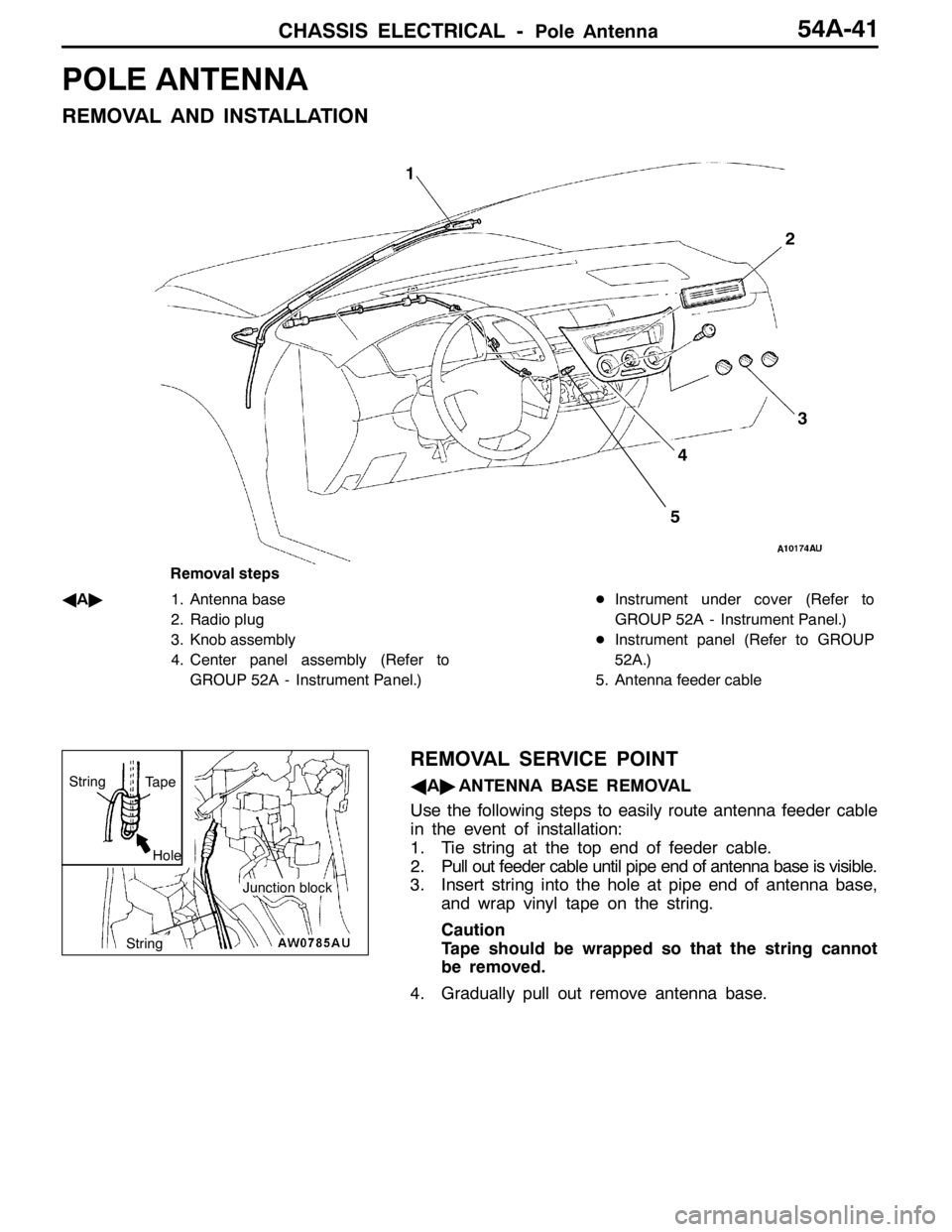

CHASSIS ELECTRICAL -Pole Antenna54A-41

POLE ANTENNA

REMOVAL AND INSTALLATION

3 1

2

4

5

Removal steps

A

A"1. Antenna base

2. Radio plug

3. Knob assembly

4. Center panel assembly (Refer to

GROUP 52A - Instrument Panel.)DInstrument under cover (Refer to

GROUP 52A - Instrument Panel.)

DInstrument panel (Refer to GROUP

52A.)

5. Antenna feeder cable

REMOVAL SERVICE POINT

AA"ANTENNA BASE REMOVAL

Use the following steps to easily route antenna feeder cable

in the event of installation:

1. Tie string at the top end of feeder cable.

2. Pull out feeder cable until pipe end of antenna base is visible.

3. Insert string into the hole at pipe end of antenna base,

and wrap vinyl tape on the string.

Caution

Tape should be wrapped so that the string cannot

be removed.

4. Gradually pull out remove antenna base.

Hole

Tape

Junction block

String

String

Page 1367 of 1449

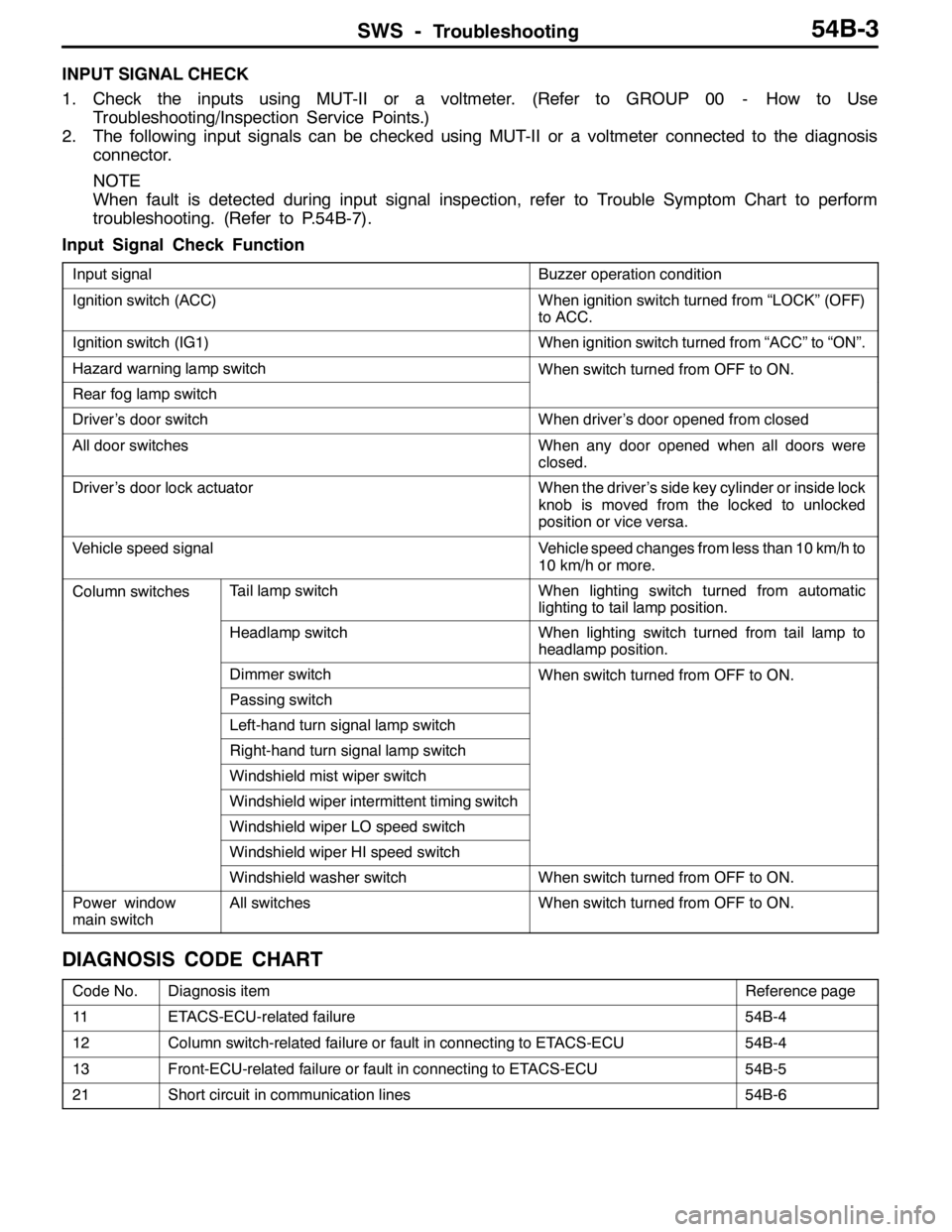

SWS -Troubleshooting54B-3

INPUT SIGNAL CHECK

1. Check the inputs using MUT-II or a voltmeter. (Refer to GROUP 00 - How to Use

Troubleshooting/Inspection Service Points.)

2. The following input signals can be checked using MUT-II or a voltmeter connected to the diagnosis

connector.

NOTE

When fault is detected during input signal inspection, refer to Trouble Symptom Chart to perform

troubleshooting. (Refer to P.54B-7).

Input Signal Check Function

Input signalBuzzer operation condition

Ignition switch (ACC)When ignition switch turned from “LOCK” (OFF)

to ACC.

Ignition switch (IG1)When ignition switch turned from “ACC” to “ON”.

Hazard warning lamp switchWhen switch turned from OFF to ON.

Rear fog lamp switch

Driver’s door switchWhen driver’s door opened from closed

All door switchesWhen any door opened when all doors were

closed.

Driver’s door lock actuatorWhen the driver’s side key cylinder or inside lock

knob is moved from the locked to unlocked

position or vice versa.

Vehicle speed signalVehicle speed changes from less than 10 km/h to

10 km/h or more.

Column switchesTail lamp switchWhen lighting switch turned from automatic

lighting to tail lamp position.

Headlamp switchWhen lighting switch turned from tail lamp to

headlamp position.

Dimmer switchWhen switch turned from OFF to ON.

Passing switch

Left-hand turn signal lamp switch

Right-hand turn signal lamp switch

Windshield mist wiper switch

Windshield wiper intermittent timing switch

Windshield wiper LO speed switch

Windshield wiper HI speed switch

Windshield washer switchWhen switch turned from OFF to ON.

Power window

main switchAll switchesWhen switch turned from OFF to ON.

DIAGNOSIS CODE CHART

Code No.Diagnosis itemReference page

11ETACS-ECU-related failure54B-4

12Column switch-related failure or fault in connecting to ETACS-ECU54B-4

13Front-ECU-related failure or fault in connecting to ETACS-ECU54B-5

21Short circuit in communication lines54B-6

Page 1371 of 1449

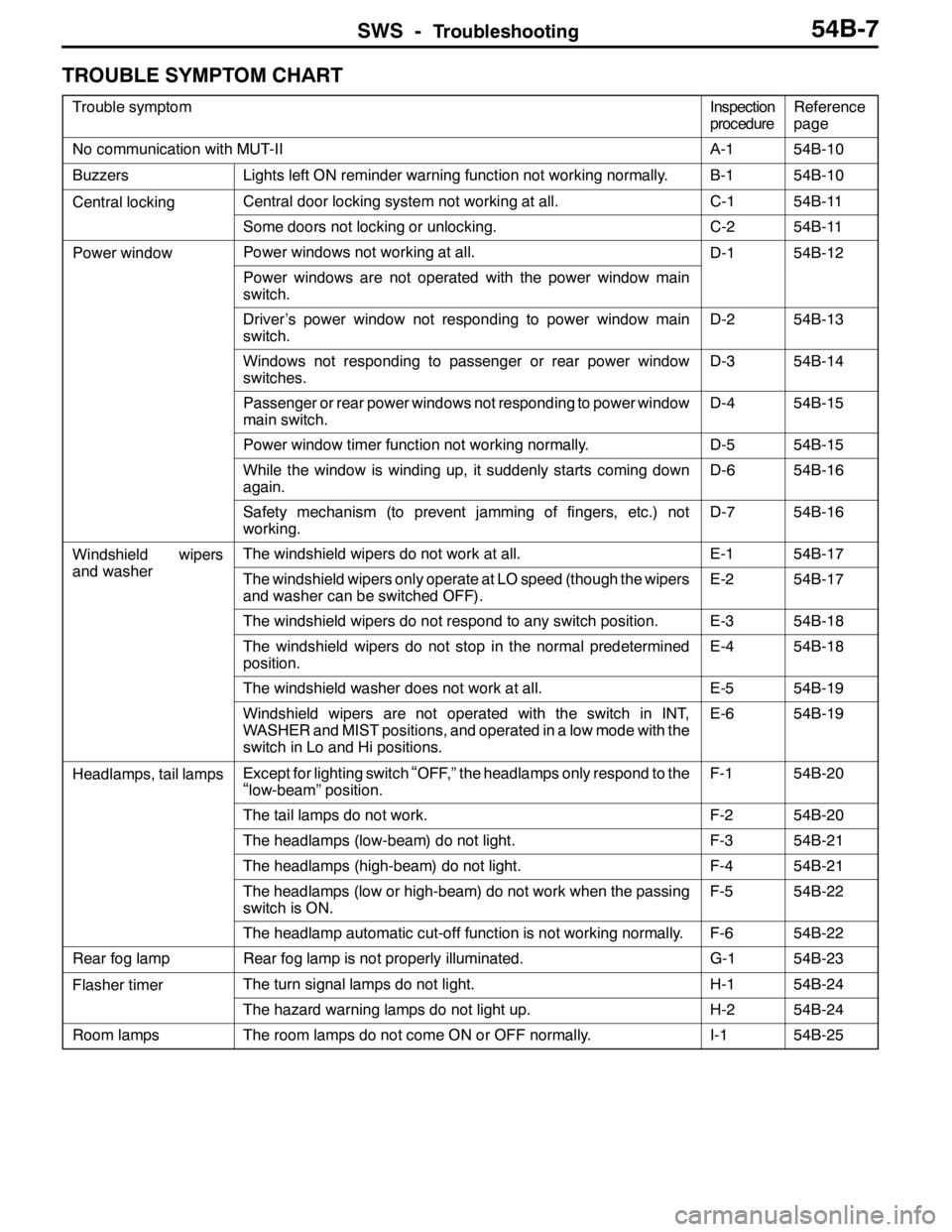

SWS -Troubleshooting54B-7

TROUBLE SYMPTOM CHART

Trouble symptomInspection

procedureReference

page

No communication with MUT-IIA-154B-10

BuzzersLights left ON reminder warning function not working normally.B-154B-10

Central lockingCentral door locking system not working at all.C-154B-11g

Some doors not locking or unlocking.C-254B-11

Power windowPower windows not working at all.D-154B-12

Power windows are not operated with the power window main

switch.

Driver’s power window not responding to power window main

switch.D-254B-13

Windows not responding to passenger or rear power window

switches.D-354B-14

Passenger or rear power windows not responding to power window

main switch.D-454B-15

Power window timer function not working normally.D-554B-15

While the window is winding up, it suddenly starts coming down

again.D-654B-16

Safety mechanism (to prevent jamming of fingers, etc.) not

working.D-754B-16

Windshield wipers

dh

The windshield wipers do not work at all.E-154B-17p

and washerThe windshield wipers only operate at LO speed (though the wipers

and washer can be switched OFF).E-254B-17

The windshield wipers do not respond to any switch position.E-354B-18

The windshield wipers do not stop in the normal predetermined

position.E-454B-18

The windshield washer does not work at all.E-554B-19

Windshield wipers are not operated with the switch in INT,

WASHER and MIST positions, and operated in a low mode with the

switch in Lo and Hi positions.E-654B-19

Headlamps, tail lampsExcept for lighting switch“OFF,” the headlamps only respond to the

“low-beam” position.

F-154B-20

The tail lamps do not work.F-254B-20

The headlamps (low-beam) do not light.F-354B-21

The headlamps (high-beam) do not light.F-454B-21

The headlamps (low or high-beam) do not work when the passing

switch is ON.F-554B-22

The headlamp automatic cut-off function is not working normally.F-654B-22

Rear fog lampRear fog lamp is not properly illuminated.G-154B-23

Flasher timerThe turn signal lamps do not light.H-154B-24

The hazard warning lamps do not light up.H-254B-24

Room lampsThe room lamps do not come ON or OFF normally.I-154B-25

Page 1372 of 1449

SWS -TroubleshootingSWS -Troubleshooting54B-8

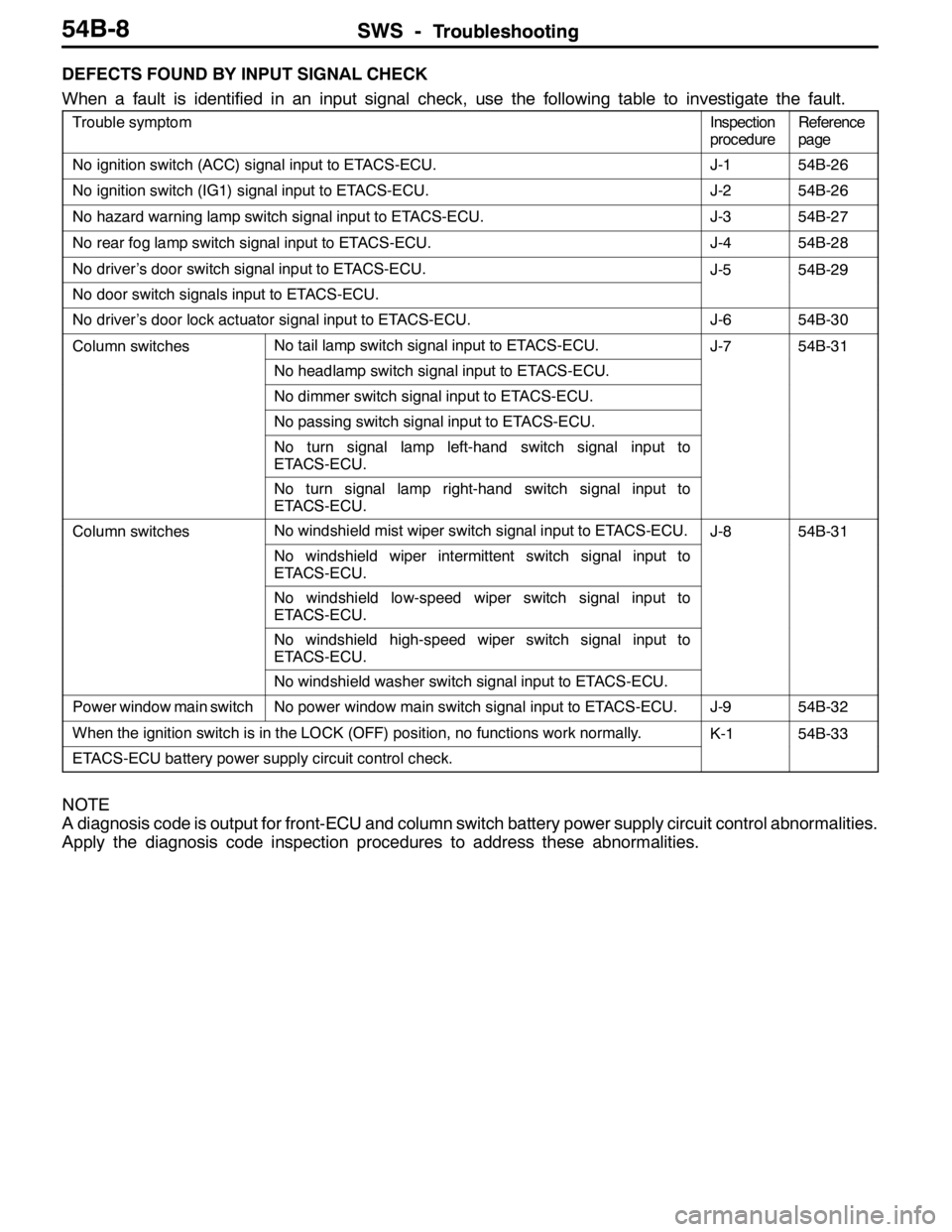

DEFECTS FOUND BY INPUT SIGNAL CHECK

When a fault is identified in an input signal check, use the following table to investigate the fault.

Trouble symptomInspection

procedureReference

page

No ignition switch (ACC) signal input to ETACS-ECU.J-154B-26

No ignition switch (IG1) signal input to ETACS-ECU.J-254B-26

No hazard warning lamp switch signal input to ETACS-ECU.J-354B-27

No rear fog lamp switch signal input to ETACS-ECU.J-454B-28

No driver’s door switch signal input to ETACS-ECU.J-554B-29

No door switch signals input to ETACS-ECU.

No driver’s door lock actuator signal input to ETACS-ECU.J-654B-30

Column switchesNo tail lamp switch signal input to ETACS-ECU.J-754B-31

No headlamp switch signal input to ETACS-ECU.

No dimmer switch signal input to ETACS-ECU.

No passing switch signal input to ETACS-ECU.

No turn signal lamp left-hand switch signal input to

ETACS-ECU.

No turn signal lamp right-hand switch signal input to

ETACS-ECU.

Column switchesNo windshield mist wiper switch signal input to ETACS-ECU.J-854B-31

No windshield wiper intermittent switch signal input to

ETACS-ECU.

No windshield low-speed wiper switch signal input to

ETACS-ECU.

No windshield high-speed wiper switch signal input to

ETACS-ECU.

No windshield washer switch signal input to ETACS-ECU.

Power window main switchNo power window main switch signal input to ETACS-ECU.J-954B-32

When the ignition switch is in the LOCK (OFF) position, no functions work normally.K-154B-33

ETACS-ECU battery power supply circuit control check.

NOTE

A diagnosis code is output for front-ECU and column switch battery power supply circuit control abnormalities.

Apply the diagnosis code inspection procedures to address these abnormalities.

Page 1373 of 1449

SWS -Troubleshooting54B-9

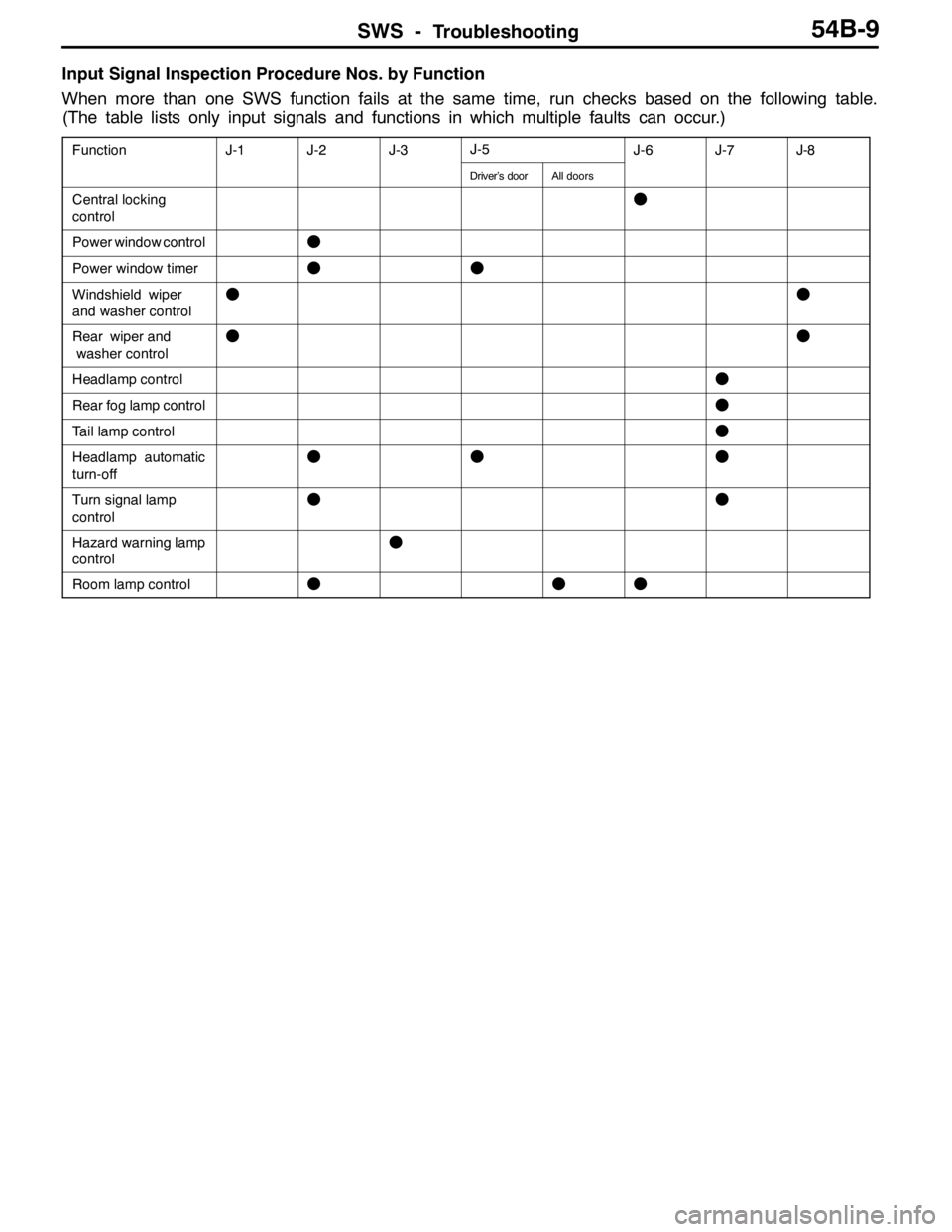

Input Signal Inspection Procedure Nos. by Function

When more than one SWS function fails at the same time, run checks based on the following table.

(The table lists only input signals and functions in which multiple faults can occur.)

FunctionJ-1J-2J-3J-5J-6J-7J-8

Driver’s doorAll doors

Central locking

controlF

Power window controlF

Power window timerFF

Windshield wiper

and washer controlFF

Rear wiper and

washer controlFF

Headlamp controlF

Rear fog lamp controlF

Tail lamp controlF

Headlamp automatic

turn-offFFF

Turn signal lamp

controlFF

Hazard warning lamp

controlF

Room lamp controlFFF