lock MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1298 of 1449

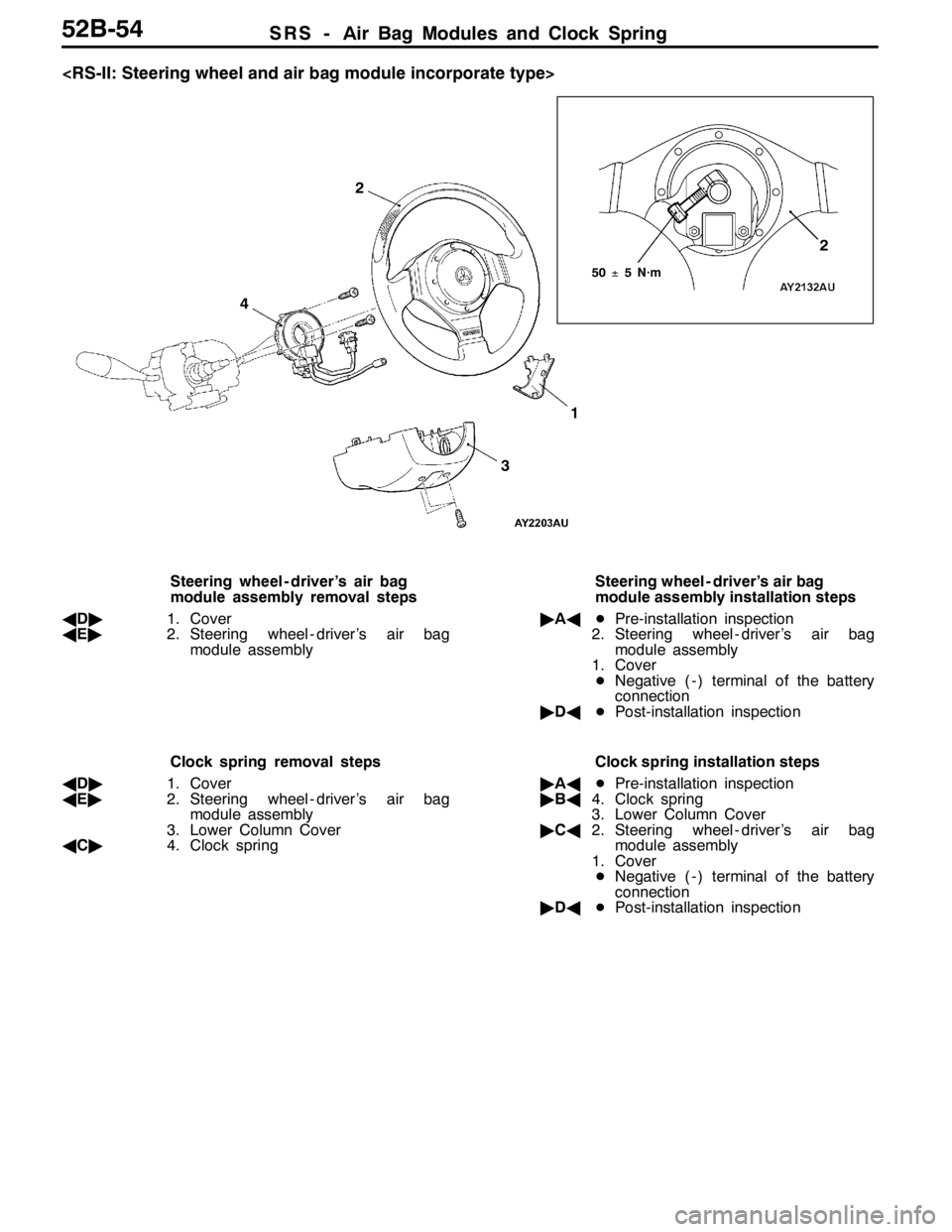

SRS -Air Bag Modules and Clock Spring52B-54

3 2

4

1

50±5 N·m

2

Steering wheel - driver’s air bag

module assembly removal steps

AD"1. Cover

AE"2. Steering wheel - driver’s air bag

module assemblySteering wheel - driver’s air bag

module assembly installation steps

"AADPre-installation inspection

2. Steering wheel - driver’s air bag

module assembly

1. Cover

DNegative ( - ) terminal of the battery

connection

"DADPost-installation inspection

Clock spring removal steps

AD"1. Cover

AE"2. Steering wheel - driver’s air bag

module assembly

3. Lower Column Cover

AC"4. Clock springClock spring installation steps

"AADPre-installation inspection

"BA4. Clock spring

3. Lower Column Cover

"CA2. Steering wheel - driver’s air bag

module assembly

1. Cover

DNegative ( - ) terminal of the battery

connection

"DADPost-installation inspection

Page 1299 of 1449

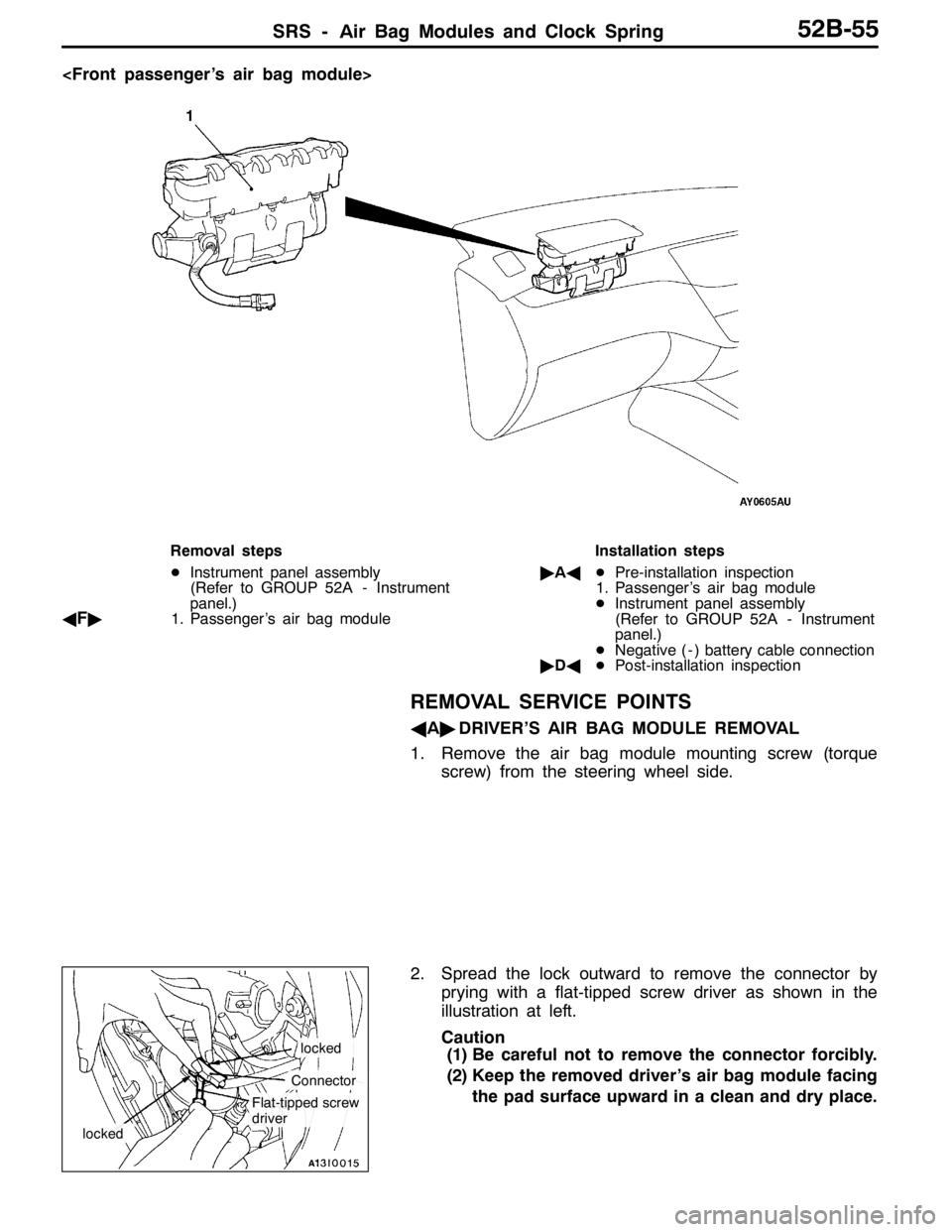

SRS - Air Bag Modules and Clock Spring52B-55

1

Removal steps

DInstrument panel assembly

(Refer to GROUP 52A - Instrument

panel.)

A

F"1. Passenger’s air bag moduleInstallation steps

"AADPre-installation inspection

1. Passenger’s air bag module

DInstrument panel assembly

(Refer to GROUP 52A - Instrument

panel.)

DNegative ( - ) battery cable connection

"DADPost-installation inspection

REMOVAL SERVICE POINTS

AA"DRIVER’S AIR BAG MODULE REMOVAL

1. Remove the air bag module mounting screw (torque

screw) from the steering wheel side.

2. Spread the lock outward to remove the connector by

prying with a flat-tipped screw driver as shown in the

illustration at left.

Caution

(1) Be careful not to remove the connector forcibly.

(2) Keep the removed driver’s air bag module facing

the pad surface upward in a clean and dry place.

locked

Connector

Flat-tipped screw

driver

locked

Page 1300 of 1449

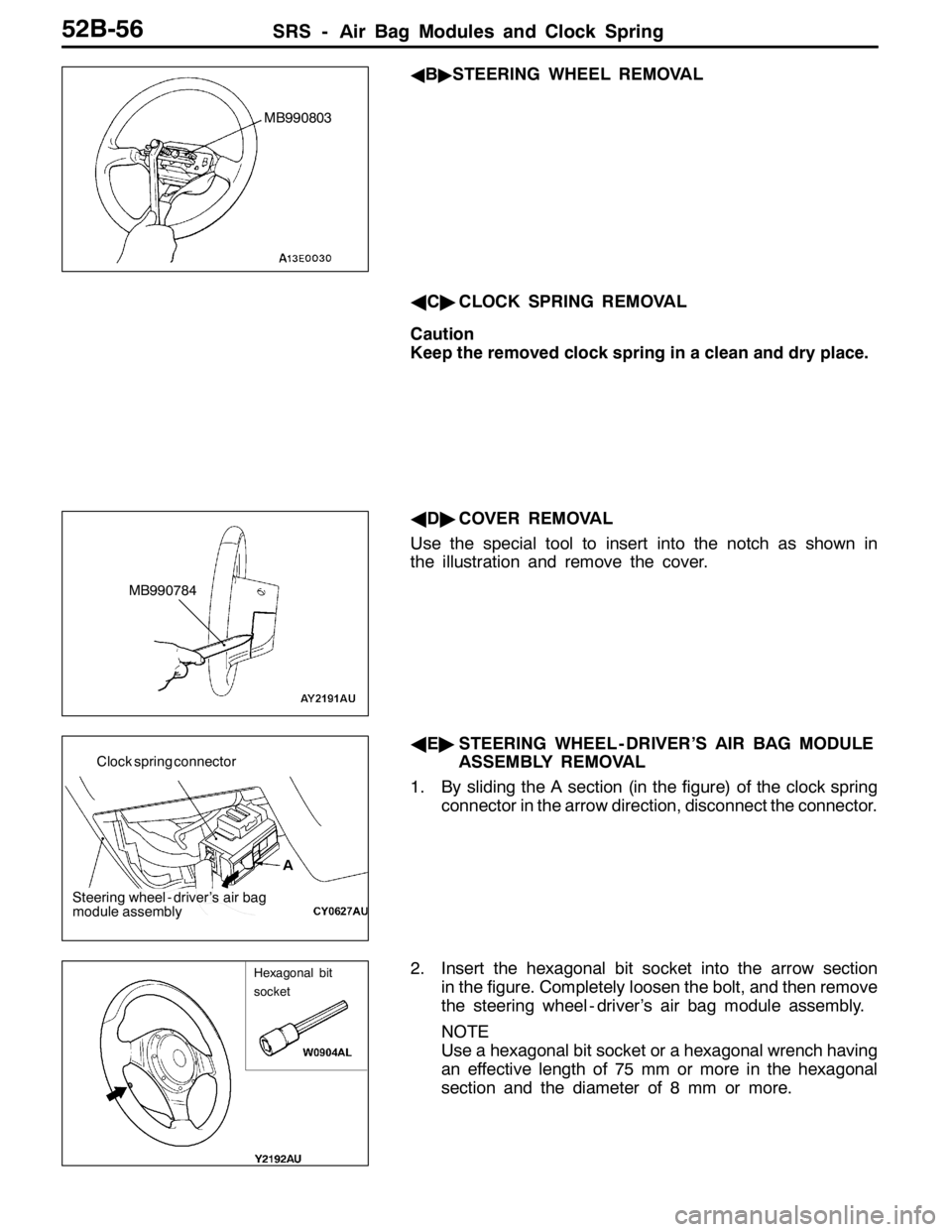

SRS - Air Bag Modules and Clock Spring52B-56

AB"STEERING WHEEL REMOVAL

AC"CLOCK SPRING REMOVAL

Caution

Keep the removed clock spring in a clean and dry place.

AD"COVER REMOVAL

Use the special tool to insert into the notch as shown in

the illustration and remove the cover.

AE"STEERING WHEEL - DRIVER’S AIR BAG MODULE

ASSEMBLY REMOVAL

1. By sliding the A section (in the figure) of the clock spring

connector in the arrow direction, disconnect the connector.

2. Insert the hexagonal bit socket into the arrow section

in the figure. Completely loosen the bolt, and then remove

the steering wheel - driver’s air bag module assembly.

NOTE

Use a hexagonal bit socket or a hexagonal wrench having

an effective length of 75 mm or more in the hexagonal

section and the diameter of 8 mm or more.

MB990803

MB990784

A Clock spring connector

Steering wheel - driver’s air bag

module assembly

Hexagonal bit

socket

Page 1301 of 1449

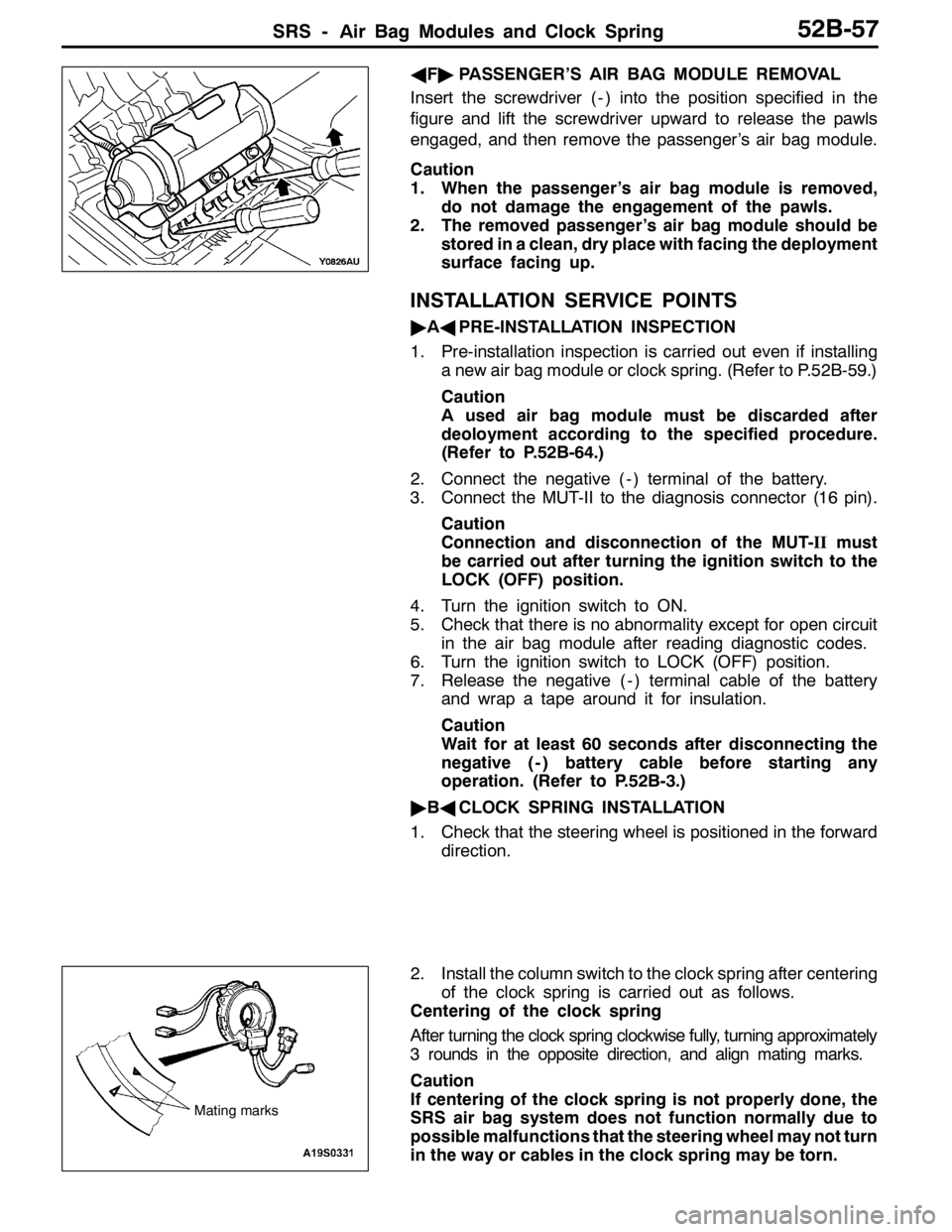

SRS - Air Bag Modules and Clock Spring52B-57

AF"PASSENGER’S AIR BAG MODULE REMOVAL

Insert the screwdriver ( - ) into the position specified in the

figure and lift the screwdriver upward to release the pawls

engaged, and then remove the passenger’s air bag module.

Caution

1. When the passenger’s air bag module is removed,

do not damage the engagement of the pawls.

2. The removed passenger’s air bag module should be

stored in a clean, dry place with facing the deployment

surface facing up.

INSTALLATION SERVICE POINTS

"AAPRE-INSTALLATION INSPECTION

1. Pre-installation inspection is carried out even if installing

a new air bag module or clock spring. (Refer to P.52B-59.)

Caution

A used air bag module must be discarded after

deoloyment according to the specified procedure.

(Refer to P.52B-64.)

2. Connect the negative ( - ) terminal of the battery.

3. Connect the MUT-II to the diagnosis connector (16 pin).

Caution

Connection and disconnection of the MUT-IImust

be carried out after turning the ignition switch to the

LOCK (OFF) position.

4. Turn the ignition switch to ON.

5. Check that there is no abnormality except for open circuit

in the air bag module after reading diagnostic codes.

6. Turn the ignition switch to LOCK (OFF) position.

7. Release the negative ( - ) terminal cable of the battery

and wrap a tape around it for insulation.

Caution

Wait for at least 60 seconds after disconnecting the

negative ( - ) battery cable before starting any

operation. (Refer to P.52B-3.)

"BACLOCK SPRING INSTALLATION

1. Check that the steering wheel is positioned in the forward

direction.

2. Install the column switch to the clock spring after centering

of the clock spring is carried out as follows.

Centering of the clock spring

After turning the clock spring clockwise fully, turning approximately

3 rounds in the opposite direction, and align mating marks.

Caution

If centering of the clock spring is not properly done, the

SRS air bag system does not function normally due to

possible malfunctions that the steering wheel may not turn

in the way or cables in the clock spring may be torn.

Mating marks

Page 1302 of 1449

SRS - Air Bag Modules and Clock Spring52B-58

"CASTEERING WHEEL/STEERING WHEEL - AIR BAG

MODULE ASSEMBLY INSTALLATION

1. After checking that centering of the clock spring has been

done, install the steering wheel or the steering wheel - air

bag module assembly.

Caution

Do not engage the harness of the clock spring when

installing the steering wheel or the steering wheel - air

bag module assembly.

2. After installation, check that no abnormalities occur when

the steering wheel is fully turned to the left or the right.

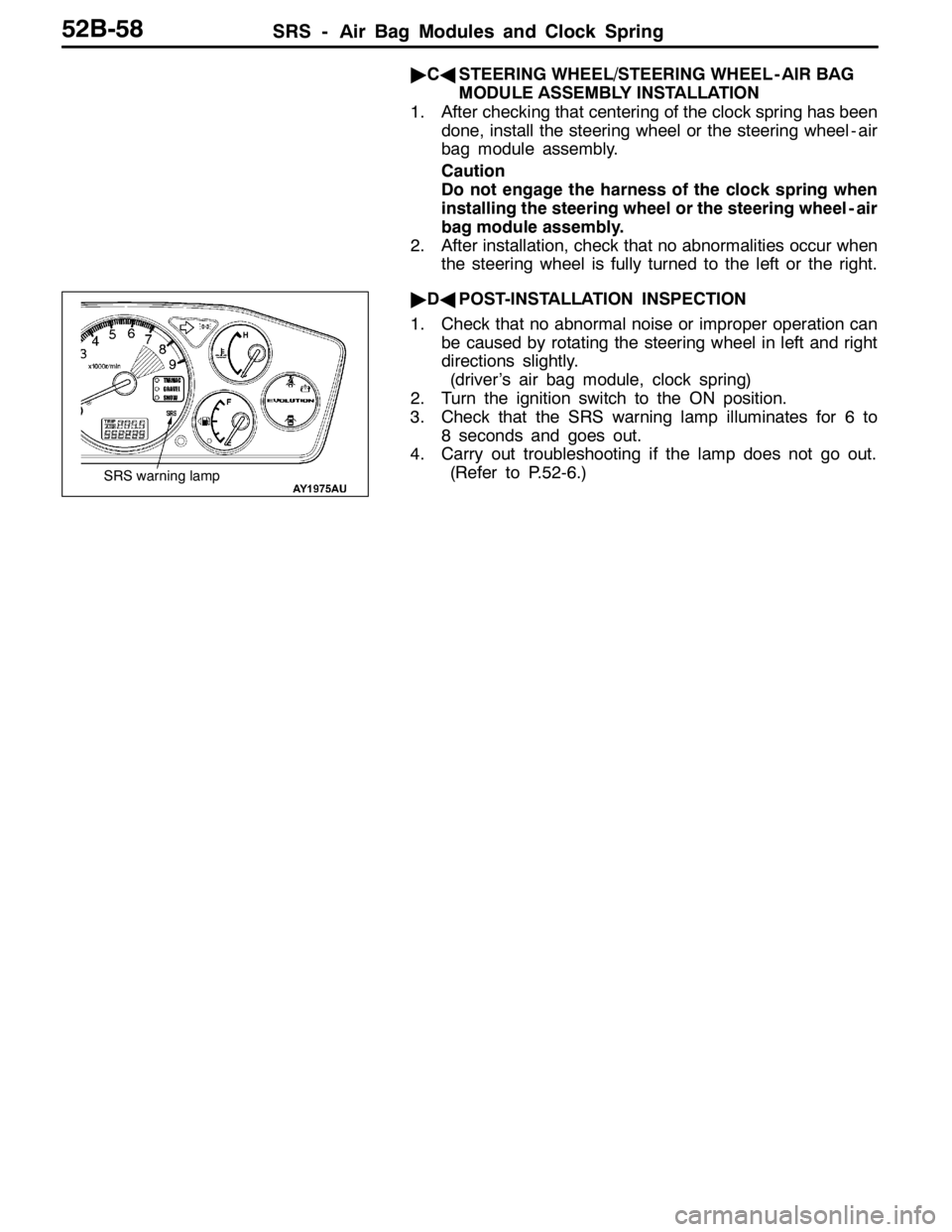

"DAPOST-INSTALLATION INSPECTION

1. Check that no abnormal noise or improper operation can

be caused by rotating the steering wheel in left and right

directions slightly.

(driver’s air bag module, clock spring)

2. Turn the ignition switch to the ON position.

3. Check that the SRS warning lamp illuminates for 6 to

8 seconds and goes out.

4. Carry out troubleshooting if the lamp does not go out.

(Refer to P.52-6.)

SRS warning lamp

Page 1303 of 1449

SRS - Air Bag Modules and Clock Spring52B-59

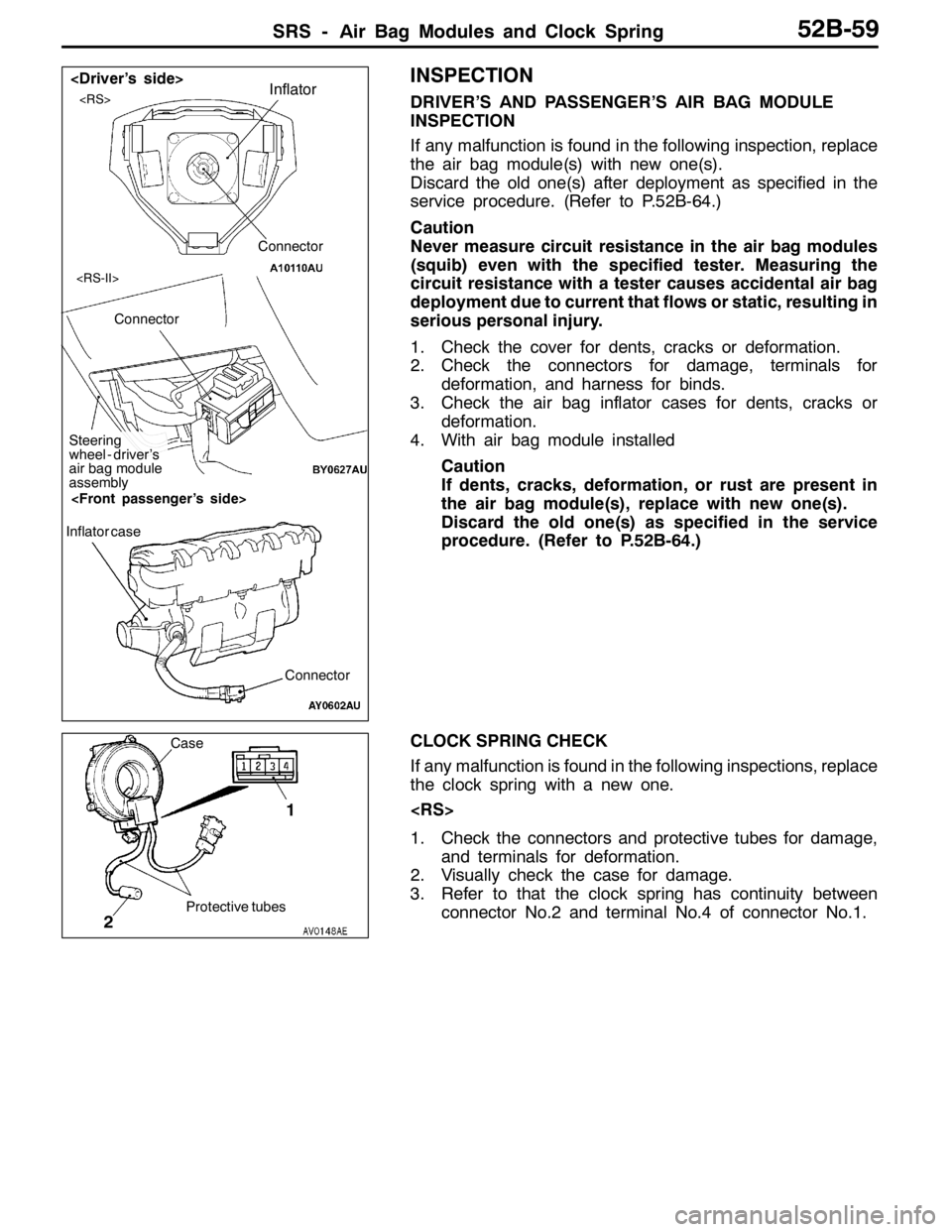

INSPECTION

DRIVER’S AND PASSENGER’S AIR BAG MODULE

INSPECTION

If any malfunction is found in the following inspection, replace

the air bag module(s) with new one(s).

Discard the old one(s) after deployment as specified in the

service procedure. (Refer to P.52B-64.)

Caution

Never measure circuit resistance in the air bag modules

(squib) even with the specified tester. Measuring the

circuit resistance with a tester causes accidental air bag

deployment due to current that flows or static, resulting in

serious personal injury.

1. Check the cover for dents, cracks or deformation.

2. Check the connectors for damage, terminals for

deformation, and harness for binds.

3. Check the air bag inflator cases for dents, cracks or

deformation.

4. With air bag module installed

Caution

If dents, cracks, deformation, or rust are present in

the air bag module(s), replace with new one(s).

Discard the old one(s) as specified in the service

procedure. (Refer to P.52B-64.)

CLOCK SPRING CHECK

If any malfunction is found in the following inspections, replace

the clock spring with a new one.

1. Check the connectors and protective tubes for damage,

and terminals for deformation.

2. Visually check the case for damage.

3. Refer to that the clock spring has continuity between

connector No.2 and terminal No.4 of connector No.1.Inflator

Connector

Connector

Steering

wheel - driver’s

air bag module

assembly

Connector Inflator case

Protective tubes Case

1

2

Page 1304 of 1449

SRS - Air Bag Modules and Clock Spring52B-60

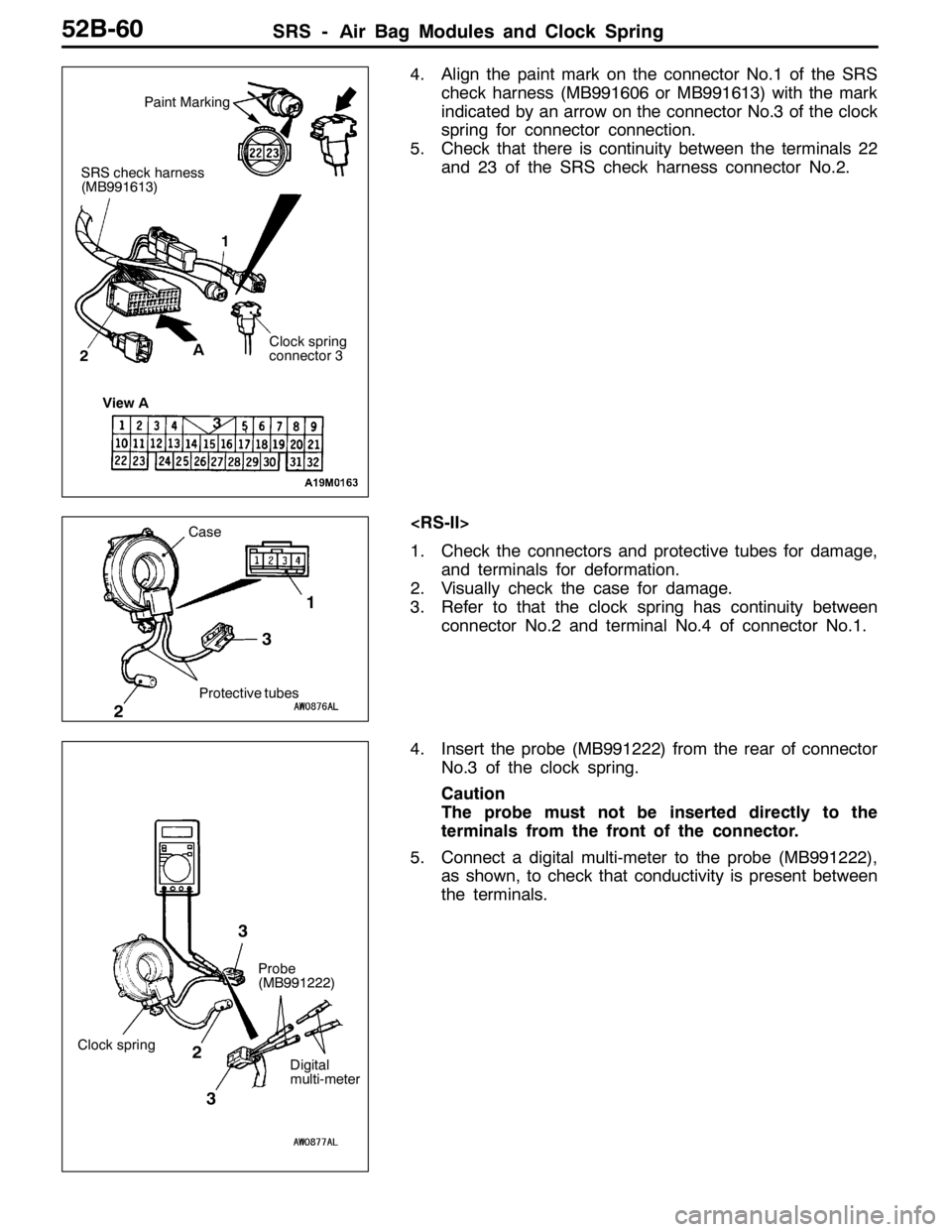

4.Align the paint mark on the connector No.1 of the SRS

check harness (MB991606 or MB991613) with the mark

indicated by an arrow on the connector No.3 of the clock

spring for connector connection.

5.Check that there is continuity between the terminals 22

and 23 of the SRS check harness connector No.2.

1. Check the connectors and protective tubes for damage,

and terminals for deformation.

2. Visually check the case for damage.

3. Refer to that the clock spring has continuity between

connector No.2 and terminal No.4 of connector No.1.

4. Insert the probe (MB991222) from the rear of connector

No.3 of the clock spring.

Caution

The probe must not be inserted directly to the

terminals from the front of the connector.

5. Connect a digital multi-meter to the probe (MB991222),

as shown, to check that conductivity is present between

the terminals.

Clock spring

connector 3 Paint Marking

View A

1

2

3 A

SRS check harness

(MB991613)

Protective tubes Case

1

2

3

Clock springProbe

(MB991222)

3

2

Digital

multi-meter

3

Page 1305 of 1449

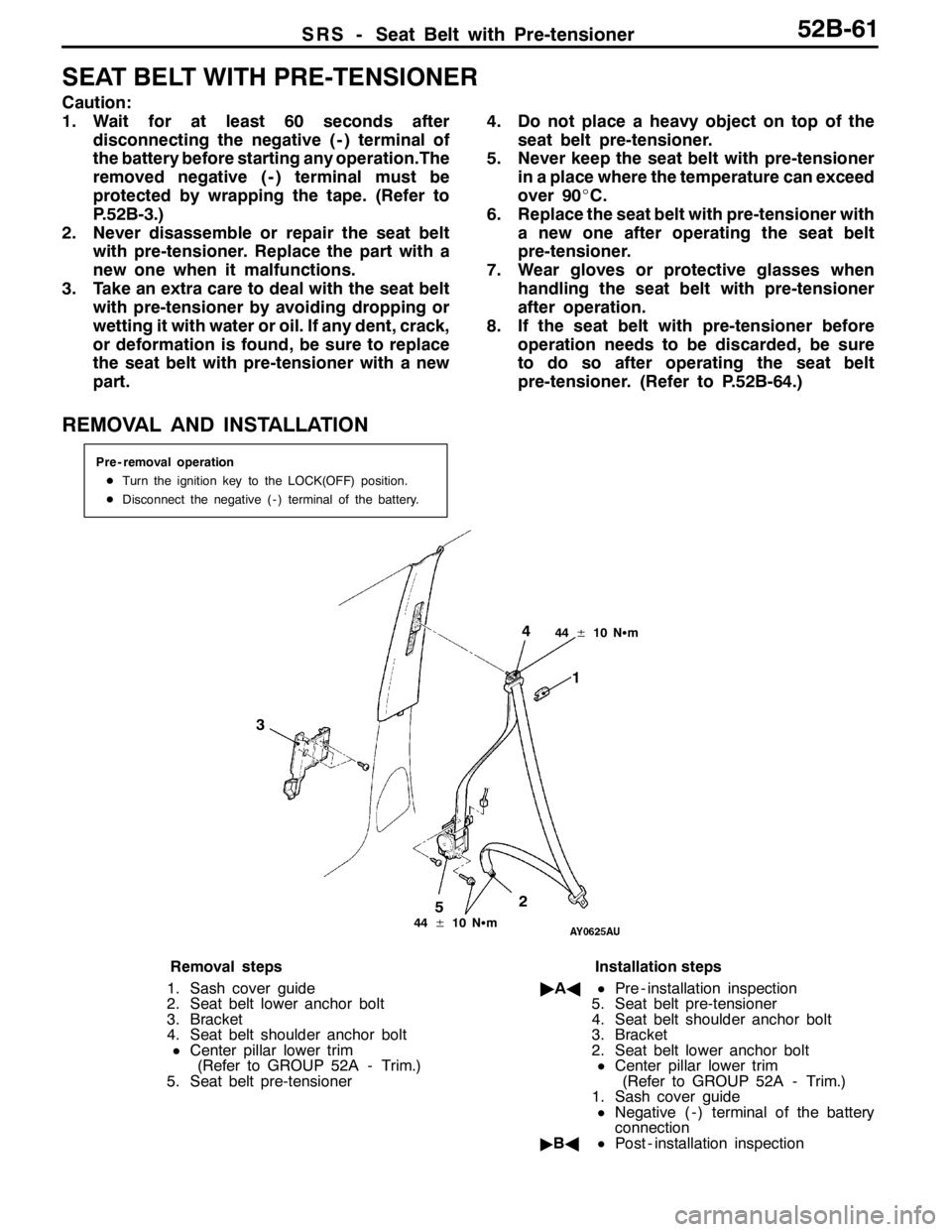

SRS -Seat Belt with Pre-tensioner52B-61

SEAT BELT WITH PRE-TENSIONER

Caution:

1. Wait for at least 60 seconds after

disconnecting the negative ( - ) terminal of

the battery before starting any operation.The

removed negative ( - ) terminal must be

protected by wrapping the tape. (Refer to

P.52B-3.)

2. Never disassemble or repair the seat belt

with pre-tensioner. Replace the part with a

new one when it malfunctions.

3. Take an extra care to deal with the seat belt

with pre-tensioner by avoiding dropping or

wetting it with water or oil. If any dent, crack,

or deformation is found, be sure to replace

the seat belt with pre-tensioner with a new

part.4. Do not place a heavy object on top of the

seat belt pre-tensioner.

5. Never keep the seat belt with pre-tensioner

in a place where the temperature can exceed

over 90_C.

6. Replace the seat belt with pre-tensioner with

a new one after operating the seat belt

pre-tensioner.

7. Wear gloves or protective glasses when

handling the seat belt with pre-tensioner

after operation.

8. If the seat belt with pre-tensioner before

operation needs to be discarded, be sure

to do so after operating the seat belt

pre-tensioner. (Refer to P.52B-64.)

REMOVAL AND INSTALLATION

Pre - removal operation

DTurn the ignition key to the LOCK(OFF) position.

DDisconnect the negative ( - ) terminal of the battery.

1 4

3

2

44±10 NSm

44±10 NSm

5

Removal steps

1. Sash cover guide

2. Seat belt lower anchor bolt

3. Bracket

4. Seat belt shoulder anchor bolt

DCenter pillar lower trim

(Refer to GROUP 52A - Trim.)

5. Seat belt pre-tensionerInstallation steps

"AA

DPre - installation inspection

5. Seat belt pre-tensioner

4. Seat belt shoulder anchor bolt

3. Bracket

2. Seat belt lower anchor bolt

DCenter pillar lower trim

(Refer to GROUP 52A - Trim.)

1. Sash cover guide

DNegative ( - ) terminal of the battery

connection

"BADPost - installation inspection

Page 1306 of 1449

SRS -Seat Belt with Pre-tensioner52B-62

INSTALLATION SERVICE POINTS

"AAPRE-INSTALLATION INSPECTION

1. Pre-installation inspection must be carried out even when

installing a new seat belt with pre-tensioner. (Refer to

Inspections.)

Caution

If the seat belt with pre-tensioner is discarded, discard

it after operating the seat belt pre-tensioner according

to the specified procedure. (Refer to P.52B-64.)

2. Connect the negative ( - ) terminal of the battery.

3. Connect the MUT-II to the diagnosis connector (16 pin).

Caution

Connection and disconnection of the MUT-II must be

carried out after turning the ignition switch to the

LOCK (OFF) position.

4. Turn the ignition switch to ON position.

5. Check that there is no abnormality except for open circuit

in the seat belt pre-tensioner after reading diagnostic

codes.

6. Turn the ignition key to LOCK (OFF) position.

7. Release the negative ( - ) terminal cable of the battery

and wrap a tape around it for insulation.

Caution

Wait for at least 60 seconds after disconnecting the

negative ( - ) battery cable before starting any

operation. (Refer to P.52B-3.)

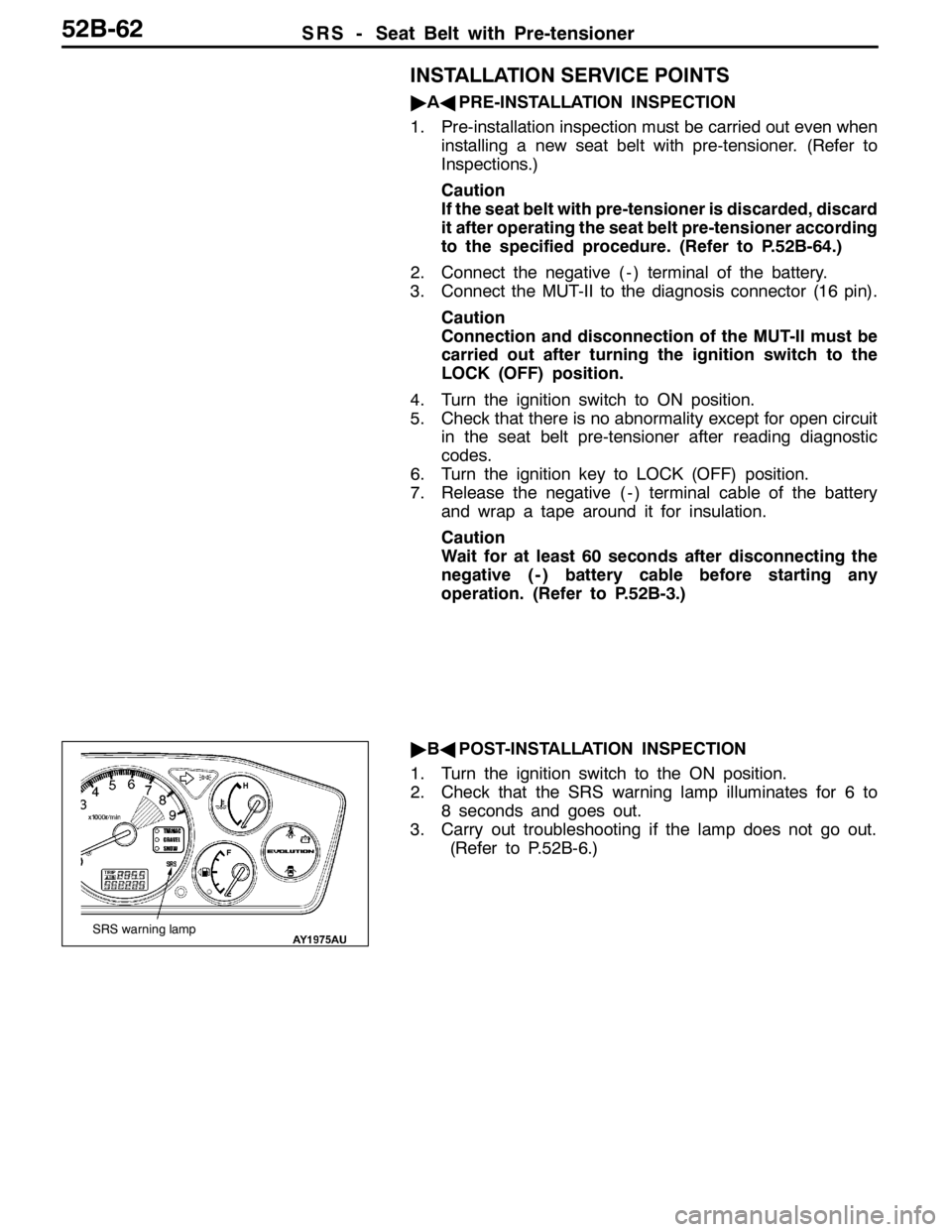

"BAPOST-INSTALLATION INSPECTION

1. Turn the ignition switch to the ON position.

2. Check that the SRS warning lamp illuminates for 6 to

8 seconds and goes out.

3. Carry out troubleshooting if the lamp does not go out.

(Refer to P.52B-6.)

SRS warning lamp

Page 1309 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-65

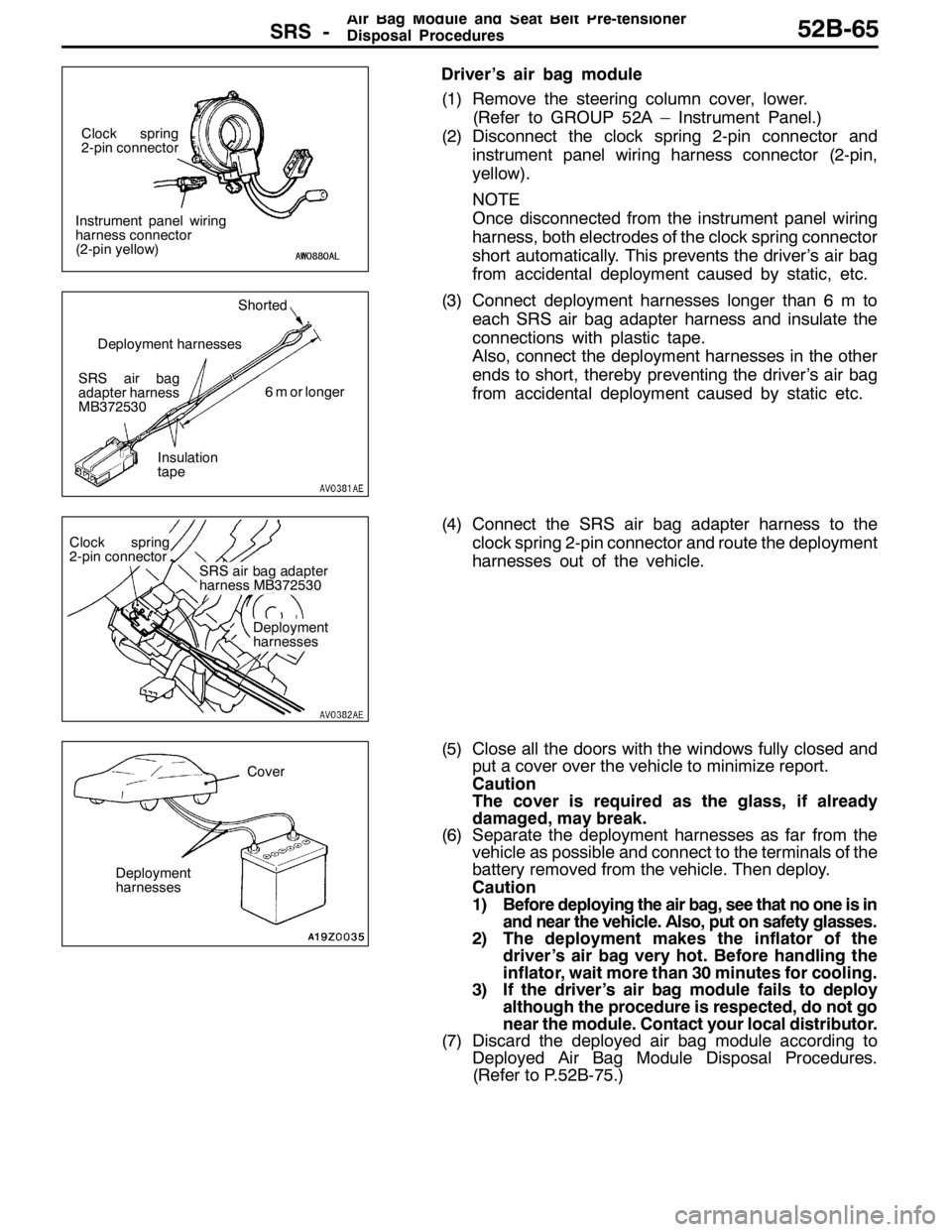

Driver’s air bag module

(1) Remove the steering column cover, lower.

(Refer to GROUP 52A – Instrument Panel.)

(2) Disconnect the clock spring 2-pin connector and

instrument panel wiring harness connector (2-pin,

yellow).

NOTE

Once disconnected from the instrument panel wiring

harness, both electrodes of the clock spring connector

short automatically. This prevents the driver’s air bag

from accidental deployment caused by static, etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the driver’s air bag

from accidental deployment caused by static etc.

(4) Connect the SRS air bag adapter harness to the

clock spring 2-pin connector and route the deployment

harnesses out of the vehicle.

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is in

and near the vehicle. Also, put on safety glasses.

2) The deployment makes the inflator of the

driver’s air bag very hot. Before handling the

inflator, wait more than 30 minutes for cooling.

3) If the driver’s air bag module fails to deploy

although the procedure is respected, do not go

near the module. Contact your local distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

Instrument panel wiring

harness connector

(2-pin yellow)Clock spring

2-pin connector

SRS air bag

adapter harness

MB372530Shorted

6 m or longer

Insulation

tape Deployment harnesses

Clock spring

2-pin connector

SRS air bag adapter

harness MB372530

Deployment

harnesses

Cover

Deployment

harnesses