ABS MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 376 of 1449

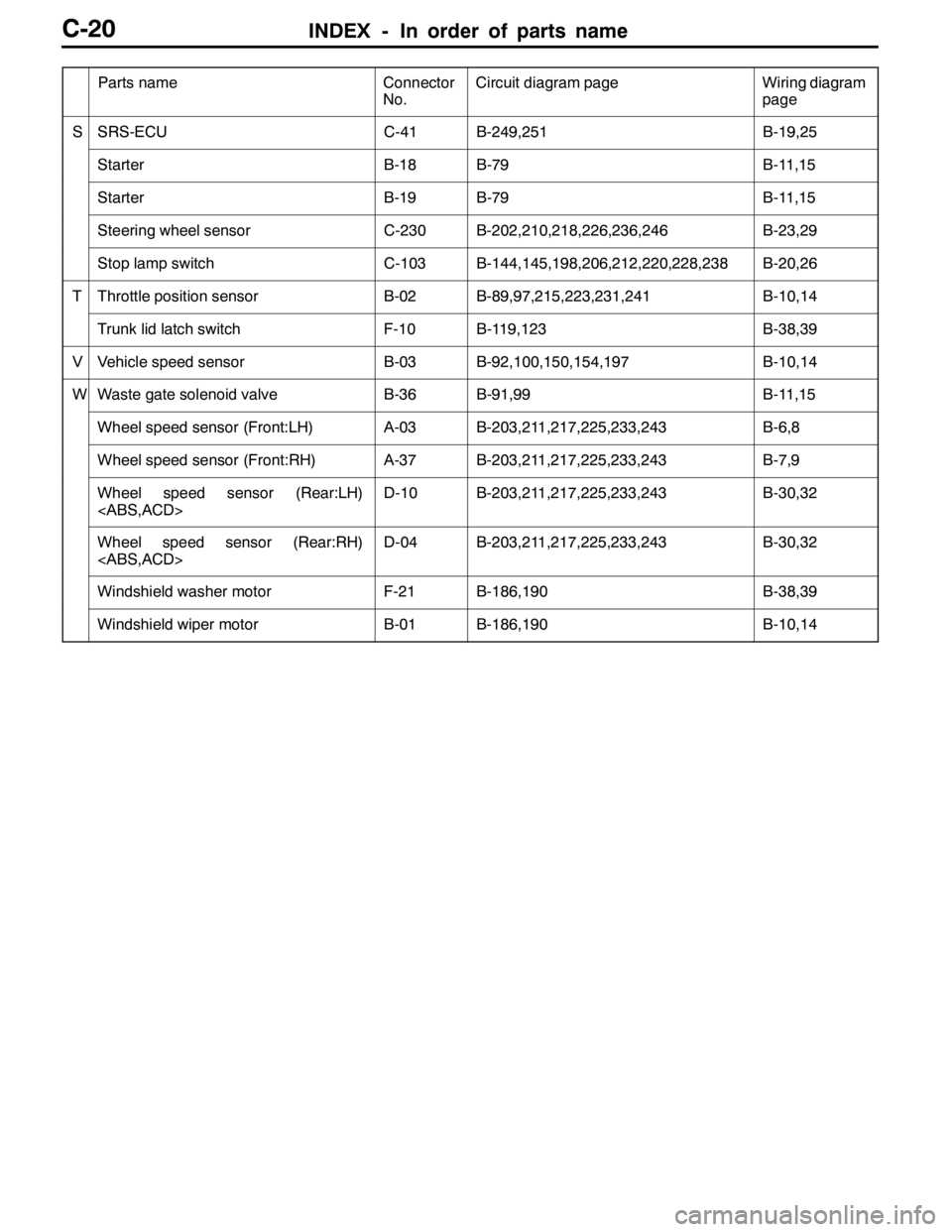

INDEX - In order of parts nameC-20

Wiring diagram

page Circuit diagram page Connector

No. Parts name

SSRS-ECUC-41B-249,251B-19,25

StarterB-18B-79B-11,15

StarterB-19B-79B-11,15

Steering wheel sensorC-230B-202,210,218,226,236,246B-23,29

Stop lamp switchC-103B-144,145,198,206,212,220,228,238B-20,26

TThrottle position sensorB-02B-89,97,215,223,231,241B-10,14

Trunk lid latch switchF-10B-119,123B-38,39

VVehicle speed sensorB-03B-92,100,150,154,197B-10,14

WWaste gate solenoid valveB-36B-91,99B-11,15

Wheel speed sensor (Front:LH)A-03B-203,211,217,225,233,243B-6,8

Wheel speed sensor (Front:RH)A-37B-203,211,217,225,233,243B-7,9

Wheel speed sensor (Rear:LH)

Wheel speed sensor (Rear:RH)

Windshield washer motorF-21B-186,190B-38,39

Windshield wiper motorB-01B-186,190B-10,14

Page 386 of 1449

GENERAL -How to Use Troubleshooting/Inspection Service Points00-8

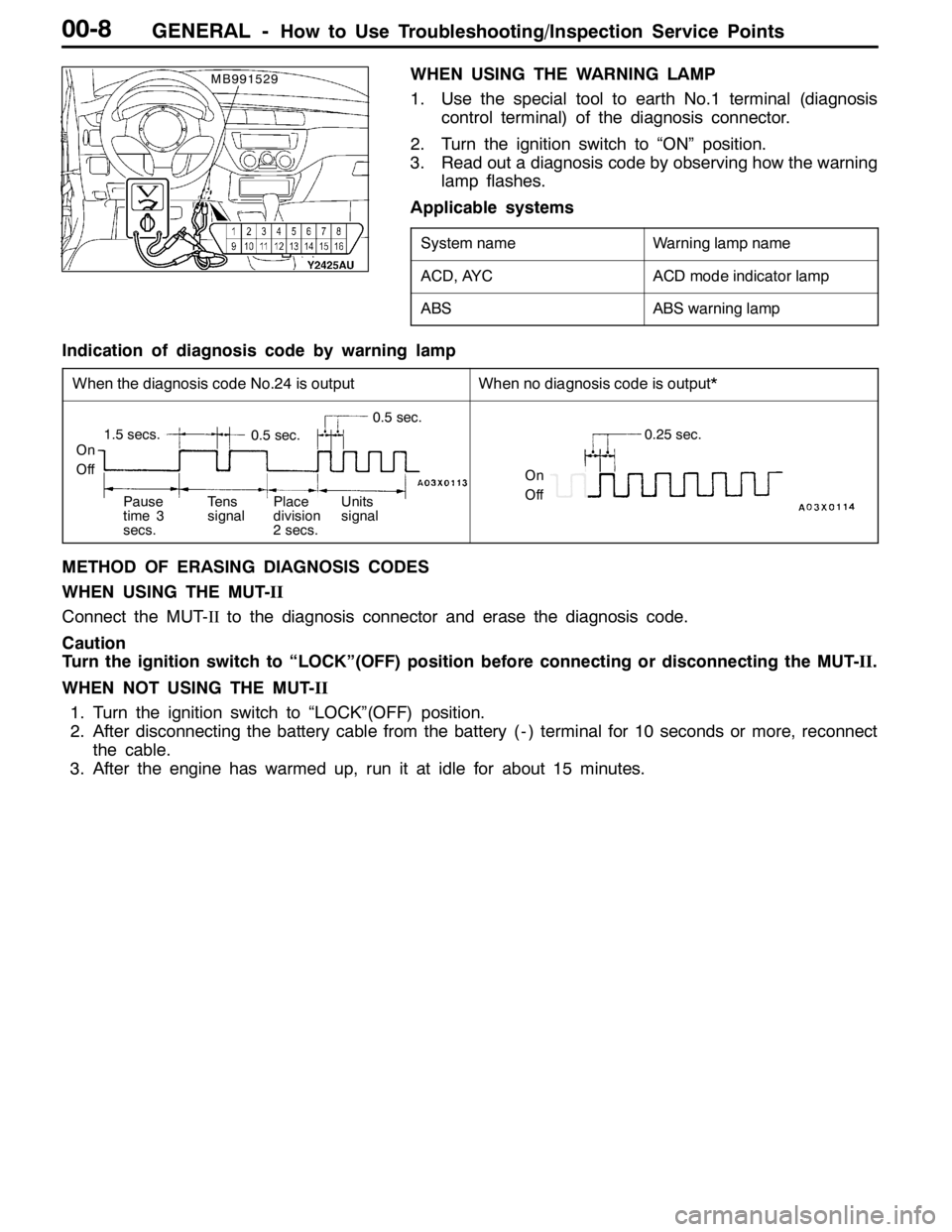

WHEN USING THE WARNING LAMP

1. Use the special tool to earth No.1 terminal (diagnosis

control terminal) of the diagnosis connector.

2. Turn the ignition switch to “ON” position.

3. Read out a diagnosis code by observing how the warning

lamp flashes.

Applicable systems

System nameWarning lamp name

ACD, AYCACD mode indicator lamp

ABSABS warning lamp

Indication of diagnosis code by warning lamp

When the diagnosis code No.24 is outputWhen no diagnosis code is output*

On

Off

1.5 secs.0.5 sec.

0.5 sec.

Pause

time 3

secs.Tens

signalPlace

division

2 secs.Units

signal

On

Off

0.25 sec.

METHOD OF ERASING DIAGNOSIS CODES

WHEN USING THE MUT-II

Connect the MUT-IIto the diagnosis connector and erase the diagnosis code.

Caution

Turn the ignition switch to “LOCK”(OFF) position before connecting or disconnecting the MUT-II.

WHEN NOT USING THE MUT-II

1. Turn the ignition switch to “LOCK”(OFF) position.

2. After disconnecting the battery cable from the battery ( - ) terminal for 10 seconds or more, reconnect

the cable.

3. After the engine has warmed up, run it at idle for about 15 minutes.

MB991529

Page 462 of 1449

ENGINE OVERHAUL -Specifications11B-8

SEALANTS

ItemSpecified sealantQuantity

Engine support bracket bolt3MTMAAD Part No. 8672 or equivalentAs required

Semi-circular packing3MTMAAD Part No. 8672 or equivalentAs required

Rocker cover3MTMAAD Part No. 8672 or equivalentAs required

Water outlet fittingMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Engine coolant temperature gauge unit3MTMAAD Part No. 8672 or equivalentAs required

Engine coolant temperature sensor3MTMAAD Part No. 8672 or equivalentAs required

Cylinder head (camshaft bearing cap mounting

section)3MTMAAD Part No. 8672 or equivalentAs required

Cam position sensor supportMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Oil pressure switch3MTMAAD Part No. 8672 or equivalentAs required

Oil panMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Oil seal caseMitsubishi Genuine Part No. MD970389 or

equivalentAs required

FORM-IN-PLACE-GASKET

FIPG is used for several members of this engine. With this gasket, caution is required to the application

amount, application procedure and state of the application surface so that the performance is sufficiently

attained.

If sufficient gasket is not applied, leaks could occur, and if too much is applied, the gasket could protrude

and plug or restrict the oil and water flow passage. Thus, to prevent leaks from the joined sections,

it is absolutely necessary to evenly apply the correct amount.

The FIPG used for the engine parts reacts with moisture in the air and hardens so use it for the normal

metal flange parts.

DISASSEMBLY

The parts assembled with FIPG can be easily disassembled without special means. However, in some

cases, the sealant on the seams must be broken by lightly tapping with a wood hammer or similar tool.

A smooth and thin gasket scraper can be lightly tapped into the seams but in this case, take care not

to damage the seams.

The special tool oil pan remover (MD998727) is set for this purpose.

WASHING THE GASKET SURFACE

Completely remove all matters adhered on the gasket surfaces with a gasket scraper or wire brush.

Confirm that the FIPG application surface is smooth. There must be no grease or foreign matter on

the gasket surface.

Always remove the old FIPG that has entered the mounting holes and screw holes.

APPLICATION PROCEDURES

Apply an even coat of FIPG within the predetermined radius. Completely cover the areas around the

mounting holes. The FIPG can be wiped off if it has not hardened. Install at the set position while the

FIPG is still wet (within 15 minutes). When installing, maker sure that the FIPG does not get on areas

other than the required areas. After installing, do not subject the application areas to oil or water or

start the engine until the FIPG has sufficiently hardened (approx. one hour). The FIPG application procedures

differ according to the member, so follow the procedures given in this manual and apply the FIPG.

Page 654 of 1449

MPI -Troubleshooting13A-122

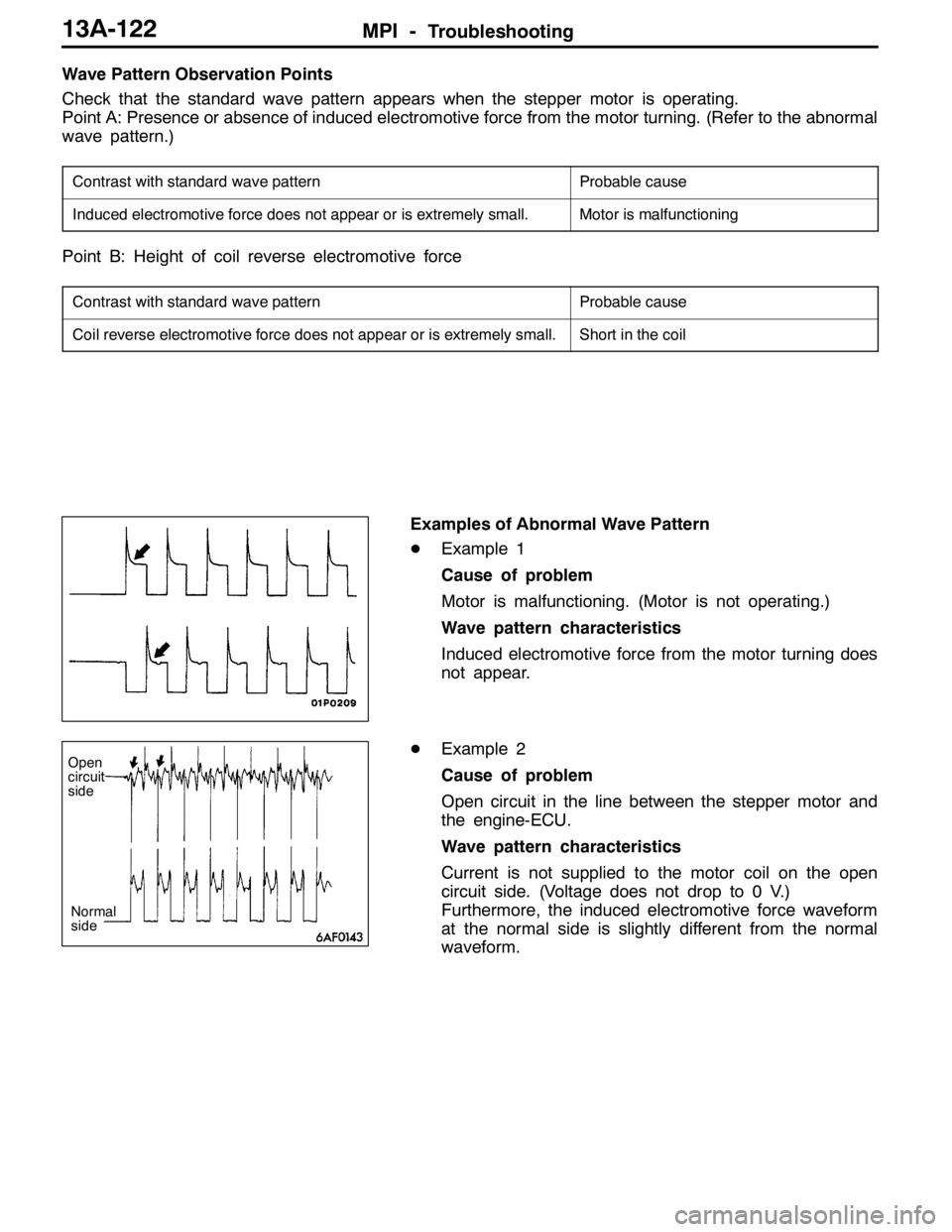

Wave Pattern Observation Points

Check that the standard wave pattern appears when the stepper motor is operating.

Point A: Presence or absence of induced electromotive force from the motor turning. (Refer to the abnormal

wave pattern.)

Contrast with standard wave patternProbable cause

Induced electromotive force does not appear or is extremely small.Motor is malfunctioning

Point B: Height of coil reverse electromotive force

Contrast with standard wave patternProbable cause

Coil reverse electromotive force does not appear or is extremely small.Short in the coil

Examples of Abnormal Wave Pattern

DExample 1

Cause of problem

Motor is malfunctioning. (Motor is not operating.)

Wave pattern characteristics

Induced electromotive force from the motor turning does

not appear.

DExample 2

Cause of problem

Open circuit in the line between the stepper motor and

the engine-ECU.

Wave pattern characteristics

Current is not supplied to the motor coil on the open

circuit side. (Voltage does not drop to 0 V.)

Furthermore, the induced electromotive force waveform

at the normal side is slightly different from the normal

waveform.

Open

circuit

side

Normal

side

Page 690 of 1449

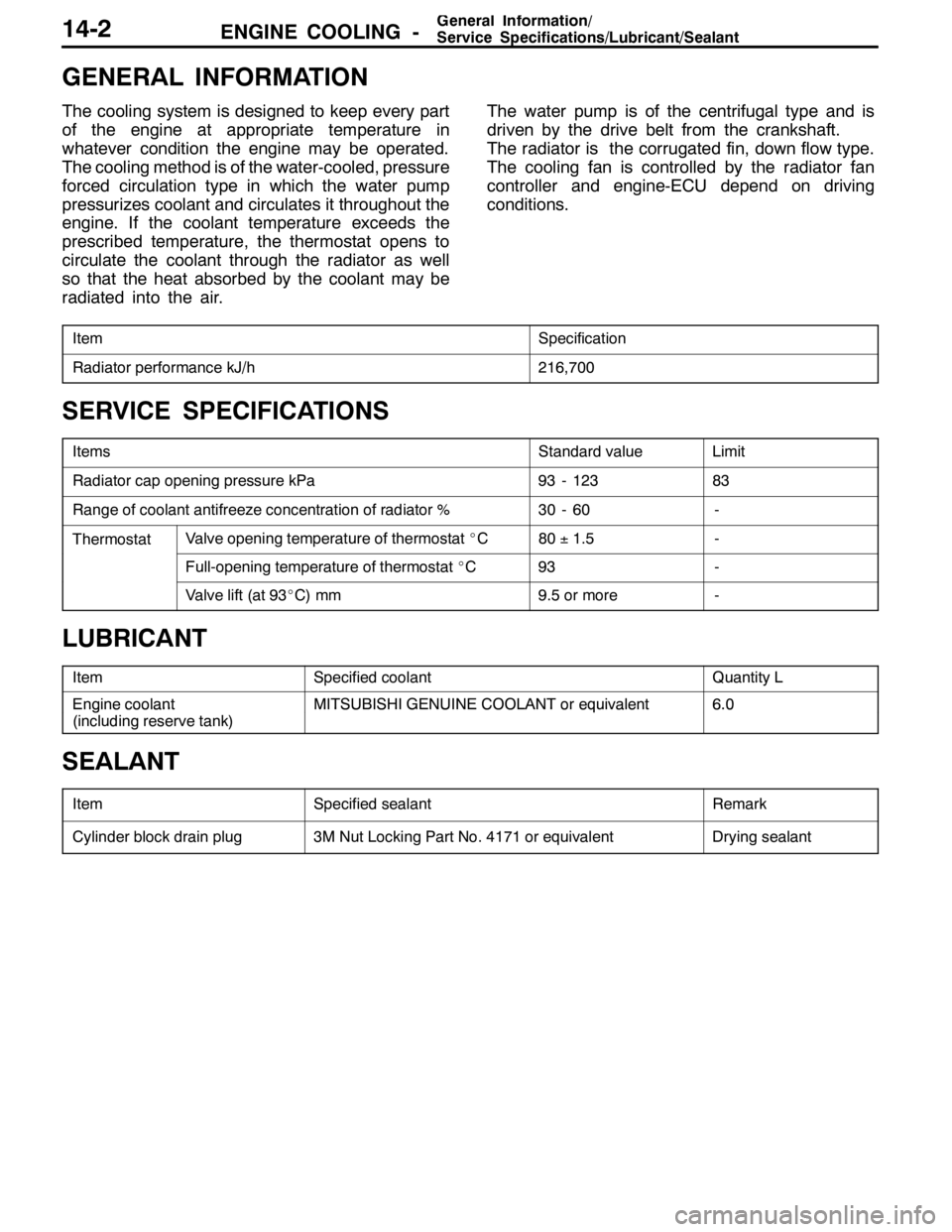

ENGINE COOLING -GeneralInformation/

Service Specifications/Lubricant/Sealant14-2

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

The cooling fan is controlled by the radiator fan

controller and engine-ECU depend on driving

conditions.

ItemSpecification

Radiator performance kJ/h216,700

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Radiator cap opening pressure kPa93 - 12383

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temperature of thermostat_C80±1.5-

Full-opening temperature of thermostat_C93-

Valve lift (at 93_C) mm9.5 or more-

LUBRICANT

ItemSpecified coolantQuantity L

Engine coolantMITSUBISHI GENUINE COOLANT or equivalent6.0Enginecoolant

(including reserve tank)

MITSUBISHIGENUINECOOLANTorequivalent6.0

SEALANT

ItemSpecified sealantRemark

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

Page 700 of 1449

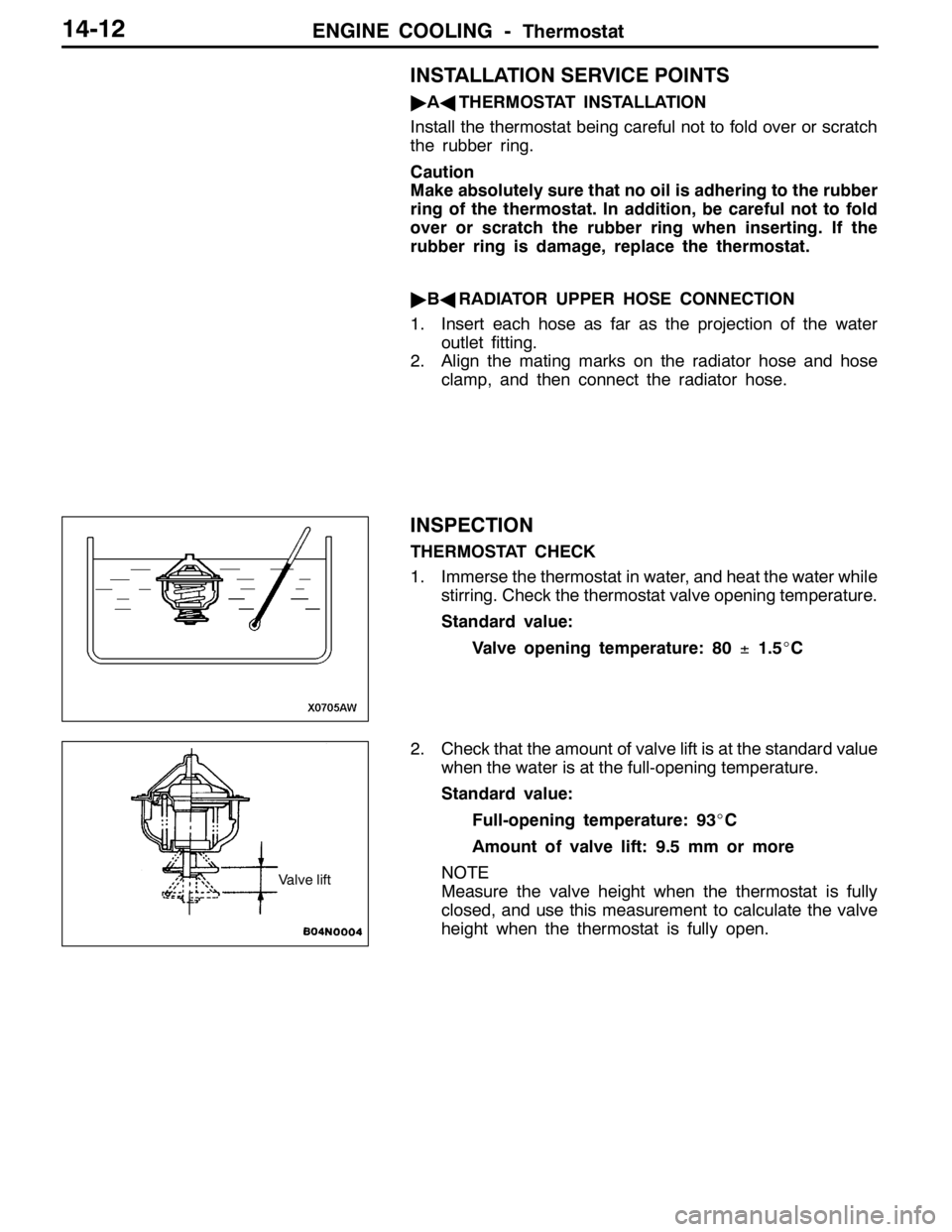

ENGINE COOLING -Thermostat14-12

INSTALLATION SERVICE POINTS

"AATHERMOSTAT INSTALLATION

Install the thermostat being careful not to fold over or scratch

the rubber ring.

Caution

Make absolutely sure that no oil is adhering to the rubber

ring of the thermostat. In addition, be careful not to fold

over or scratch the rubber ring when inserting. If the

rubber ring is damage, replace the thermostat.

"BARADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water

outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

THERMOSTAT CHECK

1. Immerse the thermostat in water, and heat the water while

stirring. Check the thermostat valve opening temperature.

Standard value:

Valve opening temperature: 80±1.5_C

2. Check that the amount of valve lift is at the standard value

when the water is at the full-opening temperature.

Standard value:

Full-opening temperature: 93_C

Amount of valve lift: 9.5 mm or more

NOTE

Measure the valve height when the thermostat is fully

closed, and use this measurement to calculate the valve

height when the thermostat is fully open.

Valve lift

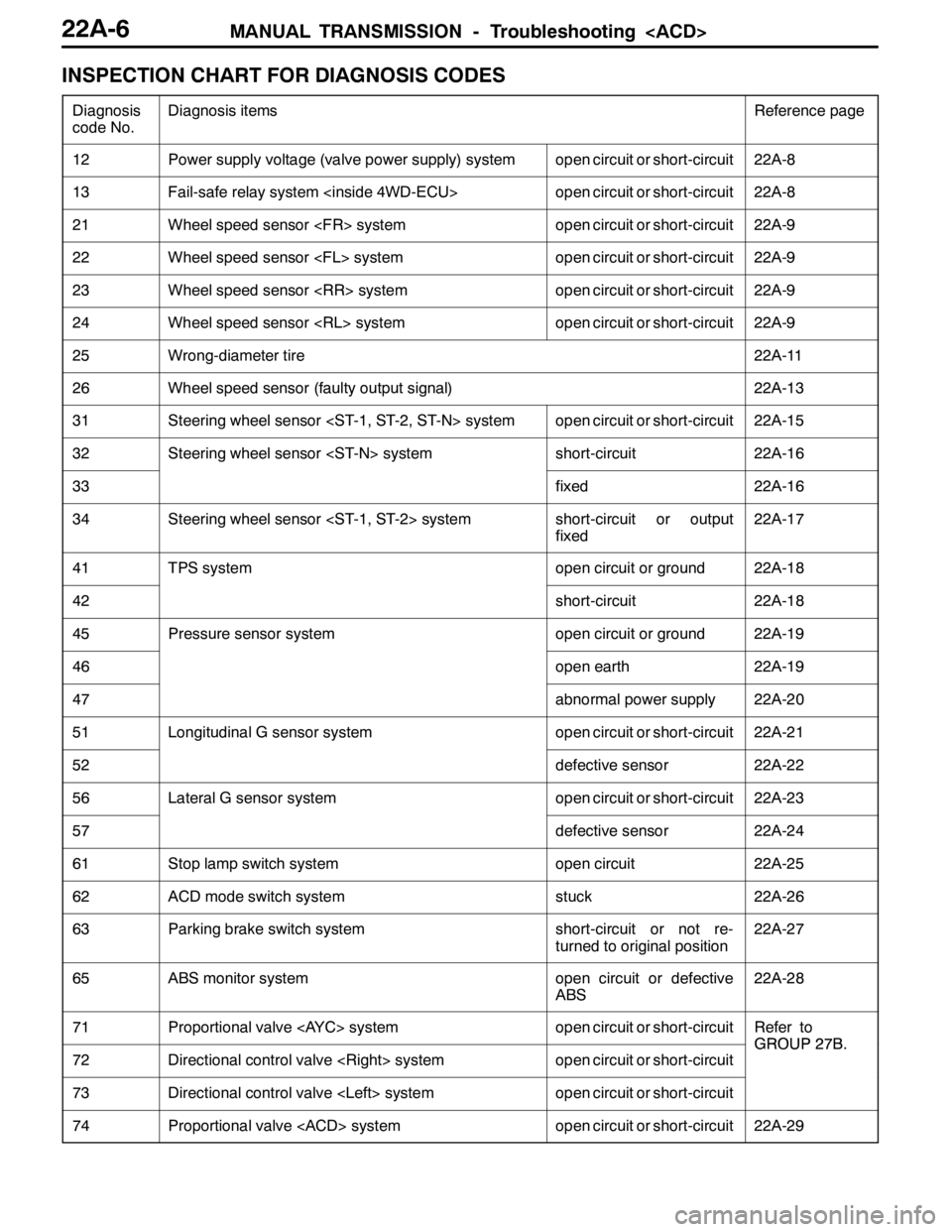

Page 814 of 1449

MANUAL TRANSMISSION - Troubleshooting

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemsReference page

12Power supply voltage (valve power supply) systemopen circuit or short-circuit22A-8

13Fail-safe relay system

21Wheel speed sensor

22Wheel speed sensor

23Wheel speed sensor

24Wheel speed sensor

25Wrong-diameter tire22A-11

26Wheel speed sensor (faulty output signal)22A-13

31Steering wheel sensor

32Steering wheel sensor

33fixed22A-16

34Steering wheel sensor

fixed22A-17

41TPS systemopen circuit or ground22A-18

42short-circuit22A-18

45Pressure sensor systemopen circuit or ground22A-19

46open earth22A-19

47abnormal power supply22A-20

51Longitudinal G sensor systemopen circuit or short-circuit22A-21

52defective sensor22A-22

56Lateral G sensor systemopen circuit or short-circuit22A-23

57defective sensor22A-24

61Stop lamp switch systemopen circuit22A-25

62ACD mode switch systemstuck22A-26

63Parking brake switch systemshort-circuit or not re-

turned to original position22A-27

65ABS monitor systemopen circuit or defective

ABS22A-28

71Proportional valve

GROUP27B

72Directional control valve

GROUP27B.

73Directional control valve

74Proportional valve

Page 817 of 1449

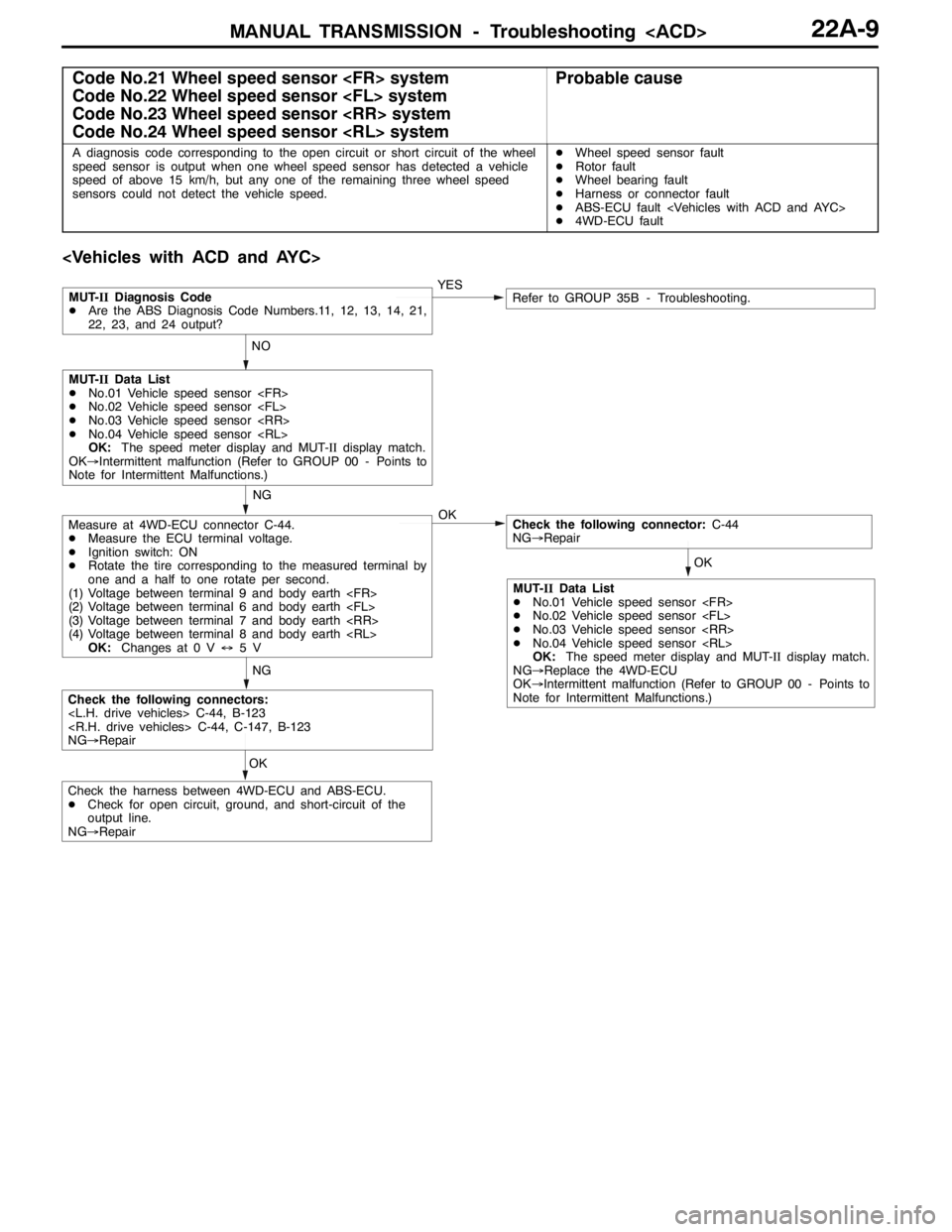

MANUAL TRANSMISSION - Troubleshooting

Code No.21 Wheel speed sensor

Code No.22 Wheel speed sensor

Code No.23 Wheel speed sensor

Code No.24 Wheel speed sensor

A diagnosis code corresponding to the open circuit or short circuit of the wheel

speed sensor is output when one wheel speed sensor has detected a vehicle

speed of above 15 km/h, but any one of the remaining three wheel speed

sensors could not detect the vehicle speed.DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OKNGYES

NO

OK

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5VCheck the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair

MUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Numbers.11, 12, 13, 14, 21,

22, 23, and 24 output?Refer to GROUP 35B - Troubleshooting.

NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

OK

Check the harness between 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground, and short-circuit of the

output line.

NG→Repair

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Page 819 of 1449

MANUAL TRANSMISSION - Troubleshooting

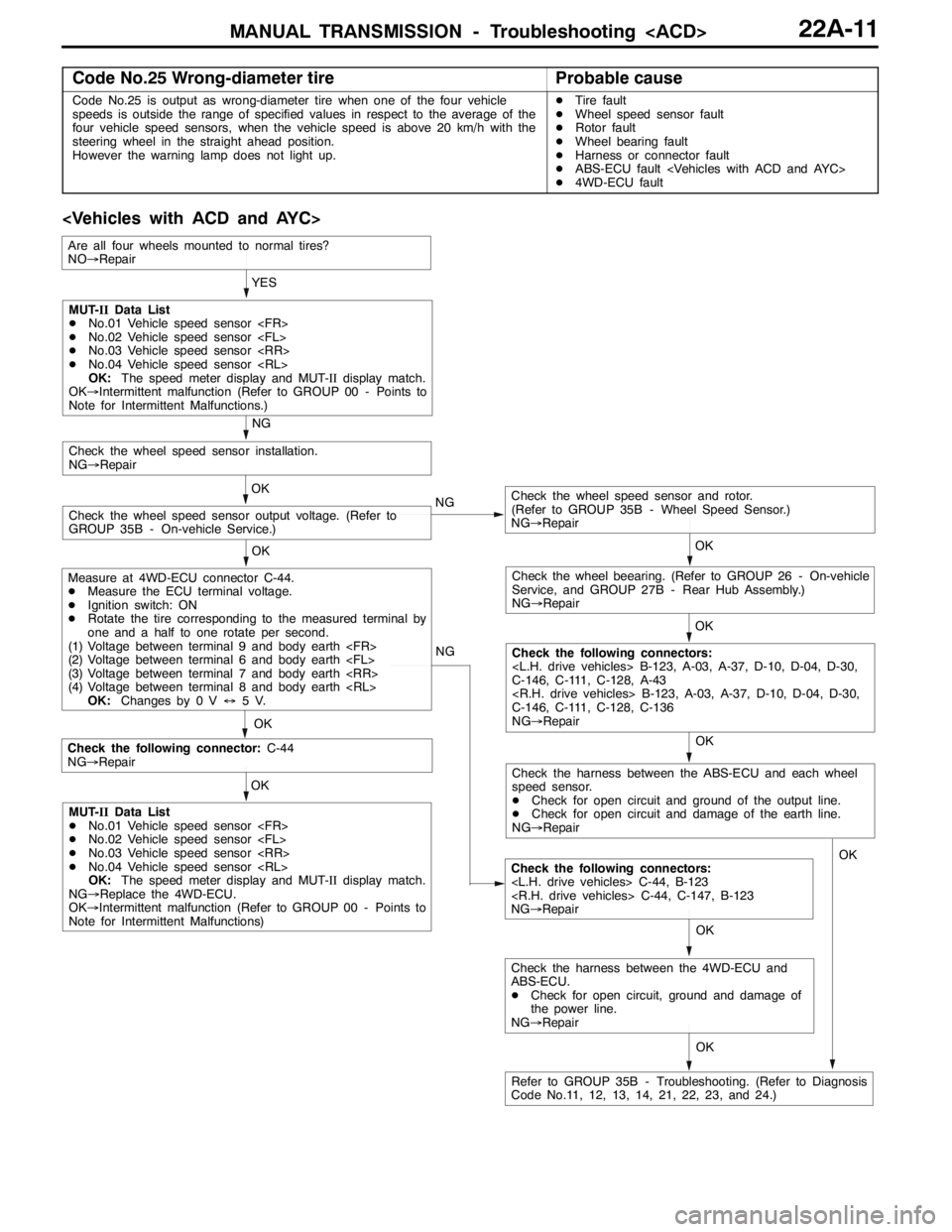

Code No.25 Wrong-diameter tireProbable cause

Code No.25 is output as wrong-diameter tire when one of the four vehicle

speeds is outside the range of specified values in respect to the average of the

four vehicle speed sensors, when the vehicle speed is above 20 km/h with the

steering wheel in the straight ahead position.

However the warning lamp does not light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OKYES

OK

OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→Repair

Check the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the wheel speed sensor installation.

NG→Repair

NG

OK

Check the wheel beearing. (Refer to GROUP 26 - On-vehicle

Service, and GROUP 27B - Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes by 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Refer to GROUP 35B - Troubleshooting. (Refer to Diagnosis

Code No.11, 12, 13, 14, 21, 22, 23, and 24.)

Are all four wheels mounted to normal tires?

NO→Repair

Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit and ground of the output line.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Check the harness between the 4WD-ECU and

ABS-ECU.

DCheck for open circuit, ground and damage of

the power line.

NG→RepairOK

Page 821 of 1449

MANUAL TRANSMISSION - Troubleshooting

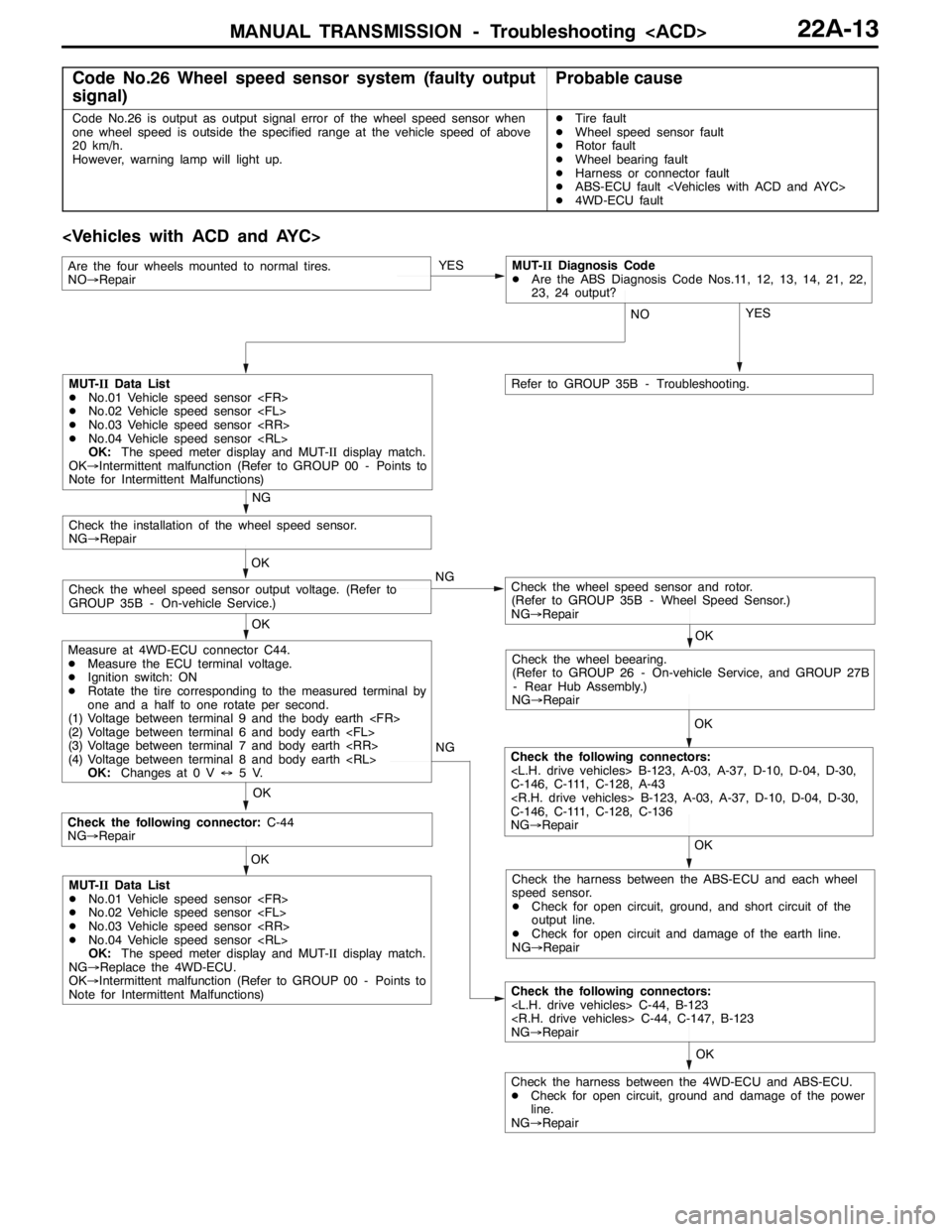

Code No.26 Wheel speed sensor system (faulty output

signal)Probable cause

Code No.26 is output as output signal error of the wheel speed sensor when

one wheel speed is outside the specified range at the vehicle speed of above

20 km/h.

However, warning lamp will light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OK

Check the harness between the 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground and damage of the power

line.

NG→RepairYES

OK OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→RepairCheck the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the installation of the wheel speed sensor.

NG→Repair

NG

OK

Check the wheel beearing.

(Refer to GROUP 26 - On-vehicle Service, and GROUP 27B

- Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Measure at 4WD-ECU connector C44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and the body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit, ground, and short circuit of the

output line.

DCheck for open circuit and damage of the earth line.

NG→Repair YES

NO

Refer to GROUP 35B - Troubleshooting.

Are the four wheels mounted to normal tires.

NO→RepairMUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Nos.11, 12, 13, 14, 21, 22,

23, 24 output?