engine coolant MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 595 of 1449

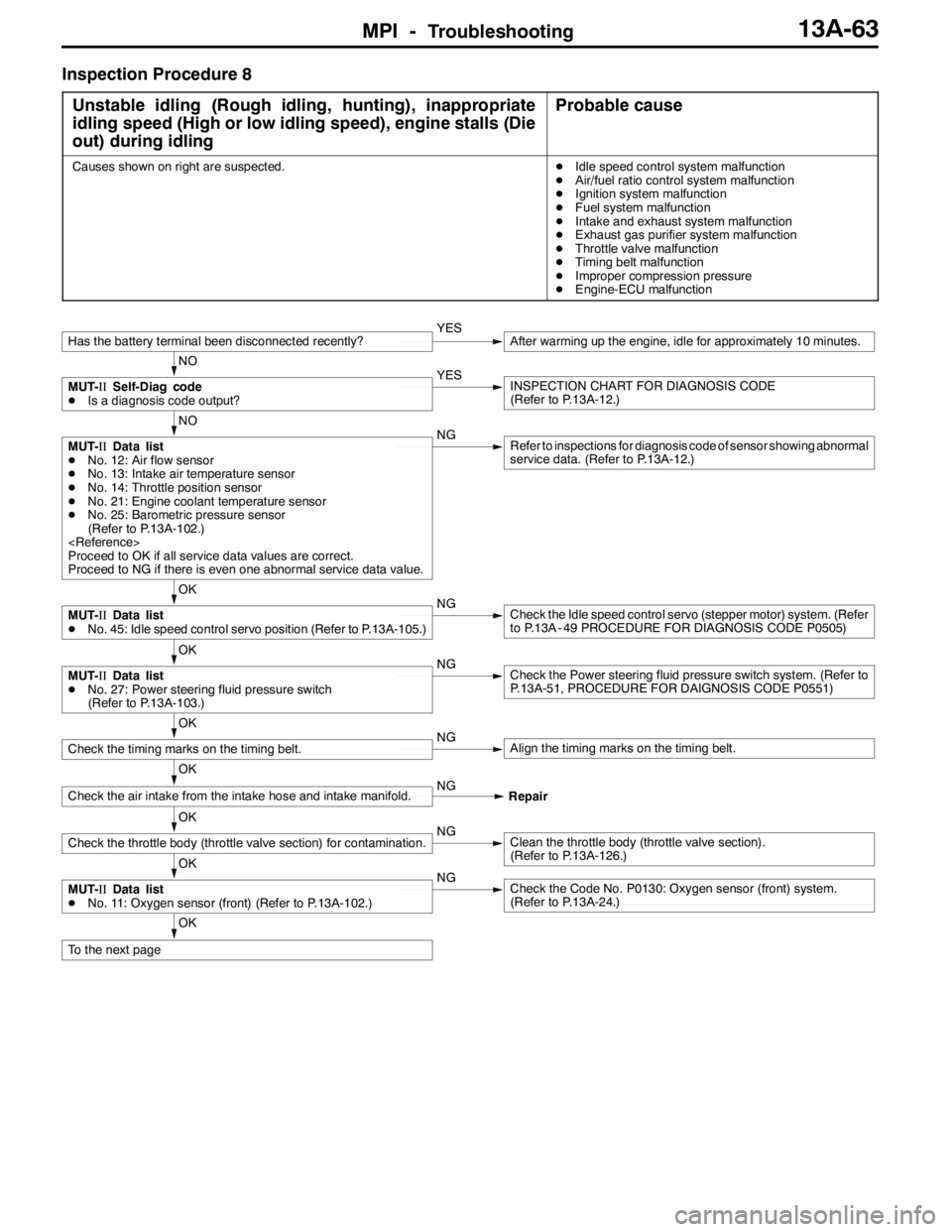

MPI -Troubleshooting13A-63

Inspection Procedure 8

Unstable idling (Rough idling, hunting), inappropriate

idling speed (High or low idling speed), engine stalls (Die

out) during idling

Probable cause

Causes shown on right are suspected.DIdle speed control system malfunction

DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DThrottle valve malfunction

DTiming belt malfunction

DImproper compression pressure

DEngine-ECU malfunction

OK

To the next page

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check the throttle body (throttle valve section) for contamination.NGClean the throttle body (throttle valve section).

(Refer to P.13A-126.)

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

Check the timing marks on the timing belt.NGAlign the timing marks on the timing belt.

OK

MUT-IIData list

DNo. 27: Power steering fluid pressure switch

(Refer to P.13A-103.)NGCheck the Power steering fluid pressure switch system. (Refer to

P.13A-51, PROCEDURE FOR DAIGNOSIS CODE P0551)

OK

MUT-IIData list

DNo. 45: Idle speed control servo position (Refer to P.13A-105.)NGCheck the Idle speed control servo (stepper motor) system. (Refer

to P.13A - 49 PROCEDURE FOR DIAGNOSIS CODE P0505)

NO

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 14: Throttle position sensor

DNo. 21: Engine coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing abnormal

service data. (Refer to P.13A-12.)

NO

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Has the battery terminal been disconnected recently?YESAfter warming up the engine, idle for approximately 10 minutes.

Page 600 of 1449

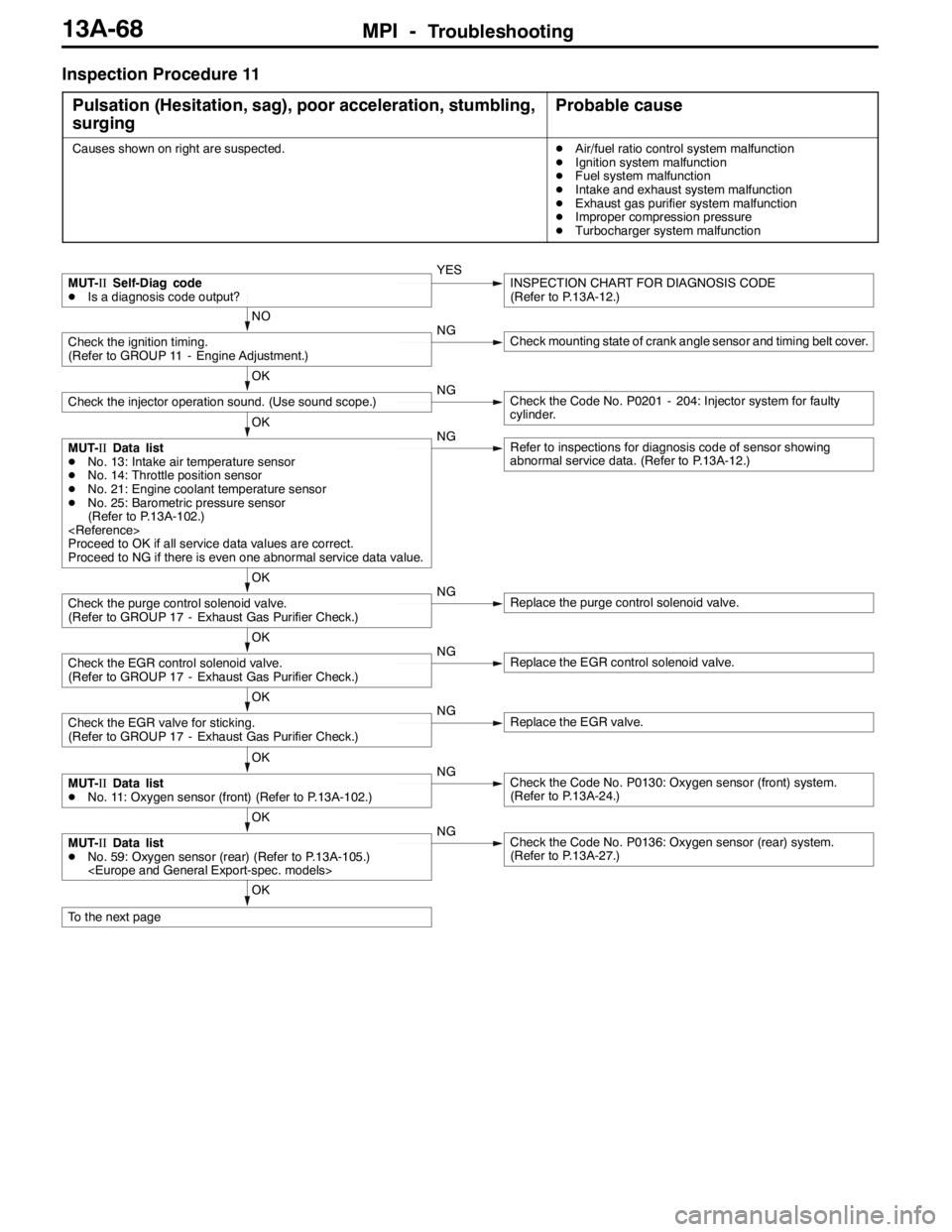

MPI -Troubleshooting13A-68

Inspection Procedure 11

Pulsation (Hesitation, sag), poor acceleration, stumbling,

surging

Probable cause

Causes shown on right are suspected.DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DImproper compression pressure

DTurbocharger system malfunction

OK

To the next page

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear) (Refer to P.13A-105.)

(Refer to P.13A-27.)

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check the EGR valve for sticking.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR valve.

OK

Check the EGR control solenoid valve.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR control solenoid valve.

OK

Check the purge control solenoid valve.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the purge control solenoid valve.

OK

MUT-IIData list

DNo. 13: Intake air temperature sensor

DNo. 14: Throttle position sensor

DNo. 21: Engine coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing

abnormal service data. (Refer to P.13A-12.)

OK

Check the injector operation sound. (Use sound scope.)NGCheck the Code No. P0201 - 204: Injector system for faulty

cylinder.

NO

Check the ignition timing.

(Refer to GROUP 11 - Engine Adjustment.)NGCheck mounting state of crank angle sensor and timing belt cover.

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

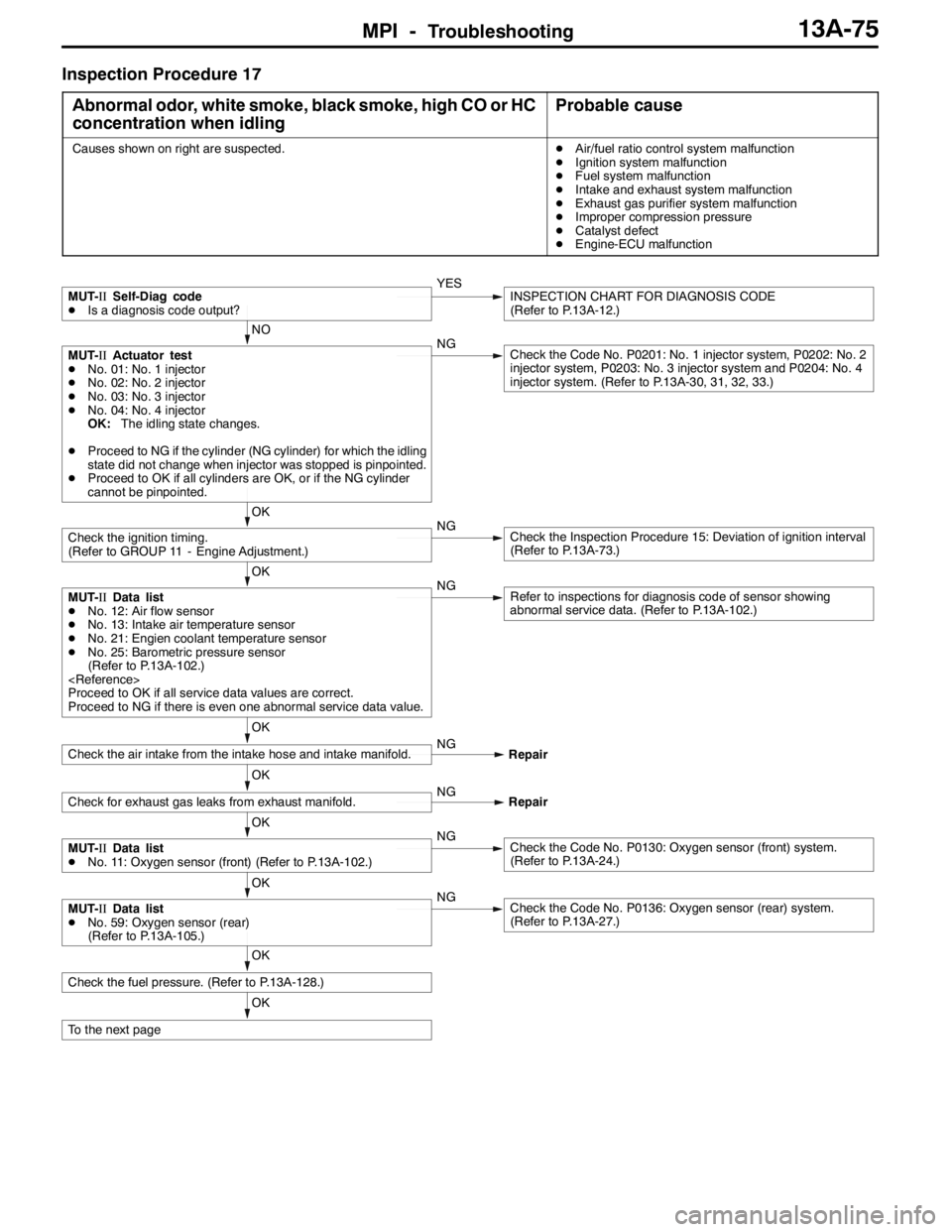

Page 607 of 1449

MPI -Troubleshooting13A-75

Inspection Procedure 17

Abnormal odor, white smoke, black smoke, high CO or HC

concentration when idling

Probable cause

Causes shown on right are suspected.DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DImproper compression pressure

DCatalyst defect

DEngine-ECU malfunction

OK

To the next page

OK

Check the fuel pressure. (Refer to P.13A-128.)

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check for exhaust gas leaks from exhaust manifold.NG

Repair

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 21: Engien coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing

abnormal service data. (Refer to P.13A-102.)

OK

Check the ignition timing.

(Refer to GROUP 11 - Engine Adjustment.)NGCheck the Inspection Procedure 15: Deviation of ignition interval

(Refer to P.13A-73.)

NO

MUT-IIActuator test

DNo. 01: No. 1 injector

DNo. 02: No. 2 injector

DNo. 03: No. 3 injector

DNo. 04: No. 4 injector

OK:The idling state changes.

DProceed to NG if the cylinder (NG cylinder) for which the idling

state did not change when injector was stopped is pinpointed.

DProceed to OK if all cylinders are OK, or if the NG cylinder

cannot be pinpointed.NGCheck the Code No. P0201: No. 1 injector system, P0202: No. 2

injector system, P0203: No. 3 injector system and P0204: No. 4

injector system. (Refer to P.13A-30, 31, 32, 33.)

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Page 611 of 1449

MPI -Troubleshooting13A-79

Inspection Procedure 19

Overheating

Probable cause

Causes shown on right are suspected.DEngine coolant insufficient or deteriorated

DFan controller malfunction

DEngine coolant temperature sensor malfunction

DThermostat malfunction

DWater pump malfunction

DCondenser fan relay malfunction

DRadiator core malfunction

DEngine-ECU malfunction

NO

NG

Replace or replenish the engine coolant.

OK

Replace the radiator core.

OK

Check the water pump. (Refer to GROUP 14 - Water pump.)NGReplace the water pump.

OK

Check the thermostat. (Refer to GROUP 14 - Thermostat.)NGReplace the thermostat.

OK

MUT-IIData list

DNo. 21: Engine coolant temperaure sensor

OK:Approximately the same as the ambient temperature

when cooled.

Between 80 - 120_C when hot.NGCheck the Code No. P0115: Engine coolant temperature

sensor system. (Refer to P.13A-19.)

MUT-IIData list

21 Engine coolant temperature sensor (Refer to P.13A-102.)

OK

MUT-IIActuator Test

DNo. 37: Condenser fan (HI)

DNo. 38: Condenser fan (LOW)

DIgnition switch: ON

OK:Condenser fan rotates (low speed).

OK:Condenser fan rotates (high speed).NGCheck the Inspection Procedure 25: Condenser fan control

relay system. (Refer to P.13A-89.)

MUT-IIActuator Test

DNo. 21: Fan controller

DIgnition switch: ON

OK:Radiator fan rotates.NGCheck the Inspection Procedure 24: Radiator fan control relay

system. (Refer to P.13A-87.)

OK

Check the engine coolant.

(Refer to GROUP 14 - On-vehicle Service.)

If the engine coolant level is low, check whether the engine

coolant has leaked, and repair if required.

MUT-IISelf-Diag Code

Is a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE (Refer to

P.13A-12.)

Page 634 of 1449

![MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual MPI -Troubleshooting13A-102

DATA LIST REFERENCE TABLE

NOTE

*1. In a new Vehicle [driven approximately 500 km or less], the air flow sensor output frequency time

is sometimes 10% longer than the standa MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual MPI -Troubleshooting13A-102

DATA LIST REFERENCE TABLE

NOTE

*1. In a new Vehicle [driven approximately 500 km or less], the air flow sensor output frequency time

is sometimes 10% longer than the standa](/img/19/57084/w960_57084-633.png)

MPI -Troubleshooting13A-102

DATA LIST REFERENCE TABLE

NOTE

*1. In a new Vehicle [driven approximately 500 km or less], the air flow sensor output frequency time

is sometimes 10% longer than the standard time.

*2. The injector drive time represents the time when the cranking speed is at 250 r/min or below when

the power supply voltage is 11 V.

*3. In a new vehicle [driven approximately 500 km or less], the injector drive time is sometimes 10%

longer than the standard time.

*4. In a new vehicle [driven approximately 500 km or less], the step of the stepper motor is sometimes

30 steps greater than the standard value.

Item

No.Inspection

itemInspection contentsNormal conditionInspection

procedure

No.Reference

page

11Oxygen

sensor

(front)Engine: After having

warmed up

(Air/fuel mixuture is

made leaner whenWhen at 4,000 r/min,

engine is suddenly de-

celerated200 mV or lessCode No.

P013013A-24

madeleanerwhen

decelerating, and is

made richer when rac-

ing.)When engine is sud-

denly raced600 - 1,000 mV

Engine: After having

warmed up

(The oxygen sensor

(front) signal is used

tochecktheair/fuel

Engine is idling400 mV or less↔

600 - 1,000 mV

(Varies)

to check the air/fuel

mixture ratio, and

control condition is

also checked by the

engine-ECU.)2,500 r/min

12Air flow

sensor*1DEngine coolant

temperature:

Idle operation17 - 43 Hz--

sensor*1temperature:

80 - 95_C

DLightningandall

2,500 r/min40 - 100 Hz

DLightning andall

accessories:

OFF

DTransmission:

NeutralAccelerationAccording to ac-

celeration, fre-

quency is ampli-

fied.

13Intake air

temperature

sensor

Ignition switch: “ON”

or engine runningWhen intake air temper-

ature is - 20_C-20_CCode No.

P011013A-13

sensorWhen intake air tem-

perature is 0_C0_C

When intake air tem-

perature is 20_C20_C

When intake air tem-

perature is 40_C40_C

When intake air tem-

perature is 80_C80_C

Page 635 of 1449

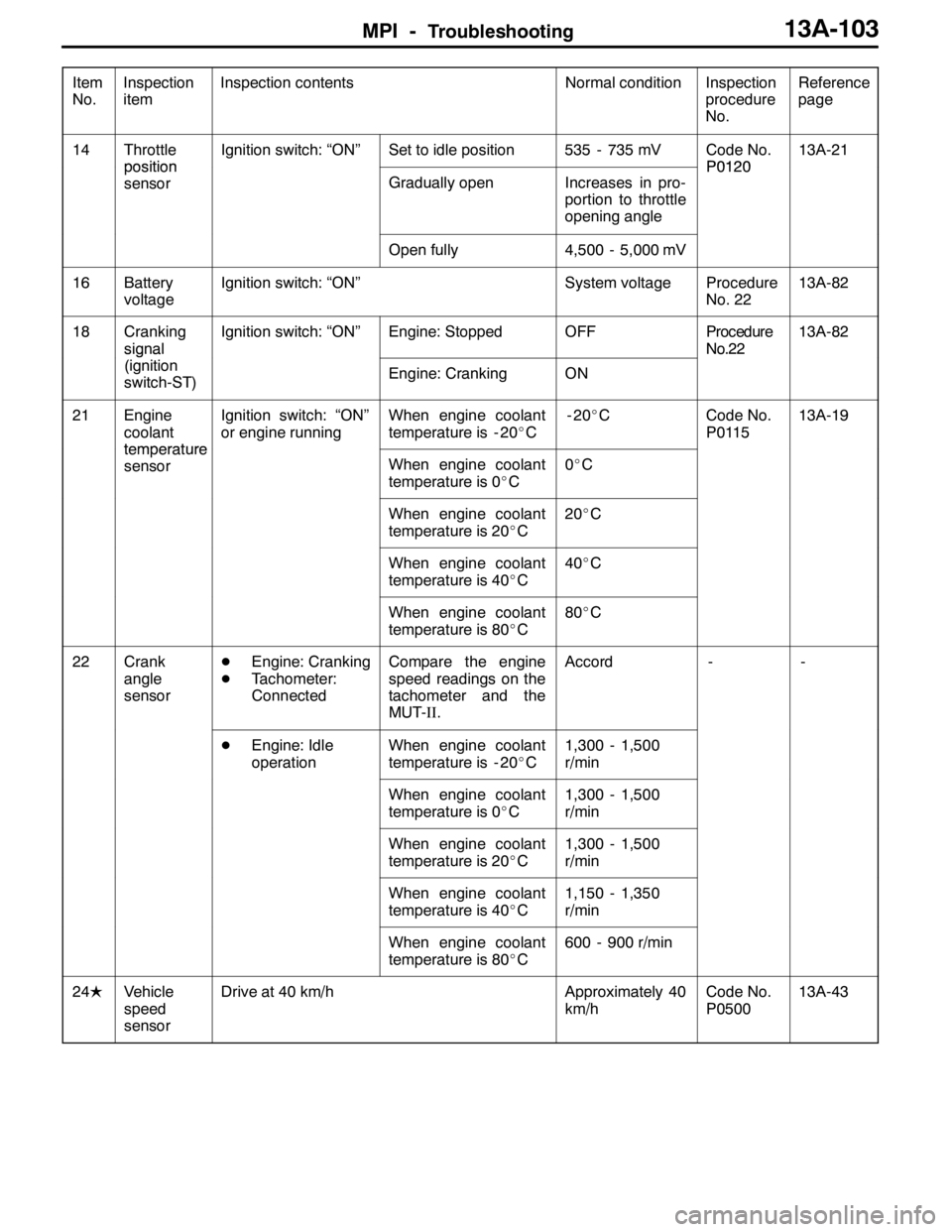

MPI -Troubleshooting13A-103

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

14Throttle

position

Ignition switch: “ON”Set to idle position535 - 735 mVCode No.

P0120

13A-21

position

sensor

Gradually openIncreases in pro-

portion to throttle

opening angle

P0120

Open fully4,500 - 5,000 mV

16Battery

voltageIgnition switch: “ON”System voltageProcedure

No. 2213A-82

18Cranking

signalIgnition switch: “ON”Engine: StoppedOFFProcedure

No.2213A-82

signal

(ignition

switch-ST)Engine: CrankingON

No.22

21Engine

coolant

temperature

Ignition switch: “ON”

or engine runningWhen engine coolant

temperature is - 20_C-20_CCode No.

P011513A-19

temperature

sensorWhen engine coolant

temperature is 0_C0_C

When engine coolant

temperature is 20_C20_C

When engine coolant

temperature is 40_C40_C

When engine coolant

temperature is 80_C80_C

22Crank

angle

sensorDEngine: Cranking

DTachometer:

ConnectedCompare the engine

speed readings on the

tachometer and the

MUT-II.Accord--

DEngine: Idle

operationWhen engine coolant

temperature is - 20_C1,300 - 1,500

r/min

When engine coolant

temperature is 0_C1,300 - 1,500

r/min

When engine coolant

temperature is 20_C1,300 - 1,500

r/min

When engine coolant

temperature is 40_C1,150 - 1,350

r/min

When engine coolant

temperature is 80_C600 - 900 r/min

24LVehicle

speed

sensorDrive at 40 km/hApproximately 40

km/hCode No.

P050013A-43

Page 636 of 1449

MPI -Troubleshooting13A-104

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

25Barometric

pressure

Ignition switch: ONAltitude: 0 m101 kPaCode No.

P0105

13A-15

pressure

sensor

Altitude: 0 m95 kPa

P0105

Altitude: 0 m88 kPa

Altitude: 0 m81 kPa

27Power

steering

fluidEngine: Idle operationSteering wheel

stationaryOFFCode No.

P055113A-46

fluid

pressure

switchSteering wheel turningON

28A/C switchEngine: Idle operation

(When A/C switch isA/C switch: OFFOFFProcedure

No. 2613A-92

(WhenA/Cswitchis

ON, A/C compressor

should be operating.)A/C switch: ONON

No.26

34Air flow

sensorEngine: After

warm-upIdle operationONCode No.

P010013A-13

sensor

reset

signal

warm up

3,000 r/minOFF

P0100

37Volumetric

efficiency

DEngine coolant

temperature:

Idle operation15 - 35%--

efficiencytemperature:

85 - 95_C

DLightningand

2,500 r/min15 - 35%

DLightning and

accessories:

OFFExcessive

accellerationAccording to ac-

celeration, volu-

metric efficiency

is increased.

41Injectors*1Engine: CrankingWhen engine coolant

temperature is 0_C

(injection is carried out

for all cylinders simulta-

neously)25 - 37 ms--

When engine coolant

temperature is 20_C15 - 22 ms

When engine coolant

temperature is 80_C4.2 - 6.3 ms

Injectors*2DEngine coolant

temperature:

80–95_C

Engine: Idle operation1.5 - 2.7 ms--

80–95_C

DLamps, electric

cooling fan and

allaccessories:

2,500 r/min1.2 - 2.4 ms

allaccessories:

OFF

DTransmission:

Neutral

When engine is sud-

denly racedIncreases

Page 637 of 1449

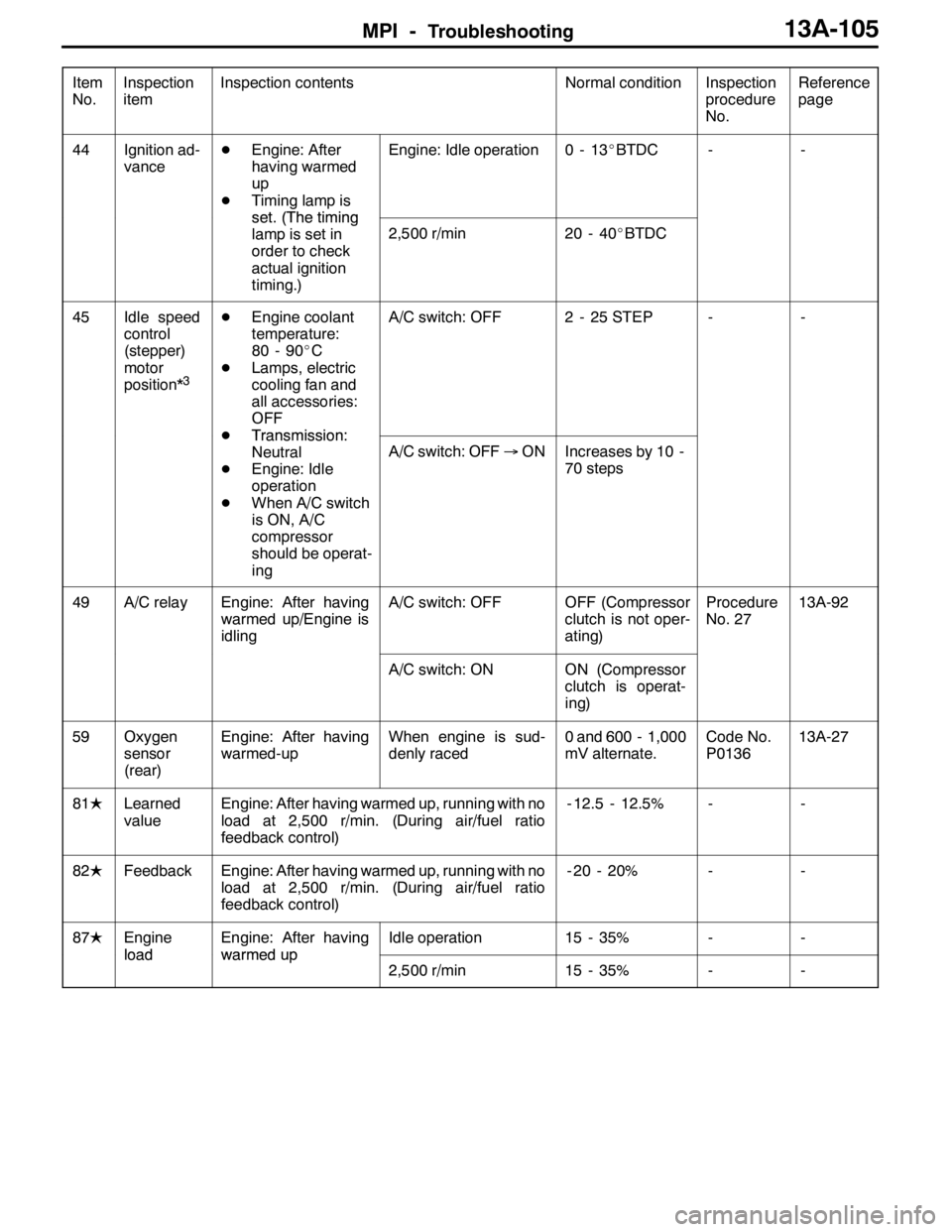

MPI -Troubleshooting13A-105

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

44Ignition ad-

vanceDEngine: After

having warmed

up

DTiming lamp is

set(Thetiming

Engine: Idle operation0-13_BTDC--

set.(Thetiming

lamp is set in

order to check

actual ignition

timing.)

2,500 r/min20 - 40_BTDC

45Idle speed

control

(stepper)

motor

position*

3

DEngine coolant

temperature:

80 - 90_C

DLamps, electric

cooling fan and

all accessories:

OFF

DTransmission:

A/C switch: OFF2 - 25 STEP--

DTransmission:

Neutral

DEngine: Idle

operation

DWhen A/C switch

is ON, A/C

compressor

should be operat-

ing

A/C switch: OFF→ONIncreases by 10 -

70 steps

49A/C relayEngine: After having

warmed up/Engine is

idlingA/C switch: OFFOFF (Compressor

clutch is not oper-

ating)Procedure

No. 2713A-92

A/C switch: ONON (Compressor

clutch is operat-

ing)

59Oxygen

sensor

(rear)Engine: After having

warmed-upWhen engine is sud-

denly raced0 and 600 - 1,000

mV alternate.Code No.

P013613A-27

81LLearned

valueEngine: After having warmed up, running with no

load at 2,500 r/min. (During air/fuel ratio

feedback control)- 12.5 - 12.5%--

82LFeedbackEngine: After having warmed up, running with no

load at 2,500 r/min. (During air/fuel ratio

feedback control)- 20 - 20%--

87LEngine

load

Engine: After having

warmedup

Idle operation15 - 35%--

loadwarmedup

2,500 r/min15 - 35%--

Page 642 of 1449

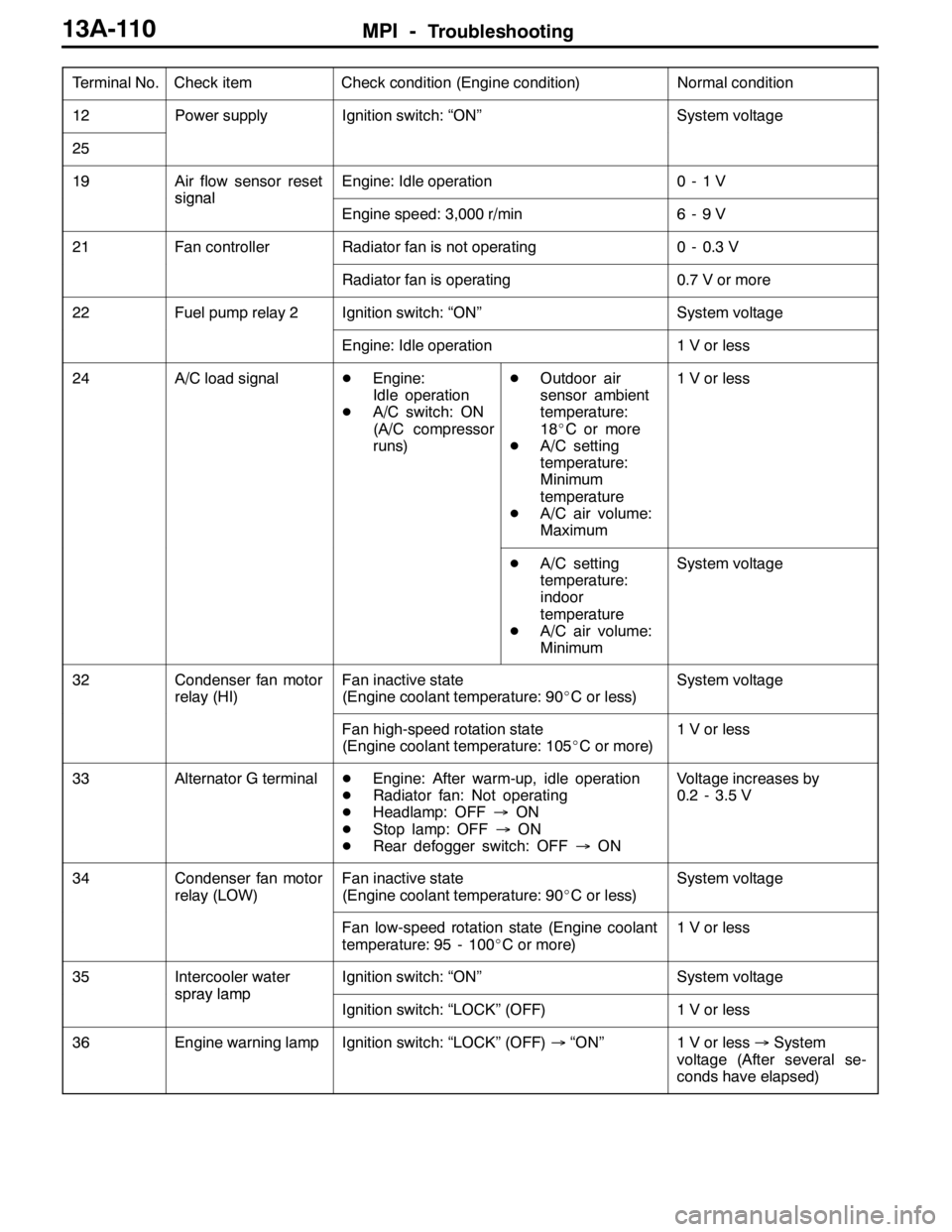

MPI -Troubleshooting13A-110

Terminal No.Normal condition Check condition (Engine condition) Check item

12Power supplyIgnition switch: “ON”System voltage

25

19Air flow sensor reset

signal

Engine: Idle operation0-1V

signal

Engine speed: 3,000 r/min6-9V

21Fan controllerRadiator fan is not operating0 - 0.3 V

Radiator fan is operating0.7 V or more

22Fuel pump relay 2Ignition switch: “ON”System voltage

Engine: Idle operation1 V or less

24A/C load signalDEngine:

Idle operation

DA/C switch: ON

(A/C compressor

runs)DOutdoor air

sensor ambient

temperature:

18_C or more

DA/C setting

temperature:

Minimum

temperature

DA/C air volume:

Maximum1 V or less

DA/C setting

temperature:

indoor

temperature

DA/C air volume:

MinimumSystem voltage

32Condenser fan motor

relay (HI)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan high-speed rotation state

(Engine coolant temperature: 105_C or more)1 V or less

33Alternator G terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHeadlamp: OFF→ON

DStop lamp: OFF→ON

DRear defogger switch: OFF→ONVoltage increases by

0.2 - 3.5 V

34Condenser fan motor

relay (LOW)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan low-speed rotation state (Engine coolant

temperature: 95 - 100_C or more)1 V or less

35Intercooler water

spraylamp

Ignition switch: “ON”System voltage

spraylamp

Ignition switch: “LOCK” (OFF)1 V or less

36Engine warning lampIgnition switch: “LOCK” (OFF)→“ON”1 V or less→System

voltage (After several se-

conds have elapsed)

Page 644 of 1449

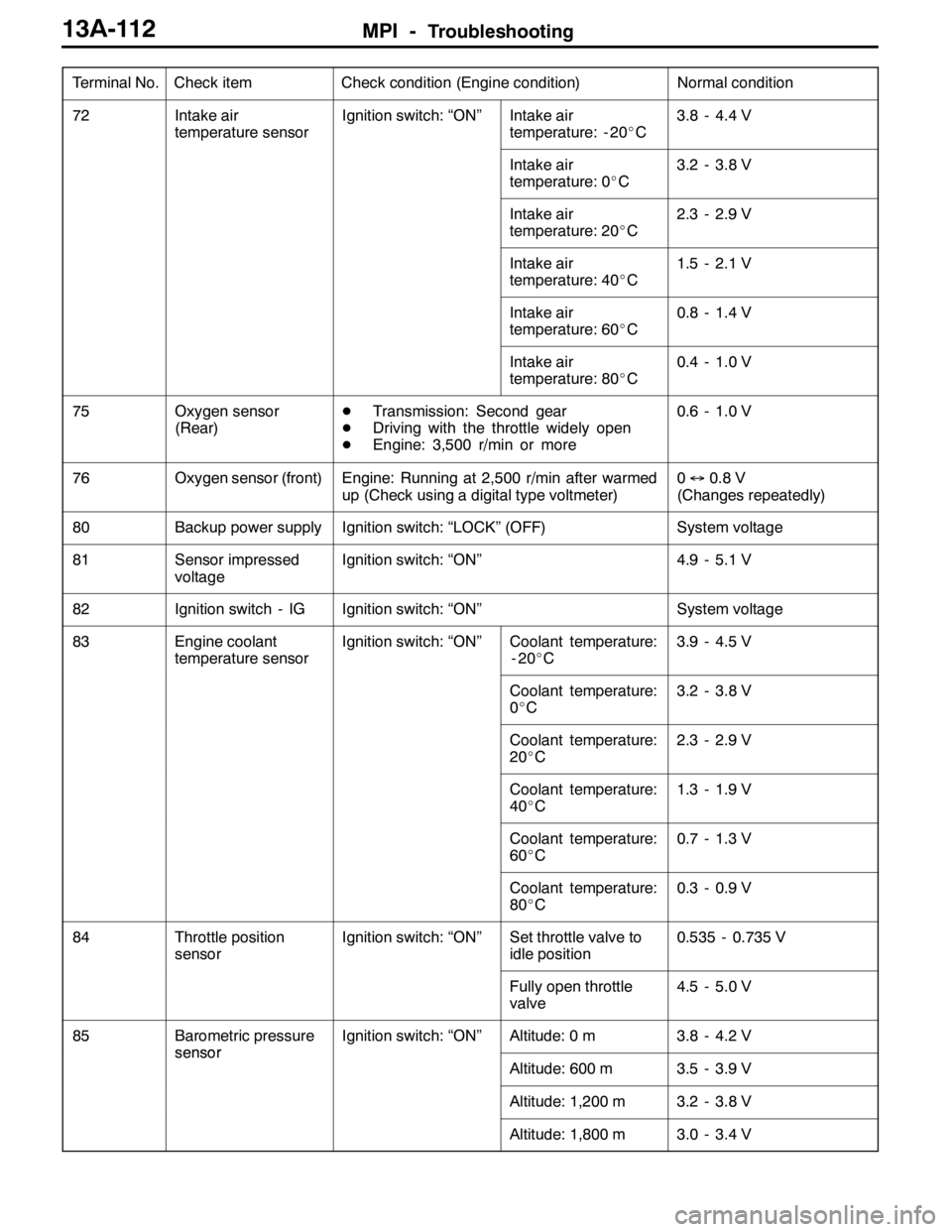

MPI -Troubleshooting13A-112

Terminal No.Normal condition Check condition (Engine condition) Check item

72Intake air

temperature sensorIgnition switch: “ON”Intake air

temperature: - 20_C3.8 - 4.4 V

Intake air

temperature: 0_C3.2 - 3.8 V

Intake air

temperature: 20_C2.3 - 2.9 V

Intake air

temperature: 40_C1.5 - 2.1 V

Intake air

temperature: 60_C0.8 - 1.4 V

Intake air

temperature: 80_C0.4 - 1.0 V

75Oxygen sensor

(Rear)DTransmission: Second gear

DDriving with the throttle widely open

DEngine: 3,500 r/min or more0.6 - 1.0 V

76Oxygen sensor (front)Engine: Running at 2,500 r/min after warmed

up (Check using a digital type voltmeter)0↔0.8 V

(Changes repeatedly)

80Backup power supplyIgnition switch: “LOCK” (OFF)System voltage

81Sensor impressed

voltageIgnition switch: “ON”4.9 - 5.1 V

82Ignition switch - IGIgnition switch: “ON”System voltage

83Engine coolant

temperature sensorIgnition switch: “ON”Coolant temperature:

-20_C3.9 - 4.5 V

Coolant temperature:

0_C3.2 - 3.8 V

Coolant temperature:

20_C2.3 - 2.9 V

Coolant temperature:

40_C1.3 - 1.9 V

Coolant temperature:

60_C0.7 - 1.3 V

Coolant temperature:

80_C0.3 - 0.9 V

84Throttle position

sensorIgnition switch: “ON”Set throttle valve to

idle position0.535 - 0.735 V

Fully open throttle

valve4.5 - 5.0 V

85Barometric pressure

sensor

Ignition switch: “ON”Altitude: 0 m3.8 - 4.2 V

sensor

Altitude: 600 m3.5 - 3.9 V

Altitude: 1,200 m3.2 - 3.8 V

Altitude: 1,800 m3.0 - 3.4 V