lock MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 431 of 1449

ENGINE -Oil Pan11A-25

INSTALLATION SERVICE POINTS

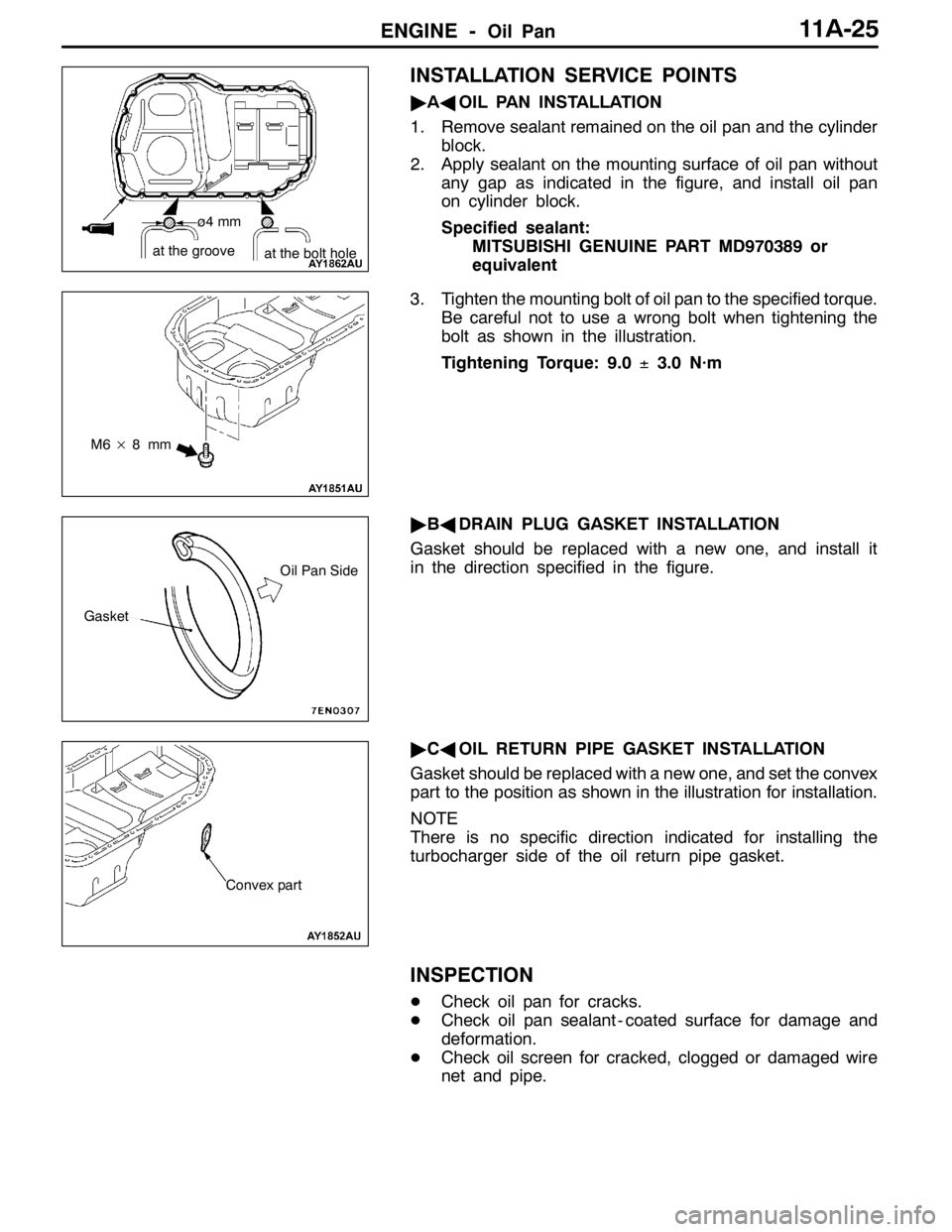

"AAOIL PAN INSTALLATION

1. Remove sealant remained on the oil pan and the cylinder

block.

2. Apply sealant on the mounting surface of oil pan without

any gap as indicated in the figure, and install oil pan

on cylinder block.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Tighten the mounting bolt of oil pan to the specified torque.

Be careful not to use a wrong bolt when tightening the

bolt as shown in the illustration.

Tightening Torque: 9.0±3.0 N·m

"BADRAIN PLUG GASKET INSTALLATION

Gasket should be replaced with a new one, and install it

in the direction specified in the figure.

"CAOIL RETURN PIPE GASKET INSTALLATION

Gasket should be replaced with a new one, and set the convex

part to the position as shown in the illustration for installation.

NOTE

There is no specific direction indicated for installing the

turbocharger side of the oil return pipe gasket.

INSPECTION

DCheck oil pan for cracks.

DCheck oil pan sealant - coated surface for damage and

deformation.

DCheck oil screen for cracked, clogged or damaged wire

net and pipe.

ø4 mm

at the groove

at the bolt hole

M6×8mm

Gasket

Oil Pan Side

Convex part

Page 441 of 1449

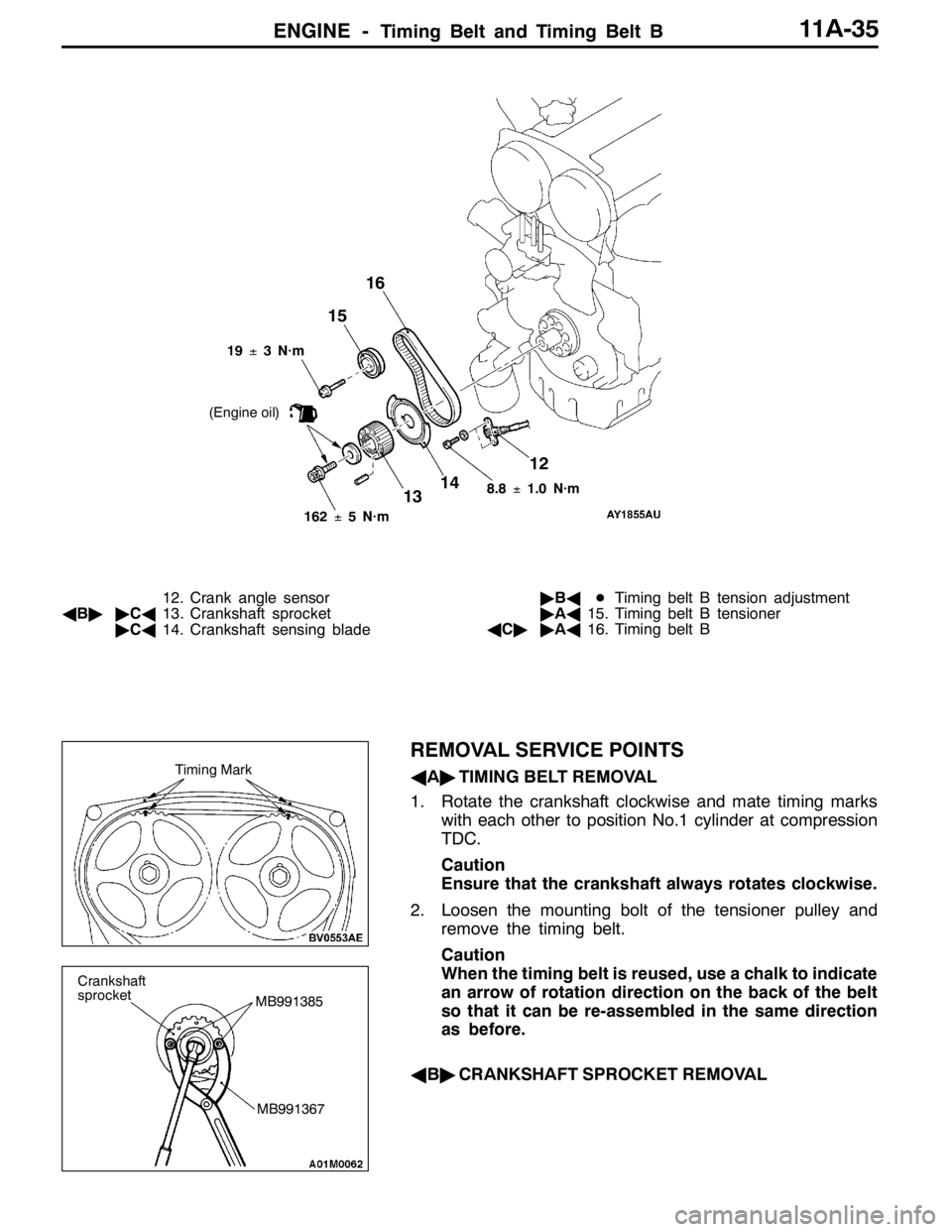

ENGINE -Timing Belt and Timing Belt B11A-35

12

1314 1516

8.8±1.0 N·m

162±5 N·m 19±3 N·m

(Engine oil)

12. Crank angle sensor

AB""CA13. Crankshaft sprocket

"CA14. Crankshaft sensing blade"BADTiming belt B tension adjustment

"AA15. Timing belt B tensioner

AC""AA16. Timing belt B

REMOVAL SERVICE POINTS

AA"TIMING BELT REMOVAL

1. Rotate the crankshaft clockwise and mate timing marks

with each other to position No.1 cylinder at compression

TDC.

Caution

Ensure that the crankshaft always rotates clockwise.

2. Loosen the mounting bolt of the tensioner pulley and

remove the timing belt.

Caution

When the timing belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

AB"CRANKSHAFT SPROCKET REMOVALTiming Mark

MB991367

Crankshaft

sprocket

MB991385

Page 443 of 1449

ENGINE -Timing Belt and Timing Belt B11A-37

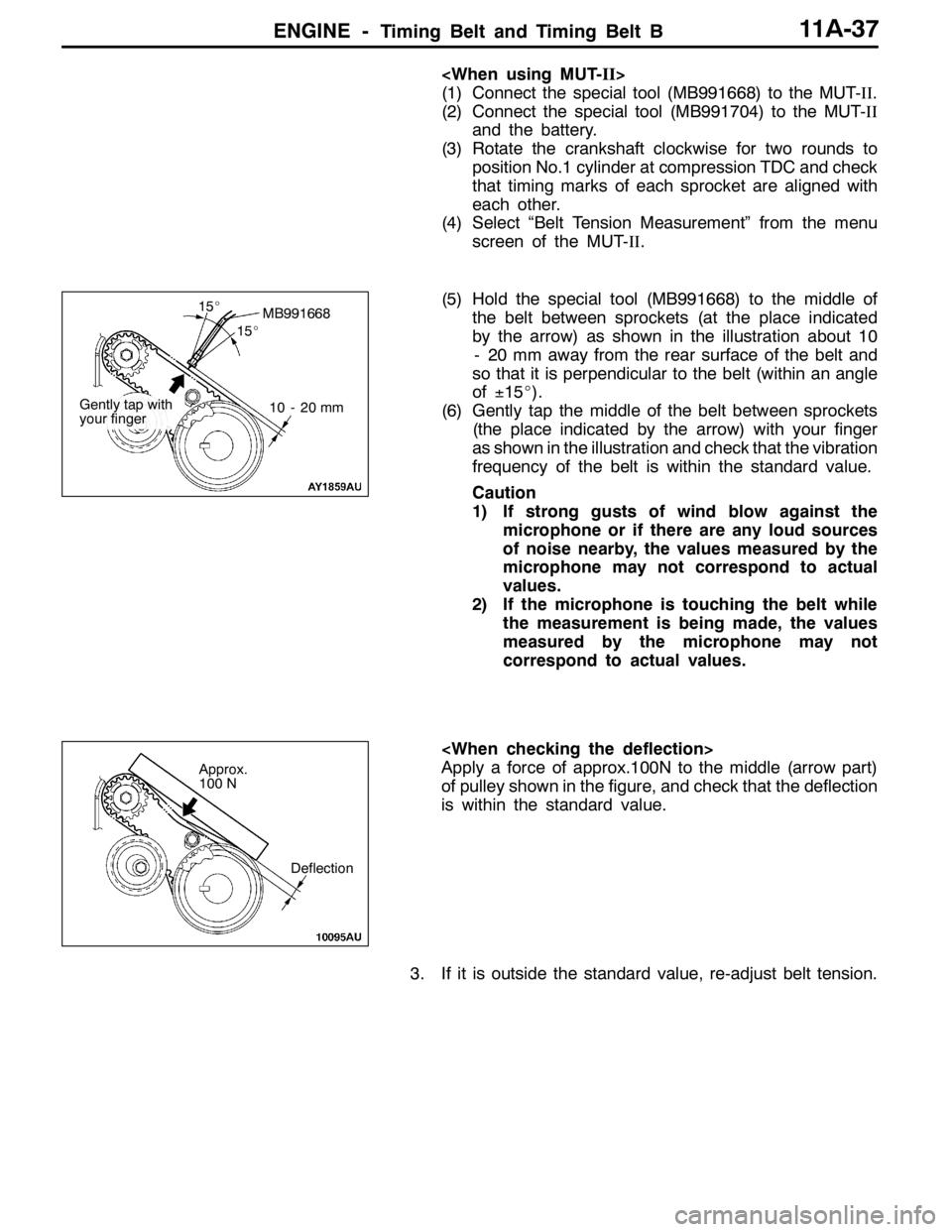

(1) Connect the special tool (MB991668) to the MUT-II.

(2) Connect the special tool (MB991704) to the MUT-II

and the battery.

(3) Rotate the crankshaft clockwise for two rounds to

position No.1 cylinder at compression TDC and check

that timing marks of each sprocket are aligned with

each other.

(4) Select “Belt Tension Measurement” from the menu

screen of the MUT-II.

(5) Hold the special tool (MB991668) to the middle of

the belt between sprockets (at the place indicated

by the arrow) as shown in the illustration about 10

- 20 mm away from the rear surface of the belt and

so that it is perpendicular to the belt (within an angle

of±15_).

(6) Gently tap the middle of the belt between sprockets

(the place indicated by the arrow) with your finger

as shown in the illustration and check that the vibration

frequency of the belt is within the standard value.

Caution

1) If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values.

2) If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not

correspond to actual values.

Apply a force of approx.100N to the middle (arrow part)

of pulley shown in the figure, and check that the deflection

is within the standard value.

3. If it is outside the standard value, re-adjust belt tension.

MB991668

10 - 20 mm

15_

15_

Gently tap with

your finger

Deflection

Approx.

100 N

Page 445 of 1449

ENGINE -Timing Belt and Timing Belt B11A-39

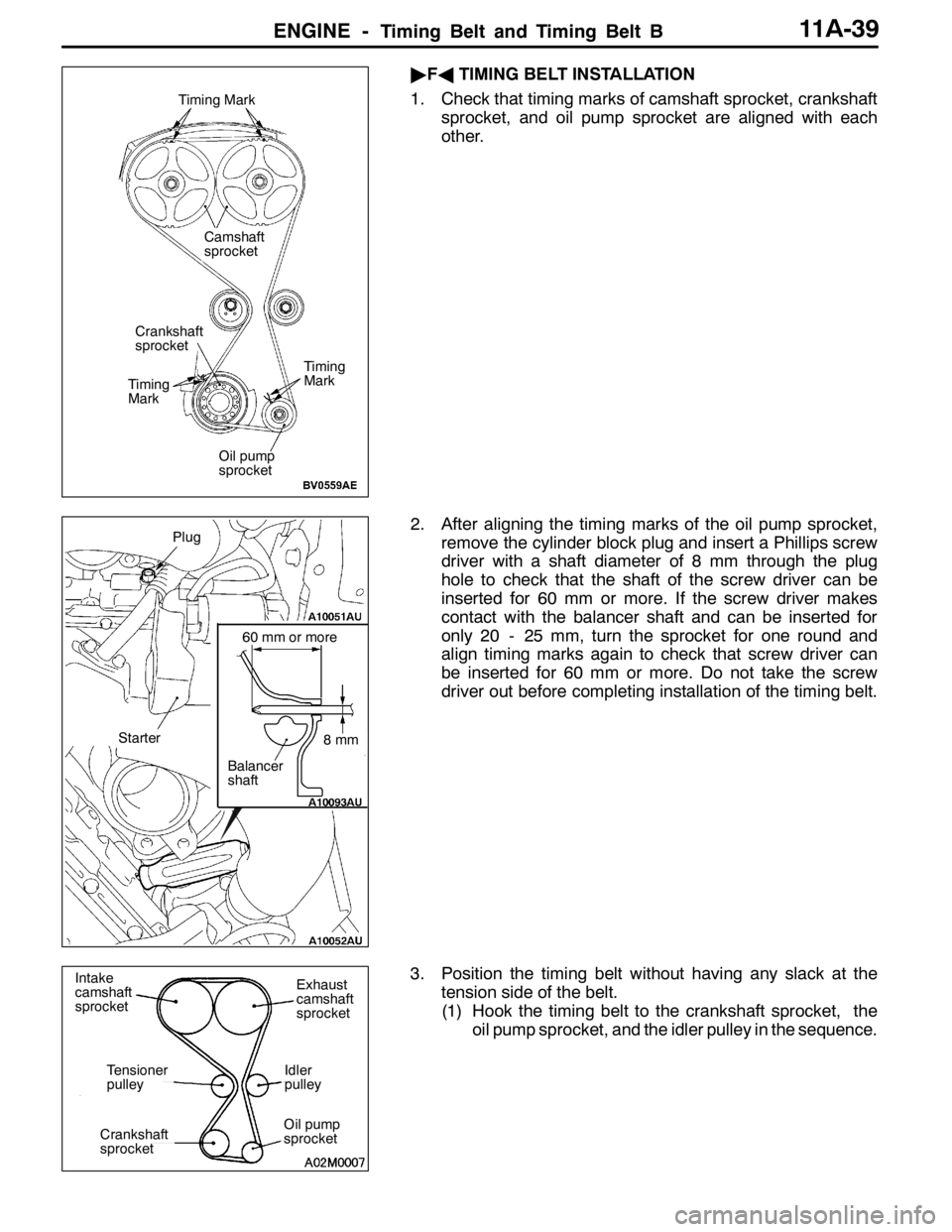

"FATIMING BELT INSTALLATION

1. Check that timing marks of camshaft sprocket, crankshaft

sprocket, and oil pump sprocket are aligned with each

other.

2. After aligning the timing marks of the oil pump sprocket,

remove the cylinder block plug and insert a Phillips screw

driver with a shaft diameter of 8 mm through the plug

hole to check that the shaft of the screw driver can be

inserted for 60 mm or more. If the screw driver makes

contact with the balancer shaft and can be inserted for

only 20 - 25 mm, turn the sprocket for one round and

align timing marks again to check that screw driver can

be inserted for 60 mm or more. Do not take the screw

driver out before completing installation of the timing belt.

3. Position the timing belt without having any slack at the

tension side of the belt.

(1) Hook the timing belt to the crankshaft sprocket, the

oil pump sprocket, and the idler pulley in the sequence.

Timing Mark

Timing

Mark

Timing

Mark

Crankshaft

sprocket

Oil pump

sprocket

Camshaft

sprocket

8mm

60 mm or more

Balancer

shaft

Plug

Starter

Intake

camshaft

sprocketExhaust

camshaft

sprocket

Idler

pulley

Oil pump

sprocketCrankshaft

sprocket

Tensioner

pulley

Page 446 of 1449

ENGINE -Timing Belt and Timing Belt B11A-40

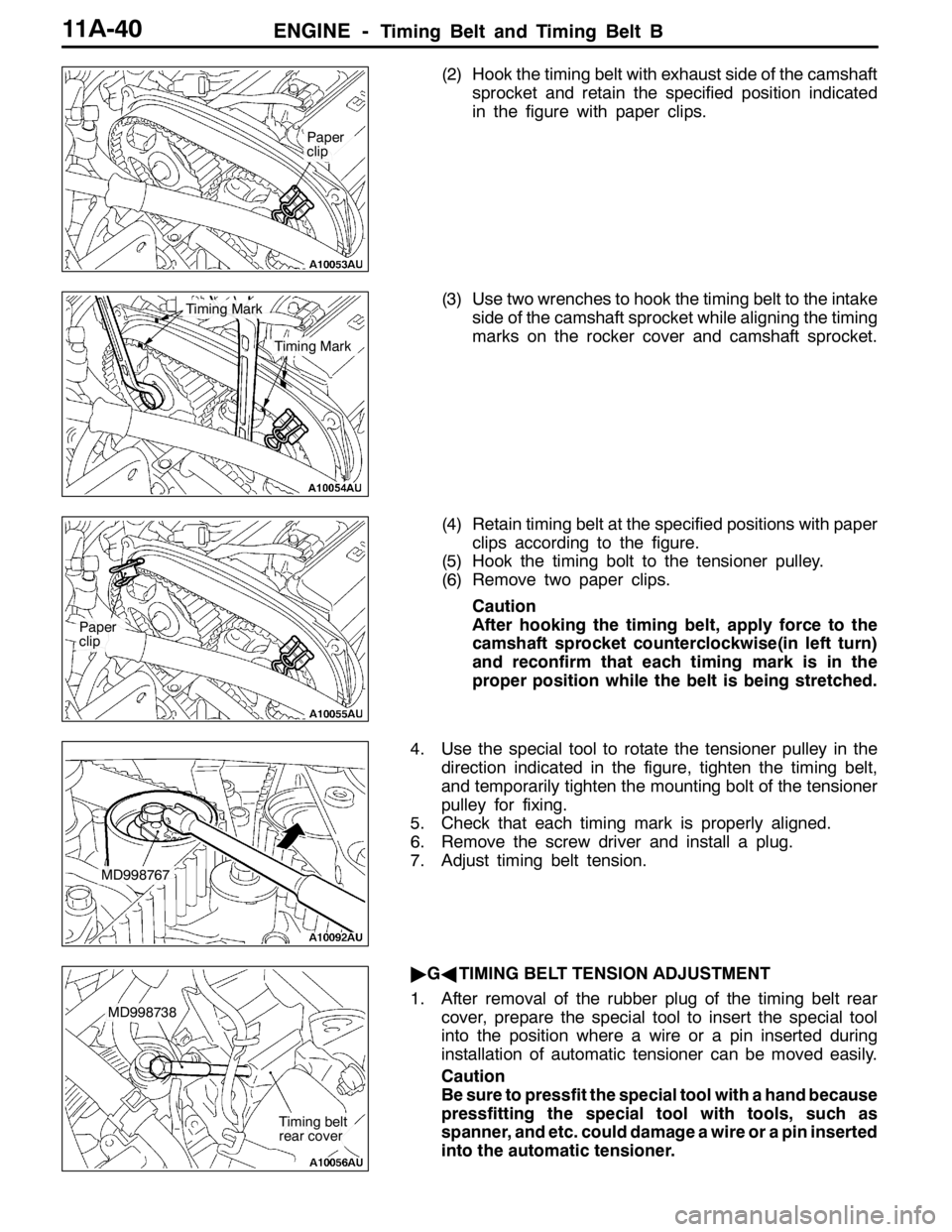

(2) Hook the timing belt with exhaust side of the camshaft

sprocket and retain the specified position indicated

in the figure with paper clips.

(3) Use two wrenches to hook the timing belt to the intake

side of the camshaft sprocket while aligning the timing

marks on the rocker cover and camshaft sprocket.

(4) Retain timing belt at the specified positions with paper

clips according to the figure.

(5) Hook the timing bolt to the tensioner pulley.

(6) Remove two paper clips.

Caution

After hooking the timing belt, apply force to the

camshaft sprocket counterclockwise(in left turn)

and reconfirm that each timing mark is in the

proper position while the belt is being stretched.

4. Use the special tool to rotate the tensioner pulley in the

direction indicated in the figure, tighten the timing belt,

and temporarily tighten the mounting bolt of the tensioner

pulley for fixing.

5. Check that each timing mark is properly aligned.

6. Remove the screw driver and install a plug.

7. Adjust timing belt tension.

"GATIMING BELT TENSION ADJUSTMENT

1. After removal of the rubber plug of the timing belt rear

cover, prepare the special tool to insert the special tool

into the position where a wire or a pin inserted during

installation of automatic tensioner can be moved easily.

Caution

Be sure to pressfit the special tool with a hand because

pressfitting the special tool with tools, such as

spanner, and etc. could damage a wire or a pin inserted

into the automatic tensioner.

Paper

clip

Timing Mark

Timing Mark

Paper

clip

MD998767

MD998738

Timing belt

rear cover

Page 447 of 1449

ENGINE -Timing Belt and Timing Belt B11A-41

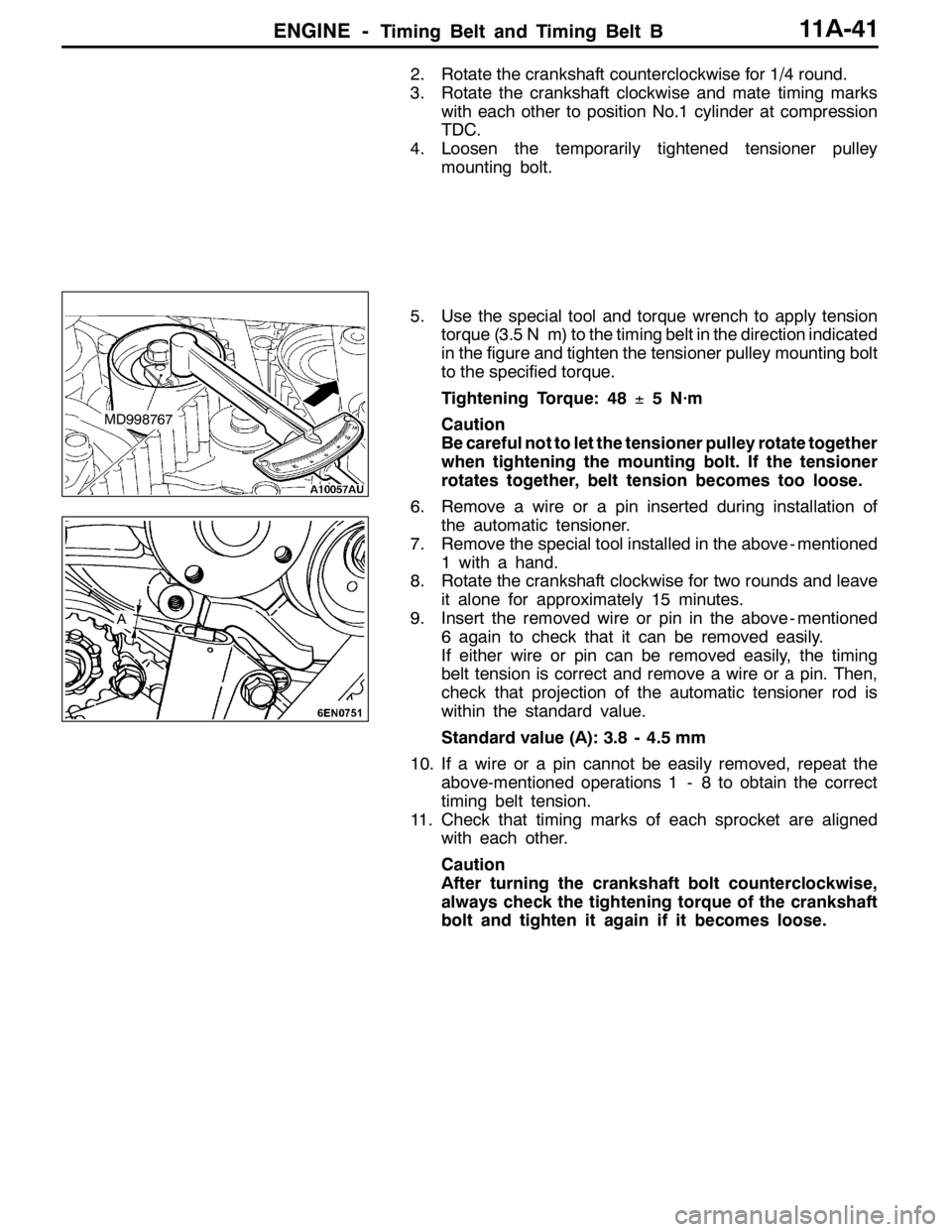

2. Rotate the crankshaft counterclockwise for 1/4 round.

3. Rotate the crankshaft clockwise and mate timing marks

with each other to position No.1 cylinder at compression

TDC.

4. Loosen the temporarily tightened tensioner pulley

mounting bolt.

5. Use the special tool and torque wrench to apply tension

torque (3.5 N��m) to the timing belt in the direction indicated

in the figure and tighten the tensioner pulley mounting bolt

to the specified torque.

Tightening Torque: 48±5 N·m

Caution

Be careful not to let the tensioner pulley rotate together

when tightening the mounting bolt. If the tensioner

rotates together, belt tension becomes too loose.

6. Remove a wire or a pin inserted during installation of

the automatic tensioner.

7. Remove the special tool installed in the above - mentioned

1 with a hand.

8. Rotate the crankshaft clockwise for two rounds and leave

it alone for approximately 15 minutes.

9. Insert the removed wire or pin in the above - mentioned

6 again to check that it can be removed easily.

If either wire or pin can be removed easily, the timing

belt tension is correct and remove a wire or a pin. Then,

check that projection of the automatic tensioner rod is

within the standard value.

Standard value (A): 3.8 - 4.5 mm

10. If a wire or a pin cannot be easily removed, repeat the

above-mentioned operations 1 - 8 to obtain the correct

timing belt tension.

11. Check that timing marks of each sprocket are aligned

with each other.

Caution

After turning the crankshaft bolt counterclockwise,

always check the tightening torque of the crankshaft

bolt and tighten it again if it becomes loose.

MD998767

A

Page 448 of 1449

ENGINE -Timing belt and timing belt B11A-42

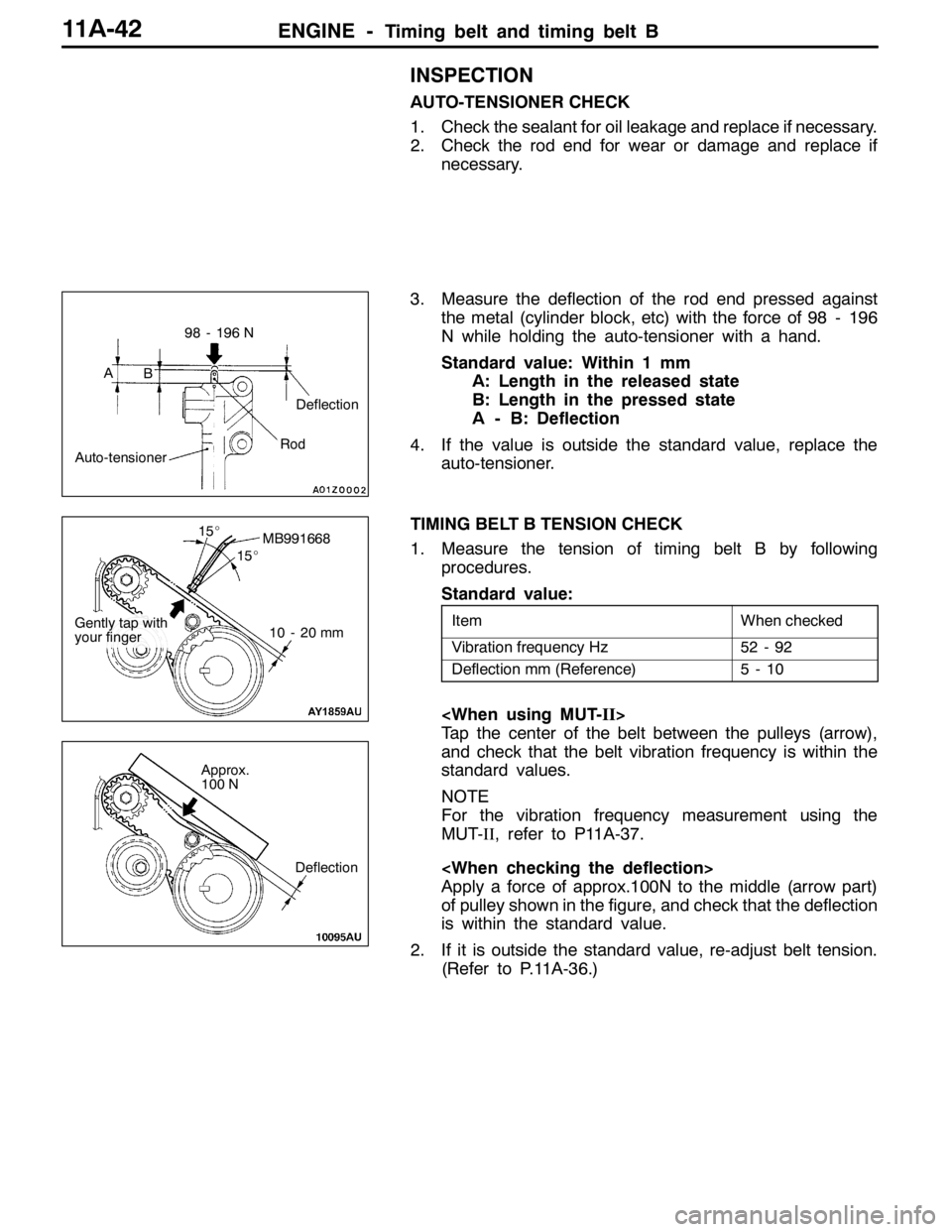

INSPECTION

AUTO-TENSIONER CHECK

1. Check the sealant for oil leakage and replace if necessary.

2. Check the rod end for wear or damage and replace if

necessary.

3. Measure the deflection of the rod end pressed against

the metal (cylinder block, etc) with the force of 98 - 196

N while holding the auto-tensioner with a hand.

Standard value: Within 1 mm

A: Length in the released state

B: Length in the pressed state

A - B: Deflection

4. If the value is outside the standard value, replace the

auto-tensioner.

TIMING BELT B TENSION CHECK

1. Measure the tension of timing belt B by following

procedures.

Standard value:

ItemWhen checked

Vibration frequency Hz52 - 92

Deflection mm (Reference)5-10

Tap the center of the belt between the pulleys (arrow),

and check that the belt vibration frequency is within the

standard values.

NOTE

For the vibration frequency measurement using the

MUT-II, refer to P11A-37.

Apply a force of approx.100N to the middle (arrow part)

of pulley shown in the figure, and check that the deflection

is within the standard value.

2. If it is outside the standard value, re-adjust belt tension.

(Refer to P.11A-36.)

AB

Auto-tensioner

98 - 196 N

Deflection

Rod

MB991668

10 - 20 mm

15_

15_

Gently tap with

your finger

Deflection

Approx.

100 N

Page 452 of 1449

ENGINE -Engine Assembly11A-46

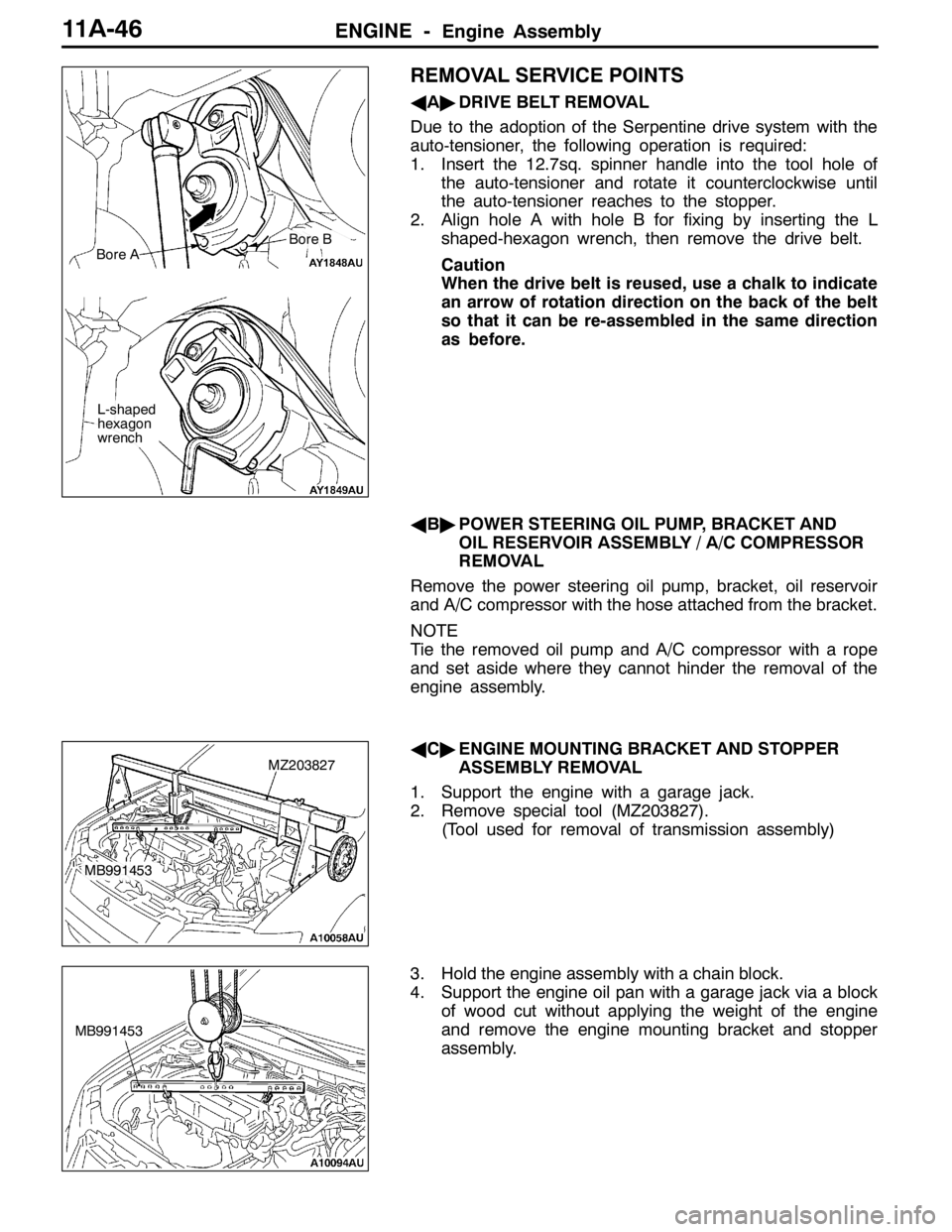

REMOVAL SERVICE POINTS

AA"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle into the tool hole of

the auto-tensioner and rotate it counterclockwise until

the auto-tensioner reaches to the stopper.

2. Align hole A with hole B for fixing by inserting the L

shaped-hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

AB"POWER STEERING OIL PUMP, BRACKET AND

OIL RESERVOIR ASSEMBLY / A/C COMPRESSOR

REMOVAL

Remove the power steering oil pump, bracket, oil reservoir

and A/C compressor with the hose attached from the bracket.

NOTE

Tie the removed oil pump and A/C compressor with a rope

and set aside where they cannot hinder the removal of the

engine assembly.

AC"ENGINE MOUNTING BRACKET AND STOPPER

ASSEMBLY REMOVAL

1. Support the engine with a garage jack.

2. Remove special tool (MZ203827).

(Tool used for removal of transmission assembly)

3. Hold the engine assembly with a chain block.

4. Support the engine oil pan with a garage jack via a block

of wood cut without applying the weight of the engine

and remove the engine mounting bracket and stopper

assembly.

Bore A

L-shaped

hexagon

wrench

Bore B

MZ203827

MB991453

MB991453

Page 453 of 1449

ENGINE -Engine Assembly11A-47

AD"ENGINE ASSEMBLY REMOVAL

After checking that all the cables, hoses, and harness

connectors have been disconnected, lift the engine with a

chain block slowly and remove the engine assembly located

at the upper engine room.

INSTALLATION SERVICE POINTS

"AAENGINE ASSEMBLY INSTALLATION

Install the engine assembly while checking that none of cables,

hoses, or harness connectors, etc. has been engaged.

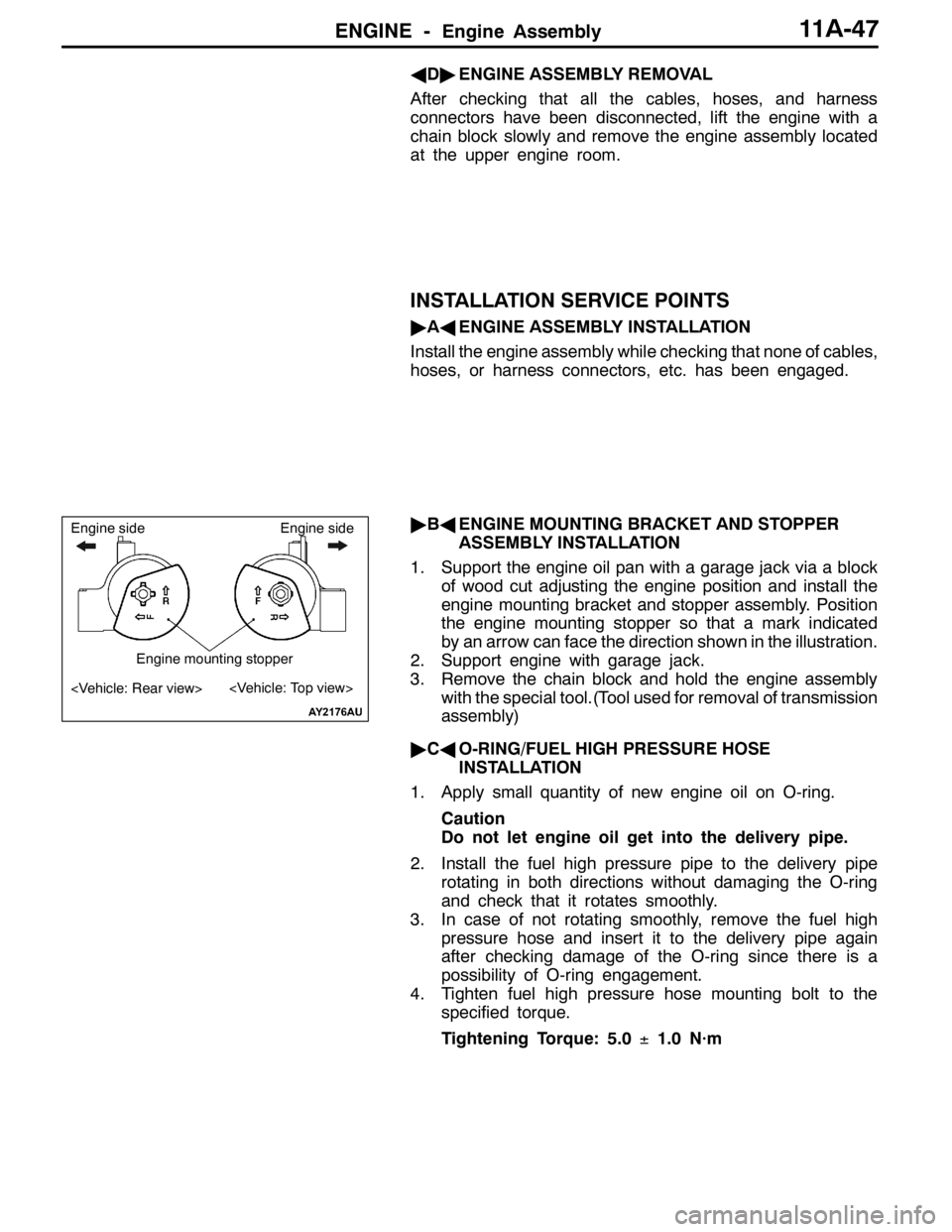

"BAENGINE MOUNTING BRACKET AND STOPPER

ASSEMBLY INSTALLATION

1. Support the engine oil pan with a garage jack via a block

of wood cut adjusting the engine position and install the

engine mounting bracket and stopper assembly. Position

the engine mounting stopper so that a mark indicated

by an arrow can face the direction shown in the illustration.

2. Support engine with garage jack.

3. Remove the chain block and hold the engine assembly

with the special tool.(Tool used for removal of transmission

assembly)

"CAO-RING/FUEL HIGH PRESSURE HOSE

INSTALLATION

1. Apply small quantity of new engine oil on O-ring.

Caution

Do not let engine oil get into the delivery pipe.

2. Install the fuel high pressure pipe to the delivery pipe

rotating in both directions without damaging the O-ring

and check that it rotates smoothly.

3. In case of not rotating smoothly, remove the fuel high

pressure hose and insert it to the delivery pipe again

after checking damage of the O-ring since there is a

possibility of O-ring engagement.

4. Tighten fuel high pressure hose mounting bolt to the

specified torque.

Tightening Torque: 5.0±1.0 N·m

Engine mounting stopper

Engine side

Page 455 of 1449

11B-1

ENGINE

OVERHAUL

CONTENTS

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 3..........................

Service Specifications 3.........................

Machining Standards 5.........................

Tightening Torque 5............................

Sealants 8.....................................

Form-In-Place Gasket 8........................

SPECIAL TOOLS 9...........................

ALTERNATOR AND IGNITION SYSTEM 12....

TIMING BELT 13.............................

FUEL SYSTEM 26............................SECONDARY AIR SYSTEM AND INTAKE

MANIFOLD 28...............................

EXHAUST MANIFOLD 30.....................

WATER PUMP AND WATER HOSE 32........

ROCKER ARMS AND CAMSHAFT 34.........

CYLINDER HEAD AND VALVE 40.............

OIL PUMP AND OIL PAN 47.................

PISTON AND CONNECTING ROD 56..........

CRANKSHAFT AND CYLINDER BLOCK 64....