lock MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 490 of 1449

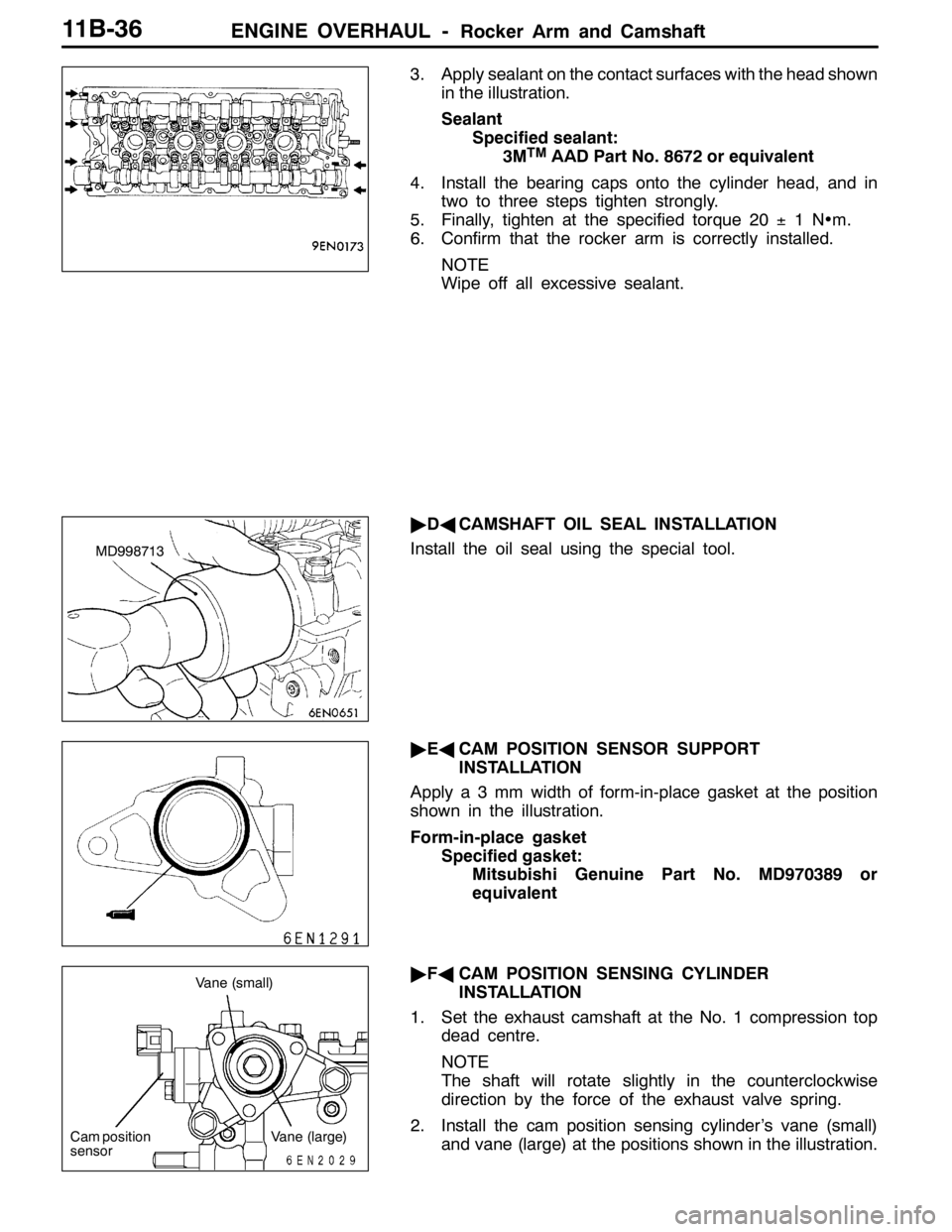

ENGINE OVERHAUL -Rocker Arm and Camshaft11B-36

3. Apply sealant on the contact surfaces with the head shown

in the illustration.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

4. Install the bearing caps onto the cylinder head, and in

two to three steps tighten strongly.

5. Finally, tighten at the specified torque 20±1N•m.

6. Confirm that the rocker arm is correctly installed.

NOTE

Wipe off all excessive sealant.

"DACAMSHAFT OIL SEAL INSTALLATION

Install the oil seal using the special tool.

"EACAM POSITION SENSOR SUPPORT

INSTALLATION

Apply a 3 mm width of form-in-place gasket at the position

shown in the illustration.

Form-in-place gasket

Specified gasket:

Mitsubishi Genuine Part No. MD970389 or

equivalent

"FACAM POSITION SENSING CYLINDER

INSTALLATION

1. Set the exhaust camshaft at the No. 1 compression top

dead centre.

NOTE

The shaft will rotate slightly in the counterclockwise

direction by the force of the exhaust valve spring.

2. Install the cam position sensing cylinder’s vane (small)

and vane (large) at the positions shown in the illustration.

MD998713

Vane (small)

Cam position

sensorVane (large)

Page 494 of 1449

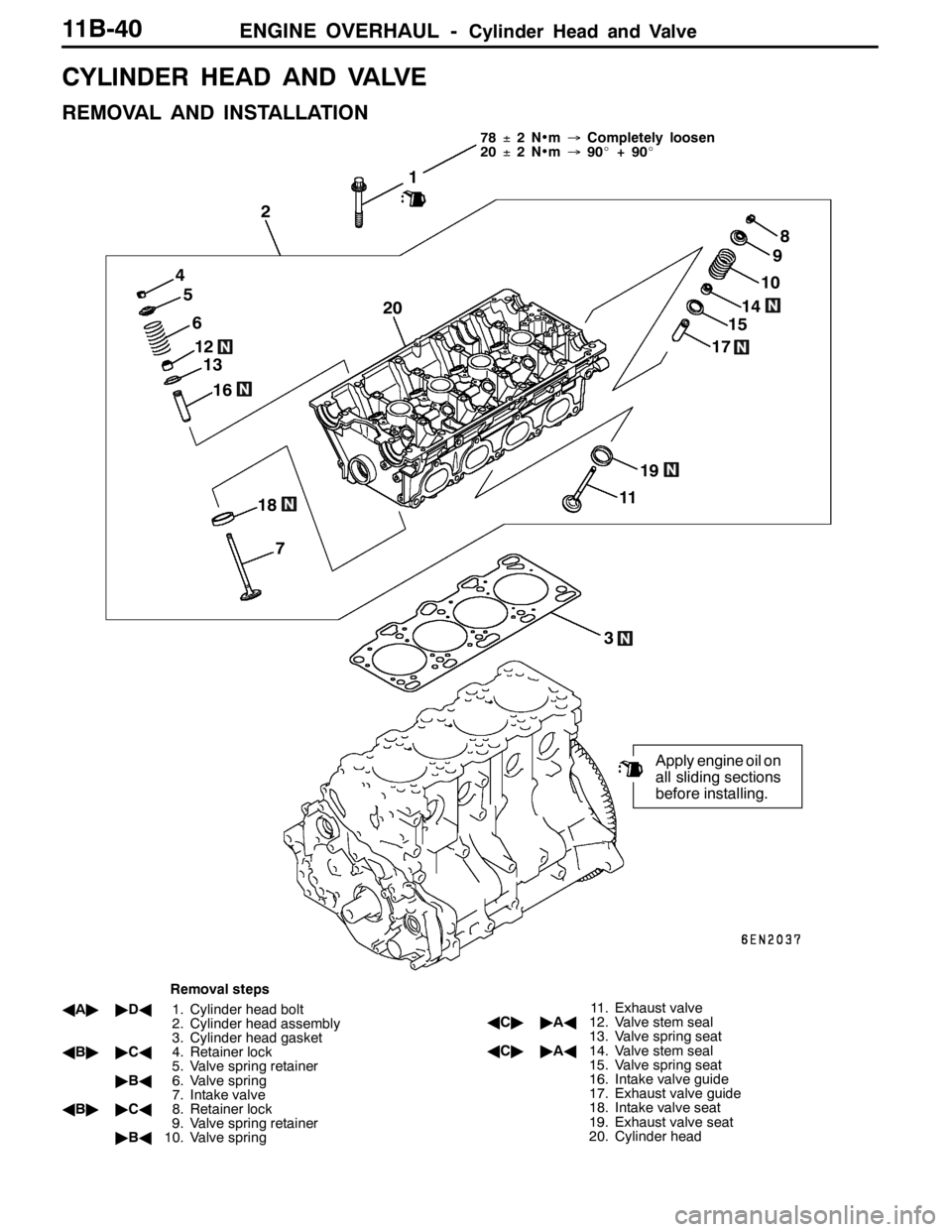

ENGINE OVERHAUL -Cylinder Head and Valve11B-40

CYLINDER HEAD AND VALVE

REMOVAL AND INSTALLATION

78±2N•m→Completely loosen

20±2N•m→90_+90_

2

1

Apply engine oil on

all sliding sections

before installing.

4

5

6

12

13

16

18

720

38

9

10

14

15

17

19

11

Removal steps

AA""DA1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

AB""CA4. Retainer lock

5. Valve spring retainer

"BA6. Valve spring

7. Intake valve

AB""CA8. Retainer lock

9. Valve spring retainer

"BA10. Valve spring11. Exhaust valve

AC""AA12. Valve stem seal

13. Valve spring seat

AC""AA14. Valve stem seal

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head

Page 495 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-41

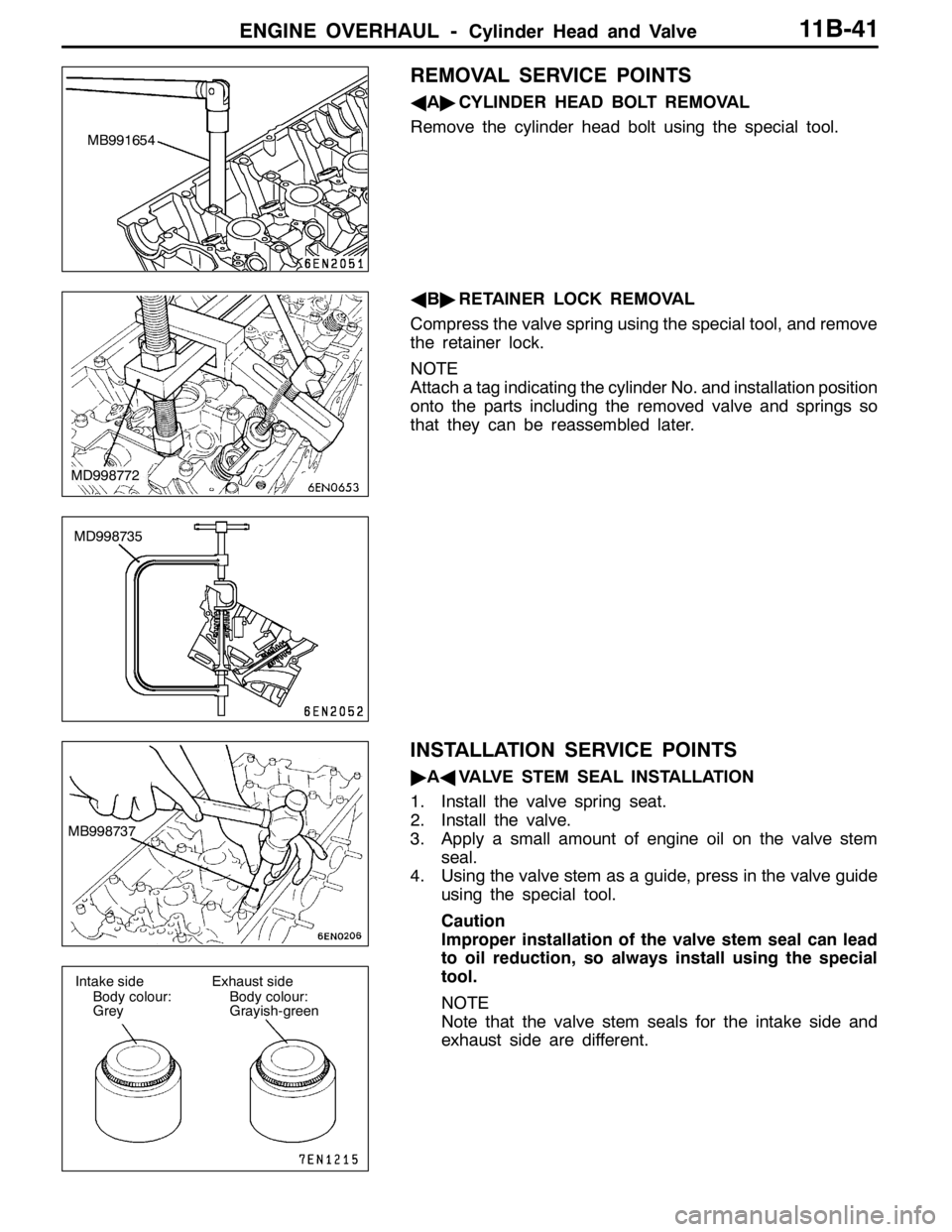

REMOVAL SERVICE POINTS

AA"CYLINDER HEAD BOLT REMOVAL

Remove the cylinder head bolt using the special tool.

AB"RETAINER LOCK REMOVAL

Compress the valve spring using the special tool, and remove

the retainer lock.

NOTE

Attach a tag indicating the cylinder No. and installation position

onto the parts including the removed valve and springs so

that they can be reassembled later.

INSTALLATION SERVICE POINTS

"AAVALVE STEM SEAL INSTALLATION

1. Install the valve spring seat.

2. Install the valve.

3. Apply a small amount of engine oil on the valve stem

seal.

4. Using the valve stem as a guide, press in the valve guide

using the special tool.

Caution

Improper installation of the valve stem seal can lead

to oil reduction, so always install using the special

tool.

NOTE

Note that the valve stem seals for the intake side and

exhaust side are different.

MB991654

MD998772

MD998735

MB998737

Body colour:

GreyBody colour:

Grayish-green Intake side Exhaust side

Page 496 of 1449

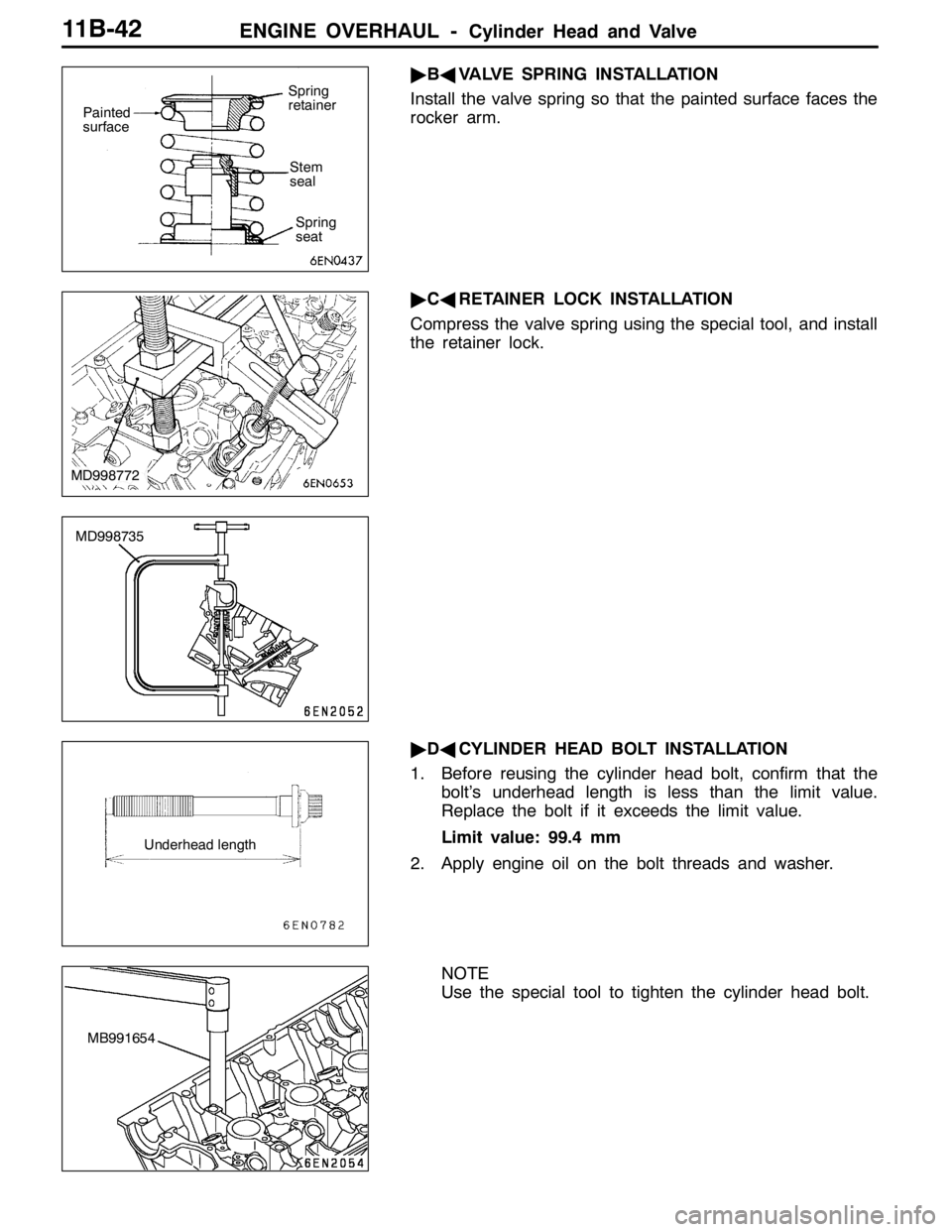

ENGINE OVERHAUL -Cylinder Head and Valve11B-42

"BAVALVE SPRING INSTALLATION

Install the valve spring so that the painted surface faces the

rocker arm.

"CARETAINER LOCK INSTALLATION

Compress the valve spring using the special tool, and install

the retainer lock.

"DACYLINDER HEAD BOLT INSTALLATION

1. Before reusing the cylinder head bolt, confirm that the

bolt’s underhead length is less than the limit value.

Replace the bolt if it exceeds the limit value.

Limit value: 99.4 mm

2. Apply engine oil on the bolt threads and washer.

NOTE

Use the special tool to tighten the cylinder head bolt.

Painted

surfaceSpring

retainer

Stem

seal

Spring

seat

MD998772

MD998735

Underhead length

MB991654

Page 497 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-43

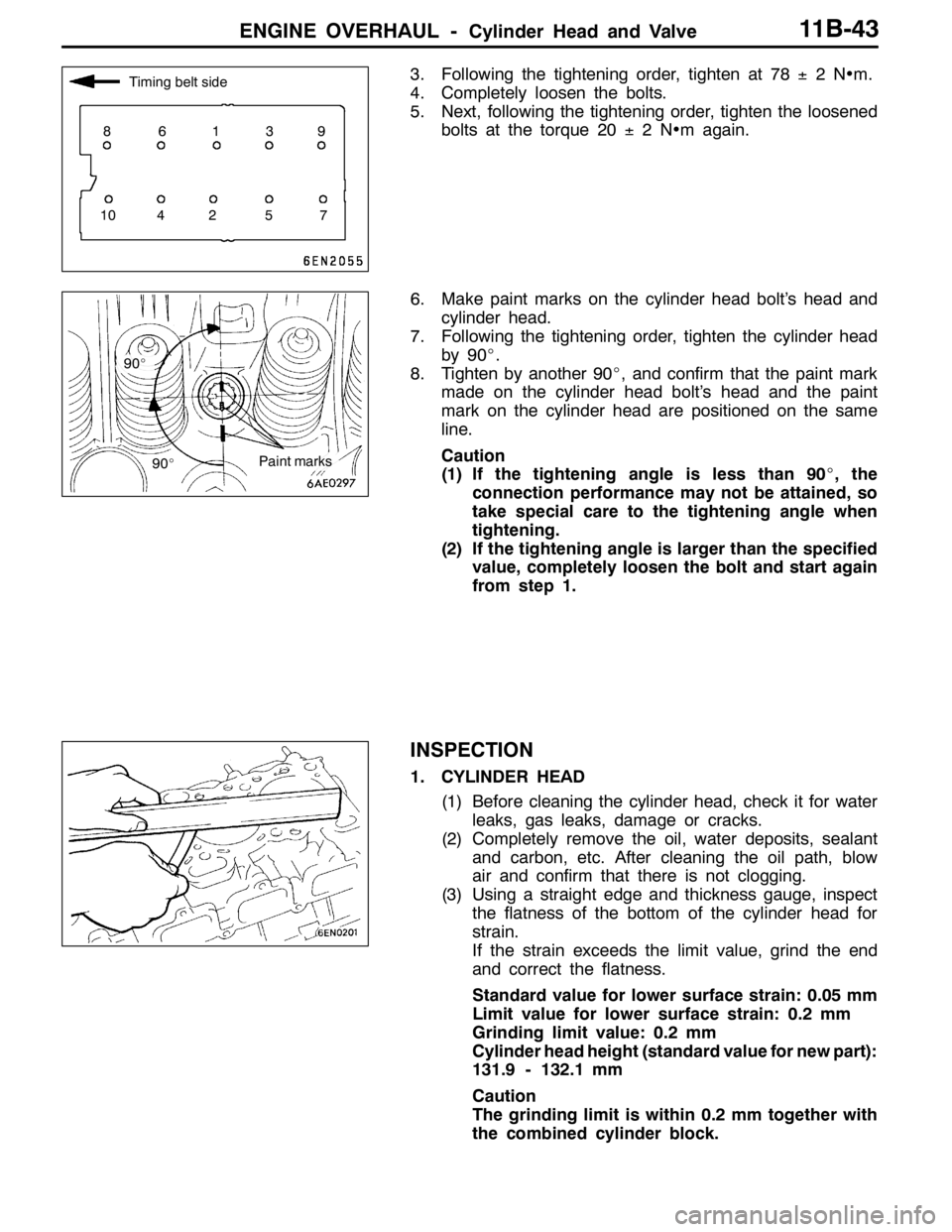

3. Following the tightening order, tighten at 78±2N•m.

4. Completely loosen the bolts.

5. Next, following the tightening order, tighten the loosened

bolts at the torque 20±2N•m again.

6. Make paint marks on the cylinder head bolt’s head and

cylinder head.

7. Following the tightening order, tighten the cylinder head

by 90_.

8. Tighten by another 90_, and confirm that the paint mark

made on the cylinder head bolt’s head and the paint

mark on the cylinder head are positioned on the same

line.

Caution

(1) If the tightening angle is less than 90_, the

connection performance may not be attained, so

take special care to the tightening angle when

tightening.

(2) If the tightening angle is larger than the specified

value, completely loosen the bolt and start again

from step 1.

INSPECTION

1. CYLINDER HEAD

(1) Before cleaning the cylinder head, check it for water

leaks, gas leaks, damage or cracks.

(2) Completely remove the oil, water deposits, sealant

and carbon, etc. After cleaning the oil path, blow

air and confirm that there is not clogging.

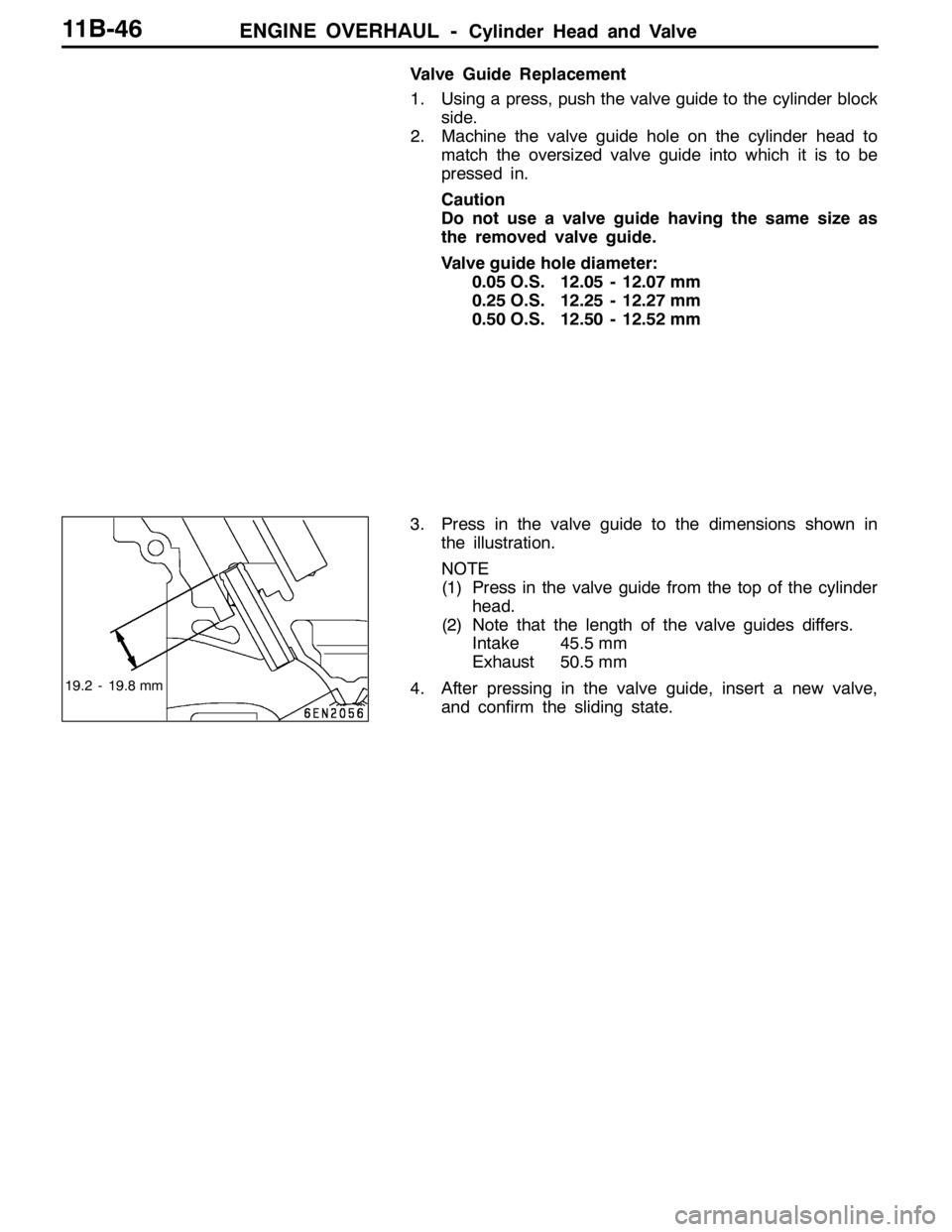

(3) Using a straight edge and thickness gauge, inspect

the flatness of the bottom of the cylinder head for

strain.

If the strain exceeds the limit value, grind the end

and correct the flatness.

Standard value for lower surface strain: 0.05 mm

Limit value for lower surface strain: 0.2 mm

Grinding limit value: 0.2 mm

Cylinder head height (standard value for new part):

131.9 - 132.1 mm

Caution

The grinding limit is within 0.2 mm together with

the combined cylinder block.

Timing belt side

86139

10 4 2 5 7

90_

90_

Paint marks

Page 500 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-46

Valve Guide Replacement

1. Using a press, push the valve guide to the cylinder block

side.

2. Machine the valve guide hole on the cylinder head to

match the oversized valve guide into which it is to be

pressed in.

Caution

Do not use a valve guide having the same size as

the removed valve guide.

Valve guide hole diameter:

0.05 O.S. 12.05 - 12.07 mm

0.25 O.S. 12.25 - 12.27 mm

0.50 O.S. 12.50 - 12.52 mm

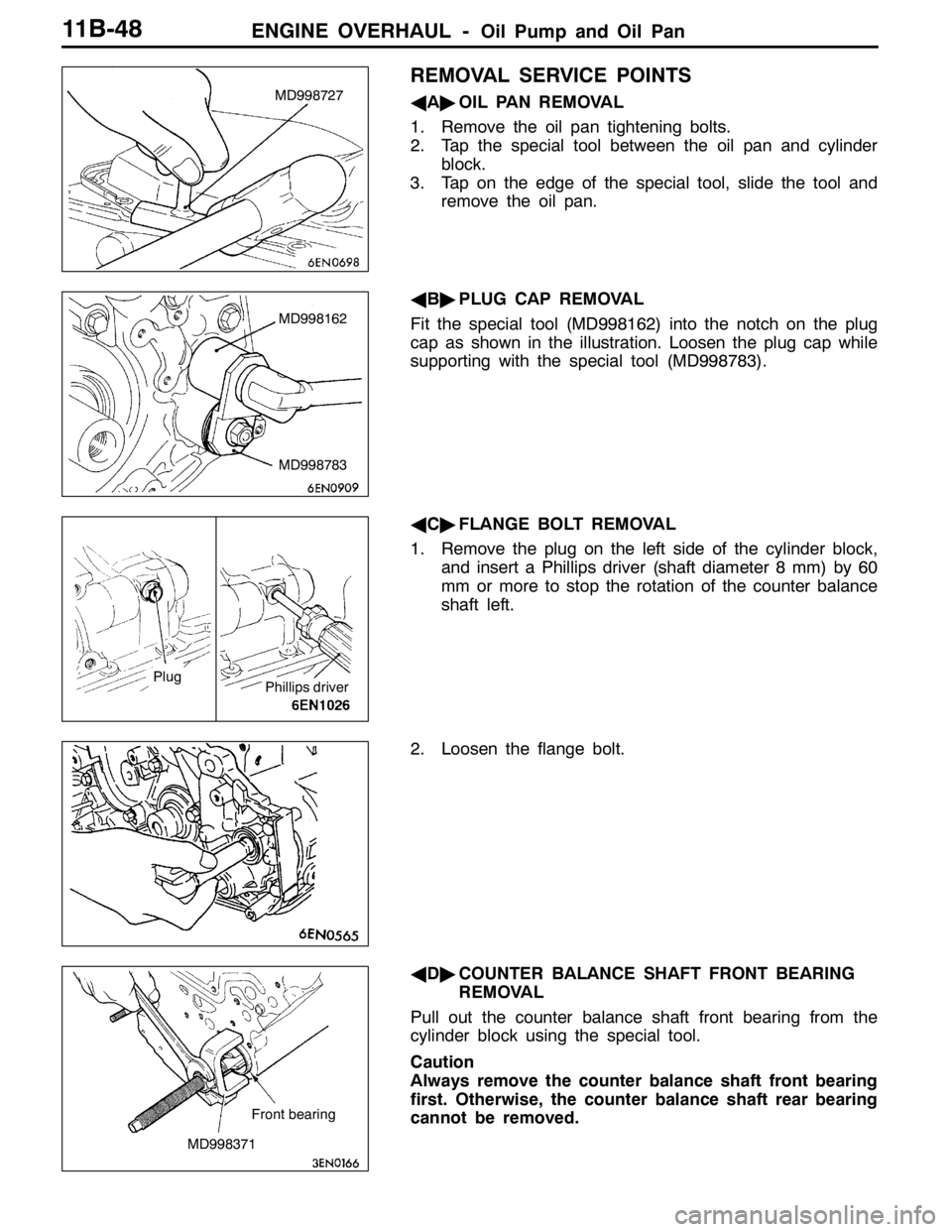

3. Press in the valve guide to the dimensions shown in

the illustration.

NOTE

(1) Press in the valve guide from the top of the cylinder

head.

(2) Note that the length of the valve guides differs.

Intake 45.5 mm

Exhaust 50.5 mm

4. After pressing in the valve guide, insert a new valve,

and confirm the sliding state.

19.2 - 19.8 mm

Page 502 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-48

REMOVAL SERVICE POINTS

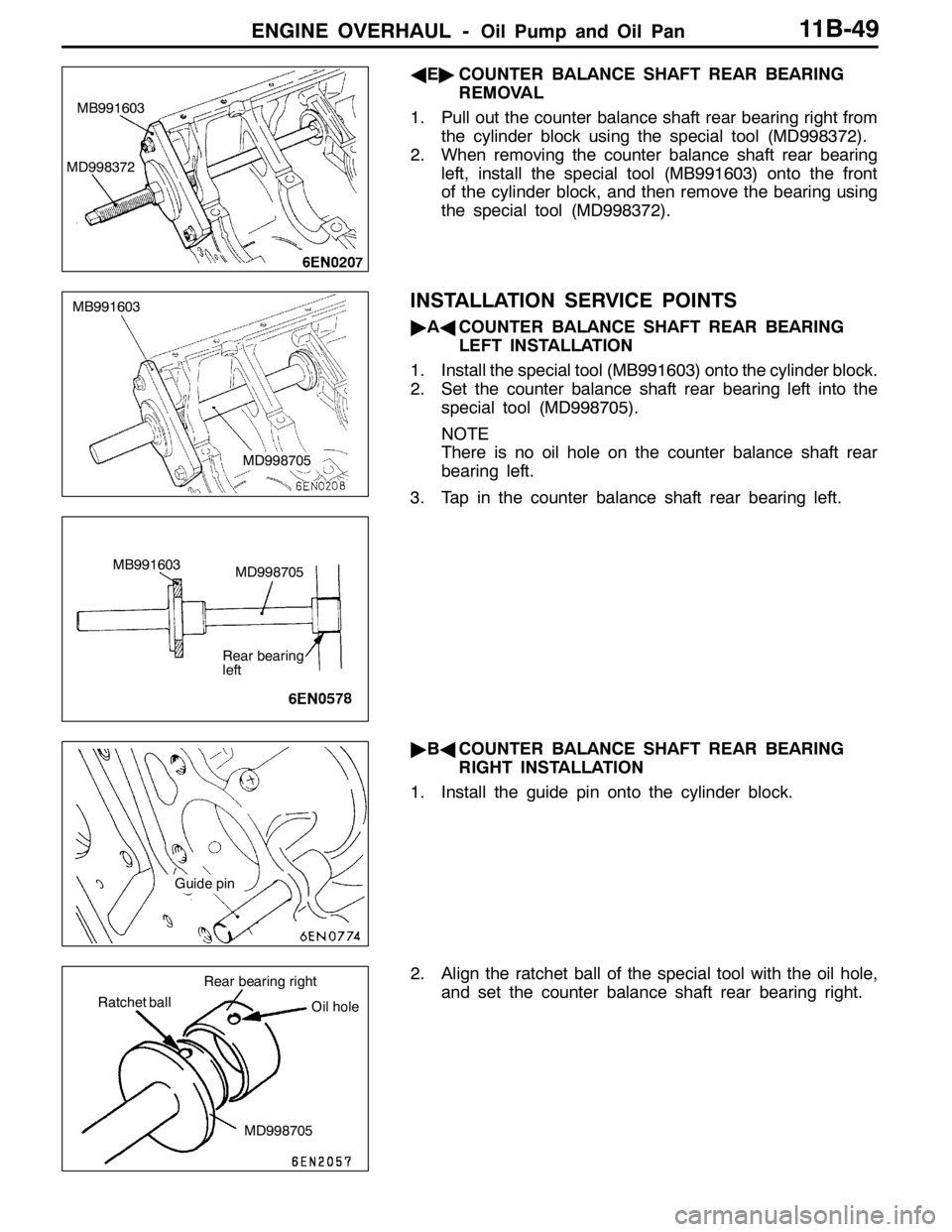

AA"OIL PAN REMOVAL

1. Remove the oil pan tightening bolts.

2. Tap the special tool between the oil pan and cylinder

block.

3. Tap on the edge of the special tool, slide the tool and

remove the oil pan.

AB"PLUG CAP REMOVAL

Fit the special tool (MD998162) into the notch on the plug

cap as shown in the illustration. Loosen the plug cap while

supporting with the special tool (MD998783).

AC"FLANGE BOLT REMOVAL

1. Remove the plug on the left side of the cylinder block,

and insert a Phillips driver (shaft diameter 8 mm) by 60

mm or more to stop the rotation of the counter balance

shaft left.

2. Loosen the flange bolt.

AD"COUNTER BALANCE SHAFT FRONT BEARING

REMOVAL

Pull out the counter balance shaft front bearing from the

cylinder block using the special tool.

Caution

Always remove the counter balance shaft front bearing

first. Otherwise, the counter balance shaft rear bearing

cannot be removed.MD998727

MD998162

MD998783

Plug

Phillips driver

MD998371Front bearing

Page 503 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-49

AE"COUNTER BALANCE SHAFT REAR BEARING

REMOVAL

1. Pull out the counter balance shaft rear bearing right from

the cylinder block using the special tool (MD998372).

2. When removing the counter balance shaft rear bearing

left, install the special tool (MB991603) onto the front

of the cylinder block, and then remove the bearing using

the special tool (MD998372).

INSTALLATION SERVICE POINTS

"AACOUNTER BALANCE SHAFT REAR BEARING

LEFT INSTALLATION

1. Install the special tool (MB991603) onto the cylinder block.

2. Set the counter balance shaft rear bearing left into the

special tool (MD998705).

NOTE

There is no oil hole on the counter balance shaft rear

bearing left.

3. Tap in the counter balance shaft rear bearing left.

"BACOUNTER BALANCE SHAFT REAR BEARING

RIGHT INSTALLATION

1. Install the guide pin onto the cylinder block.

2. Align the ratchet ball of the special tool with the oil hole,

and set the counter balance shaft rear bearing right.

MB991603

MD998372

MB991603

MD998705

MB991603

MD998705

Rear bearing

left

Guide pin

Ratchet ball

MD998705 Rear bearing right

Oil hole

Page 504 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-50

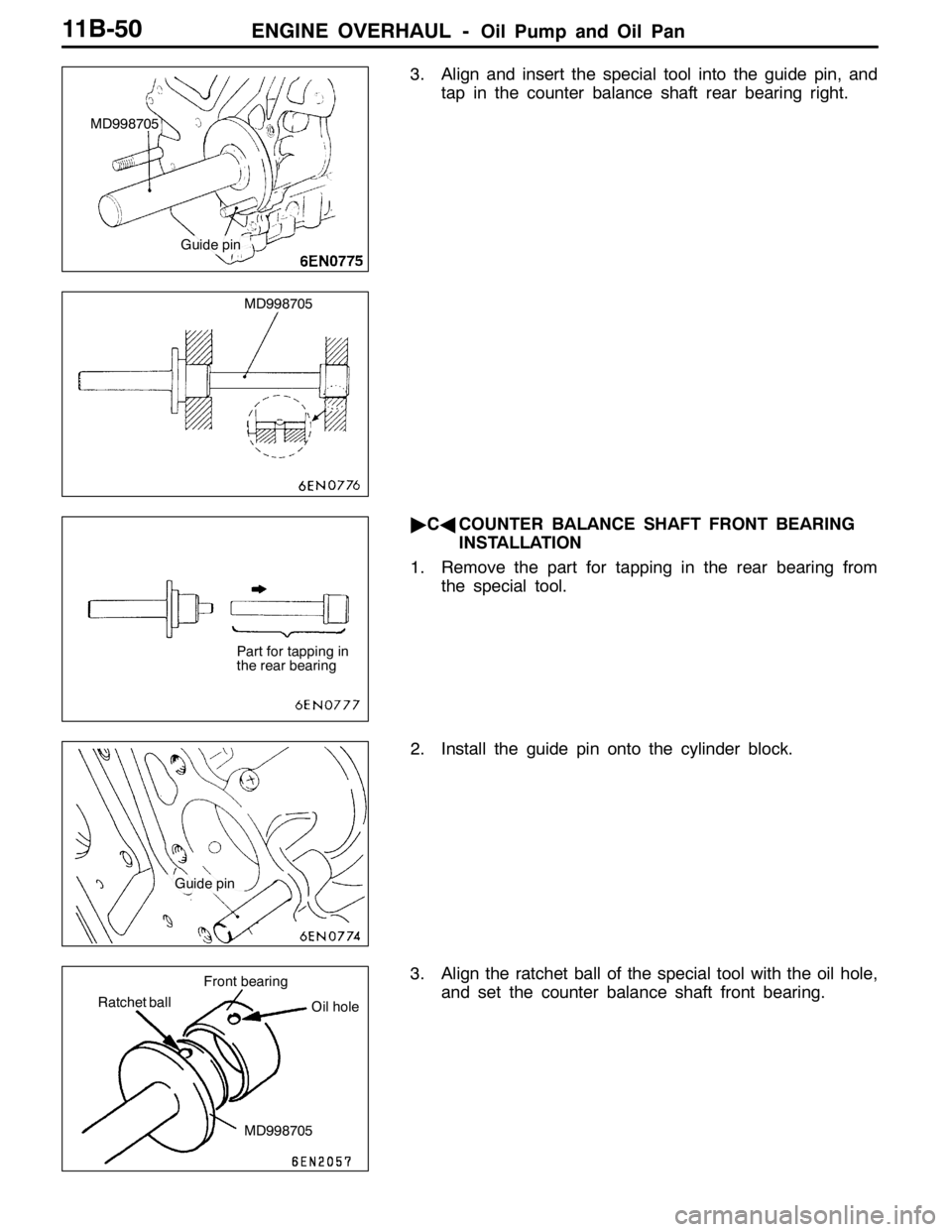

3. Align and insert the special tool into the guide pin, and

tap in the counter balance shaft rear bearing right.

"CACOUNTER BALANCE SHAFT FRONT BEARING

INSTALLATION

1. Remove the part for tapping in the rear bearing from

the special tool.

2. Install the guide pin onto the cylinder block.

3. Align the ratchet ball of the special tool with the oil hole,

and set the counter balance shaft front bearing.

MD998705

Guide pin

MD998705

Part for tapping in

the rear bearing

Guide pin

Ratchet ball

MD998705 Front bearing

Oil hole

Page 506 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-52

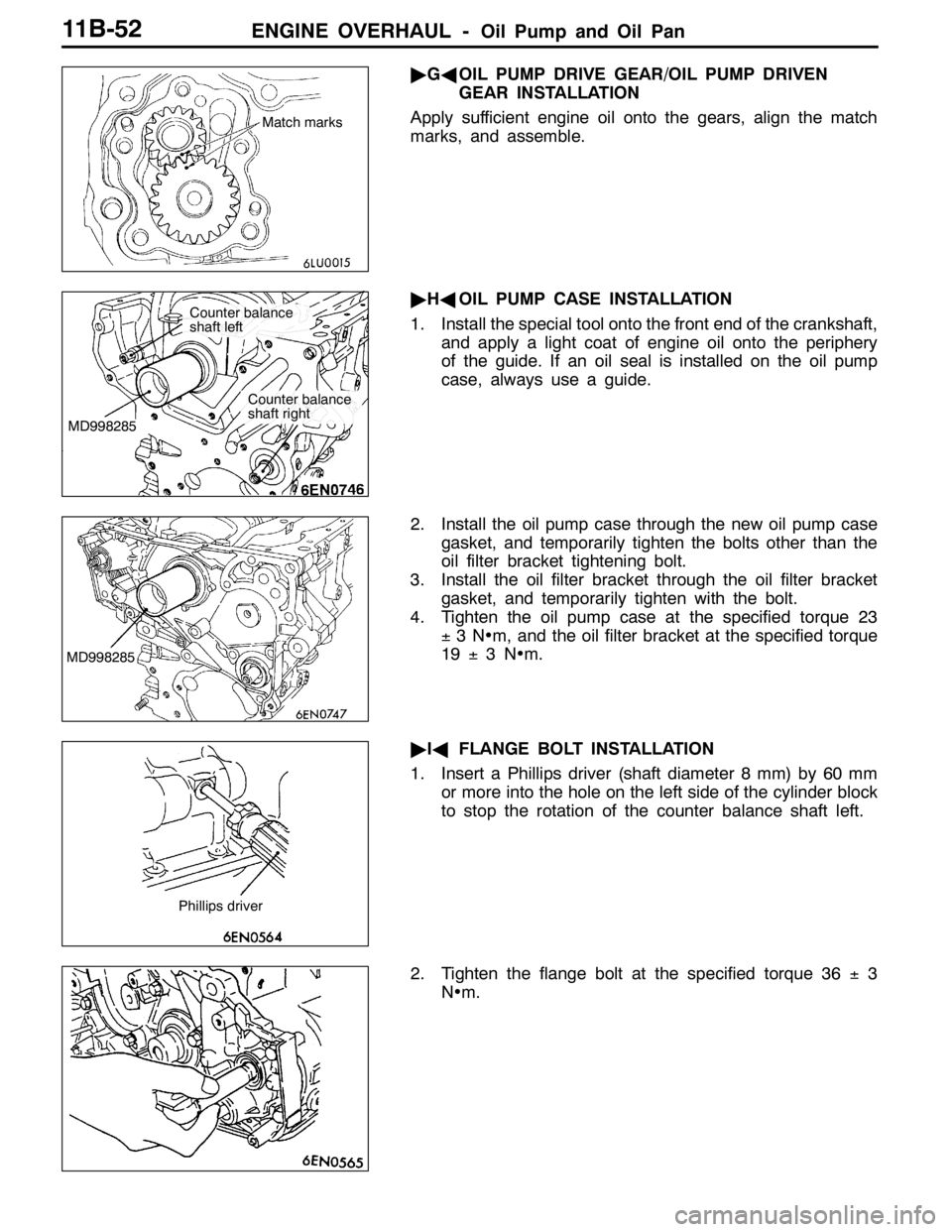

"GAOIL PUMP DRIVE GEAR/OIL PUMP DRIVEN

GEAR INSTALLATION

Apply sufficient engine oil onto the gears, align the match

marks, and assemble.

"HAOIL PUMP CASE INSTALLATION

1. Install the special tool onto the front end of the crankshaft,

and apply a light coat of engine oil onto the periphery

of the guide. If an oil seal is installed on the oil pump

case, always use a guide.

2. Install the oil pump case through the new oil pump case

gasket, and temporarily tighten the bolts other than the

oil filter bracket tightening bolt.

3. Install the oil filter bracket through the oil filter bracket

gasket, and temporarily tighten with the bolt.

4. Tighten the oil pump case at the specified torque 23

±3N•m, and the oil filter bracket at the specified torque

19±3N•m.

"IAFLANGE BOLT INSTALLATION

1. Insert a Phillips driver (shaft diameter 8 mm) by 60 mm

or more into the hole on the left side of the cylinder block

to stop the rotation of the counter balance shaft left.

2. Tighten the flange bolt at the specified torque 36±3

N•m.

Match marks

MD998285

Counter balance

shaft left

Counter balance

shaft right

MD998285

Phillips driver