lock MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 404 of 1449

GENERAL -Support Locations for Lifting and Jacking00-26

PLATE TYPE LIFT

To avoid damaging the side sill garnish, put a wooden block between the side sill and a lift.

NOTE

The wooden block should be 100 mm wide and 50 mm high.

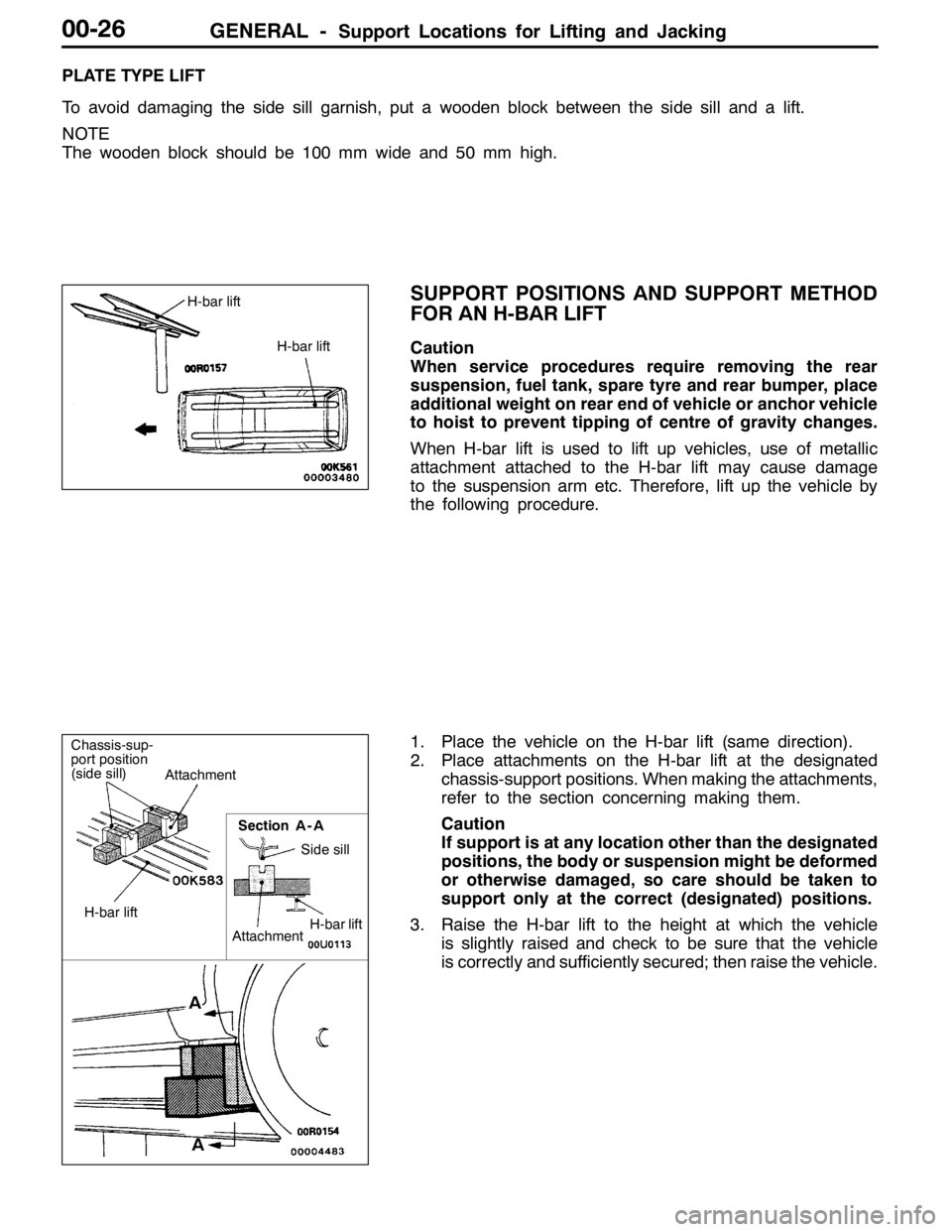

SUPPORT POSITIONS AND SUPPORT METHOD

FOR AN H-BAR LIFT

Caution

When service procedures require removing the rear

suspension, fuel tank, spare tyre and rear bumper, place

additional weight on rear end of vehicle or anchor vehicle

to hoist to prevent tipping of centre of gravity changes.

When H-bar lift is used to lift up vehicles, use of metallic

attachment attached to the H-bar lift may cause damage

to the suspension arm etc. Therefore, lift up the vehicle by

the following procedure.

1. Place the vehicle on the H-bar lift (same direction).

2. Place attachments on the H-bar lift at the designated

chassis-support positions. When making the attachments,

refer to the section concerning making them.

Caution

If support is at any location other than the designated

positions, the body or suspension might be deformed

or otherwise damaged, so care should be taken to

support only at the correct (designated) positions.

3. Raise the H-bar lift to the height at which the vehicle

is slightly raised and check to be sure that the vehicle

is correctly and sufficiently secured; then raise the vehicle.

H-bar lift

H-bar lift

A

Chassis-sup-

port position

(side sill)

Attachment

H-bar liftSection A - A

Side sill

AttachmentH-bar lift

A

Page 405 of 1449

GENERAL -Support Locations for Lifting and Jacking00-27

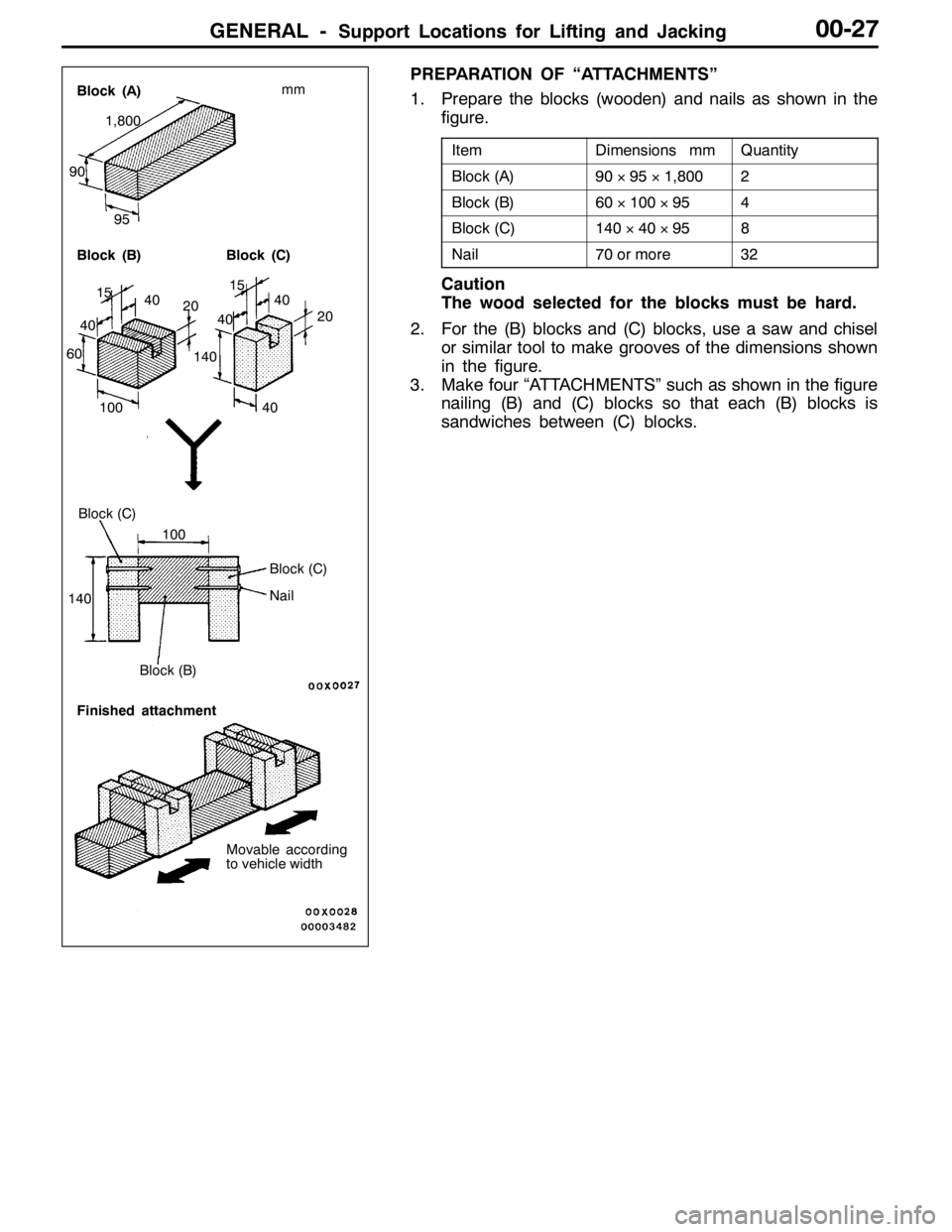

PREPARATION OF “ATTACHMENTS”

1. Prepare the blocks (wooden) and nails as shown in the

figure.

ItemDimensions mmQuantity

Block (A)90×95×1,8002

Block (B)60×100×954

Block (C)140×40×958

Nail70 or more32

Caution

The wood selected for the blocks must be hard.

2. For the (B) blocks and (C) blocks, use a saw and chisel

or similar tool to make grooves of the dimensions shown

in the figure.

3. Make four “ATTACHMENTS” such as shown in the figure

nailing (B) and (C) blocks so that each (B) blocks is

sandwiches between (C) blocks.

Block (A)mm

1,800

90

95

Block (B) Block (C)

15

40

60

10040

2015

40

14040

20

40

Block (C)

140100

Block (C)

Nail

Block (B)

Finished attachment

Movable according

to vehicle width

Page 406 of 1449

GENERAL -Standard Part/Tightening-Torque Table00-28

STANDARD PART/TIGHTENING-TORQUE TABLE

Each torque value in the table is a standard value

for tightening under the following conditions.

(1) Bolts, nuts and washers are all made of steel

and plated with zinc.

(2) The threads and bearing surface of bolts and

nuts are all in dry condition.The values in the table are not applicable:

(1) If toothed washers are inserted.

(2) If plastic parts are fastened.

(3) If bolts are tightened to plastic or die-cast

inserted nuts.

(4) If self-tapping screws or self-locking nuts are

used.

Standard bolt and nut tightening torque

Thread sizeTorque N·m

Bolt nominal

diameter (mm)Pitch (mm)Head mark “4”Head mark “7”Head mark “8”

M50.82.50.55.01.06.01.0

M61.05.01.09.02.0102

M81.25122224254

M101.252444410537

M121.2541883129812

M141.573121402015525

M161.511 0202103023535

M181.5165253004034050

M201.5225354106048070

M221.5300405558564595

M241.539555735105855125

Flange bolt and nut tightening torque

Thread sizeTorque N·m

Bolt nominal

diameter (mm)Pitch (mm)Head mark “4”Head mark “7”Head mark “8”

M61.05.01.0102122

M81.25132244275

M101.25264499587

M101.52444585510

M121.25468951510515

M121.7543883129812

NOTE

1. Be sure to use only the specified bolts and nuts, and always tighten them to the specified torques.

2. Bolts marked with indications such as 4T or 7T are reinforced bolts. The larger the number, the

greater the bolt strength.

Page 413 of 1449

ENGINE -On-vehicle Service11A-7

ON-VEHICLE SERVICE

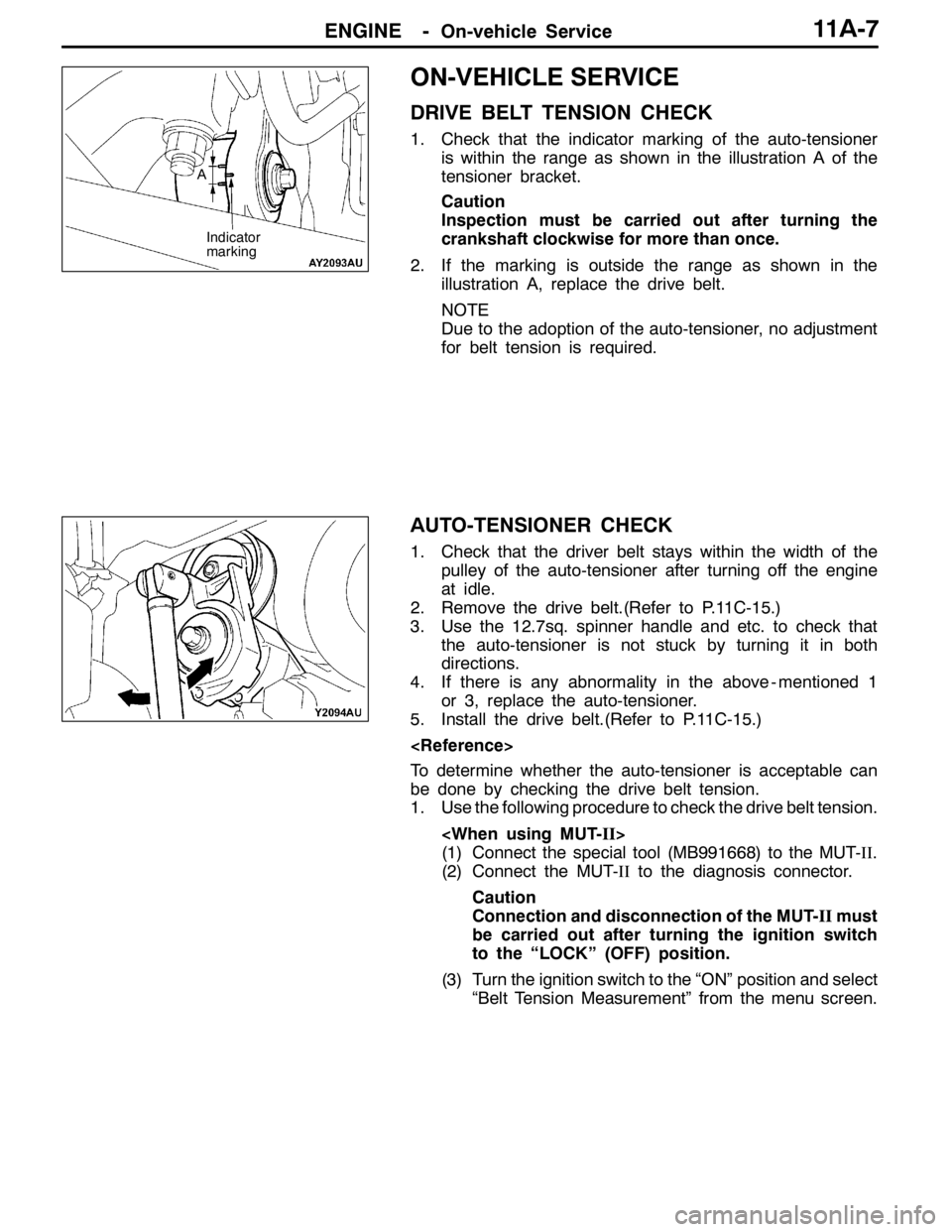

DRIVE BELT TENSION CHECK

1. Check that the indicator marking of the auto-tensioner

is within the range as shown in the illustration A of the

tensioner bracket.

Caution

Inspection must be carried out after turning the

crankshaft clockwise for more than once.

2. If the marking is outside the range as shown in the

illustration A, replace the drive belt.

NOTE

Due to the adoption of the auto-tensioner, no adjustment

for belt tension is required.

AUTO-TENSIONER CHECK

1. Check that the driver belt stays within the width of the

pulley of the auto-tensioner after turning off the engine

at idle.

2. Remove the drive belt.(Refer to P.11C-15.)

3. Use the 12.7sq. spinner handle and etc. to check that

the auto-tensioner is not stuck by turning it in both

directions.

4. If there is any abnormality in the above - mentioned 1

or 3, replace the auto-tensioner.

5. Install the drive belt.(Refer to P.11C-15.)

To determine whether the auto-tensioner is acceptable can

be done by checking the drive belt tension.

1. Use the following procedure to check the drive belt tension.

(1) Connect the special tool (MB991668) to the MUT-II.

(2) Connect the MUT-IIto the diagnosis connector.

Caution

Connection and disconnection of the MUT-IImust

be carried out after turning the ignition switch

to the “LOCK” (OFF) position.

(3) Turn the ignition switch to the “ON” position and select

“Belt Tension Measurement” from the menu screen.

Indicator

marking

A

Page 415 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-9

IGNITION TIMING CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position and

then connect the MUT-IIto the diagnosis connector.

3. Set up a timing light.

4. Start the engine and run at idle.

5. Check that engine idle speed is within the standard value.

Standard value: 850±100 r/min

6. Select No.17 of the MUT-IIActuator test.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3_

8. If the basic ignition timing is outside the standard value,

inspect the MPI system while referring to GROUP 13A

- Troubleshooting.

9. Press the MUT-IIclear key (Select a forced driving cancel

mode) to release the Actuator test.

Caution

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this condition

may damage the engine.

10. Check that ignition timing is at the standard value.

Standard value: approximately 5_BTDC

NOTE

(1) Ignition timing is variable within about±7, even under

normal operating.

(2) And it is automatically further advanced by

approximately 5_from standard value at higher

altitudes.

11. Remove the timing light.

12. Turn the ignition switch to “LOCK” (OFF) position and

then remove the MUT-II.

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position, and

then connect the MUT-IIto the diagnosis connector.

3. Set the timing light.

4. Check that the basic ignition timing is within the standard

value.

MUT-II

MUT-II

Page 416 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-10

Standard value: 5_BTDC±3_

5. Run the engine at idle for 2 minutes.

6. Check the idle speed. Select item No. 22 and take a

reading of the idle speed.

Curb idle speed: 850±100 r/min

NOTE

The idle speed is controlled automatically by the idle speed

control (ISC) system.

7. If the idle speed is outside the standard value, check

the MPI components by referring to GROUP 13A -

Troubleshooting.

8. Remove the timing light.

9. Turn the ignition switch to the “LOCK” (OFF) position

and then remove the MUT-II.

IDLE MIXTURE CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to the “LOCK” (OFF) position,

and then connect the MUT-IIto the diagnosis connector.

3. Set the timing light.

4. Check that the basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3_

5. Run the engine at 2,500 r/min for 2 minutes.

6. Set the CO, HC tester.

7. Check the CO contents and the HC contents at idle.

Standard value

CO contents: 0.1% or less

HC contents: 100 ppm or less

8. If there is a deviation from the standard value, check the

following items:

DDiagnosis output

DClosed-loop control (When the closed-loop control

is normal, the output signal of the oxygen sensor

changes between 0 - 400 mV and 600 - 1,000 mV

at idle.)

DFuel pressure

DInjector

DIgnition coil, spark plug cable, spark plug

DEvaporative emission control system

DCompression pressure

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

9. Remove the timing light.

MUT-II

Page 417 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-11

10. Turn the ignition switch to the “LOCK” (OFF) position

and then remove the MUT-II.

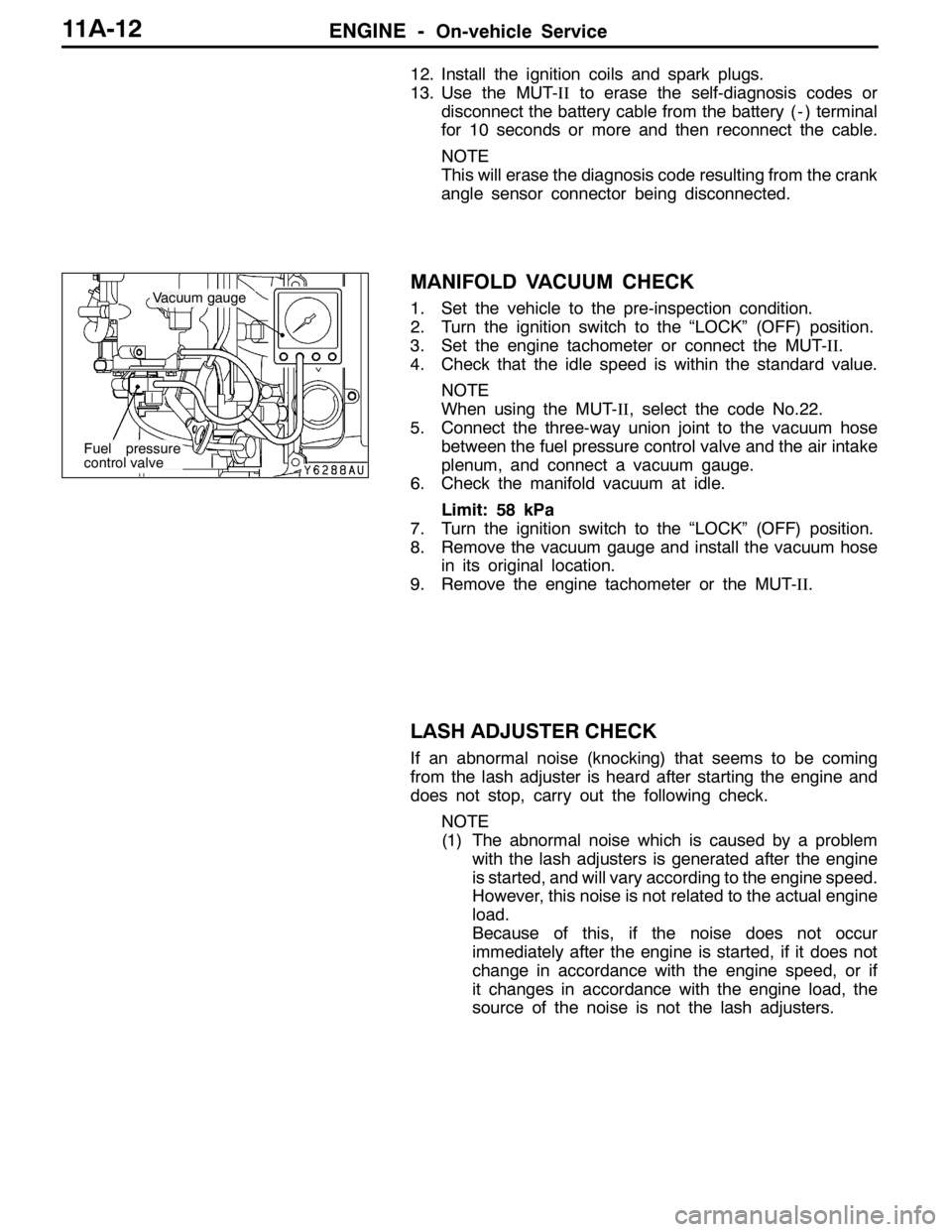

COMPRESSION PRESSURE CHECK

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Remove the ignition coils and spark plug cables.

3. Remove all of the spark plugs.

4. Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU from carrying out

ignition and fuel injection.

5. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

(1) Keep away from the spark plug hole when

cranking.

(2) If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

6. Set compression gauge to one of the spark plug holes.

7. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 250 r/min):

1,128 kPa

Limit (at engine speed of 250 r/min):

Min. 951 kPa

8. Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders are

below the limit.

Limit: Max. 98 kPa

9. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 7 and 8.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

10. Connect the crank angle sensor connector.

11. Install the spark plugs.

Crank angle sensor

connector

Page 418 of 1449

ENGINE -On-vehicle Service11A-12

12. Install the ignition coils and spark plugs.

13. Use the MUT-IIto erase the self-diagnosis codes or

disconnect the battery cable from the battery ( - ) terminal

for 10 seconds or more and then reconnect the cable.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

MANIFOLD VACUUM CHECK

1. Set the vehicle to the pre-inspection condition.

2. Turn the ignition switch to the “LOCK” (OFF) position.

3. Set the engine tachometer or connect the MUT-II.

4. Check that the idle speed is within the standard value.

NOTE

When using the MUT-II, select the code No.22.

5. Connect the three-way union joint to the vacuum hose

between the fuel pressure control valve and the air intake

plenum, and connect a vacuum gauge.

6. Check the manifold vacuum at idle.

Limit: 58 kPa

7. Turn the ignition switch to the “LOCK” (OFF) position.

8. Remove the vacuum gauge and install the vacuum hose

in its original location.

9. Remove the engine tachometer or the MUT-II.

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not the lash adjusters.

Vacuum gauge

Fuel pressure

control valve

Page 422 of 1449

ENGINE -Crankshaft Pulley/Camshaft and Camshaft Oil Seal11A-16

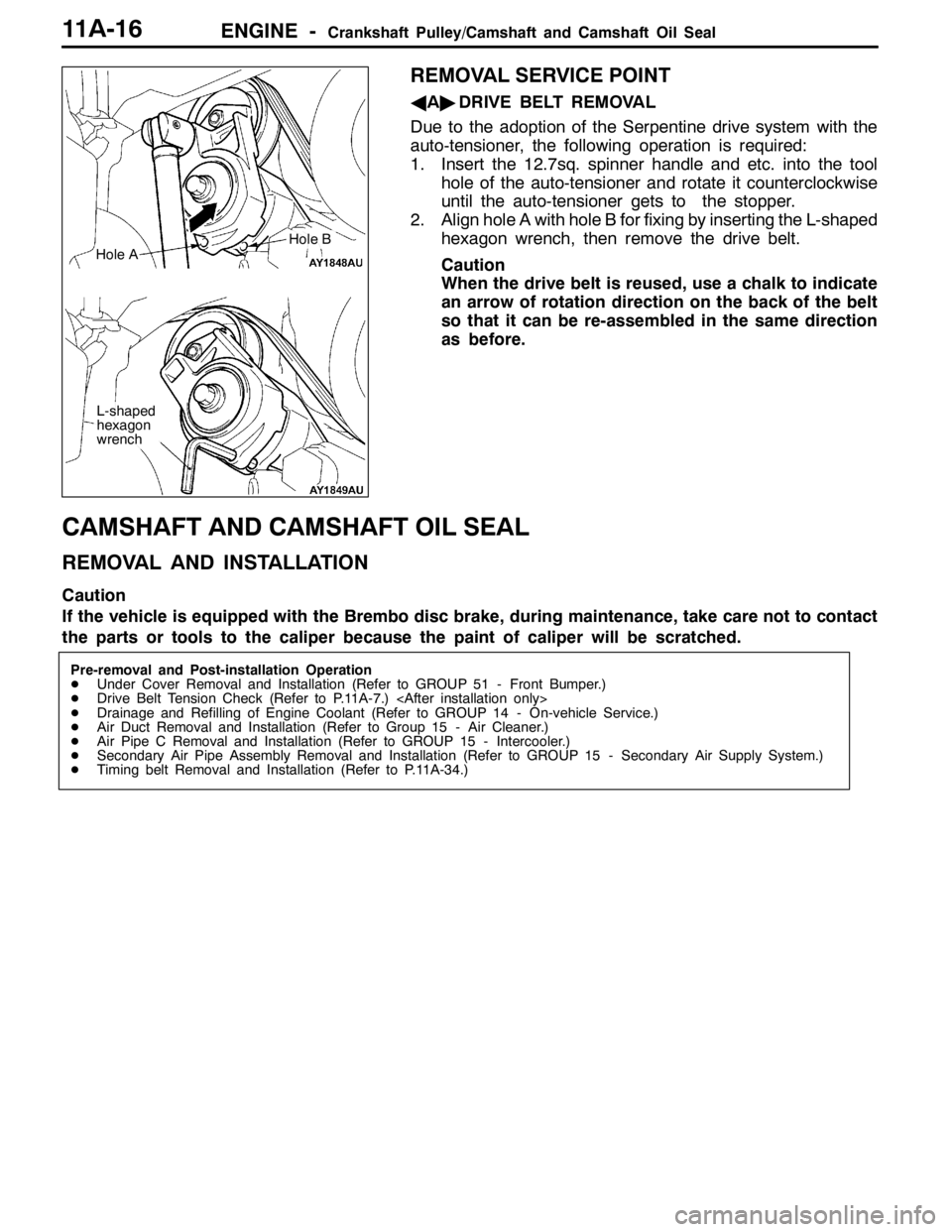

REMOVAL SERVICE POINT

AA"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle and etc. into the tool

hole of the auto-tensioner and rotate it counterclockwise

until the auto-tensioner gets to the stopper.

2. Align hole A with hole B for fixing by inserting the L-shaped

hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DDrive Belt Tension Check (Refer to P.11A-7.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Duct Removal and Installation (Refer to Group 15 - Air Cleaner.)

DAir Pipe C Removal and Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Pipe Assembly Removal and Installation (Refer to GROUP 15 - Secondary Air Supply System.)

DTiming belt Removal and Installation (Refer to P.11A-34.)

Hole A

L-shaped

hexagon

wrench

Hole B

Page 428 of 1449

ENGINE -Camshaft and Camshaft Oil Seal11A-22

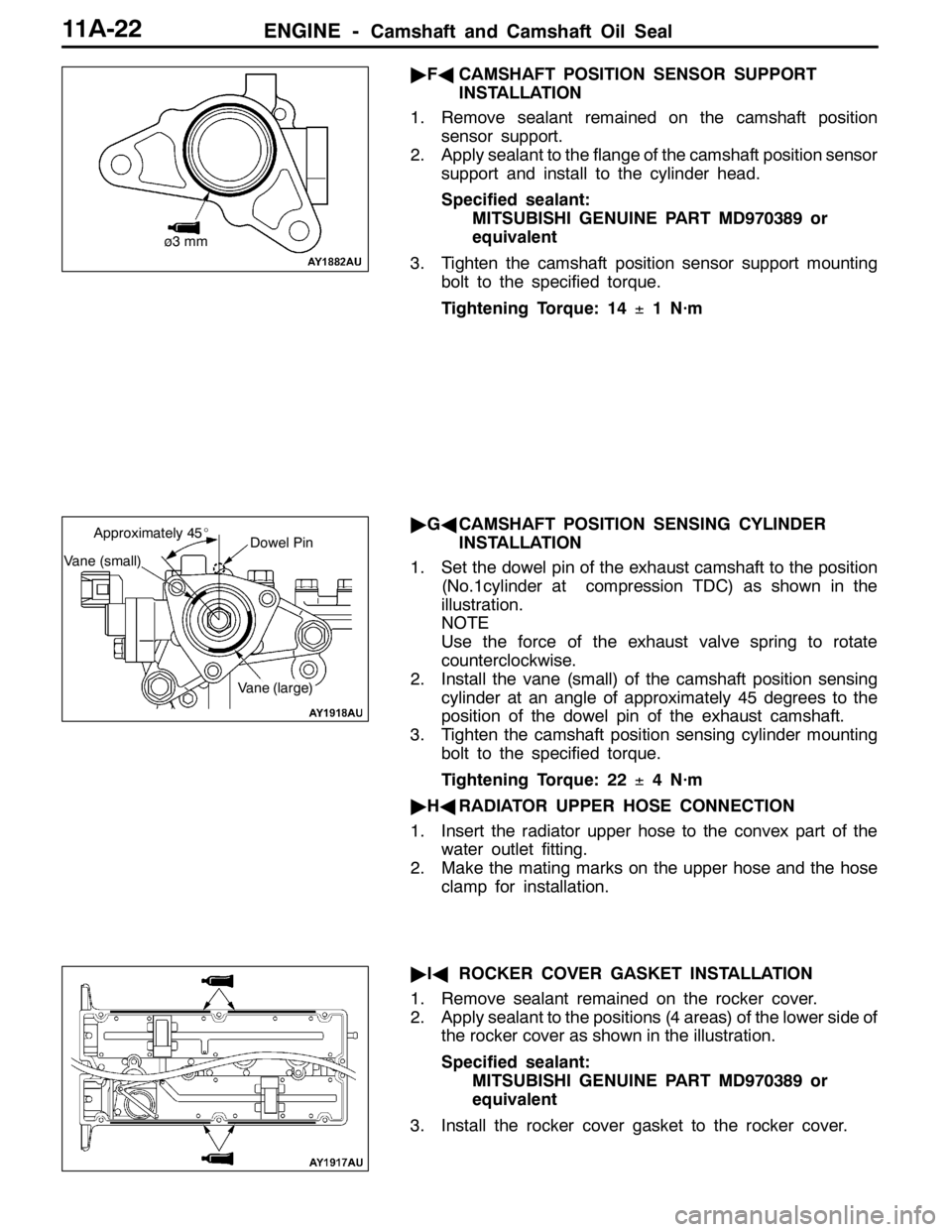

"FACAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

1. Remove sealant remained on the camshaft position

sensor support.

2. Apply sealant to the flange of the camshaft position sensor

support and install to the cylinder head.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Tighten the camshaft position sensor support mounting

bolt to the specified torque.

Tightening Torque: 14±1 N·m

"GACAMSHAFT POSITION SENSING CYLINDER

INSTALLATION

1. Set the dowel pin of the exhaust camshaft to the position

(No.1cylinder at compression TDC) as shown in the

illustration.

NOTE

Use the force of the exhaust valve spring to rotate

counterclockwise.

2. Install the vane (small) of the camshaft position sensing

cylinder at an angle of approximately 45 degrees to the

position of the dowel pin of the exhaust camshaft.

3. Tighten the camshaft position sensing cylinder mounting

bolt to the specified torque.

Tightening Torque: 22±4 N·m

"HARADIATOR UPPER HOSE CONNECTION

1. Insert the radiator upper hose to the convex part of the

water outlet fitting.

2. Make the mating marks on the upper hose and the hose

clamp for installation.

"IAROCKER COVER GASKET INSTALLATION

1. Remove sealant remained on the rocker cover.

2. Apply sealant to the positions (4 areas) of the lower side of

the rocker cover as shown in the illustration.

Specified sealant:

MITSUBISHI GENUINE PART MD970389 or

equivalent

3. Install the rocker cover gasket to the rocker cover.

ø3 mm

Dowel Pin

Vane (small)

Approximately 45_

Vane (large)