battery MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1080 of 1449

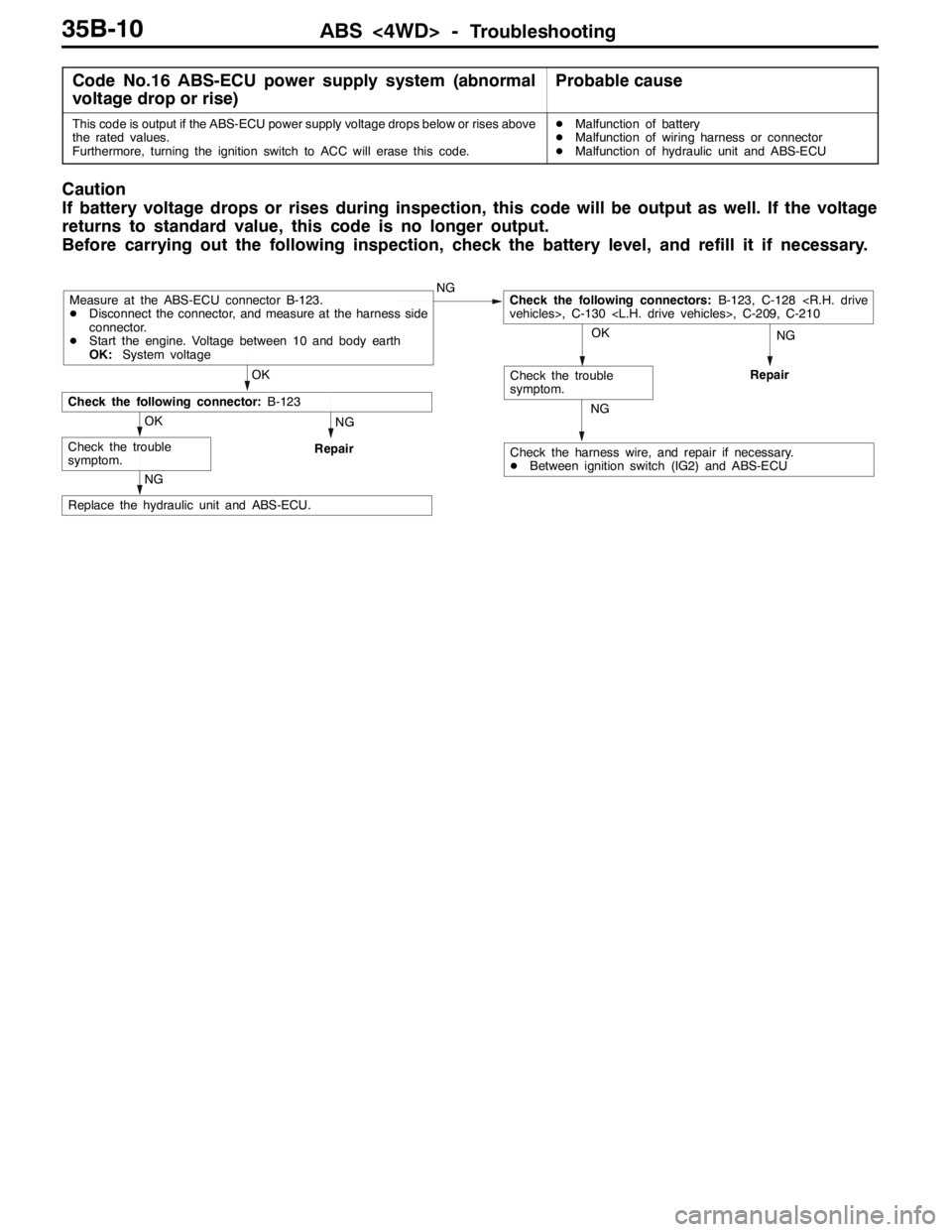

ABS <4WD> -Troubleshooting35B-10

Code No.16 ABS-ECU power supply system (abnormal

voltage drop or rise)Probable cause

This code is output if the ABS-ECU power supply voltage drops below or rises above

the rated values.

Furthermore, turning the ignition switch to ACC will erase this code.DMalfunction of battery

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

Caution

If battery voltage drops or rises during inspection, this code will be output as well. If the voltage

returns to standard value, this code is no longer output.

Before carrying out the following inspection, check the battery level, and refill it if necessary.

NGNG

Repair

NG

Replace the hydraulic unit and ABS-ECU.

NG

Repair

Check the harness wire, and repair if necessary.

DBetween ignition switch (IG2) and ABS-ECU

OK

Check the trouble

symptom.

OK

Check the trouble

symptom.

OK

Check the following connector:B-123

NGCheck the following connectors:B-123, C-128

DDisconnect the connector, and measure at the harness side

connector.

DStart the engine. Voltage between 10 and body earth

OK:System voltage

Page 1082 of 1449

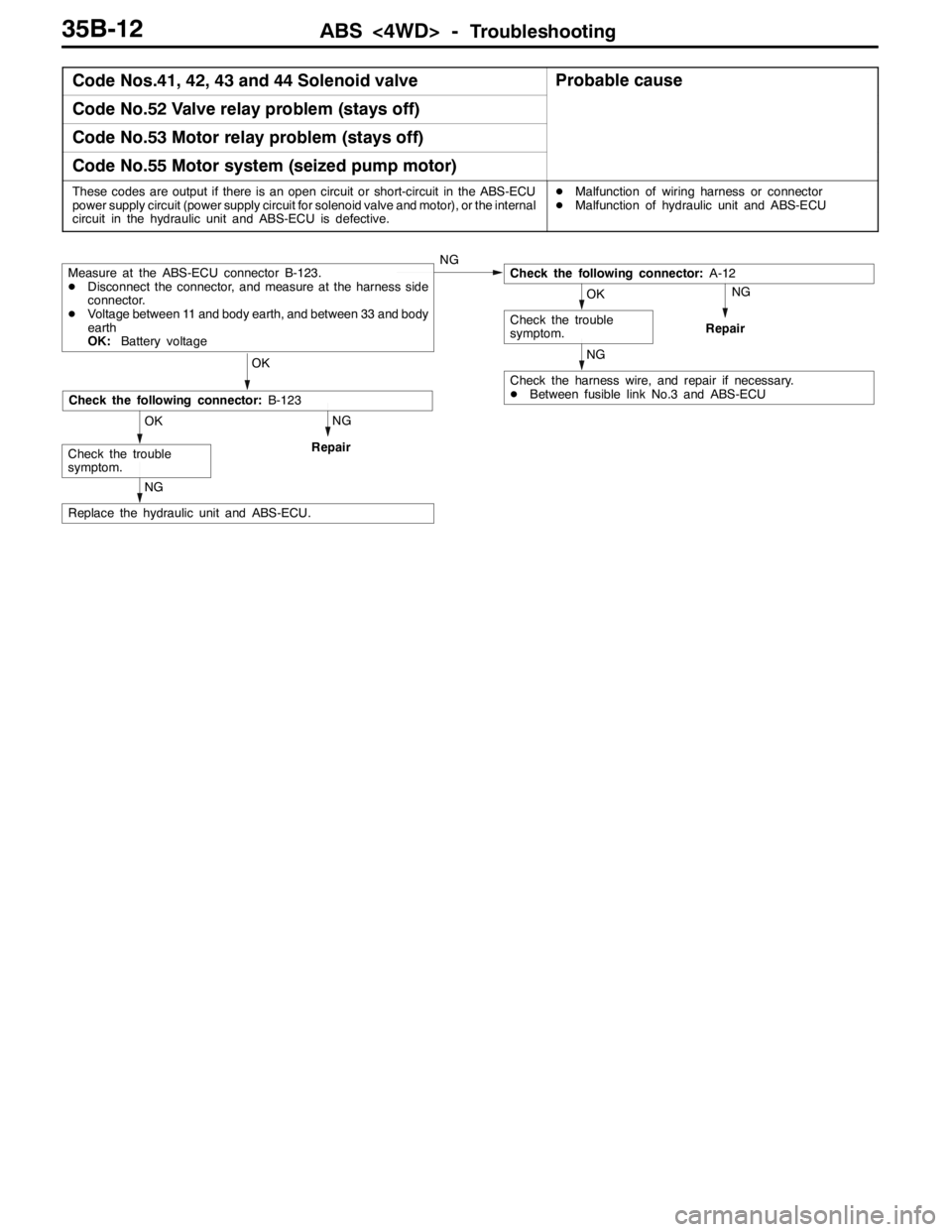

ABS <4WD> -Troubleshooting35B-12

Code Nos.41, 42, 43 and 44 Solenoid valveProbable cause

Code No.52 Valve relay problem (stays off)

Code No.53 Motor relay problem (stays off)

Code No.55 Motor system (seized pump motor)

These codes are output if there is an open circuit or short-circuit in the ABS-ECU

power supply circuit (power supply circuit for solenoid valve and motor), or the internal

circuit in the hydraulic unit and ABS-ECU is defective.DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween fusible link No.3 and ABS-ECU

NG

Repair

NG

Replace the hydraulic unit and ABS-ECU.

OK

Check the trouble

symptom.

Check the following connector:B-123

OK

OK

Check the trouble

symptom.

Check the following connector:A-12Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DVoltage between 11 and body earth, and between 33 and body

earth

OK:Battery voltageNG

Page 1090 of 1449

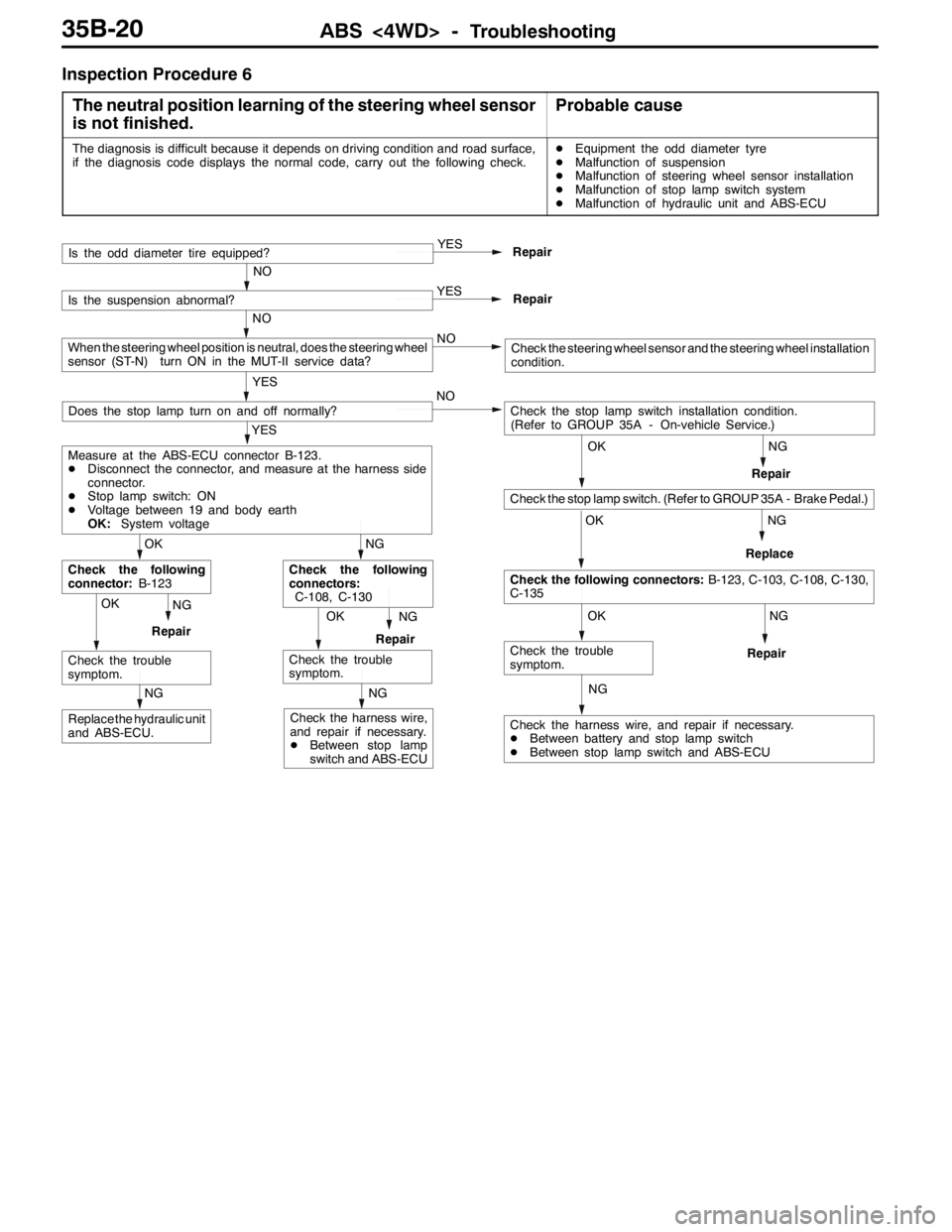

ABS <4WD> -Troubleshooting35B-20

Inspection Procedure 6

The neutral position learning of the steering wheel sensor

is not finished.

Probable cause

The diagnosis is difficult because it depends on driving condition and road surface,

if the diagnosis code displays the normal code, carry out the following check.DEquipment the odd diameter tyre

DMalfunction of suspension

DMalfunction of steering wheel sensor installation

DMalfunction of stop lamp switch system

DMalfunction of hydraulic unit and ABS-ECU

NG

NG

NG

NG

Check the harness wire, and repair if necessary.

DBetween battery and stop lamp switch

DBetween stop lamp switch and ABS-ECU

OK

Check the trouble

symptom.

OK

Check the following connectors:B-123, C-103, C-108, C-130,

C-135

OK

Check the stop lamp switch. (Refer to GROUP 35A - Brake Pedal.)

Check the stop lamp switch installation condition.

(Refer to GROUP 35A - On-vehicle Service.) NO

Repair

OKNG

RepairOKNG

RepairReplace

NG

Replace the hydraulic unit

and ABS-ECU.

NG

Check the harness wire,

and repair if necessary.

DBetween stop lamp

switch and ABS-ECURepair

Check the trouble

symptom.

NG

Check the following

connectors:

C-108, C-130

Check the trouble

symptom.

OK

Check the following

connector:B-123

YES

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DStop lamp switch: ON

DVoltage between 19 and body earth

OK:System voltage

Does the stop lamp turn on and off normally?

YES

Repair

NO

Is the odd diameter tire equipped?

YES

Repair

NO

Is the suspension abnormal?

NO

YES

When the steering wheel position is neutral, does the steering wheel

sensor (ST-N) turn ON in the MUT-II service data?Check the steering wheel sensor and the steering wheel installation

condition.

Page 1099 of 1449

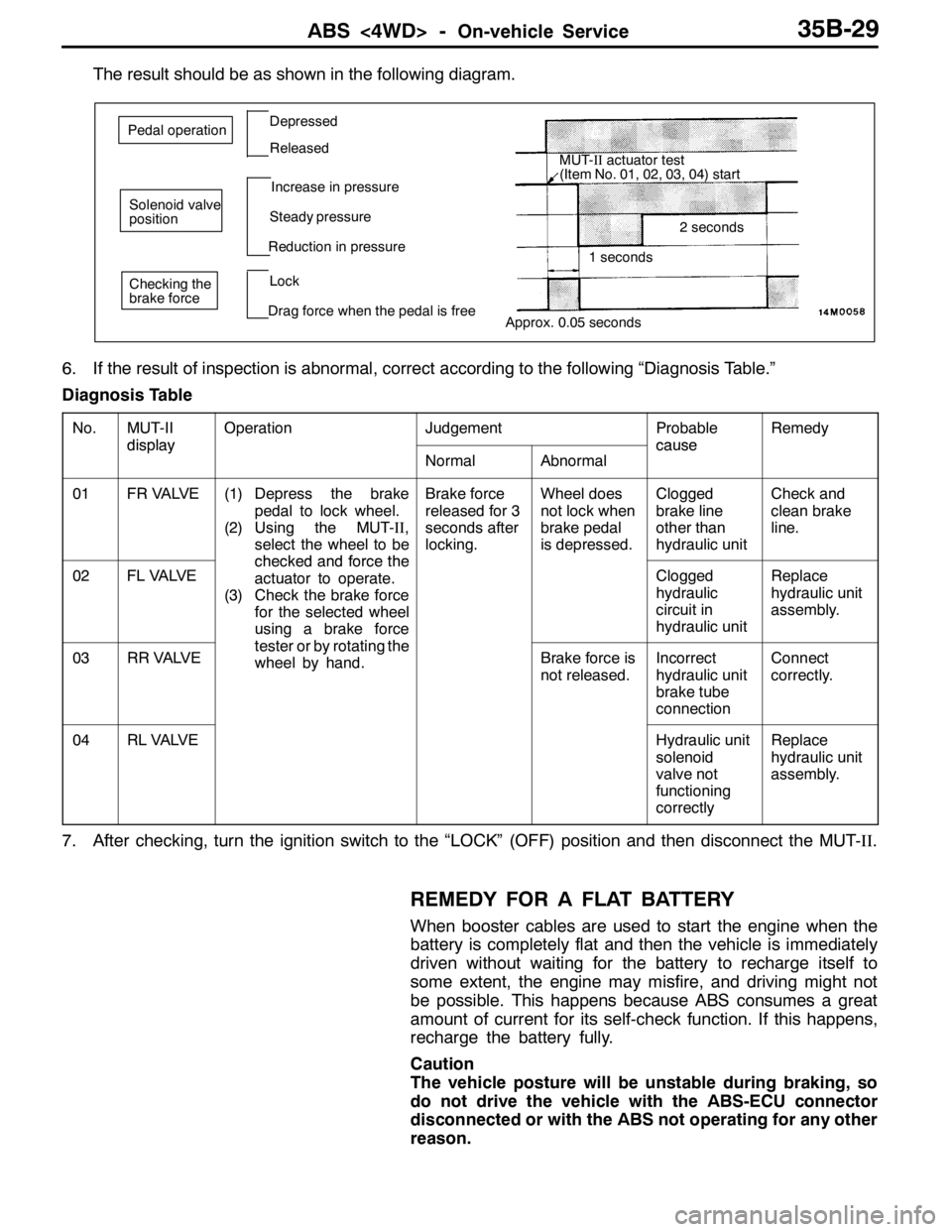

ABS <4WD> -On-vehicle Service35B-29

The result should be as shown in the following diagram.

Approx. 0.05 seconds

Pedal operationDepressed

Released

Solenoid valve

positionIncrease in pressure

Steady pressure

Reduction in pressure

Checking the

brake forceLock

Drag force when the pedal is freeMUT-IIactuator test

(Item No. 01, 02, 03, 04) start

2 seconds

1 seconds

6. If the result of inspection is abnormal, correct according to the following “Diagnosis Table.”

Diagnosis Table

No.MUT-II

display

OperationJudgementProbable

cause

Remedy

display

NormalAbnormal

cause

01FR VALVE(1) Depress the brake

pedal to lock wheel.

(2) Using the MUT-II,

select the wheel to be

checkedandforcethe

Brake force

released for 3

seconds after

locking.Wheel does

not lock when

brake pedal

is depressed.Clogged

brake line

other than

hydraulic unitCheck and

clean brake

line.

02FL VALVEchecked and force the

actuator to operate.

(3) Check the brake force

for the selected wheel

using a brake force

ttbttith

Clogged

hydraulic

circuit in

hydraulic unitReplace

hydraulic unit

assembly.

03RR VALVE

g

tester or by rotating the

wheel by hand.Brake force is

not released.Incorrect

hydraulic unit

brake tube

connectionConnect

correctly.

04RL VALVEHydraulic unit

solenoid

valve not

functioning

correctlyReplace

hydraulic unit

assembly.

7. After checking, turn the ignition switch to the “LOCK” (OFF) position and then disconnect the MUT-II.

REMEDY FOR A FLAT BATTERY

When booster cables are used to start the engine when the

battery is completely flat and then the vehicle is immediately

driven without waiting for the battery to recharge itself to

some extent, the engine may misfire, and driving might not

be possible. This happens because ABS consumes a great

amount of current for its self-check function. If this happens,

recharge the battery fully.

Caution

The vehicle posture will be unstable during braking, so

do not drive the vehicle with the ABS-ECU connector

disconnected or with the ABS not operating for any other

reason.

Page 1182 of 1449

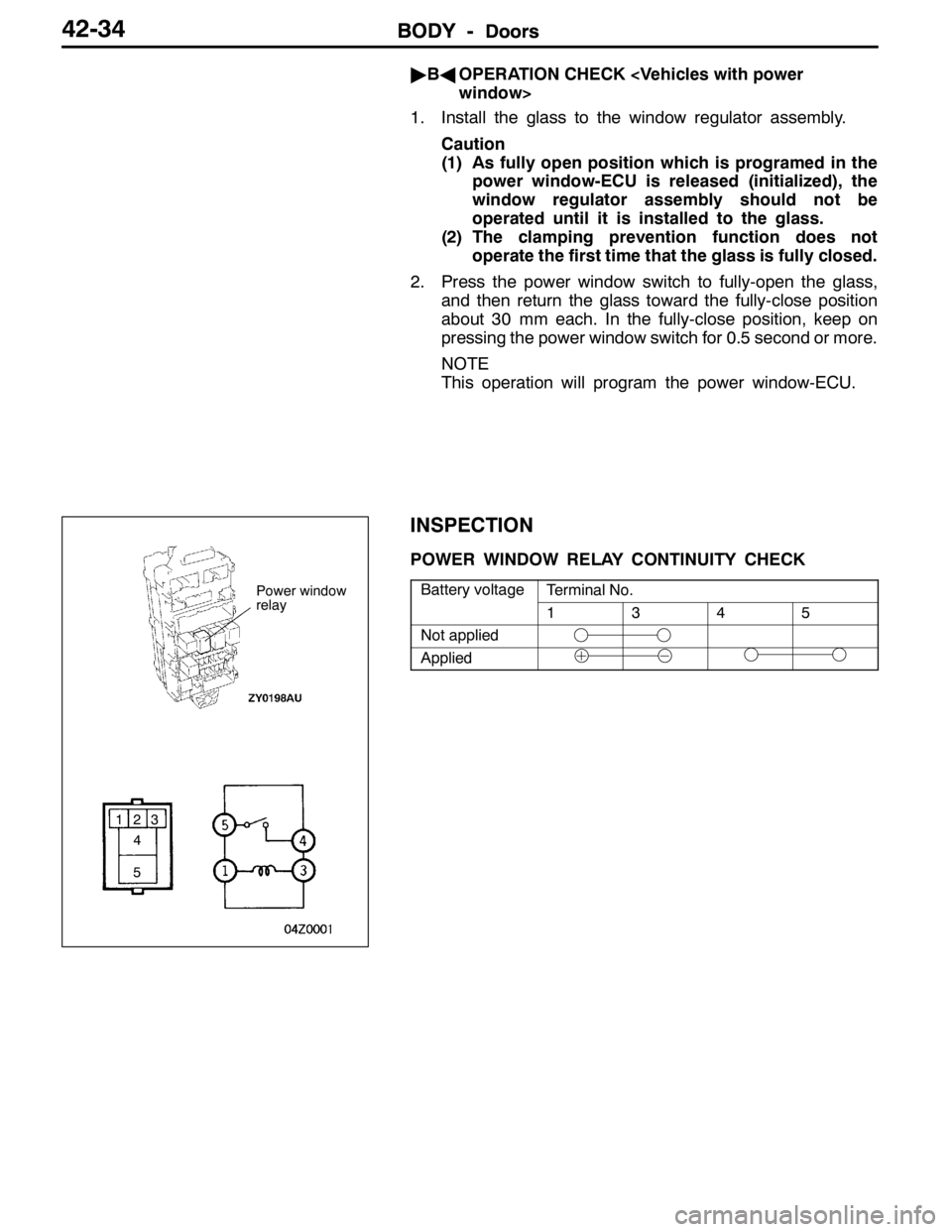

BODY -DoorsBODY -Doors42-34

"BAOPERATION CHECK

1. Install the glass to the window regulator assembly.

Caution

(1) As fully open position which is programed in the

power window-ECU is released (initialized), the

window regulator assembly should not be

operated until it is installed to the glass.

(2) The clamping prevention function does not

operate the first time that the glass is fully closed.

2. Press the power window switch to fully-open the glass,

and then return the glass toward the fully-close position

about 30 mm each. In the fully-close position, keep on

pressing the power window switch for 0.5 second or more.

NOTE

This operation will program the power window-ECU.

INSPECTION

POWER WINDOW RELAY CONTINUITY CHECK

Battery voltageTerminal No.yg

1345

Not applied

Applied

Power window

relay

123

4

5

Page 1209 of 1449

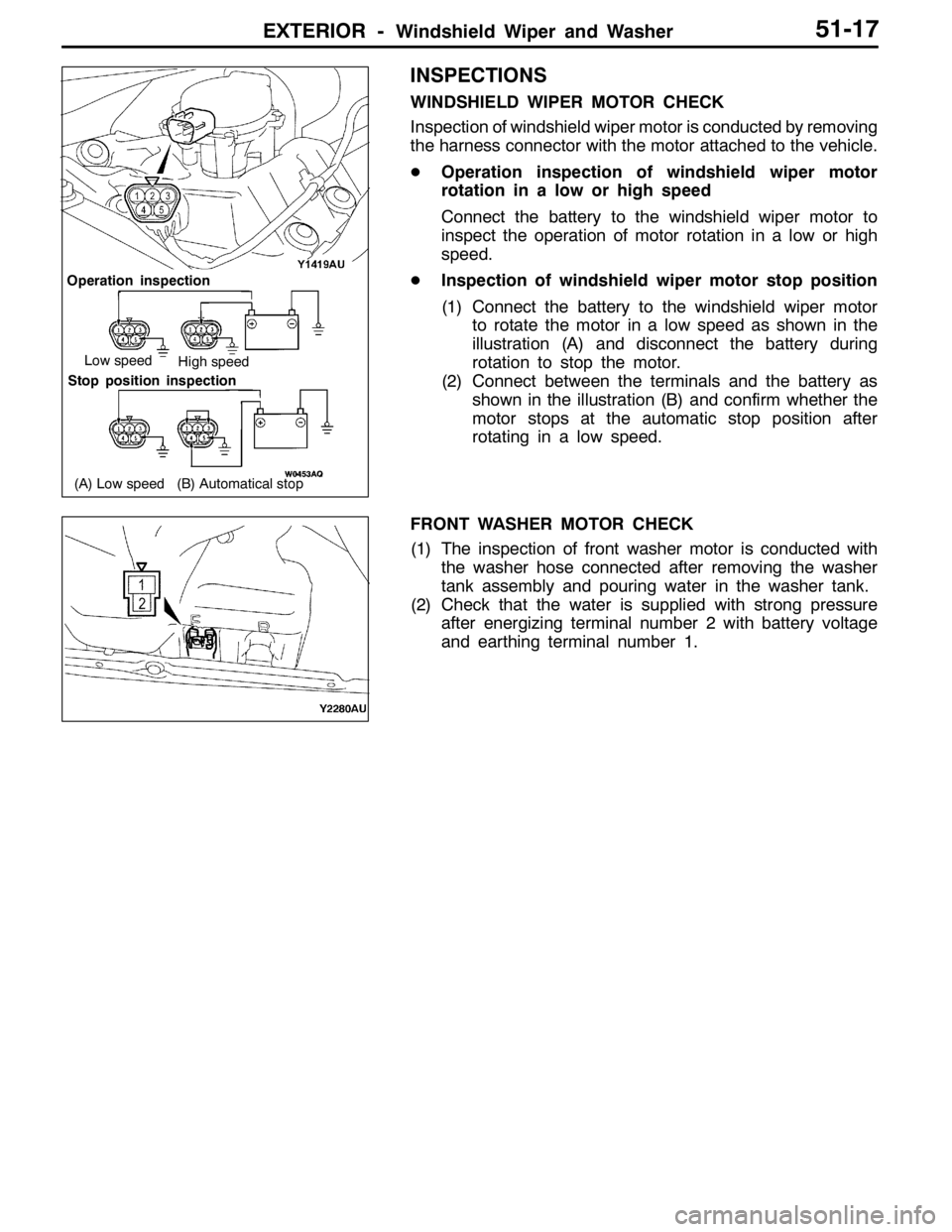

EXTERIOR -Windshield Wiper and Washer51-17

INSPECTIONS

WINDSHIELD WIPER MOTOR CHECK

Inspection of windshield wiper motor is conducted by removing

the harness connector with the motor attached to the vehicle.

DOperation inspection of windshield wiper motor

rotation in a low or high speed

Connect the battery to the windshield wiper motor to

inspect the operation of motor rotation in a low or high

speed.

DInspection of windshield wiper motor stop position

(1) Connect the battery to the windshield wiper motor

to rotate the motor in a low speed as shown in the

illustration (A) and disconnect the battery during

rotation to stop the motor.

(2) Connect between the terminals and the battery as

shown in the illustration (B) and confirm whether the

motor stops at the automatic stop position after

rotating in a low speed.

FRONT WASHER MOTOR CHECK

(1) The inspection of front washer motor is conducted with

the washer hose connected after removing the washer

tank assembly and pouring water in the washer tank.

(2) Check that the water is supplied with strong pressure

after energizing terminal number 2 with battery voltage

and earthing terminal number 1.

(B) Automatical stop

Operation inspection

Low speedHigh speed

Stop position inspection

(A) Low speed

Page 1216 of 1449

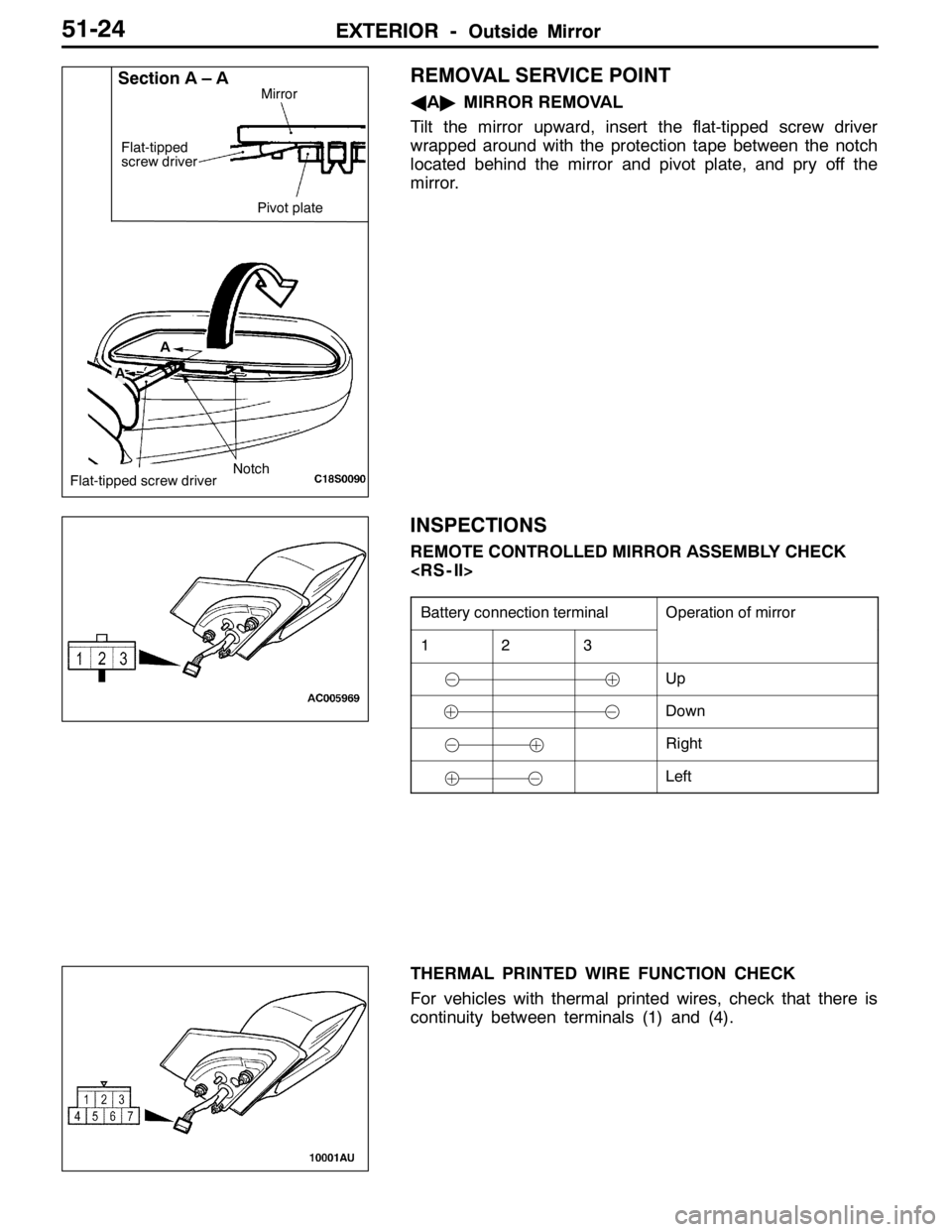

EXTERIOR -Outside MirrorEXTERIOR -Outside Mirror51-24

REMOVAL SERVICE POINT

AA"MIRROR REMOVAL

Tilt the mirror upward, insert the flat-tipped screw driver

wrapped around with the protection tape between the notch

located behind the mirror and pivot plate, and pry off the

mirror.

INSPECTIONS

REMOTE CONTROLLED MIRROR ASSEMBLY CHECK

Battery connection terminalOperation of mirror

123

Up

Down

Right

Left

THERMAL PRINTED WIRE FUNCTION CHECK

For vehicles with thermal printed wires, check that there is

continuity between terminals (1) and (4).

Section A – A

Notch Flat-tipped

screw driver

Pivot plate

AMirrorFlat-tipped screw driverA

Page 1247 of 1449

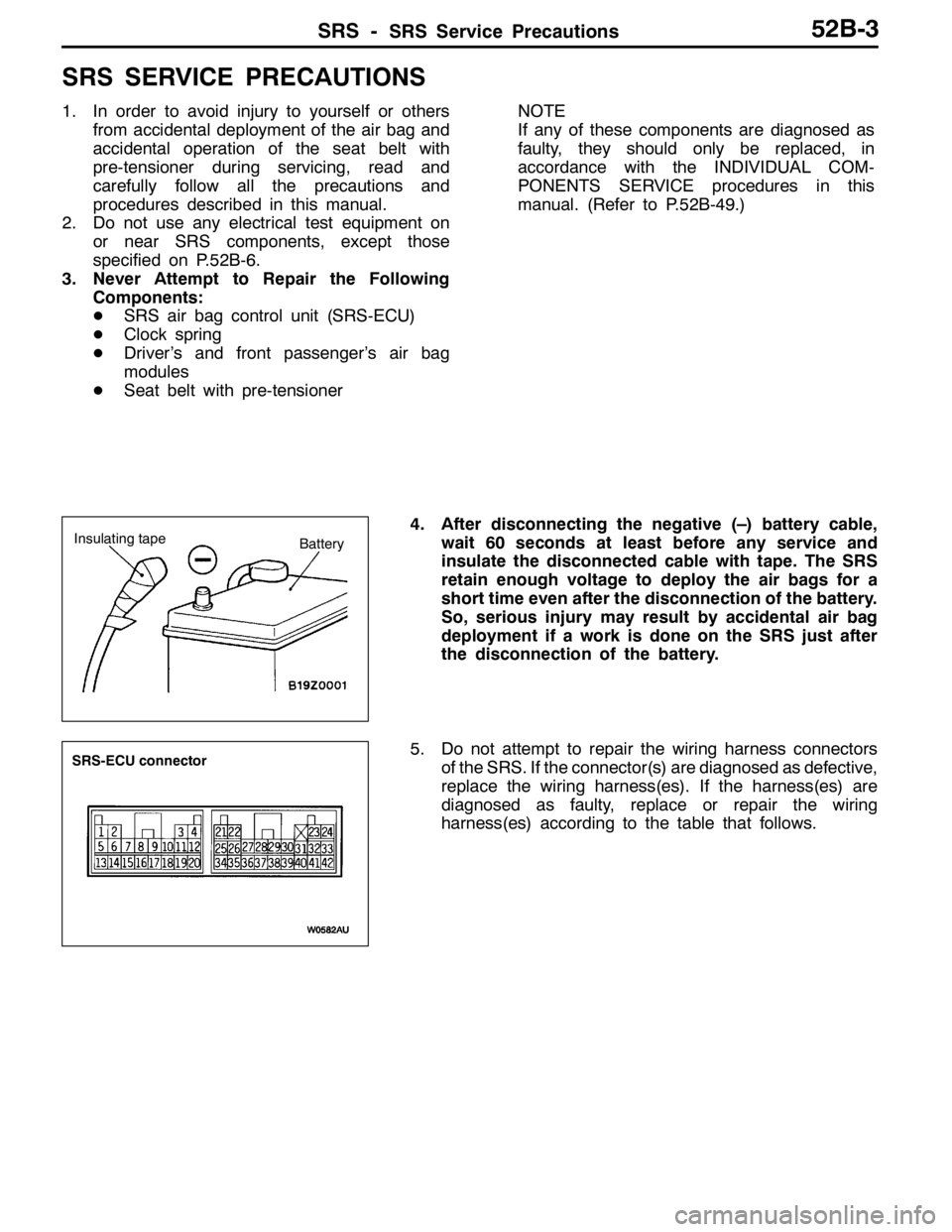

SRS -SRS Service Precautions52B-3

SRS SERVICE PRECAUTIONS

1. In order to avoid injury to yourself or others

from accidental deployment of the air bag and

accidental operation of the seat belt with

pre-tensioner during servicing, read and

carefully follow all the precautions and

procedures described in this manual.

2. Do not use any electrical test equipment on

or near SRS components, except those

specified on P.52B-6.

3. Never Attempt to Repair the Following

Components:

DSRS air bag control unit (SRS-ECU)

DClock spring

DDriver’s and front passenger’s air bag

modules

DSeat belt with pre-tensionerNOTE

If any of these components are diagnosed as

faulty, they should only be replaced, in

accordance with the INDIVIDUAL COM-

PONENTS SERVICE procedures in this

manual. (Refer to P.52B-49.)

4. After disconnecting the negative (–) battery cable,

wait 60 seconds at least before any service and

insulate the disconnected cable with tape. The SRS

retain enough voltage to deploy the air bags for a

short time even after the disconnection of the battery.

So, serious injury may result by accidental air bag

deployment if a work is done on the SRS just after

the disconnection of the battery.

5. Do not attempt to repair the wiring harness connectors

of the SRS. If the connector(s) are diagnosed as defective,

replace the wiring harness(es). If the harness(es) are

diagnosed as faulty, replace or repair the wiring

harness(es) according to the table that follows.

Insulating tape

Battery

SRS-ECU connector

Page 1254 of 1449

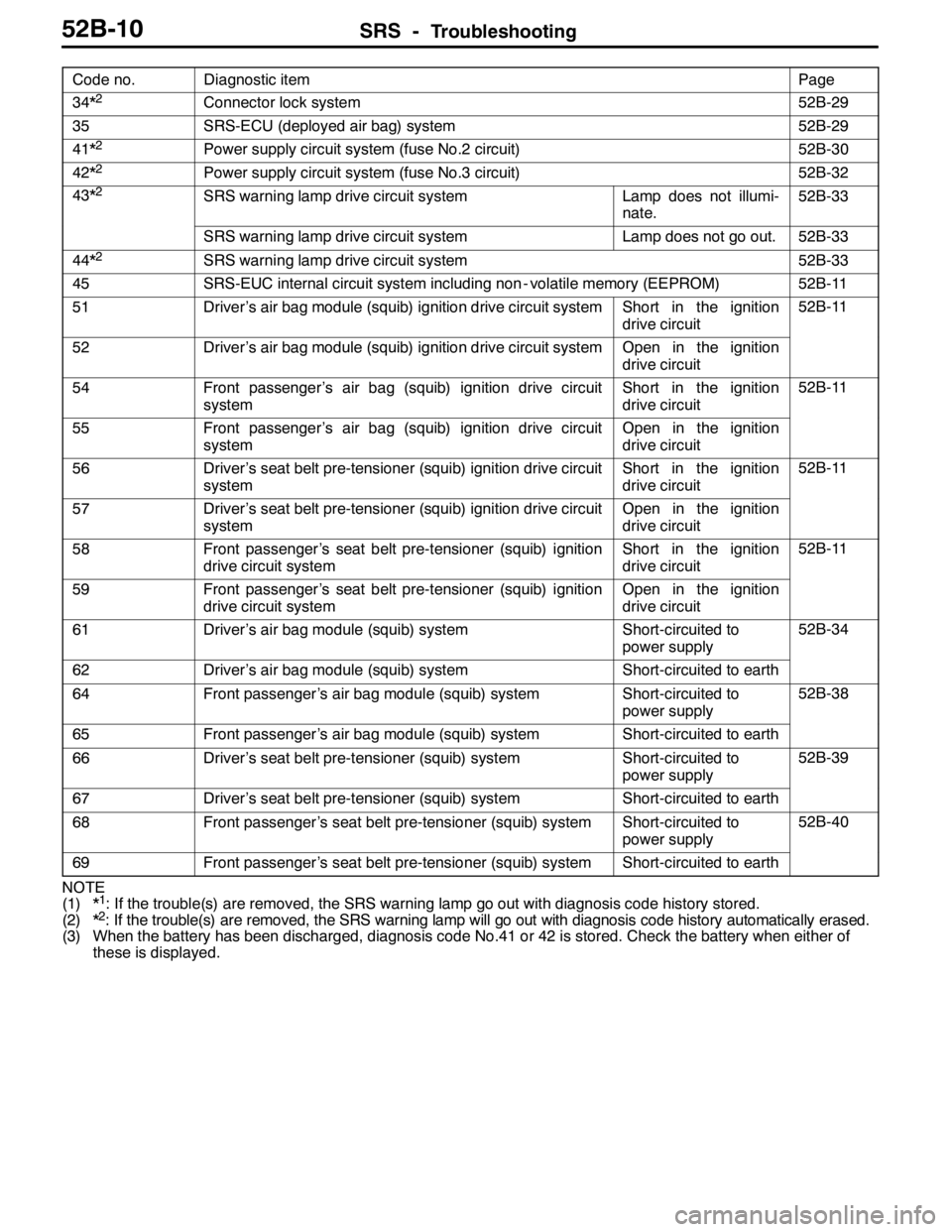

SRS -Troubleshooting52B-10

Code no.Page Diagnostic item

34*2Connector lock system52B-29

35SRS-ECU (deployed air bag) system52B-29

41*2Power supply circuit system (fuse No.2 circuit)52B-30

42*2Power supply circuit system (fuse No.3 circuit)52B-32

43*2SRS warning lamp drive circuit systemLamp does not illumi-

nate.52B-33

SRS warning lamp drive circuit systemLamp does not go out.52B-33

44*2SRS warning lamp drive circuit system52B-33

45SRS-EUC internal circuit system including non - volatile memory (EEPROM)52B-11

51Driver’s air bag module (squib) ignition drive circuit systemShort in the ignition

drive circuit52B-11

52Driver’s air bag module (squib) ignition drive circuit systemOpen in the ignition

drive circuit

54Front passenger’s air bag (squib) ignition drive circuit

systemShort in the ignition

drive circuit52B-11

55Front passenger’s air bag (squib) ignition drive circuit

systemOpen in the ignition

drive circuit

56Driver’s seat belt pre-tensioner (squib) ignition drive circuit

systemShort in the ignition

drive circuit52B-11

57Driver’s seat belt pre-tensioner (squib) ignition drive circuit

systemOpen in the ignition

drive circuit

58Front passenger’s seat belt pre-tensioner (squib) ignition

drive circuit systemShort in the ignition

drive circuit52B-11

59Front passenger’s seat belt pre-tensioner (squib) ignition

drive circuit systemOpen in the ignition

drive circuit

61Driver’s air bag module (squib) systemShort-circuited to

power supply52B-34

62Driver’s air bag module (squib) systemShort-circuited to earth

64Front passenger’s air bag module (squib) systemShort-circuited to

power supply52B-38

65Front passenger’s air bag module (squib) systemShort-circuited to earth

66Driver’s seat belt pre-tensioner (squib) systemShort-circuited to

power supply52B-39

67Driver’s seat belt pre-tensioner (squib) systemShort-circuited to earth

68Front passenger’s seat belt pre-tensioner (squib) systemShort-circuited to

power supply52B-40

69Front passenger’s seat belt pre-tensioner (squib) systemShort-circuited to earth

NOTE

(1) *1: If the trouble(s) are removed, the SRS warning lamp go out with diagnosis code history stored.

(2) *2: If the trouble(s) are removed, the SRS warning lamp will go out with diagnosis code history automatically erased.

(3) When the battery has been discharged, diagnosis code No.41 or 42 is stored. Check the battery when either of

these is displayed.

Page 1255 of 1449

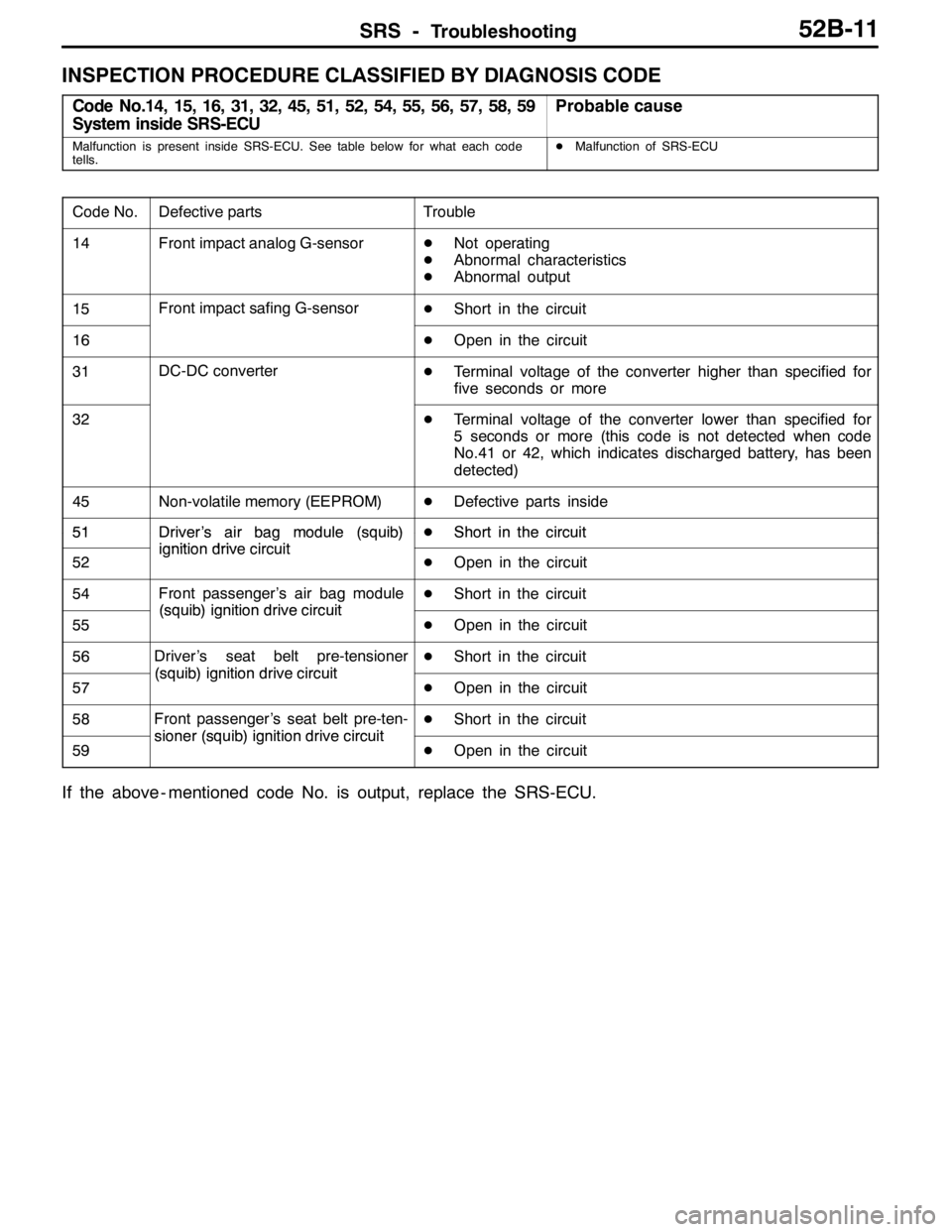

SRS -Troubleshooting52B-11

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No.14, 15, 16, 31, 32, 45, 51, 52, 54, 55, 56, 57, 58, 59

System inside SRS-ECUProbable cause

Malfunction is present inside SRS-ECU. See table below for what each code

tells.DMalfunction of SRS-ECU

Code No.Defective partsTrouble

14Front impact analog G-sensorDNot operating

DAbnormal characteristics

DAbnormal output

15Front impact safing G-sensorDShort in the circuit

16DOpen in the circuit

31DC-DC converterDTerminal voltage of the converter higher than specified for

five seconds or more

32DTerminal voltage of the converter lower than specified for

5 seconds or more (this code is not detected when code

No.41 or 42, which indicates discharged battery, has been

detected)

45Non-volatile memory (EEPROM)DDefective parts inside

51Driver’sairbagmodule(squib)DShortinthecircuit51Driver’sairbag module(squib)

ignitiondrivecircuit

DShortinthecircuit

52ignition drive circuitDOpen in the circuit

54Front passenger’s air bag module

(squib)ignitiondrivecircuit

DShort in the circuit

55(squib)ignitiondrive circuitDOpen in the circuit

56Driver’s seat belt pre-tensioner

(squib)ignitiondrivecircuit

DShort in the circuit

57(squib)ignitiondrive circuitDOpen in the circuit

58Front passenger’s seat belt pre-ten-

sioner(squib)ignitiondrivecircuit

DShort in the circuit

59sioner(squib)ignitiondrive circuitDOpen in the circuit

If the above - mentioned code No. is output, replace the SRS-ECU.