MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 701 of 1449

ENGINE COOLING -Water Pump14-13

WATER PUMP

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DTiming Belt Removal and installation (Refer to GROUP 11A.)

1

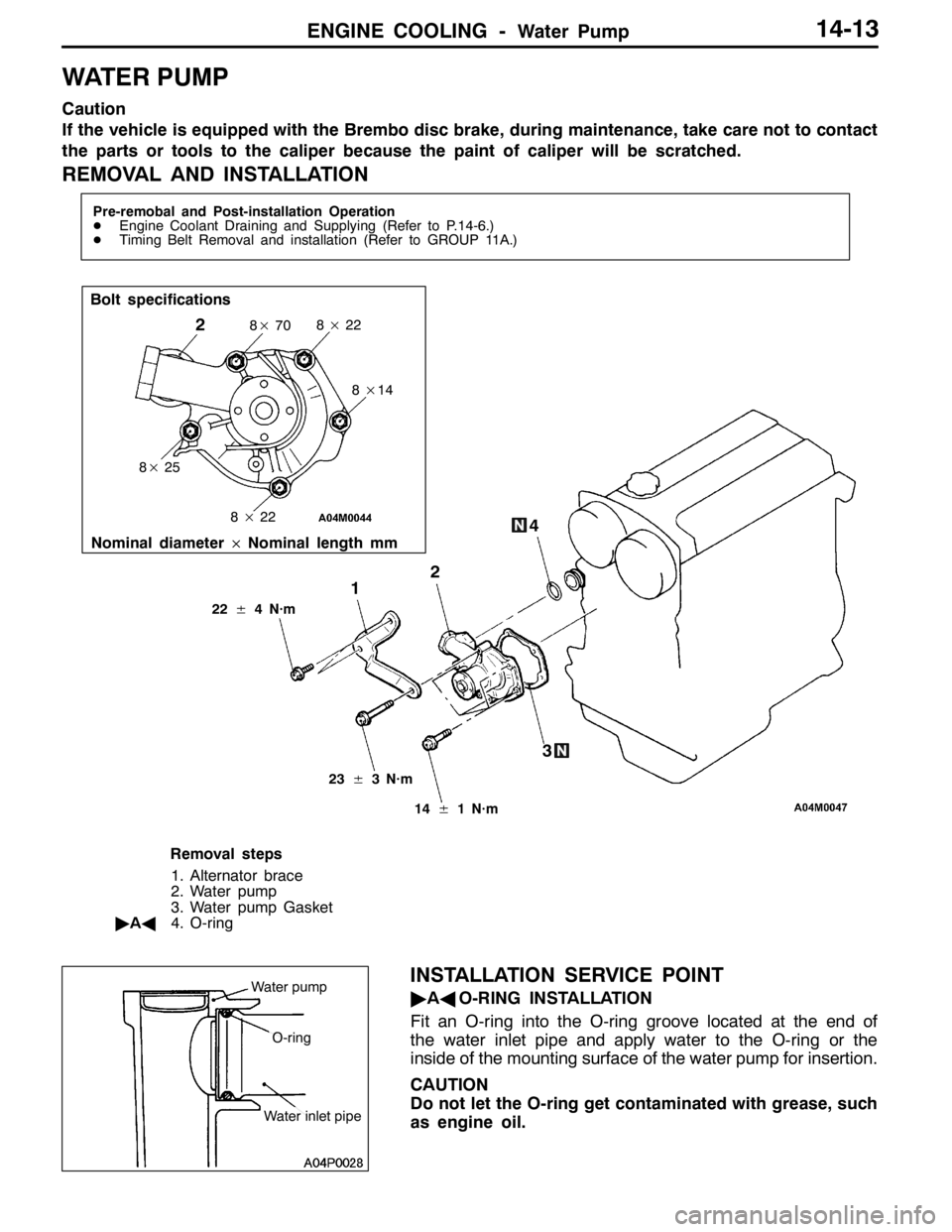

Bolt specifications

28×22

2

23±3 N·m

14±1 N·m

Nominal diameter×Nominal length mm

8×70

8×14

8×22 8×25

3 4

22±4 N·m

Removal steps

1. Alternator brace

2. Water pump

3. Water pump Gasket

"AA4. O-ring

INSTALLATION SERVICE POINT

"AAO-RING INSTALLATION

Fit an O-ring into the O-ring groove located at the end of

the water inlet pipe and apply water to the O-ring or the

inside of the mounting surface of the water pump for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.Water pump

O-ring

Water inlet pipe

Page 702 of 1449

ENGINE COOLING -Water Hose and Water Pipe14-14

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15 - Air Cleaner.)

DAir Bypass Valve Assembly, Air Bypass Hose, Air Hose E and Air Pipe C, Air Hose D Removal and

Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Control Valve Bracket Removal and Installation

(Refer to GROUP 15 - Secondary Air Supply System.)

DBattery, Battery Tray Removal and Installation

3 4

5 6

7 8

9

1012

10±1 N·m

42±7 N·m 13±2 N·m

11

1

2

23±4 N·m

18

1716 1514

13

19

10±1 N·m

42±7 N·m

10±1 N·m

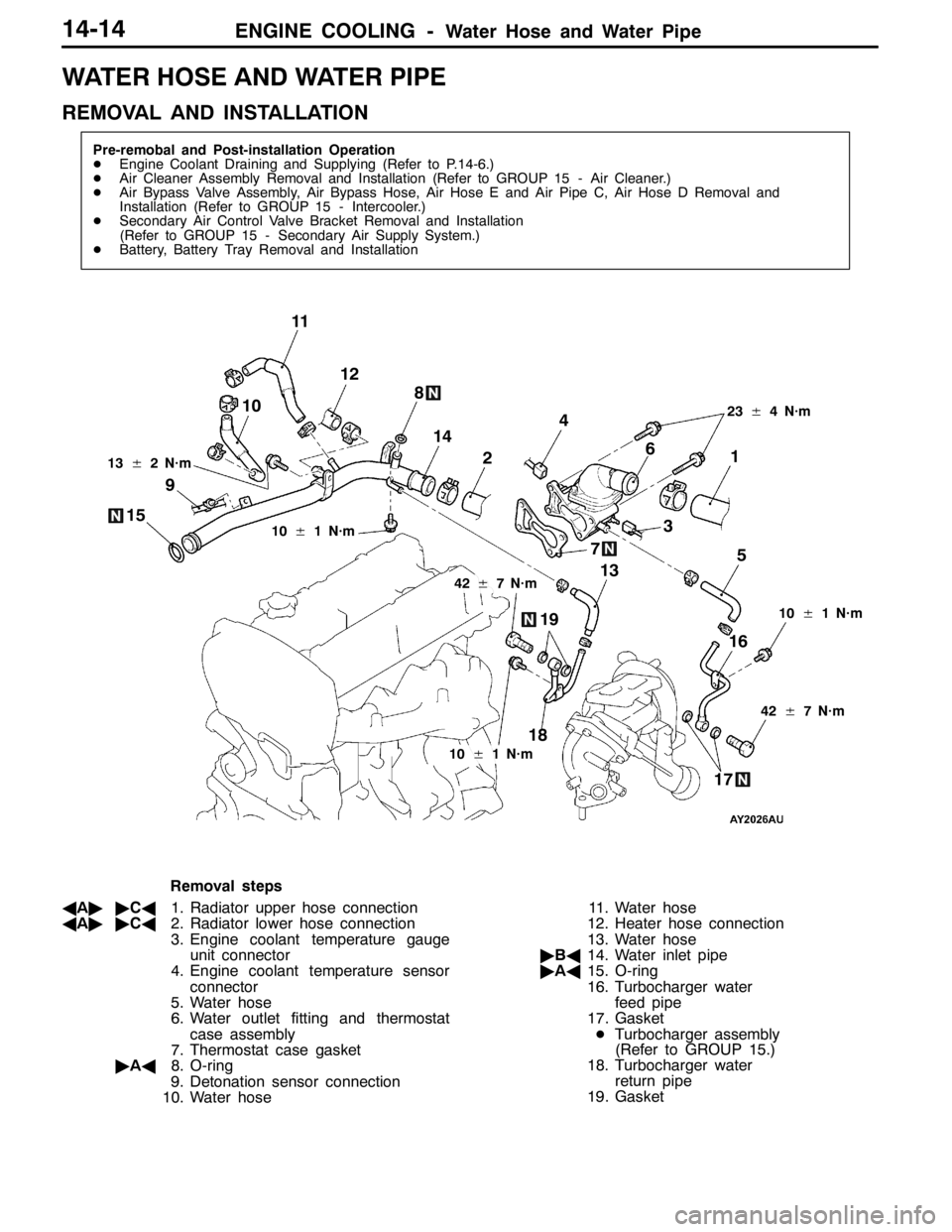

Removal steps

AA""CA1. Radiator upper hose connection

AA""CA2. Radiator lower hose connection

3. Engine coolant temperature gauge

unit connector

4. Engine coolant temperature sensor

connector

5. Water hose

6. Water outlet fitting and thermostat

case assembly

7. Thermostat case gasket

"AA8. O-ring

9. Detonation sensor connection

10. Water hose11. Water hose

12. Heater hose connection

13. Water hose

"BA14. Water inlet pipe

"AA15. O-ring

16. Turbocharger water

feed pipe

17. Gasket

DTurbocharger assembly

(Refer to GROUP 15.)

18. Turbocharger water

return pipe

19. Gasket

Page 703 of 1449

ENGINE COOLING -Water Hose and Water Pipe/Radiator14-15

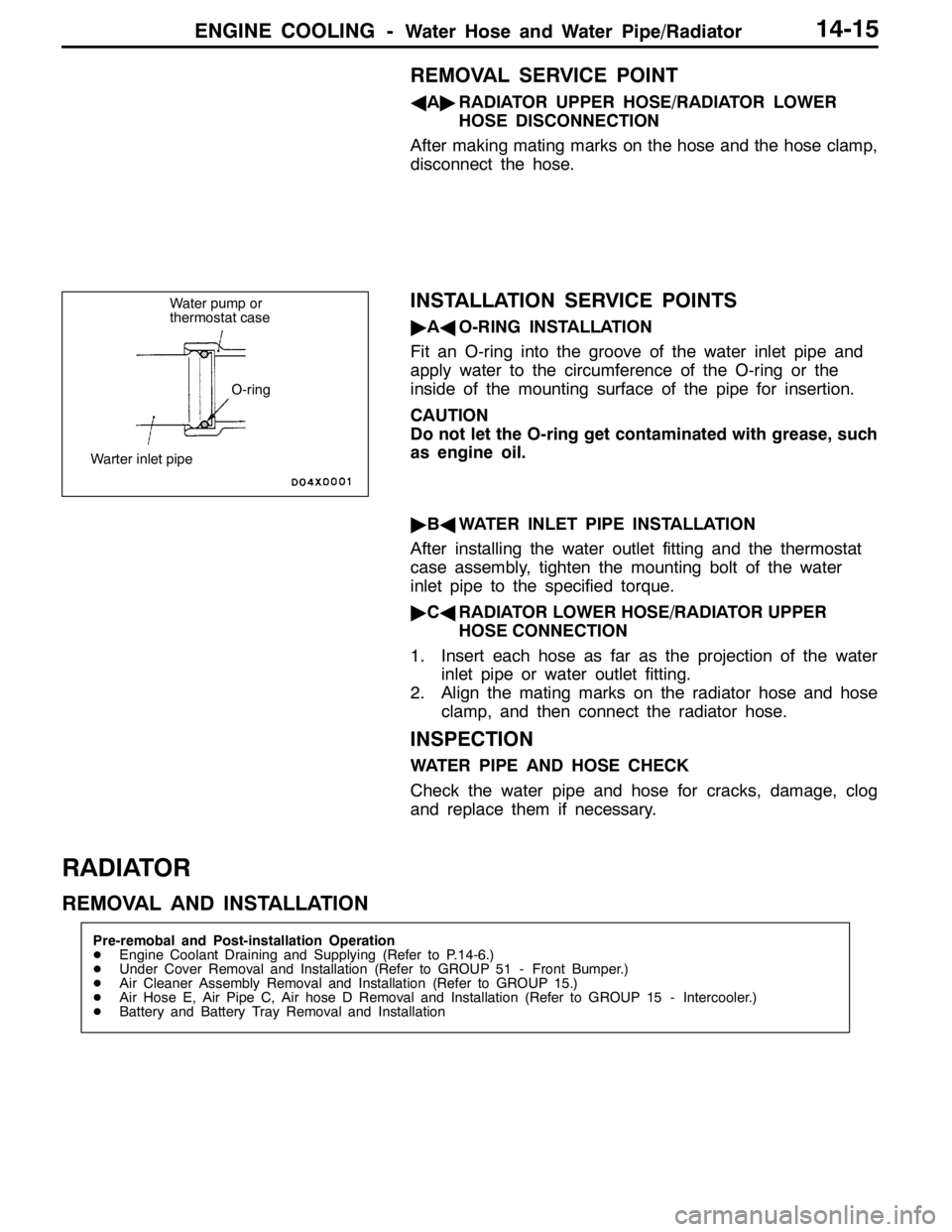

REMOVAL SERVICE POINT

AA"RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE DISCONNECTION

After making mating marks on the hose and the hose clamp,

disconnect the hose.

INSTALLATION SERVICE POINTS

"AAO-RING INSTALLATION

Fit an O-ring into the groove of the water inlet pipe and

apply water to the circumference of the O-ring or the

inside of the mounting surface of the pipe for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.

"BAWATER INLET PIPE INSTALLATION

After installing the water outlet fitting and the thermostat

case assembly, tighten the mounting bolt of the water

inlet pipe to the specified torque.

"CARADIATOR LOWER HOSE/RADIATOR UPPER

HOSE CONNECTION

1. Insert each hose as far as the projection of the water

inlet pipe or water outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

WATER PIPE AND HOSE CHECK

Check the water pipe and hose for cracks, damage, clog

and replace them if necessary.

RADIATOR

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15.)

DAir Hose E, Air Pipe C, Air hose D Removal and Installation (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

Water pump or

thermostat case

O-ring

Warter inlet pipe

Page 704 of 1449

ENGINE COOLING -Radiator14-16

1 23

45

6

7

12±2 N·m

9

16

14 19

18 12

17 10

8

13

15 10

20 21

12±2 N·m5.0±1.0 N·m

3.5±0.4 N·m

4.5±0.4 N·m4.0±0.4 N·m

13

1112±1 N·m

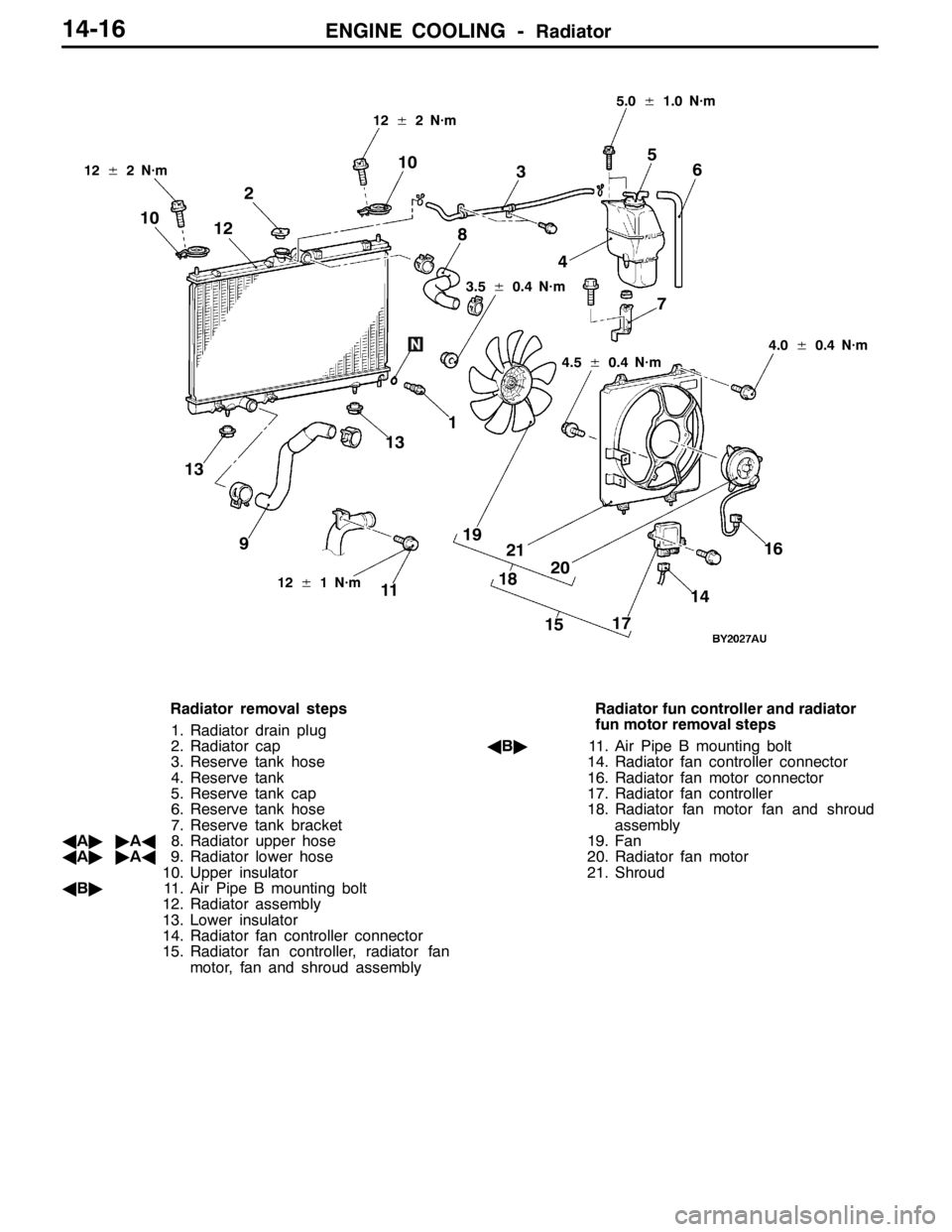

Radiator removal steps

1. Radiator drain plug

2. Radiator cap

3. Reserve tank hose

4. Reserve tank

5. Reserve tank cap

6. Reserve tank hose

7. Reserve tank bracket

AA""AA8. Radiator upper hose

AA""AA9. Radiator lower hose

10. Upper insulator

AB"11. Air Pipe B mounting bolt

12. Radiator assembly

13. Lower insulator

14. Radiator fan controller connector

15. Radiator fan controller, radiator fan

motor, fan and shroud assemblyRadiator fun controller and radiator

fun motor removal steps

AB"11. Air Pipe B mounting bolt

14. Radiator fan controller connector

16. Radiator fan motor connector

17. Radiator fan controller

18. Radiator fan motor fan and shroud

assembly

19. Fan

20. Radiator fan motor

21. Shroud

Page 705 of 1449

ENGINE COOLING -RadiatorENGINE COOLING -Radiator14-17

REMOVAL SERVICE POINTS

AA"RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE REMOVAL

After making mating marks on the radiator hose and the hose

clamp,disconnect the radiator hose.

AB"AIR PIPE B MOUNTING BOLT REMOVAL

After removing the bolt, position air pipe B out of the way

so that the pipe does not interfere with the radiator assembly

or the radiator fan motor, the fan and shroud assembly.

INSTALLATION SERVICE POINT

"AARADIATOR LOWER HOSE/RADIATOR UPPER

HOSE INSTALLATION

1. Insert each hose as far as the projection of the water

inlet pipe, water outlet fitting or radiator.

2. Align the mating marks on the radiator upper hose and

hose clamp, and then connect the radiator hose.

Page 706 of 1449

NOTES

Page 707 of 1449

15-1

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATION 3..................

SPECIAL TOOL 3............................

ON-VEHICLE SERVICE 3.....................

Turbocharger Supercharging Pressure Check 3...

Supercharging Pressure Control System

Check 4.......................................

Waste Gate Actuator Check 4...................

Waste Gate Solenoid Valve Check 5.............

Air Bypass Valve Check 5......................

Intake Manifold Pressure Check 6...............

Secondary Air Control System Check 6..........

Secondary Air Control Solenoid Valve Check 6...

Secondary Air Valve Check 7...................Vacuum Tank Check 7.........................

AIR CLEANER 8.............................

INTERCOOLER 9............................

INTERCOOLER WATER SPRAY 10............

SECONDARY AIR SUPPLY SYSTEM 14.......

INTAKE MANIFOLD 16.......................

EXHAUST MANIFOLD 19.....................

TURBOCHARGER 22.........................

EXHAUST PIPE AND MAIN MUFFLER 26.....

CATALYTIC CONVERTER

(REFER TO GROUP 17.) ....................

Page 708 of 1449

INTAKE AND EXHAUST -General Information15-2

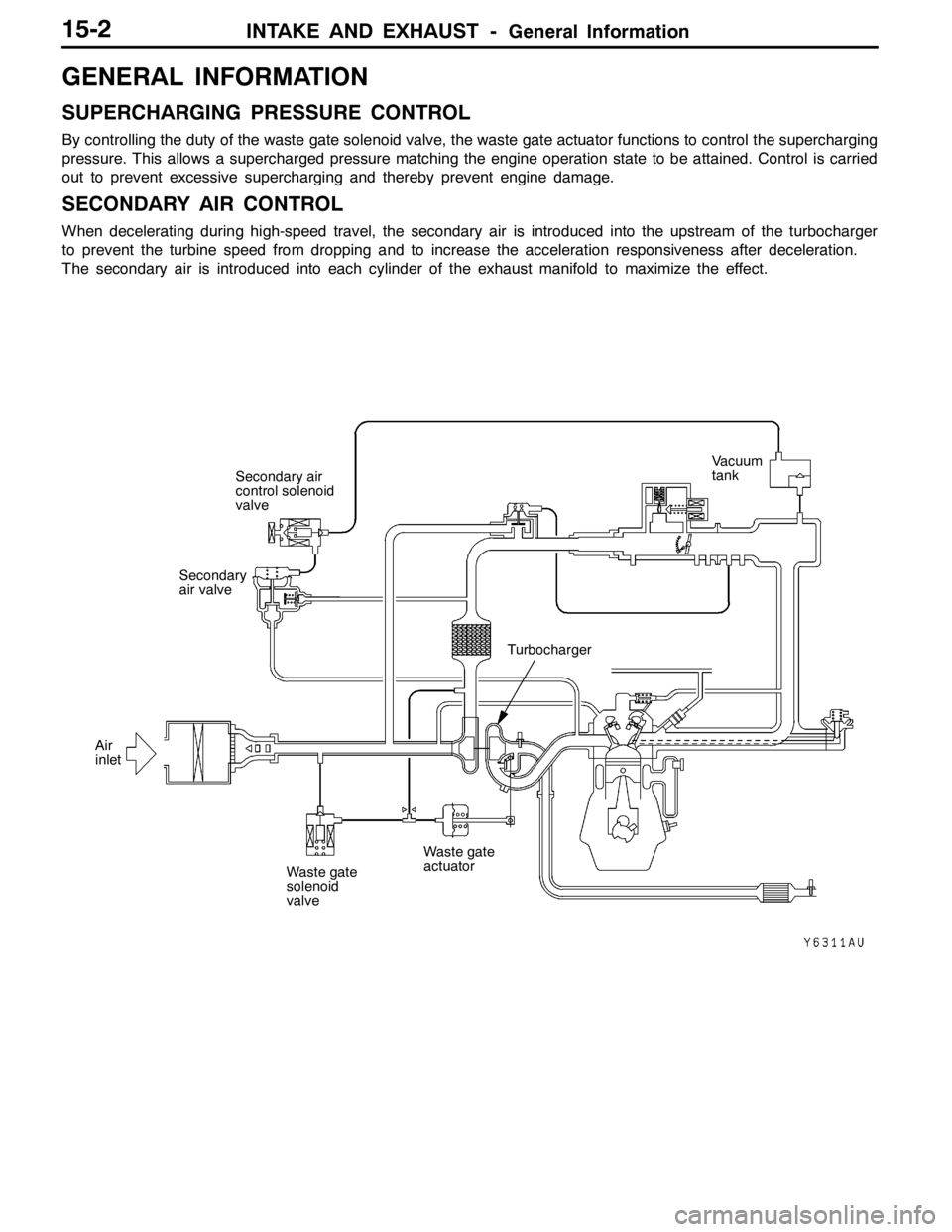

GENERAL INFORMATION

SUPERCHARGING PRESSURE CONTROL

By controlling the duty of the waste gate solenoid valve, the waste gate actuator functions to control the supercharging

pressure. This allows a supercharged pressure matching the engine operation state to be attained. Control is carried

out to prevent excessive supercharging and thereby prevent engine damage.

SECONDARY AIR CONTROL

When decelerating during high-speed travel, the secondary air is introduced into the upstream of the turbocharger

to prevent the turbine speed from dropping and to increase the acceleration responsiveness after deceleration.

The secondary air is introduced into each cylinder of the exhaust manifold to maximize the effect.

Secondary air

control solenoid

valve

Air

inletSecondary

air valve

Waste gate

solenoid

valve

Waste gate

actuator

TurbochargerVacuum

tank

Page 709 of 1449

INTAKE AND EXHAUST -Service Specifications/Special Tool/On-vehicle Service15-3

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Turbocharger supercharging pressure (waste gate solenoid

valve not operating) kPa59 - 84-

Initial activation pressure of waste gate actuator (at the stroke

of approximately 1 mm) kPaApproximately 100-

Waste gate solenoid valve coil resistance (at 20_C)Ω29 - 35-

Initial activation pressure of air bypass valve kPaApproximately 53-

Secondary air control solenoid valve coil resistance

(at 20_C)Ω29 - 35-

Manifold distortion of the installation surface mm0.15 or less0.20

SPECIAL TOOL

ToolNumberNameUse

MD998770Oxygen sensor wrenchRemoval and installation of oxygen sensor

ON-VEHICLE SERVICE

TURBOCHARGER SUPERCHARGING

PRESSURE CHECK

Caution

Two persons should be in the vehicle when the test is

conducted; the person in the passenger seat should read

the indications shown by the pressure meter.

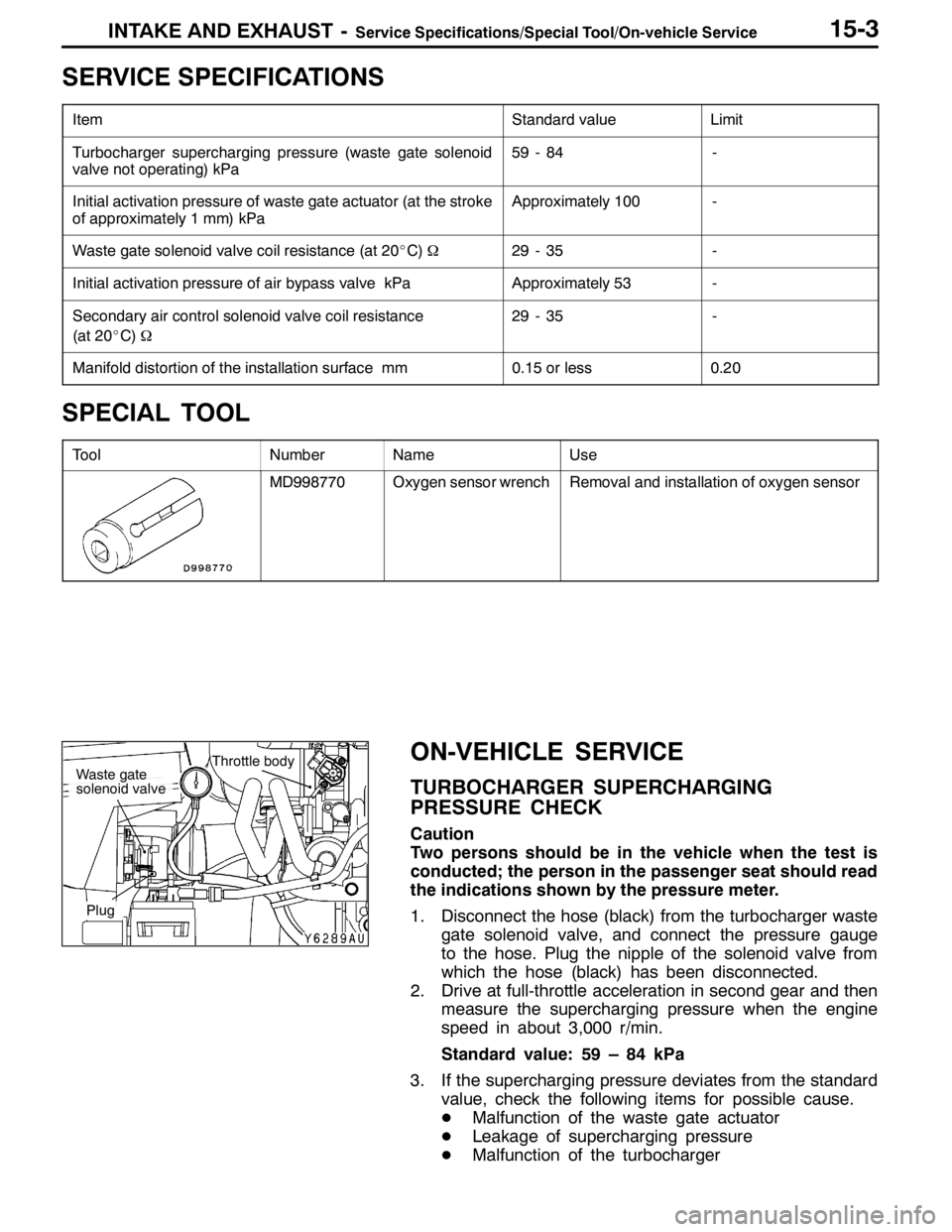

1. Disconnect the hose (black) from the turbocharger waste

gate solenoid valve, and connect the pressure gauge

to the hose. Plug the nipple of the solenoid valve from

which the hose (black) has been disconnected.

2. Drive at full-throttle acceleration in second gear and then

measure the supercharging pressure when the engine

speed in about 3,000 r/min.

Standard value: 59 – 84 kPa

3. If the supercharging pressure deviates from the standard

value, check the following items for possible cause.

DMalfunction of the waste gate actuator

DLeakage of supercharging pressure

DMalfunction of the turbocharger

Throttle bodyWaste gate

solenoid valve

Plug

Page 710 of 1449

INTAKE AND EXHAUST -On-vehicle Service15-4

4. When the indicated supercharging is more than standard

value, supercharging control may be faulty, therefore

check the followings.

DMalfunction of the waste gate actuator

DMalfunction of waste gate valve

DDisconnection or cracks of the waste gate actuator

rubber hose

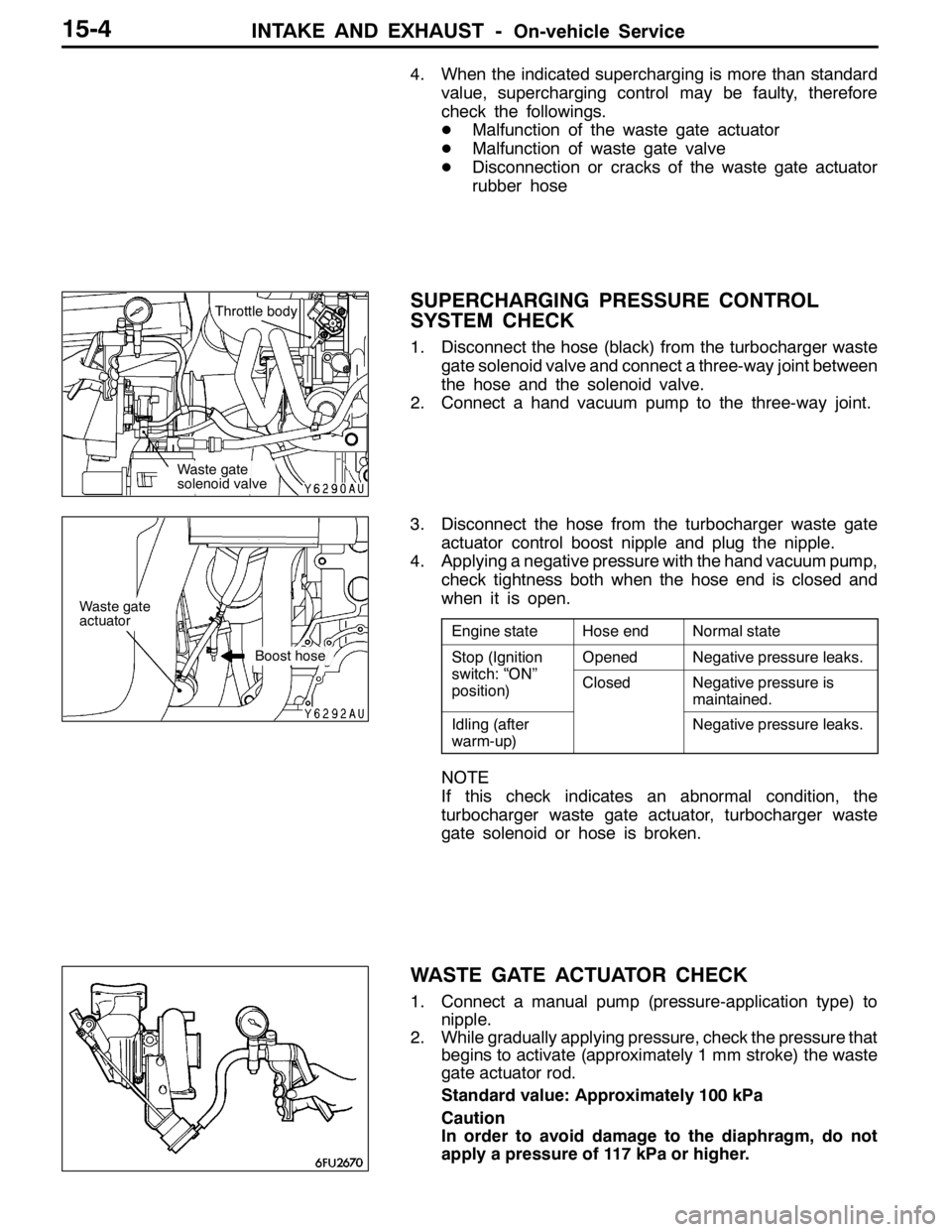

SUPERCHARGING PRESSURE CONTROL

SYSTEM CHECK

1. Disconnect the hose (black) from the turbocharger waste

gate solenoid valve and connect a three-way joint between

the hose and the solenoid valve.

2. Connect a hand vacuum pump to the three-way joint.

3. Disconnect the hose from the turbocharger waste gate

actuator control boost nipple and plug the nipple.

4. Applying a negative pressure with the hand vacuum pump,

check tightness both when the hose end is closed and

when it is open.

Engine stateHose endNormal state

Stop (Ignition

it h“ON”

OpenedNegative pressure leaks.p(g

switch: “ON”

position)ClosedNegative pressure is

maintained.

Idling (after

warm-up)Negative pressure leaks.

NOTE

If this check indicates an abnormal condition, the

turbocharger waste gate actuator, turbocharger waste

gate solenoid or hose is broken.

WASTE GATE ACTUATOR CHECK

1. Connect a manual pump (pressure-application type) to

nipple.

2. While gradually applying pressure, check the pressure that

begins to activate (approximately 1 mm stroke) the waste

gate actuator rod.

Standard value: Approximately 100 kPa

Caution

In order to avoid damage to the diaphragm, do not

apply a pressure of 117 kPa or higher.

Waste gate

solenoid valveThrottle body

Waste gate

actuator

Boost hose