MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 731 of 1449

INTAKE AND EXHAUST -Turbocharger15-25

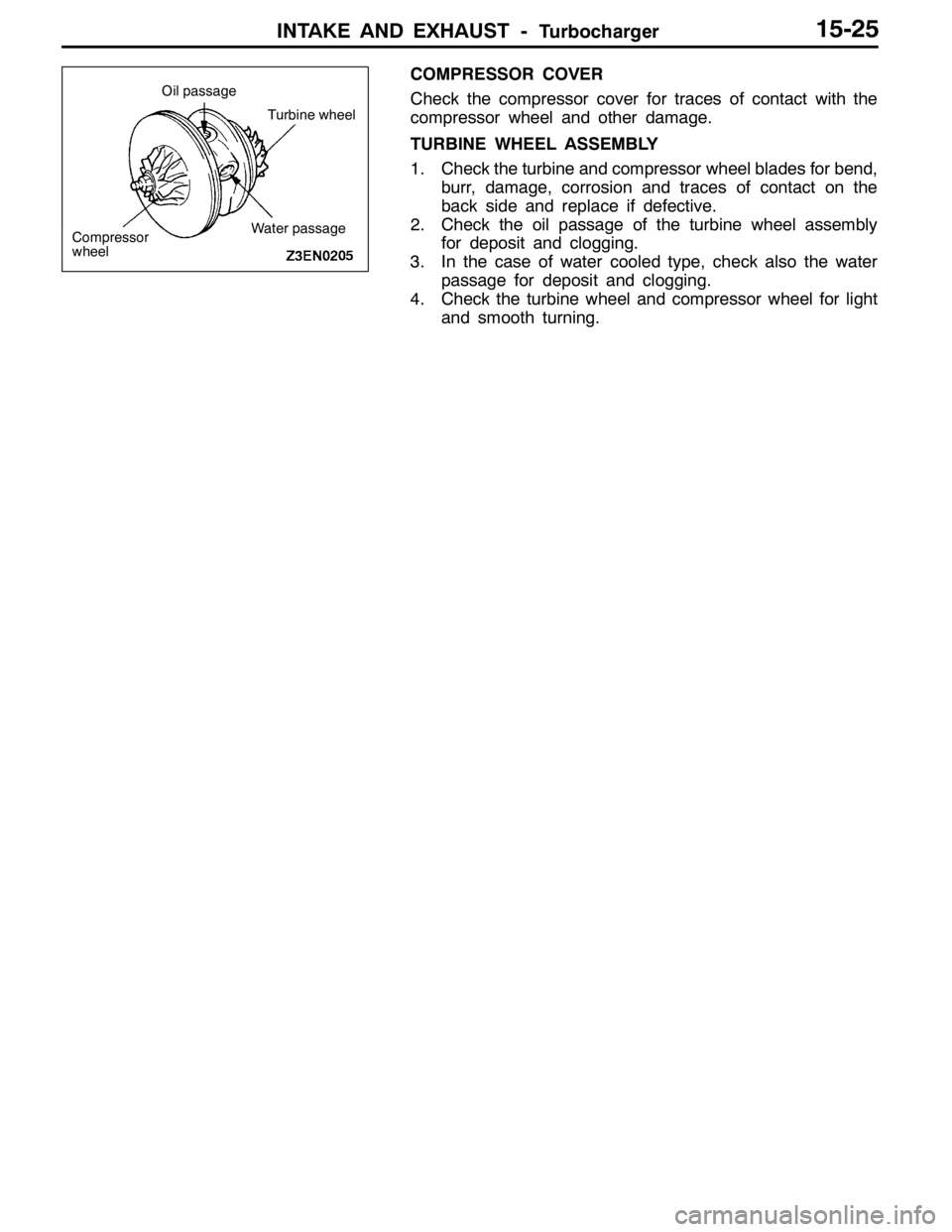

COMPRESSOR COVER

Check the compressor cover for traces of contact with the

compressor wheel and other damage.

TURBINE WHEEL ASSEMBLY

1. Check the turbine and compressor wheel blades for bend,

burr, damage, corrosion and traces of contact on the

back side and replace if defective.

2. Check the oil passage of the turbine wheel assembly

for deposit and clogging.

3. In the case of water cooled type, check also the water

passage for deposit and clogging.

4. Check the turbine wheel and compressor wheel for light

and smooth turning.

Oil passage

Turbine wheel

Water passageCompressor

wheel

Page 732 of 1449

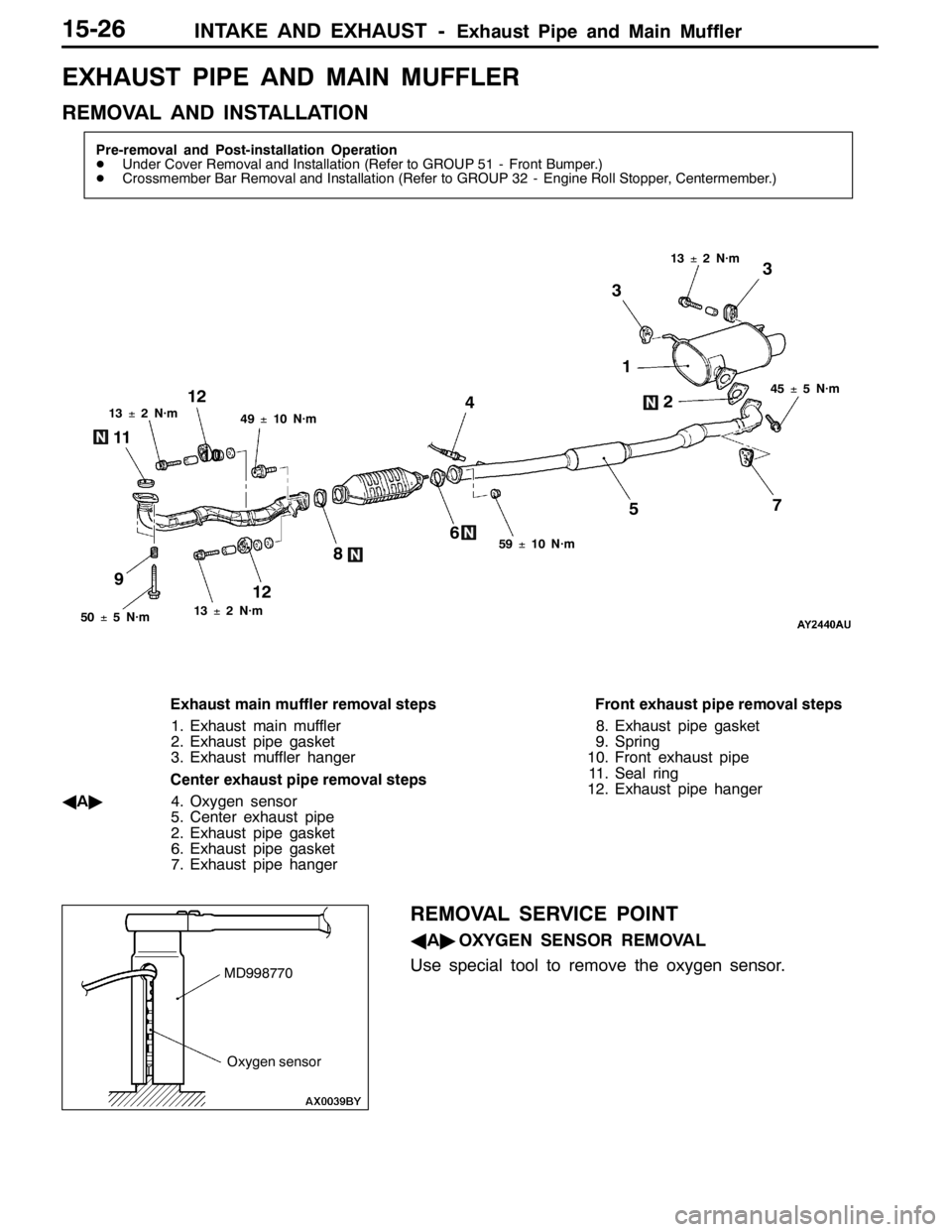

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler15-26

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DCrossmember Bar Removal and Installation (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

91

2 3

5

8

11

6 12

10

3

7

12

13±2 N·m

50±5 N·m13±2 N·m49±10 N·m

59±10 N·m13±2 N·m

45±5 N·m4

Exhaust main muffler removal steps

1. Exhaust main muffler

2. Exhaust pipe gasket

3. Exhaust muffler hanger

Center exhaust pipe removal steps

AA"4. Oxygen sensor

5. Center exhaust pipe

2. Exhaust pipe gasket

6. Exhaust pipe gasket

7. Exhaust pipe hangerFront exhaust pipe removal steps

8. Exhaust pipe gasket

9. Spring

10. Front exhaust pipe

11. Seal ring

12. Exhaust pipe hanger

REMOVAL SERVICE POINT

AA"OXYGEN SENSOR REMOVAL

Use special tool to remove the oxygen sensor.

MD998770

Oxygen sensor

Page 733 of 1449

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3...............

SPECIAL TOOL 3..........................

ON-VEHICLE SERVICE 4...................

Alternator Output Line Voltage Drop Test 4......

Output Current Test 5........................

Regulated Voltage Test 7.....................

Waveform Check Using An Analyzer 8..........

ALTERNATOR 10..........................

STARTING SYSTEM 17................

GENERAL INFORMATION 17...............

SERVICE SPECIFICATIONS 17..............

ON-VEHICLE SERVICE 18..................

STARTER 18..............................

IGNITION SYSTEM 26.................

GENERAL INFORMATION 26...............

SERVICE SPECIFICATIONS 27..............

SPECIAL TOOL 27.........................

ON-VEHICLE SERVICE 28..................

Ignition Coil (With Built-in Power Transistor)

Check 28...................................

Resistive Cord Check 28.....................

Spark Plug Check, Cleaning and Replacement 29

Camshaft Position Sensor Check 29...........

Crank Angle Sensor Check 29................

Detonation Sensor Check 29..................

Waveform Check Using An Analyzer 30........

IGNITION COIL 34.........................

CAMSHAFT POSITION SENSOR 35.........

CRANK ANGLE SENSOR 35................

DETONATION SENSOR 37.................

Page 734 of 1449

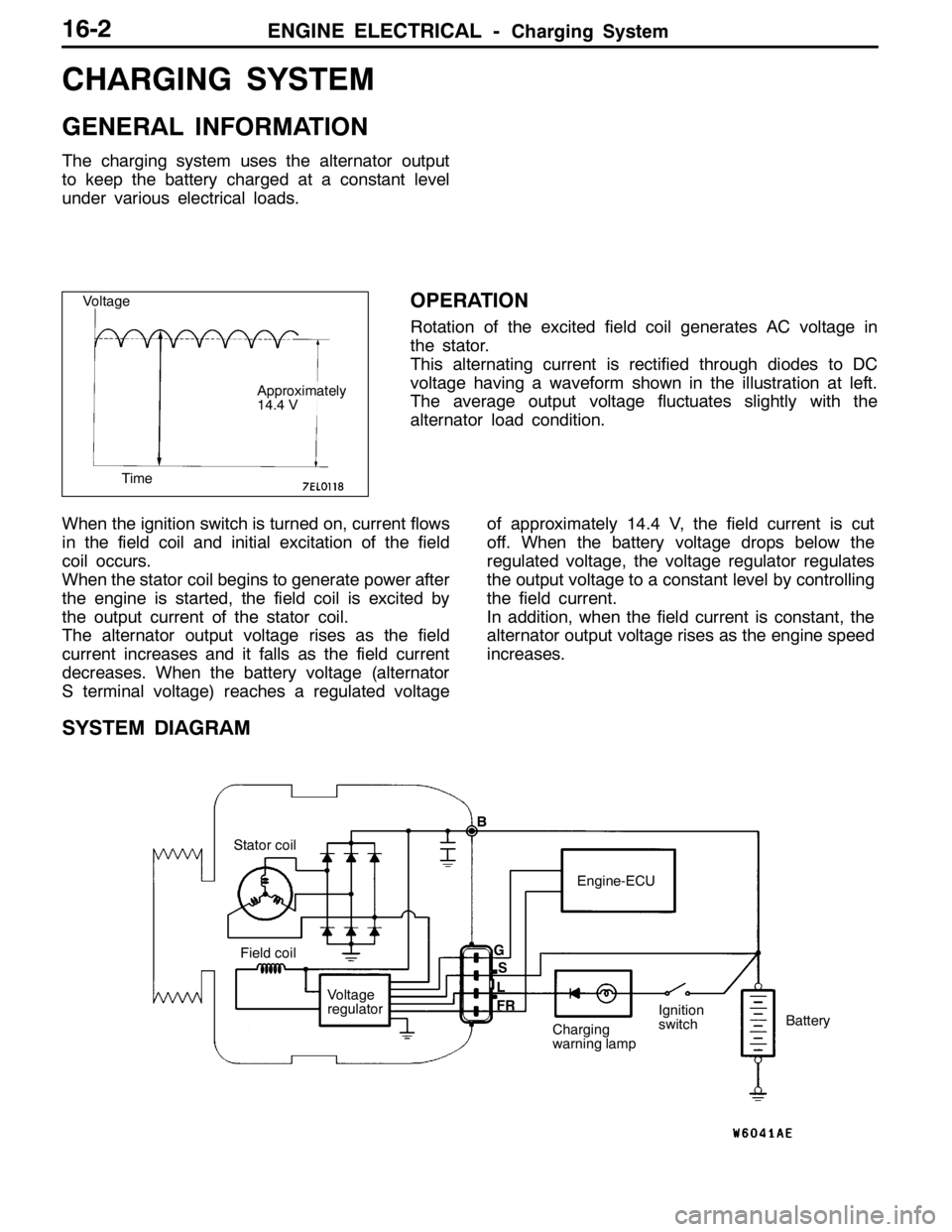

ENGINE ELECTRICAL -Charging System16-2

CHARGING SYSTEM

GENERAL INFORMATION

The charging system uses the alternator output

to keep the battery charged at a constant level

under various electrical loads.

OPERATION

Rotation of the excited field coil generates AC voltage in

the stator.

This alternating current is rectified through diodes to DC

voltage having a waveform shown in the illustration at left.

The average output voltage fluctuates slightly with the

alternator load condition.

When the ignition switch is turned on, current flows

in the field coil and initial excitation of the field

coil occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by

the output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When the battery voltage (alternator

S terminal voltage) reaches a regulated voltageof approximately 14.4 V, the field current is cut

off. When the battery voltage drops below the

regulated voltage, the voltage regulator regulates

the output voltage to a constant level by controlling

the field current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

SYSTEM DIAGRAM

Stator coil

Field coil

Voltage

regulatorEngine-ECU

Charging

warning lampIgnition

switchBattery B

G

L

FRS

Voltage

Time

Approximately

14.4 V

Page 735 of 1449

ENGINE ELECTRICAL -Charging System16-3

ALTERNATOR SPECIFICATIONS

ItemsSpecifications

TypeBattery voltage sensing

Rated output V/A12/90

Voltage regulatorElectronic built-in type

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Alternator output line voltage drop (at 30 A) V-max. 0.3

Regulated voltage ambient

tempatvoltageregulatorV

-20_C14.2 - 15.4-

temp. atvoltage regulatorV

20_C13.9 - 14.9-

60_C13.4 - 14.6-

80_C13.1 - 14.5-

Output current-70 % of normal output current

Rotor coil resistanceΩApprox. 3 - 5-

Protrusion length of brush mm-2

SPECIAL TOOL

ToolNumberNameUse

MB991519Alternator test

harnessChecking the alternator (S terminal voltage)

Page 736 of 1449

ENGINE ELECTRICAL -Charging System16-4

ON-VEHICLE SERVICE

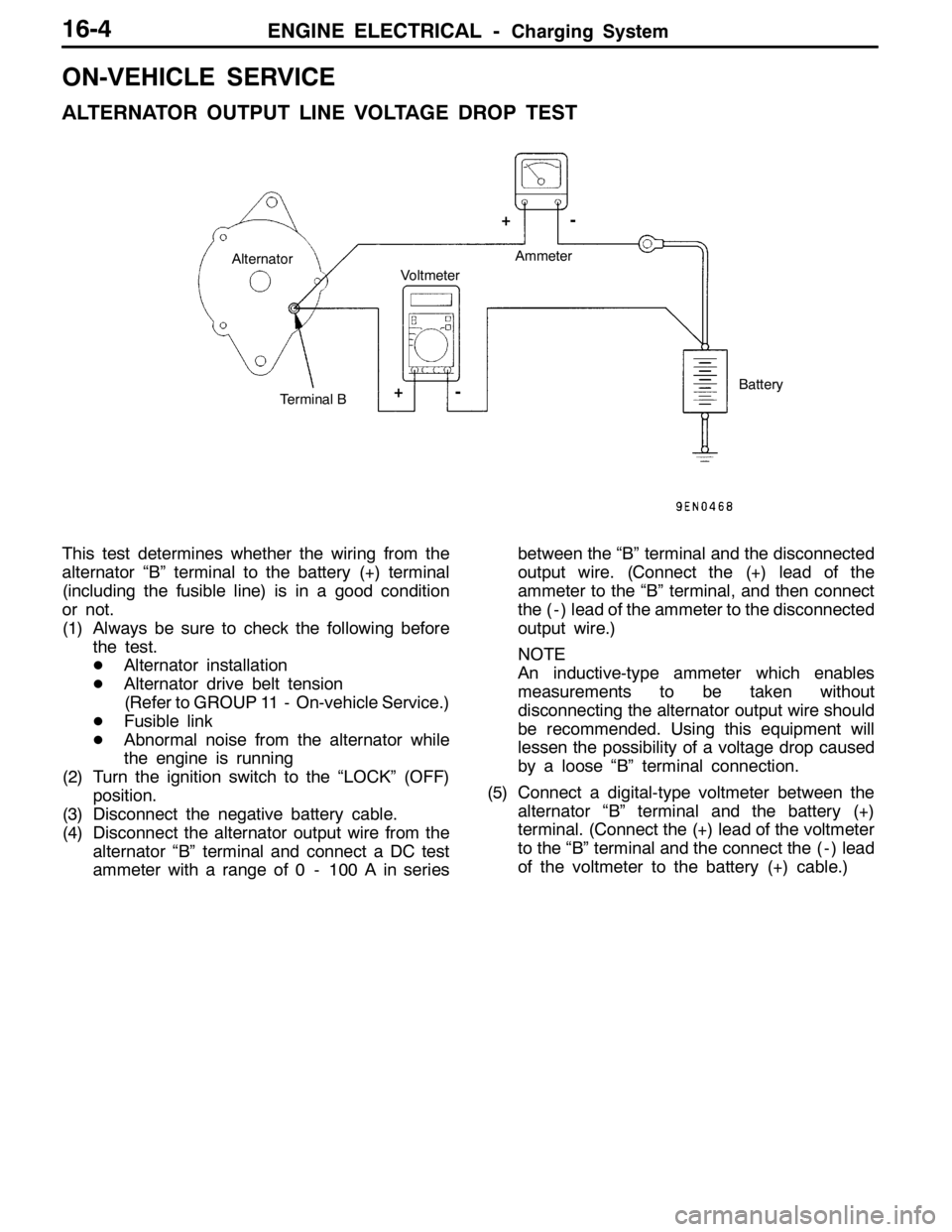

ALTERNATOR OUTPUT LINE VOLTAGE DROP TEST

Alternator

Terminal BVoltmeterAmmeter

Battery

+-

+-

This test determines whether the wiring from the

alternator “B” terminal to the battery (+) terminal

(including the fusible line) is in a good condition

or not.

(1) Always be sure to check the following before

the test.

DAlternator installation

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Disconnect the alternator output wire from the

alternator “B” terminal and connect a DC test

ammeter with a range of 0 - 100 A in seriesbetween the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal, and then connect

the ( - ) lead of the ammeter to the disconnected

output wire.)

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended. Using this equipment will

lessen the possibility of a voltage drop caused

by a loose “B” terminal connection.

(5) Connect a digital-type voltmeter between the

alternator “B” terminal and the battery (+)

terminal. (Connect the (+) lead of the voltmeter

to the “B” terminal and the connect the ( - ) lead

of the voltmeter to the battery (+) cable.)

Page 737 of 1449

ENGINE ELECTRICAL -Charging System16-5

(6) Reconnect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Start the engine.

(10)With the engine running at 2,500 r/min, turn

the headlamps and other lamps on and off

to adjust the alternator load so that the value

displayed on the ammeter is slightly above 30

A.

Adjust the engine speed by gradually

decreasing it until the value displayed on the

ammeter is 30 A. Take a reading of the value

displayed on the voltmeter at this time.

Limit: max. 0.3 V

NOTE

When the alternator output is high and the value

displayed on the ammeter does not decrease

until 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is max.

0.4 V.(11) If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction

in the alternator output wire, so check the wiring

between the alternator “B” terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

(12)After the test, run the engine at idle.

(13)Turn off all lamps and the ignition switch.

(14)Remove the tachometer or the MUT-II.

(15)Disconnect the negative battery cable.

(16)Disconnect the ammeter and voltmeter.

(17)Connect the alternator output wire to the

alternator “B” terminal.

(18)Connect the negative battery cable.

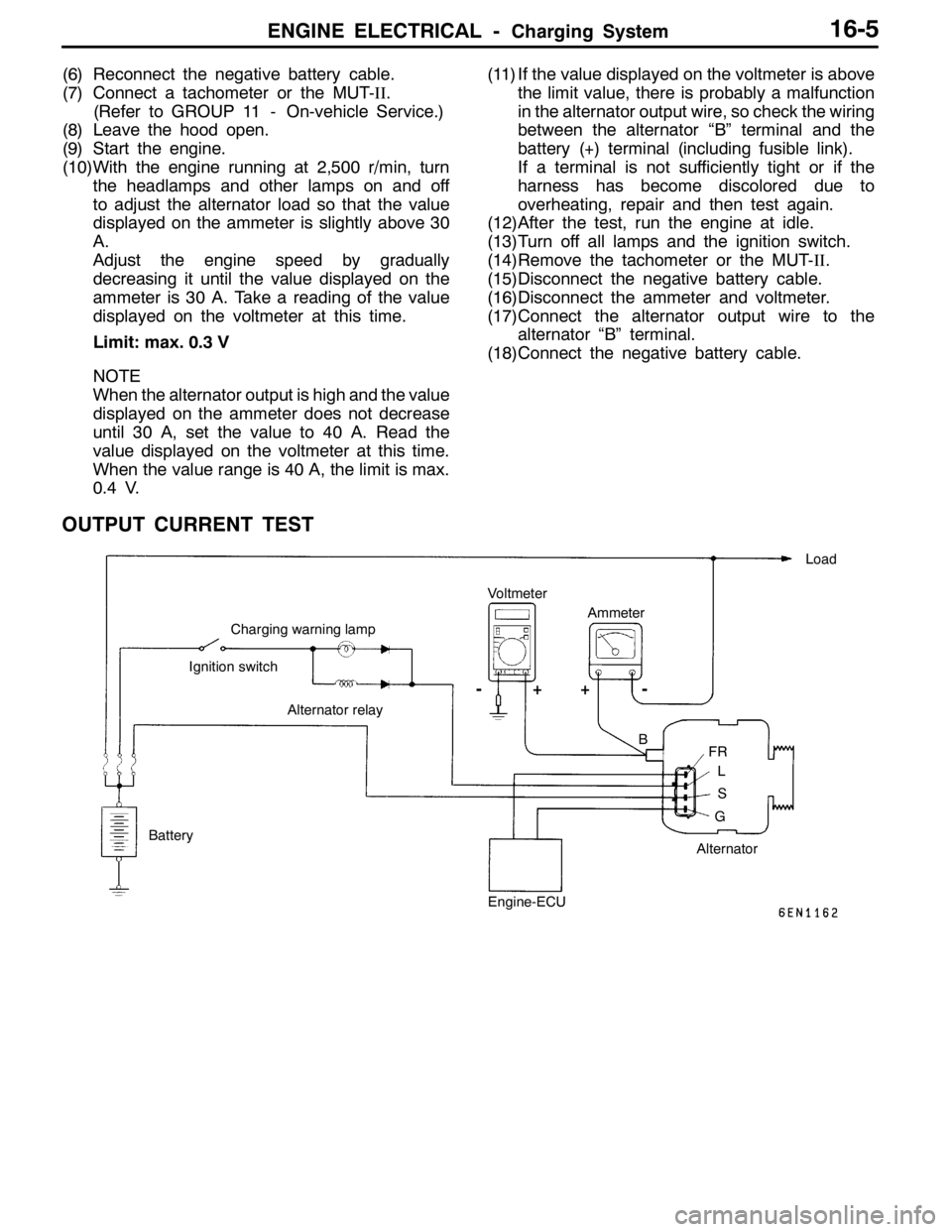

OUTPUT CURRENT TEST

Charging warning lampVoltmeter

Ammeter

Ignition switch

Alternator relayLoad

Battery

Engine-ECUAlternatorFR

L

S

G

+ -+-

B

Page 738 of 1449

ENGINE ELECTRICAL -Charging System16-6

This test determines whether the alternator output

current is normal.

(1) Before the test, always be sure to check the

following.

DAlternator installation

DBattery (Refer to GROUP 54 - Battery.)

NOTE

The battery should be slightly discharged.

The load needed by a fully-charged battery

is insufficient for an accurate test.

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running.

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Disconnect the alternator output wire from the

alternator “B” terminal. Connect a DC test

ammeter with a range of 0 - 100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal. Connect the ( - )

lead of the ammeter to the disconnected output

wire.)

Caution

Never use clips but tighten bolts and nuts

to connect the line. Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended.

(5) Connect a voltmeter with a range of 0 - 20 V

between the alternator “B” terminal and the

earth. (Connect the (+) lead of the voltmeter

to the “B” terminal, and then connect the ( - )

lead of the voltmeter to the earth.)

(6) Connect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “B” terminal and the battery (+)

terminal.(10)Turn the light switch on to turn on headlamps

and then start the engine.

(11) Immediately after setting the headlamps to high

beam and turning the heater blower switch to

the high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70 % of normal current output

NOTE

DFor the nominal current output, refer to the

Alternator Specifications.

DBecause the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.

DThe current output value will depend on

the electrical load and the temperature of

the alternator body.

DIf the electrical load is small while testing,

the specified level of current may not be

output even though the alternator is normal.

In such cases, increase the electrical load

by leaving the headlamps turned on for

some time to discharge the battery or by

using the lighting system in another vehicle,

and then test again.

DThe specified level of current also may not

be output if the temperature of the alternator

body or the ambient temperature is too

high. In such cases, cool the alternator and

then test again.

(12)The reading on the ammeter should be above

the limit value. If the reading is below the limit

value and the alternator output wire is normal,

remove the alternator from the engine and

check the alternator.

(13)Run the engine at idle after the test.

(14)Turn the ignition switch to the “LOCK” (OFF)

position.

(15)Remove the tachometer or the MUT-II.

(16)Disconnect the negative battery cable.

(17)Disconnect the ammeter and voltmeter.

(18)Connect the alternator output wire to the

alternator “B” terminal.

(19)Connect the negative battery cable.

Page 739 of 1449

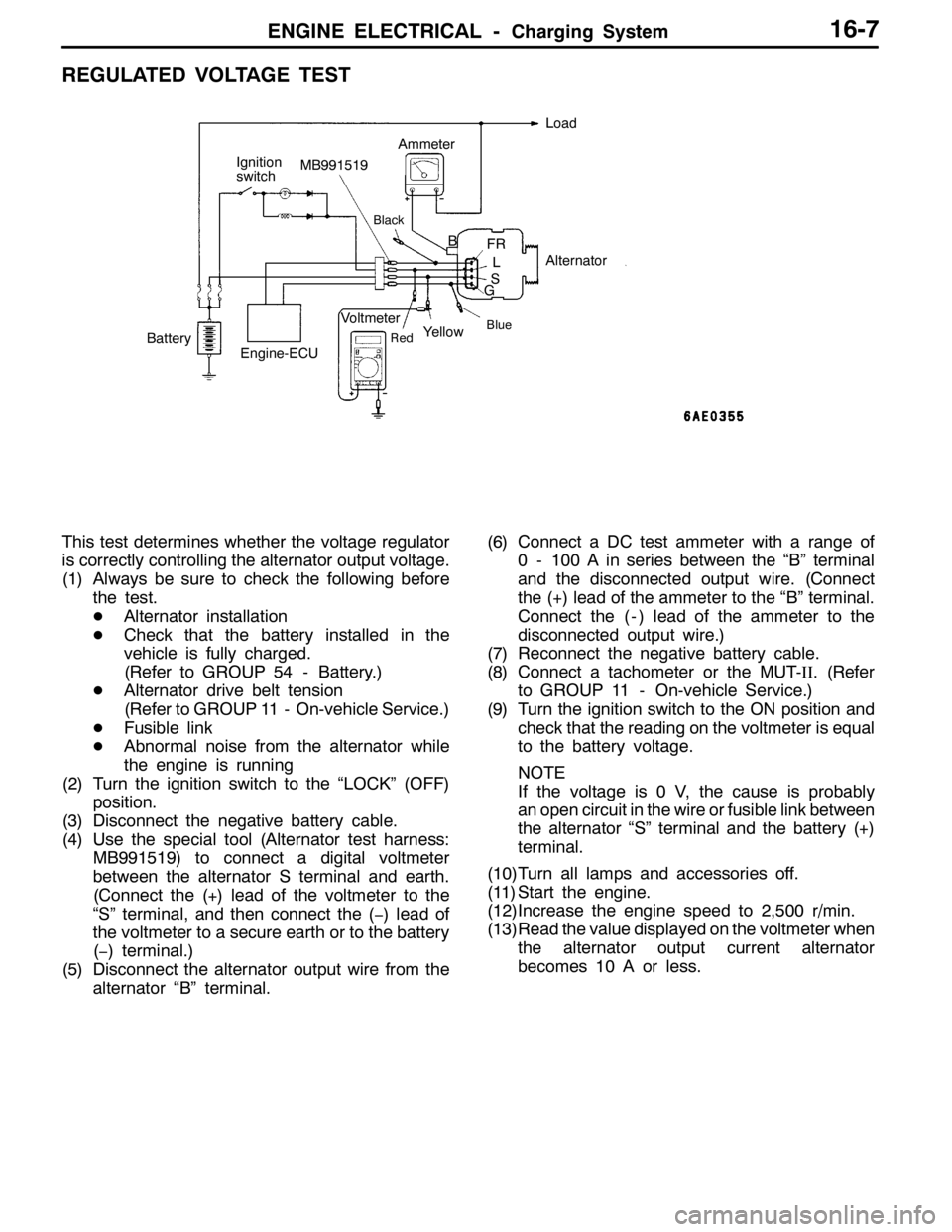

ENGINE ELECTRICAL -Charging System16-7

REGULATED VOLTAGE TEST

B

BlueRed

Ignition

switchLoad

FR

L

S

GMB991519

Alternator

BatteryVoltmeterAmmeter

Yellow

Engine-ECU

Black

This test determines whether the voltage regulator

is correctly controlling the alternator output voltage.

(1) Always be sure to check the following before

the test.

DAlternator installation

DCheck that the battery installed in the

vehicle is fully charged.

(Refer to GROUP 54 - Battery.)

DAlternator drive belt tension

(Refer to GROUP 11 - On-vehicle Service.)

DFusible link

DAbnormal noise from the alternator while

the engine is running

(2) Turn the ignition switch to the “LOCK” (OFF)

position.

(3) Disconnect the negative battery cable.

(4) Use the special tool (Alternator test harness:

MB991519) to connect a digital voltmeter

between the alternator S terminal and earth.

(Connect the (+) lead of the voltmeter to the

“S” terminal, and then connect the (−) lead of

the voltmeter to a secure earth or to the battery

(−) terminal.)

(5) Disconnect the alternator output wire from the

alternator “B” terminal.(6) Connect a DC test ammeter with a range of

0 - 100 A in series between the “B” terminal

and the disconnected output wire. (Connect

the (+) lead of the ammeter to the “B” terminal.

Connect the ( - ) lead of the ammeter to the

disconnected output wire.)

(7) Reconnect the negative battery cable.

(8) Connect a tachometer or the MUT-II. (Refer

to GROUP 11 - On-vehicle Service.)

(9) Turn the ignition switch to the ON position and

check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “S” terminal and the battery (+)

terminal.

(10)Turn all lamps and accessories off.

(11) Start the engine.

(12)Increase the engine speed to 2,500 r/min.

(13)Read the value displayed on the voltmeter when

the alternator output current alternator

becomes 10 A or less.

Page 740 of 1449

ENGINE ELECTRICAL -Charging System16-8

(14)If the voltage reading conforms to the value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

(15)After the test, lower the engine speed to the

idle speed.

(16)Turn the ignition switch to the “LOCK” (OFF)

position.(17)Remove the tachometer or the MUT-II.

(18)Disconnect the negative battery cable.

(19)Disconnect the ammeter and voltmeter.

(20)Connect the alternator output wire to the

alternator “B” terminal.

(21)Remove the special tool, and return the

connector to the original condition.

(22)Connect the negative battery cable.

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient temperature_CVoltage V

Terminal “S”-2014.2 - 15.4

2013.9 - 14.9

6013.4 - 14.6

8013.1 - 14.5

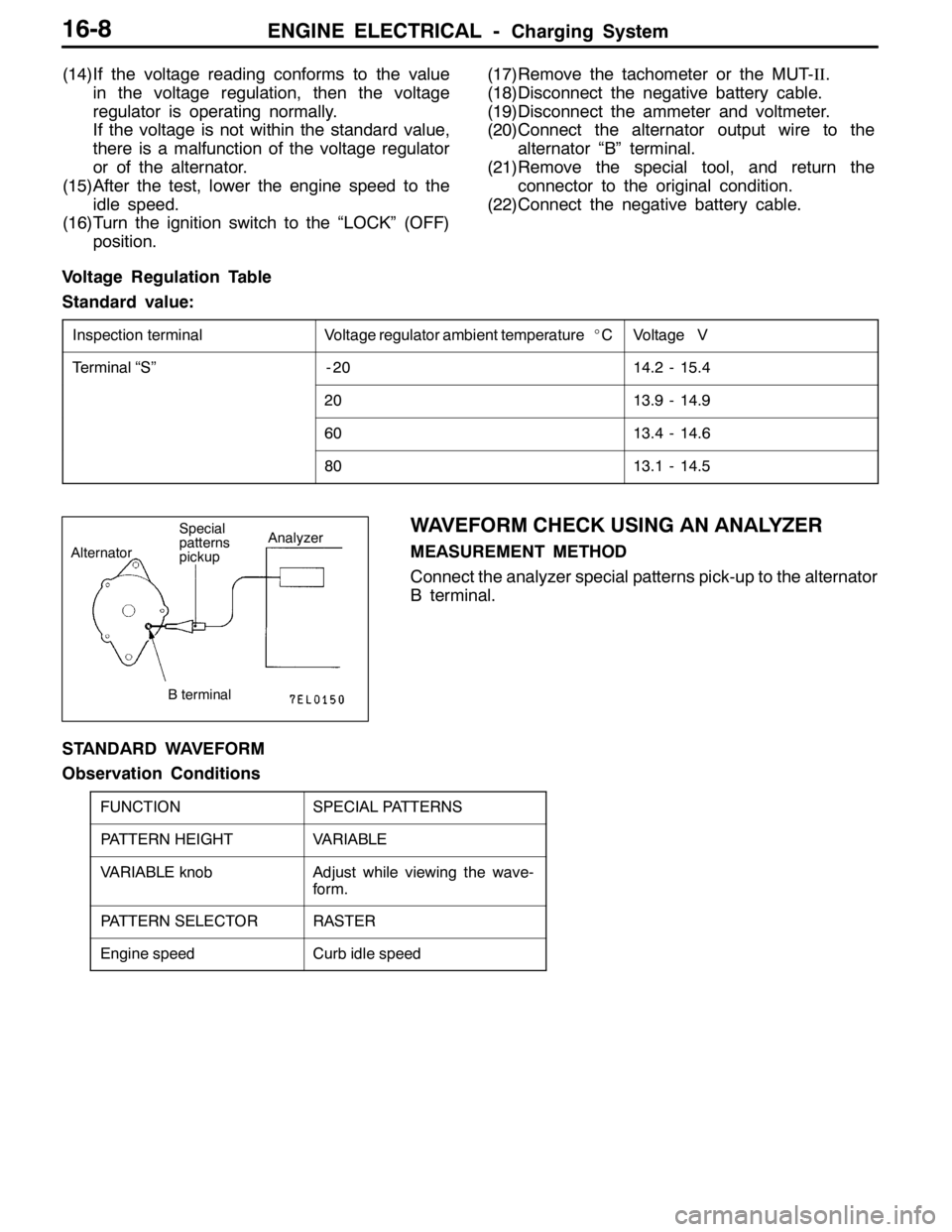

WAVEFORM CHECK USING AN ANALYZER

MEASUREMENT METHOD

Connect the analyzer special patterns pick-up to the alternator

B terminal.

STANDARD WAVEFORM

Observation Conditions

FUNCTIONSPECIAL PATTERNS

PATTERN HEIGHTVARIABLE

VARIABLE knobAdjust while viewing the wave-

form.

PATTERN SELECTORRASTER

Engine speedCurb idle speed

AlternatorSpecial

patterns

pickupAnalyzer

B terminal