MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 691 of 1449

ENGINE COOLING -Special Tools/Troubleshooting14-3

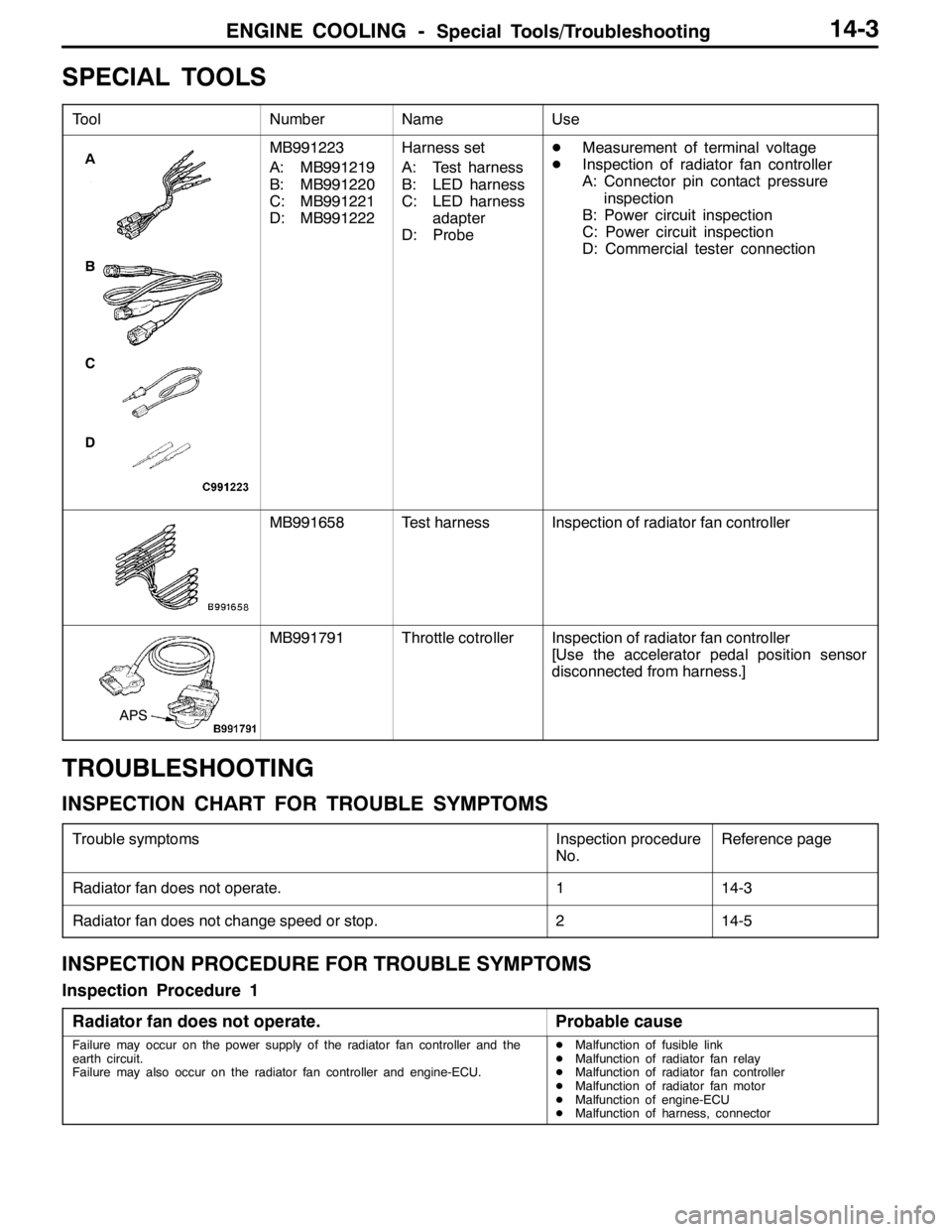

SPECIAL TOOLS

ToolNumberNameUse

A

B

C

DMB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeDMeasurement of terminal voltage

DInspection of radiator fan controller

A: Connector pin contact pressure

inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

MB991658Test harnessInspection of radiator fan controller

APS

MB991791Throttle cotrollerInspection of radiator fan controller

[Use the accelerator pedal position sensor

disconnected from harness.]

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomsInspection procedure

No.Reference page

Radiator fan does not operate.114-3

Radiator fan does not change speed or stop.214-5

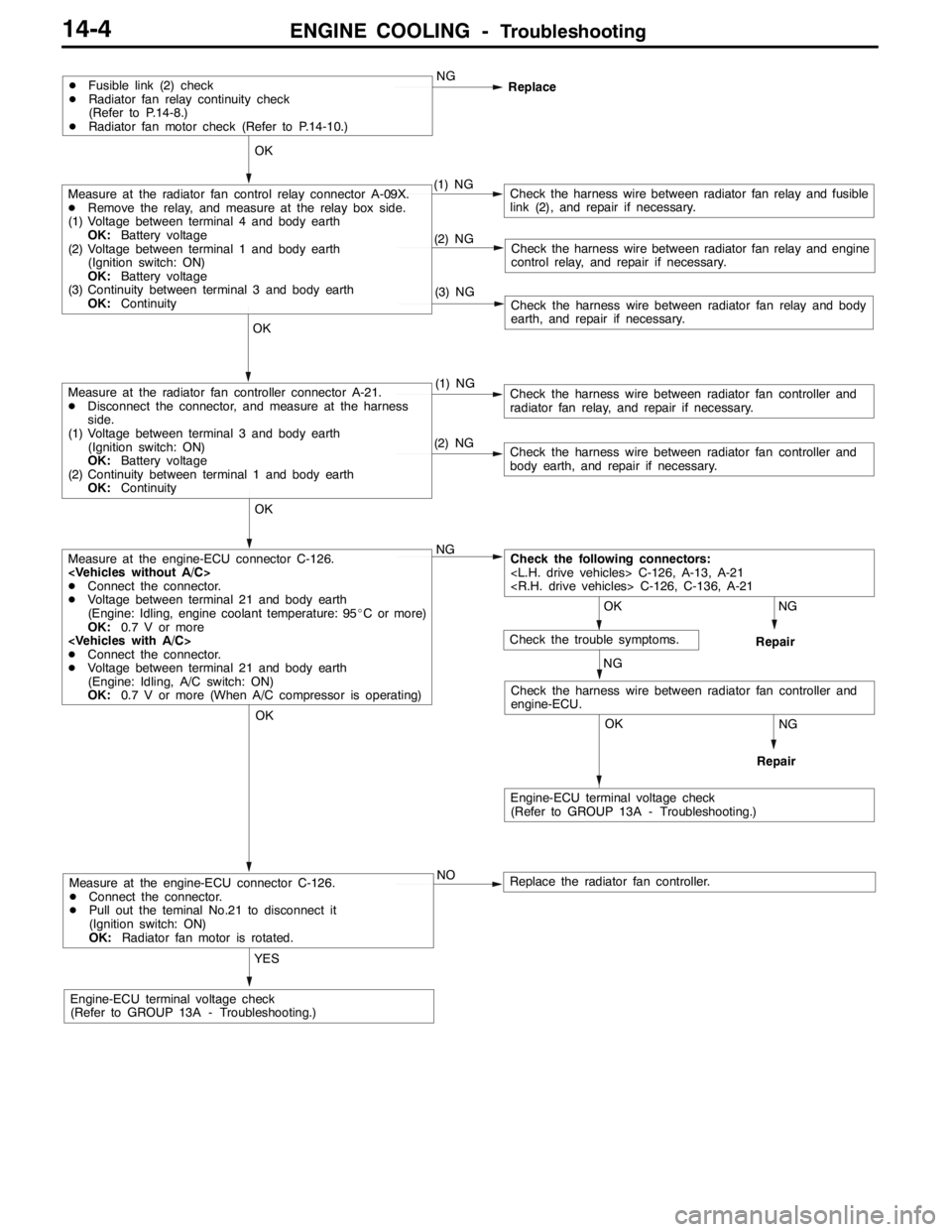

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure 1

Radiator fan does not operate.

Probable cause

Failure may occur on the power supply of the radiator fan controller and the

earth circuit.

Failure may also occur on the radiator fan controller and engine-ECU.DMalfunction of fusible link

DMalfunction of radiator fan relay

DMalfunction of radiator fan controller

DMalfunction of radiator fan motor

DMalfunction of engine-ECU

DMalfunction of harness, connector

Page 692 of 1449

ENGINE COOLING -Troubleshooting14-4

Measure at the engine-ECU connector C-126.

DConnect the connector.

DPull out the teminal No.21 to disconnect it

(Ignition switch: ON)

OK:Radiator fan motor is rotated.

YES

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)NO

Replace the radiator fan controller.

NG

Repair

OK

NG

Repair

OK

Check the harness wire between radiator fan controller and

engine-ECU.

Measure at the engine-ECU connector C-126.

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 95_C or more)

OK:0.7 V or more

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, A/C switch: ON)

OK:0.7 V or more (When A/C compressor is operating)NG

(2) NGCheck the harness wire between radiator fan controller and

body earth, and repair if necessary.

OK

Measure at the radiator fan controller connector A-21.

DDisconnect the connector, and measure at the harness

side.

(1) Voltage between terminal 3 and body earth

(Ignition switch: ON)

OK:Battery voltage

(2) Continuity between terminal 1 and body earth

OK:Continuity(1) NGCheck the harness wire between radiator fan controller and

radiator fan relay, and repair if necessary.

(3) NGCheck the harness wire between radiator fan relay and body

earth, and repair if necessary.

(2) NGCheck the harness wire between radiator fan relay and engine

control relay, and repair if necessary.

OK

Measure at the radiator fan control relay connector A-09X.

DRemove the relay, and measure at the relay box side.

(1) Voltage between terminal 4 and body earth

OK:Battery voltage

(2) Voltage between terminal 1 and body earth

(Ignition switch: ON)

OK:Battery voltage

(3) Continuity between terminal 3 and body earth

OK:Continuity(1) NGCheck the harness wire between radiator fan relay and fusible

link (2), and repair if necessary.

DFusible link (2) check

DRadiator fan relay continuity check

(Refer to P.14-8.)

DRadiator fan motor check (Refer to P.14-10.)NG

Replace

OK

OK

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)

Check the following connectors:

NG

Check the trouble symptoms.

Page 693 of 1449

ENGINE COOLING -Troubleshooting14-5

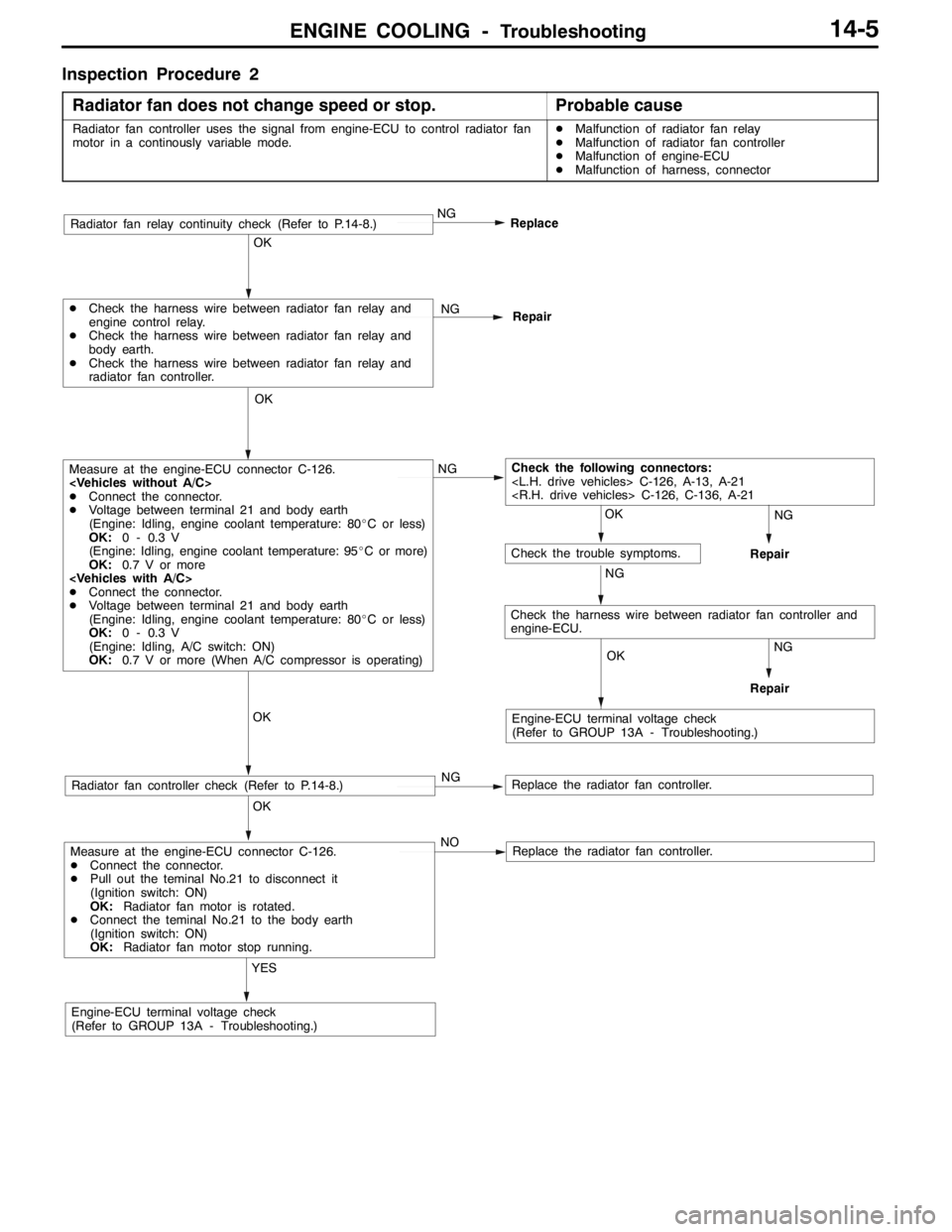

Inspection Procedure 2

Radiator fan does not change speed or stop.

Probable cause

Radiator fan controller uses the signal from engine-ECU to control radiator fan

motor in a continously variable mode.DMalfunction of radiator fan relay

DMalfunction of radiator fan controller

DMalfunction of engine-ECU

DMalfunction of harness, connector

Measure at the engine-ECU connector C-126.

DConnect the connector.

DPull out the teminal No.21 to disconnect it

(Ignition switch: ON)

OK:Radiator fan motor is rotated.

DConnect the teminal No.21 to the body earth

(Ignition switch: ON)

OK:Radiator fan motor stop running.

YES

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)NO

Replace the radiator fan controller.

OK

Radiator fan controller check (Refer to P.14-8.)NGReplace the radiator fan controller.

OK

Measure at the engine-ECU connector C-126.

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 80_C or less)

OK:0 - 0.3 V

(Engine: Idling, engine coolant temperature: 95_C or more)

OK:0.7 V or more

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 80_C or less)

OK:0 - 0.3 V

(Engine: Idling, A/C switch: ON)

OK:0.7 V or more (When A/C compressor is operating)NG

OK

DCheck the harness wire between radiator fan relay and

engine control relay.

DCheck the harness wire between radiator fan relay and

body earth.

DCheck the harness wire between radiator fan relay and

radiator fan controller.NG

Repair

NG

Replace

OK

OK

OK

Check the following connectors:

NG

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)

Check the trouble symptoms.

NG

NG

Repair

Repair

Radiator fan relay continuity check (Refer to P.14-8.)

Check the harness wire between radiator fan controller and

engine-ECU.

Page 694 of 1449

ENGINE COOLING -On-vehicle Service14-6

ON-VEHICLE SERVICE

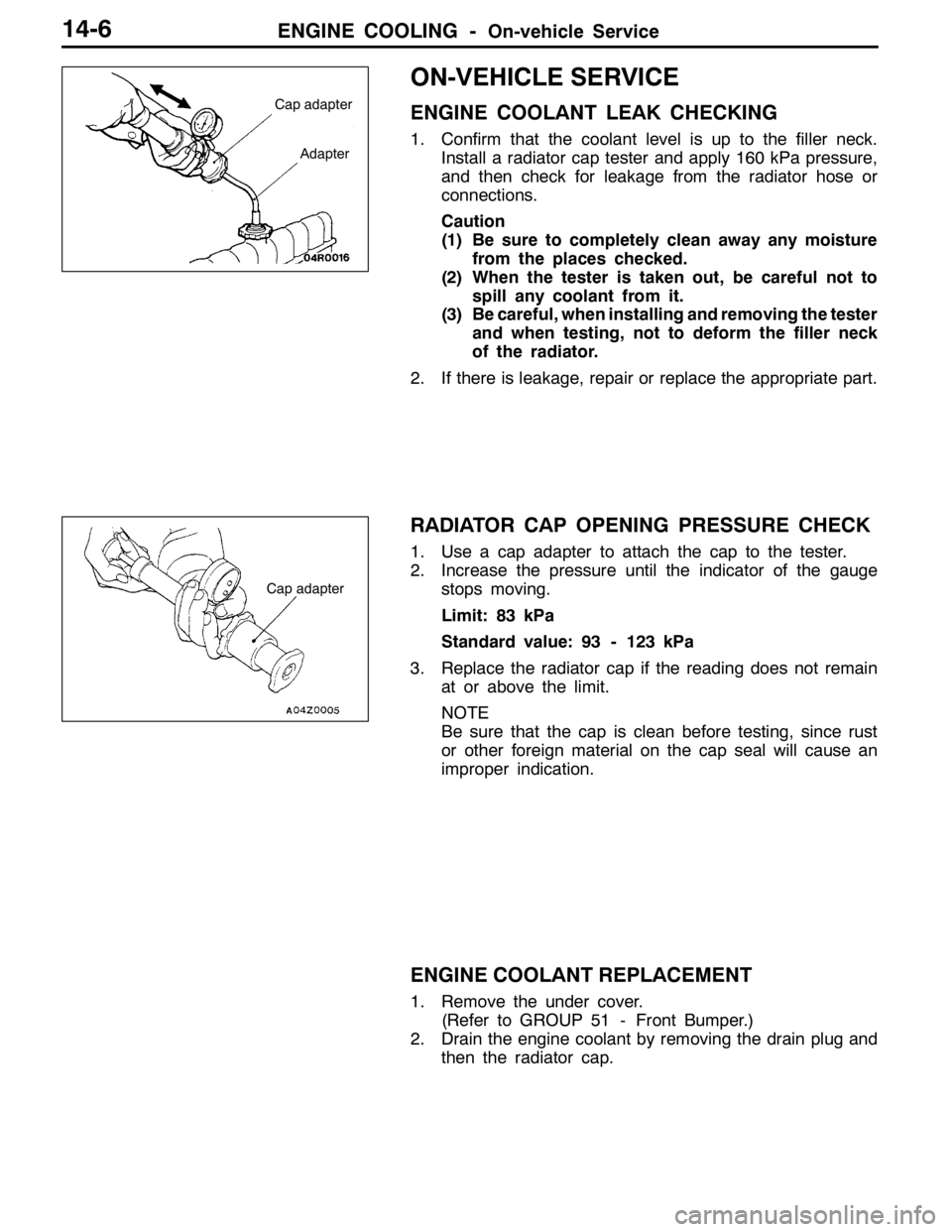

ENGINE COOLANT LEAK CHECKING

1. Confirm that the coolant level is up to the filler neck.

Install a radiator cap tester and apply 160 kPa pressure,

and then check for leakage from the radiator hose or

connections.

Caution

(1) Be sure to completely clean away any moisture

from the places checked.

(2) When the tester is taken out, be careful not to

spill any coolant from it.

(3) Be careful, when installing and removing the tester

and when testing, not to deform the filler neck

of the radiator.

2. If there is leakage, repair or replace the appropriate part.

RADIATOR CAP OPENING PRESSURE CHECK

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge

stops moving.

Limit: 83 kPa

Standard value: 93 - 123 kPa

3. Replace the radiator cap if the reading does not remain

at or above the limit.

NOTE

Be sure that the cap is clean before testing, since rust

or other foreign material on the cap seal will cause an

improper indication.

ENGINE COOLANT REPLACEMENT

1. Remove the under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Drain the engine coolant by removing the drain plug and

then the radiator cap.

Cap adapter

Adapter

Cap adapter

Page 695 of 1449

ENGINE COOLING -On-vehicle ServiceENGINE COOLING -On-vehicle Service14-7

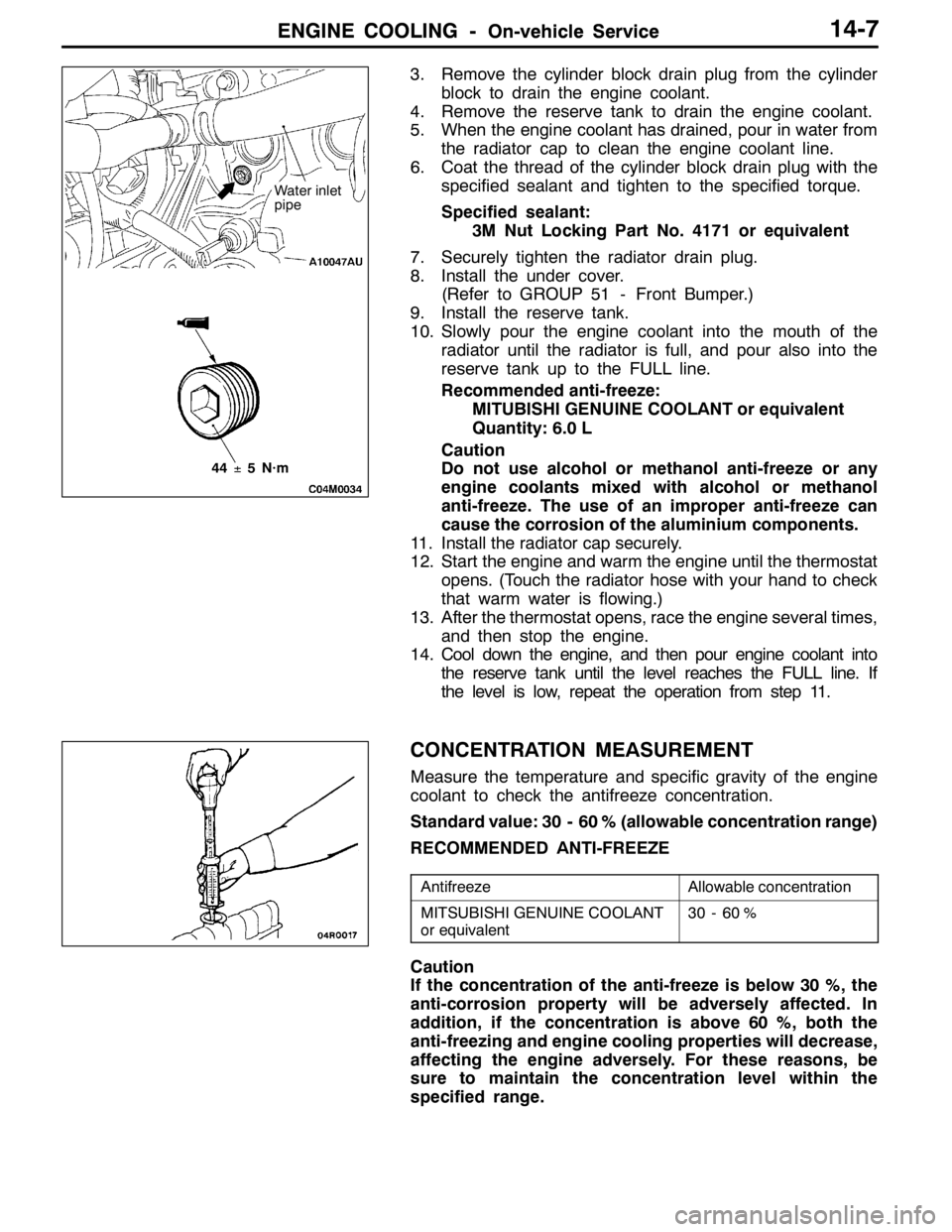

3. Remove the cylinder block drain plug from the cylinder

block to drain the engine coolant.

4. Remove the reserve tank to drain the engine coolant.

5. When the engine coolant has drained, pour in water from

the radiator cap to clean the engine coolant line.

6. Coat the thread of the cylinder block drain plug with the

specified sealant and tighten to the specified torque.

Specified sealant:

3M Nut Locking Part No. 4171 or equivalent

7. Securely tighten the radiator drain plug.

8. Install the under cover.

(Refer to GROUP 51 - Front Bumper.)

9. Install the reserve tank.

10. Slowly pour the engine coolant into the mouth of the

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended anti-freeze:

MITUBISHI GENUINE COOLANT or equivalent

Quantity: 6.0 L

Caution

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze can

cause the corrosion of the aluminium components.

11. Install the radiator cap securely.

12. Start the engine and warm the engine until the thermostat

opens. (Touch the radiator hose with your hand to check

that warm water is flowing.)

13. After the thermostat opens, race the engine several times,

and then stop the engine.

14. Cool down the engine, and then pour engine coolant into

the reserve tank until the level reaches the FULL line. If

the level is low, repeat the operation from step 11.

CONCENTRATION MEASUREMENT

Measure the temperature and specific gravity of the engine

coolant to check the antifreeze concentration.

Standard value: 30 - 60 % (allowable concentration range)

RECOMMENDED ANTI-FREEZE

AntifreezeAllowable concentration

MITSUBISHI GENUINE COOLANT

or equivalent30 - 60 %

Caution

If the concentration of the anti-freeze is below 30 %, the

anti-corrosion property will be adversely affected. In

addition, if the concentration is above 60 %, both the

anti-freezing and engine cooling properties will decrease,

affecting the engine adversely. For these reasons, be

sure to maintain the concentration level within the

specified range.

44±5N·m

Water inlet

pipe

Page 696 of 1449

ENGINE COOLING -On-vehicle Service14-8

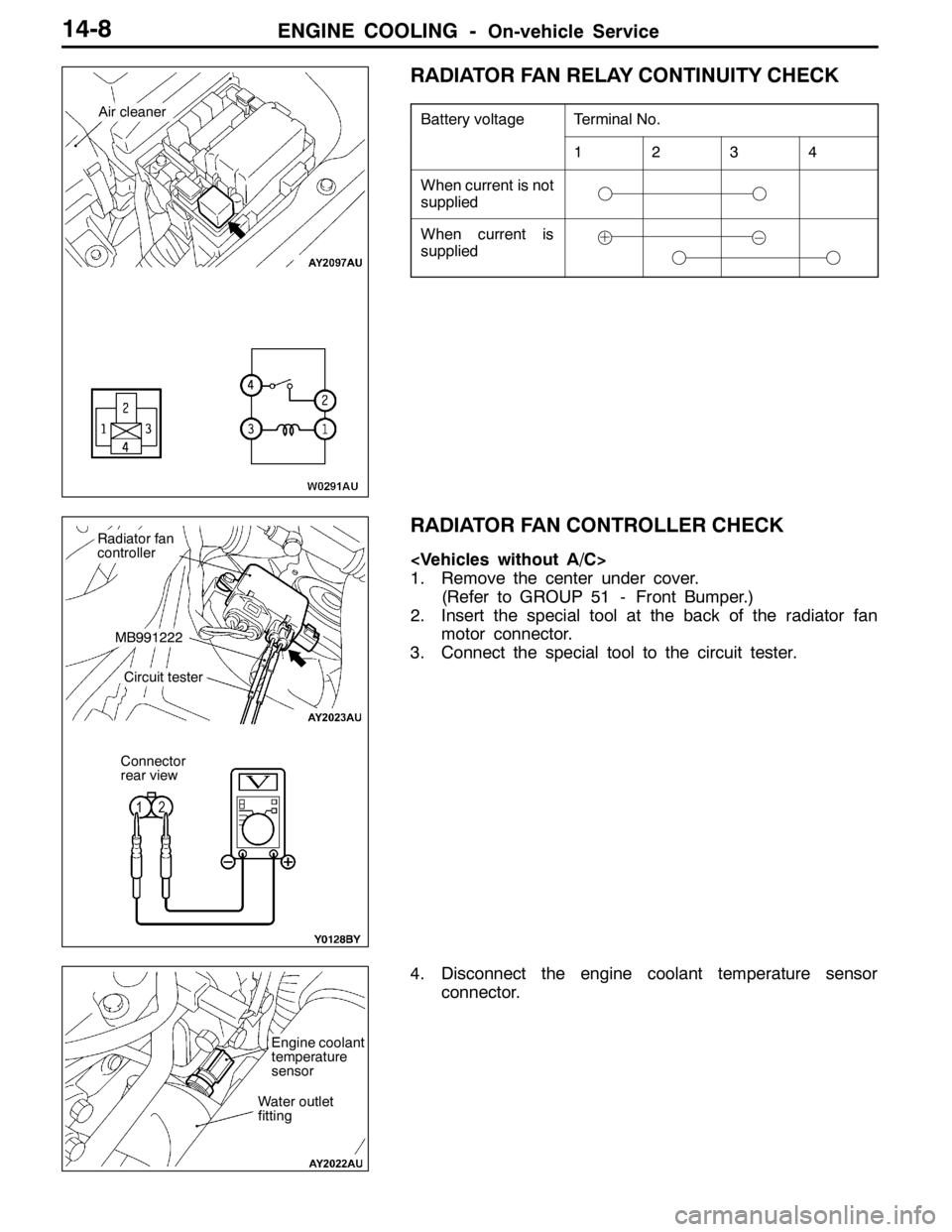

RADIATOR FAN RELAY CONTINUITY CHECK

Battery voltageTerminal No.

1234

When current is not

supplied

When current is

supplied

RADIATOR FAN CONTROLLER CHECK

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Insert the special tool at the back of the radiator fan

motor connector.

3. Connect the special tool to the circuit tester.

4. Disconnect the engine coolant temperature sensor

connector.

Air cleaner

Radiator fan

controller

MB991222

Circuit tester

Connector

rear view

Water outlet

fitting

Engine coolant

temperature

sensor

Page 697 of 1449

![MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the](/img/19/57084/w960_57084-696.png)

ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the special

tool (MB991658).

7. Start the engine and let it run at idle.

NOTE

Since the resistance value of the special tool (APS)

indicates a low engine coolant temperature, engine speed

increases.

8. When the lever of the special tool (APS) is turned to

the end, check that the engine speed decreases and

the radiator fan motor rotates.

9. When the lever of the special tool (APS) is turned to

the reverse direction, check that the voltage between

terminals of the radiator fan motor connector gradually

decreases from the battery voltage to 0 V.

10. If inoperable, replace the radiator fan controller.

(Refer to P.14-15.)

11. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)

12. Connect the engine coolant temperature sensor

connector.

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Insert the special tool at the back of the radiator fan

motor connector.

3. Connect the special tool to the circuit tester.

4. Start the engine and run it at idle.

5. Turn the A/C switch to the ON position and hold the

engine coolant temperature at 80_C or lower.

6. When the voltage between the terminals of the radiator

fan motor connector, the following values of (1) - (3)

can be detected at random.

(1) 0 V

(2) 8.22.6 V

(3) Battery voltage2.6 V

7. If inoperable, replace the radiator fan controller.

(Refer to P.14-15.)

8. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)

Engine coolant

temperature sensor

connector

(harness side)

MB991791(APS)

MB991658

MB991658Lever

MB991791(APS)

Radiator fan

controller

MB991222

Circuit tester

Connector

rear view

Page 698 of 1449

ENGINE COOLING -On - vehicle Service14-10

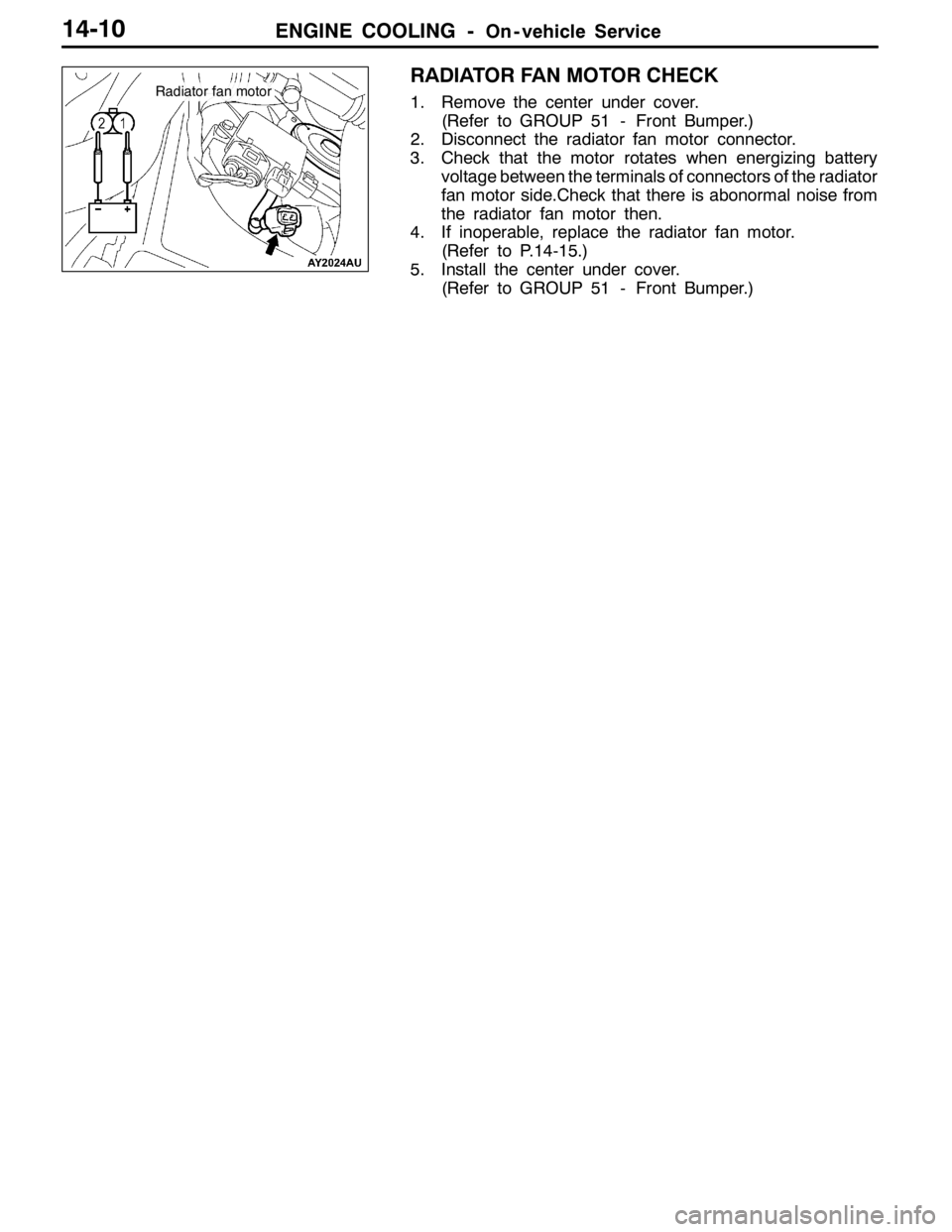

RADIATOR FAN MOTOR CHECK

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Disconnect the radiator fan motor connector.

3. Check that the motor rotates when energizing battery

voltage between the terminals of connectors of the radiator

fan motor side.Check that there is abonormal noise from

the radiator fan motor then.

4. If inoperable, replace the radiator fan motor.

(Refer to P.14-15.)

5. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)Radiator fan motor

Page 699 of 1449

ENGINE COOLING -ThermostatENGINE COOLING -Thermostat14-11

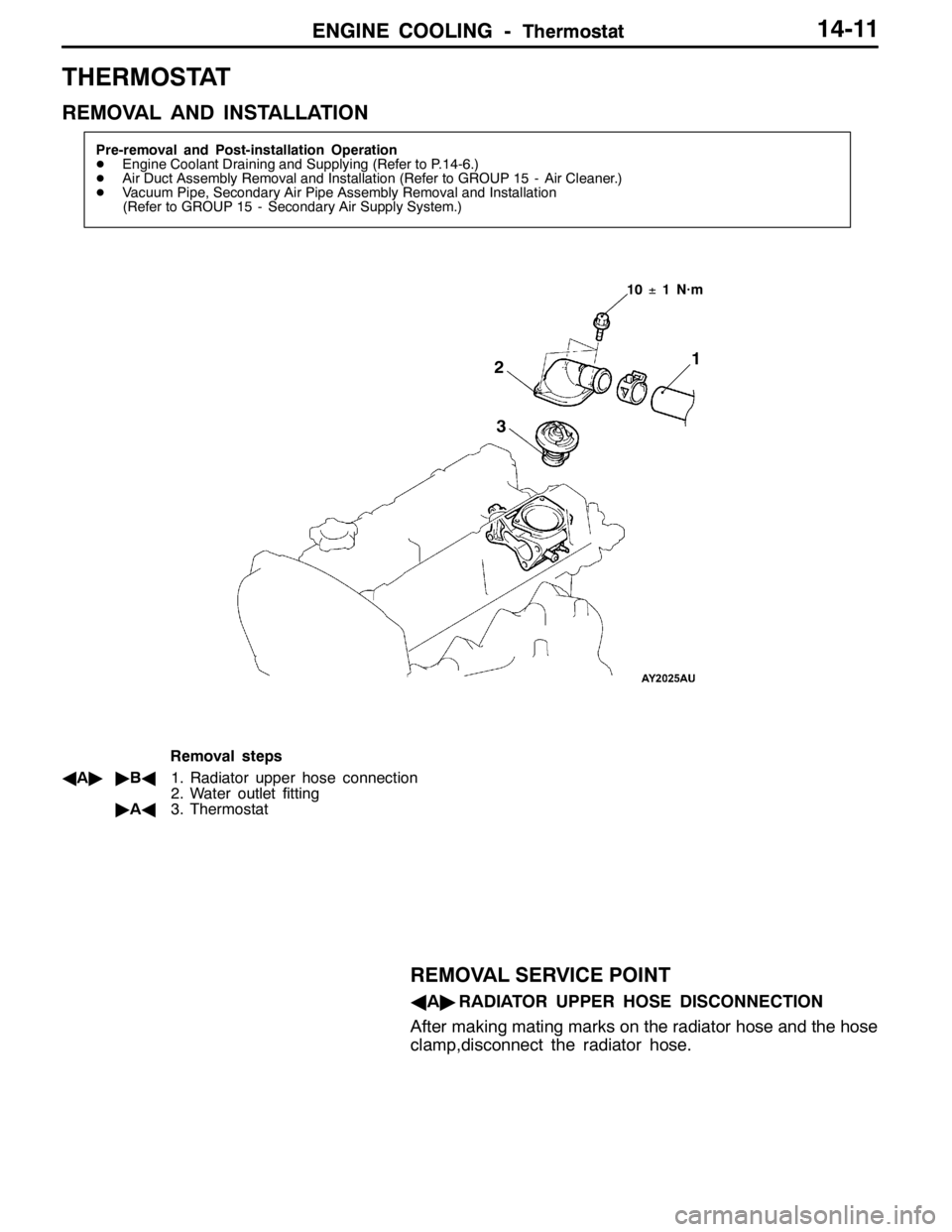

THERMOSTAT

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DAir Duct Assembly Removal and Installation (Refer to GROUP 15 - Air Cleaner.)

DVacuum Pipe, Secondary Air Pipe Assembly Removal and Installation

(Refer to GROUP 15 - Secondary Air Supply System.)

1

2

3

10±1 N·m

Removal steps

AA""BA1. Radiator upper hose connection

2. Water outlet fitting

"AA3. Thermostat

REMOVAL SERVICE POINT

AA"RADIATOR UPPER HOSE DISCONNECTION

After making mating marks on the radiator hose and the hose

clamp,disconnect the radiator hose.

Page 700 of 1449

ENGINE COOLING -Thermostat14-12

INSTALLATION SERVICE POINTS

"AATHERMOSTAT INSTALLATION

Install the thermostat being careful not to fold over or scratch

the rubber ring.

Caution

Make absolutely sure that no oil is adhering to the rubber

ring of the thermostat. In addition, be careful not to fold

over or scratch the rubber ring when inserting. If the

rubber ring is damage, replace the thermostat.

"BARADIATOR UPPER HOSE CONNECTION

1. Insert each hose as far as the projection of the water

outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

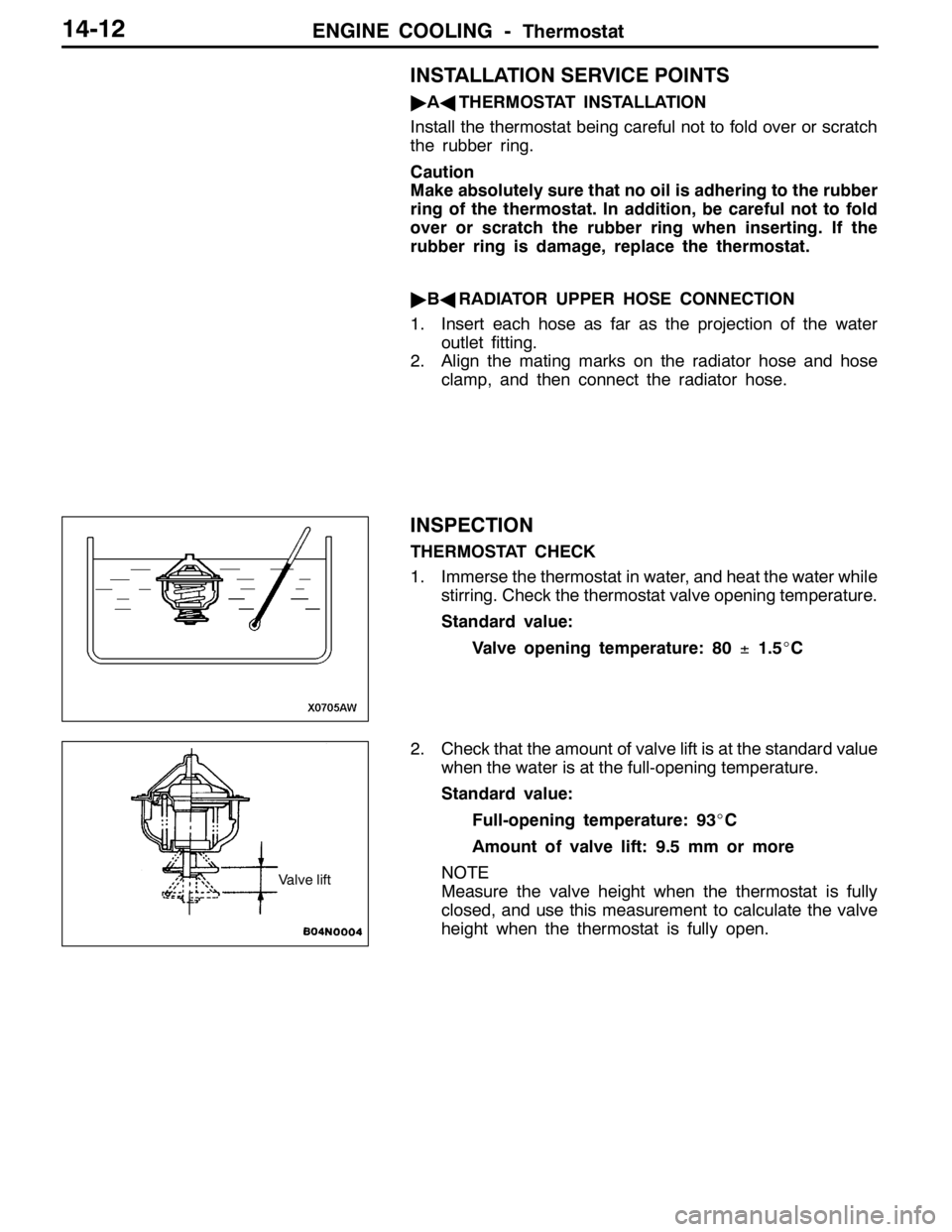

THERMOSTAT CHECK

1. Immerse the thermostat in water, and heat the water while

stirring. Check the thermostat valve opening temperature.

Standard value:

Valve opening temperature: 80±1.5_C

2. Check that the amount of valve lift is at the standard value

when the water is at the full-opening temperature.

Standard value:

Full-opening temperature: 93_C

Amount of valve lift: 9.5 mm or more

NOTE

Measure the valve height when the thermostat is fully

closed, and use this measurement to calculate the valve

height when the thermostat is fully open.

Valve lift