MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 661 of 1449

MPI -On-vehicle Service13A-129

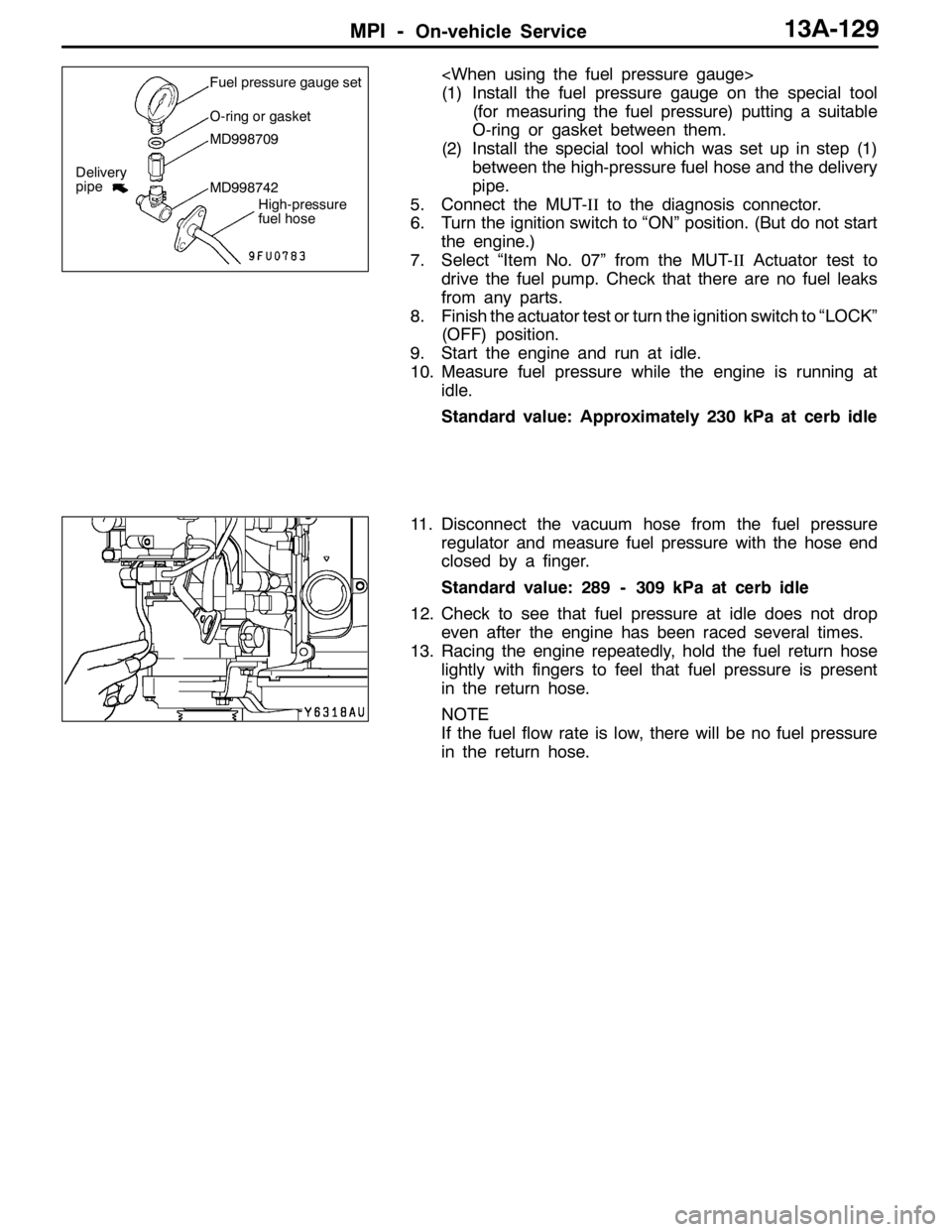

(1) Install the fuel pressure gauge on the special tool

(for measuring the fuel pressure) putting a suitable

O-ring or gasket between them.

(2) Install the special tool which was set up in step (1)

between the high-pressure fuel hose and the delivery

pipe.

5. Connect the MUT-IIto the diagnosis connector.

6. Turn the ignition switch to “ON” position. (But do not start

the engine.)

7. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump. Check that there are no fuel leaks

from any parts.

8. Finish the actuator test or turn the ignition switch to “LOCK”

(OFF) position.

9. Start the engine and run at idle.

10. Measure fuel pressure while the engine is running at

idle.

Standard value: Approximately 230 kPa at cerb idle

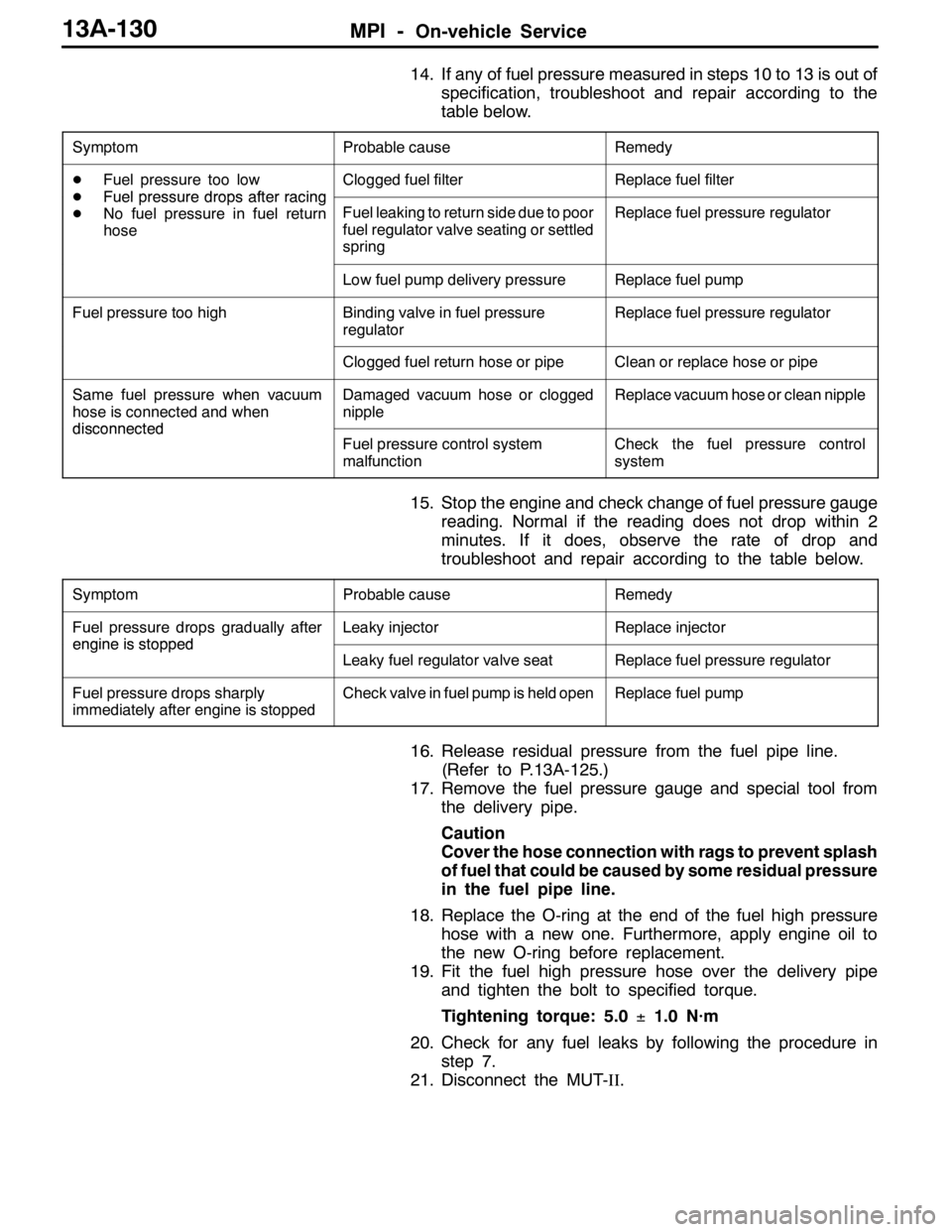

11. Disconnect the vacuum hose from the fuel pressure

regulator and measure fuel pressure with the hose end

closed by a finger.

Standard value: 289 - 309 kPa at cerb idle

12. Check to see that fuel pressure at idle does not drop

even after the engine has been raced several times.

13. Racing the engine repeatedly, hold the fuel return hose

lightly with fingers to feel that fuel pressure is present

in the return hose.

NOTE

If the fuel flow rate is low, there will be no fuel pressure

in the return hose.Fuel pressure gauge set

O-ring or gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe

Page 662 of 1449

MPI -On-vehicle Service13A-130

14. If any of fuel pressure measured in steps 10 to 13 is out of

specification, troubleshoot and repair according to the

table below.

SymptomProbable causeRemedy

DFuel pressure too low

DFuelpressuredropsafterracing

Clogged fuel filterReplace fuel filter

DFuelpressuredrops after racing

DNo fuel pressure in fuel return

hose

Fuel leaking to return side due to poor

fuel regulator valve seating or settled

springReplace fuel pressure regulator

Low fuel pump delivery pressureReplace fuel pump

Fuel pressure too highBinding valve in fuel pressure

regulatorReplace fuel pressure regulator

Clogged fuel return hose or pipeClean or replace hose or pipe

Same fuel pressure when vacuum

hose is connected and when

disconnected

Damaged vacuum hose or clogged

nippleReplace vacuum hose or clean nipple

disconnectedFuel pressure control system

malfunctionCheck the fuel pressure control

system

15. Stop the engine and check change of fuel pressure gauge

reading. Normal if the reading does not drop within 2

minutes. If it does, observe the rate of drop and

troubleshoot and repair according to the table below.

SymptomProbable causeRemedy

Fuel pressure drops gradually after

engineisstopped

Leaky injectorReplace injector

engineisstopped

Leaky fuel regulator valve seatReplace fuel pressure regulator

Fuel pressure drops sharply

immediately after engine is stoppedCheck valve in fuel pump is held openReplace fuel pump

16. Release residual pressure from the fuel pipe line.

(Refer to P.13A-125.)

17. Remove the fuel pressure gauge and special tool from

the delivery pipe.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

18. Replace the O-ring at the end of the fuel high pressure

hose with a new one. Furthermore, apply engine oil to

the new O-ring before replacement.

19. Fit the fuel high pressure hose over the delivery pipe

and tighten the bolt to specified torque.

Tightening torque: 5.0±1.0 N·m

20. Check for any fuel leaks by following the procedure in

step 7.

21. Disconnect the MUT-II.

Page 663 of 1449

MPI -On-vehicle Service13A-131

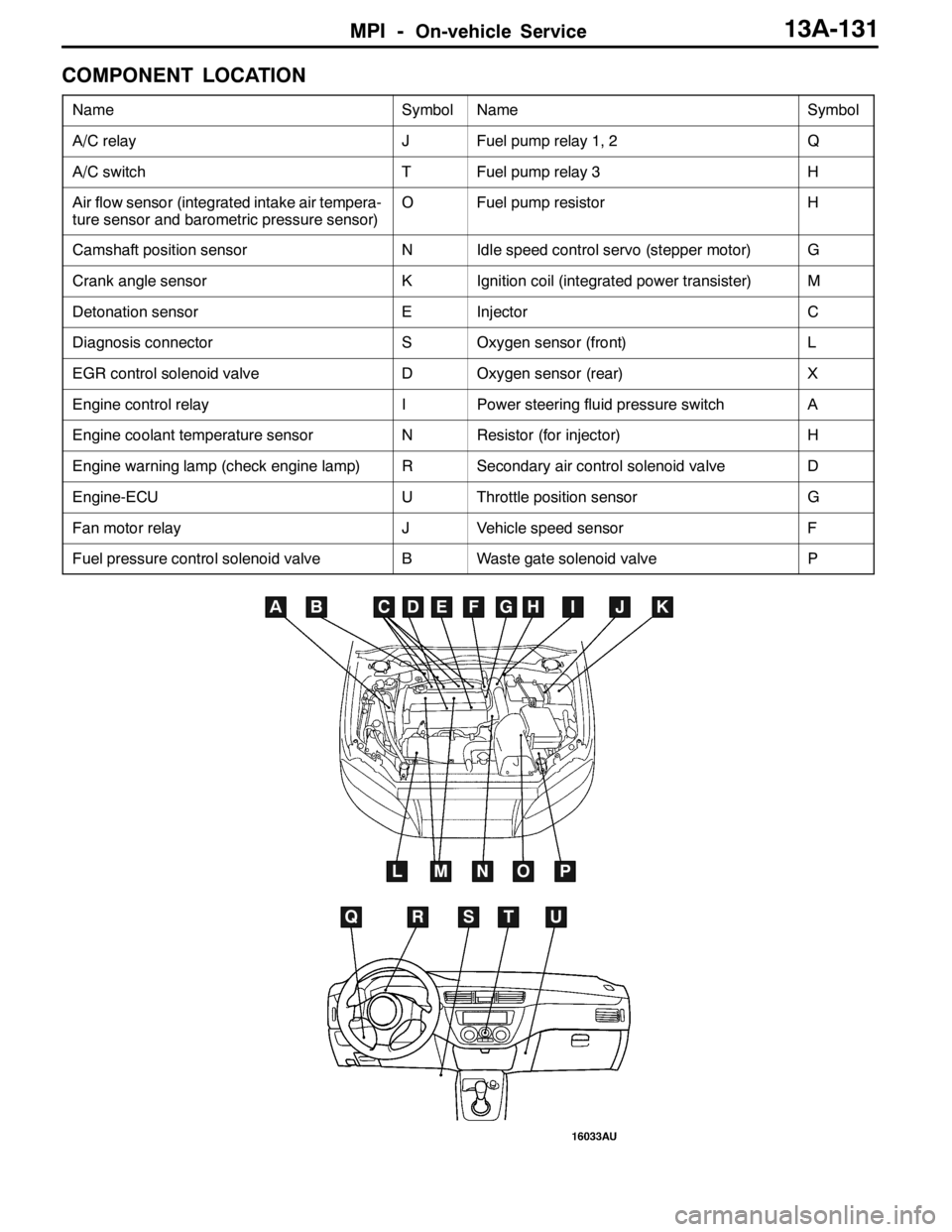

COMPONENT LOCATION

NameSymbolNameSymbol

A/C relayJFuel pump relay 1, 2Q

A/C switchTFuel pump relay 3H

Air flow sensor (integrated intake air tempera-

ture sensor and barometric pressure sensor)OFuel pump resistorH

Camshaft position sensorNIdle speed control servo (stepper motor)G

Crank angle sensorKIgnition coil (integrated power transister)M

Detonation sensorEInjectorC

Diagnosis connectorSOxygen sensor (front)L

EGR control solenoid valveDOxygen sensor (rear)X

Engine control relayIPower steering fluid pressure switchA

Engine coolant temperature sensorNResistor (for injector)H

Engine warning lamp (check engine lamp)RSecondary air control solenoid valveD

Engine-ECUUThrottle position sensorG

Fan motor relayJVehicle speed sensorF

Fuel pressure control solenoid valveBWaste gate solenoid valveP

ABCDEFGHIJK

LMNOP

QRSTU

Page 664 of 1449

MPI -On-vehicle Service13A-132

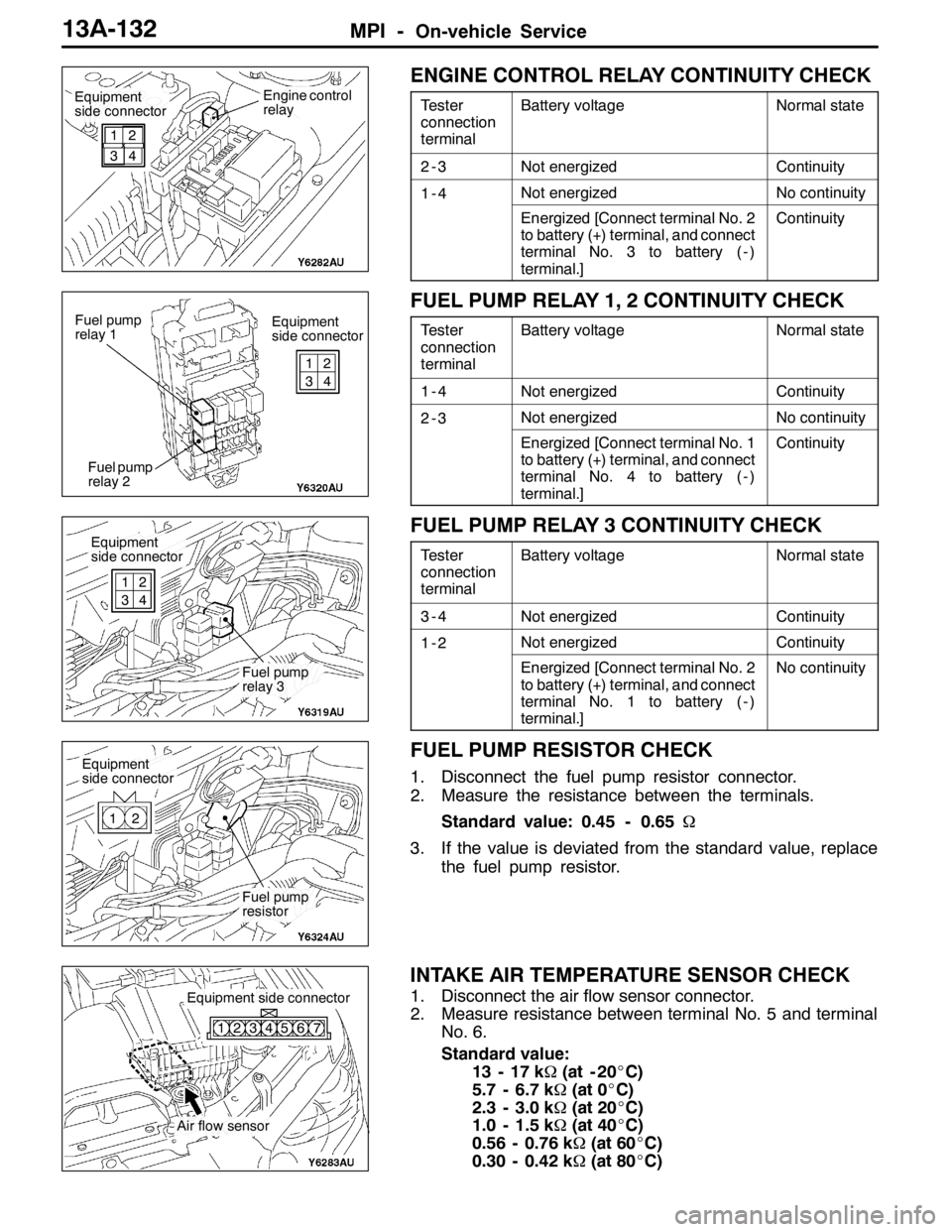

ENGINE CONTROL RELAY CONTINUITY CHECK

Tester

connection

terminalBattery voltageNormal state

2-3Not energizedContinuity

1-4Not energizedNo continuity

Energized [Connect terminal No. 2

to battery (+) terminal, and connect

terminal No. 3 to battery ( - )

terminal.]Continuity

FUEL PUMP RELAY 1, 2 CONTINUITY CHECK

Tester

connection

terminalBattery voltageNormal state

1-4Not energizedContinuity

2-3Not energizedNo continuity

Energized [Connect terminal No. 1

to battery (+) terminal, and connect

terminal No. 4 to battery ( - )

terminal.]Continuity

FUEL PUMP RELAY 3 CONTINUITY CHECK

Tester

connection

terminalBattery voltageNormal state

3-4Not energizedContinuity

1-2Not energizedContinuity

Energized [Connect terminal No. 2

to battery (+) terminal, and connect

terminal No. 1 to battery ( - )

terminal.]No continuity

FUEL PUMP RESISTOR CHECK

1. Disconnect the fuel pump resistor connector.

2. Measure the resistance between the terminals.

Standard value: 0.45 - 0.65Ω

3. If the value is deviated from the standard value, replace

the fuel pump resistor.

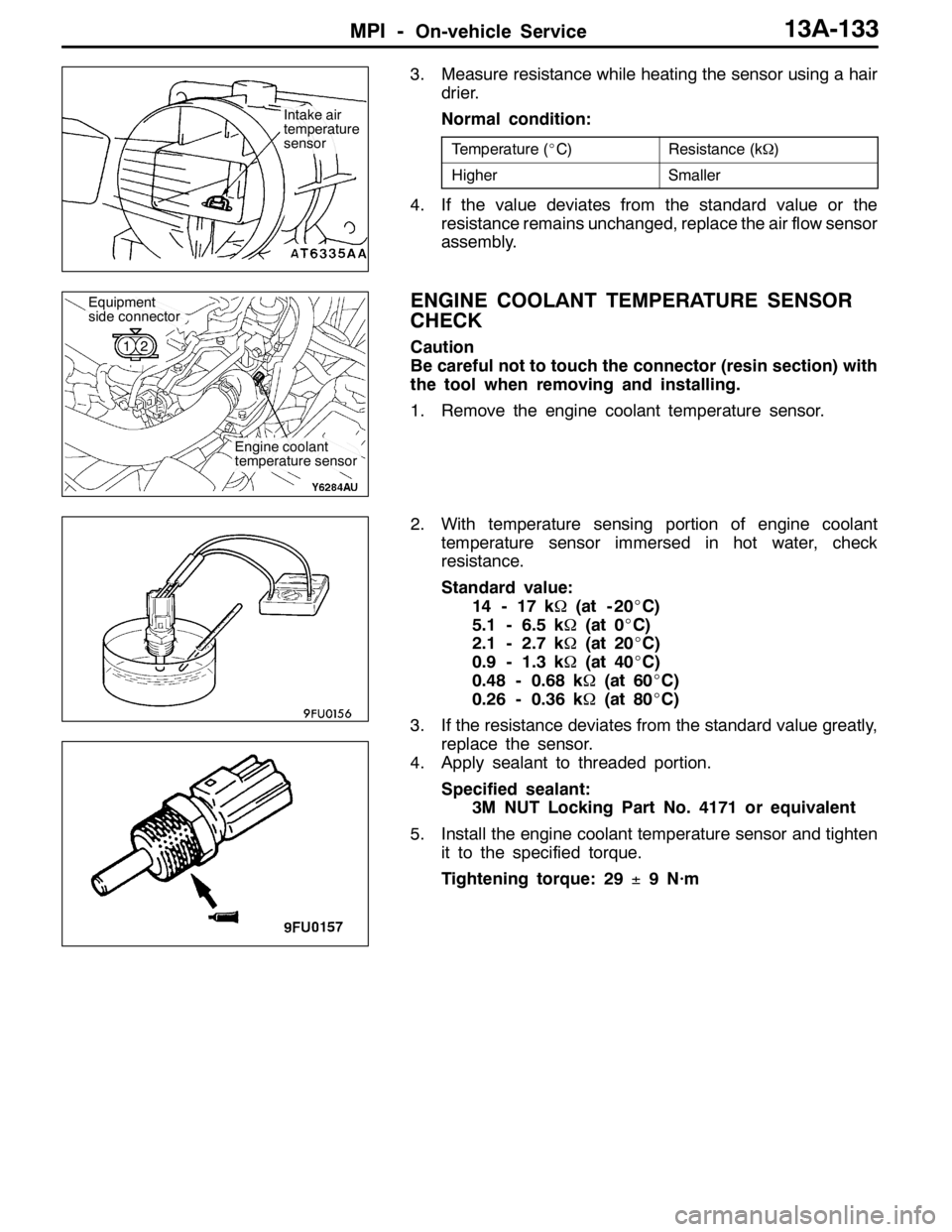

INTAKE AIR TEMPERATURE SENSOR CHECK

1. Disconnect the air flow sensor connector.

2. Measure resistance between terminal No. 5 and terminal

No. 6.

Standard value:

13 - 17 kΩ(at - 20_C)

5.7 - 6.7 kΩ(at 0_C)

2.3 - 3.0 kΩ(at 20_C)

1.0 - 1.5 kΩ(at 40_C)

0.56 - 0.76 kΩ(at 60_C)

0.30 - 0.42 kΩ(at 80_C)

Equipment

side connectorEngine control

relay

1

32

4

Equipment

side connector Fuel pump

relay 1

Fuel pump

relay 21

32

4

Equipment

side connector

Fuel pump

relay 3 1

32

4

Equipment

side connector

Fuel pump

resistor 12

Air flow sensor

Equipment side connector

123456 7

Page 665 of 1449

MPI -On-vehicle Service13A-133

3. Measure resistance while heating the sensor using a hair

drier.

Normal condition:

Temperature (_C)Resistance (kΩ)

HigherSmaller

4. If the value deviates from the standard value or the

resistance remains unchanged, replace the air flow sensor

assembly.

ENGINE COOLANT TEMPERATURE SENSOR

CHECK

Caution

Be careful not to touch the connector (resin section) with

the tool when removing and installing.

1. Remove the engine coolant temperature sensor.

2. With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check

resistance.

Standard value:

14 - 17 kΩ(at - 20_C)

5.1 - 6.5 kΩ(at 0_C)

2.1 - 2.7 kΩ(at 20_C)

0.9 - 1.3 kΩ(at 40_C)

0.48 - 0.68 kΩ(at 60_C)

0.26 - 0.36 kΩ(at 80_C)

3. If the resistance deviates from the standard value greatly,

replace the sensor.

4. Apply sealant to threaded portion.

Specified sealant:

3M NUT Locking Part No. 4171 or equivalent

5. Install the engine coolant temperature sensor and tighten

it to the specified torque.

Tightening torque: 29±9 N·m

Intake air

temperature

sensor

Engine coolant

temperature sensor

Equipment

side connector

12

Page 666 of 1449

MPI -On-vehicle Service13A-134

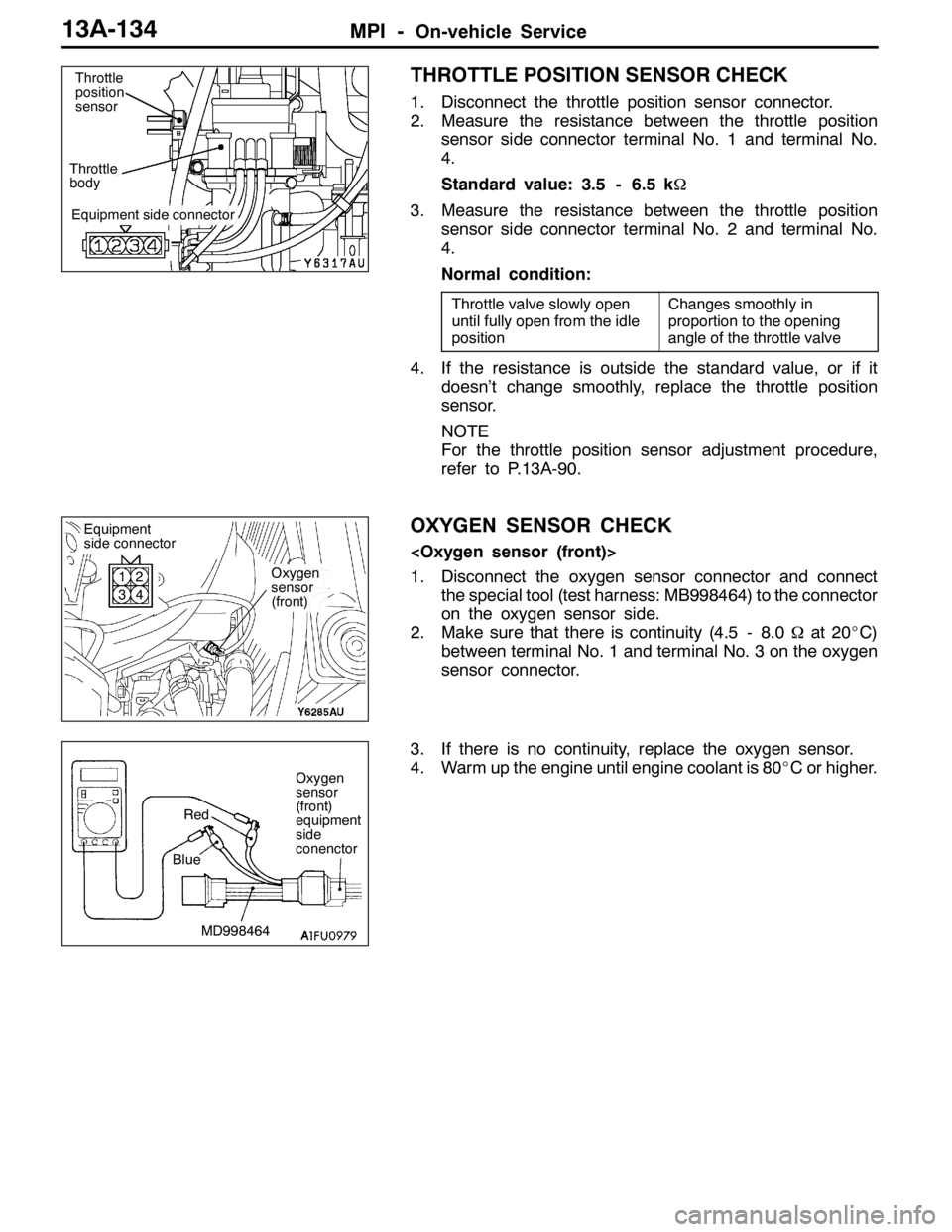

THROTTLE POSITION SENSOR CHECK

1. Disconnect the throttle position sensor connector.

2. Measure the resistance between the throttle position

sensor side connector terminal No. 1 and terminal No.

4.

Standard value: 3.5 - 6.5 kΩ

3. Measure the resistance between the throttle position

sensor side connector terminal No. 2 and terminal No.

4.

Normal condition:

Throttle valve slowly open

until fully open from the idle

positionChanges smoothly in

proportion to the opening

angle of the throttle valve

4. If the resistance is outside the standard value, or if it

doesn’t change smoothly, replace the throttle position

sensor.

NOTE

For the throttle position sensor adjustment procedure,

refer to P.13A-90.

OXYGEN SENSOR CHECK

1. Disconnect the oxygen sensor connector and connect

the special tool (test harness: MB998464) to the connector

on the oxygen sensor side.

2. Make sure that there is continuity (4.5 - 8.0Ωat 20_C)

between terminal No. 1 and terminal No. 3 on the oxygen

sensor connector.

3. If there is no continuity, replace the oxygen sensor.

4. Warm up the engine until engine coolant is 80_C or higher.

Equipment side connector

Throttle

bodyThrottle

position

sensor

Oxygen

sensor

(front)

Equipment

side connector

1

32

4

Oxygen

sensor

(front)

equipment

side

conenctor

MD998464 BlueRed

Page 667 of 1449

MPI -On-vehicle Service13A-135

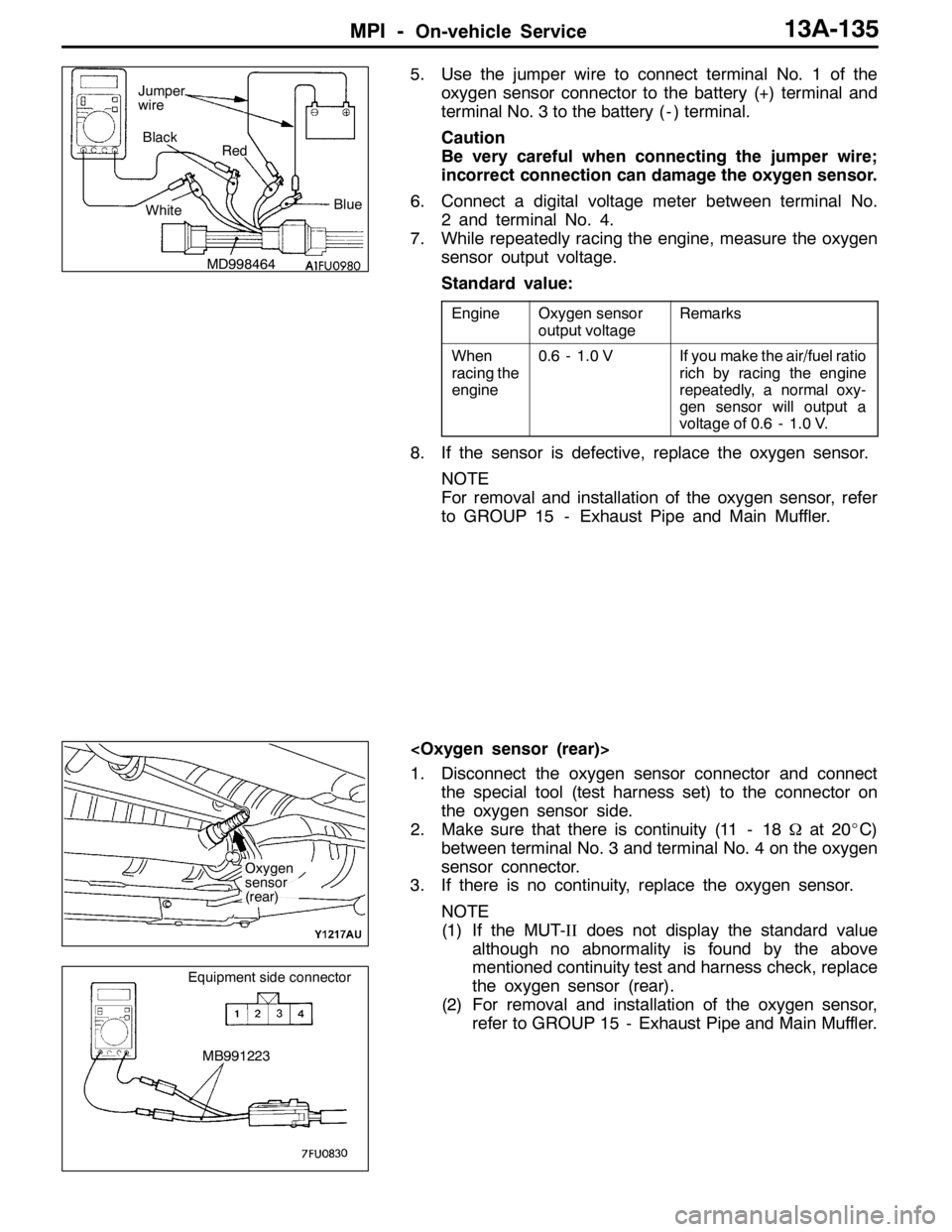

5. Use the jumper wire to connect terminal No. 1 of the

oxygen sensor connector to the battery (+) terminal and

terminal No. 3 to the battery ( - ) terminal.

Caution

Be very careful when connecting the jumper wire;

incorrect connection can damage the oxygen sensor.

6. Connect a digital voltage meter between terminal No.

2 and terminal No. 4.

7. While repeatedly racing the engine, measure the oxygen

sensor output voltage.

Standard value:

EngineOxygen sensor

output voltageRemarks

When

racing the

engine0.6 - 1.0 VIf you make the air/fuel ratio

rich by racing the engine

repeatedly, a normal oxy-

gen sensor will output a

voltage of 0.6 - 1.0 V.

8. If the sensor is defective, replace the oxygen sensor.

NOTE

For removal and installation of the oxygen sensor, refer

to GROUP 15 - Exhaust Pipe and Main Muffler.

1. Disconnect the oxygen sensor connector and connect

the special tool (test harness set) to the connector on

the oxygen sensor side.

2. Make sure that there is continuity (11 - 18Ωat 20_C)

between terminal No. 3 and terminal No. 4 on the oxygen

sensor connector.

3. If there is no continuity, replace the oxygen sensor.

NOTE

(1) If the MUT-IIdoes not display the standard value

although no abnormality is found by the above

mentioned continuity test and harness check, replace

the oxygen sensor (rear).

(2) For removal and installation of the oxygen sensor,

refer to GROUP 15 - Exhaust Pipe and Main Muffler.

MD998464Blue Black

Red

White Jumper

wire

Oxygen

sensor

(rear)

MB991223

Equipment side connector

Page 668 of 1449

MPI -On-vehicle Service13A-136

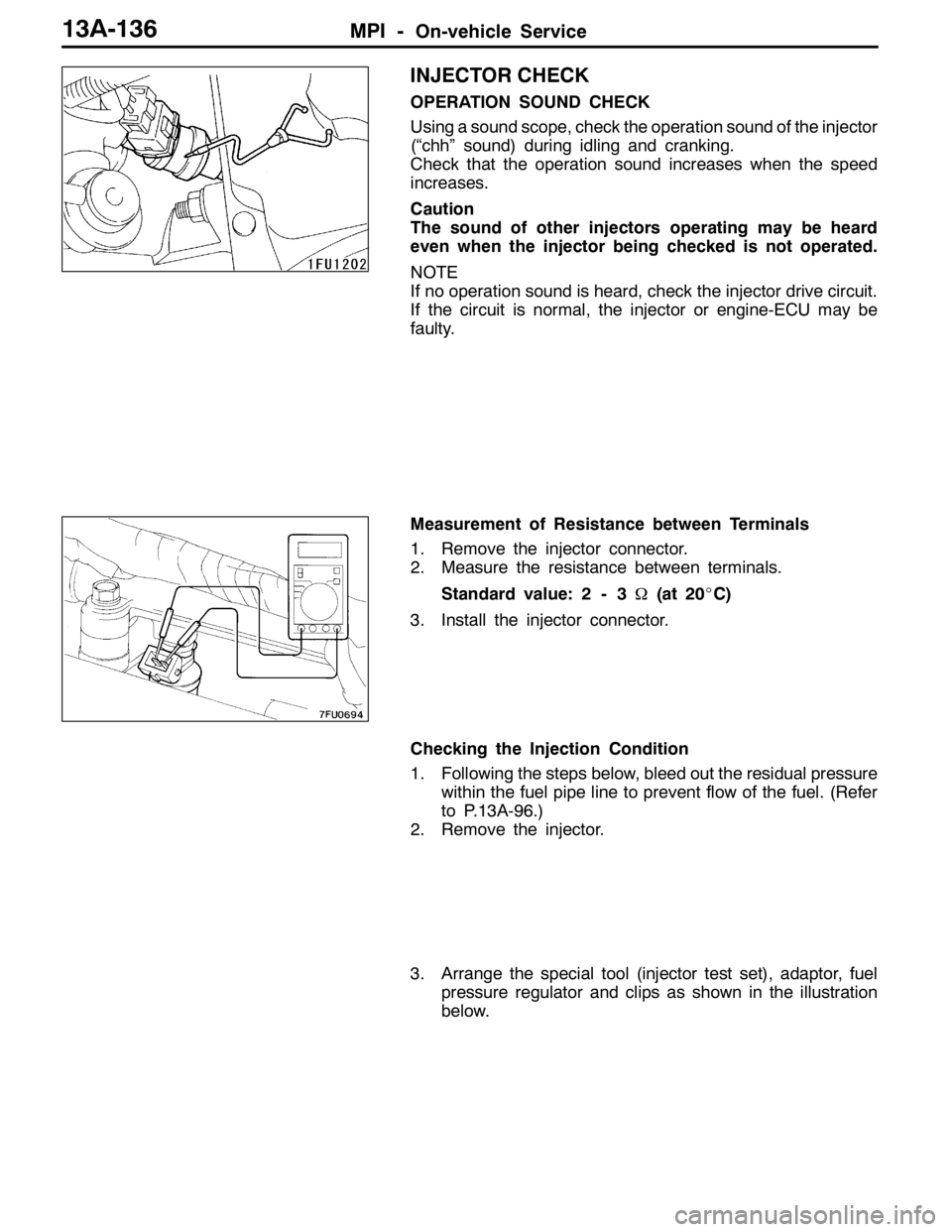

INJECTOR CHECK

OPERATION SOUND CHECK

Using a sound scope, check the operation sound of the injector

(“chh” sound) during idling and cranking.

Check that the operation sound increases when the speed

increases.

Caution

The sound of other injectors operating may be heard

even when the injector being checked is not operated.

NOTE

If no operation sound is heard, check the injector drive circuit.

If the circuit is normal, the injector or engine-ECU may be

faulty.

Measurement of Resistance between Terminals

1. Remove the injector connector.

2. Measure the resistance between terminals.

Standard value: 2 - 3Ω(at 20_C)

3. Install the injector connector.

Checking the Injection Condition

1. Following the steps below, bleed out the residual pressure

within the fuel pipe line to prevent flow of the fuel. (Refer

to P.13A-96.)

2. Remove the injector.

3. Arrange the special tool (injector test set), adaptor, fuel

pressure regulator and clips as shown in the illustration

below.

Page 669 of 1449

MPI -On-vehicle Service13A-137

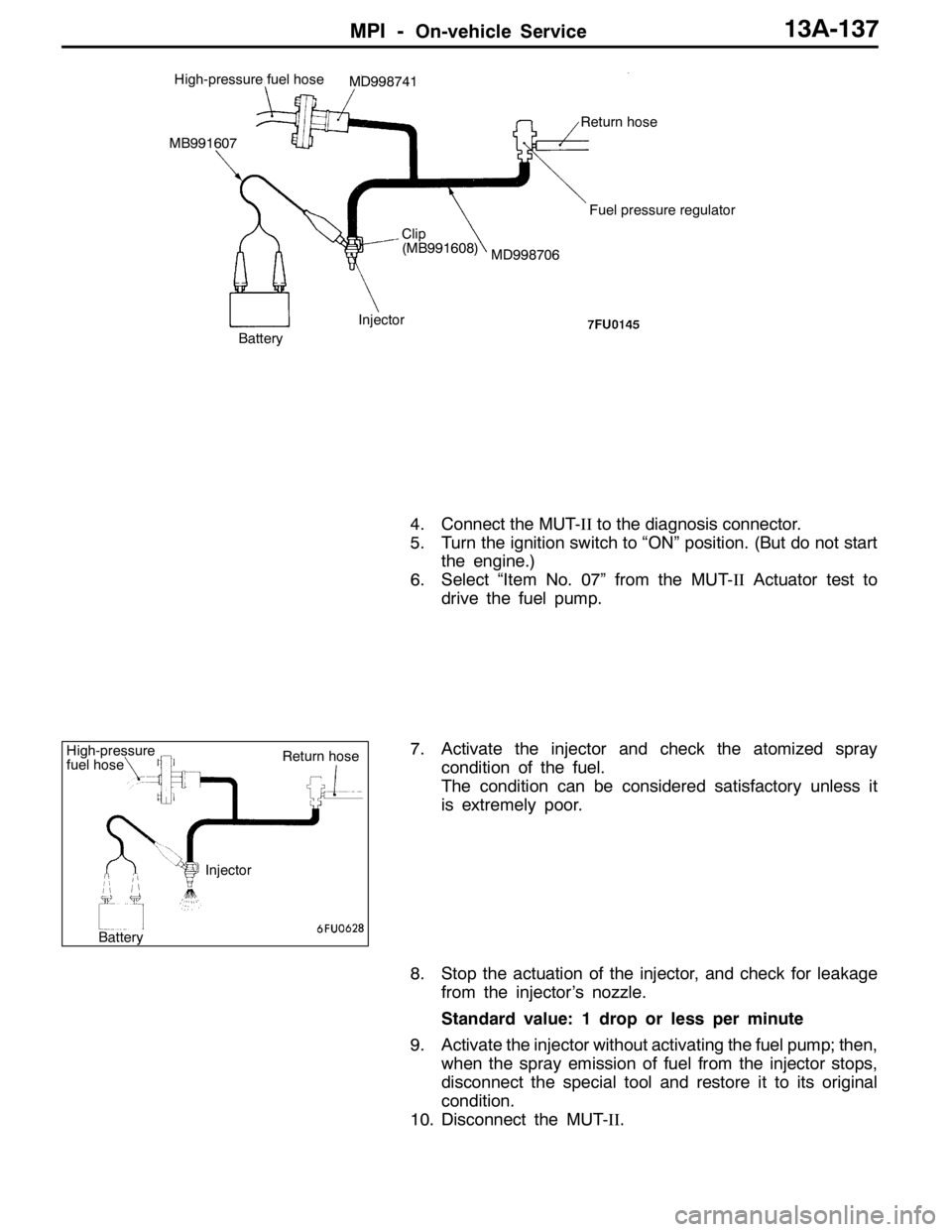

MB991607

High-pressure fuel hoseMD998741

MD998706Return hose

BatteryInjectorFuel pressure regulator

Clip

(MB991608)

4. Connect the MUT-IIto the diagnosis connector.

5. Turn the ignition switch to “ON” position. (But do not start

the engine.)

6. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump.

7. Activate the injector and check the atomized spray

condition of the fuel.

The condition can be considered satisfactory unless it

is extremely poor.

8. Stop the actuation of the injector, and check for leakage

from the injector’s nozzle.

Standard value: 1 drop or less per minute

9. Activate the injector without activating the fuel pump; then,

when the spray emission of fuel from the injector stops,

disconnect the special tool and restore it to its original

condition.

10. Disconnect the MUT-II.

High-pressure

fuel hose

BatteryInjectorReturn hose

Page 670 of 1449

MPI -On-vehicle Service13A-138

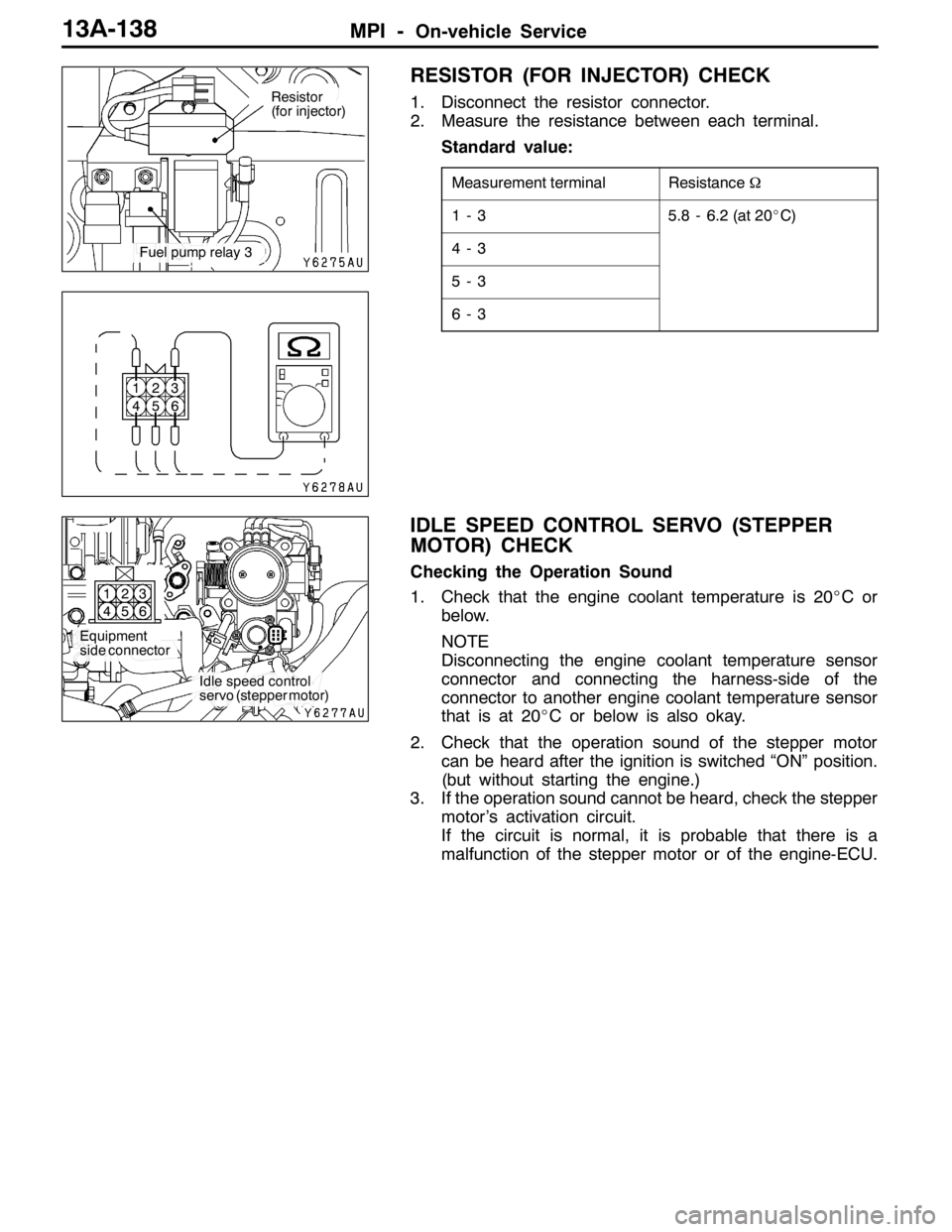

RESISTOR (FOR INJECTOR) CHECK

1. Disconnect the resistor connector.

2. Measure the resistance between each terminal.

Standard value:

Measurement terminalResistanceΩ

1-35.8 - 6.2 (at 20_C)

4-3

5-3

6-3

IDLE SPEED CONTROL SERVO (STEPPER

MOTOR) CHECK

Checking the Operation Sound

1. Check that the engine coolant temperature is 20_Cor

below.

NOTE

Disconnecting the engine coolant temperature sensor

connector and connecting the harness-side of the

connector to another engine coolant temperature sensor

that is at 20_C or below is also okay.

2. Check that the operation sound of the stepper motor

can be heard after the ignition is switched “ON” position.

(but without starting the engine.)

3. If the operation sound cannot be heard, check the stepper

motor’s activation circuit.

If the circuit is normal, it is probable that there is a

malfunction of the stepper motor or of the engine-ECU.

Resistor

(for injector)

Fuel pump relay 3

1

42

53

6

Equipment

side connector

Idle speed control

servo (stepper motor) 1

42

53

6