Functions MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 8 of 241

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

CHASSIS ELECTRICAL54A-27

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

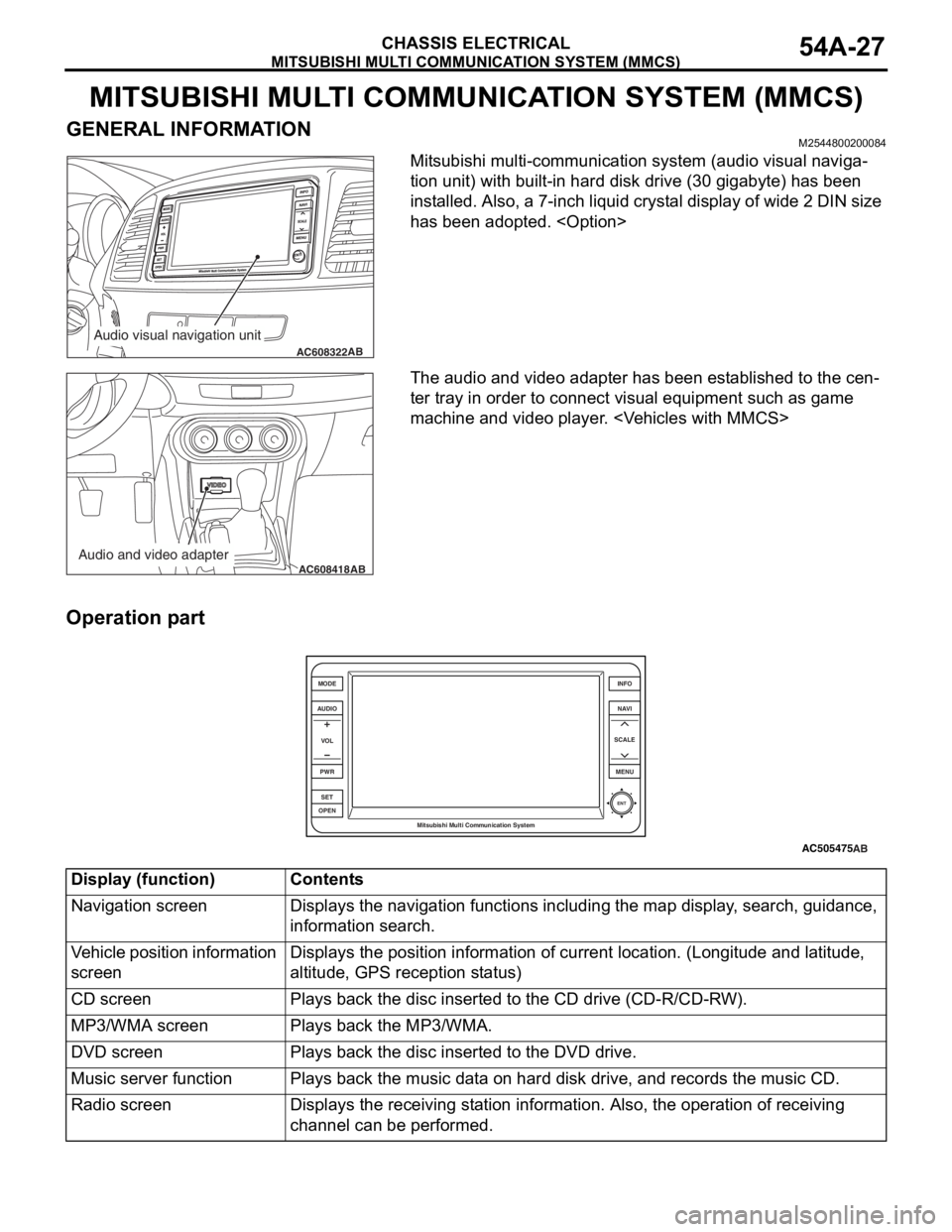

GENERAL INFORMATIONM2544800200084

Mitsubishi multi-communication system (audio visual naviga-

tion unit) with built-in hard disk drive (30 gigabyte) has been

installed. Also, a 7-inch liquid crystal display of wide 2 DIN size

has been adopted.

Page 9 of 241

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

CHASSIS ELECTRICAL54A-28

Navigation function

The storage of very large map data is now possible,

and the following contents have been adopted.

•Map type navigation

•NAVTEQ map database

•Map data stored in hard disc drive

•U.S. English, French, and Spanish are available

to select.

Audio and visual function

The following functions are in addition to the naviga-

tion function:

•Music server function

•DVD drive unit

•FM/AM radio

•MP3/WMA playback function

•Control by steering wheel audio remote comtrol

switch

•Integrated 4-ch power amplifier (MAX: 180 W)

•Correspond to Rockford Fosgate® premium

sound system

•Output of DVD video 5.1 channel data

•Connect with satellite radio tuner

Other function

The following functions are in addition to the naviga-

tion, audio and visual function:

•Clock display

•Connect with hands free unit

•A/C information display

•Outside temperature display

•Trip information display (Average fuel consump-

tion etc.)

•Function customize

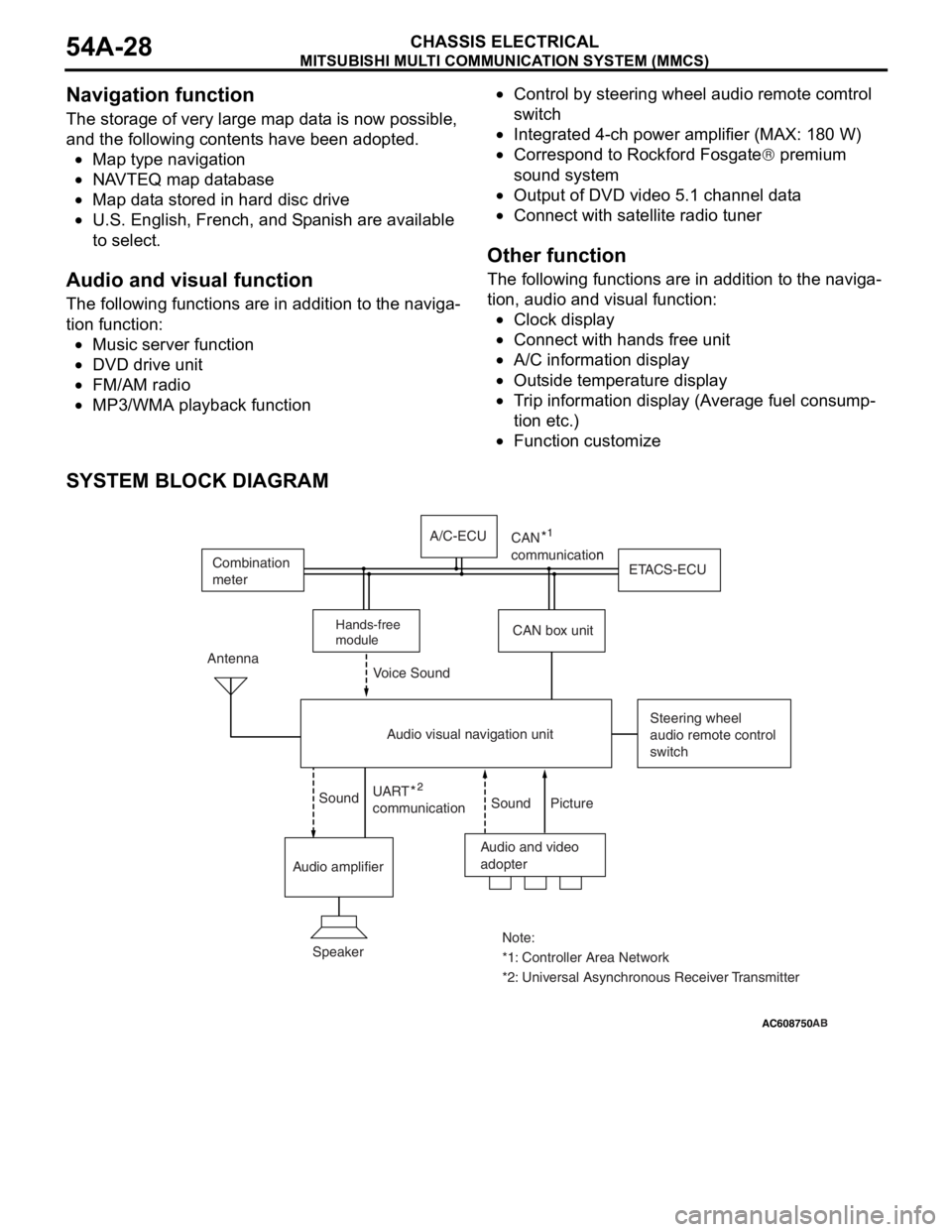

SYSTEM BLOCK DIAGRAM

AC505476

AC608750 ZC3050180000

Audio and video

adopter Antenna

Steering wheel

audio remote control

switch

Speaker

*1: Controller Area Network Note:

*2: Universal Asynchronous Receiver Transmitter UART

communicationn

Sound Sound Voice Sound

Picture

Audio amplifierCAN box unitETACS-ECU Combination

meter

Audio visual navigation unitA/C-ECU

Hands-free

module

CAN

communication

AB

Page 39 of 241

A/C-ECU

HEATER, AIR CONDITIONING AND VENTILATION55-7

A/C-ECUM2551001200265

CONTROL

.

FORCED DEF CONTROL

When air outlet position is switched to DEF, A/C is

automatically turned ON, and outside/inside air

selection damper is set to the fresh air position to

quickly defrost the windshield screen.

.

MAX A/C CONTROL

When the temperature adjustment knob is turned to

the maximum A/C position with the blower knob at

position other than OFF, the following controls are

made by the A/C-ECU.

NOTE: "*" Manual operation is disabled during max

A/C control.

.

MAX COOL, MAX HOT CONTROL

When the set temperature is at 18.0 °C <61°F>

(MAX COOL) or at 32.0

°C <89°F> (MAX HOT) with

the air outlet and air volume at the AUTO positions,

the following controls are made automatically by the

A/C-ECU.

NOTE: "*" indicates that when the automatic control

is not cancelled using the customise function, the

manual operation is disabled.

.

REAR WINDOW DEFOGGER TIMER

CONTROL

In order to prevent battery consumption, the defog-

ger is automatically turned OFF, 20 minutes after it is

turned ON.

.

IDLE-UP CONTROL

A/C-ECU and the engine ECU communicate with

each other through the CAN communication. The

idle-up speed of the engine is controlled in two steps

depending on the A/C load to secure the air cooling

performance during summer and to enhance fuel

economy in seasons with moderate temperature.

.

DETECTION CONTROL FOR

REFRIGERANT LEAKS

A/C-ECU determines if the refrigerant amount is less

than specified or refrigerant pressure is abnormal by

using the ambient temperature (ambient temperature

sensor to measure refrigerant inflation rate) and

refrigerant pressure (measured by the A/C pressure

sensor). When refrigerant amount or refrigerant pres

-

sure is judged abnormal, the compressor is cut-off to

protect the A/C system.

NOTE: When abnormality occurs, the A/C indicator

flashes.

.

PROTECTION CONTROL AT AIR BAG

DEPLOYMENT (DURING COLLISION)

When the air bag deployment is detected, the A/C

system is stopped.

.

CUSTOMISE FUNCTION

Depending on the user's preference, the following

functions can be selected. The programmed informa

-

tion is held even when the battery is disconnected.

•Automatic control for inside/outside air selection

Press and hold (approximately for 10 seconds)

the inside/outside air selection switch to cancel

the automatic control for inside/outside air selec

-

tion.

•A/C automatic control

Press and hold (approximately for 10 seconds)

the A/C switch to cancel the A/C automatic con

-

trol.

Subject to controlMAX COOL

Air mix damperMAX COOL position

Air outlet modeSelected position

Air volumeSelected position

Outside/inside air

selection damperAir recirculation position*

Air conditioner switchON*

Subject to

controlMAX COOLMAX HOT

Air mix

damperMAX COOL

positionMAX HOT

position

Air outlet

modeFACE positionFOOT position

Air volumeMaximumMaximum

Outside/insid

e air

selection

damperAir recirculation

position*Fresh air

position*

Air

conditioner

switchON*OFF*

Page 40 of 241

A/C-ECU

HEATER, AIR CONDITIONING AND VENTILATION55-8

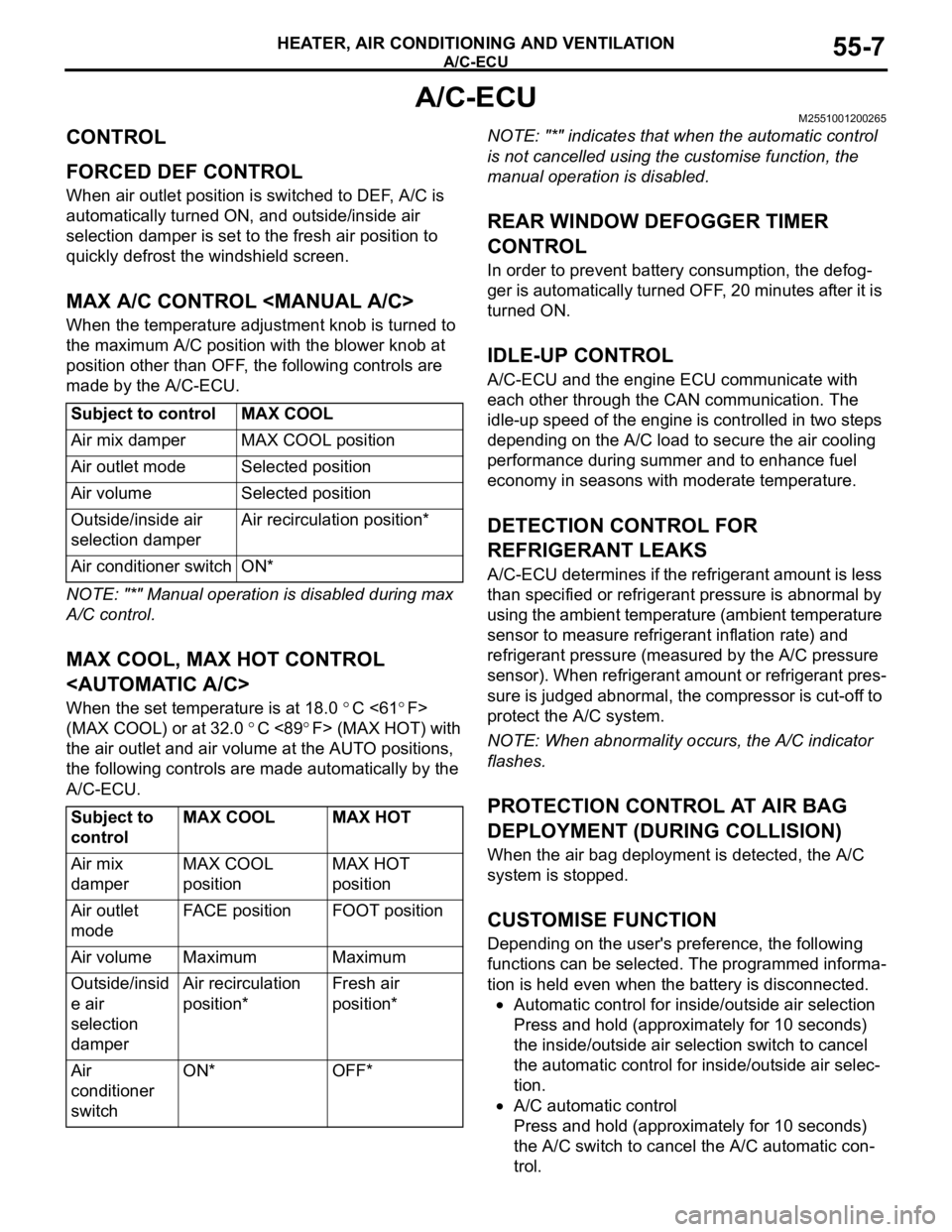

COMMUNICATION

A/C-ECU performs the signal transmission and

reception with each ECU via CAN (Controller Area

Network)*

1. Also, with the heater control panel, it

transmits and receives signals via serial communica

-

tion.

NOTE: : For details of CAN communication, refer to

GROUP 54C

− Controller Area Network P.54C-2.

CAN COMMUNICATION INPUT SIGNALS TABLE

DIAGNOSTIC FUNCTION

A/C-ECU has the following functions for easier sys-

tem checks.

•DIAGNOSTIC FUNCTION

•Service data output

•Actuator test

NOTE: For each item, refer to the Workshop Manual.

AC506202

ETACS-ECU Heater control panelSRS-ECU

Engine-ECU

Combination meter A/C-ECU

: Interactive communicationCAN communication

SERIAL communication

AC

SignalTransmitter ECU

Engine coolant temperature signalENGINE-ECU

Vehicle speed signal

Engine speed signal

Ambient temperature signalETACS-ECU

Wiper signal

Ignition key signal

Average ambient temperature signalCOMBINATION METER

Page 66 of 241

AUTO-CRUISE CONTROL SYSTEM

ENGINE AND EMISSION CONTROL17-4

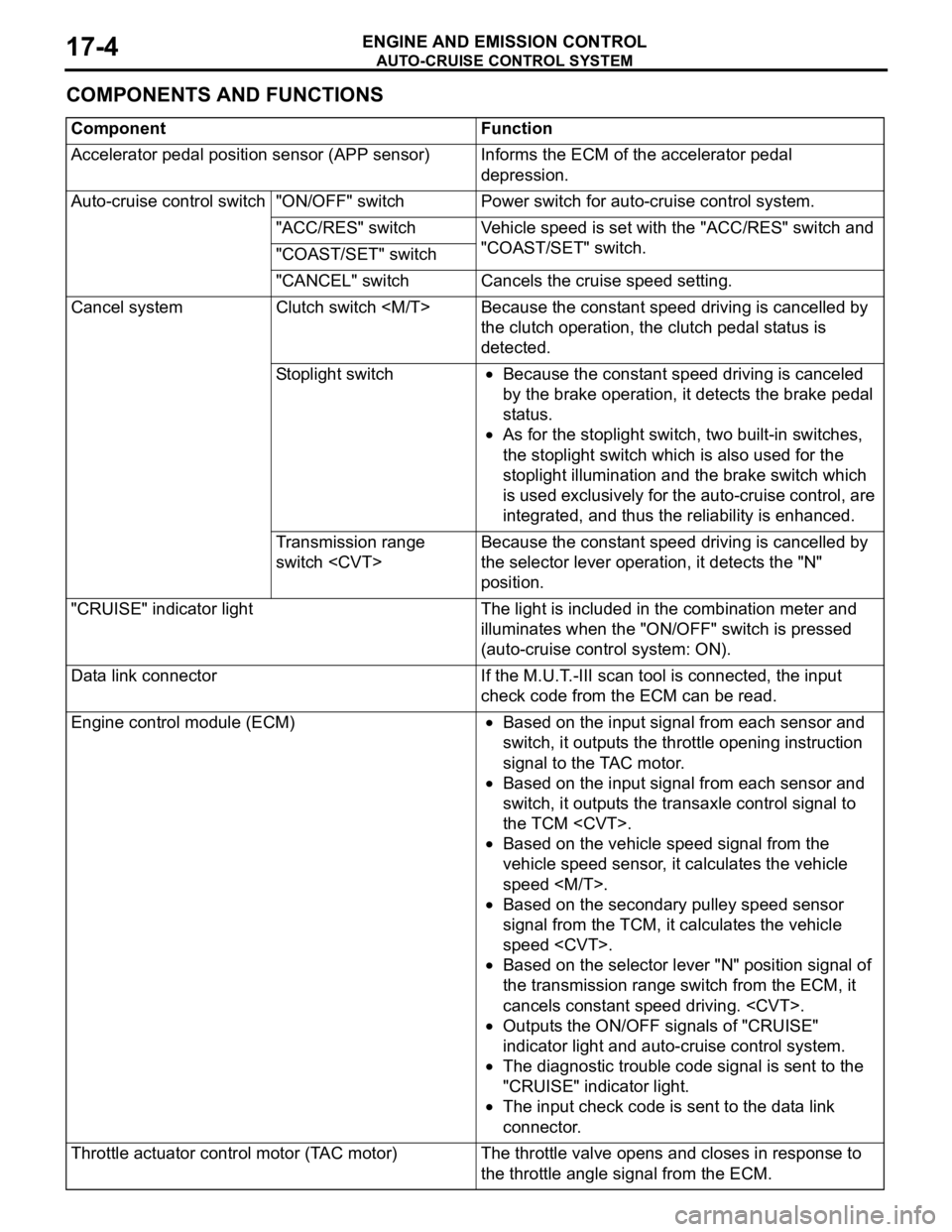

COMPONENTS AND FUNCTIONS

ComponentFunction

Accelerator pedal position sensor (APP sensor)Informs the ECM of the accelerator pedal

depression.

Auto-cruise control switch"ON/OFF" switchPower switch for auto-cruise control system.

"ACC/RES" switchVehicle speed is set with the "ACC/RES" switch and

"COAST/SET" switch.

"COAST/SET" switch

"CANCEL" switchCancels the cruise speed setting.

Cancel systemClutch switch

the clutch operation, the clutch pedal status is

detected.

Stoplight switch•Because the constant speed driving is canceled

by the brake operation, it detects the brake pedal

status.

•As for the stoplight switch, two built-in switches,

the stoplight switch which is also used for the

stoplight illumination and the brake switch which

is used exclusively for the auto-cruise control, are

integrated, and thus the reliability is enhanced.

Transmission range

switch

the selector lever operation, it detects the "N"

position.

"CRUISE" indicator lightThe light is included in the combination meter and

illuminates when the "ON/OFF" switch is pressed

(auto-cruise control system: ON).

Data link connectorIf the M.U.T.-III scan tool is connected, the input

check code from the ECM can be read.

Engine control module (ECM)•Based on the input signal from each sensor and

switch, it outputs the throttle opening instruction

signal to the TAC motor.

•Based on the input signal from each sensor and

switch, it outputs the transaxle control signal to

the TCM

•Based on the vehicle speed signal from the

vehicle speed sensor, it calculates the vehicle

speed

•Based on the secondary pulley speed sensor

signal from the TCM, it calculates the vehicle

speed

•Based on the selector lever "N" position signal of

the transmission range switch from the ECM, it

cancels constant speed driving.

•Outputs the ON/OFF signals of "CRUISE"

indicator light and auto-cruise control system.

•The diagnostic trouble code signal is sent to the

"CRUISE" indicator light.

•The input check code is sent to the data link

connector.

Throttle actuator control motor (TAC motor)The throttle valve opens and closes in response to

the throttle angle signal from the ECM.

Page 68 of 241

AUTO-CRUISE CONTROL SYSTEM

ENGINE AND EMISSION CONTROL17-6

SYSTEM FUNCTIONS

.

SET FUNCTION

1. During driving with the vehicle speed range from

approximately 40 to 200 km/h (25 to 125 mph),

press and release the "COAST/SET" switch.

2. The vehicle speed when the "COAST/SET" switch

is released is memorized. Thereafter, the constant

speed driving is performed at that vehicle speed.

3. When the "COAST/SET" switch is operated

during the driving with the vehicle speed of

approximately 200 km/h (125 mph) or more, the

constant speed driving will not be performed.

.

COAST FUNCTION

1. When the "COAST/SET" switch is continuously

pressed for 0.5 seconds or longer during constant

speed driving, the throttle valve becomes fully

closed while the switch is pressed, and the

vehicle is decelerated.

2. When the "COAST/SET" switch is released, the

vehicle speed at that time is now memorized.

Thereafter, the constant speed driving is

performed at that vehicle speed.

3. Also when the "COAST/SET" switch is pressed

for less than 0.5 second, the vehicle is

decelerated 1.6 km/h (1 mph) from the vehicle

speed of constant speed driving, and the

decelerated vehicle speed is now memorized.

Thereafter, the constant speed driving is

performed at that vehicle speed.

4. When the "COAST/SET" switch is continuously

pressed and the vehicle speed is decelerated to

approximately 40 km/h (25 mph) or less, the set

function and coast function are cancelled, and the

constant speed driving is cancelled.

.

RESUME FUNCTION

1. When the "CANCEL" switch is pressed or the

brake pedal is depressed during the constant

speed driving, it cancels the constant speed

driving.

2. Subsequently, when the "ACC/RES" switch is

pressed during driving with the vehicle speed of

approximately 40 km/h (25 mph) or more, the

constant speed driving is performed with the

vehicle speed memorized at the last cancellation

of constant speed driving.

.

ACCEL FUNCTION

1. When the "ACC/RES" switch is continuously

pressed for 0.5 second or more during constant

driving, it accelerates the vehicle with specified

acceleration while the switch is pressed.

2. Then, when the "ACC/RES" switch is released,

the vehicle speed at that time is now memorized.

Thereafter, the constant speed driving is

performed at that vehicle speed.

3. Also, when the "ACC/RES" switch is pressed for

less than 0.5 second, the vehicle is accelerated

1.6 km/h (1 mph) from the vehicle speed of

constant speed driving, and the accelerated

vehicle speed is now memorized. Thereafter, the

constant speed driving is performed at that

vehicle speed.

4. It is possible to keep pressing the "ACC/RES"

switch until the vehicle speed is accelerated to

approximately 200 km/h (125 mph) or above.

However, after the "ACC/RES" switch is released,

the vehicle speed of approximately 200 km/h (125

mph) becomes the newly memorized vehicle

speed. Thereafter, the constant speed driving is

performed at that speed.

.

CANCEL FUNCTION

When any of the following conditions are satisfied,

the constant speed driving will be cancelled.

•The auto-cruise control system is stopped by the

pressing the "ON OFF" switch.

•The "CANCEL" switch is pressed.

•The brake pedal is depressed.

•The clutch pedal is depressed

•The selector lever is shifted to the "N" position

•The vehicle speed becomes approximately 40

km/h (25 mph) or less.

•The vehicle speed is reduced 15 km/h (9 mph) or

more from the speed at which the constant speed

driving was started.

•An abnormality occurs in the vehicle speed sig-

nal.

•The engine coolant temperature becomes abnor-

mally high.

•An abnormality occurs to the ECM.

•An abnormality occurs to the TCM

•An abnormality occurs to the CAN communica-

tion.

.

Page 113 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-20

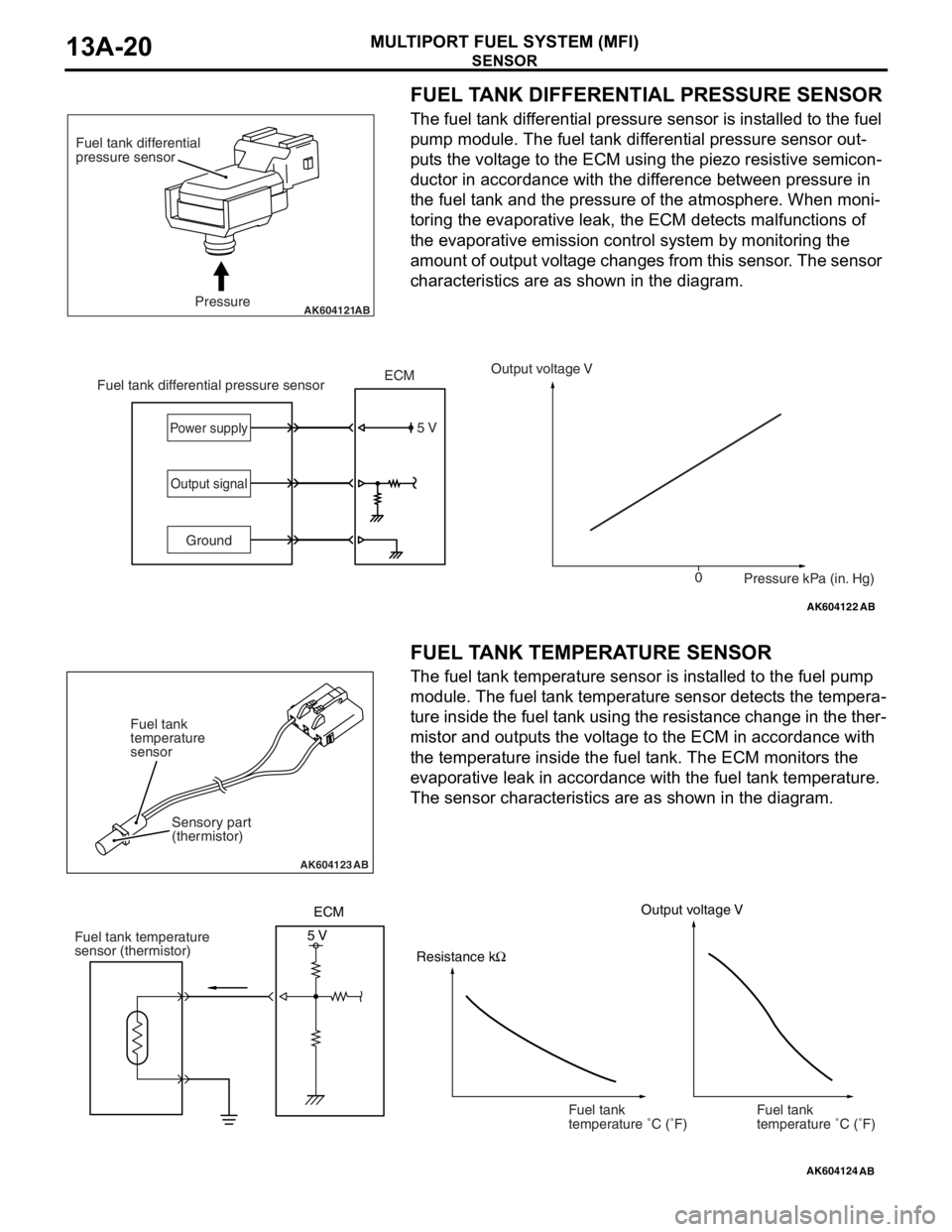

FUEL TANK DIFFERENTIAL PRESSURE SENSOR

The fuel tank differential pressure sensor is installed to the fuel

pump module. The fuel tank differential pressure sensor out

-

puts the voltage to the ECM using the piezo resistive semicon-

ductor in accordance with the difference between pressure in

the fuel tank and the pressure of the atmosphere. When moni

-

toring the evaporative leak, the ECM detects malfunctions of

the evaporative emission control system by monitoring the

amount of output voltage changes from this sensor. The sensor

characteristics are as shown in the diagram.

.

FUEL TANK TEMPERATURE SENSOR

The fuel tank temperature sensor is installed to the fuel pump

module. The fuel tank temperature sensor detects the tempera

-

ture inside the fuel tank using the resistance change in the ther-

mistor and outputs the voltage to the ECM in accordance with

the temperature inside the fuel tank. The ECM monitors the

evaporative leak in accordance with the fuel tank temperature.

The sensor characteristics are as shown in the diagram.

AK604121Pressure Fuel tank differential

pressure sensorAB

AK604122

5 V

0 GroundOutput voltage V

Pressure kPa (in. Hg) Fuel tank differential pressure sensorECMPower supply

Output signal

AB

AK604123AB

Sensory part

(thermistor) Fuel tank

temperature

sensor

AK604124

ECM

Resistance kΩOutput voltage V

5 V

AB

Fuel tank temperature

sensor (thermistor)

Fuel tank

temperature �C (�F)Fuel tank

temperature �C (�F)

Page 212 of 241

GENERAL INFORMATION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-3

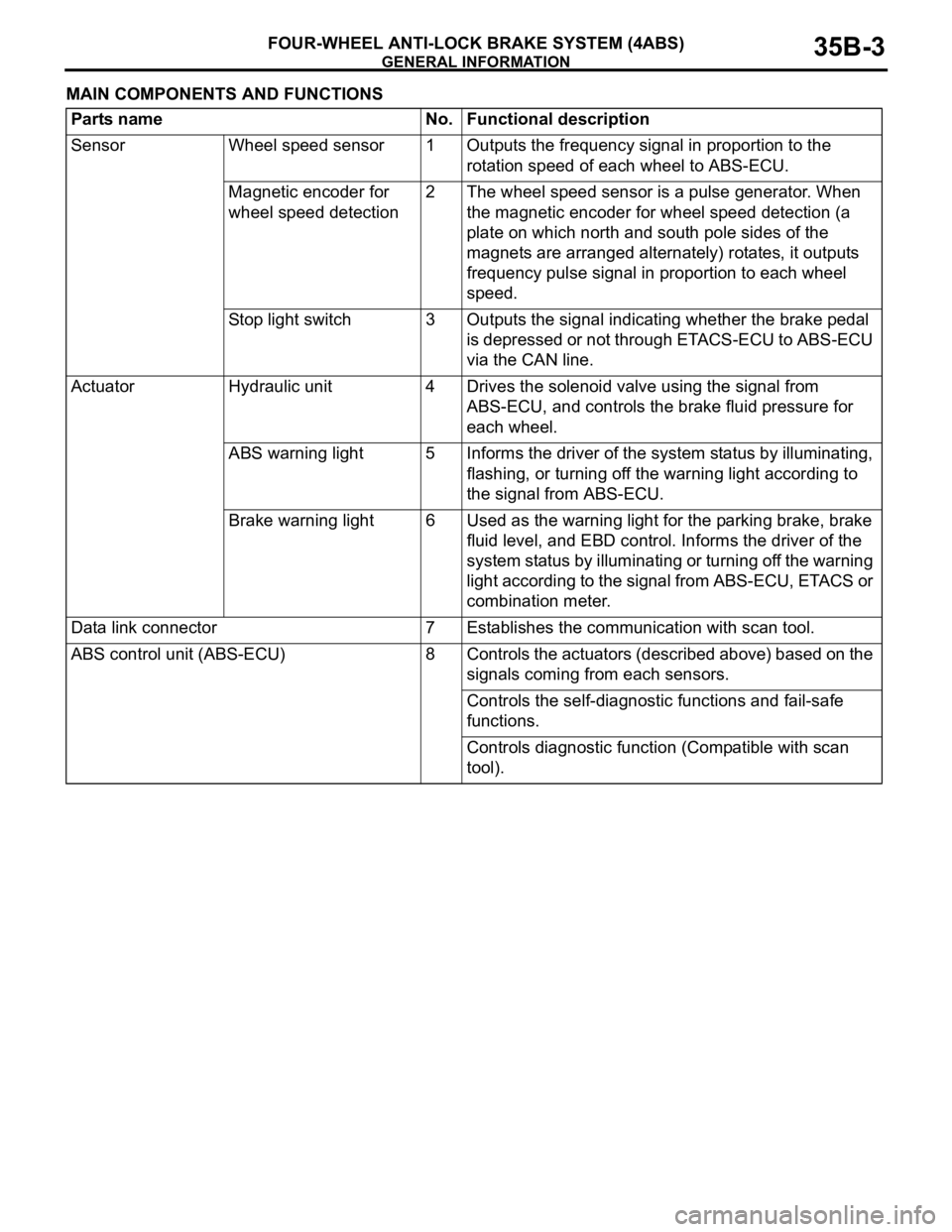

MAIN COMPONENTS AND FUNCTIONS

.

Parts nameNo.Functional description

SensorWheel speed sensor1Outputs the frequency signal in proportion to the

rotation speed of each wheel to ABS-ECU.

Magnetic encoder for

wheel speed detection2The wheel speed sensor is a pulse generator. When

the magnetic encoder for wheel speed detection (a

plate on which north and south pole sides of the

magnets are arranged alternately) rotates, it outputs

frequency pulse signal in proportion to each wheel

speed.

Stop light switch3Outputs the signal indicating whether the brake pedal

is depressed or not through ETACS-ECU to ABS-ECU

via the CAN line.

ActuatorHydraulic unit4Drives the solenoid valve using the signal from

ABS-ECU, and controls the brake fluid pressure for

each wheel.

ABS warning light5Informs the driver of the system status by illuminating,

flashing, or turning off the warning light according to

the signal from ABS-ECU.

Brake warning light6Used as the warning light for the parking brake, brake

fluid level, and EBD control. Informs the driver of the

system status by illuminating or turning off the warning

light according to the signal from ABS-ECU, ETACS or

combination meter.

Data link connector7Establishes the communication with scan tool.

ABS control unit (ABS-ECU)8Controls the actuators (described above) based on the

signals coming from each sensors.

Controls the self-diagnostic functions and fail-safe

functions.

Controls diagnostic function (Compatible with scan

tool).

Page 216 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-7

ABS-ECUM2351003000520

•By integrating ABS-ECU into the hydraulic unit,

no wiring harness for sending drive signal of the

solenoid valve and pump motor is required,

assuring higher reliability.

•Self-diagnostic and memory functions are inte-

grated into ABS-ECU. If any malfunction is

detected by the self-diagnostic function,

ABS-ECU activates a fail-safe function and illumi

-

nates the ABS warning light and brake warning

light

*.

NOTE: *: The brake warning light is used as the

EBD control warning light.

•ABS-ECU detects vehicle speed from the signals

of the wheel speed sensor and its recognizes the

wheel rotation status, estimates the wheel slip

condition based on the preprogrammed algo

-

rithm, and then controls the solenoid valve in the

hydraulic unit so that the wheels do not lock.

ABS hydraulic pressure control

ABS control cycle

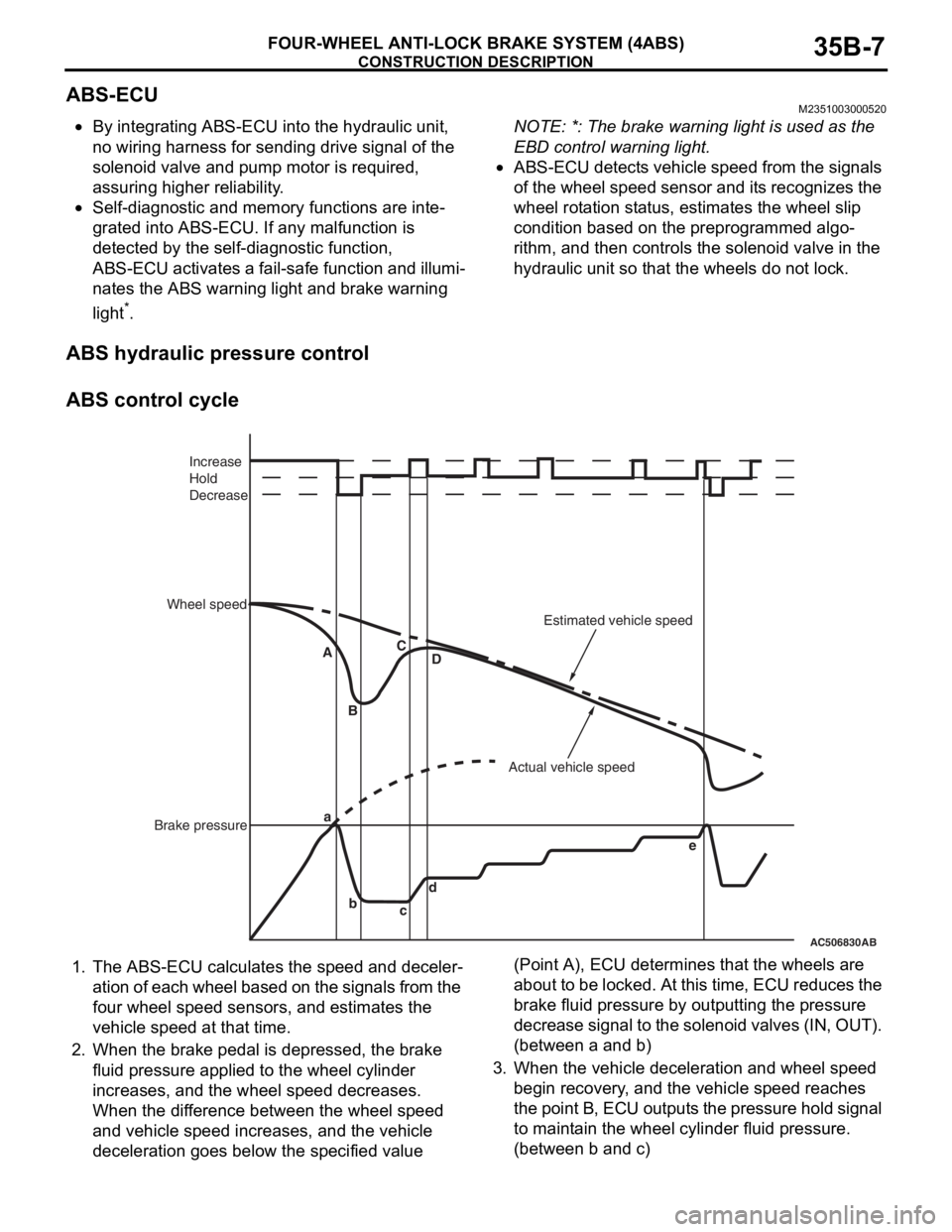

1. The ABS-ECU calculates the speed and deceler-

ation of each wheel based on the signals from the

four wheel speed sensors, and estimates the

vehicle speed at that time.

2. When the brake pedal is depressed, the brake

fluid pressure applied to the wheel cylinder

increases, and the wheel speed decreases.

When the difference between the wheel speed

and vehicle speed increases, and the vehicle

deceleration goes below the specified value (Point A), ECU determines that the wheels are

about to be locked. At this time, ECU reduces the

brake fluid pressure by outputting the pressure

decrease signal to the solenoid valves (IN, OUT).

(between a and b)

3. When the vehicle deceleration and wheel speed

begin recovery, and the vehicle speed reaches

the point B, ECU outputs the pressure hold signal

to maintain the wheel cylinder fluid pressure.

(between b and c)

AC506830AB

a

b

cd A

BC

D

e Increase

Hold

Decrease

Wheel speed

Brake pressureActual vehicle speedEstimated vehicle speed

Page 217 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-8

4. When the wheel speed deceleration is further

recovered and overpasses the point C, ECU

determines that the wheel lock possibility has

been eliminated and increases the brake fluid

pressure by outputting the pressure increase sig

-

nal again. (between c and d)

5. Brake fluid pressure is controlled by repeating the

increase and hold of the pressure. (between d

and e)

6. When the wheel deceleration goes below the

threshold again, ABS-ECU controls the brake

fluid pressure by repeating the cycle (Step 2 to 5).

Four-wheel control

ABS fluid pressure is controlled independently for

four wheels.

EBD fluid pressure control

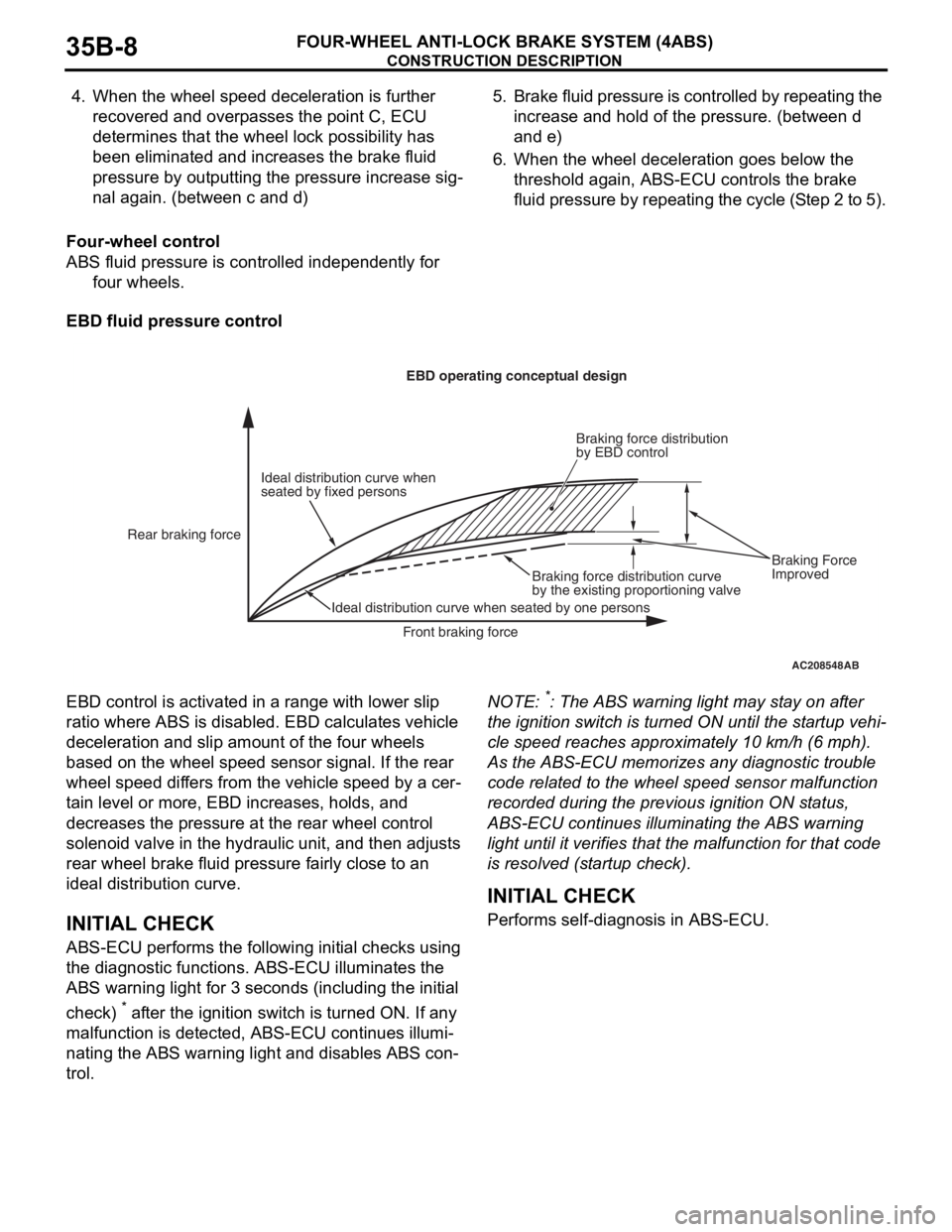

EBD control is activated in a range with lower slip

ratio where ABS is disabled. EBD calculates vehicle

deceleration and slip amount of the four wheels

based on the wheel speed sensor signal. If the rear

wheel speed differs from the vehicle speed by a cer

-

tain level or more, EBD increases, holds, and

decreases the pressure at the rear wheel control

solenoid valve in the hydraulic unit, and then adjusts

rear wheel brake fluid pressure fairly close to an

ideal distribution curve.

INITIAL CHECK

ABS-ECU performs the following initial checks using

the diagnostic functions. ABS-ECU illuminates the

ABS warning light for 3 seconds (including the initial

check)

* after the ignition switch is turned ON. If any

malfunction is detected, ABS-ECU continues illumi

-

nating the ABS warning light and disables ABS con-

trol.

NOTE: *: The ABS warning light may stay on after

the ignition switch is turned ON until the startup vehi

-

cle speed reaches approximately 10 km/h (6 mph).

As the ABS-ECU memorizes any diagnostic trouble

code related to the wheel speed sensor malfunction

recorded during the previous ignition ON status,

ABS-ECU continues illuminating the ABS warning

light until it verifies that the malfunction for that code

is resolved (startup check).

.

INITIAL CHECK

Performs self-diagnosis in ABS-ECU.

AC208548AB

Ideal distribution curve when

seated by fixed personsEBD operating conceptual design

Rear braking force

Ideal distribution curve when seated by one personsBraking force distribution curve

by the existing proportioning valveBraking force distribution

by EBD control

Front braking forceBraking Force

Improved