abs MITSUBISHI LANCER EVOLUTION X 2008 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 220 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-11

NOTE: .

•*1 This diagnostic trouble code is not set within

the vehicle speed of 20 km/h (12 mph) or less.

•*2 Turns ON when two or more wheels are faulty.

•*3 Stays ON until the vehicle speed reaches 10

km/h (6 mph) when the ignition switch is turned to

ON next time.

DIAGNOSTIC FUNCTION

ABS-ECU has the following functions for easier sys-

tem checks. The following items can be diagnosed

using scan tool.

•Diagnostic trouble code set

•Service data output

•Actuator test.

DIAGNOSTIC TROUBLE CODE SET

There are 43 diagnosis items. Since all the diagnos-

tic results are recorded in volatile memory

(EEPROM*), they are stored in the memory even

though the battery terminals are disconnected.

NOTE: .

•*EEPROM (Electrical Erasable & Programmable

ROM): Special type of memory that can be pro

-

grammed or erased electrically

•For each diagnosis item, refer to Service Manual.

.

SERVICE DATA OUTPUT

Using scan tool, the input data sent from the sensors

and switches can be read.

NOTE: For service data items, refer to Service Man-

ual.

.

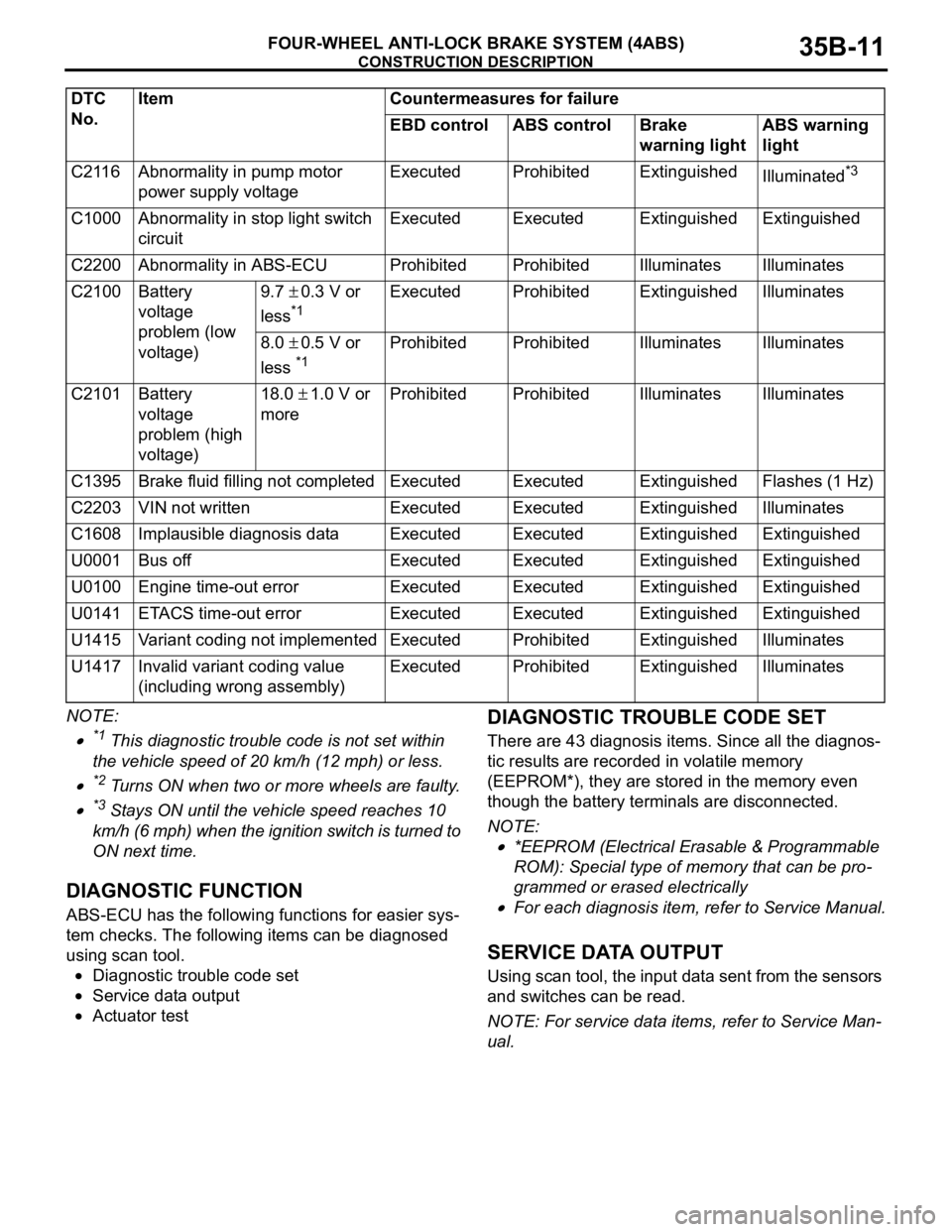

C2116Abnormality in pump motor

power supply voltageExecutedProhibitedExtinguishedIlluminated*3

C1000Abnormality in stop light switch

circuitExecutedExecutedExtinguishedExtinguished

C2200Abnormality in ABS-ECUProhibitedProhibitedIlluminatesIlluminates

C2100Battery

voltage

problem (low

voltage)9.7 ± 0.3 V or

less

*1

ExecutedProhibitedExtinguishedIlluminates

8.0 ± 0.5 V or

less

*1

ProhibitedProhibitedIlluminatesIlluminates

C2101Battery

voltage

problem (high

voltage)18.0 ± 1.0 V or

moreProhibitedProhibitedIlluminatesIlluminates

C1395Brake fluid filling not completedExecutedExecutedExtinguishedFlashes (1 Hz)

C2203VIN not writtenExecutedExecutedExtinguishedIlluminates

C1608Implausible diagnosis dataExecutedExecutedExtinguishedExtinguished

U0001Bus offExecutedExecutedExtinguishedExtinguished

U0100Engine time-out errorExecutedExecutedExtinguishedExtinguished

U0141ETACS time-out errorExecutedExecutedExtinguishedExtinguished

U1415Variant coding not implementedExecutedProhibitedExtinguishedIlluminates

U1417Invalid variant coding value

(including wrong assembly)ExecutedProhibitedExtinguishedIlluminates

DTC

No.Item Countermeasures for failure

EBD control ABS control Brake

warning lightABS warning

light

Page 221 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-12

ACTUATOR TEST

Using scan tool, the actuators can be forcibly oper-

ated.

NOTE: .

•When ABS-ECU is disabled, the actuator test

cannot be performed.

•The actuator test can be performed only when

the vehicle is stationary. When the vehicle speed

reaches 10 km/h (6 mph), the forcible actuator

operation is disabled.

•During actuator test, the ABS warning light

flashes in 2Hz, and ABS control is prohibited.

•For the actuator test specification, refer to Ser-

vice Manual.

Page 223 of 241

GENERAL INFORMATION

REAR SUSPENSION34-2

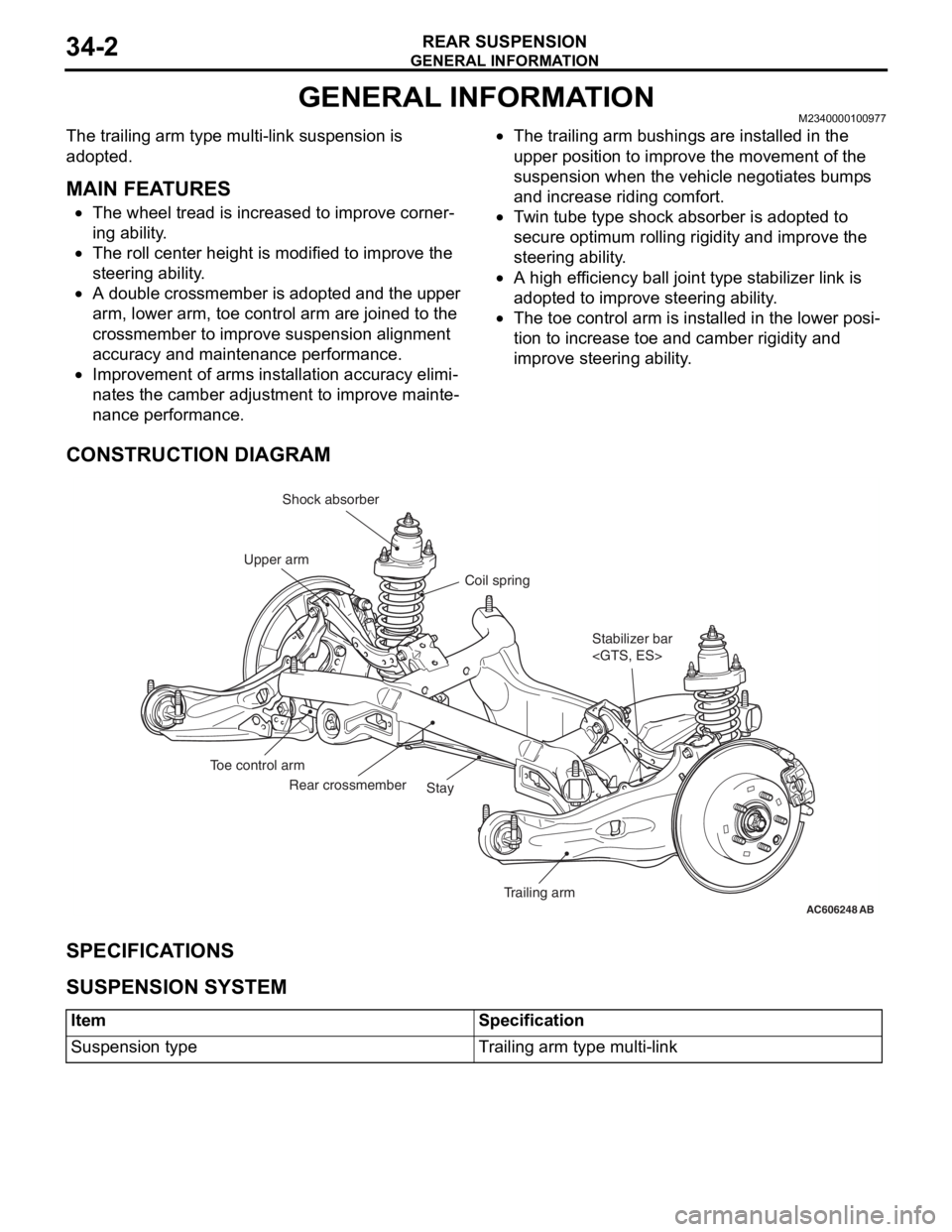

GENERAL INFORMATIONM2340000100977

The trailing arm type multi-link suspension is

adopted.

.

MAIN FEATURES

•The wheel tread is increased to improve corner-

ing ability.

•The roll center height is modified to improve the

steering ability.

•A double crossmember is adopted and the upper

arm, lower arm, toe control arm are joined to the

crossmember to improve suspension alignment

accuracy and maintenance performance.

•Improvement of arms installation accuracy elimi-

nates the camber adjustment to improve mainte-

nance performance.

•The trailing arm bushings are installed in the

upper position to improve the movement of the

suspension when the vehicle negotiates bumps

and increase riding comfort.

•Twin tube type shock absorber is adopted to

secure optimum rolling rigidity and improve the

steering ability.

•A high efficiency ball joint type stabilizer link is

adopted to improve steering ability.

•The toe control arm is installed in the lower posi-

tion to increase toe and camber rigidity and

improve steering ability.

CONSTRUCTION DIAGRAM

SPECIFICATIONS

.

SUSPENSION SYSTEM

.

AC606248AB

Stabilizer bar

Trailing arm Stay Rear crossmember Toe control armCoil spring Shock absorber

Upper arm

ItemSpecification

Suspension typeTrailing arm type multi-link

Page 233 of 241

GENERAL INFORMATION

REAR AXLE27-2

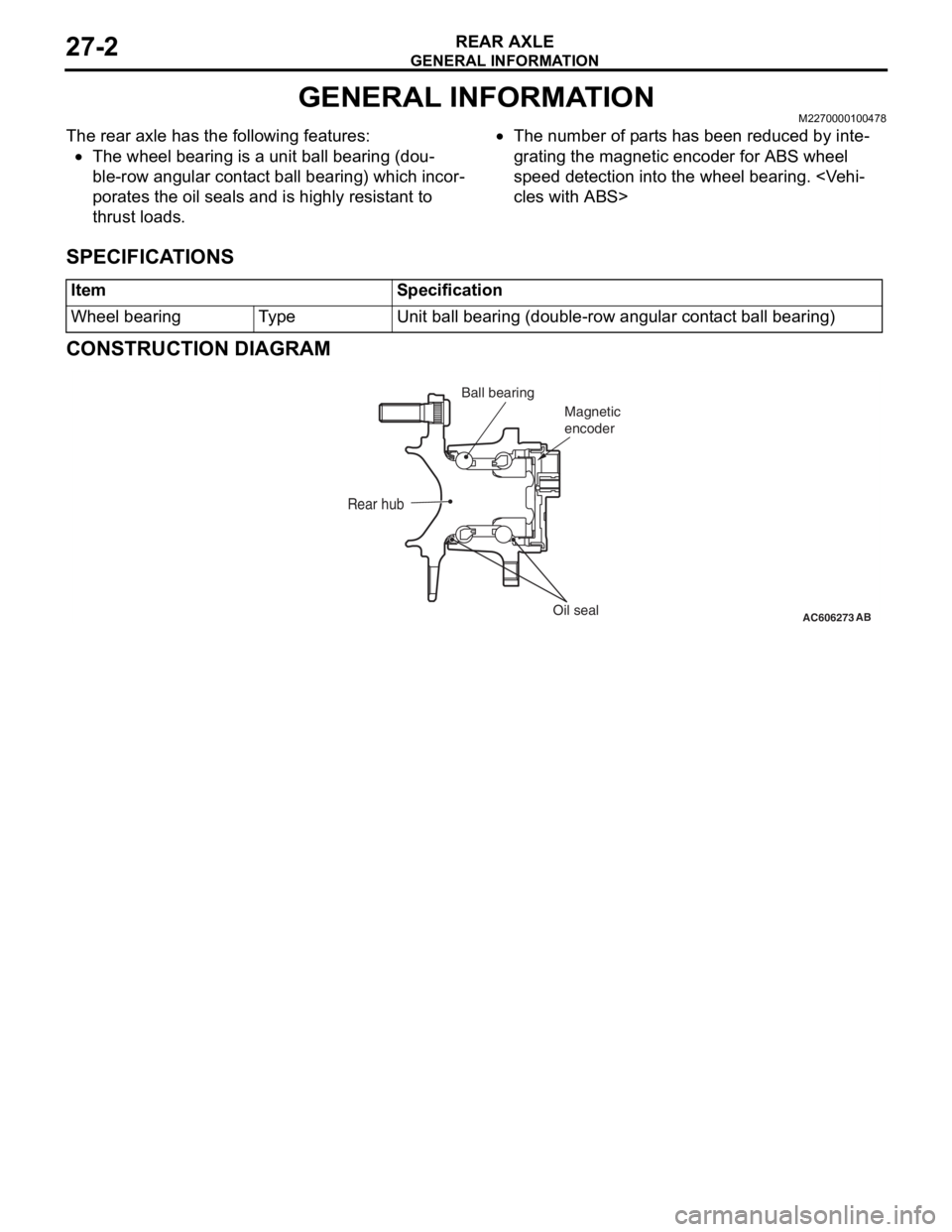

GENERAL INFORMATIONM2270000100478

The rear axle has the following features:

•The wheel bearing is a unit ball bearing (dou-

ble-row angular contact ball bearing) which incor-

porates the oil seals and is highly resistant to

thrust loads.

•The number of parts has been reduced by inte-

grating the magnetic encoder for ABS wheel

speed detection into the wheel bearing.

cles with ABS>

SPECIFICATIONS

CONSTRUCTION DIAGRAM

ItemSpecification

Wheel bearingTy p eUnit ball bearing (double-row angular contact ball bearing)

AC606273

Rear hub

Oil seal Ball bearing

Magnetic

encoderAB

Page 235 of 241

GENERAL INFORMATION

POWER STEERING37-2

GENERAL INFORMATIONM2370000101003

FEATURES

A hydraulic power steering system has been adopted

to all models.

This steering system offers the following features:

•The support method of the steering gear to the

crossmember is realised by the left and right

internal bushings with inner cylinders. This sup

-

port method achieves higher rigidity of the steer-

ing gear and improves the steering feeling.

•Configuring the optimum flow characteristics and

gear valve feature improves the handling stability.

•Appropriate application of friction to the steering

gear cuts off the disturbance from the road sur

-

face and improves the stability during the

straight-ahead driving.

•Optimisation of the flexible tube in the high pres-

sure hose reduces the pump noise.

SPECIFICATIONS

ItemsSpecifications

Steering wheelTy p eThree-spoke type

Outside diameter mm (in)375 (14.7)

Maximum number of turns3.16

Steering columnColumn mechanismShock absorbing

mechanism and Tilt steering

mechanism

Power steering typeIntegral type (Engine

speed-dependent type)

Oil pumpTy p eVane type with fluid flow

amount control system

Basic discharge amount cm3/rev. (cu in/rev)8.1 (0.49)

Relief pressure MPa (psi)8.8 (1,276)

Reservoir typeSeparate type (Resin made)

Steering gearTy p eRack and pinion type

Stroke ratio (Rack stroke/Steering wheel

Maximum turning radius) mm/rev (in/rev)45.58 mm/rev (1.79 in/rev)

Rack stroke mm (in)144

Steering angleInner wheel40°50’

Outer wheel33°50’

Power steering fluidSpecified lubricantsGENUINE MITSUBISHI

POWER STEERING FLUID

Quantity dm3 (qt)Approximately 1.0 (1.06)

Page 238 of 241

STEERING SHAFT AND COLUMN

POWER STEERING37-5

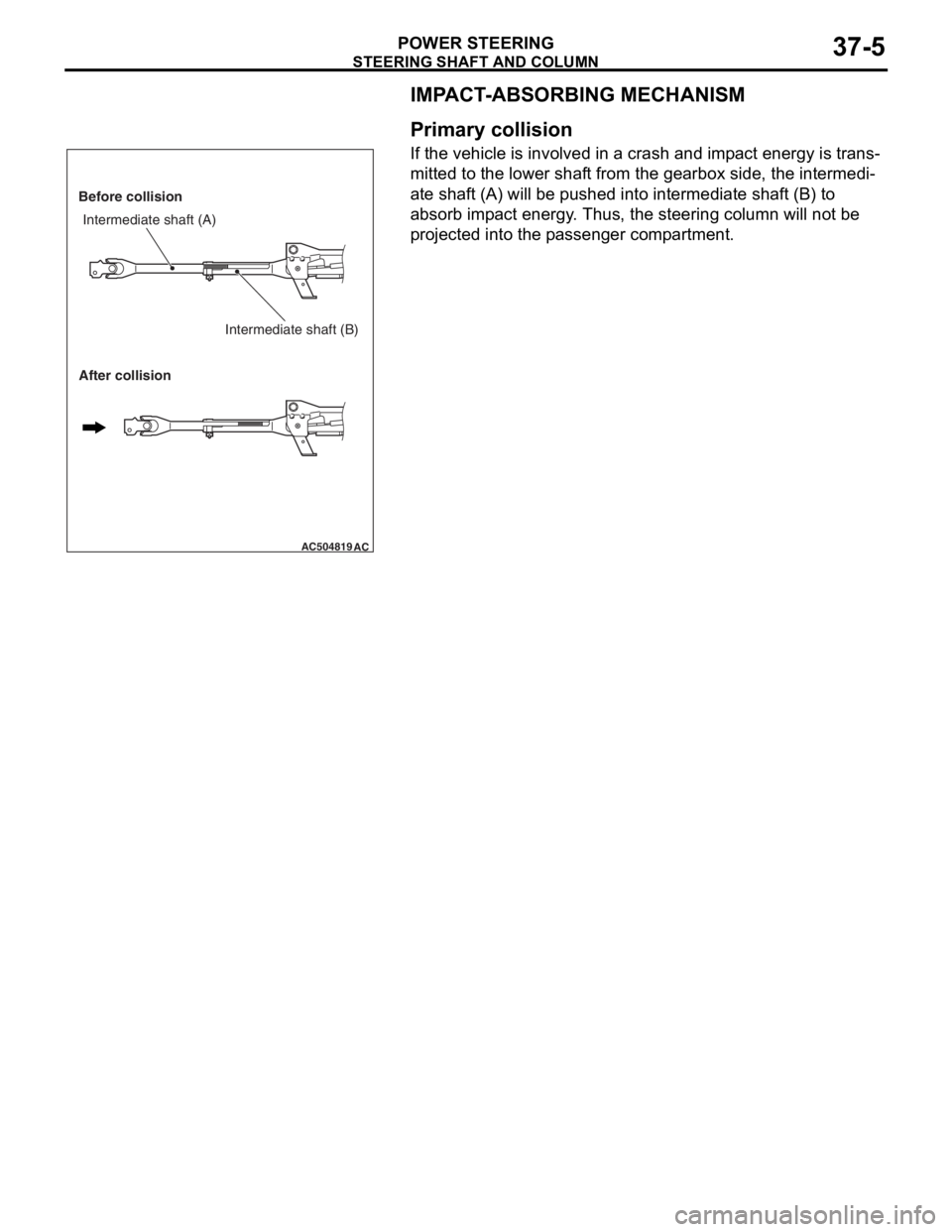

IMPACT-ABSORBING MECHANISM

.

Primary collision

If the vehicle is involved in a crash and impact energy is trans-

mitted to the lower shaft from the gearbox side, the intermedi-

ate shaft (A) will be pushed into intermediate shaft (B) to

absorb impact energy. Thus, the steering column will not be

projected into the passenger compartment.

.

AC504819AC

Before collision

After collisionIntermediate shaft (A)

Intermediate shaft (B)