MITSUBISHI LANCER IX 2006 Service Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 171 of 800

32-1

GROUP 32

POWER PLANT

MOUNT

CONTENTS

GENERAL INFORMATIO N . . . . . . . .32-2

SERVICE SPECIFICATION . . . . . . . .32-3

SPECIAL TOOL . . . . . . . . . . . . . . . . .32-3

ENGINE MOUNTING . . . . . . . . . . . . .32-4

REMOVAL AND INSTALLATION . . . . . . . . 32-4

TRANSMISSION MOUNTING . . . . . .32-5

REMOVAL AND INSTALLATION . . . . . . . . 32-5

ENGINE ROLL STOPPER,

CENTREMEMBER . . . . . . . . . . . . . . .32-7

REMOVAL AND INSTALLATION . . . . . . . . 32-7

CROSSMEMBER . . . . . . . . . . . . . . . .32-8

REMOVAL AND INSTALLATION . . . . . . . . 32-8

Page 172 of 800

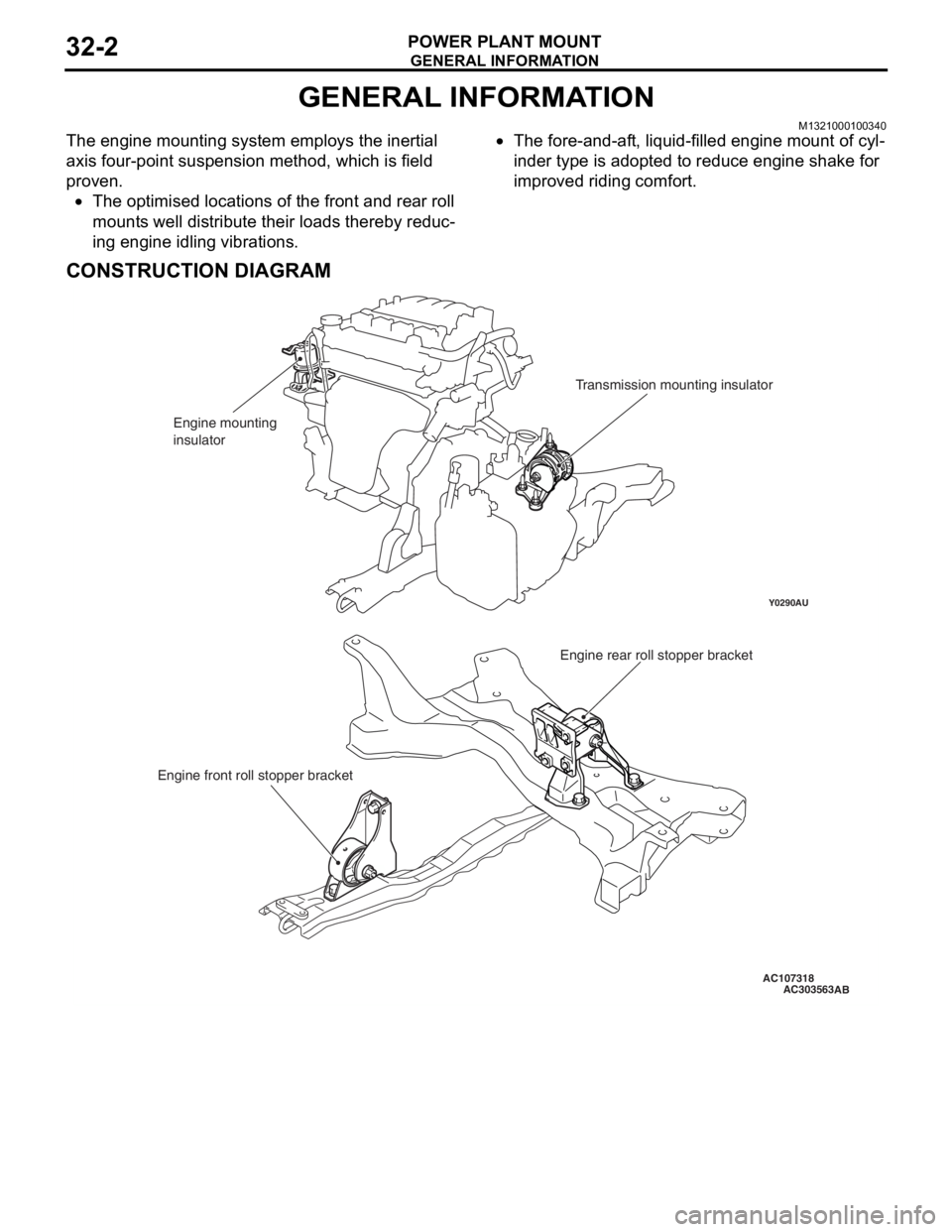

GENERAL INFORMATION

POWER PLANT MOUNT32-2

GENERAL INFORMATION

M1321000100340

The engine mounting system employs the inertial

axis four-point suspension method, which is field

proven.

•The optimised locations of the front and rear roll

mounts well distribute their loads thereby reduc

-

ing engine idling vibrations.

•The fore-and-aft, liquid-filled engine mount of cyl-

inder type is adopted to reduce engine shake for

improved riding comfort.

CONSTRUCTION DIAGRAM

AC107318

Y0290AU

AC303563

Engine mounting

insulatorTransmission mounting insulator

Engine rear roll stopper bracket

Engine front roll stopper bracket

AB

Page 173 of 800

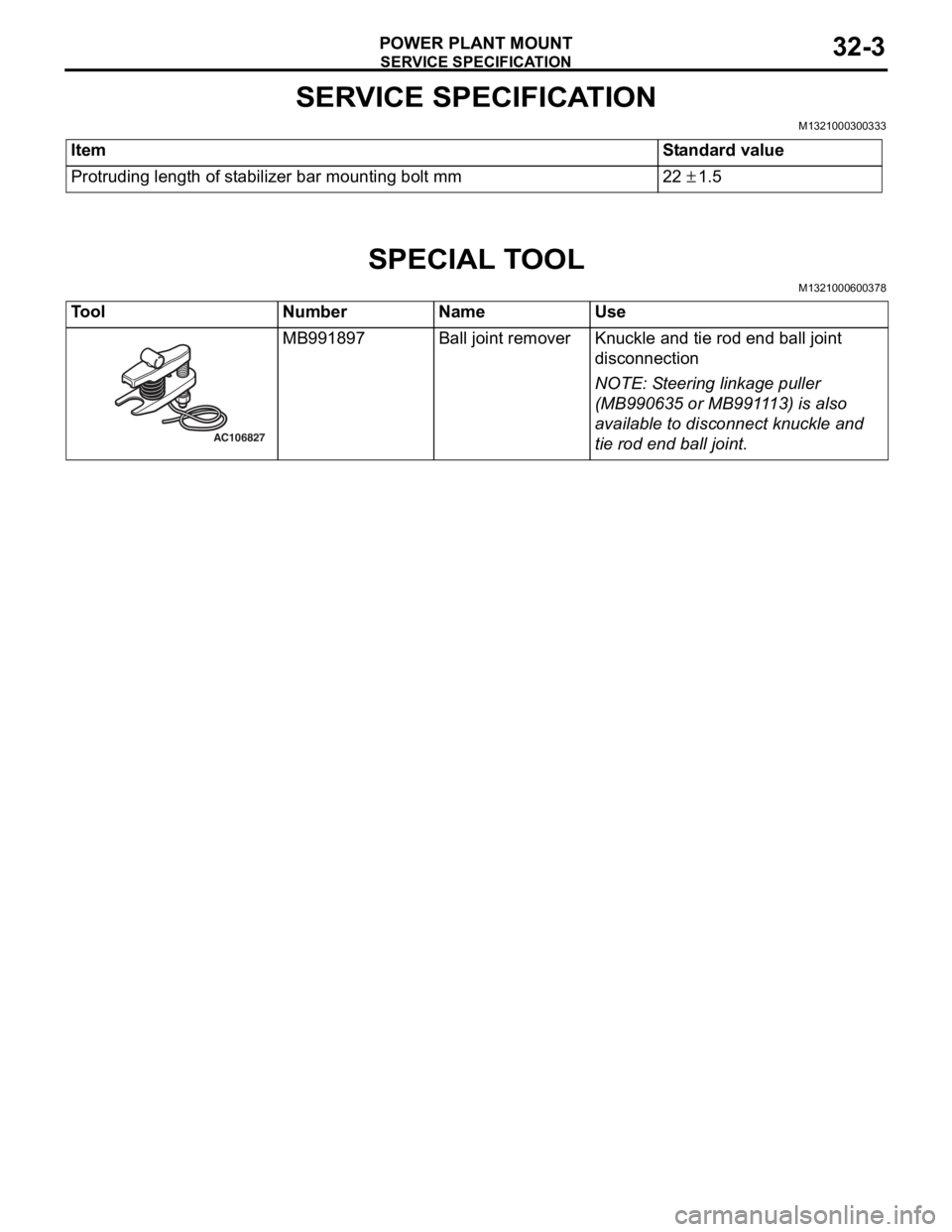

SERVICE SPECIFICATION

POWER PLANT MOUNT32-3

SERVICE SPECIFICATION

M1321000300333

ItemStandard value

Protruding length of stabilizer bar mounting bolt mm22 ± 1.5

SPECIAL TOOL

M1321000600378

ToolNumberNameUse

AC106827

MB991897Ball j o in t remo verKnuckle and tie rod e nd ball joint

discon

nection

NOTE: St eering linkage pu lle r

(MB990 635 o r MB991 1 13) is also

ava

ilab

l e to disconn ect knuckle and

tie ro

d end ball joint.

Page 174 of 800

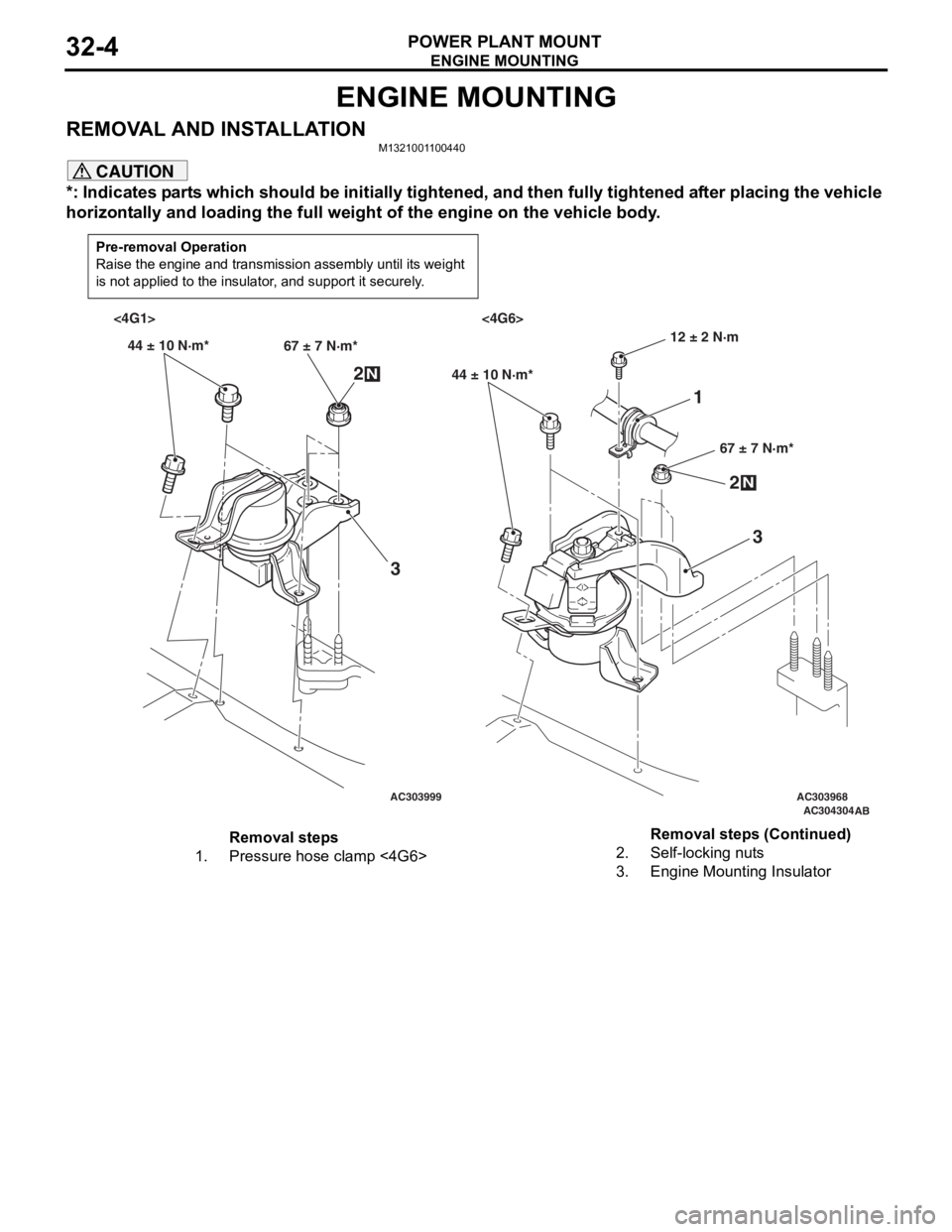

ENGINE MOUNTING

POWER PLANT MOUNT32-4

ENGINE MOUNTING

REMOVAL AND INSTALLATIONM1321001100440

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transmission assembly until its weight

is not applied to the insulator, and support it securely.

AC303999AC303968AC304304AB

<4G1> <4G6>

44 ± 10 N·m* 67 ± 7 N·m*

2N

3

44 ± 10 N·m*

67 ± 7 N·m*

2N

3

12 ± 2 N·m

1

Removal steps

1.Pressure hose clamp <4G6>2.Self-locking nuts

3.Engine Mounting Insulator

Removal steps (Continued)

Page 175 of 800

TRANSMISSION MOUNTING

POWER PLANT MOUNT32-5

TRANSMISSION MOUNTING

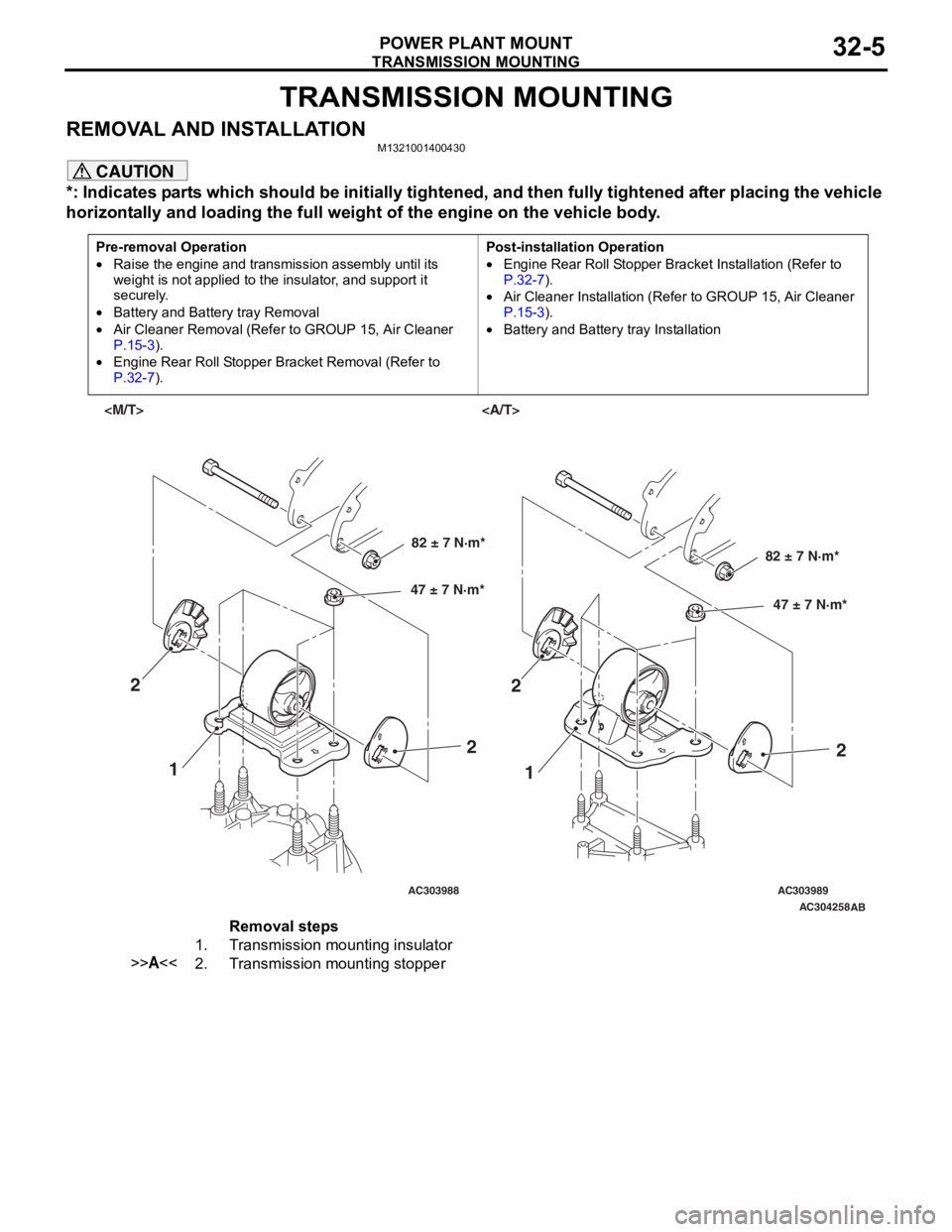

REMOVAL AND INSTALLATIONM1321001400430

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

•Raise the engine and transmission assembly until its

weight is not applied to the insulator, and support it

securely.

•Battery and Battery tray Removal

•Air Cleaner Removal (Refer to GROUP 15, Air Cleaner

P.15-3).

•Engine Rear Roll Stopper Bracket Removal (Refer to

P.32-7).

Post-installation Operation

•Engine Rear Roll Stopper Bracket Installation (Refer to

P.32-7).

•Air Cleaner Installation (Refer to GROUP 15, Air Cleaner

P.15-3).

•Battery and Battery tray Installation

AC303988AC303989AC304258

AB

82 ± 7 N·m*

47 ± 7 N·m*82 ± 7 N·m*

47 ± 7 N·m*

1 1

2

22

2

Removal steps

1.Transmission mounting insulator

>>A<<2.Transmission mounting stopper

Page 176 of 800

TRANSMISSION MOUNTING

POWER PLANT MOUNT32-6

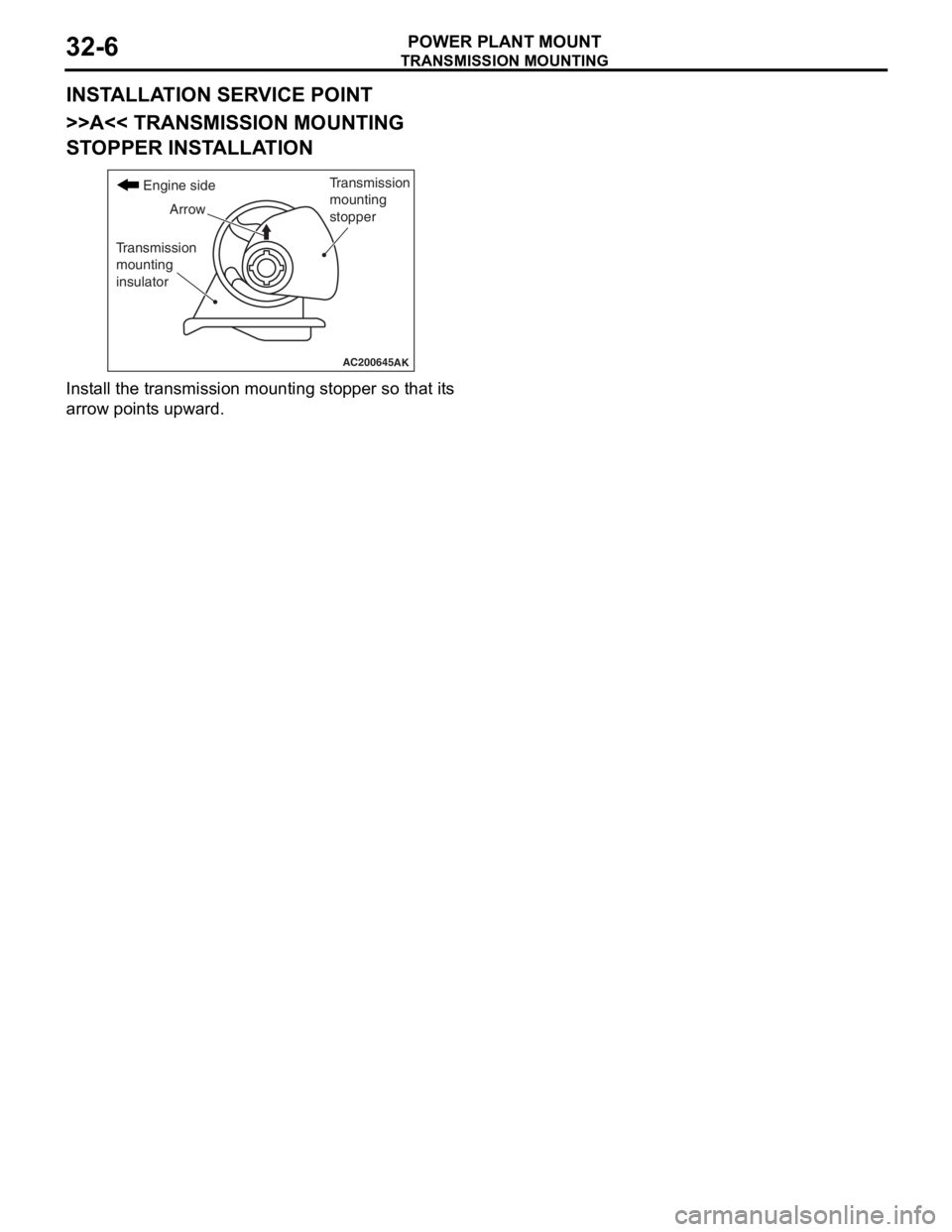

INSTALLATION SERVICE POINT

>>A<< TRANSMISSION MOUNTING

STOPPER INSTALLATION

AC200645

Transmission

mounting

stopper

Arrow

Transmission

mounting

insulator

Engine side

AK

Install the t r ansmissio n mo untin g sto pper so that it s

arrow point

s upward .

Page 177 of 800

ENGINE ROLL STOPPER, CENTREMEMBER

POWER PLANT MOUNT32-7

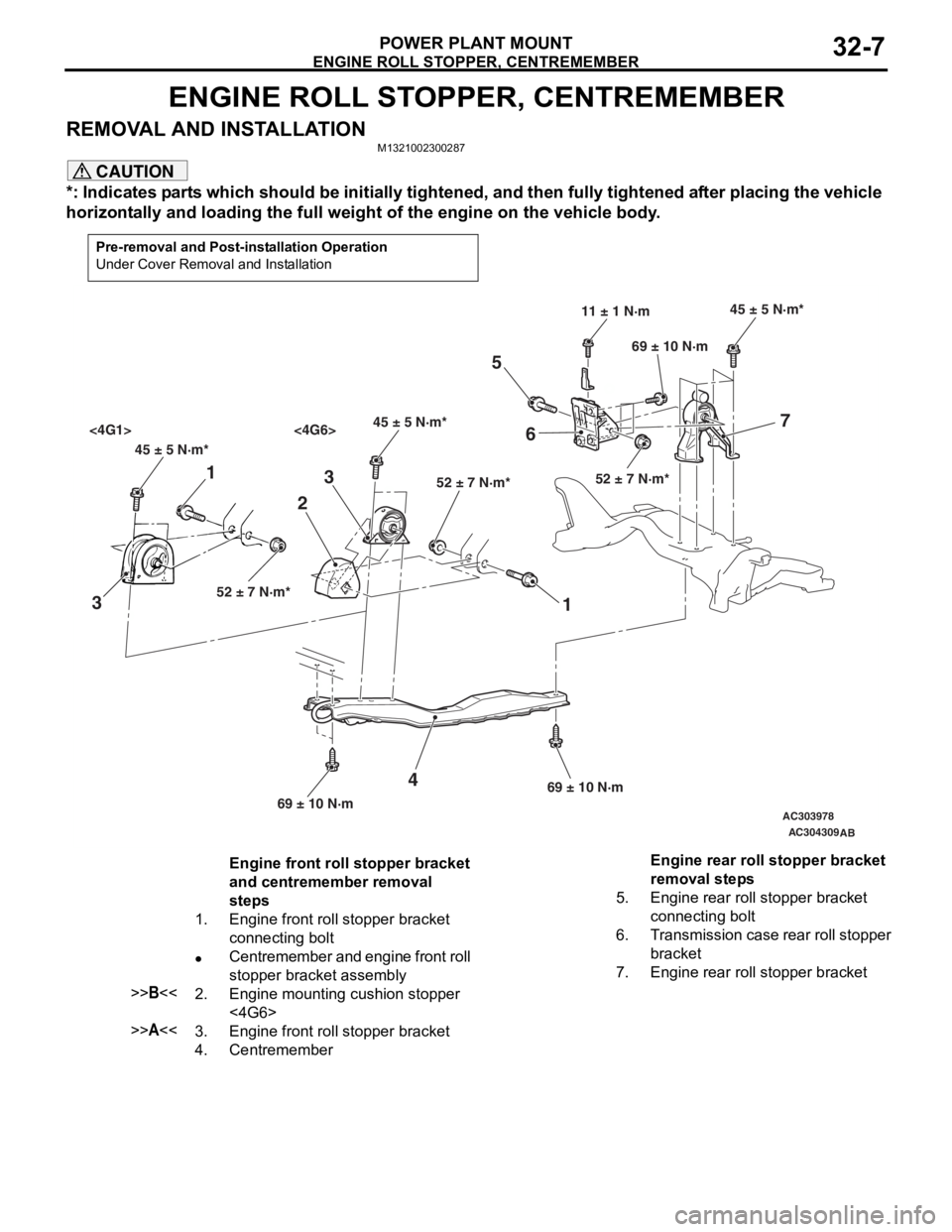

ENGINE ROLL STOPPER, CENTREMEMBER

REMOVAL AND INSTALLATIONM1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

AC303978

AC304309

45 ± 5 N·m*45 ± 5 N·m*

<4G1> <4G6>

52 ± 7 N·m* 52 ± 7 N·m*

45 ± 5 N·m*

52 ± 7 N·m*

11 ± 1 N·m

69 ± 10 N·m

69 ± 10 N·m 69 ± 10 N·m

1

3 2

1

3

4

56 7

AB

Engine front roll stopper bracket

and centremember removal

steps

1.Engine front roll stopper bracket

connecting bolt

•Centremember and engine front roll

stopper bracket assembly

>>B<<2.Engine mounting cushion stopper

<4G6>

>>A<<3.Engine front roll stopper bracket

4.Centremember

Engine rear roll stopper bracket

removal steps

5.Engine rear roll stopper bracket

connecting bolt

6.Transmission case rear roll stopper

bracket

7.Engine rear roll stopper bracket

Page 178 of 800

CROSSMEMBER

POWER PLANT MOUNT32-8

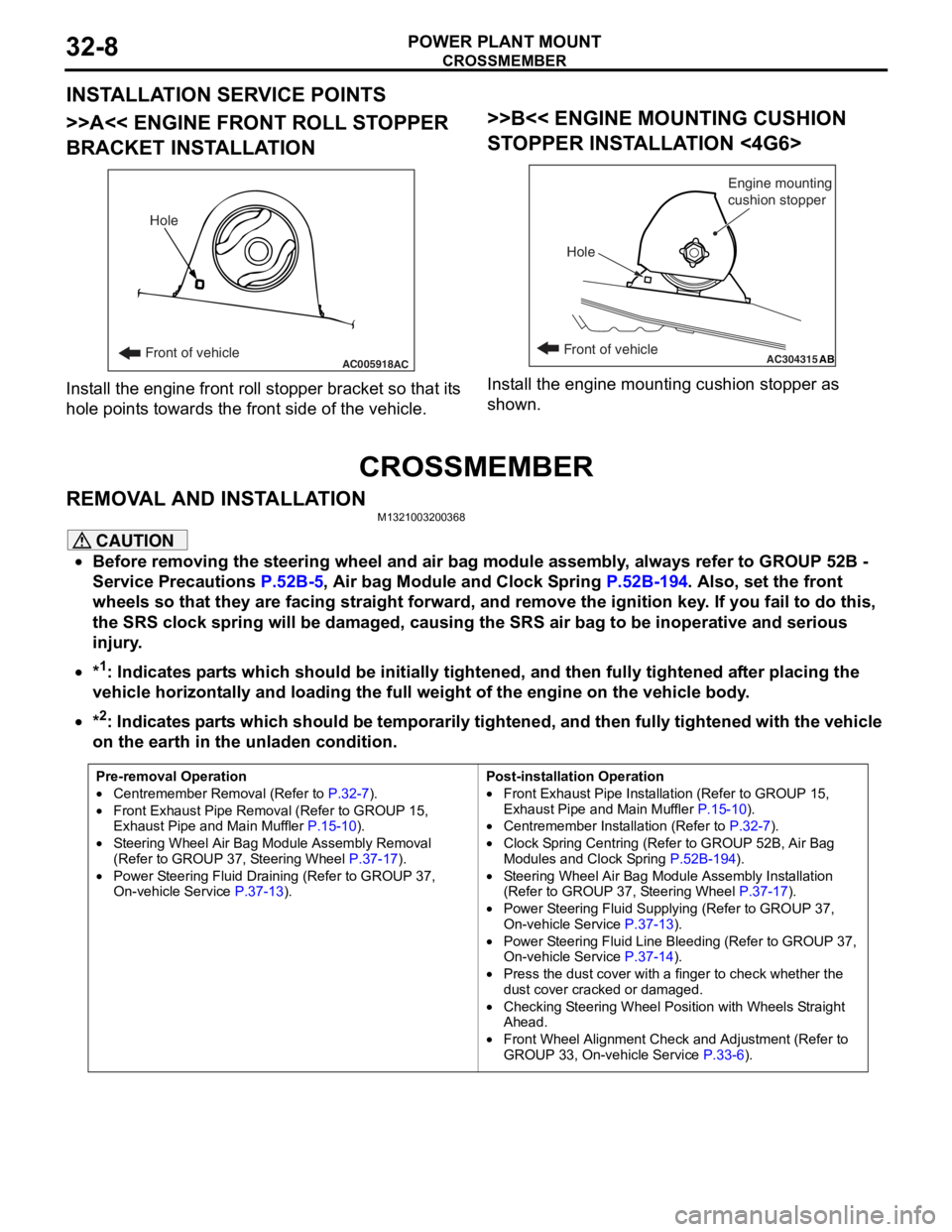

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

AC005918Front of vehicleHoleAC

Inst

all th e en gine fron t roll stop per b r acket so that it s

hole

point s towards the fro n t side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

ST

OPPER INST ALLA TION <4G6>

AC304315ABFront of vehicle

Hole Engine mounting

cushion stopper

Inst

all the e ngin e mo untin g cushio n sto pper a s

shown.

CROSSMEMBER

REMOVA L AND INST ALLA TIONM13210032 0036 8

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions

P.52B-5, Air bag Module and Clock Spring P.52B-194. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•

Pre-removal Operation

•Centremember Removal (Refer to P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

•Steering Wheel Air Bag Mo dule Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler

P.15-10).

•Centremember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-14).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-6).

*2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

Page 179 of 800

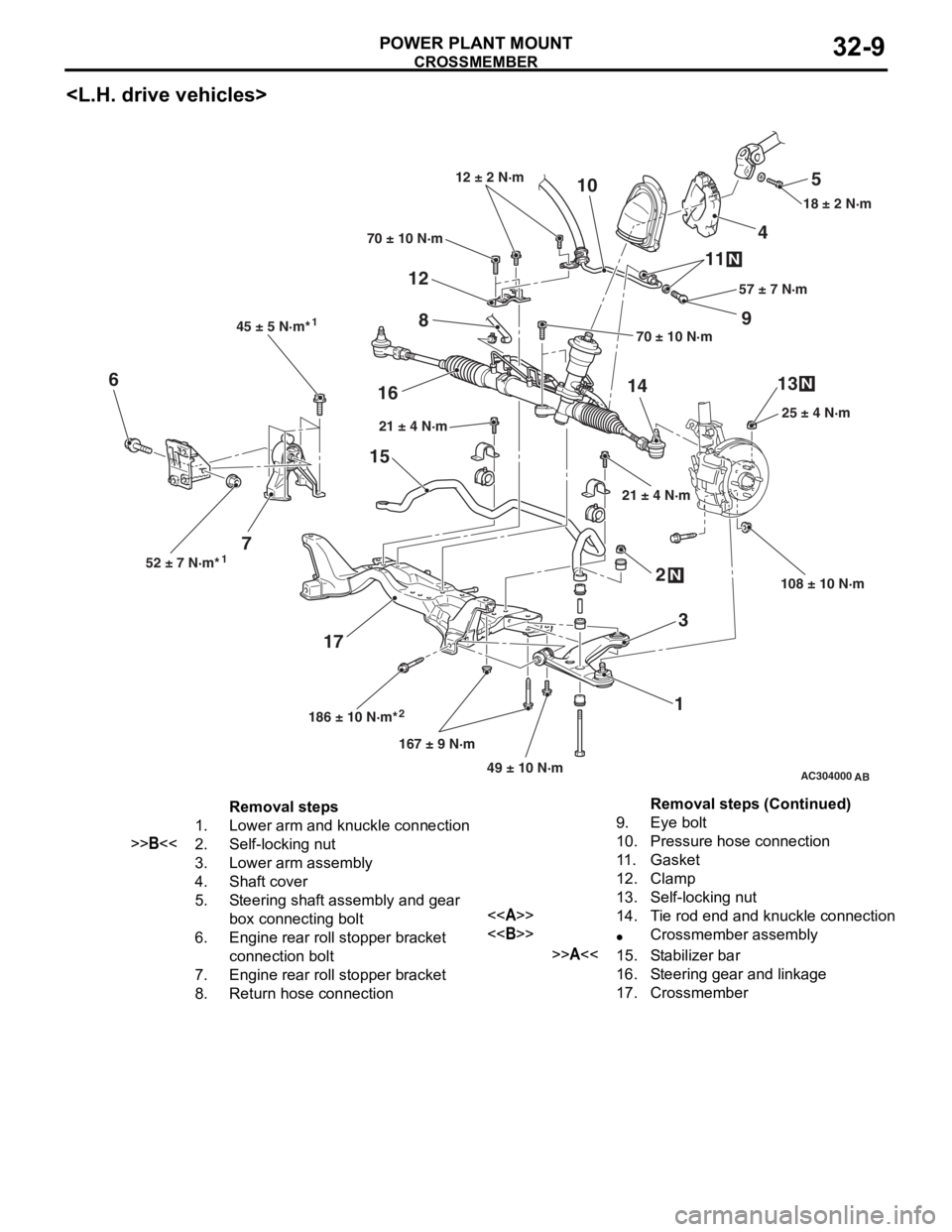

CROSSMEMBER

POWER PLANT MOUNT32-9

AC304000

108 ± 10 N·m25 ± 4 N·m 18 ± 2 N·m

70 ± 10 N·m

21 ± 4 N·m

21 ± 4 N·m

186 ± 10 N·m* 167 ± 9 N·m49 ± 10 N·m

52 ± 7 N·m* 45 ± 5 N·m*

70 ± 10 N·m

57 ± 7 N·m

12 ± 2 N·m

5

4

10

9

11

8

12

1413

6

7 16

15

17 2

3

1

N

N

N

2

1 1

AB

Removal steps

1.Lower arm and knuckle connection

>>B<<2.Self-locking nut

3.Lower arm assembly

4.Shaft cover

5.Steering shaft assembly and gear

box connecting bolt

6.Engine rear roll stopper bracket

connection bolt

7.Engine rear roll stopper bracket

8.Return hose connection

9.Eye bolt

10.Pressure hose connection

11 .Gasket

12.Clamp

13.Self-locking nut

<>14.Tie rod end and knuckle connection

<>•Crossmember assembly

>>A<<15.Stabilizer bar

16.Steering gear and linkage

17.Crossmember

Removal steps (Continued)

Page 180 of 800

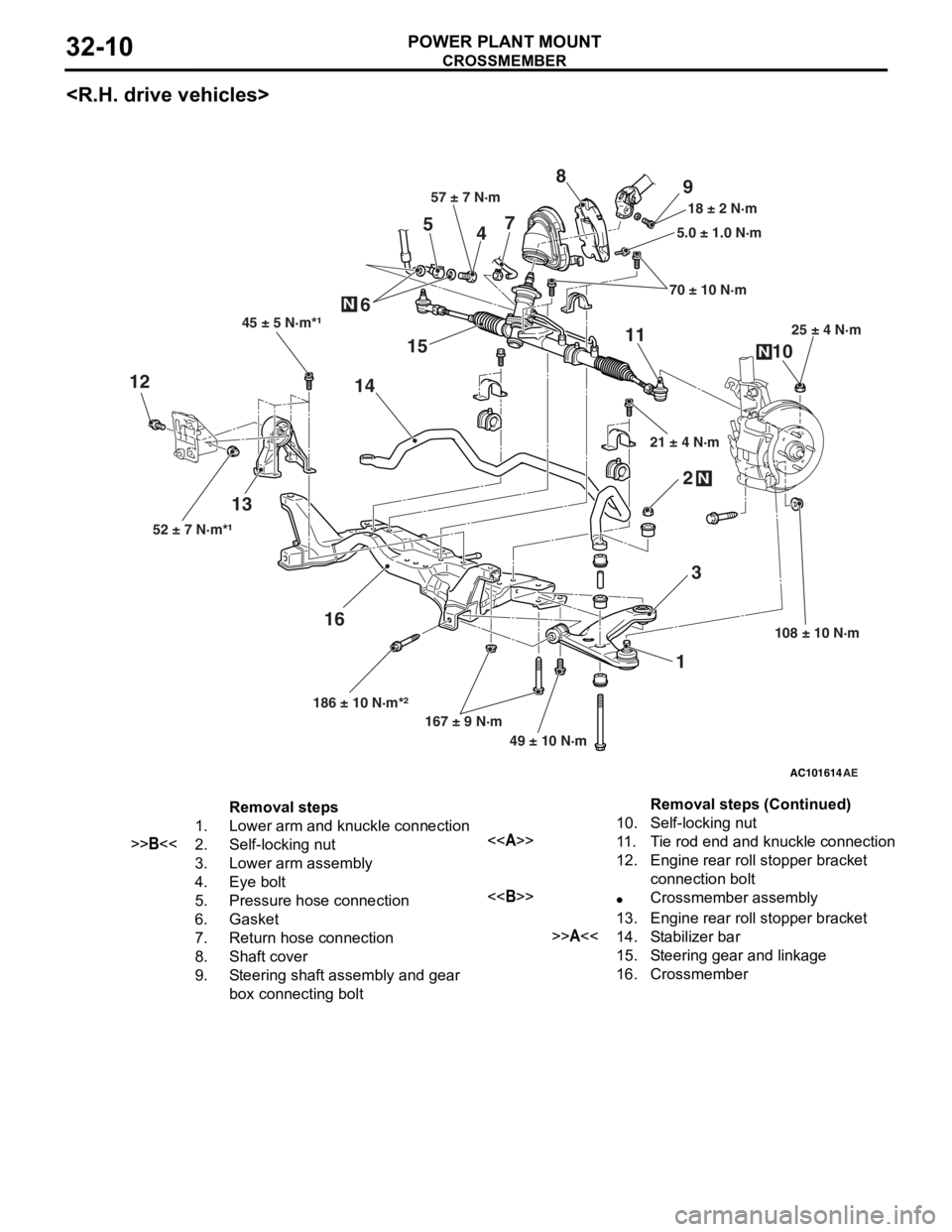

CROSSMEMBER

POWER PLANT MOUNT32-10

AC101614

12

3

4

5

6 7

8

9

10

11

12

13 14

15

16

45 ± 5 N·m*¹

52 ± 7 N·m*¹ 186 ± 10 N·m*²167 ± 9 N·m

49 ± 10 N·m 108 ± 10 N·m25 ± 4 N·m

21 ± 4 N·m 70 ± 10 N·m

5.0 ± 1.0 N·m

18 ± 2 N·m

57 ± 7 N·m

N

N

N

AE

Removal steps

1.Lower arm and knuckle connection

>>B<<2.Self-locking nut

3.Lower arm assembly

4.Eye bolt

5.Pressure hose connection

6.Gasket

7.Return hose connection

8.Shaft cover

9.Steering shaft assembly and gear

box connecting bolt

10.Self-locking nut

<>11 .Tie rod end and knuckle connection

12.Engine rear roll stopper bracket

connection bolt

<>•Crossmember assembly

13.Engine rear roll stopper bracket

>>A<<14.Stabilizer bar

15.Steering gear and linkage

16.Crossmember

Removal steps (Continued)