MITSUBISHI LANCER IX 2006 Service Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 181 of 800

Page 182 of 800

NOTES

Page 183 of 800

33-1

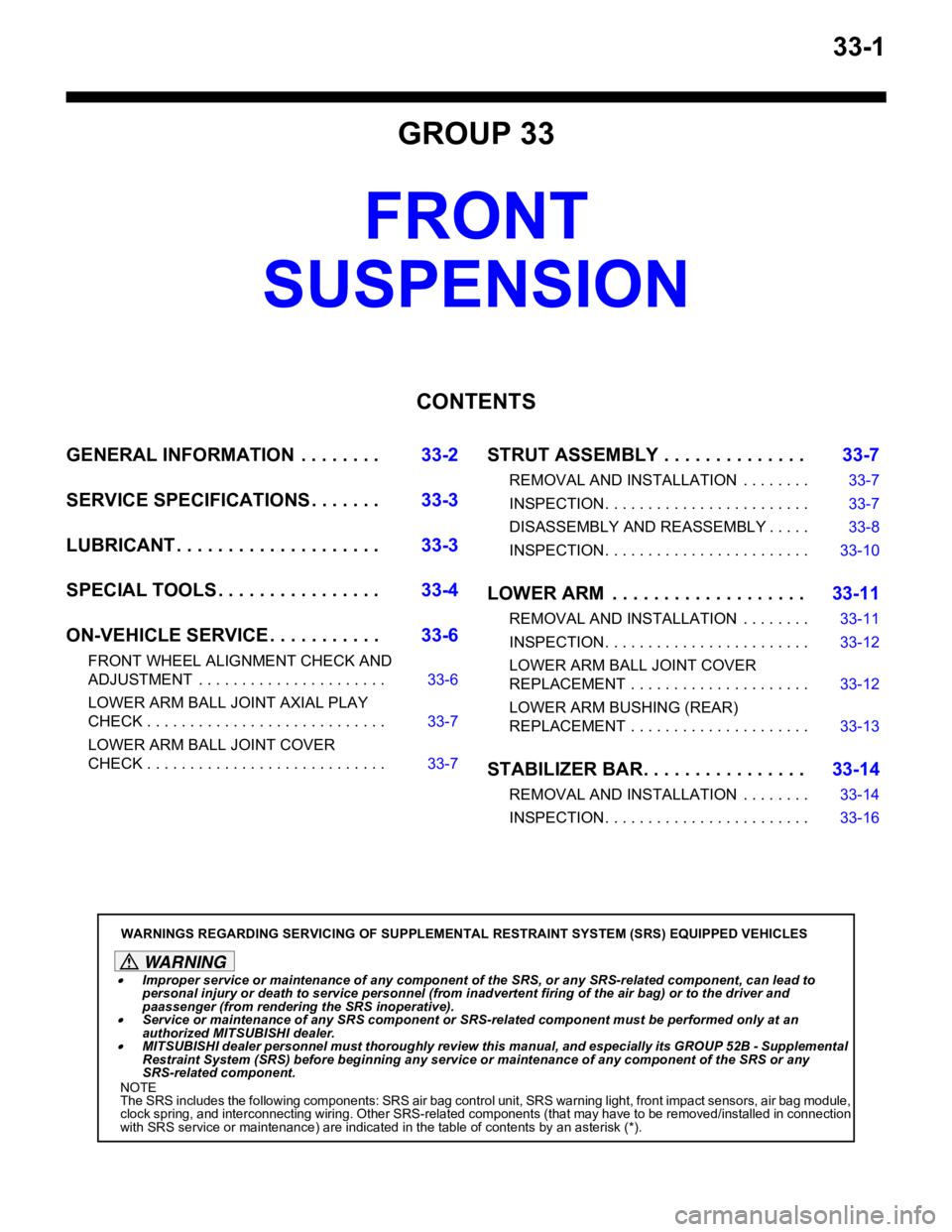

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-6

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR. . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-16

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 184 of 800

GENERAL INFORMATION

FRONT SUSPENSION33-2

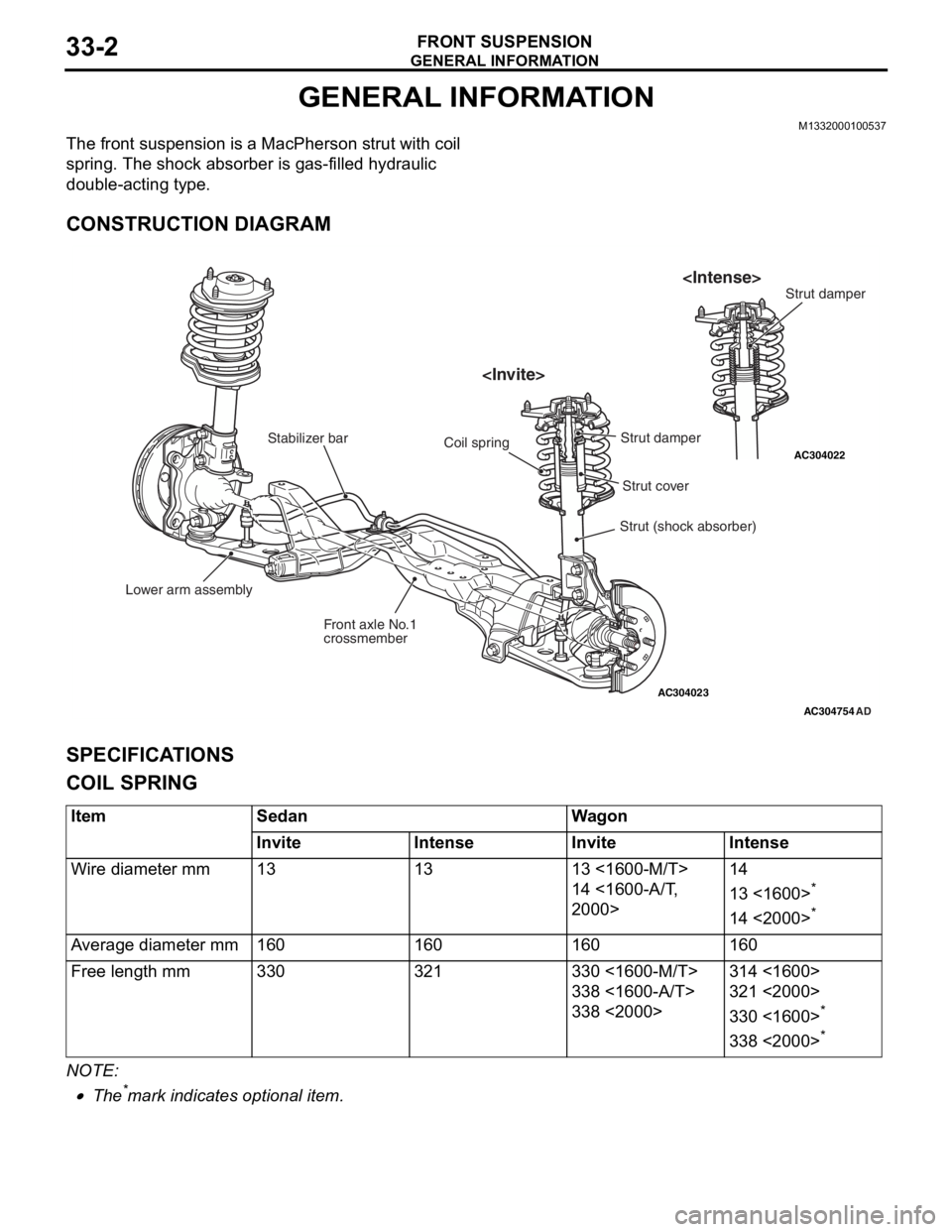

GENERAL INFORMATION

M1332000100537

The front suspension is a MacPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

AC304023

AC304022

AC304754

Lower arm assembly Front axle No.1

crossmember

Stabilizer bar

Strut (shock absorber)

Coil spring

AD

Strut cover

Strut damper

SPECIFICA

T IONS

COIL SPRING

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm131313 <1600-M/T>

14 <1600-A/T,

2000>

14

13 <1600>*

14 <2000>*

Average diameter mm160160160160

Free length mm330321330 <1600-M/T>

338 <1600-A/T>

338 <2000>

314 <1600>

321 <2000>

330 <1600>*

338 <2000>*

NOTE: .

•The*mark indicat e s op tiona l it em.

Page 185 of 800

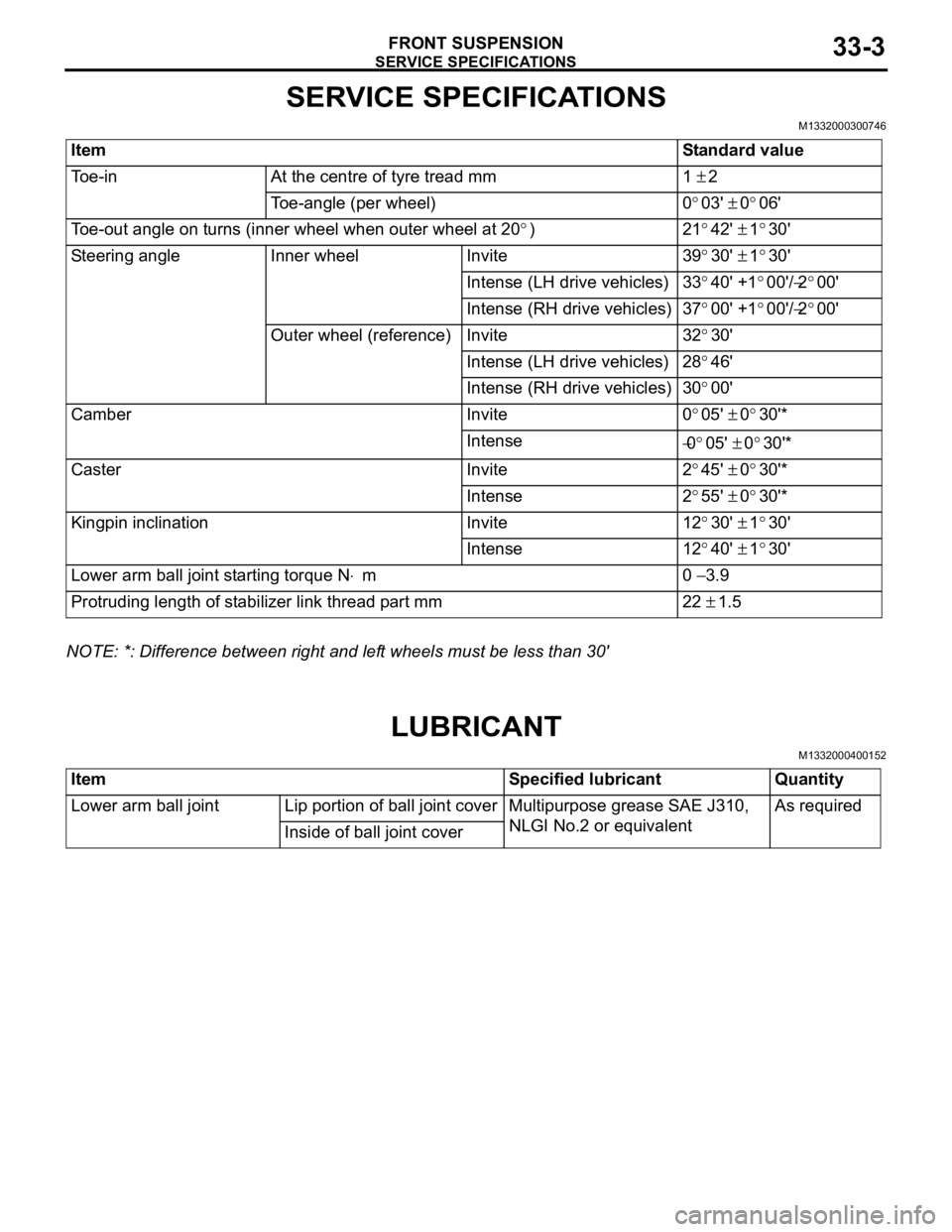

SERVICE SPECIFICATIONS

FRONT SUSPENSION33-3

SERVICE SPECIFICATIONS

M1332000300746

ItemStandard value

Toe-inAt the centre of tyre tread mm1 ± 2

Toe-angle (per wheel)0°03' ± 0°06'

Toe-out angle on turns (inner wheel when outer wheel at 20°)21°42' ± 1°30'

Steering angleInner wheelInvite39°30' ± 1°30'

Intense (LH drive vehicles)33°40' +1°00'/−2°00'

Intense (RH drive vehicles)37°00' +1°00'/−2°00'

Outer wheel (reference)Invite32°30'

Intense (LH drive vehicles)28°46'

Intense (RH drive vehicles)30°00'

CamberInvite0°05' ± 0°30'*

Intense−0°05' ± 0°30'*

CasterInvite2°45' ± 0°30'*

Intense2°55' ± 0°30'*

Kingpin inclinationInvite12°30' ± 1°30'

Intense12°40' ± 1°30'

Lower arm ball joint starting torque N⋅m0 − 3.9

Protruding length of stabilizer link thread part mm22 ± 1.5

NOTE: *: Difference between right and left wheels must be less than 30'

LUBRICANT

M1332000400152

ItemSpecified lubricantQuantity

Lower arm ball jointLip portion of ball joint coverMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Inside of ball joint cover

Page 186 of 800

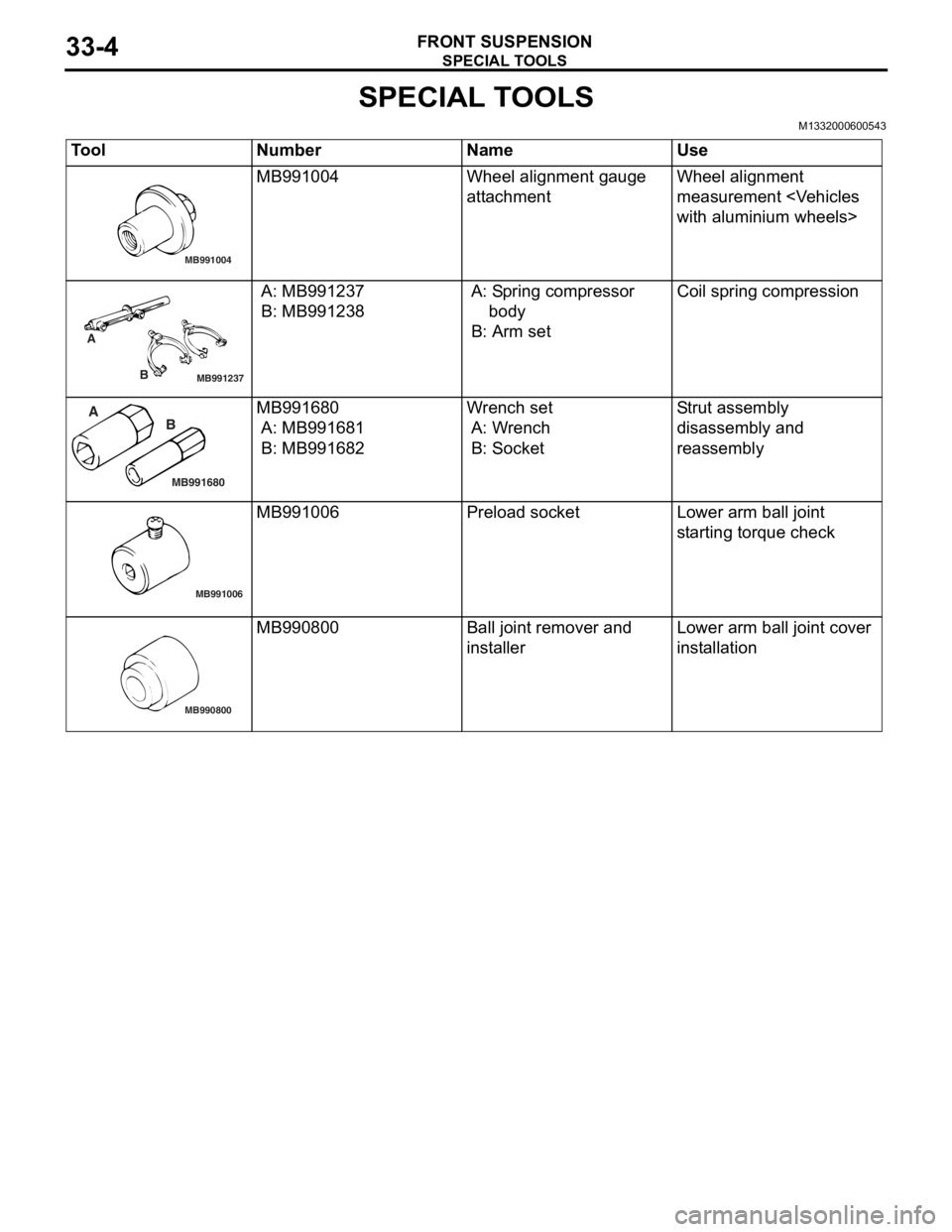

SPECIAL TOOLS

FRONT SUSPENSION33-4

SPECIAL TOOLS

M1332000600543

ToolNumberNameUse

MB991004

MB991004Wheel alignme n t gau ge

att

a chmentWheel alig nme n t

measurement

with aluminium wheels>

MB991237

A

B

A: MB9912 37

B: MB991238

A: Sp ring compressor

b ody

B: Arm set

Coil spring compression

MB991680

A BMB991680

A: MB9916 81

B: MB991682

Wr ench set

A: W r ench

B: Socket

Str u t a s s e m b l y

d

i sa ssembly an d

reassembly

MB991006

MB991006Prel oad socketLo wer arm ball joint

st

arting torque check

MB990800

MB990800Ball j o int remo ver an d

inst

al lerLo wer arm ball joint cover

inst

allation

Page 187 of 800

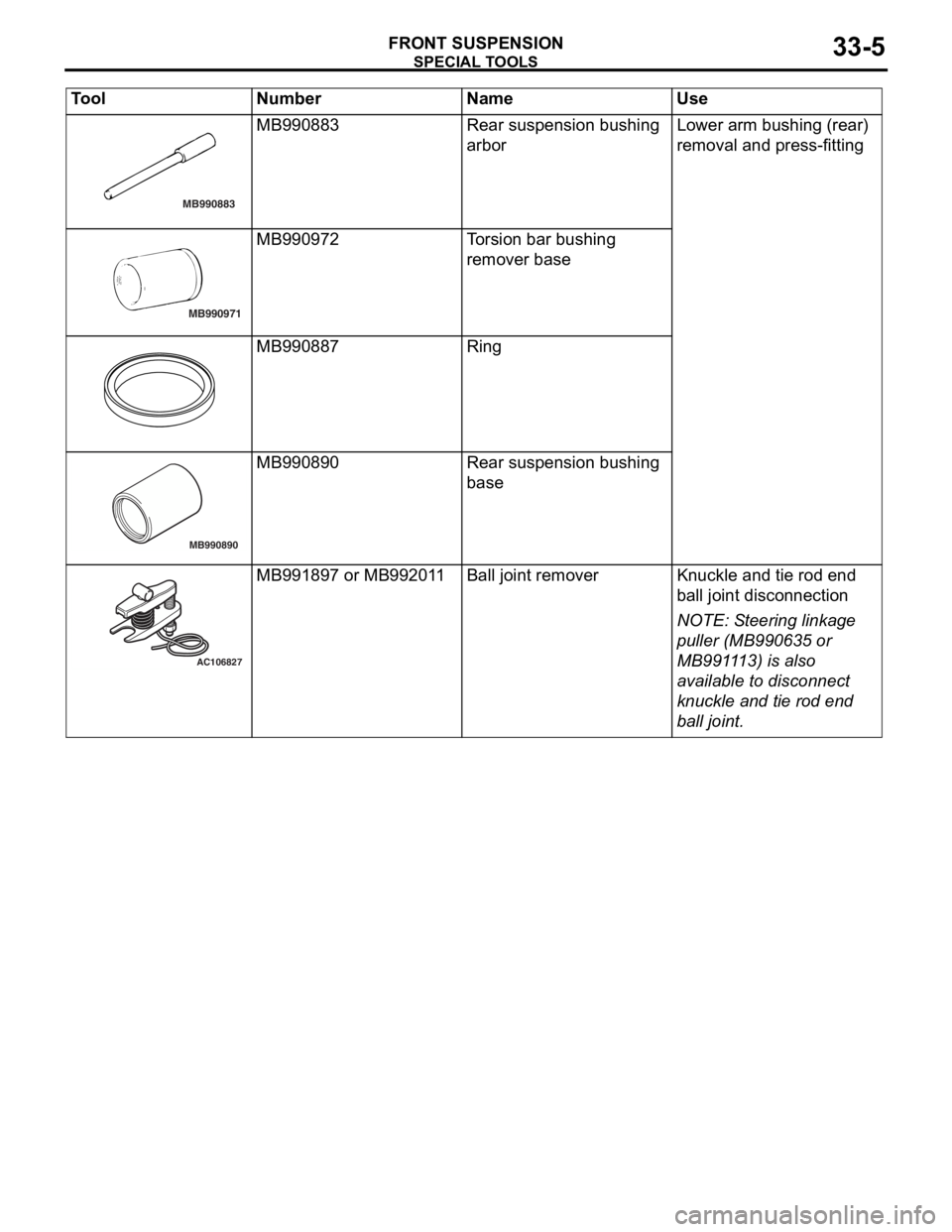

MB990883

SPECIA L T OOLS

FRONT SU SPENSION33-5

MB990883Rear suspension bushing

arborLo wer arm bushing (rear)

re

moval a nd press-fittin g

MB990971

MB990972To rsion b a r bushin g

remover base

MB990887Ring

MB990890

MB990 890Rear suspension bushing

base

AC106827

MB991897 or MB9920 1 1Ball j o int remo verKnuckle an d tie rod end

b

a ll joint disco nnection

NOTE: St eering linka ge

p

u

ller (MB99 0635 o r

MB991

1 13) is also

a

v

ailable to d i sconne ct

knuckle and t i e rod end

b

a

ll

joi

n t.

T ool Nu mber Na me Use

Page 188 of 800

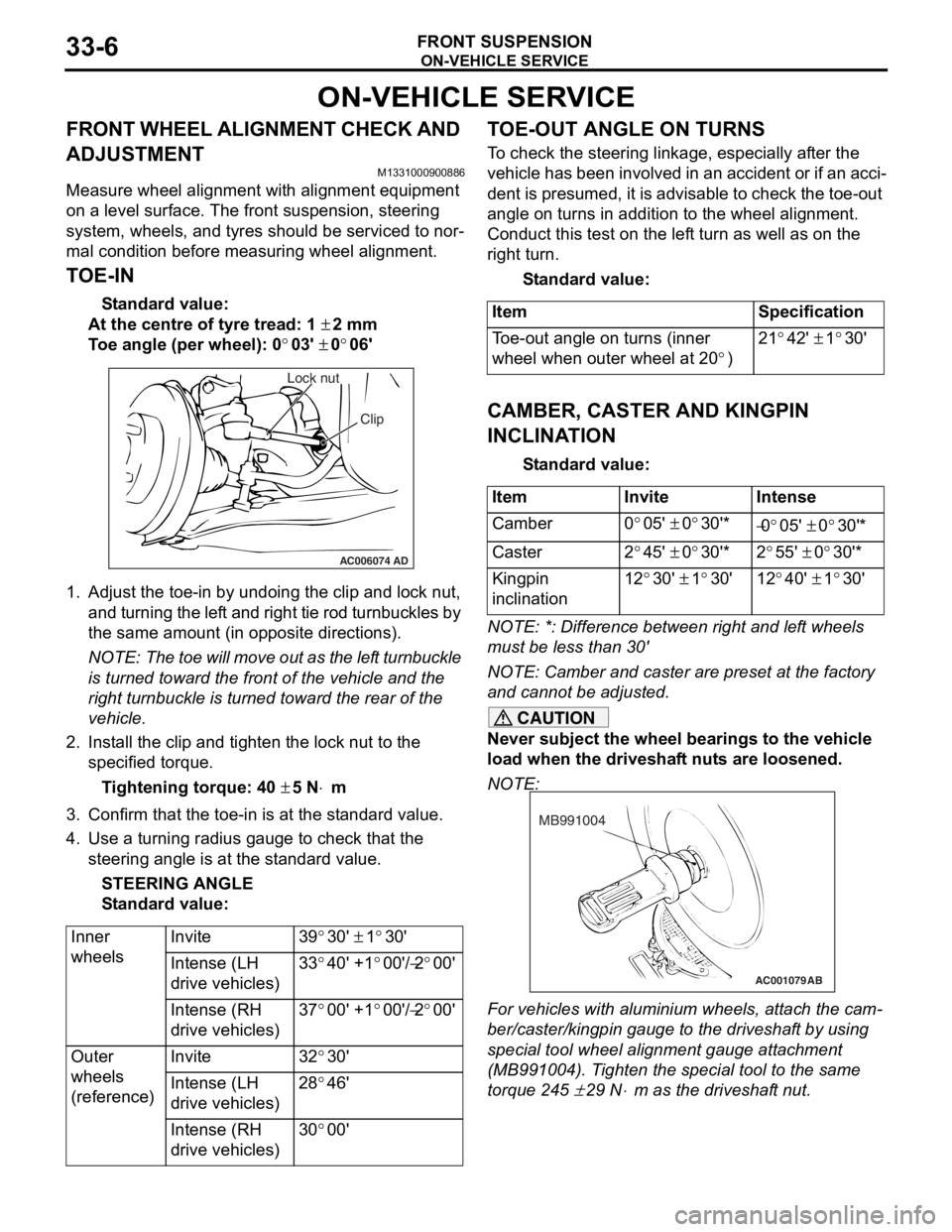

ON-VEHICLE SERVICE

FRONT SUSPENSION33-6

ON-VEHICLE SERVICE

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000900886

Measure wheel alignment with alignment equipment

on a level surface. The front suspension, steering

system, wheels, and tyres should be serviced to nor

-

mal condition before measuring wheel alignment.

TOE-IN

Standard value:

At the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 0°06'

AC006074 AD

Lock nut

Clip

1.Adjust the to e-in by undoing th e clip and lock nut,

and turning th e lef t and rig h t tie rod turnbu ckles by

th e same amount (in op posite direct ions).

NOTE: The toe will move out as th e lef t turnbuckle

is turn

ed toward the fro n t of th e ve hicle an d the

right tu

rnbuckle is turned t o ward the rear of the

vehicle.

2. In st all the clip and tighten the lock nut to the

specifie d torqu e .

Ti ghte n ing torque: 40 ± 5 N⋅m

3.Conf irm t hat the toe-in is at the st anda rd value.

4.Use a turn ing ra dius gaug e to check tha t the

steering ang le is at the st an dard value .

STEE R I N G AN G L E

St andard va lue:

Inner

wheelsInvite39°30' ± 1°30'

Intense (LH

drive vehicles)33°40' +1°00'/−2°00'

Intense (RH

drive vehicles)37°00' +1°00'/−2°00'

Outer

wheels

(reference)Invite32°30'

Intense (LH

drive vehicles)28°46'

Intense (RH

drive vehicles)30°00'

TO E-OUT ANGLE ON TURNS

To check the stee ring linkage, e s pe cially af ter the

vehicle has been invo

lve d in an accid ent or if an a cci

-

dent is pres umed, it is advisab le to check th e toe-ou t

angle

on tu rns in addition to the wh eel a lig nmen t.

Conduct this test on th e lef t tu rn as we ll a s on the

right turn.

St andard va lue:

ItemSpecification

Toe-out angle on turns (inner

wheel when outer wheel at 20

°)

21°42' ± 1°30'

CAMBER, CASTER AND KINGPIN

INCLINA

T ION

St andard va lue:

ItemInviteIntense

Camber0°05' ± 0°30'*−0°05' ± 0°30'*

Caster2°45' ± 0°30'*2°55' ± 0°30'*

Kingpin

inclination12°30' ± 1°30'12°40' ± 1°30'

NOTE: *: Diffe rence between right and lef t wheels

must be less than 30'

NOTE: Camber and caster are prese t at th e factory

and cannot be adjust ed.

CAUTION

Never subject the wheel bearings to the vehicle

load when the driveshaft nuts are loosened.

NOTE:

AC001079

MB991004

AB

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the driveshaft by using

special tool wheel alignment gauge attachment

(MB991004). Tighten the special tool to the same

torque 245

± 29 N⋅m as the driveshaft nut.

Page 189 of 800

STRUT ASSEMBLY

FRONT SUSPENSION33-7

LOWER ARM BALL JOINT AXIAL PLAY

CHECK

M1332011300074

1. Raise the vehicle.

2. Remove the stabilizer link from the lower arm.

3. Move the lower arm up and down with your hands to check for an excessive play in the axial

direction of the ball joint. If there is an excessive

play, replace the lower arm assembly.

LOWER ARM BALL JOINT COVER

CHECK

M1332008600321

1. Press the lower arm ball joint cover with your finger to check that there are no cracks or

damage in the lower arm ball joint cover.

2. If the lower arm ball joint cover is cracked or damaged, replace the lower arm assembly.

NOTE: If the lower arm ball joint cover is cracked

or damaged, it is possible that there may also be

damage to the ball joint.

STRUT ASSEMBLY

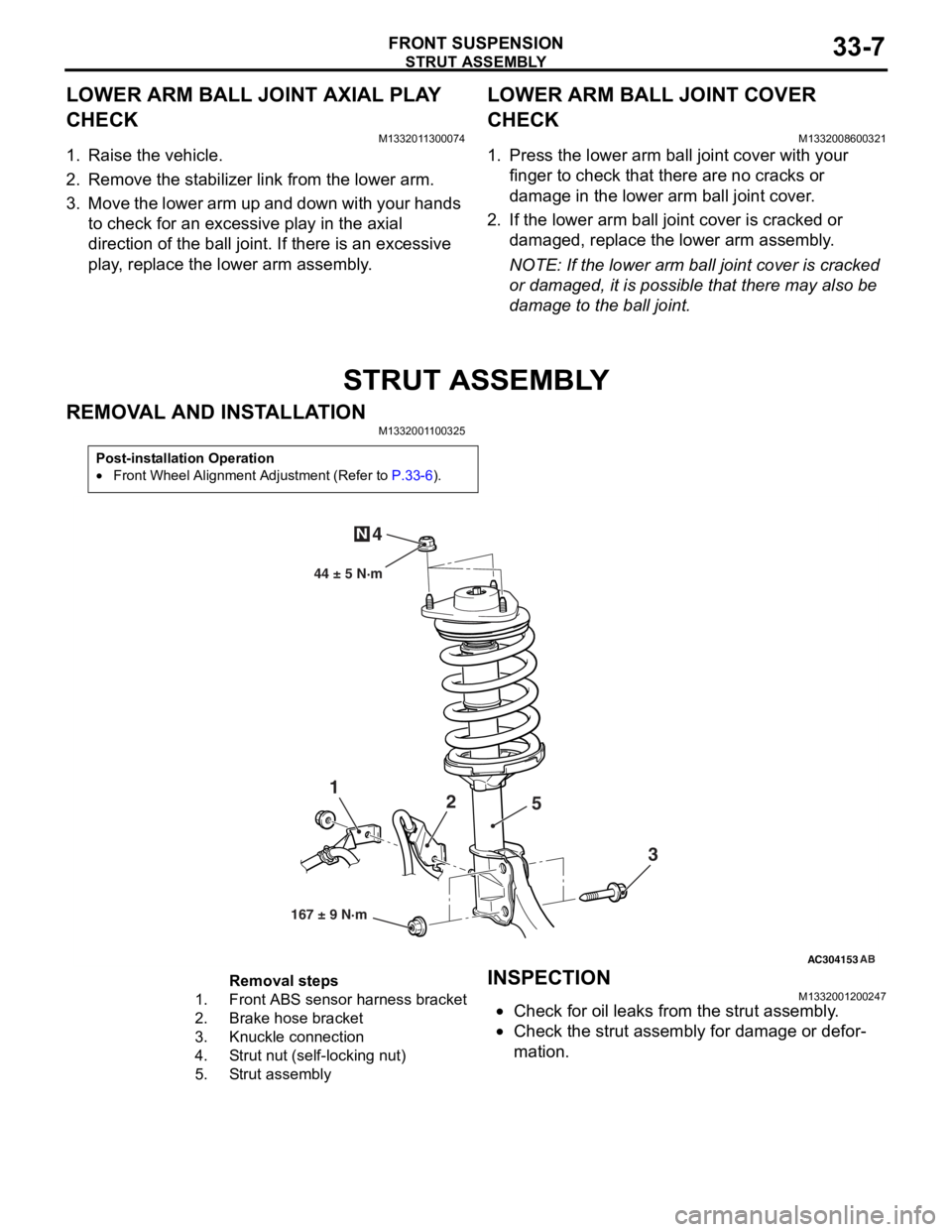

REMOVAL AND INSTALLATION

M1332001100325

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-6).

AC304153

44 ± 5 N·m

1 2

3

4

N

AB

167 ± 9 N·m

5

Removal steps

1.Front ABS sensor

harness bracket

2.Brake hose bracket

3.Knuckle connection

4.Strut nut (self-locking nut)

5.Strut assembly

INSPECTION

M13320012 0024 7

•Check for oil leaks fro m the stru t assemb ly .

•Check the stru t assemb ly for damage o r defor-

mation.

Page 190 of 800

STRUT ASSEMBLY

FRONT SUSPENSION33-8

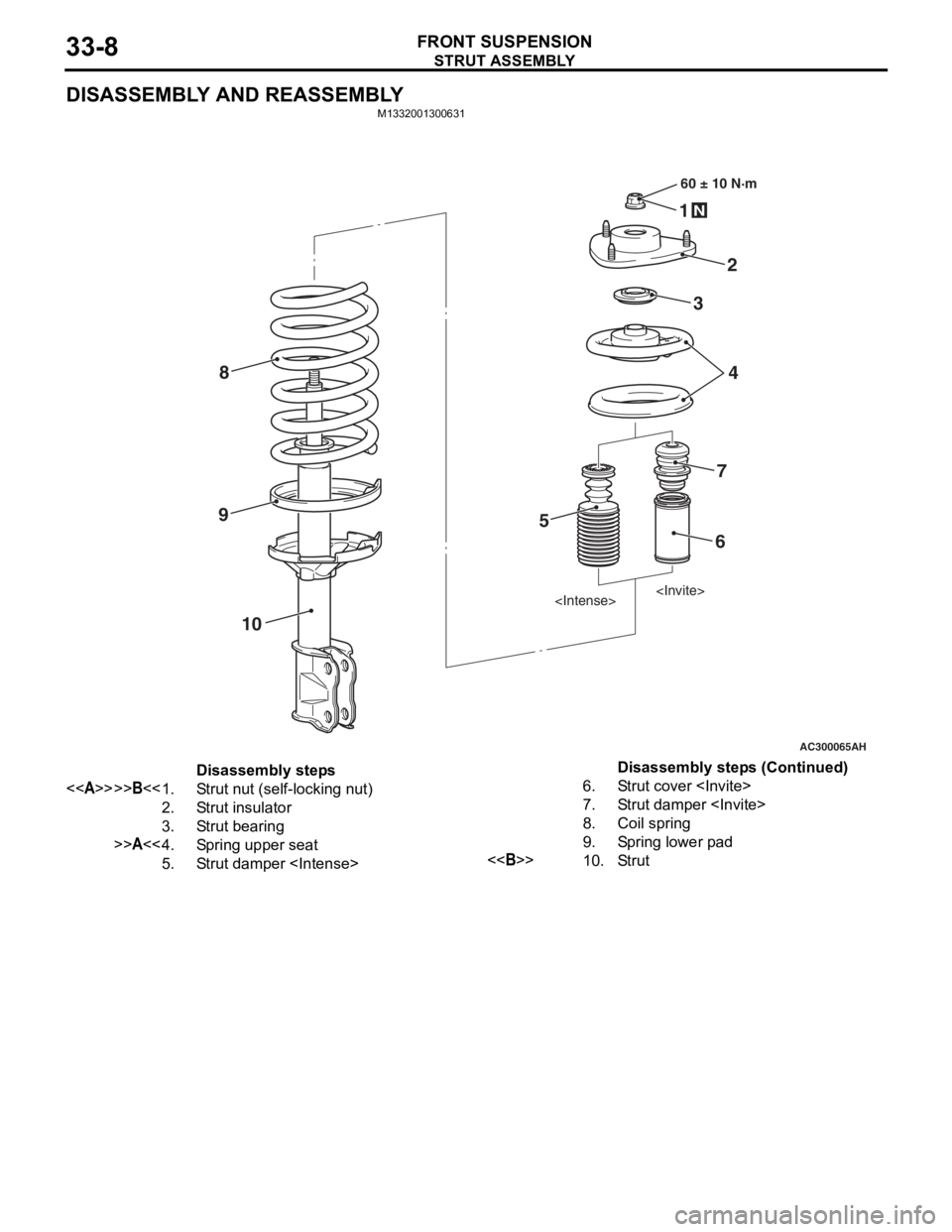

DISASSEMBLY AND REASSEMBLY

M1332001300631

AC300065

60 ± 10 N·m

2

1

N

AH

3

4

5

6

7

8

9

10

Disassembly steps

<>>>B<<1.Strut nut (self-locking nut)

2.Strut insulator

3.Strut bearing

>>A<<4.Spring upper seat

5.Strut damper

6.Strut cover

7.Strut damper

8.Coil spring

9.Spring lower pad

<>10.Str ut

Disassembly steps (Continued)