MITSUBISHI LANCER IX 2006 Service Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 191 of 800

Page 192 of 800

STRUT ASSEMBLY

FRONT SUSPENSION33-10

>>B<< STRUT NUT (SELF-LOCKING NUT)

INSTALLATION

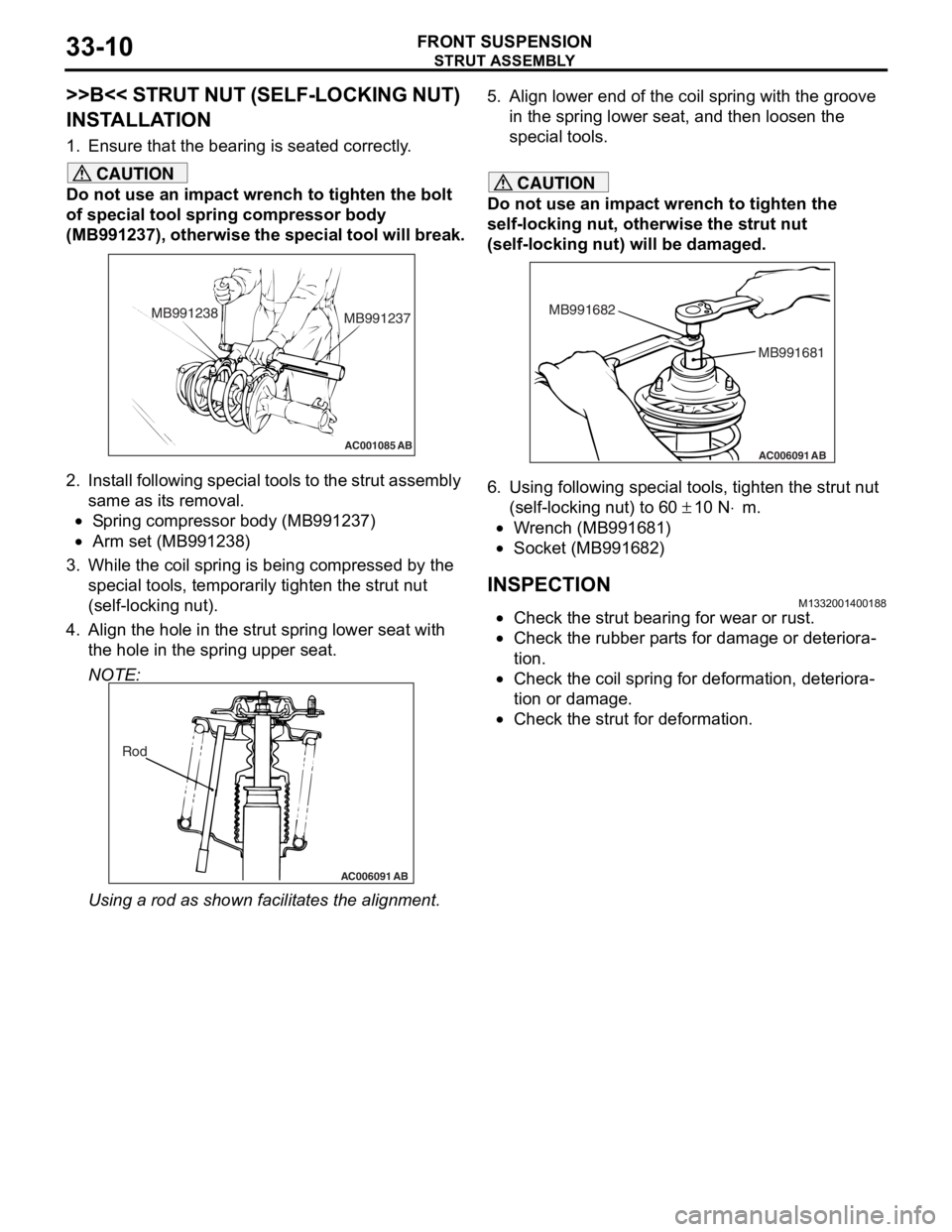

1. Ensure that the bearing is seated correctly.

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237), otherwise the special tool will break.

AC001085 AB

MB991238MB991237

2. Install following special tools to the strut assembly

same as its removal.

•Spring compressor body (MB991237)

•Arm set (MB991238)

3. While the coil spring is being compressed by the

special tools, temporarily tighten the strut nut

(self-locking nut).

4. Align the hole in the strut spring lower seat with the hole in the spring upper seat.

NOTE:

AC006091 AB

Rod

Using a rod as shown fa cilitates the alignment.

5. Align lower end of the coil spring with the groove

in the spring lower seat, and then loosen the

special tools.

CAUTION

Do not use an impact wrench to tighten the

self-locking nut, otherwise the strut nut

(self-locking nut) will be damaged.

AC006091 AB

MB991681

MB991682

6. Using following special tools, tighten the strut nut

(self-locking nut) to 60

± 10 N⋅m.

•Wrench (MB991681)

•Socket (MB991682)

INSPECTIONM1332001400188

•Check the strut bearing for wear or rust.

•Check the rubber parts for damage or deteriora-

tion.

•Check the coil spring for deformation, deteriora-

tion or damage.

•Check the strut for deformation.

Page 193 of 800

LOWER ARM

FRONT SUSPENSION33-11

LOWER ARM

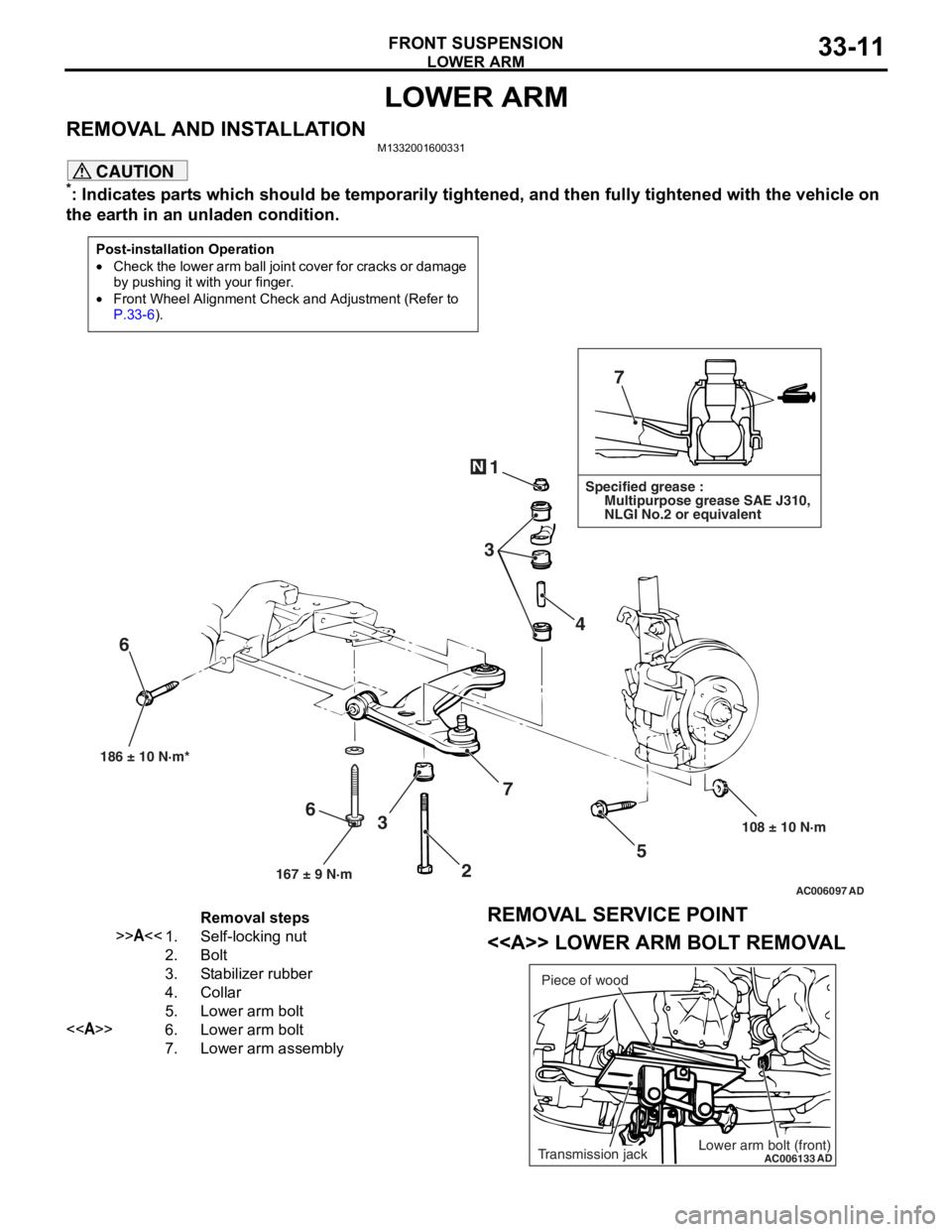

REMOVAL AND INSTALLATIONM1332001600331

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in an unladen condition.

Post-installation Operation

•Check the lower arm ball join t cover for cracks or damage

by pushing it with your finger.

•Front Wheel Alignment Check and Adjustment (Refer to

P.33-6).

AC006097 AD

7

1

3 4

5

108 ± 10 N·m

186 ± 10 N·m*

7

3

6

N

Specified grease :

Multipurpose grease SAE J310,

NLGI No.2 or equivalent

167 ± 9 N·m

6

2

Removal steps

>>A<<1.Self-locking nut

2.Bolt

3.Stabilizer rubber

4.Collar

5.Lower arm bolt

<>6.Lower arm bolt

7.Lower arm assembly

REMOVAL SERVICE POINT

<> LOWER ARM BOLT REMOVAL

AC006133

ADLower arm bolt (front)Transmission jackPiece of wood

Page 194 of 800

LOWER ARM

FRONT SUSPENSION33-12

As for the L.H. lower arm assembly, withdraw the

lower arm bolt (front) with the transmission lift up by

using a transmission jack.

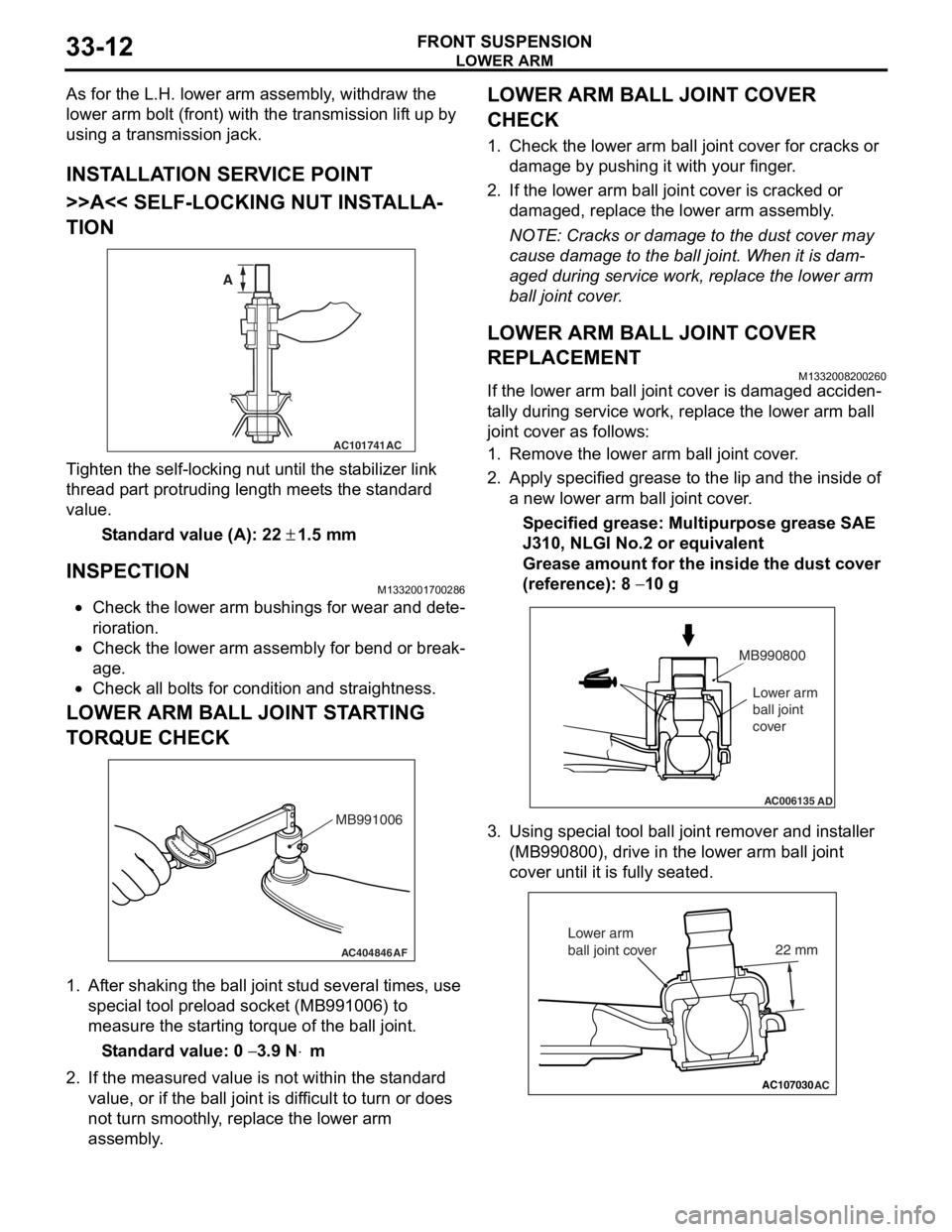

INSTALLATION SERVICE POINT

>>A<< SELF-LOCKING NUT INSTALLA-

TION

AC101741AC

A

T i ghten the self-locking nut un til t he st abilizer link

thread p

a rt protrud i ng length meet s the st a ndard

valu

e.

St andard va lue (A): 22 ± 1.5 m m

INSPECTION

M1332 0017 0028 6

•Check the lower arm bushing s for wear and det e-

riora t i o n.

•Check th e lo we r arm assemb ly for be nd or break-

age.

•Check all bo lt s for c ond ition and straightness.

LOWER ARM BALL JOINT ST ARTING

T

O RQUE CHECK

AC404846AF

MB991006

1.Af ter shaking the b a ll joint stud several times, use

special tool p r eloa d socke t (MB991 006) to

measure the st artin g torqu e of the ball joint.

St andard va lue: 0 − 3.9 N⋅m

2.If the measu r ed value is n o t within the st anda rd

value , or if the ba ll joint is dif f icu l t to t u rn or d oes

no t turn smo o thly , replace the lower a r m

asse mbly .

LOWER ARM BALL JOINT COVER

CHECK

1.Check t he lo we r arm b a ll joint co ver fo r cracks or

d a mag e by push i ng it with your finger .

2.If the lower arm ball joint co ver is cracked or

d a mag ed, rep l ace the lower arm assemb ly .

NOTE: Cracks or dama ge to t he dust co ver may

cause damage to the b a ll join t. When it is dam

-

aged du ring service wo rk, rep l ace the lower arm

b

a ll j o in t cover .

LOWER ARM BALL JOINT COVER

REPLACEMENT

M13320082 0026 0

If the lower arm ball jo int cove r is dama ged acciden-

ta lly durin g ser v ice work, repla c e th e lower arm b a ll

join

t cover as follows:

1.Remove the lower arm ball joint cover .

2.App l y specified grea se to the lip an d the inside of

a new lower arm ba ll join t cover .

Specified grease: Multipurpos e grease SAE

J310,

NLGI No.2 o r e quivale n t

Grease amount for the insi de the du st cove r

(re

f erence): 8

− 10 g

AC006135AD

MB990800

Lower arm

ball joint

cover

3. Using special tool ball joint remover and inst aller

(MB99080 0), drive in the lower arm ball jo int

cove r until it is fu lly se ated.

AC107030AC

22 mm

Lower arm

ball joint cover

Page 195 of 800

LOWER ARM

FRONT SUSPENSION33-13

4. Position the lower arm ball joint cover as shown in the illustration. Make sure that there is no

abnormal bulge or pressure applied on the lower

arm ball joint cover.

5. Check the lower arm ball joint cover for cracks or damage by pushing it with your finger.

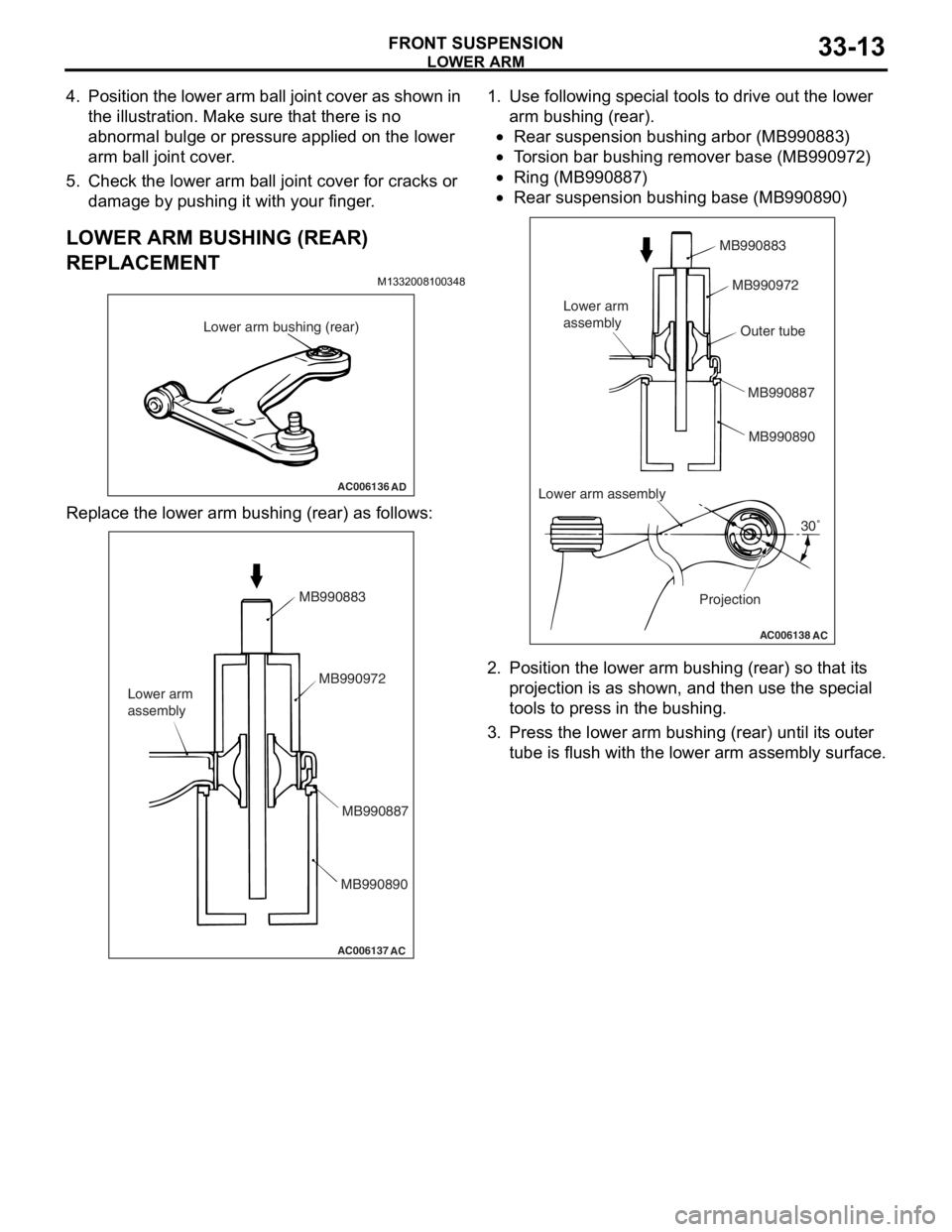

LOWER ARM BUSHING (REAR)

REPLACEMENT

M1332008100348

AC006136 AD

Lower arm bushing (rear)

Repl ace the lower arm bushing (rear) a s follows:

AC006137

AC

MB990883

MB990972

MB990887

MB990890

Lower arm

assembly

1.

Use following special tool s to drive out t he lo we r

a r m bushin g (rear).

•Rear suspension bu shing arb o r (MB99 0883)

•To rsion bar b u sh ing re mover base (MB9 90972 )

•Ring (MB990 887)

•

AC006138

AC

MB990883

MB990972

MB990887MB990890

Lower arm

assembly

Projection30˚

Lower arm assembly Outer tube

Rear susp

ension bu shing base (MB99089 0)

2.Position the lower ar m bushin g (rear) so tha t it s

p r ojection is as shown, an d then use the special

to ols to press in the bush i ng.

3.Press th e lower arm b u shing (rea r) until it s outer

tu be is flush with the lower a r m asse mbly surface.

Page 196 of 800

STABILIZER BAR

FRONT SUSPENSION33-14

STABILIZER BAR

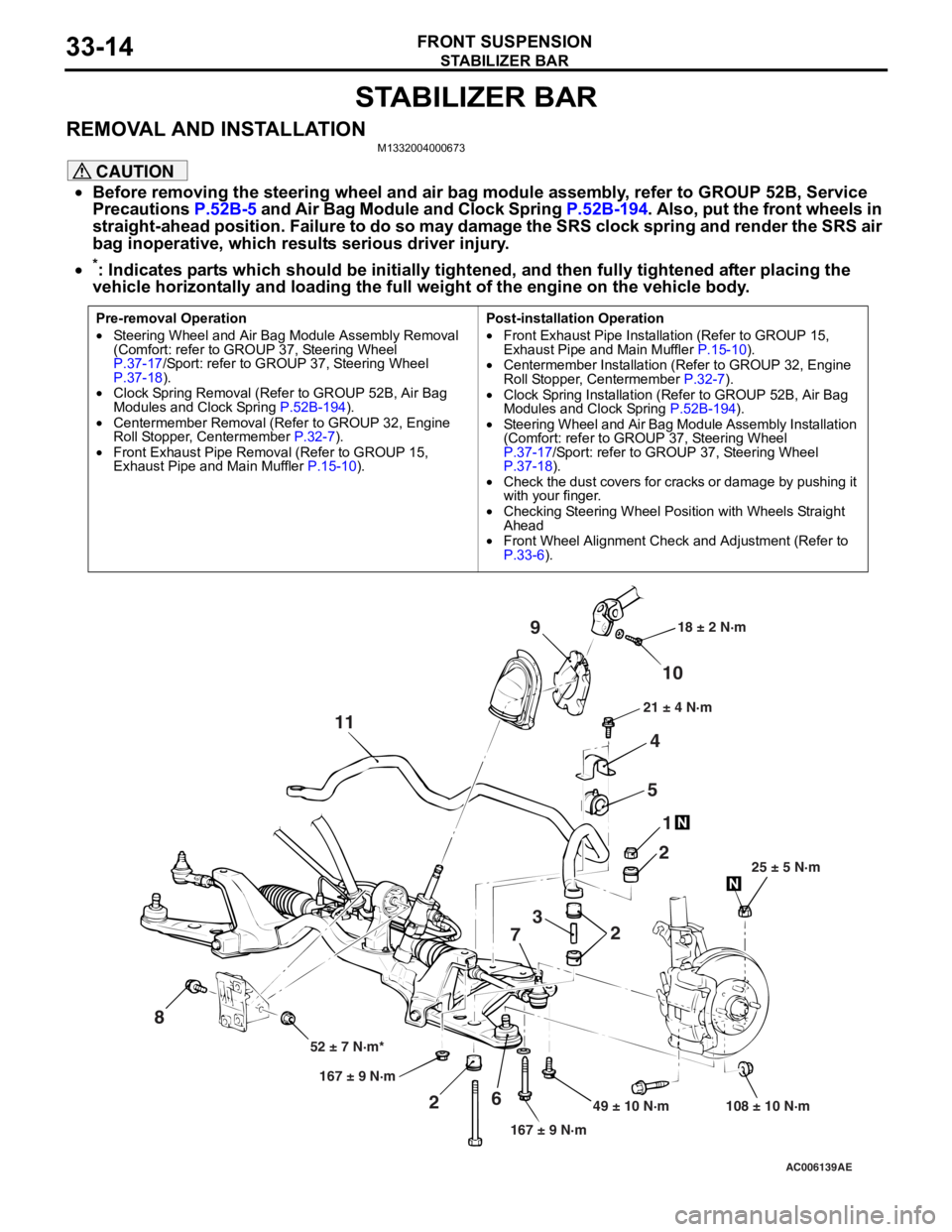

REMOVAL AND INSTALLATIONM1332004000673

CAUTION

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Service

Precautions

P.52B-5 and Air Bag Module and Clock Spring P.52B-194. Also, put the front wheels in

straight-ahead position. Failure to do so may damage the SRS clock spring and render the SRS air

bag inoperative, which results serious driver injury.

•

Pre-removal Operation

•Steering Wheel and Air Bag Module Assembly Removal

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel P.37-18).•Clock Spring Removal (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Centermember Removal (Ref er to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Front Exhaust Pipe Remova l (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-10).•Centermember Installation (Refer to GROUP 32, Engine

Roll Stopper, Centermember P.32-7).

•Clock Spring Installation (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-194).

•Steering Wheel and Air Bag Module Assembly Installation

(Comfort: refer to GROUP 37, Steering Wheel

P.37-17/Sport: refer to GROUP 37, Steering Wheel P.37-18).•Check the dust covers for cracks or damage by pushing it

with your finger.

•Checking Steering Wheel Position with Wheels Straight

Ahead

•Front Wheel Alignment Check and Adjustment (Refer to P.33-6).

AC006139 AE

49 ± 10 N·m 108 ± 10 N·m

167 ± 9 N·m

167 ± 9 N·m

52 ± 7 N·m* 25 ± 5 N·m

21 ± 4 N·m

18 ± 2 N·m

10

9

4

5 1

2

2

3

7

6

2

11

8

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Page 197 of 800

Removal steps

>>B<<1.Self-locking nut

2.Stabilizer rubber

3.Collar

>>A<<4.Stabilizer bar bracket

>>A<<5.Stabilizer bushing

6.Lower arm and knuckle

connection

<>7.Tie rod end and knuckle

connection

8.Engine rear roll stopper

bracket connecting bolt

9.Steering shaft cover

10.Steering gear and joint

connecting bolt

<>>>A<<11 .Stabilizer bar

STABILIZER BA R

FRONT SU SPENSION33-15

REMOVA L SER V ICE POINTS

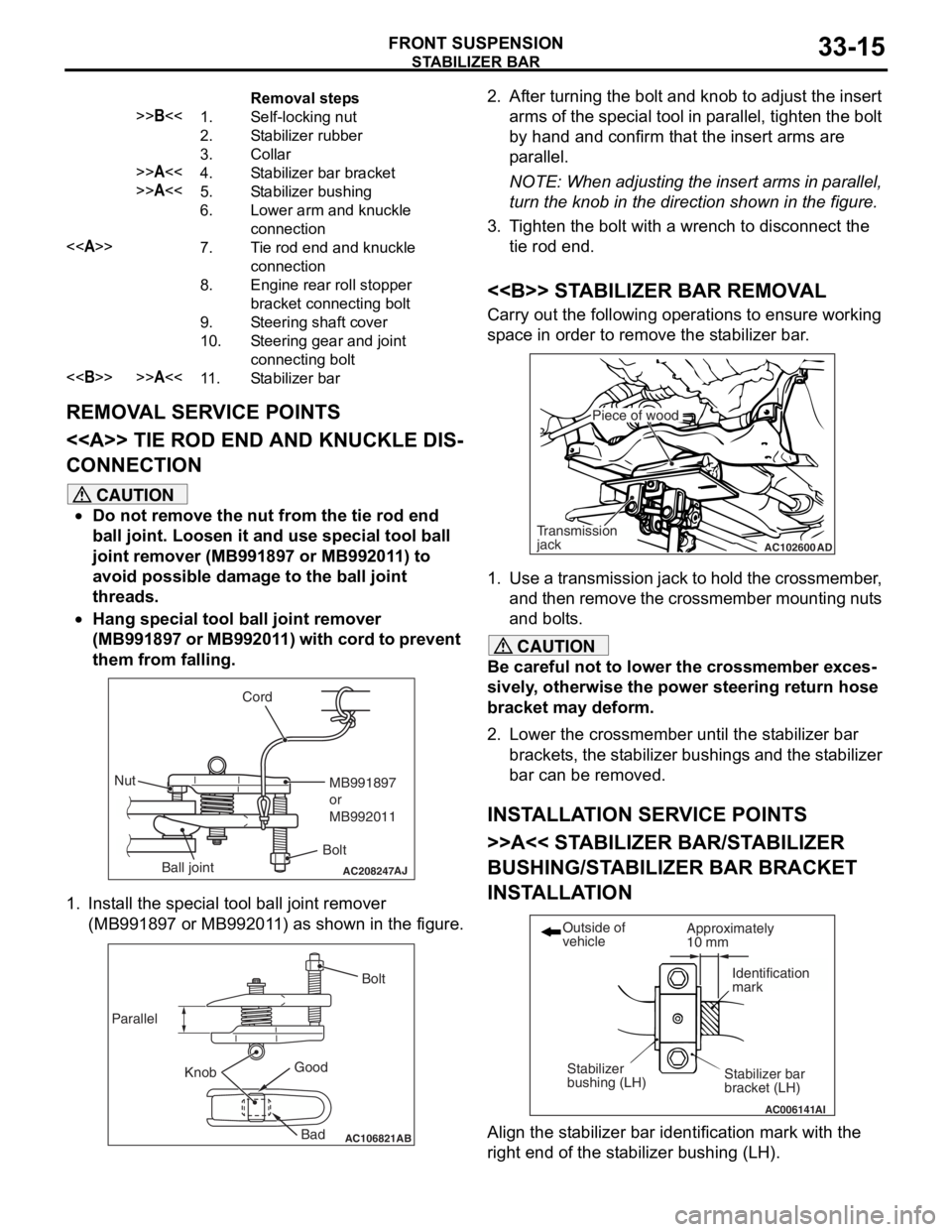

<> TIE ROD END AND KNUCKLE DIS-

CONNECTION

CAUTION

•Do not remove the nut from the tie rod end

ball joint. Loosen it and use special tool ball

joint remover (MB991897 or MB992011) to

avoid possible damage to the ball joint

threads.

•

AC208247AJ

Cord

BoltMB991897

or

MB992011

Nut

Ball joint

Hang special tool ball joint remover

(MB991897 or MB992011) with cord to prevent

them from falling.

1. Install the special tool ball joint remover (MB991897 or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Good Bad

AB

2. After turning the bolt and knob to adjust the insert arms of the special tool in parallel, tighten the bolt

by hand and confirm that the insert arms are

parallel.

NOTE: When adjusting the insert arms in parallel,

turn the knob in the direction shown in the figure.

3. Tighten the bolt with a wrench to disconnect the tie rod end.

<> STABILIZER BAR REMOVAL

Carry out the following operations to ensure working

space in order to remove the stabilizer bar.

AC102600 AD

Piece of wood

Transmission

jack

1. Use a transmission jack to hold the crossmember,

and then remove the crossmember mounting nuts

and bolts.

CAUTION

Be careful not to lower the crossmember exces-

sively, otherwise the power steering return hose

bracket may deform.

2. Lower the crossmember until the stabilizer bar

brackets, the stabilizer bush ings and the stabilizer

bar can be removed.

INSTALLATION SERVICE POINTS

>>A<< STABILIZER BAR/STABILIZER

BUSHING/STABILIZ ER BAR BRACKET

INSTALLATION

AC006141 AI

Stabilizer bar

bracket (LH)

Outside of

vehicle

Stabilizer

bushing (LH) Approximately

10 mm

Identification

mark

Align the stabilizer bar iden

tification mark with the

right end of the stabilizer bushing (LH).

Page 198 of 800

STABILIZER BAR

FRONT SUSPENSION33-16

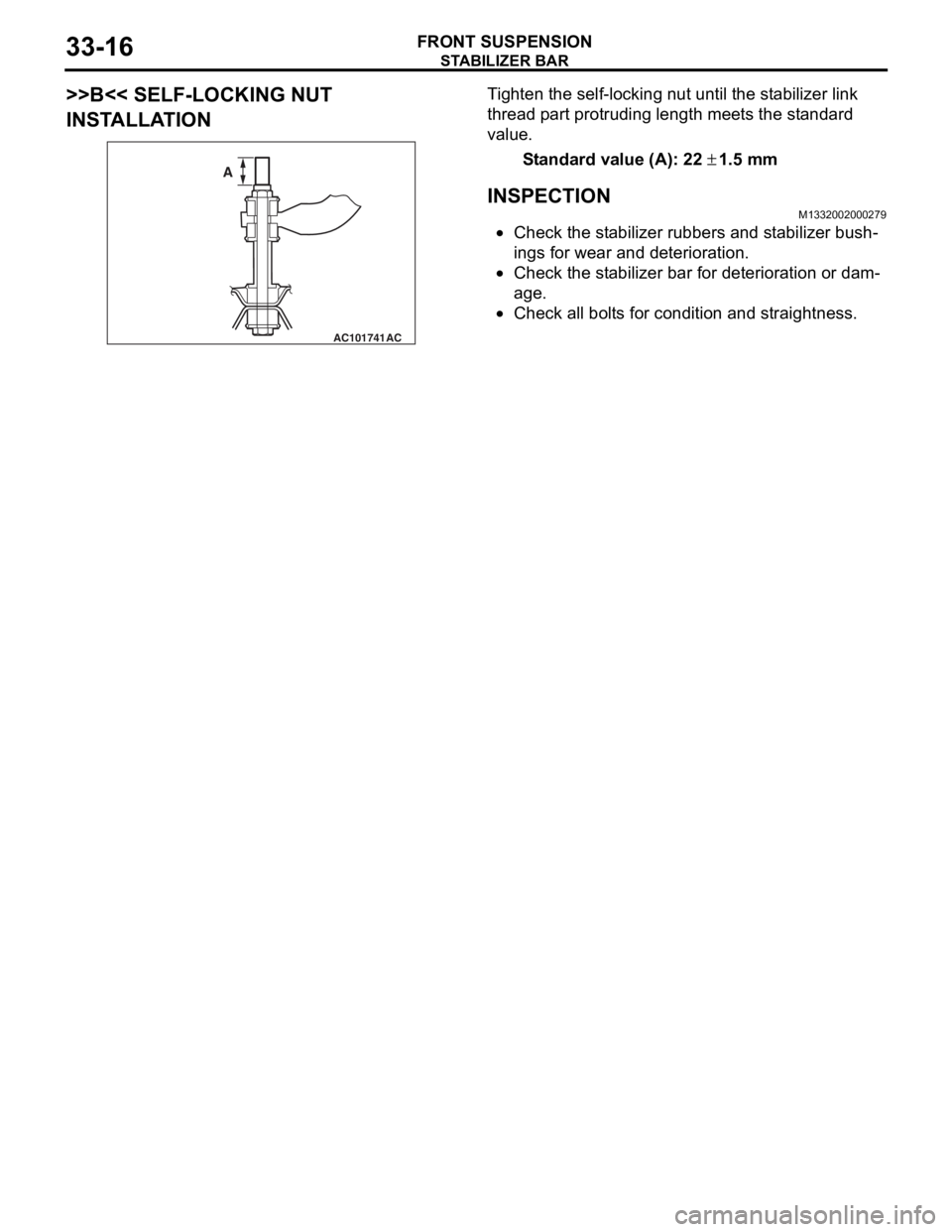

>>B<< SELF-LOCKING NUT

INSTALLATION

AC101741AC

A

Ti ghten the self-locking nut un til t he st ab ilizer link

thread

p a rt protrud i ng length mee t s the st a ndard

value.

St andard va lue (A): 22 ± 1.5 m m

INSPECTION

M1332 0020 0027 9

•Check the st abilizer rubb ers a nd st ab ilizer b u sh-

ings fo r wear and deterioration.

•Check the st abilizer bar for dete r iorat i on o r dam-

age.

•Check all bo lt s for cond itio n and straightness.

Page 199 of 800

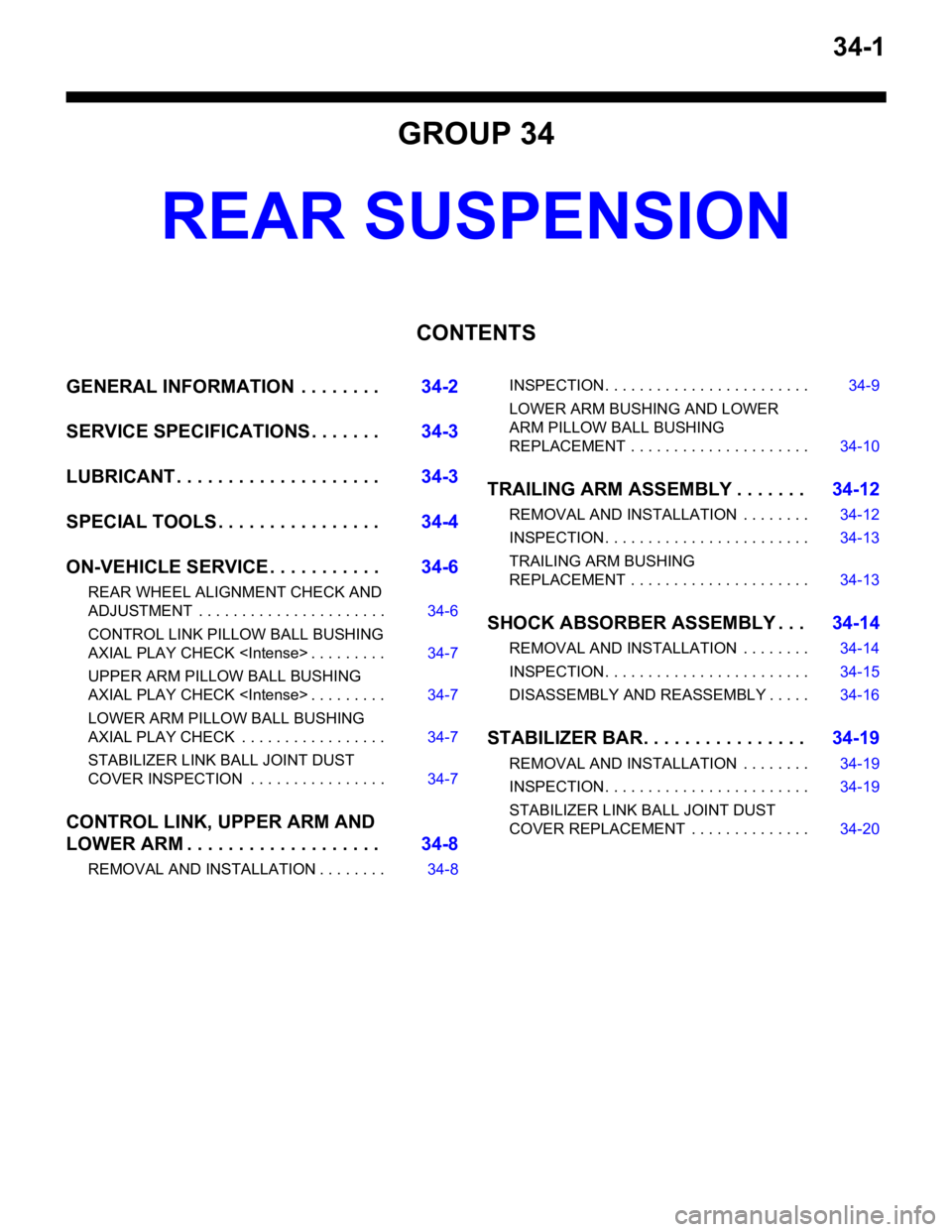

34-1

GROUP 34

REAR SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .34-2

SERVICE SPECIFICATIONS . . . . . . .34-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .34-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .34-4

ON-VEHICLE SERVICE . . . . . . . . . . .34-6

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 34-6

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK . . . . . . . . . . . . . . . . . 34-7

STABILIZER LINK BALL JOINT DUST

COVER INSPECTION . . . . . . . . . . . . . . . . 34-7

CONTROL LINK, UPPER ARM AND

LOWER ARM . . . . . . . . . . . . . . . . . . .34-8

REMOVAL AND INSTALLATION . . . . . . . . 34-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 34-9

LOWER ARM BUSHING AND LOWER

ARM PILLOW BALL BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-10

TRAILING ARM ASSEMBLY . . . . . . .34-12

REMOVAL AND INSTALLATION . . . . . . . . 34-12

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 34-13

TRAILING ARM BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-13

SHOCK ABSORBER ASSEMBLY . . .34-14

REMOVAL AND INSTALLATION . . . . . . . . 34-14

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 34-15

DISASSEMBLY AND REASSEMBLY . . . . . 34-16

STABILIZER BAR. . . . . . . . . . . . . . . .34-19

REMOVAL AND INSTALLATION . . . . . . . . 34-19

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 34-19

STABILIZER LINK BALL JOINT DUST

COVER REPLACEMENT . . . . . . . . . . . . . . 34-20

Page 200 of 800

GENERAL INFORMATION

REAR SUSPENSION34-2

GENERAL INFORMATION

M1341000100717

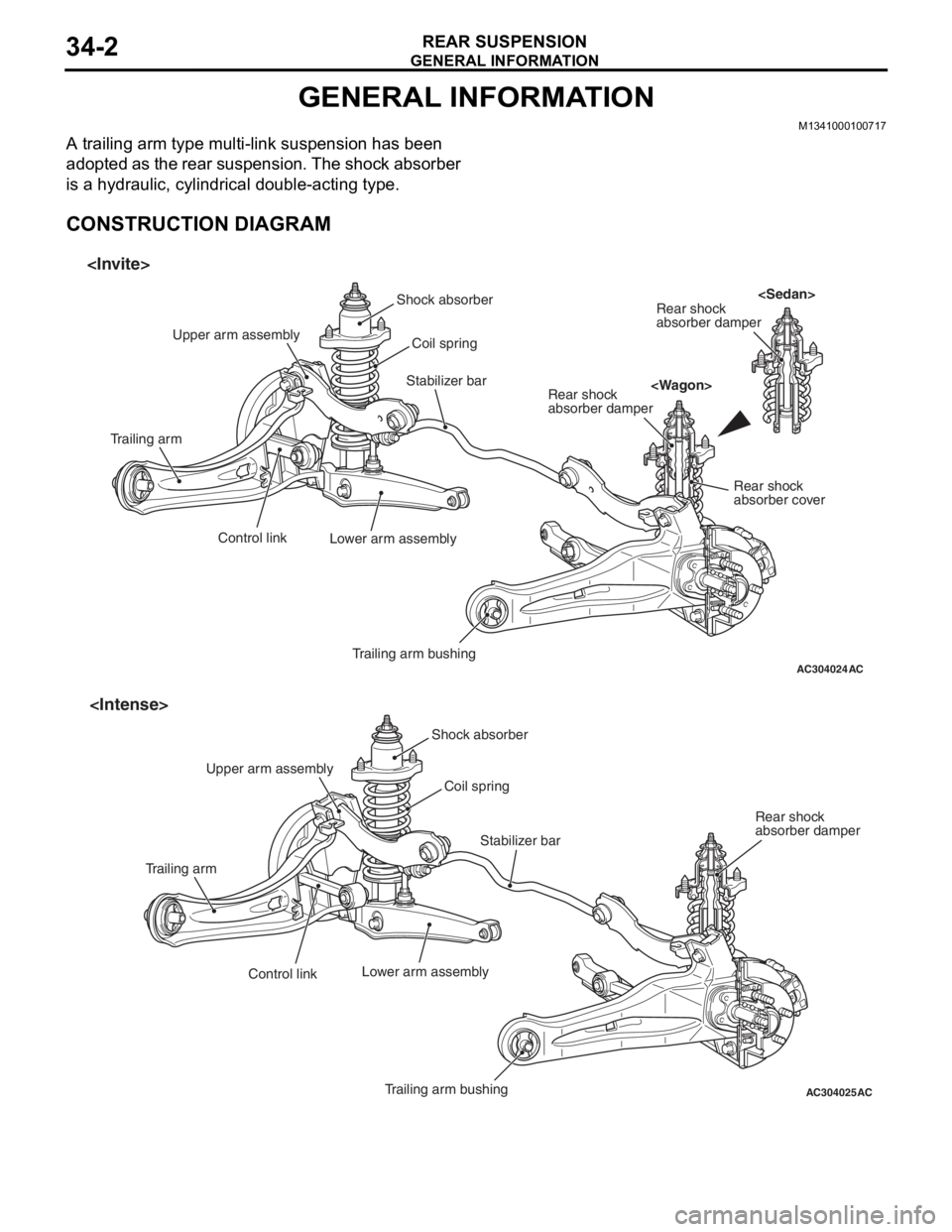

A trailing arm type multi-link suspension has been

adopted as the rear suspension. The shock absorber

is a hydraulic, cylindrical double-acting type.

CONSTRUCTION DIAGRAM

AC304024AC

Shock absorberCoil spring

Trailing arm bushing

Lower arm assembly

Control link

Trailing arm Upper arm assembly

Stabilizer barRear shock

absorber damper

Rear shock

absorber damper Rear shock

absorber cover

AC304025AC

Shock absorber

Trailing arm bushing

Control link

Trailing arm

Stabilizer bar

Coil spring

Lower arm assembly

Rear shock

absorber damper

Upper arm assembly