MITSUBISHI LANCER IX 2006 Service Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 201 of 800

SERVICE SPECIFICATIONS

REAR SUSPENSION34-3

SPECIFICATION

COIL SPRING

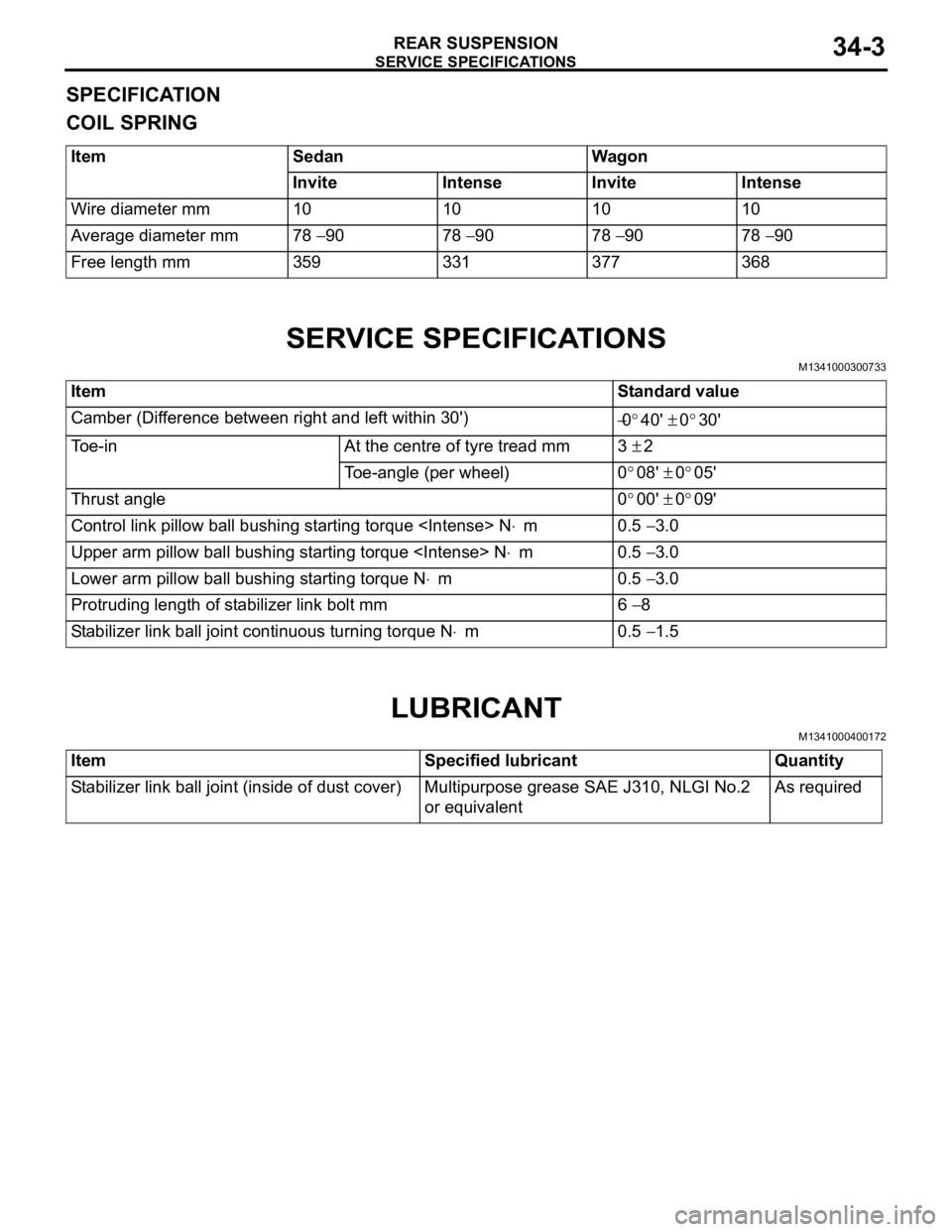

ItemSedanWagon

InviteIntenseInviteIntense

Wire diameter mm10101010

Average diameter mm78 − 9078 − 9078 − 9078 − 90

Free length mm359331377368

SERVICE SPECIFICATIONS

M1341000300733

ItemStandard value

Camber (Difference between right and left within 30') −0°40' ± 0°30'

Toe-inAt the centre of tyre tread mm3 ± 2

Toe-angle (per wheel)0°08' ± 0°05'

Thrust angle0°00' ± 0°09'

Control link pillow ball bushing starting torque

Upper arm pillow ball bushing starting torque

Lower arm pillow ball bushing starting torque N⋅m0.5 − 3.0

Protruding length of stabilizer link bolt mm6 − 8

Stabilizer link ball joint continuous turning torque N⋅m0.5 − 1.5

LUBRICANT

M1341000400172

ItemSpecified lubricantQuantity

Stabilizer link ball joint (inside of dust cover)Multipurpose grease SAE J310, NLGI No.2

or equivalentAs required

Page 202 of 800

SPECIAL TOOLS

REAR SUSPENSION34-4

SPECIAL TOOLS

M1341000600392

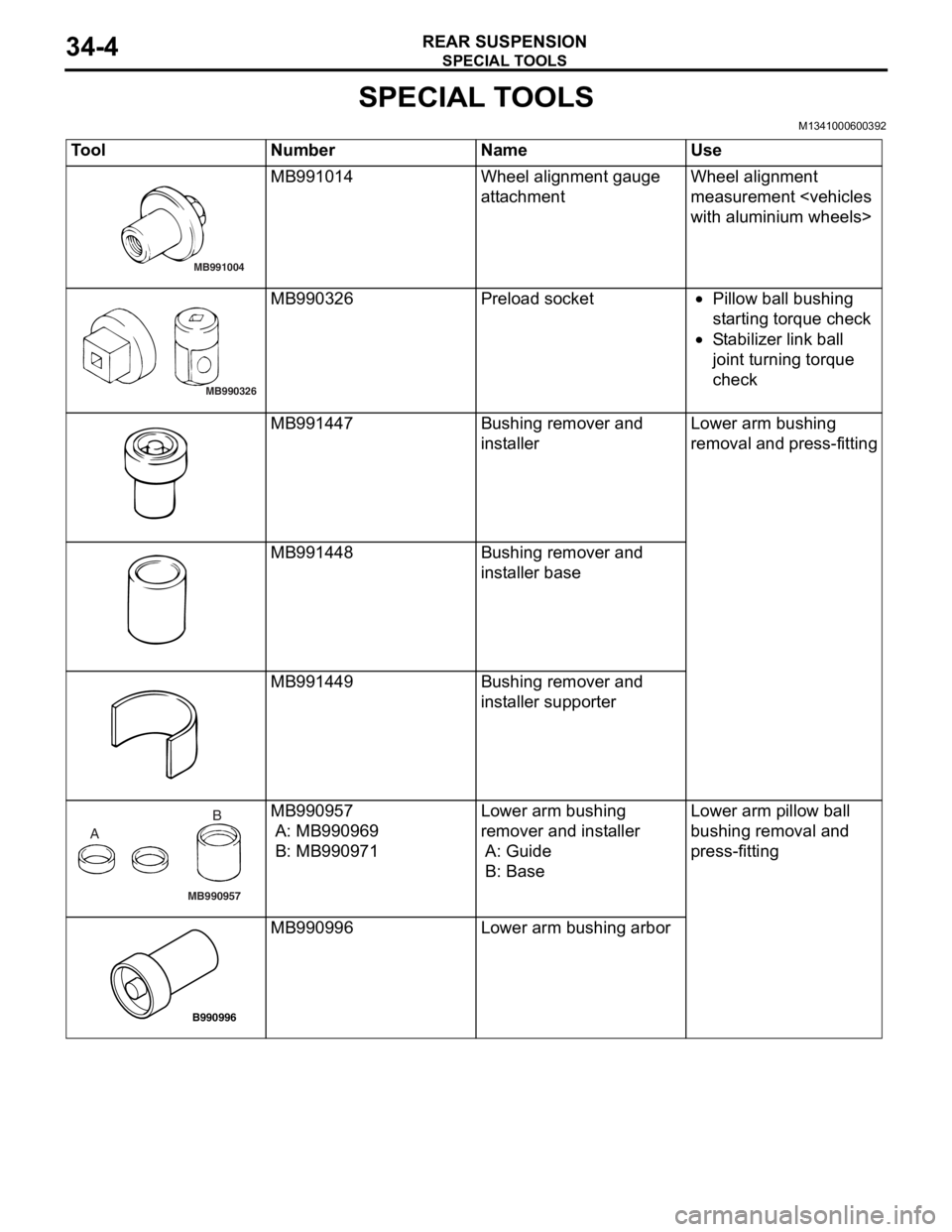

ToolNumberNameUse

MB991004

MB991014Wheel alignme n t gau ge

att

a chmentWheel alig nme n t

measurement

MB990326

MB990326Prel oad socket•Pillow ba ll b u shing

st

a r ting t o rque check

•St abil i ze r lin k ba ll

joint t

u rnin g torque

check

MB991447Bushing remove r and

inst

al lerLo wer arm bushing

re

moval and press-fit t ing

MB991448Bushing remove r and

inst

al ler b a se

MB991449Bushing remove r and

inst

aller suppo rter

MB990957

A B

MB990

957

A: MB9909 69

B: MB990971

Lower arm bushing

remover an

d inst a lle r

A: Guide

B: Base

Lo wer arm pillow ball

b

u shing removal an d

p

r ess-fitting

B990996

MB990 996Lower arm bushing arbor

Page 203 of 800

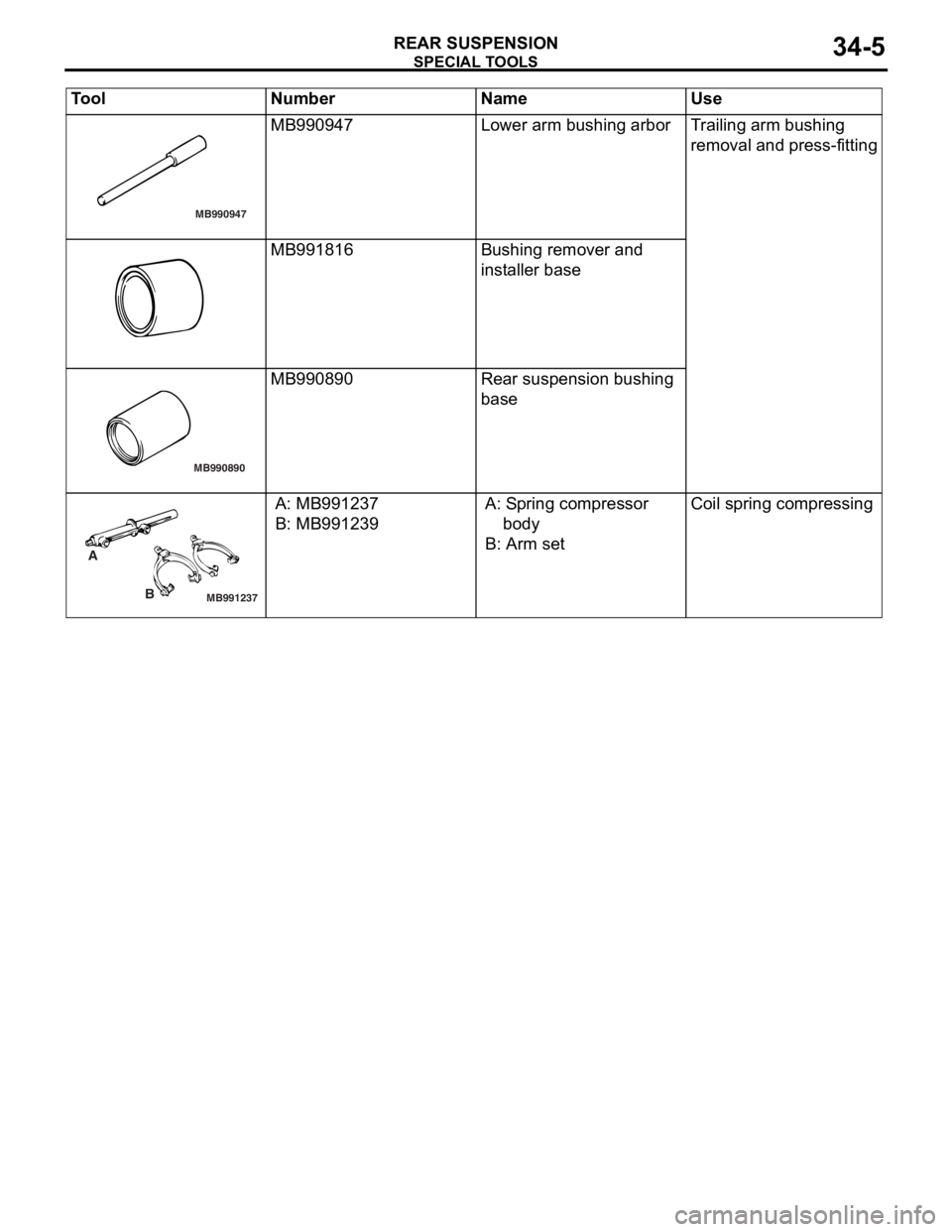

MB990947

SPECIA L T OOLS

REAR SU SPENS I ON34-5

MB990947Lower arm bushing arborTr a iling arm bushing

re

moval and press-fit t ing

MB991816Bushing remove r and

inst

al ler b a se

MB990890

MB990890Rear suspension bushing

base

MB991237

A

B

A: MB9912 37

B: MB991239

A: Sp ring compressor

bo dy

B: Arm set

Coil spring compressing

Tool Nu mber Na me Use

Page 204 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-6

ON-VEHICLE SERVICE

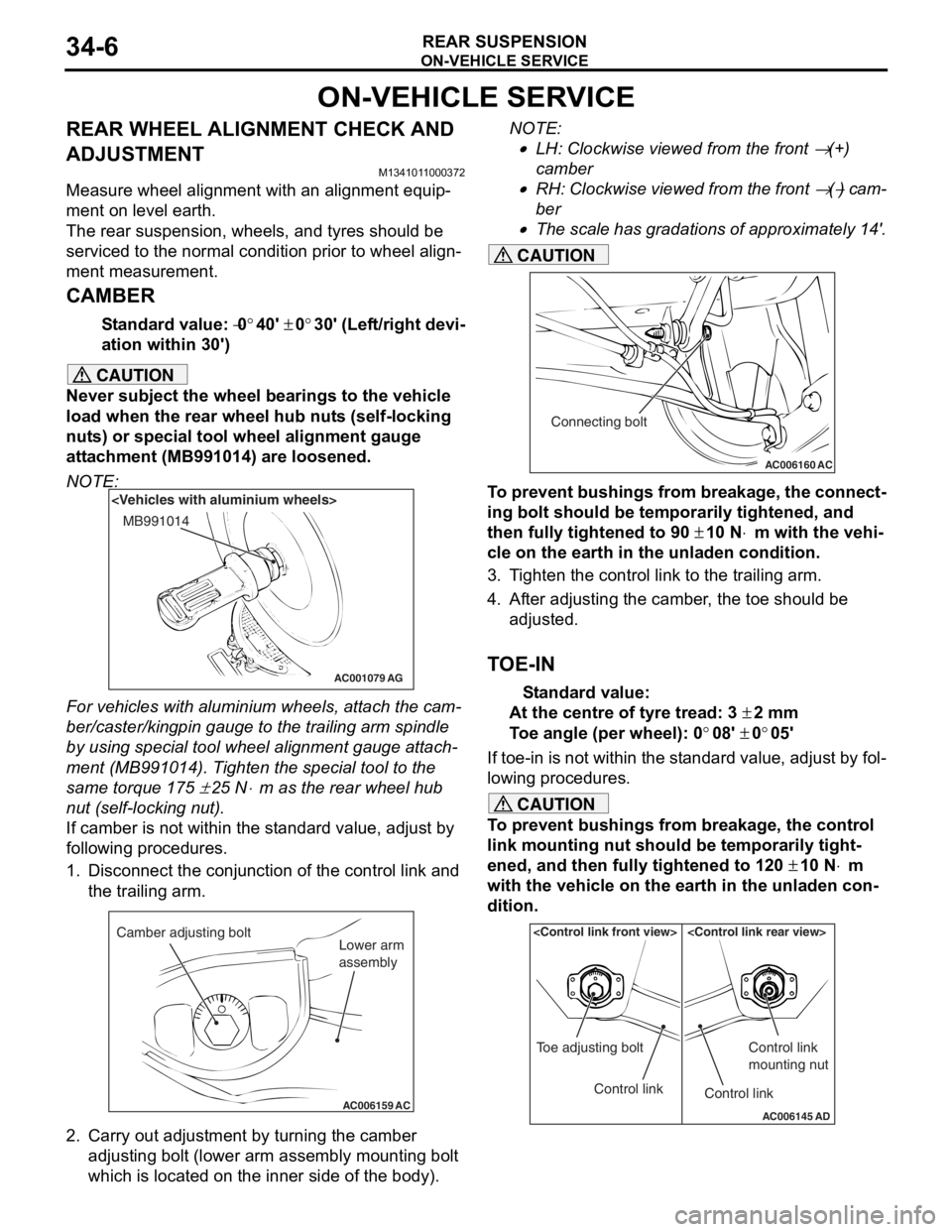

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000372

Measure wheel alignment with an alignment equip-

ment on level earth.

The rear suspension, wheels, and tyres should be

serviced to the normal condition prior to wheel align

-

ment measurement.

CAMBER

Standard value: −0°40' ± 0°30' (Left/right devi-

ation within 30')

CAUTION

Never subject the wheel bearings to the vehicle

load when the rear wheel hub nuts (self-locking

nuts) or special tool wheel alignment gauge

attachment (MB991014) are loosened.

NOTE:

AC001079

MB991014

AG

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the trailing arm spindle

by using special tool wheel alignment gauge attach

-

ment (MB991014). Tighten the special tool to the

same torque 175

± 25 N⋅m as the rear wheel hub

nut (self-locking nut).

If camber is not within the standard value, adjust by

following procedures.

1. Disconnect the conjunction of the control link and the trailing arm.

AC006159 AC

Camber adjusting bolt

Lower arm

assembly

2. Carry out adjustment by turning the camber

adjusting bolt (lower arm assembly mounting bolt

which is located on the inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → (+)

camber

•RH: Clockwise viewed from the front → (−) cam-

ber

•

AC006160 AC

Connecting bolt

The scale has gradations of approximately 14'.

CAUTION

To prevent bushings from breakage, the connect-

ing bolt should be temporarily tightened, and

then fully tightened to 90

± 10 N⋅m with the vehi-

cle on the earth in the unladen condition.

3. Tighten the control link to the trailing arm.

4. After adjusting the camber, the toe should be

adjusted.

TOE-IN

Standard value:

At the centre of tyre tread: 3 ± 2 mm

Toe angle (per wheel): 0°08' ± 0°05'

If toe-in is not within the standard value, adjust by fol-

lowing procedures.

CAUTION

To prevent bushings from breakage, the control

link mounting nut should be temporarily tight

-

ened, and then fully tightened to 120 ± 10 N⋅m

with the vehicle on the earth in the unladen con

-

dition.

AC006145 AD

Control link

Toe adjusting boltControl link

Control link

mounting nut

Page 205 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-7

Carry out adjustment by turning the toe adjusting bolt

(control link mounting bolt which is located on the

inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → To e - i n

•RH: Clockwise viewed from the front → Toe-out

•Turning the toe adjusting bolt by one groove of

the scale, toe can be changed approximately 2.6

mm (single side toe angle equivalent to 16').

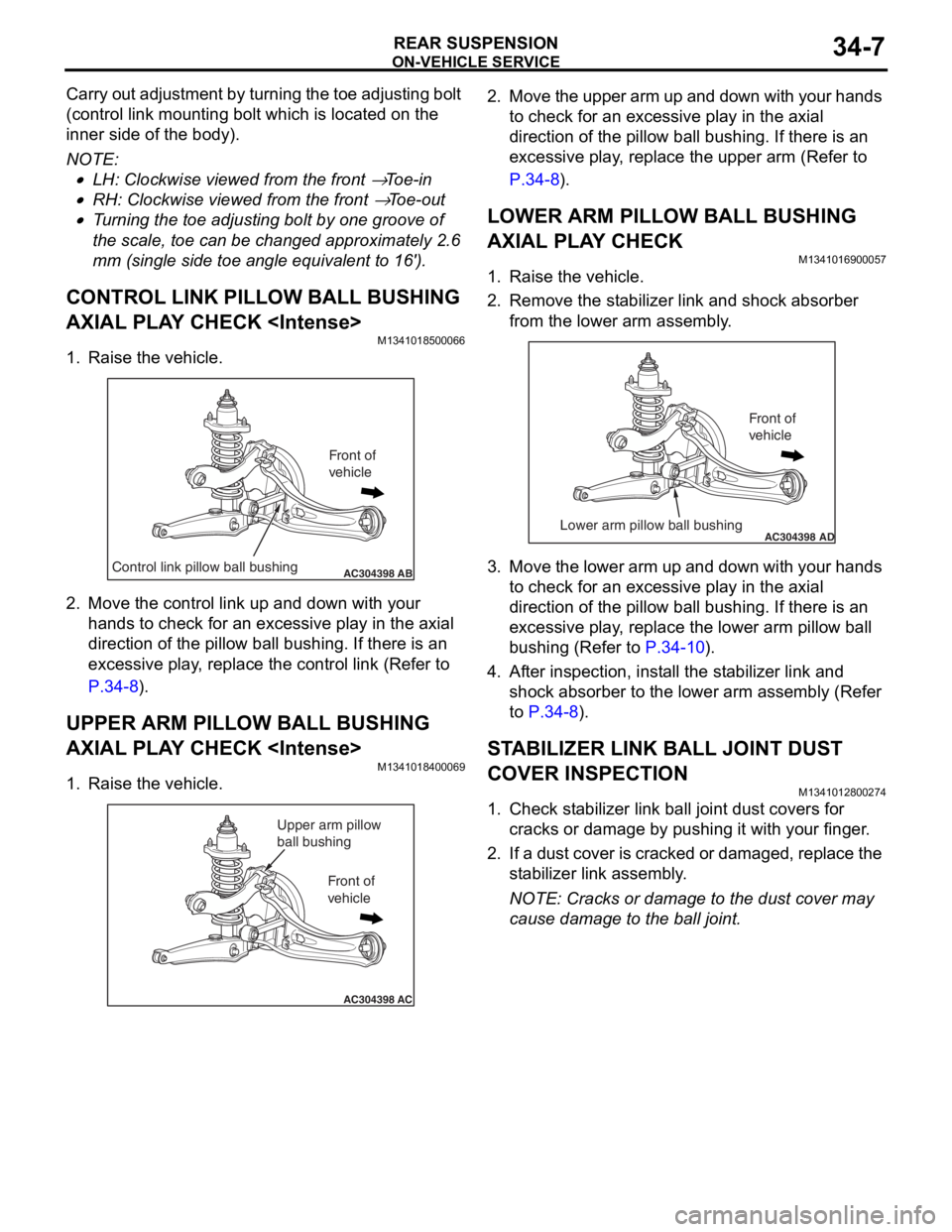

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

M1341018500066

1. Raise the vehicle.

AC304398ABControl link pillow ball bushing

Front of

vehicle

2.Move the control link up and d o wn with your

ha nds to ch eck for an excessive pla y in the a x ia l

direct ion o f the p illow ball bushing . If the r e is an

exce ssive play , re place the cont rol link (Re f er to

P.34-8).

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M13410184 0006 9

1.Raise th e ve hicle.

AC304398AC

Upper arm pillow

ball bushing

Front of

vehicle

2. Move the up per arm up and down with you r hand s

to che ck for an e xce ssive play in the axial

d i rection o f the p illow ball bushing . If the r e is an

e xce ssive play , re place the upper arm (Refe r to

P.34-8).

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M13410169 0005 7

1.Raise th e ve hicle.

2.Remove the st a b ilizer link and shock a b sorb er

f r om t h e l o we r arm a s s e mb l y .

AC304398ADLower arm pillow ball bushing

Front of

vehicle

3.Move the lower a r m u p and down with your h ands

to che ck for an e xce ssive play in the axial

d i rection o f the p illow ball bushing . If the r e is an

e xce ssive play , re place the lower a r m pillo w b a ll

b u shing (Refer to

P.34-10).

4.Af ter inspe c tio n , in st all the st a b ilizer link and

shock a b sorb er to the lower arm assembly (Refer

to

P.34-8).

STABILIZER LINK BALL JOINT DUST

COVER INSPECTION

M1341 0128 0027 4

1.Check st abilize r lin k ba ll joint dust covers f o r

cracks o r damage by pushing it wit h you r fing er .

2. If a du st cove r is crack ed or da mag ed, rep l ace t he

st a b ili zer link assembly .

NOTE: Cracks or dama ge to t he dust co ver may

cause damage to the b a ll join t.

Page 206 of 800

CONTROL LINK, UPPER ARM AND LOWER ARM

REAR SUSPENSION34-8

CONTROL LINK, UPPER ARM AND LOWER ARM

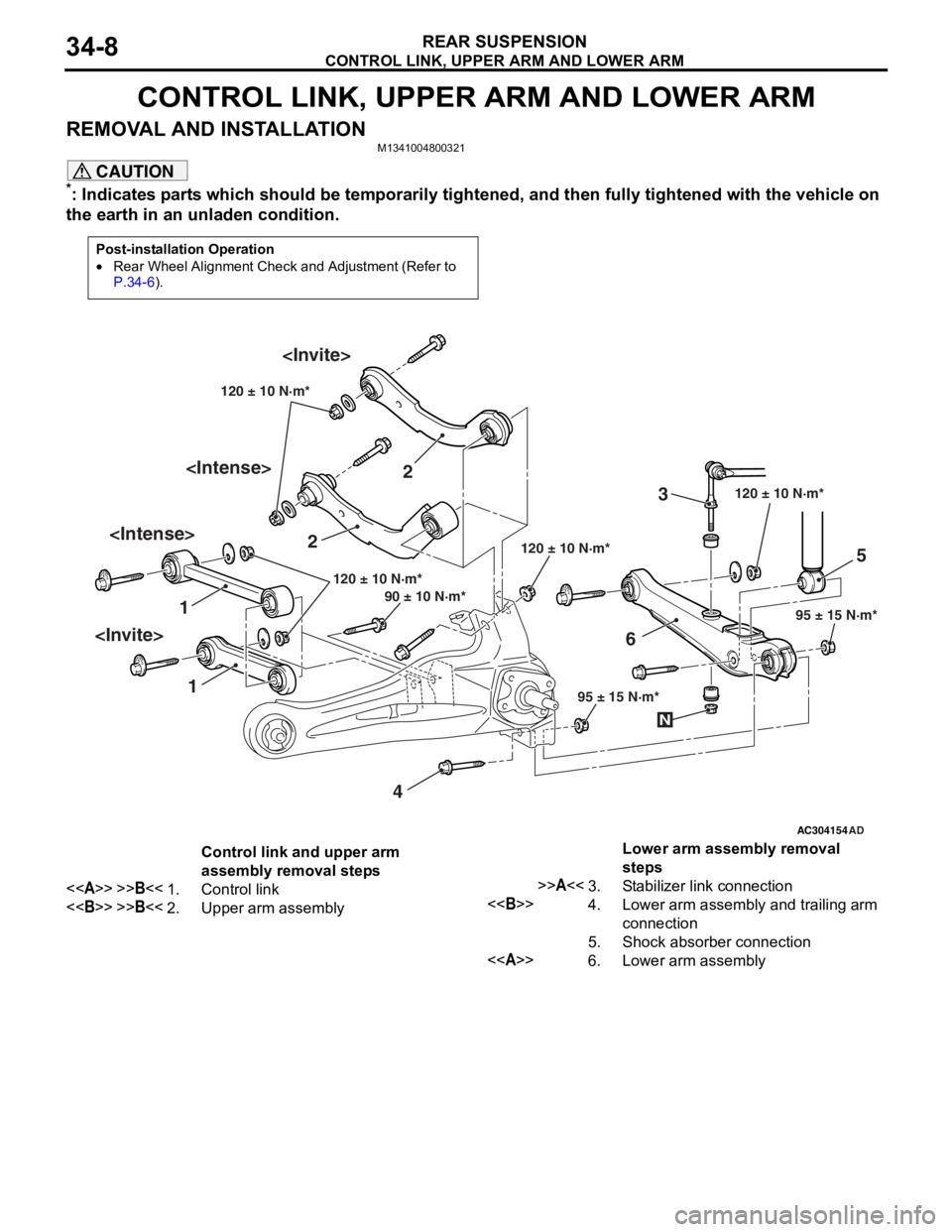

REMOVAL AND INSTALLATIONM1341004800321

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in an unladen condition.

Post-installation Operation

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-6).

AC304154

1 2

3

4 5

6

AD

120 ± 10 N·m*

95 ± 15 N·m*

120 ± 10 N·m*

120 ± 10 N·m*

95 ± 15 N·m*

90 ± 10 N·m* 120 ± 10 N·m*

N

Control link and upper arm

assembly removal steps

<>>>B<<1.Control link

<>>>B<<2.Upper arm assembly

Lower arm assembly removal

steps

>>A<<3.Stabilizer link connection

<>4.Lower arm assembly and trailing arm

connection

5.Shock absorber connection

<>6.Lower arm assembly

Page 207 of 800

Page 208 of 800

CONTROL LINK, UPPER ARM AND LOWER ARM

REAR SUSPENSION34-10

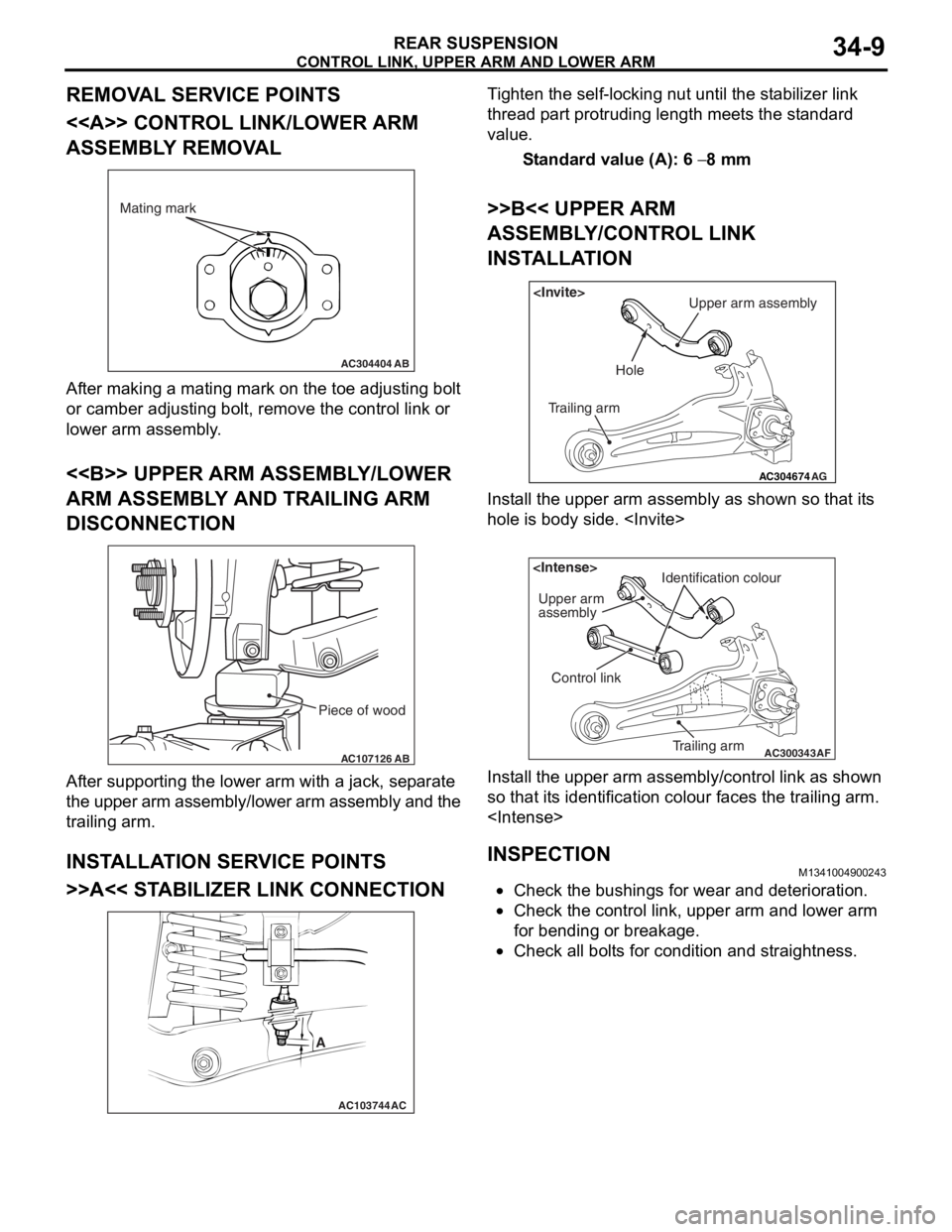

CONTROL LINK

BUSHING STARTING TORQUE CHECK

AC107127AG

Lower arm pillow ball bushing

Upper arm pillow ball bushing

Che

c k each pillow ball bu shing as follows.

1.In sert the mou n ting bo lt t o th e pillo w ball b u shing.

In the op posite direction, inse rt a wash er , the n

inst all the moun ting n u t.

AC102498AC

MB990326

2.Af ter rot a ting the inner sleeve (cont aine d washer)

seve ral times, me asure the st a r ting torque o f the

pillow ball bushing using sp ecial to ol pre l oad

socket (MB990326 ).

St andard va lue: 0.5 − 3.0 N⋅m

3.If the measu r ed value exceeds the st a ndard

value , replace the control lin k, the upper arm, o r

th e lower a r m pillo w ball bushing.

4.If the measu r ed value is lower tha n the st andard

value , che c k that th e pillow ba ll b u shing turn s

smoo thly withou t excessive play . If the r e is no

exce ssive play and it turns smooth l y , the pillow

ba ll b u shing can be reused.

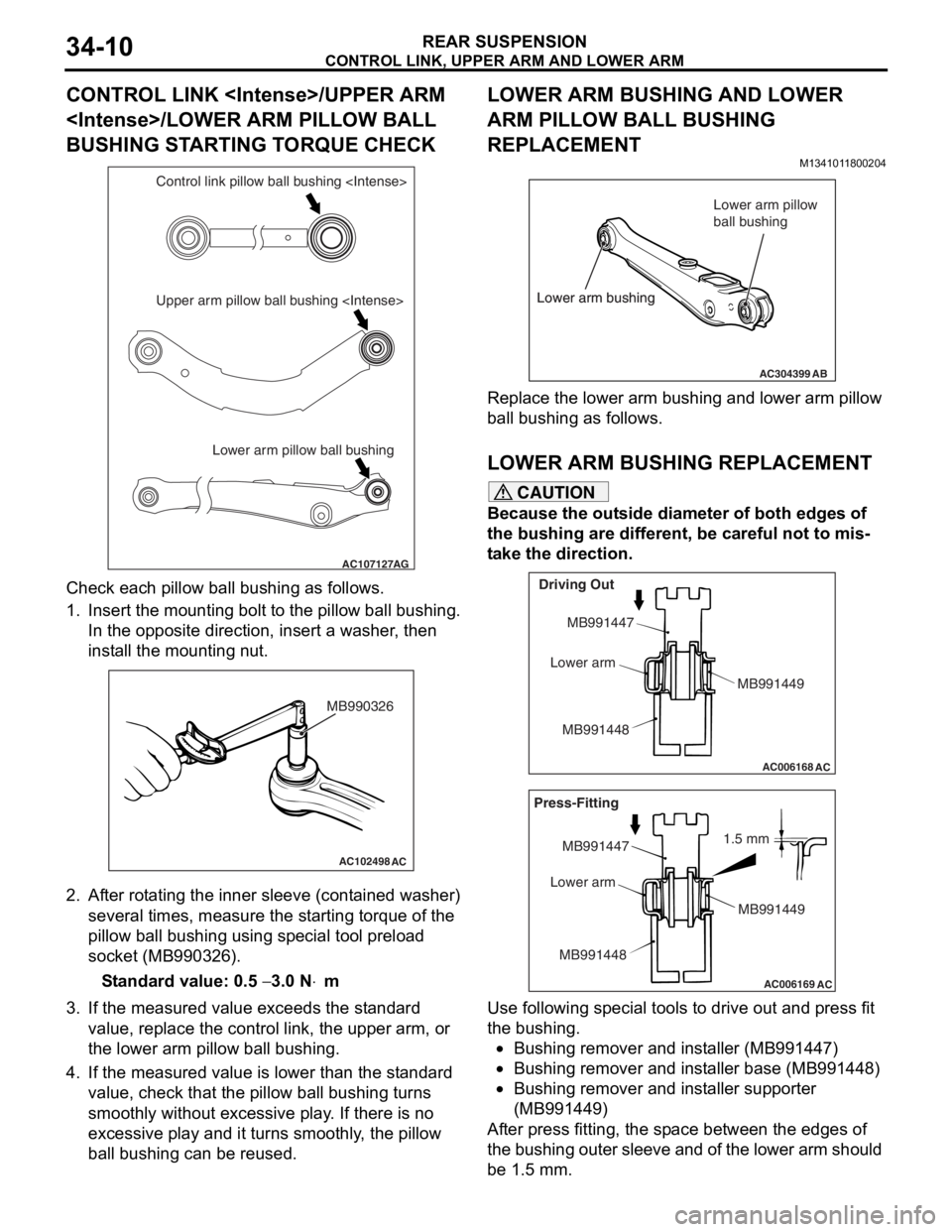

LOWER ARM BUSHING AND LOWER

ARM PILLOW BALL BUSHING

REPLACEMENT

M134101 18 0020 4

AC304399AB

Lower arm bushing Lower arm pillow

ball bushing

Lower arm bushing

Re place the lower a r m bu shing an d lower arm p illow

ball bushing

as fo llows.

LO WER ARM BUSHING REPLACEM ENT

CAUTION

Because the outside diameter of both edges of

the bushing are different, be careful not to mis

-

take the direction.

AC006168

AC

Driving Out

MB991447

Lower arm

MB991448 MB991449

AC006169

AC

1.5 mm

Press-Fitting

MB991447

Lower arm

MB991448 MB991449

Use following special tools to drive out and press fit

the bushing.

•Bushing remover and installer (MB991447)

•Bushing remover and installer base (MB991448)

•Bushing remover and installer supporter

(MB991449)

After press fitting, the space between the edges of

the bushing outer sleeve and of the lower arm should

be 1.5 mm.

Page 209 of 800

CONTROL LINK, UPPER ARM AND LOWER ARM

REAR SUSPENSION34-11

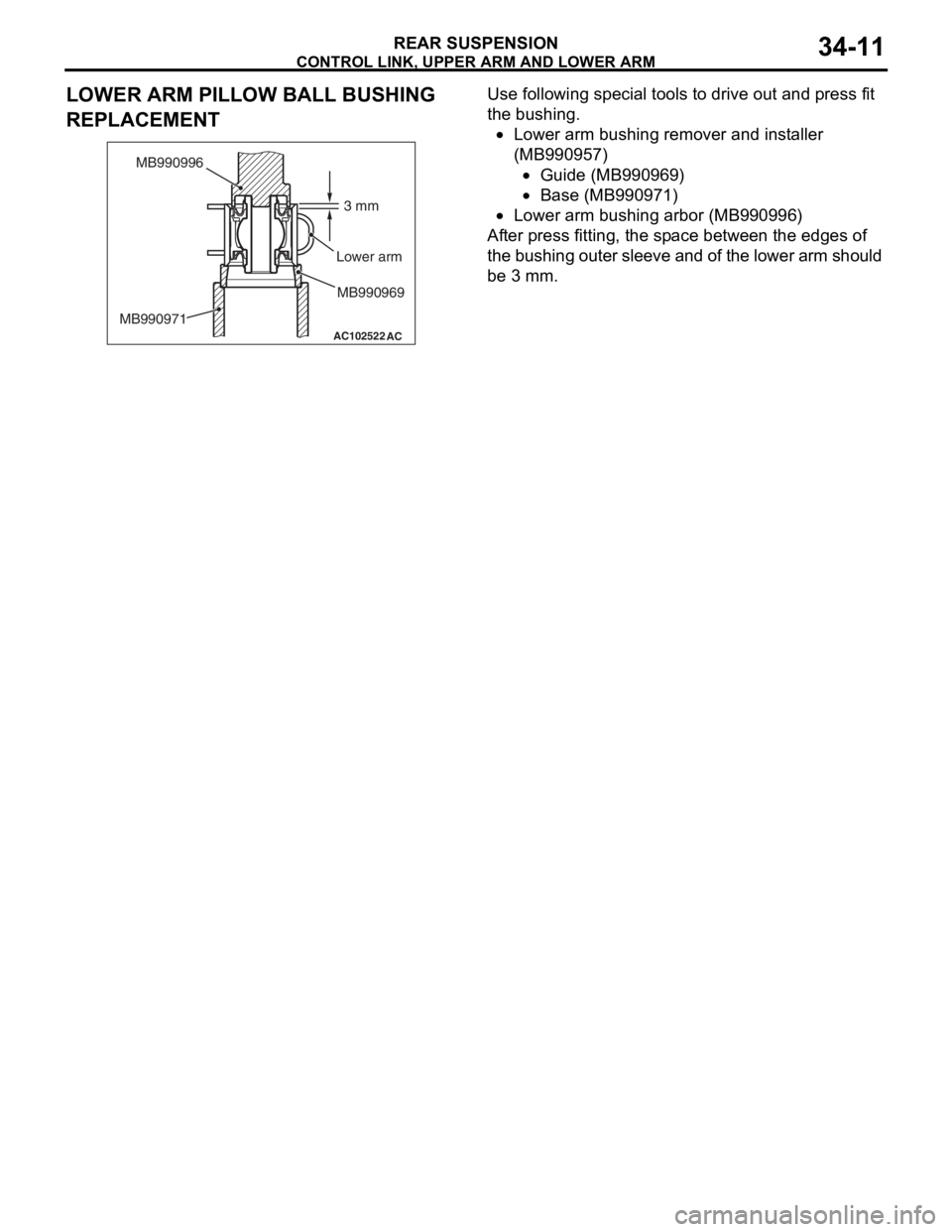

LOWER ARM PILLOW BALL BUSHING

REPLACEMENT

AC102522

AC

3 mm

MB990996

Lower arm

MB990971 MB990969

Use followin

g spe c ia l too l s t o drive ou t and p r ess fit

the bushin

g .

•Lower arm b u shing remove r and inst aller

(MB9

90957 )

•Guide (MB990969 )

•Base (MB99097 1)

•Lower arm b u shing arb o r (MB99 0996)

After p r ess fitting, t he sp ace bet we en the edges of

t

he bushin g ou ter sleeve and of the lower a r m sh ould

be 3 mm.

Page 210 of 800

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

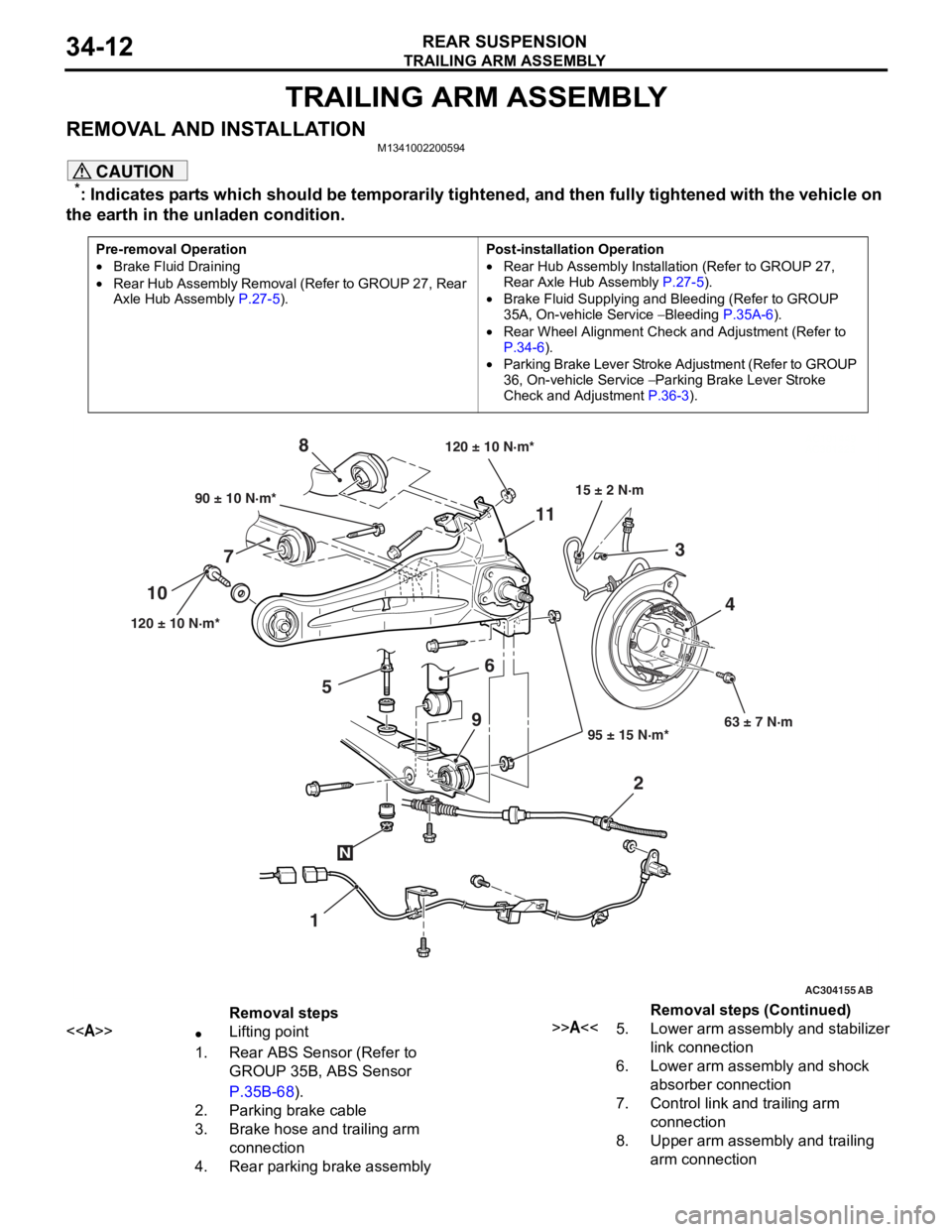

TRAILING ARM ASSEMBLY

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).

Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly

P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service

− Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-6).

•Parking Brake Lever Stroke Ad justment (Refer to GROUP

36, On-vehicle Service

− Parking Brake Lever Stroke

Check and Adjustment

P.36-3).

AC101449

AC301223

AC304155 AB

90 ± 10 N·m*

120 ± 10 N·m* 95 ± 15 N·m*63 ± 7 N·m

6

7 8

1

10

11

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1.Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-68).

2.Parking brake cable

3.Brake hose and trailing arm

connection

4.Rear parking brake assembly

>>A<<5.Lower arm assembly and stabilizer

link connection

6.Lower arm assembly and shock

absorber connection

7.Control link and trailing arm

connection

8.Upper arm assembly and trailing

arm connection

Removal steps (Continued)