lock MITSUBISHI LANCER IX 2006 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 276 of 800

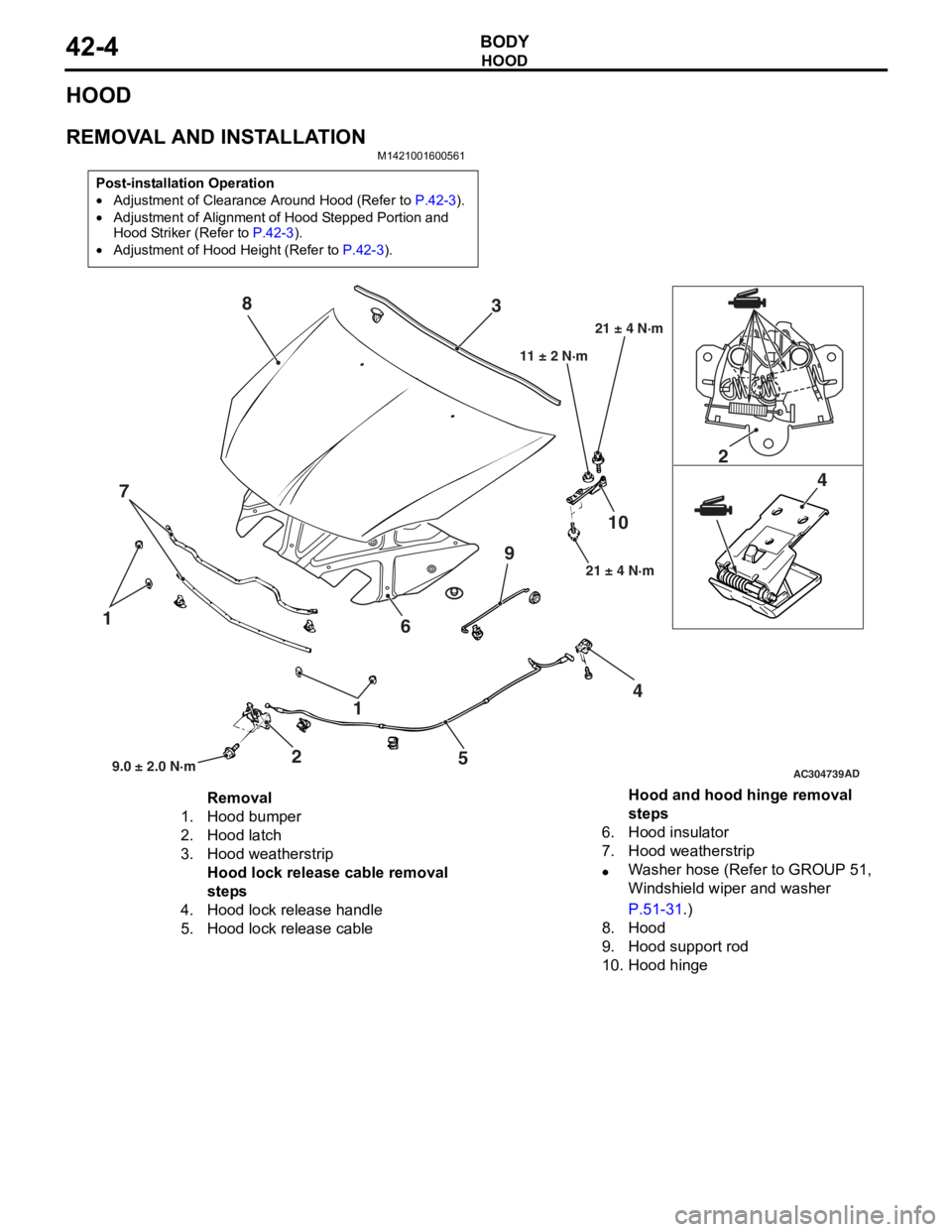

HOOD

BODY42-4

HOOD

REMOVAL AND INSTALLATION

M1421001600561

Post-installation Operation

•Adjustment of Clearance Around Hood (Refer to P.42-3).

•Adjustment of Alignment of Hood Stepped Portion and

Hood Striker (Refer to

P.42-3).

•Adjustment of Hood Height (Refer to P.42-3).

AC304739

1

1

2 2

4 4

5

6

7 3

8

910

AD9.0 ± 2.0 N·m 21 ± 4 N·m

11 ± 2 N·m

21 ± 4 N·m

Removal

1.Hood bumper

2.Hood latch

3.Hood weatherstrip

Hood lock release cable removal

steps

4.Hood lock release handle

5.Hood lock release cable

Hood and hood hinge removal

steps

6.Hood insulator

7.Hood weatherstrip

•Washer hose (Refer to GROUP 51,

Windshield wiper and washer

P.51-31.)

8.Hood

9.Hood support rod

10.Hood hinge

Page 280 of 800

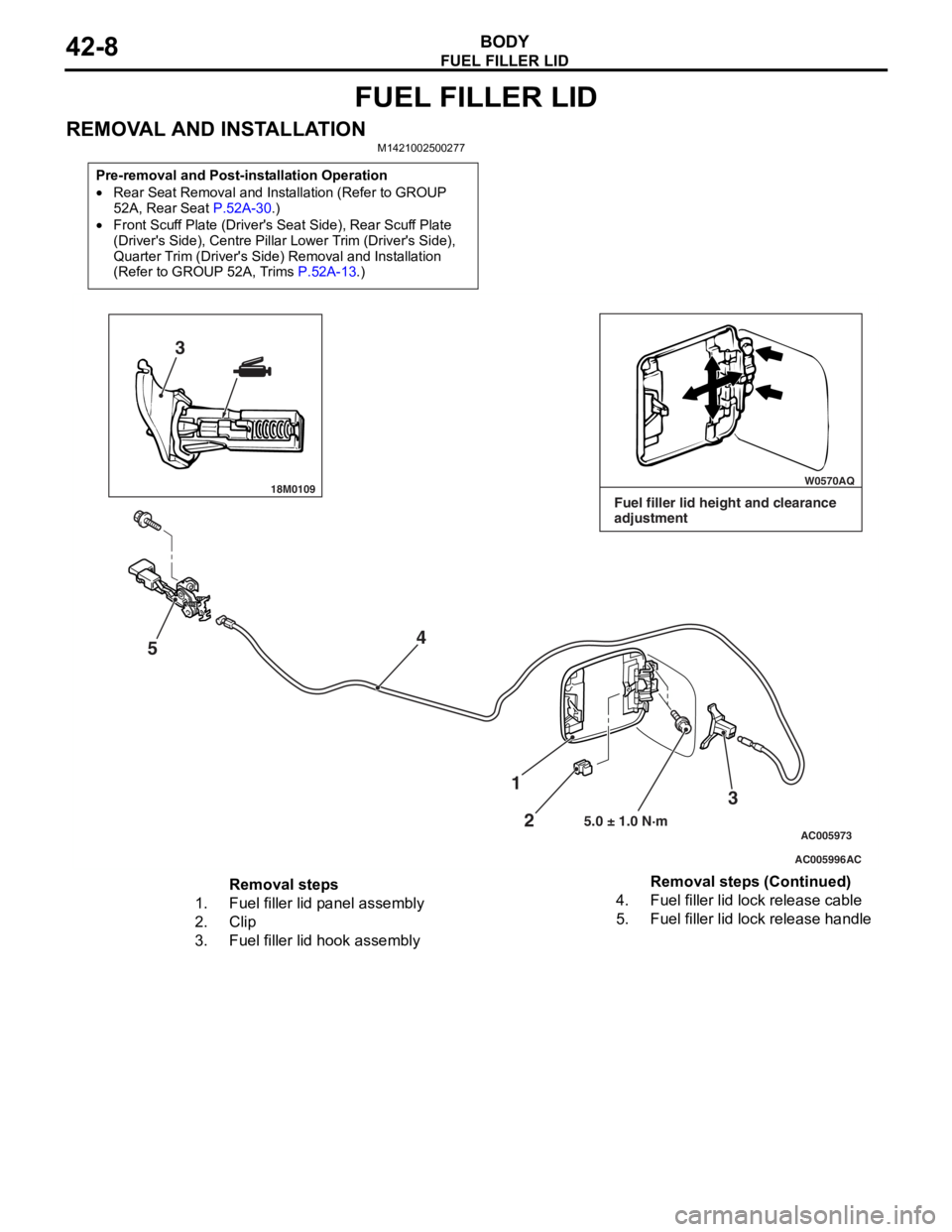

FUEL FILLER LID

BODY42-8

FUEL FILLER LID

REMOVAL AND INSTALLATIONM1421002500277

Pre-removal and Post-installation Operation

•Rear Seat Removal and Installation (Refer to GROUP

52A, Rear Seat

P.52A-30.)

•Front Scuff Plate (Driver's Seat Side), Rear Scuff Plate

(Driver's Side), Centre Pillar Lower Trim (Driver's Side),

Quarter Trim (Driver's Side) Removal and Installation

(Refer to GROUP 52A, Trims

P.52A-13.)

18M0109 W0570AQ

AC005996

AC005973

3

5 4

3

2

1

5.0 ± 1.0 N·m

AC

Fuel filler lid height and clearance

adjustment

Removal steps

1.Fuel filler lid panel assembly

2.Clip

3.Fuel filler lid hook assembly

4.Fuel filler lid lock release cable

5.Fuel filler lid lock release handle

Removal steps (Continued)

Page 283 of 800

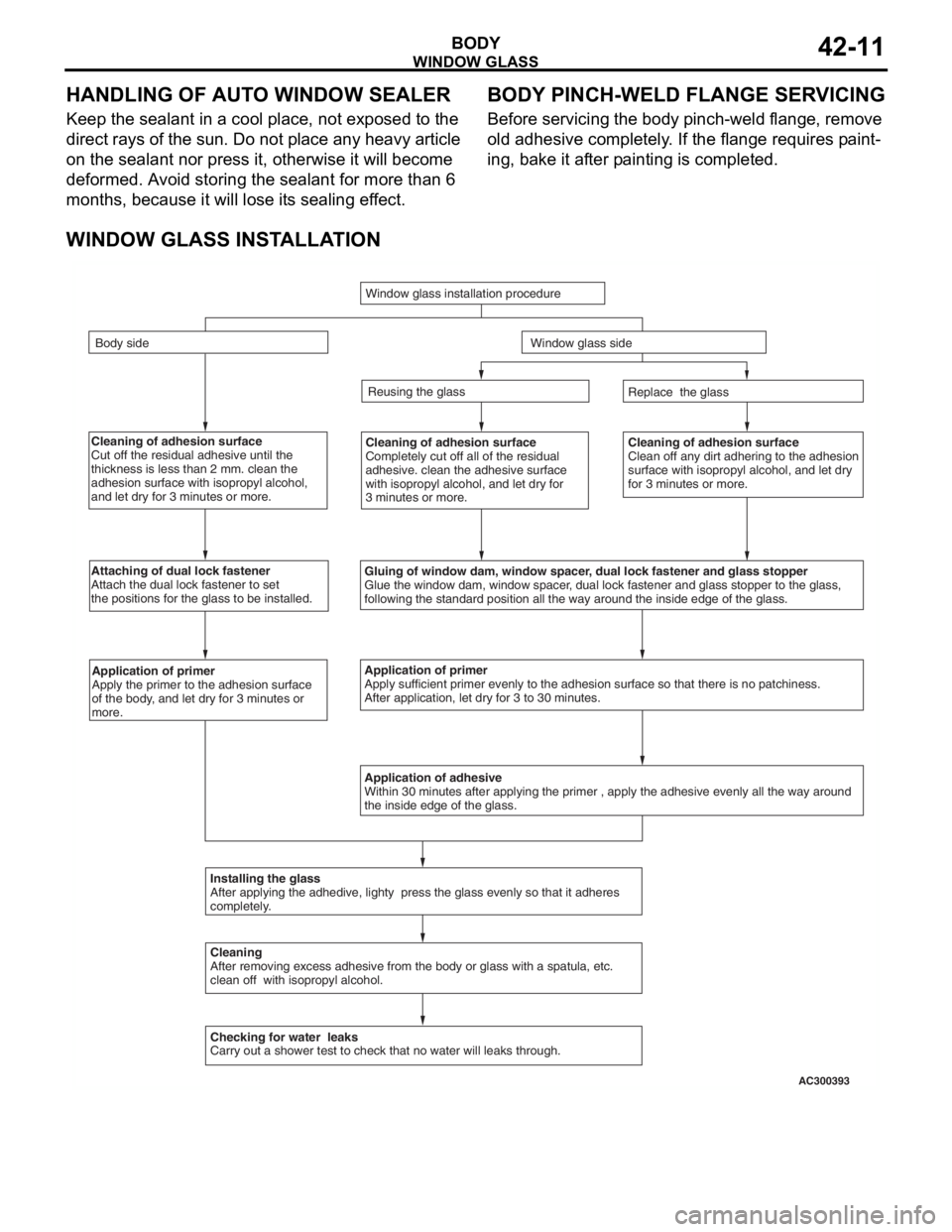

WINDOW GLASS

BODY42-11

HANDLING OF AUTO WINDOW SEALER

Keep the sealant in a cool place, not exposed to the

direct rays of the sun. Do not place any heavy article

on the sealant nor press it, otherwise it will become

deformed. Avoid storing the sealant for more than 6

months, because it will lose its sealing effect.

BODY PINCH-WELD FLANGE SERVICING

Before servicing the body pinch-weld flange, remove

old adhesive completely. If the flange requires paint

-

ing, bake it after painting is completed.

WINDOW GLASS INSTALLATION

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm. clean the

adhesion surface with isopropyl alcohol,

and let dry for 3 minutes or more.Cleaning of adhesion surface

Completely cut off all of the residual

adhesive. clean the adhesive surface

with isopropyl alcohol, and let dry for

3 minutes or more.Cleaning of adhesion surface

Clean off any dirt adhering to the adhesion

surface with isopropyl alcohol, and let dry

for 3 minutes or more.

Attaching of dual lock fastener

Attach the dual lock fastener to set

the positions for the glass to be installed.

Gluing of window dam, window spacer, dual lock fastener and glass stopper

Glue the window dam, window spacer, dual lock fastener and glass stopper to the glass,

following the standard position all the way around the inside edge of th\

e glass.

Application of primer

Apply the primer to the adhesion surface

of the body, and let dry for 3 minutes or

more.Application of primer

Apply sufficient primer evenly to the adhesion surface so that there is \

no patchiness.

After application, let dry for 3 to 30 minutes.

Application of adhesive

Within 30 minutes after applying the primer , apply the adhesive evenly \

all the way around

the inside edge of the glass.

Installing the glass

After applying the adhedive, lighty press the glass evenly so that it a\

dheres

completely.

Cleaning

After removing excess adhesive from the body or glass with a spatula, et\

c.

clean off with isopropyl alcohol.

Checking for water leaks

Carry out a shower test to check that no water will leaks through. Replace the glass

Reusing the glass

Window glass installation procedure

Body side

Window glass side

AC300393

Page 292 of 800

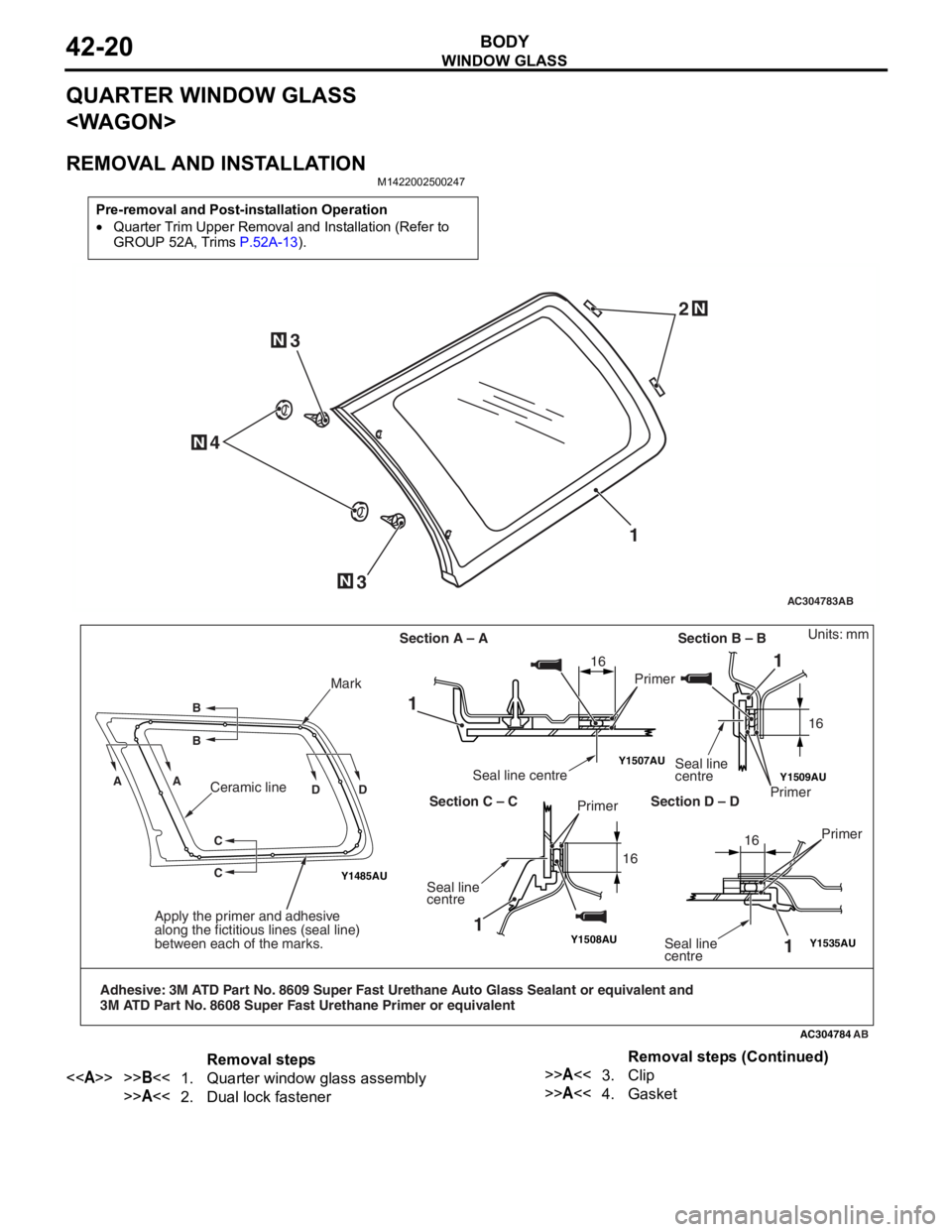

WINDOW GLASS

BODY42-20

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION

M1422002500247

Pre-removal and Post-installation Operation

•Quarter Trim Upper Removal and Installation (Refer to

GROUP 52A, Trims

P.52A-13).

AC304783

N

N

N

12

3

N3

4

AB

Y1509AU

Y1508AU

Y1507AU

Y1485AU

Y1535AU

AC304784

AA B B

DD

C

C

Mark

Apply the primer and adhesive

along the fictitious lines (seal line)

between each of the marks.

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

1

1

1

Seal line centrePrimer

Section A – A Section B – BSeal line

centre

Primer

Section C – C Section D – D

Seal line

centre Primer

1Seal line

centre

Units: mm

Primer

16

16 1616

Ceramic line

AB

Removal steps

<>>>B<<1.Quarter window glass assembly

>>A<<2.Dual lock fastener

>>A<<3.Clip

>>A<<4.Gasket

Removal steps (Continued)

Page 294 of 800

WINDOW GLASS

BODY42-22

INSTALLATION SERVICE POINTS

>>A<< GASKET/CLIP/DUAL LOCK FAS-

TENER INSTALLATION

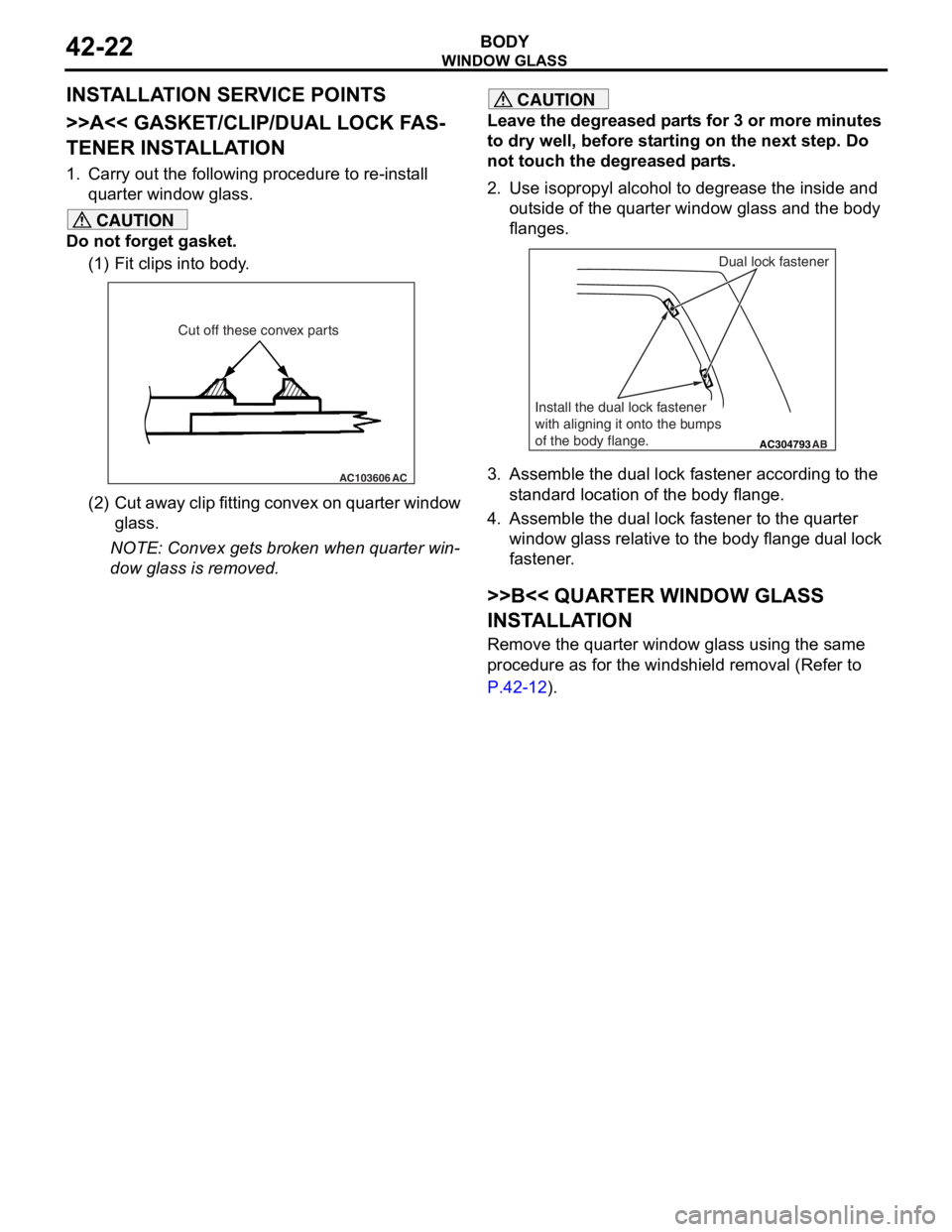

1. Carry out the following procedure to re-install quarter window glass.

CAUTION

Do not forget gasket.

(1) Fit clips into body.

AC103606 AC

Cut off these convex parts

(2) Cut away clip fitting convex on quarter window

glass.

NOTE: Convex gets broken when quarter win-

dow glass is removed.

CAUTION

Leave the degreased parts for 3 or more minutes

to dry well, before starting on the next step. Do

not touch the degreased parts.

2. Use isopropyl alcohol to degrease the inside and

outside of the quarter window glass and the body

flanges.

AC304793AB

Dual lock fastener

Install the dual lock fastener

with aligning it onto the bumps

of the body flange.

3. Assemble the dual lock fastener according to the standard location of the body flange.

4. Assemble the dual lock fastener to the quarter window glass relative to the body flange dual lock

fastener.

>>B<< QUARTER WINDOW GLASS

INSTALLATION

Remove the quarter window glass using the same

procedure as for the windshield removal (Refer to

P.42-12).

Page 296 of 800

Removal steps

1.Connecting the harness connector

<>>>B<<2.Tailgate window glass

>>A<<3.Window lower dam

>>A<<4.Window side dam

>>A<<5.Dual lock fastener

>>A<<6.Glass stopper

>>A<<7.Window spacer

WI ND OW GLAS S

BODY42-24

REMOVA L SER V ICE POINT

<> TA ILGA TE WINDOW GLASS

REMOV

A L

Remove the t a ilgate window g l ass using the same

proce

dure as for th e windshie l d (Refe r to

P.42-12).

INSTALLA T ION SER VICE POINTS

>>A<< WI NDOW SP ACER/GLASS ST OP-

PER/DUAL LOCK FA STENER/WINDOW

DAM INST

ALLA TION

CAUTION

Leave the degreased parts for 3 or more minutes

to dry well, before starting on the next step. Do

not touch the degreased parts.

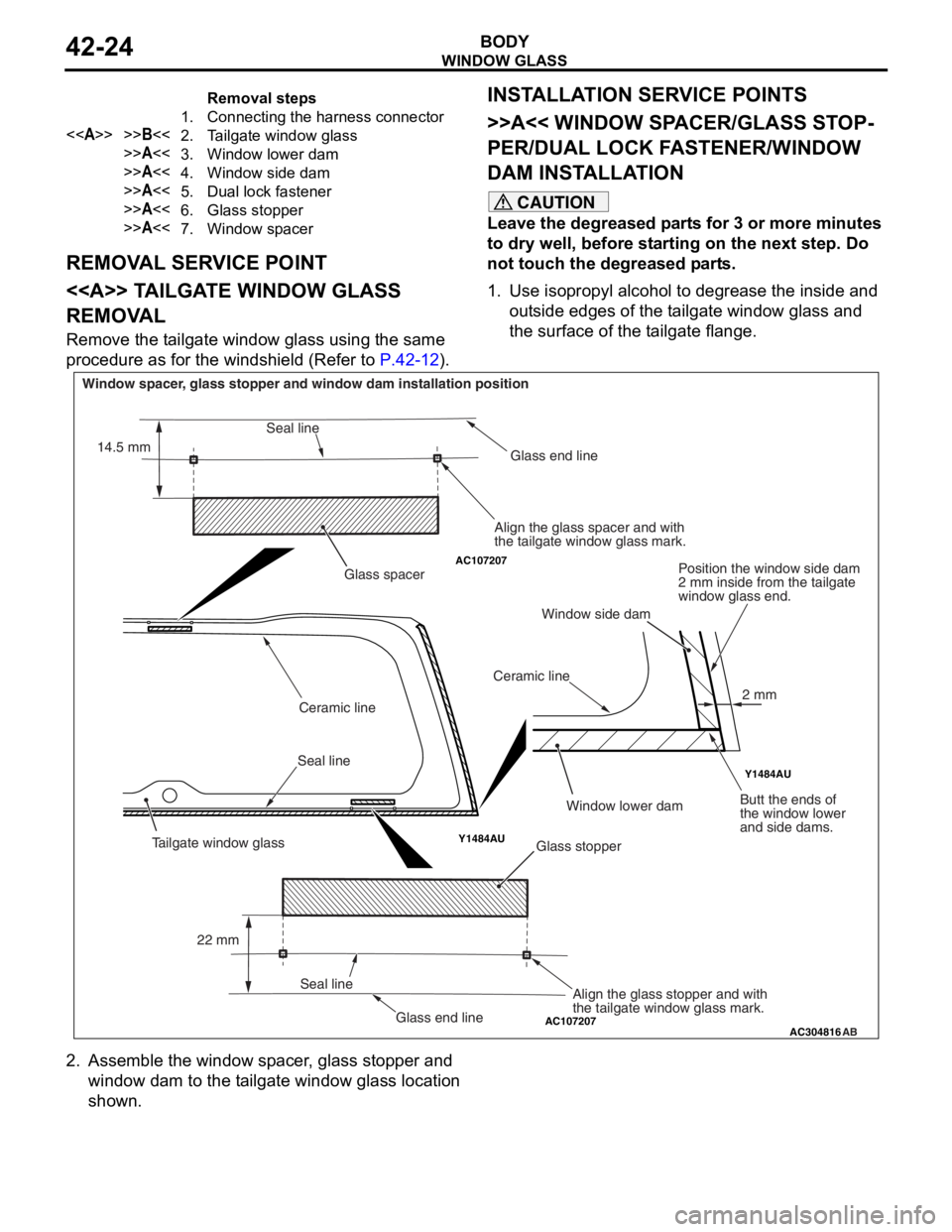

1. Use isopropyl alcohol to degrease the inside and outside edges of the tailgate window glass and

the surface of the tailgate flange.

AC107207

AC107207

Y1484AU Y1484AU

AC304816

AB

Glass stopper

Glass spacer

Seal line Ceramic line

Ceramic lineGlass end line

Glass end line

Window spacer, glass stopper and window dam installation position

Align the glass spacer and with

the tailgate window glass mark.Position the window side dam

2 mm inside from the tailgate

window glass end.

Butt the ends of

the window lower

and side dams.

Align the glass stopper and with

the tailgate window glass mark.

Seal line

Seal line

22 mm

14.5 mm

2 mm

Tailgate window glass

Window lower dam

Window side dam

2. Assemble the window spacer, glass stopper and

window dam to the tailgate window glass location

shown.

Page 297 of 800

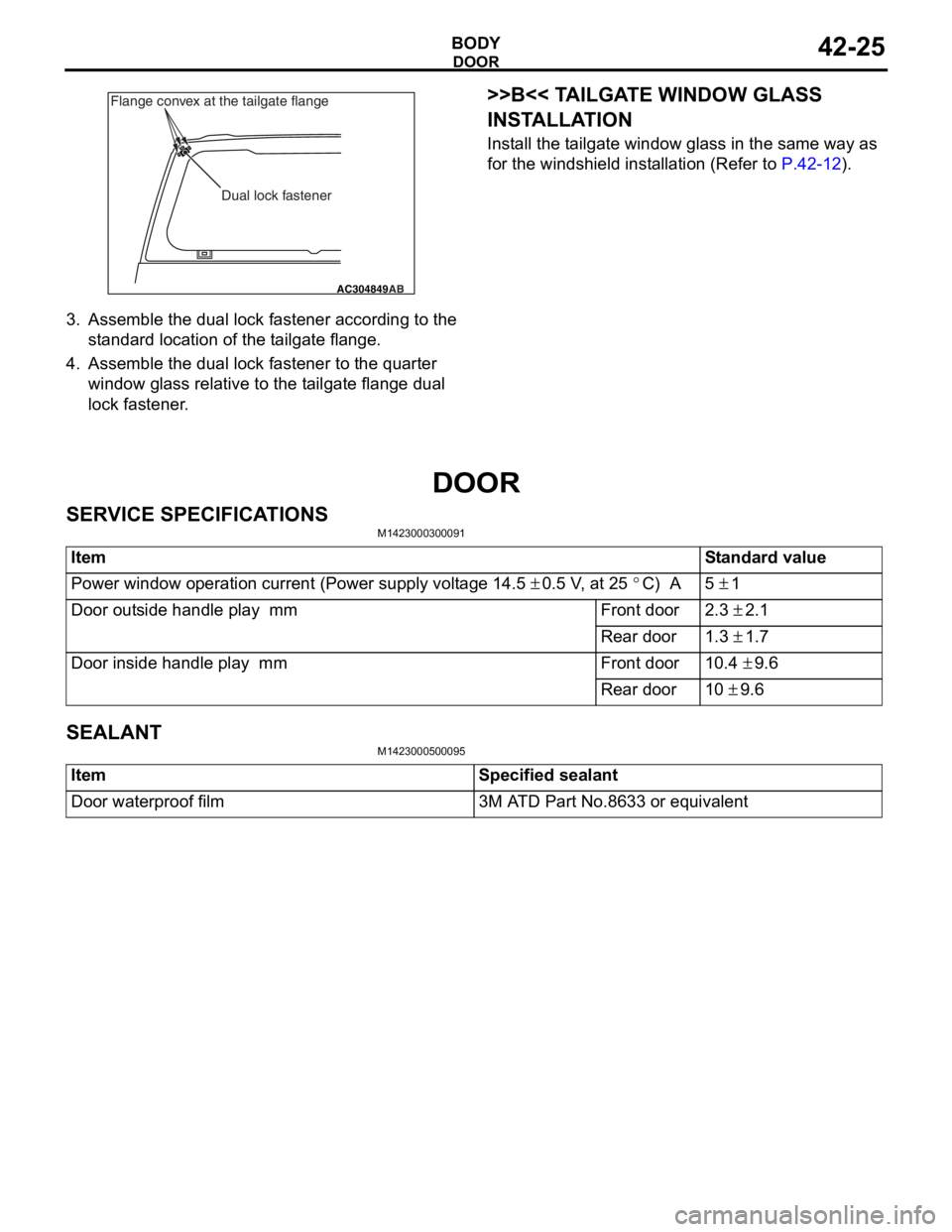

AC304849AB

Dual lock fastener

Flange convex at the tailgate flange

DOOR

BO

D Y42-25

3.Assemble the dua l lo ck faste ner accord ing t o the

st a ndard loca tion of the t a ilgat e flan ge.

4.Assemble the dua l lo ck faste ner to t he qua rter

win dow gla ss relative to the t a ilgate flan ge dua l

lock fastener .

>>B<< TA ILGA TE WINDOW GLASS

INST

ALLA TION

Install the t a ilgat e window g l ass in the same wa y as

for the

windsh i eld inst a lla tion ( R ef er to

P.42-12).

DOOR

SER V ICE SPECIFICA T IONS

M14230003 0009 1

ItemStandard value

Power window operation current (Power supply voltage 14.5 ± 0.5 V, at 25 °C) A5 ± 1

Door outside handle play mmFront door2.3 ± 2.1

Rear door1.3 ± 1.7

Door inside handle play mmFront door10.4 ± 9.6

Rear door10 ± 9.6

SEALANT

M14230005 0009 5

ItemSpecified sealant

Door waterproof film3M ATD Part No.8633 or equivalent

Page 299 of 800

DOOR

BODY42-27

ON-VEHICLE SERVICE

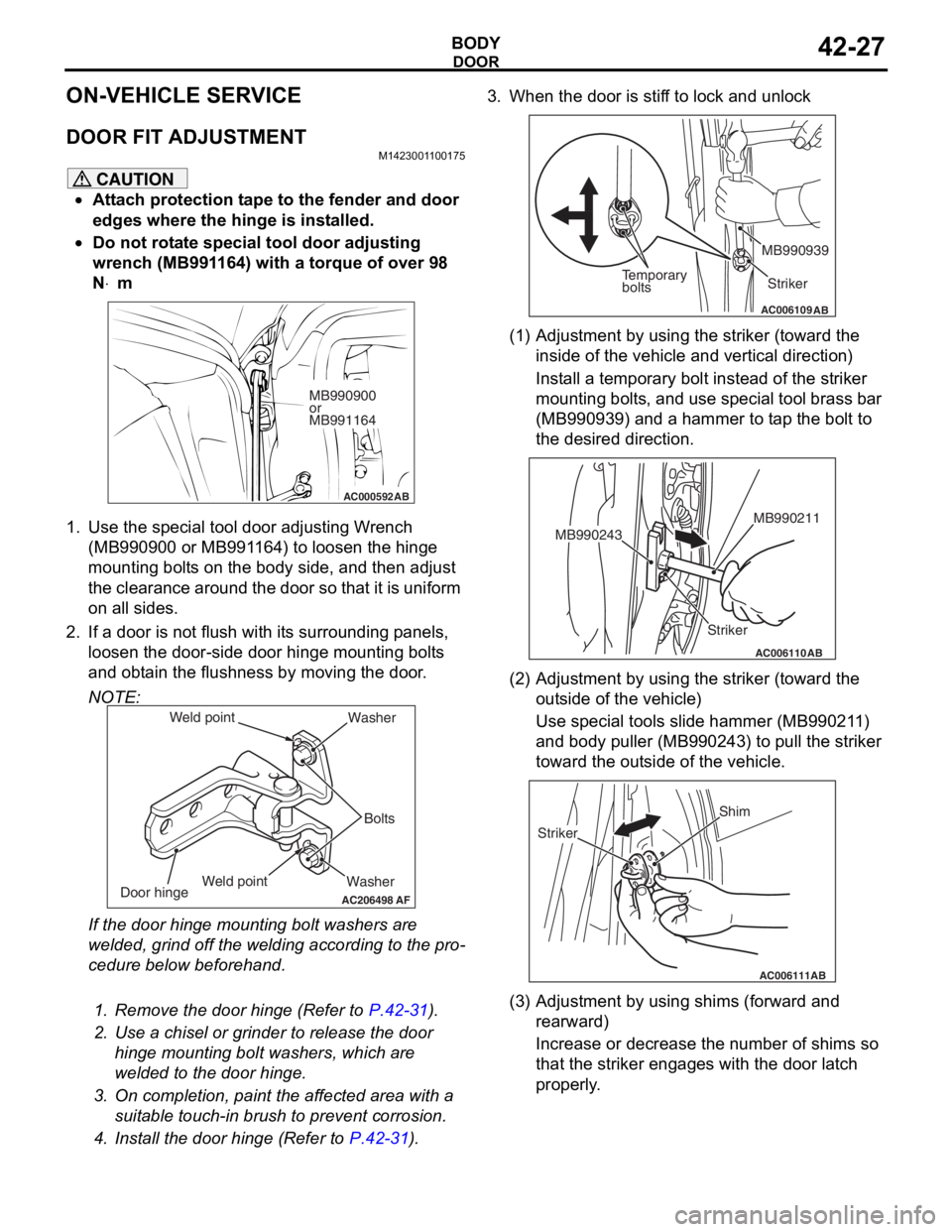

DOOR FIT ADJUSTMENT

M1423001100175

CAUTION

•Attach protection tape to the fender and door

edges where the hinge is installed.

•Do not rotate special tool door adjusting

wrench (MB991164) with a torque of over 98

N

⋅m

AC000592

MB990900

or

MB991164

AB

1. Use the special tool door adjusting Wrench (MB990900 or MB991164) to loosen the hinge

mounting bolts on the body side, and then adjust

the clearance around the door so that it is uniform

on all sides.

2. If a door is not flush with its surrounding panels,

loosen the door-side d oor hinge mounting bolts

and obtain the flushness by moving the door.

NOTE:

AC206498

Washer Bolts

Washer

Door hinge

AF

Weld point

Weld point

If the door hinge mounting bolt washers are

welded, grind off the welding according to the pro

-

cedure below beforehand.

.

1. Remove the door hinge (Refer to P.42-31).

2. Use a chisel or grinder to release the door

hinge mounting bolt washers, which are

welded to the door hinge.

3. On completion, paint the affected area with a suitable touch-in brush to prevent corrosion.

4. Install the door hinge (Refer to P.42-31).

3. When the door is stiff to lock and unlock

AC006109AB

Temporary

bolts Striker

MB990939

(1) Adjustment by using the striker (toward the

inside of the vehicle and vertical direction)

Install a temporary bolt instead of the striker

mounting bolts, and use special tool brass bar

(MB990939) and a hammer to tap the bolt to

the desired direction.

AC006110

Striker MB990211

MB990243

AB

(2) Adjustment by using the striker (toward the

outside of the vehicle)

Use special tools slide hammer (MB990211)

and body puller (MB990243) to pull the striker

toward the outside of the vehicle.

AC006111AB

Shim

Striker

(3) Adjustment by using shims (forward and rearward)

Increase or decrease the number of shims so

that the striker engages with the door latch

properly.

Page 301 of 800

DOOR

BODY42-29

3. If the operation current is outside the standard value, refer to GROUP 54B, Troubleshooting

P.54B-15, refer to GROUP 54C, Troubleshooting

P.54C-4.

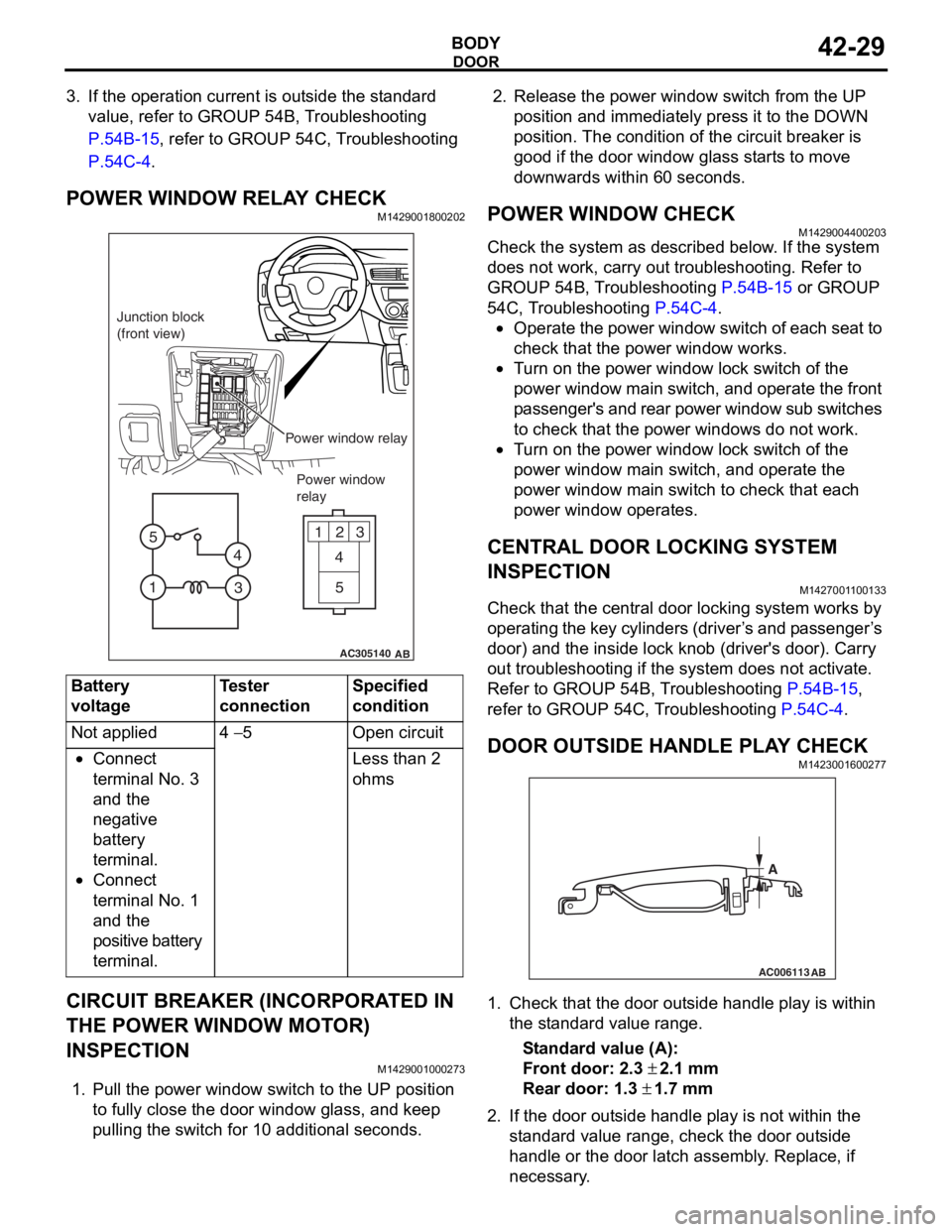

POWER WINDOW RELAY CHECKM1429001800202

AC305140

123

4

5

1 3

4

5

AB

Junction block

(front view)

Power window relayPower window

relay

Bat t ery

voltage

Teste r

co

nnectionSpecified

condition

Not applied4 − 5Ope n ci rcui t

•Connect

te

rmin al No. 3

an

d the

ne

gative

ba

ttery

te

rmin al.

•Connect

te

rmin al No. 1

an

d the

positive batt

e ry

te

rmin al.

Less than 2

ohms

CIRCUIT BREAKER (INCORPORA T ED IN

THE POW

E R W I NDOW MOT O R)

INSPECTION

M14290010 0027 3

1.Pull the p o wer windo w switch to th e UP position

to f u lly close the do or windo w g l ass, an d ke ep

pullin g the switch for 1 0 addition al secon d s.

2.Rele ase the power window switch from t he UP

position an d immediately pre ss it to t he DOW N

position. Th e con d ition of the circu i t brea ker is

goo d if t he doo r window g l ass st art s to mo ve

downward s with in 60 seconds.

POWER WI NDOW CHECKM14290044 0020 3

Check the system a s de scribed b e low . I f the system

does not work, car

r y out troublesh ootin g. Refer to

GROUP 54

B, T r ouble s hoo ting

P.54B-15 or GROUP

54C, T r oublesh ootin g P.54C-4.

•Operate the powe r wind ow switch of e a ch se at to

check that

the power window works.

•Tu rn o n the power wind ow lock switch of the

power wind

ow main swit ch, and ope rate the front

p

a ssenger's and rear power window su b switches

to check th

at the p o wer windo ws do n o t work.

•Tu rn o n the power wind ow lock switch of the

power

window main switch, and operate the

power

window main switch to check tha t each

power window

op erates.

CENTRAL DOOR LOCKING SYSTEM

INSPECTION

M142700 1 1 0013 3

Check that th e ce ntral door locking system wo rks by

op

er atin g th e key cylin de rs (d rive r ’ s an d p a sse n g e r ’ s

door) an

d the inside lock kno b (driver's door). Ca rry

out trou

bleshooting if the system does not activate.

Re

fer to GROUP 54B, T r ou bleshooting

P.54B-15,

refer to GROUP 54 C, T r o uble s hoo ting P.54C-4.

DOOR OUTSIDE HANDLE PL A Y CHECKM14230016 0027 7

AC006113

AB

A

1.Check t hat the door o u t s ide handle play is with in

th e st and ard va lue range.

St andard va lue (A):

Fron t door: 2.3 ± 2.1 m m

Rear door: 1.3 ± 1.7 mm

2. If the do or out side ha ndle play is not wit h in th e

st a ndard valu e rang e, ch eck the do or out side

h andle or the door latch assemb ly . Replace, if

ne c e ss a r y .

Page 308 of 800

DOOR

BODY42-36

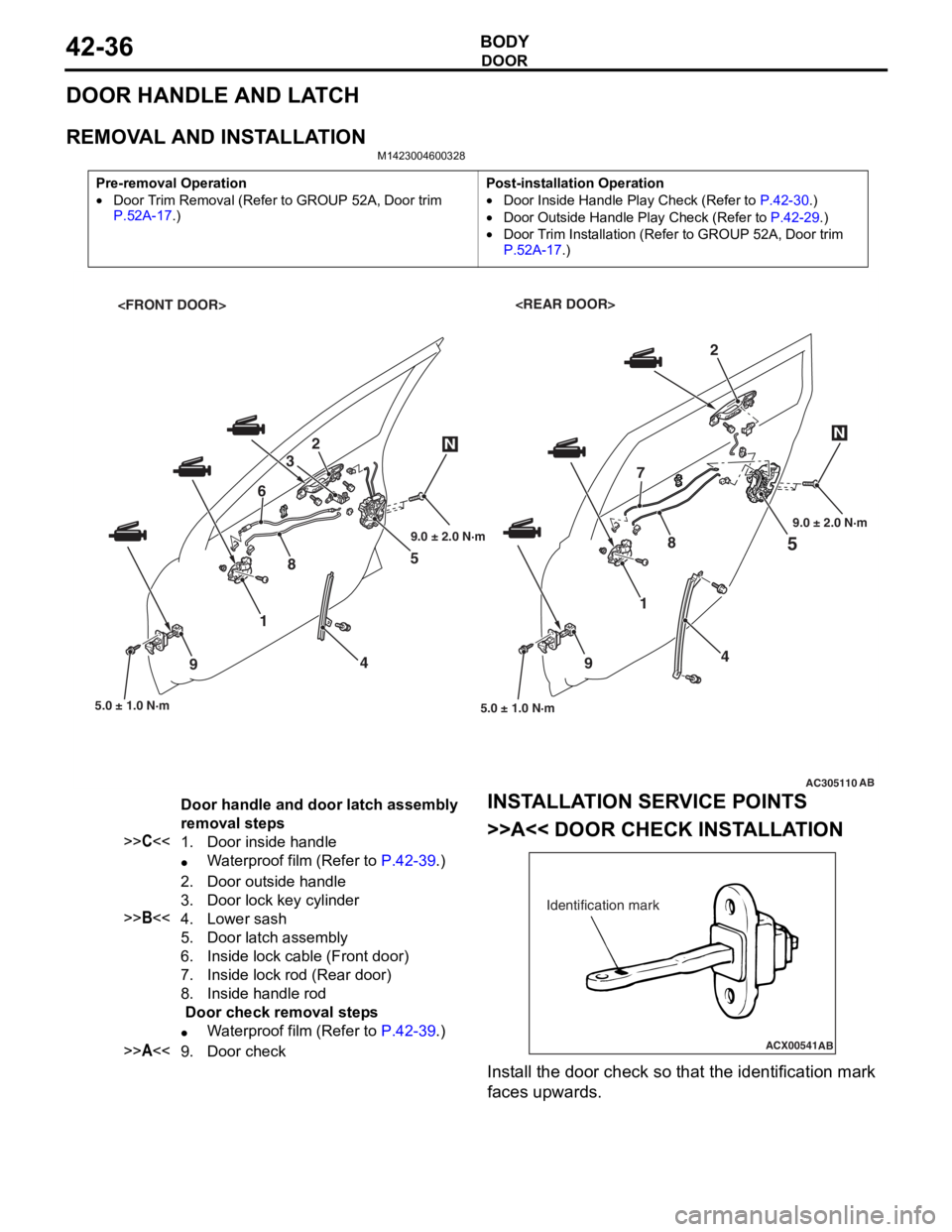

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATION

M1423004600328

Pre-removal Operation

•Door Trim Removal (Refer to GROUP 52A, Door trim P.52A-17.)

Post-installation Operation

•Door Inside Handle Play Check (Refer to P.42-30.)

•Door Outside Handle Play Check (Refer to P.42-29.)

•Door Trim Installation (Refer to GROUP 52A, Door trim

P.52A-17.)

AC305110

5

5.0 ± 1.0 N·m

1

4

9

2

AB

4 5

2

3

8 7

5.0 ± 1.0 N·m

1

6

9

NN

89.0 ± 2.0 N·m 9.0 ± 2.0 N·m

Door handle and door latch assembly

removal steps

>>C<<1.Door inside handle

•Waterproof film (Refer to P.42-39.)

2.Door outside handle

3.Door lock key cylinder

>>B<<4.Lower sash

5.Door latch assembly

6.Inside lock cable (Front door)

7.Inside lock rod (Rear door)

8.Inside handle rod

Door check removal steps

•Waterproof film (Refer to P.42-39.)

>>A<<9.Door check

INST

ALLA T ION SER VICE POINTS

>>A<< DOOR CHECK INST ALLA TION

ACX00541

Identification mark

AB

Install the d oor check so that th e ide n tification mark

faces upward

s .