lock MITSUBISHI LANCER IX 2006 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 309 of 800

ItemIdentification

mark

Front DoorLeft door39L

Right door39R

Rear DoorLeft door40L

Right door40R

DOOR

BODY42-37

>>B<< LOWER SASH INSTALLATION

Securely insert the rear lower sash into the window

rear sash.

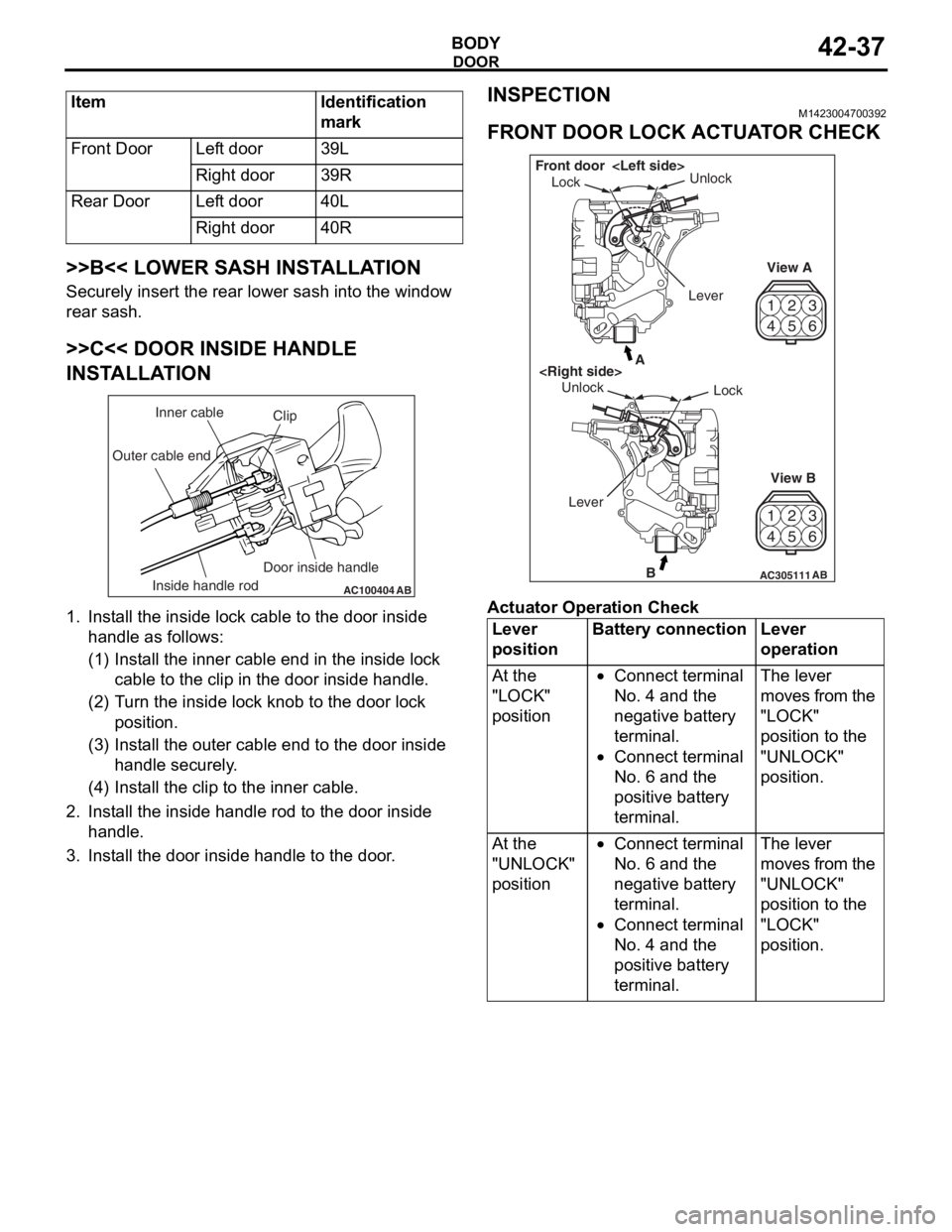

>>C<< DOOR INSIDE HANDLE

INSTALLATION

AC100404AB

Clip

Inner cable

Outer cable end

Inside handle rod Door inside handle

1.

In st all the inside lo ck cable to th e doo r inside

ha ndle as fo llo ws:

(1)I nst a ll the inne r cab l e en d in the in sid e lock

cab l e to the clip in th e door inside h andle .

(2)T urn the inside lock knob to the do or lock

positio n.

(3)I nst a ll the outer cable end to the door inside

hand le secure ly .

(4)I nst a ll the clip to the in ner cable .

2.In st all the inside han dle ro d to th e door inside

ha ndle .

3.In st all the do or inside handle to t he doo r .

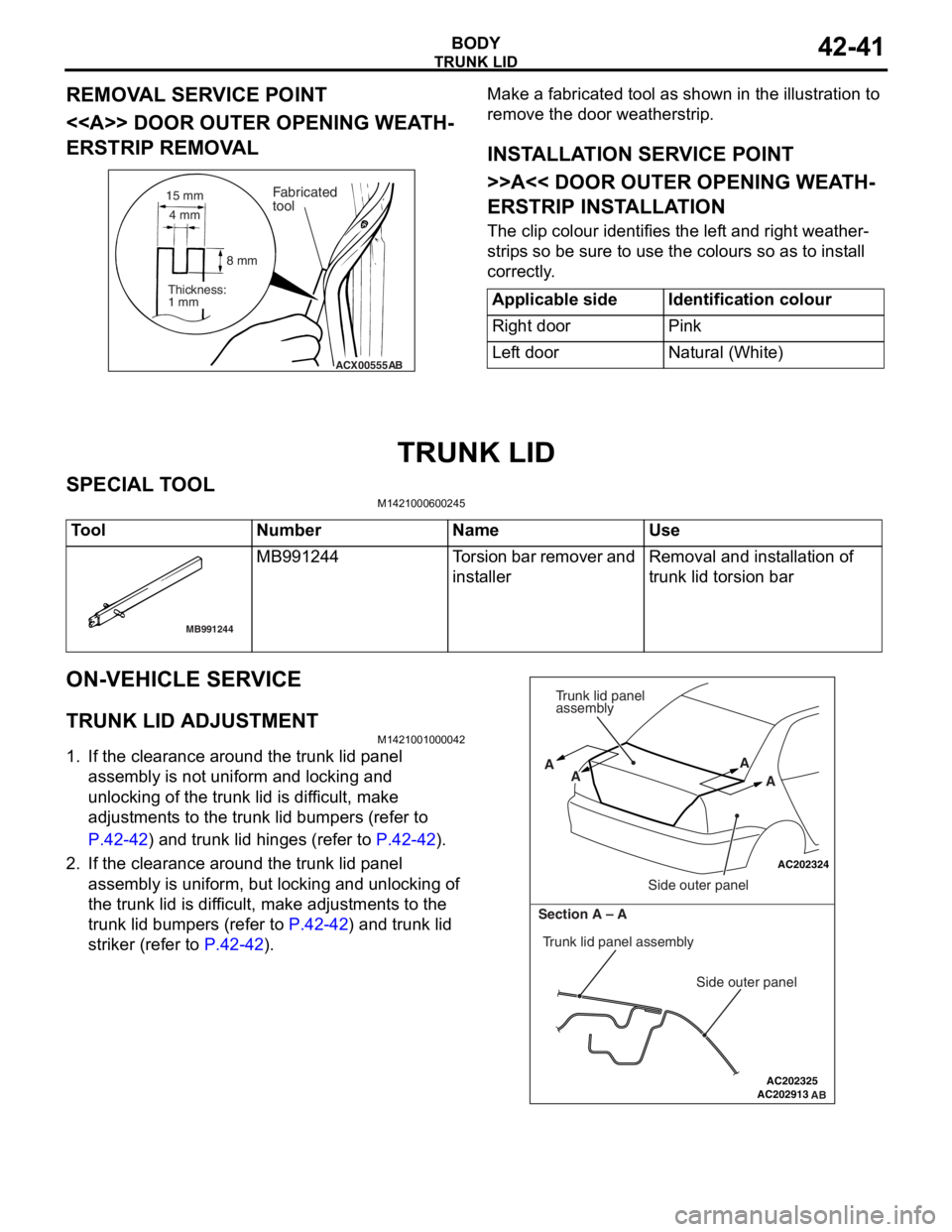

INSPECTION

M14230047 0039 2

FRONT DOOR LOCK ACTUA T O R CHECK

42

53

6

1

4 2

53

6

1

AC305111B

A

AB

Lock

Unlock

View A

View B

Unlock

Lock

Front door

Lever

Ac tuator Op era t ion Check

Lever

positionBattery connectionLever

operation

At the

"LOCK"

position•Connect terminal

No. 4 and the

negative battery

terminal.

•Connect terminal

No. 6 and the

positive battery

terminal.

The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No. 6 and the

negative battery

terminal.

•Connect terminal

No. 4 and the

positive battery

terminal.

The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

Page 310 of 800

DOOR

BODY42-38

Actuator Switch Check

Lever positionTester

connectionSpecified

condition

At the "LOCK"

position1 − 2Less than 2

ohms

1 − 3Open circuit

At the "UNLOCK"

position1 − 2Open circuit

1 − 3Less than 2

ohms

REAR DOOR LOCK ACTUATOR CHECK

23

4 1

56

23

4 1

56

AC305112B

A

AB

Rear door

Lock Unlock

View A

View B

Unlock

Lock

Lever

Ac tuator Op era t ion Check

Lever

positionBattery connectionLever

operation

At the

"LOCK"

position•Connect terminal

No. 4 and the

negative battery

terminal.

•Connect terminal

No. 6 and the

positive battery

terminal.

The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No. 6 and the

negative battery

terminal.

•Connect terminal

No. 4 and the

positive battery

terminal.

The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

DOOR LOCK KEY CYLINDER SWITCH

CHECK

AC101318

3

2

1

Switch

positionTester

connectionSpecified

condition

LOCK2 − 3Less than 2

ohms

NEUTRAL

(OFF)1 − 2, 2 − 3Open circuit

UNLOCK1 − 2Less than 2

ohms

Page 313 of 800

Page 314 of 800

TRUNK LID

BODY42-42

3. If there is a difference in height between the side outer panels and the side edges of the trunk lid

panel assembly, check the trunk lid hinges and, if

necessary, replace them

4. If the clearance around the trunk lid panel assembly is not uniform, and the trunk lid can be

locked and unlocked smoothly, make adjustments

to the trunk lid bumpers (refer to

P.42-42) and

trunk lid hinges (Refer to P.42-42).

5. If the locking and unlocking of the trunk lid still is difficult after making the above adjustments,

adjust the trunk lid striker (Refer to

P.42-42).

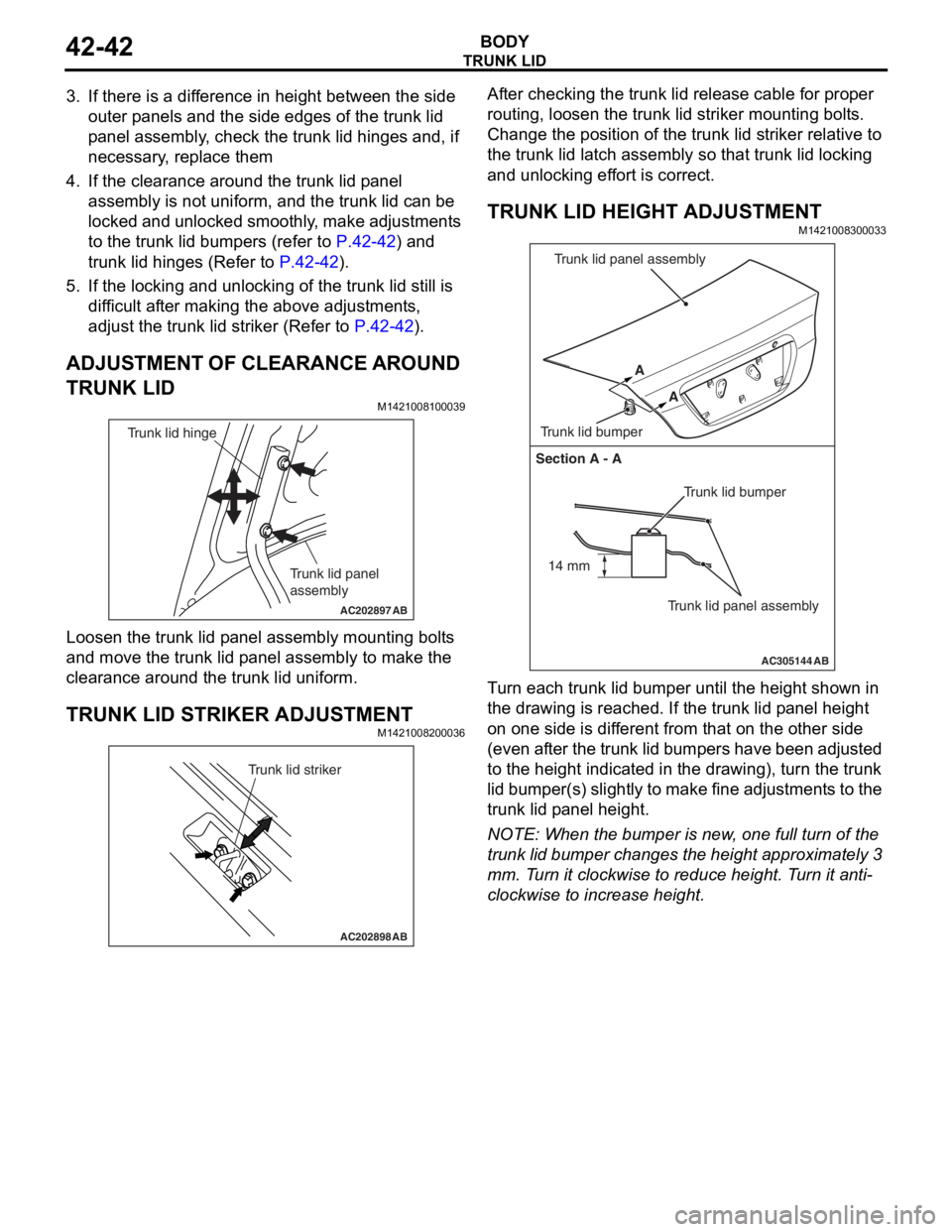

ADJUSTMENT OF CLEARANCE AROUND

TRUNK LID

M1421008100039

AC202897

Trunk lid panel

assembly

Trunk lid hinge

AB

Loosen the trunk lid p a nel a sse mbly mounting bolt s

and move

the trun k lid p anel assembly to make t he

clea

rance aroun d the t r unk lid u n iform.

TRUNK LID STRIKER ADJUSTMENT

M14210082 0003 6

AC202898

Trunk lid striker

AB

After checking the trunk lid relea s e cable for pro per

routin

g, lo osen the trun k lid striker mo untin g bolt s .

Ch

ange th e position of t he trunk lid st rike r relat i ve to

the trun

k lid la tch a s sembly so tha t trunk lid lockin g

and un

lockin g ef f o rt is corre ct.

TRUNK LID HEIGHT ADJUSTMENT

M14210083 0003 3

AC305144

Section A - A

Trunk lid bumper

Trunk lid panel assembly

A

A

Trunk lid bumper Trunk lid panel assembly

AB

14 mm

T

u rn each trun k lid bumper u n til the he ight shown in

the dra

w ing is reached. If the t r unk lid p a n e l he ight

on one

sid e is dif f erent from that on the oth e r side

(even

a f t e r th e t r un k lid bu mp ers have be en ad ju st ed

to the h

e igh t ind i ca ted in the dra w ing), tu rn the trunk

lid bumper(s)

slight ly to make fine adjustment s to the

trunk lid p

a nel h e ight .

NOTE: Whe n the b u mpe r is new , one full turn o f the

trunk lid bumper ch anges t he height appro x imately 3

mm.

T

u

rn it clockwise to r educe height. T u rn it anti

-

clockwise to increase height.

Page 315 of 800

TRUNK LID

BODY42-43

TRUNK LID

REMOVAL AND INSTALLATION

M1421002200180

AC301676

Y0636AU

Y0637AU

AB

8.9 ± 1.9 N·m

A

AB

B 15 mm

14 mm

Section A - A

Section B - B

9

5

6

4

12

9

59

7

11

10

8 3 5 1

2

Trunk lid weatherstrip removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

>>B<<1.Trunk lid weatherstrip

Trunk lid release cable and trunk lid

release handle removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

•Trunk rear side trim (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Front scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Cowl side trim (LH) (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear scuff plate (LH) (Refer to

GROUP 52A, Trims

P.52A-13.)

•Centre pillar lower trim (Refer to

GROUP 52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

•Accelerator pedal stopper (Refer to

GROUP 17, Accelerator pedal

P.17-3.)

2.Trunk lid release handle

3.Trunk lid release cable

Trunk lid striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

4.Trunk lid striker

Trunk lid panel removal steps

•Licence plate garnish (Refer to

GROUP 51, Garnishes

P.51-16.)

5.Trunk lid bumper

•Rear spoiler (Refer to GROUP 51,

Rear spoiler

P.51-25.)

6.Trunk lid lock cylinder

7.Trunk lid latch assembly

8.Trunk lid hinge mounting bolt

9.Trunk lid panel assembly

Trunk lid latch removal

7.Trunk lid latch assembly

Trunk lid hinge removal steps

•Rear shelf trim (Refer to GROUP

52A, Trims

P.52A-13.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly

P.52A-30.)

9.Trunk lid panel assembly

<>>>A<<10.Trunk lid torsion bar (RH)

<>>>A<<11 .Trunk lid torsion bar (LH)

12.Trunk lid hinge

Page 322 of 800

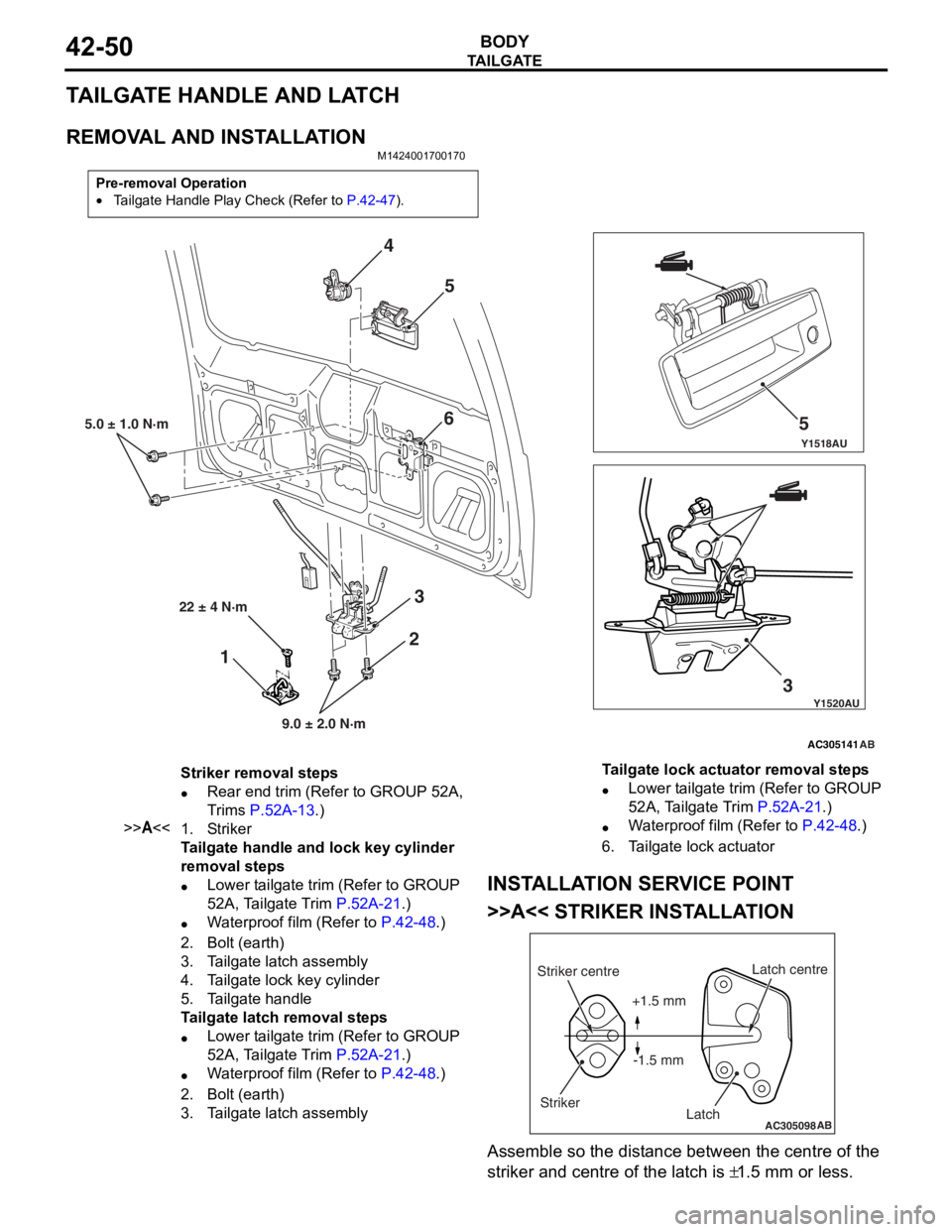

TAILGATE

BODY42-50

TAILGATE HANDLE AND LATCH

REMOVAL AND INSTALLATION

M1424001700170

Pre-removal Operation

•Tailgate Handle Play Check (Refer to P.42-47).

Y1518AU

Y1520AU

AC305141

4 5

6

3

3 5

5.0 ± 1.0 N·m

9.0 ± 2.0 N·m

AB

2

1

22 ± 4 N·m

Striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims

P.52A-13.)

>>A<<1.Strik er

Tailgate handle and lock key cylinder

removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim

P.52A-21.)

•Waterproof film (Refer to P.42-48.)

2.Bolt (earth)

3.Tailgate latch assembly

4.Tailgate lock key cylinder

5.Tailgate handle

Tailgate latch removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim

P.52A-21.)

•Waterproof film (Refer to P.42-48.)

2.Bolt (earth)

3.Tailgate latch assembly

Tailgate lock actuator removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim

P.52A-21.)

•Waterproof film (Refer to P.42-48.)

6.Tailgate lock actuator

INSTALLA T ION SER VICE POINT

>>A<< STRIKER INST ALLA TION

AC305098AB

Striker centre

Striker Latch centre

Latch

+1.5 mm

-1.5 mm

Assemble so the dist ance between the centre of the

striker an

d ce ntre of t he la tch is

±1.5 mm or less.

Page 323 of 800

KEYLESS ENTRY SYSTEM

BODY42-51

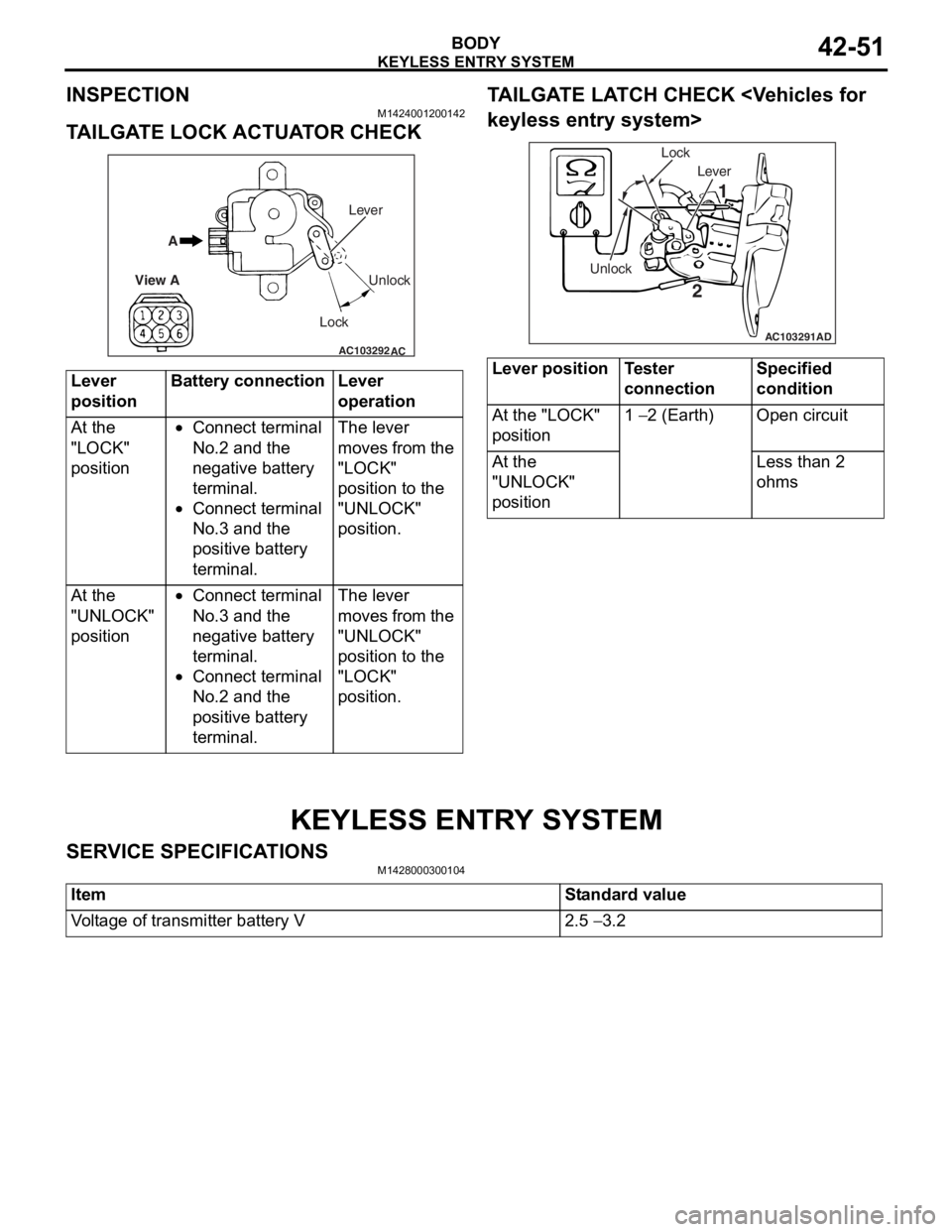

INSPECTION

M1424001200142

TAILGATE LOCK ACTUATOR CHECK

AC103292

A

View A Unlock

Lock Lever

AC

Lever

positionBatte

ry connec tionLever

o

peration

At the

"LOCK"

position•Conn ect t e rminal

No.2

and th e

ne

gative ba ttery

te

rmin al.

•Connect t e rminal

No.3

and th e

po

sit i ve battery

te

rmin al.

The le ver

moves f

r om the

"LOCK"

p

o sition t o the

"UNLOCK

"

p

o sition.

At the

"UNLOCK"

position•Conn ect t e rminal

No.3

and th e

ne

gative ba ttery

te

rmin al.

•Connect t e rminal

No.2

and th e

po

sit i ve battery

te

rmin al.

The le ver

moves f

r om the

"UNLOCK

"

p

o sition t o the

"LOCK"

p

o sition.

TA ILGA TE LA TCH CHECK

ess entry system>

AC103291

Lever

Unlock Lock

1

2

AD

Lever positionTester

connectionSpecified

condition

At the "LOCK"

position1 − 2 (Earth)Open circuit

At the

"UNLOCK"

positionLess than 2

ohms

KEYLESS ENTR Y SYSTEM

SERV ICE SPECIFICA T IONS

M14280003 0010 4

ItemStandard value

Voltage of transmitter battery V2.5 − 3.2

Page 325 of 800

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTING

M1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting

P.54B-15 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTR Y SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting

P.54B-15, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the answer-

back function works in response to door and tail-

gate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and illumi

-

nates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and illu

-

minates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and illu

-

minates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYS TEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-15, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the haz

-

ard warning lamp flashes (hazard answerback func-

tion). The hazard answerback function can be

enabled or disabled according to the following proce

-

dure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

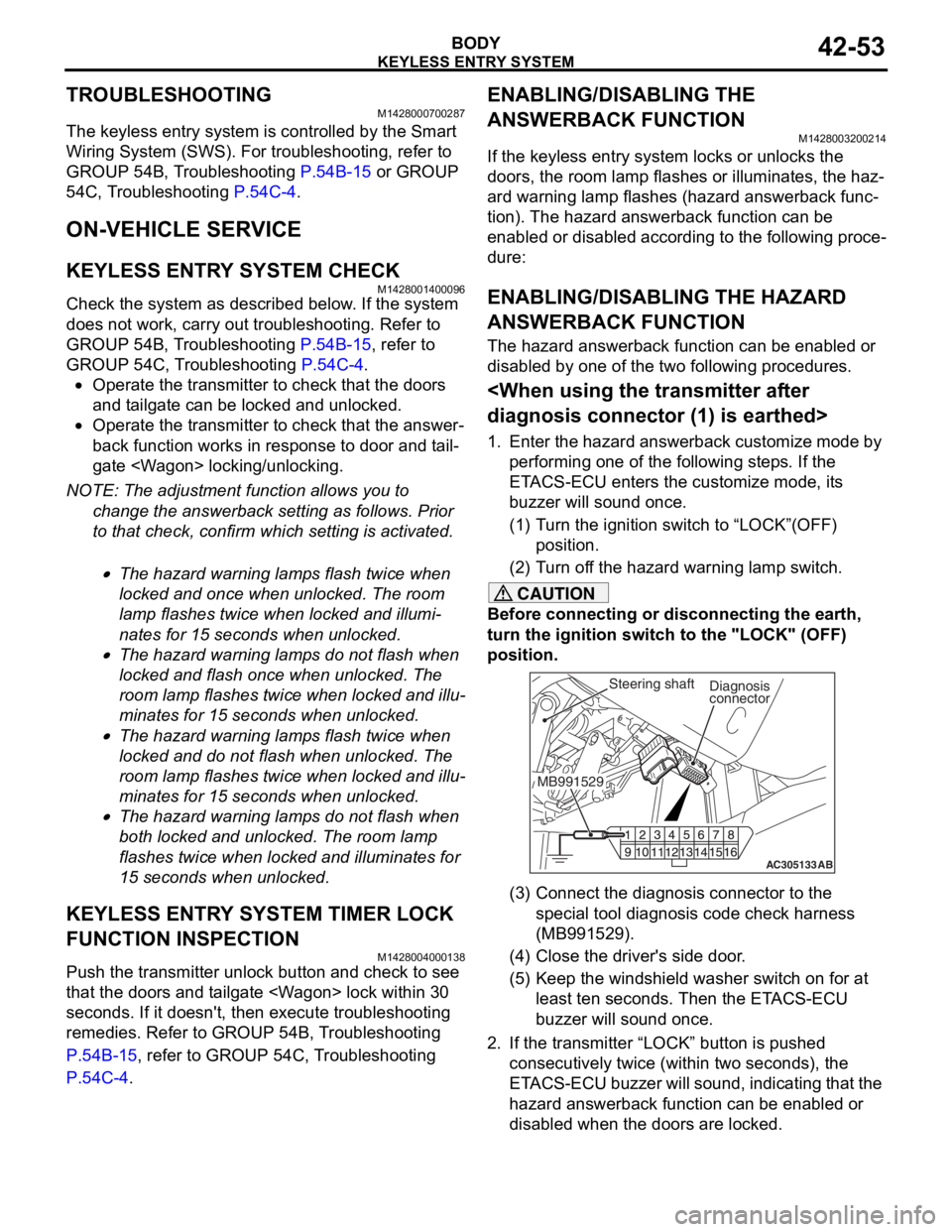

1. Enter the hazard answerback customize mode by performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

(3) Connect the diagnosis connector to the special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

Page 326 of 800

KEYLESS ENTRY SYSTEM

BODY42-54

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect diagnosis connector terminal (1) form the earth.

(2) Turn the ignition switch to position other then “LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

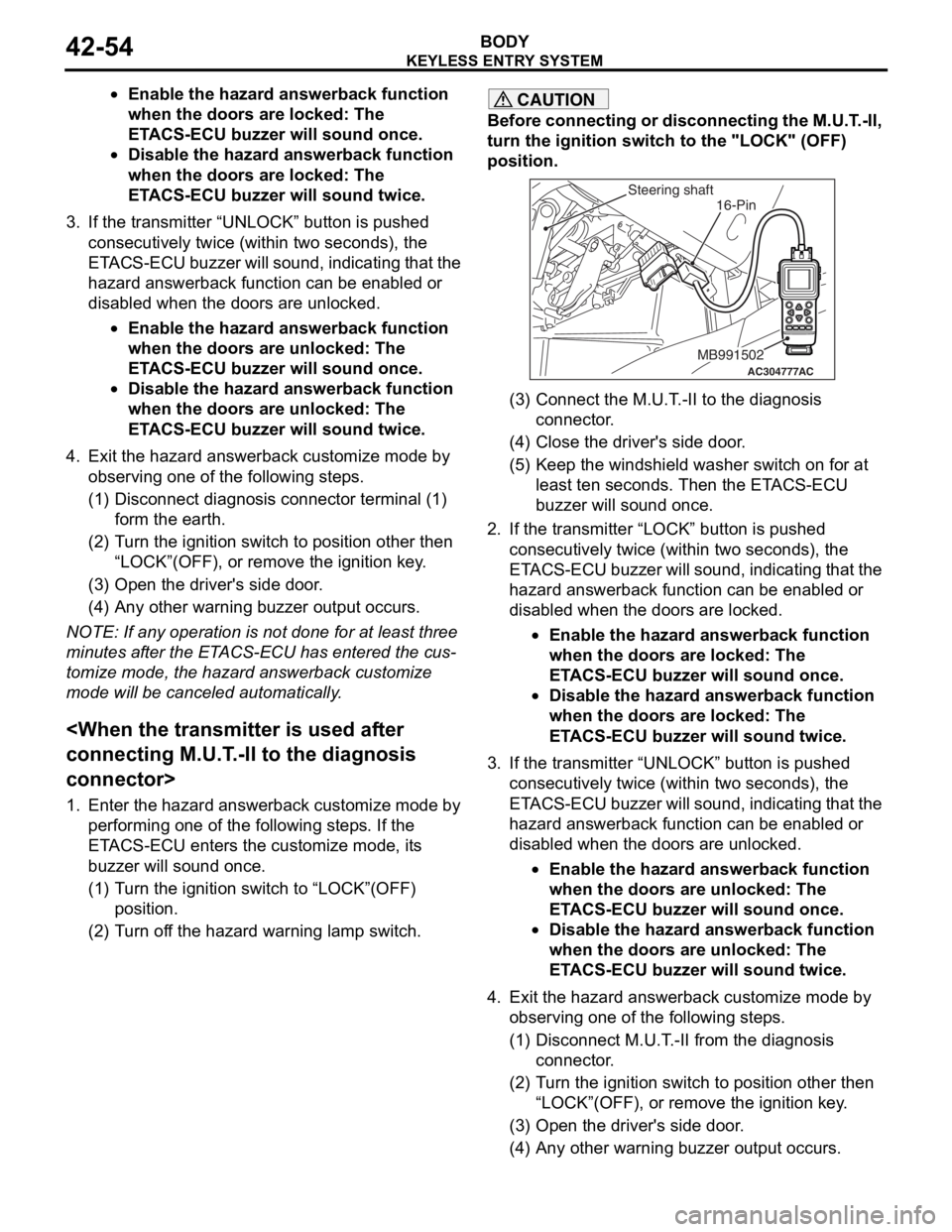

connector>

1. Enter the hazard answerback customize mode by performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

(3) Connect the M.U.T.-II to the diagnosis

connector.

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect M.U.T.-II from the diagnosis

connector.

(2) Turn the ignition switch to position other then “LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

Page 327 of 800

KEYLESS ENTRY SYSTEM

BODY42-55

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

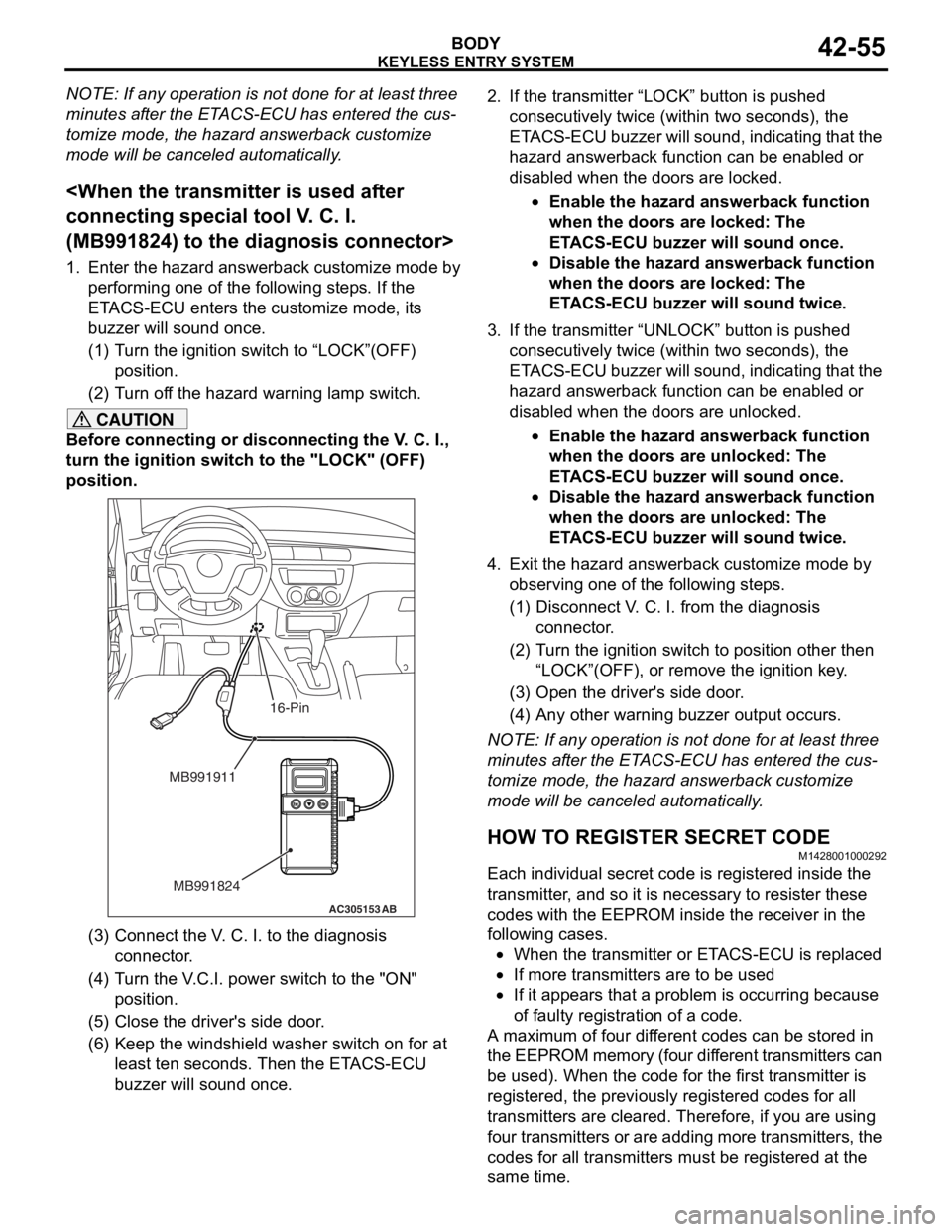

(MB991824) to the diagnosis connector>

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the V. C. I.,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305153AB

MB991911

MB991824

16-Pin

(3) Connect the V. C. I. to the diagnosis connector.

(4) Turn the V.C.I. power switch to the "ON" position.

(5) Close the driver's side door.

(6) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect V. C. I. from the diagnosis connector.

(2) Turn the ignition switch to position other then

“LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

HOW TO REGISTER SECRET CODE

M1428001000292

Each individual secret code is registered inside the

transmitter, and so it is necessary to resister these

codes with the EEPROM insi de the receiver in the

following cases.

•When the transmitter or ETACS-ECU is replaced

•If more transmitters are to be used

•If it appears that a probl em is occurring because

of faulty registration of a code.

A maximum of four different codes can be stored in

the EEPROM memory (four different transmitters can

be used). When the code for the first transmitter is

registered, the previously registered codes for all

transmitters are cleared. Therefore, if you are using

four transmitters or are adding more transmitters, the

codes for all transmitters must be registered at the

same time.