wheel MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 90 of 284

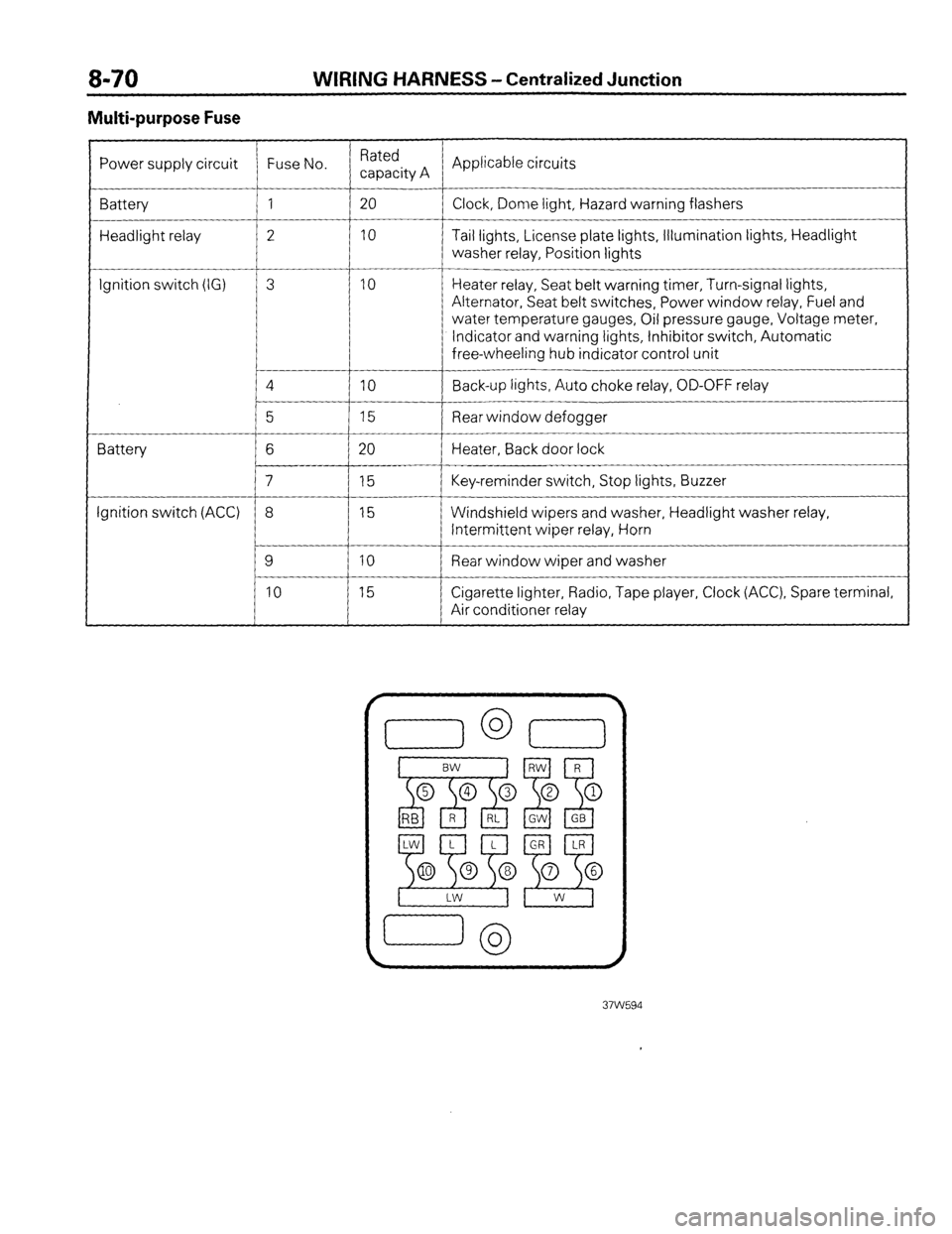

WIRING HARNESS - Centralized Junction

Multi-purpose Fuse

Power supply circuit Fuse No. Rated

capacity A Applicable circuits

Battery 1 20

Clock, Dome light, Hazard warning flashers

Headlight relay 2 10 Tail lights, License plate lights, Illumination lights, Headlight

washer relay, Position lights

__-

Ignition switch (IG) 3 10 Heater relay, Seat belt warning timer, Turn-signal lights,

Alternator, Seat belt switches, Power window relay, Fuel and

water temperature gauges, Oil pressure gauge, Voltage meter,

Indicator and warning lights, Inhibitor switch, Automatic

free-wheeling hub indicator control unit

4

IO Back-up lights, Auto choke relay, OD-OFF relay

__-

5 15 Rear window defogger

Battery 6 20 Heater, Back door lock

7 15 Key-reminder switch, Stop lights, Buzzer

Ignition switch (ACC) 8 15 Windshield wipers and washer, Headlight washer relay,

Intermittent wiper relay, Horn

9 10 Rear window wiper and washer

10 15 Cigarette lighter, Radio, Tape player, Clock (ACC), Spare terminal,

Air conditioner relay

Page 114 of 284

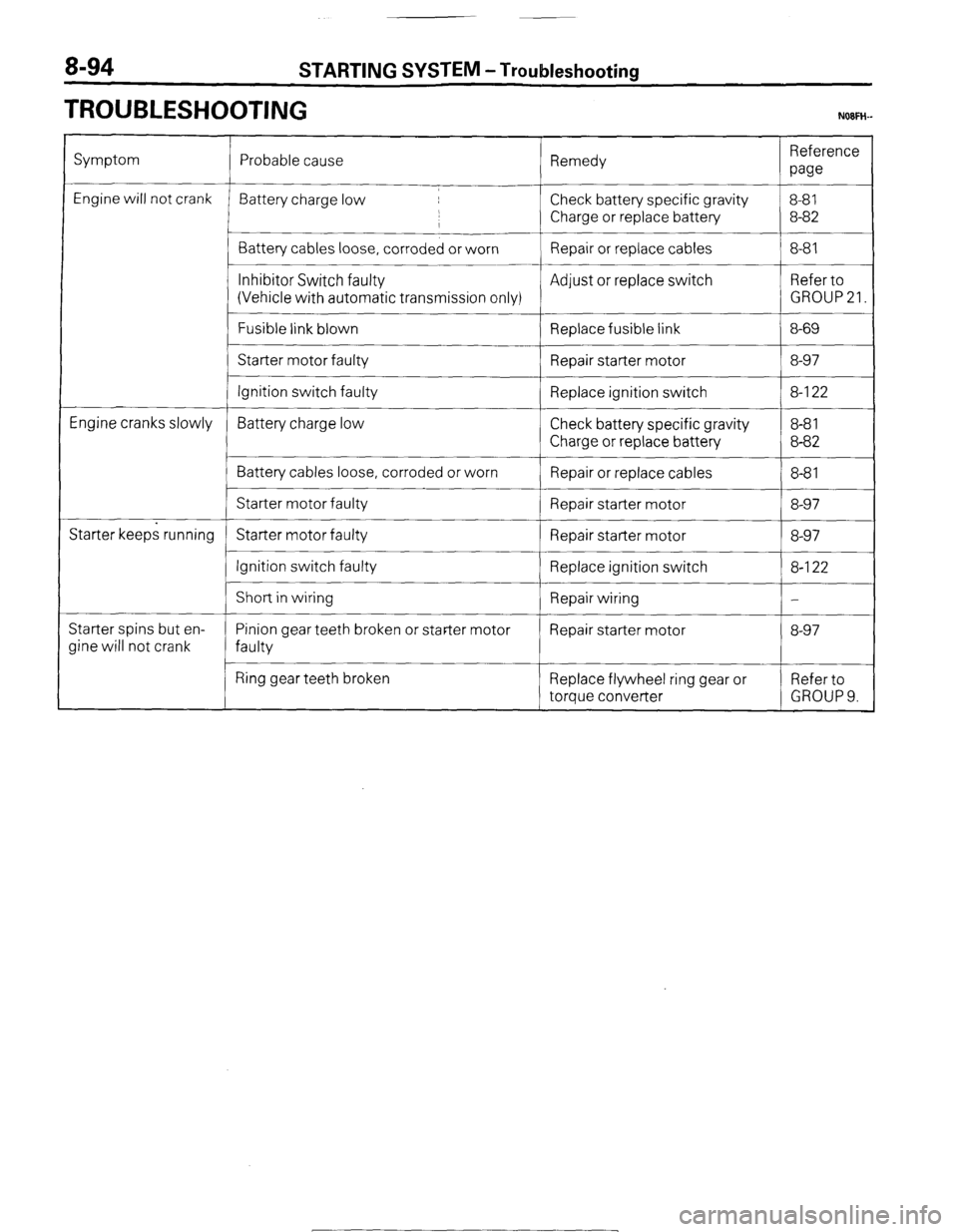

8-94 STARTING SYSTEM -Troubleshooting

TROUBLESHOOTING NOFH-

Symptom

Engine will not crank

Engine cranks slowly

Starter keeps running

Starter spins but en-

Jine will not crank Probable cause Remedy Reference

paw

Battery charge low Check battery specific gravity 8-81

,

I Charge or replace battery 8-82

Battery cables loose, corroded or worn Repair or replace cables 8-81

__~

Inhibitor Switch faulty Adjust or replace switch Refer to

(Vehicle with automatic transmission only) GROUP 21.

Fusible link blown

Replace fusible link 8-69

Starter motor faulty

Repair starter motor 8-97

Ignition switch faulty Replace ignition switch 8-l 22

Battery charge low Check battery specific gravity 8-8 1

Charge or replace battery 8-82

Battery cables loose, corroded or worn

Repair or replace cables 8-8 1

Starter motor faulty Repair starter motor 8-97

Starter motor faulty Repair starter motor 8-97

Ignition switch faulty

Replace ignition switch 8-l 22

I

Short in wiring

Repair wiring -

Pinion gear teeth broken or starter motor Repair starter motor 8-97

faulty

Ring gear teeth broken Replace flywheel ring gear or Refer to

torque converter GROUP 9.

1 STB Revision

-7

Page 143 of 284

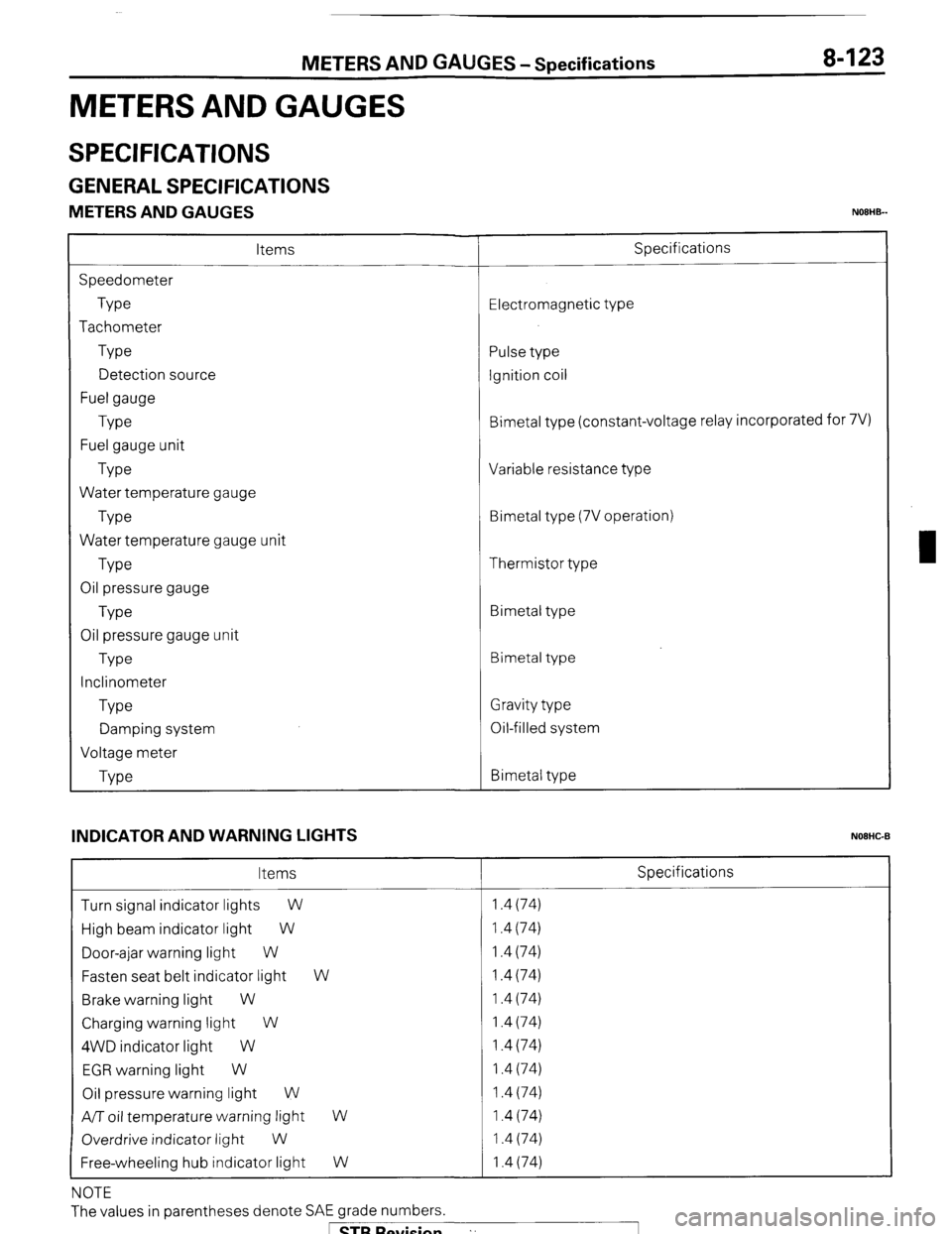

METERS AND GAUGES-Specifications

METERS AND GAUGES

8-123

SPECIFICATIONS

GENERAL SPECIFICATIONS

METERS AND GAUGES NOEHB-

Items

Speedometer

Type

Tachometer

Type

Detection source

Fuel gauge

Type

Fuel gauge unit

Type

Water temperature gauge

Type

Water temperature gauge unit

Type

Oil pressure gauge

Type

Oil pressure gauge unit

Type

Inclinometer

Type

Damping system

Voltage meter

Type Specifications

Electromagnetic type

Pulse type

Ignition coil

Bimetal type (constant-voltage relay incorporated for 7V)

Variable resistance type

Bimetal type (7V operation)

Thermistor type

Bimetal type

Bimetal type

Gravity type

Oil-filled system

Bimetal type

INDICATOR AND WARNING LIGHTS

NOEHC-B

Items Specifications

Turn signal indicator lights

W 1.4 (74)

High beam indicator light W 1.4 (74)

Door-ajar warning light W 1.4 (74)

Fasten seat belt indicator light W 1.4 (74)

Brake warning light W 1.4 (74)

Charging warning light W 1.4 (74)

4WD indicator light W 1.4 (74)

EGR warning light W 1.4 (74)

Oil pressure warning light W 1.4 (74)

A/T oil temperature warning light

W 1.4 (74)

Overdrive indicator light

W 1.4 (74)

Free-wheeling hub indicator light W 1.4 (74)

NOTE

The values in parentheses denote SAE grade numbers.

1 STB Revision ”

Page 149 of 284

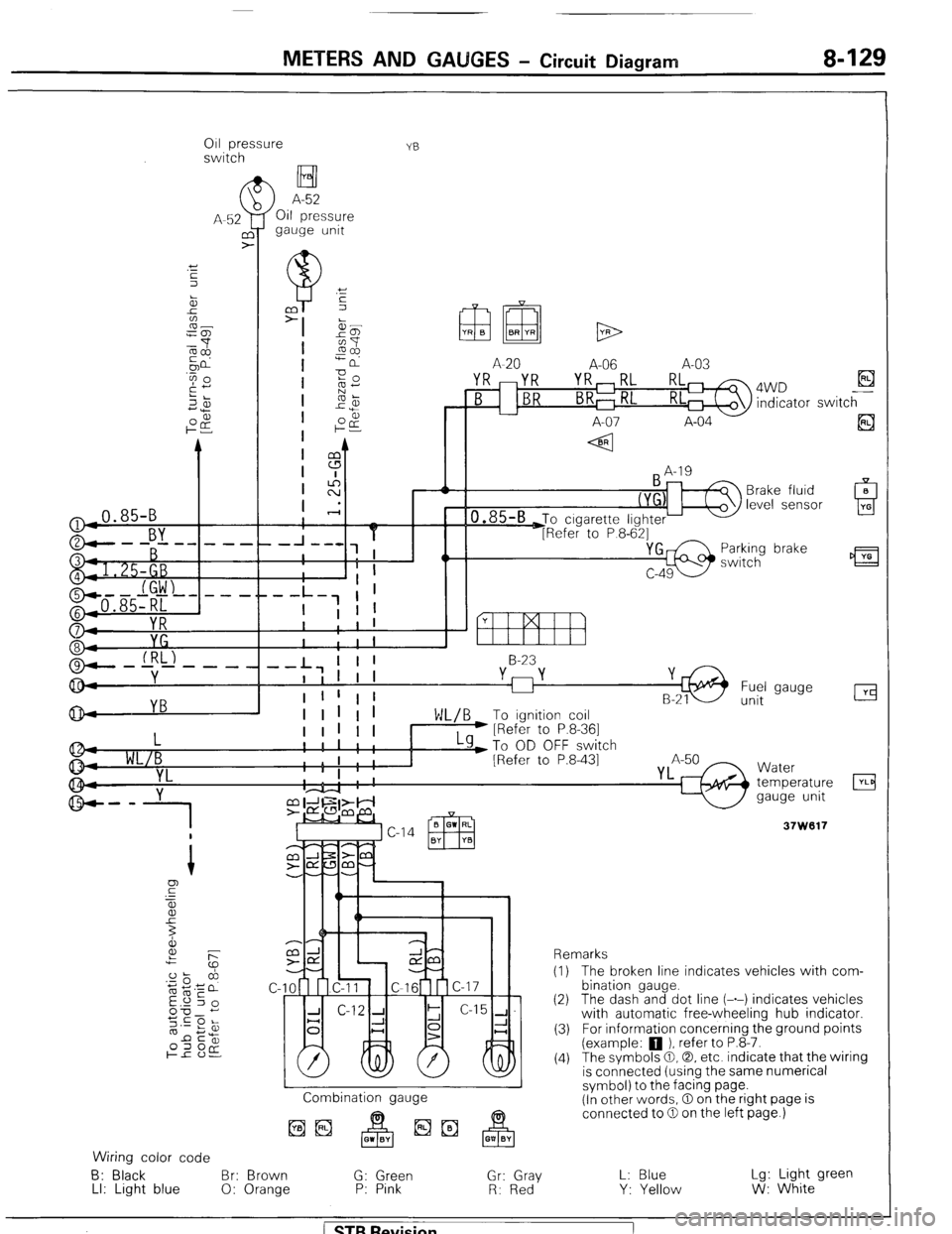

METERS AND GAUGES - Circuit Diagram 8-129

011 pressure

switch YB

H I

>

A-52

Oil pressure

gauge unit

(

A-52

UY

>

-0.85-B

r.., !

YB

A-20 A-06 A-03

YR mYR YR,RL RL 4WD El B indicator switch

-- L7 I I 1 8-23

I I I I I

I 1 !

Fuel 1 1 gauge

unit

L

WL/B

YL

g-- y

1

I

I I I I I I LY)T~ OD OFF switch

1 1 I

I ' ; [Refer to P.8-431 I I

I . . I

'4 8.

Combination gauge

Wiring color code

6: Black Br: Brown G: Green Gr: Gray

LI: Light blue 0: Orange P: Pink

R: Red

Y Water

temperature

gauge unit

Remarks

(I) The broken line indicates vehicles with com-

bination gauge.

(2) The dash and dot line (-.-) indicates vehicles

with automatic free-wheeling hub indicator.

(3) For information concerning the ground points

(example: 0 ). refer to P.8-7.

(4) The symbols @I,@, etc. indicate that the wiring

is connected (using the same numerical

symbol) to the facing page.

(In other words, 0 on the right page is

connected to 0 on the left page.)

L: Blue

Y: Yellow Lg: Light green

W: White

/ STB Revision

Page 150 of 284

8430 METERS AND GAUGES - Service Adjustment Procedures.

SERVICE BJUSTMENT. PROCEDURES

SPEEDOMETER INSPECTION NOSHIAA

I. Adjust tire inflation pressure to the standard value. (Refer

to’GROUP 22 WHEELS AND TIRES-General Specifications)

2. Use speedometer tester to make sure that the speedome-

ter indication error is within the standard value.

Standard value :

Meter with “km/h” indication km/h

20 km/h +4

-1

40 km/h +4

0

80 km/h +5

0

120 km/h + 5.5

+0.5

Meter with “mph” indication

mph

10 mph

25 mph

50 mph

75 mph +I.5

21.5

+I.5

&I.5

Caution

1 When using a speedometer tester to inspect the

speedometer, be sure to chock the non-drive wheels

to prevent the vehicle from moving. Also be sure to

set the transfer shift lever to “2H”.

2 If there is a special regulation for speedometer

indication error in the area where the ‘vehicle is

operated, be sure to meet the requirement of the

regulation.

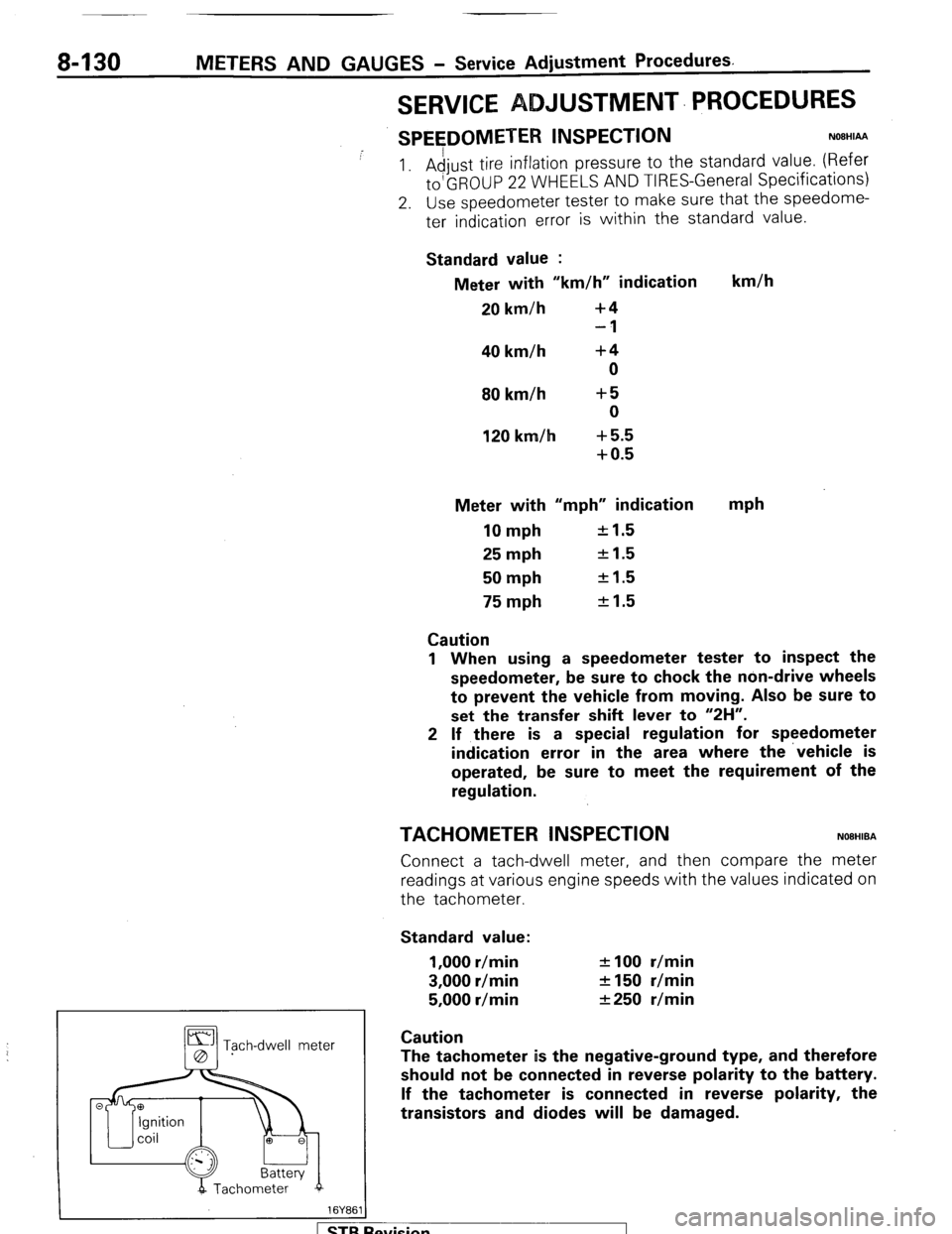

TACHOMETER INSPECTION NOBHIBA

Connect a tach-dwell meter, and then compare the meter

readings at various engine speeds with the values indicated on

the tachometer.

Standard value:

1,000 r/min

3,000 r/min

5,000 r/min f 100 r/min

2150 r/min

&250 r/min

Tgch-dwell meter Caution

The tachometer is the negative-ground type, and therefore

should not be connected in reverse polarity to the battery.

If the tachometer is connected in reverse polarity, the

transistors and diodes will be damaged.

evision

Page 161 of 284

METERS AND GAUGES - Indicators and Warning Lights 8-141

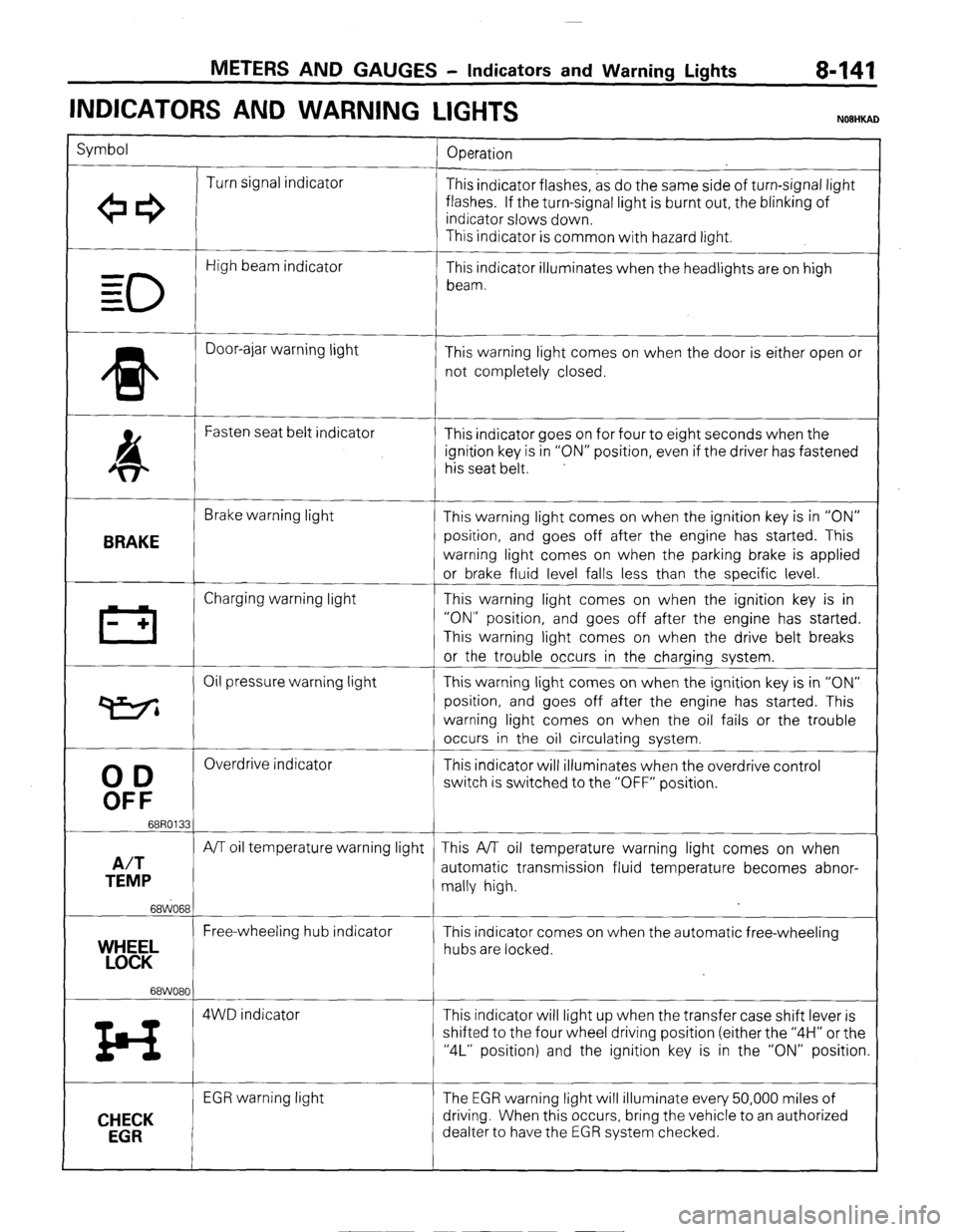

INDICATORS AND WARNING

LIGHTS

Symbol

Operation

Turn signal indicator

+e3 This indicator flashes, as do the same side of turn-signal light

flashes. If the turn-signal light is burnt out, the blinking of

indicator slows down.

This indicator is common with hazard light.

0

High beam indicator

- This indicator illuminates when the headlights are on high

= beam.

=

* Door-ajar warning light

This warning light comes on when the door is either open or

not completely closed.

4 Fasten seat belt indicator

This indicator goes on for four to eight seconds when the

ignition key is in “ON” position, even if the driver has fastened

his seat belt.

BRAKE

Brake warning light

This warning light comes on when the ignition key is in “ON”

position, and goes off after the engine has started. This

warning light comes on when the parking brake is applied

or brake fluid level falls less than the specific level.

III Charging warning light This warning light comes on when the ignition key is in

- + “ON” position, and goes off after the engine has started.

This warning light comes on when the drive belt breaks

or the trouble occurs in the charging system.

Oil pressure warning light This warning light comes on when the ignition key is in “ON”

P position, and goes off after the engine has started. This

warning light comes on when the oil fails or the trouble

occurs in the oil circulating system.

00

Overdrive indicator

This indicator will illuminates when the overdrive control

OFF

switch is switched to the “OFF” position.

68R0133

A/T

A/T oil temperature warning light This A/T oil temperature warning light comes on when

TEMP automatic transmission fluid temperature becomes abnor-

mally high.

68WO68

Free-wheeling hub indicator

YEL This indicator comes on when the automatic free-wheeling

hubs are locked.

68WO80

z4 4WD indicator This indicator will light up when the transfer case shift lever is

shifted to the four wheel driving position (either the “4H” or the

“4L” position) and the ignition key is in the “ON” position.

CHECK

EGR

EGR warning light The EGR warning light will illuminate every 50,000 miles of

driving. When this occurs, bring the vehicle to an authorized

dealter to have the EGR system checked.

) STB Revision

Page 164 of 284

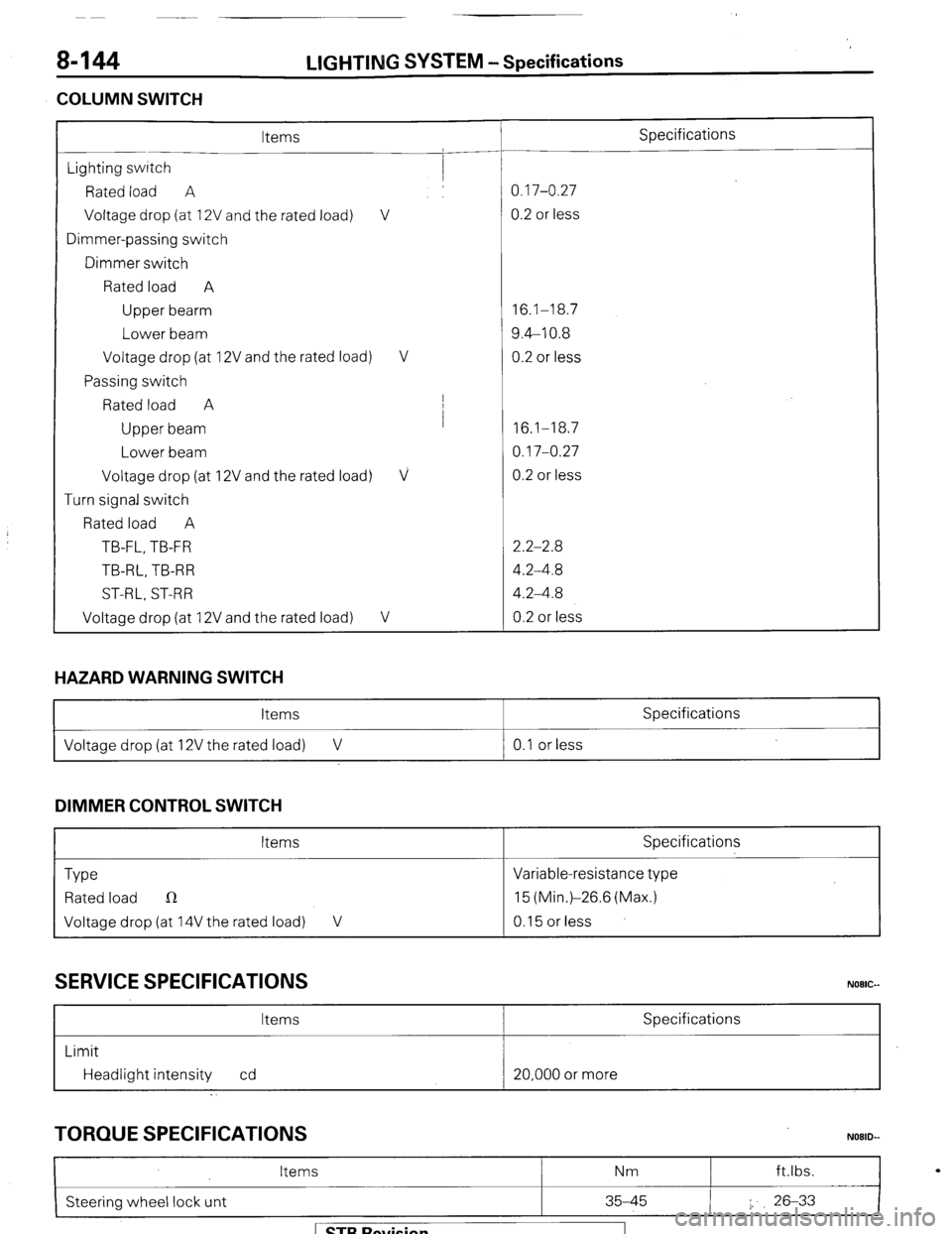

8-144

COLUMN SWITCH LIGHTING

SYSTEM -Specifications

Items Specifications

Lighting switch

Rated load A 0.17-0.27

Voltage drop (at 12V and the rated load) V 0.2 or less

Dimmer-passing switch

Dimmer switch

Rated load A

Upper bearm 16.1-18.7

Lower beam 9.4-10.8

Voltage drop (at 12V and the rated load) V 0.2 or less

Passing switch

Rated load A I

Upper beam I

16.1-18.7

Lower beam 0.17-0.27

Voltage drop (at 12V and the rated load)

V 0.2 or less

Turn signal switch

Rated load A

TB-FL, TB-FR 2.2-2.8

TB-RL, TB-R R 4.2-4.8

ST-RL, ST-RR 4.2-4.8

Voltage drop (at 12V and the rated load)

V 0.2 or less

HAZARD WARNING SWITCH

Items Specifications

I Voltage drop (at 12V the rated load) V 0.1 or less

I

DIMMER CONTROL SWITCH

Items Specifications

Type Variable-resistance type

Rated load n 15 (Min.)-26.6 (Max.)

Voltage drop (at 14V the rated load) V 0.15 or less

SERVICE SPECIFICATIONS

Items Specifications

Limit

Headlight intensity cd 20,000 or more

TORQUE SPECIFICATIONS

I

Items Nm ft.lbs.

N08lb

Steering wheel lock unt 35-45 I. 26-33

I

1 STB Revision

Page 179 of 284

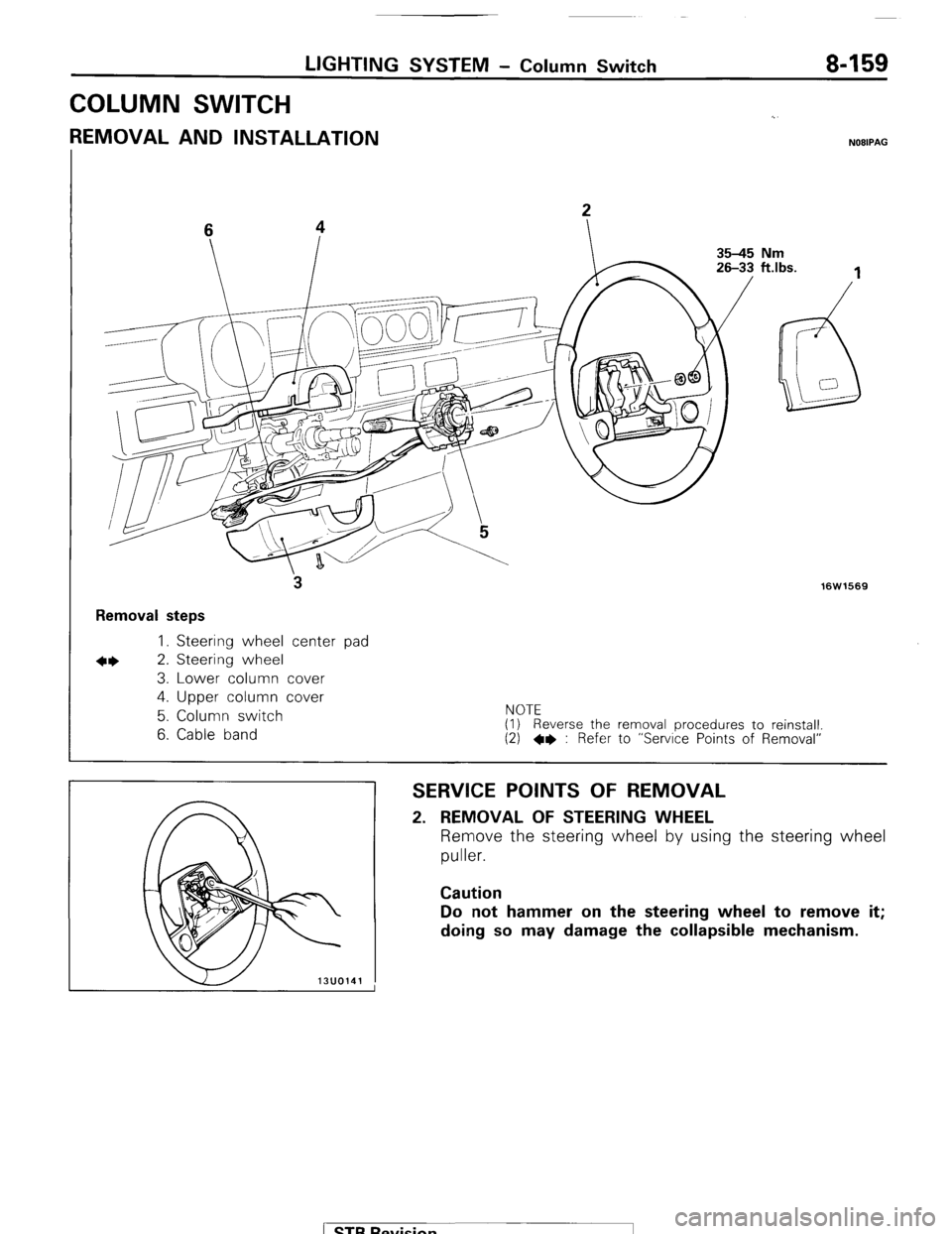

LIGHTING SYSTEM - Column Switch 8-159

COLUMN SWITCH

REMOVAL AND INSTALLATION NOBIPAG

3

Removal steps

I. Steering wheel center pad

*I) 2. Steering wheel

3. Lower column cover

4. Upper column cover

hlnTC

16W1569

5. Column switch

6. Cable band I\I”IC (I) Reverse the removal procedures to reinstall.

(2) l * : Refer to “Service Points of Removal”

SERVICE POINTS OF REMOVAL 2. REMOVAL OF STEERING WHEEL

Remove the steering wheel by using the steering wheel

puller. Caution

Do not hammer on the steering wheel to remove it;

doing so may damage the collapsible mechanism.

) STB Revision

Page 185 of 284

WIPER AND WASHER SYSETM - Specifications / Special TOOIS 8-165

TORQUE SPECIFICATIONS N08KLb-

Items Nm

Windshield wiper pivot shaft installing nut

IO-16 Windshield wiper arm locking nut

IO-16 Windshield wiper motor

7-10 Steering wheel lock nut

35-45 Rear wiper pivot shaft installing nut

8-12 Rear wiper arm locking nut

7-10 Rear wioer motor

7-10

SPECIAL TOOLS NOEKG-B

1 STB Revision

Page 198 of 284

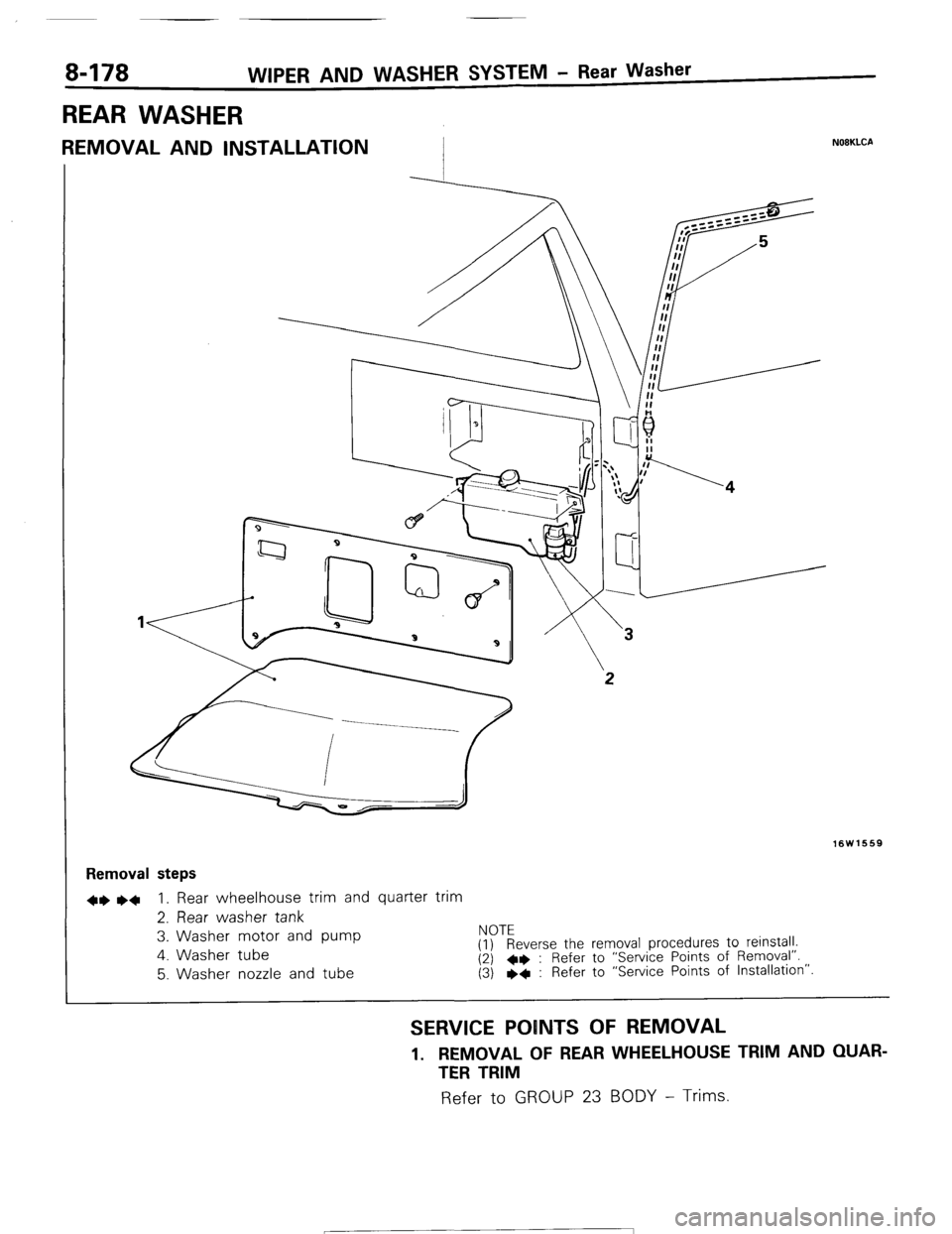

8-178 WIPER AND WASHER SYSTEM - Rear Washer

REAR WASHER

REMOVAL AND INSTALLATION I N08KLCA

16W1669

Removal steps

+e ~~ 1. Rear wheelhouse trim and quarter trim

2. Rear washer tank

3. Washer motor and pump NOTE

4. Washer tube

(1) Reverse the removal procedures to reinstall.

(2) l * : Refer to “Service Points of Removal”. 5. Washer nozzle and tube (3) l + : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

1. REMOVAL OF REAR WHEELHOUSE TRIM AND QUAR-

TER TRIM Refer to

GROUP 23 BODY - Trims.

1 STR Ravisinn -7