wheel MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1457 of 1839

52A-2

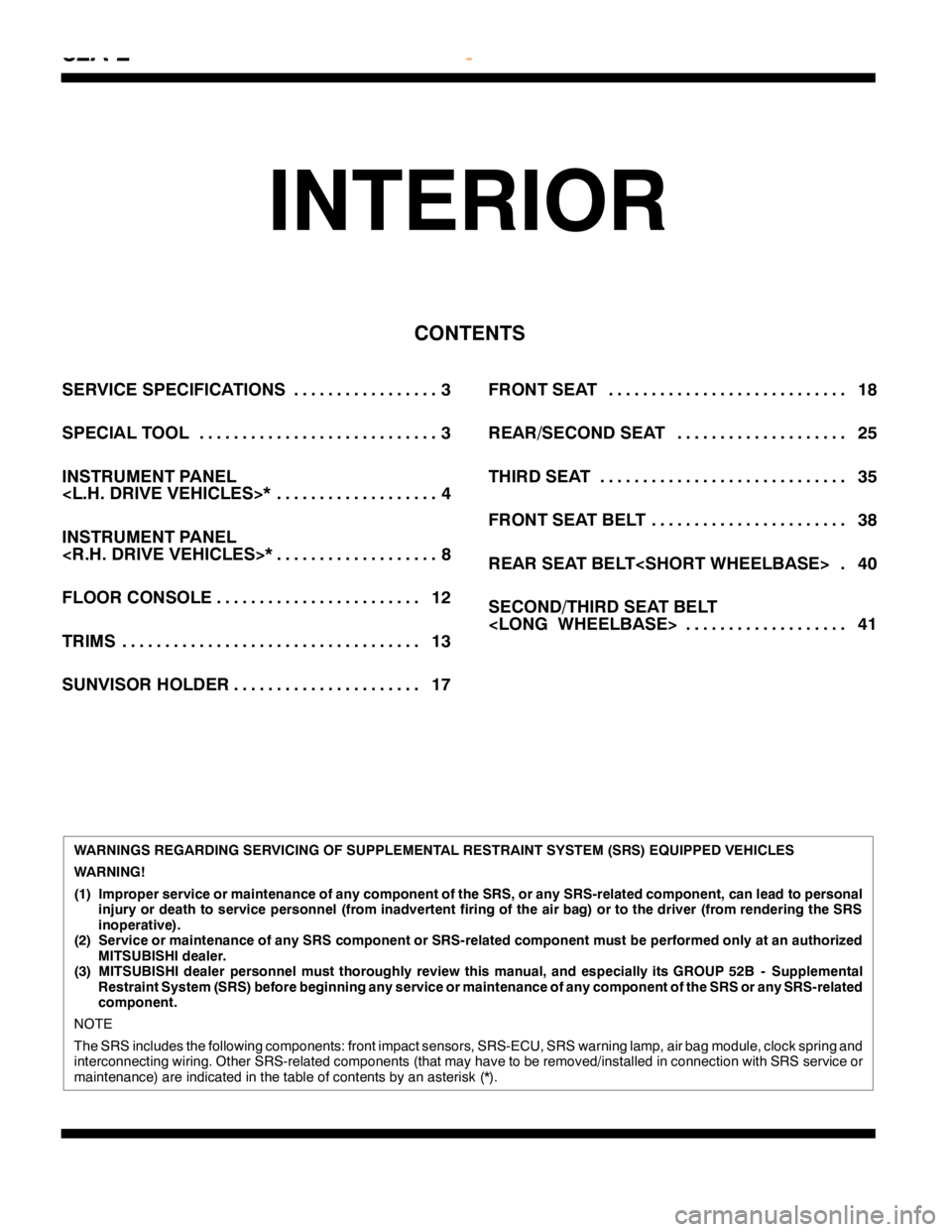

INTERIOR

CONTENTS

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOL 3............................

INSTRUMENT PANEL

INSTRUMENT PANEL

FLOOR CONSOLE 12........................

TRIMS 13...................................

SUNVISOR HOLDER 17......................FRONT SEAT 18............................

REAR/SECOND SEAT 25....................

THIRD SEAT 35.............................

FRONT SEAT BELT 38.......................

REAR SEAT BELT

SECOND/THIRD SEAT BELT

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from rendering the SRS

inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: front impact sensors, SRS-ECU, SRS warning lamp, air bag module, clock spring and

interconnecting wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or

maintenance) are indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1480 of 1839

R

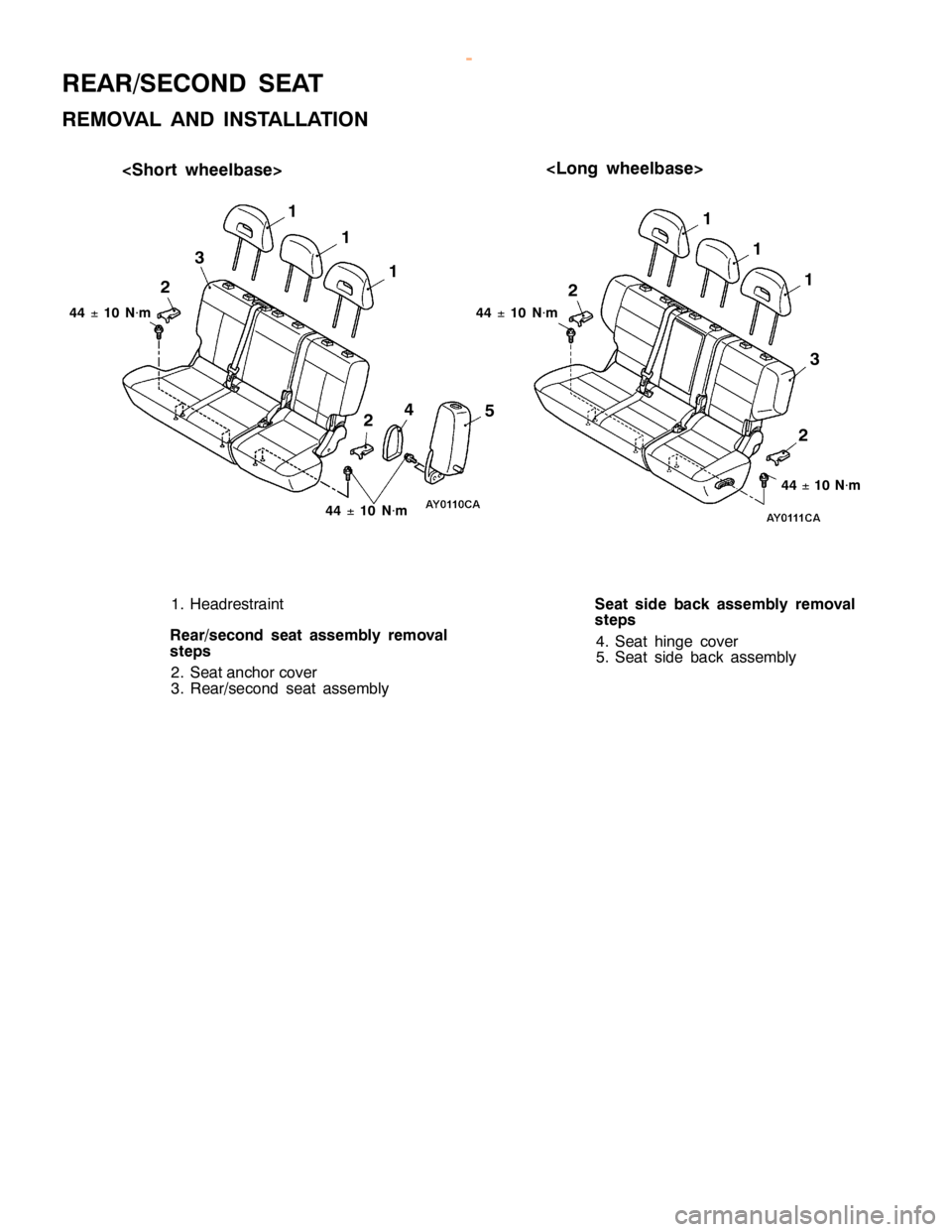

EA R/S EC O ND SEAT

R EM OVA L AND IN STA LLA TIO N <

L ong wheelb ase>

4 4 ±

10 N×

m 1

1

2

23

4 5

4

4 ±

10 N×

m

2

2

3 1

1

44 ±

10 N×

m

4

4 ±

10 N×

m

1

1

1 . H eadre str a in t

R ear/s eco nd seat assem bly re m oval

s te p s

2 . S eatanch or co ve r

3 . R ear/s e co nd se at asse m bly S

eat sid e back assem bly re m oval

s te p s

4 . S eat hin ge co ve r

5 . S eat sid e back asse m bly

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1495 of 1839

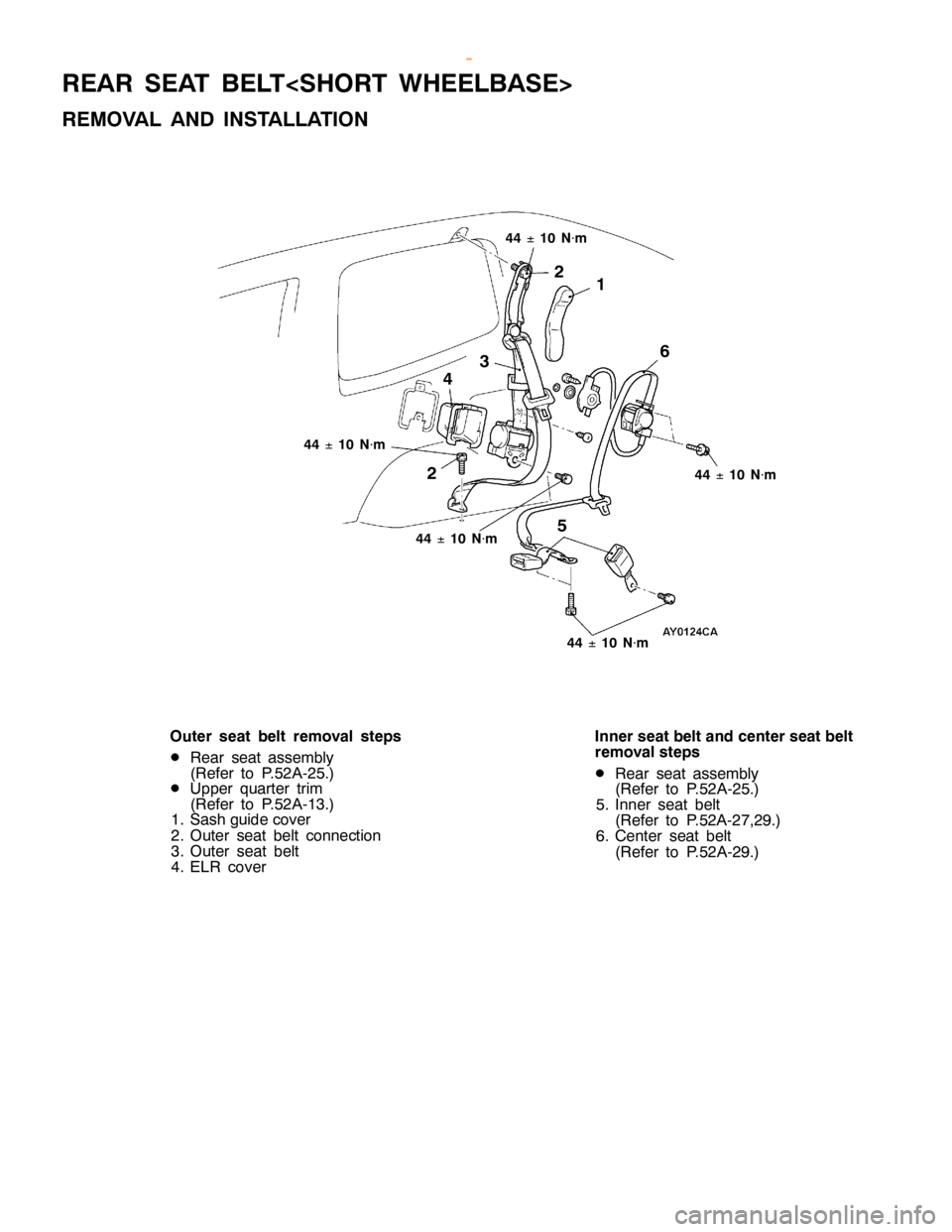

R

EA R SEAT BELT

R EM OVA L AND IN STA LLA TIO N

Page 1496 of 1839

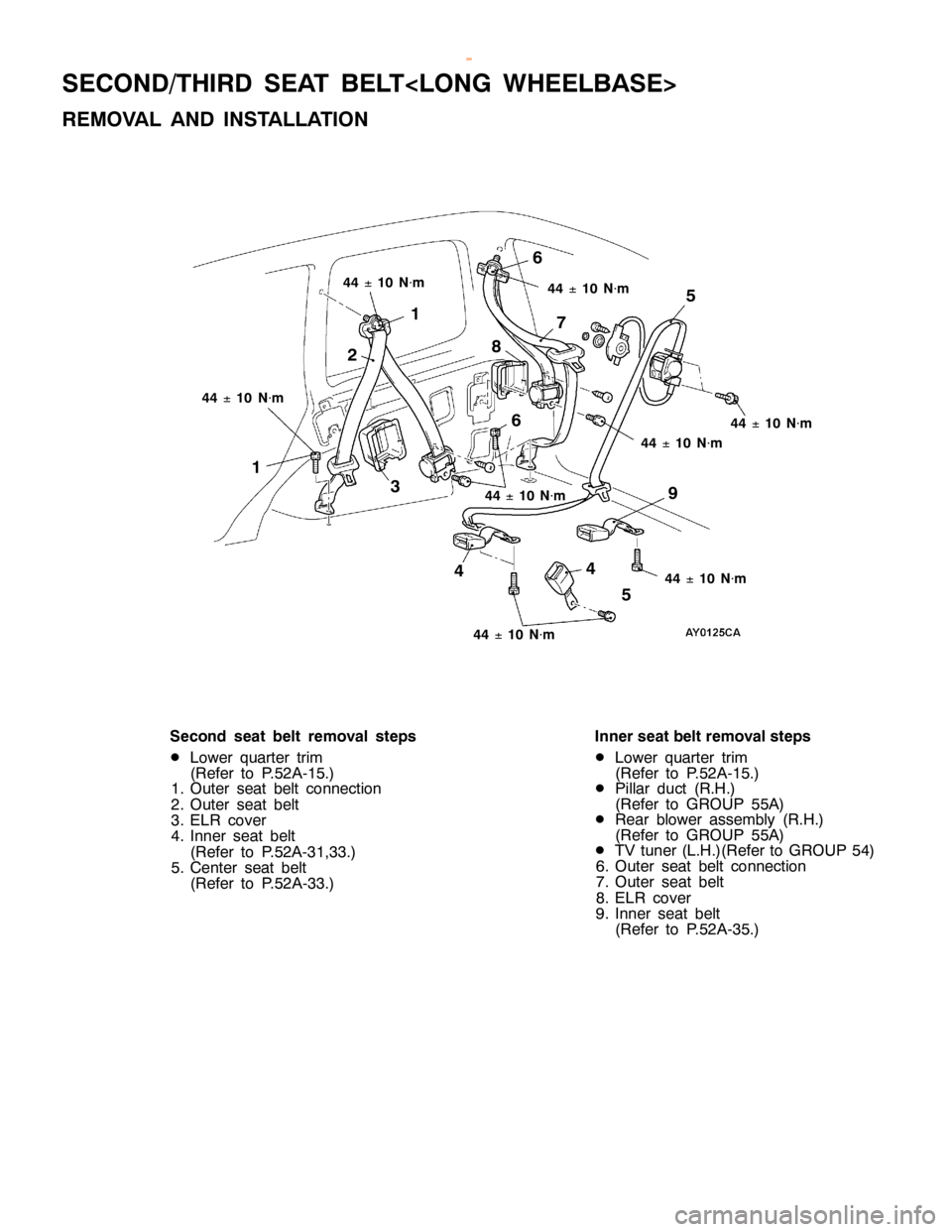

S

EC O ND/T H IR D SEAT BELT

R EM OVA L AND IN STA LLA TIO N

Page 1502 of 1839

G

EN ER AL IN FO RM ATIO N

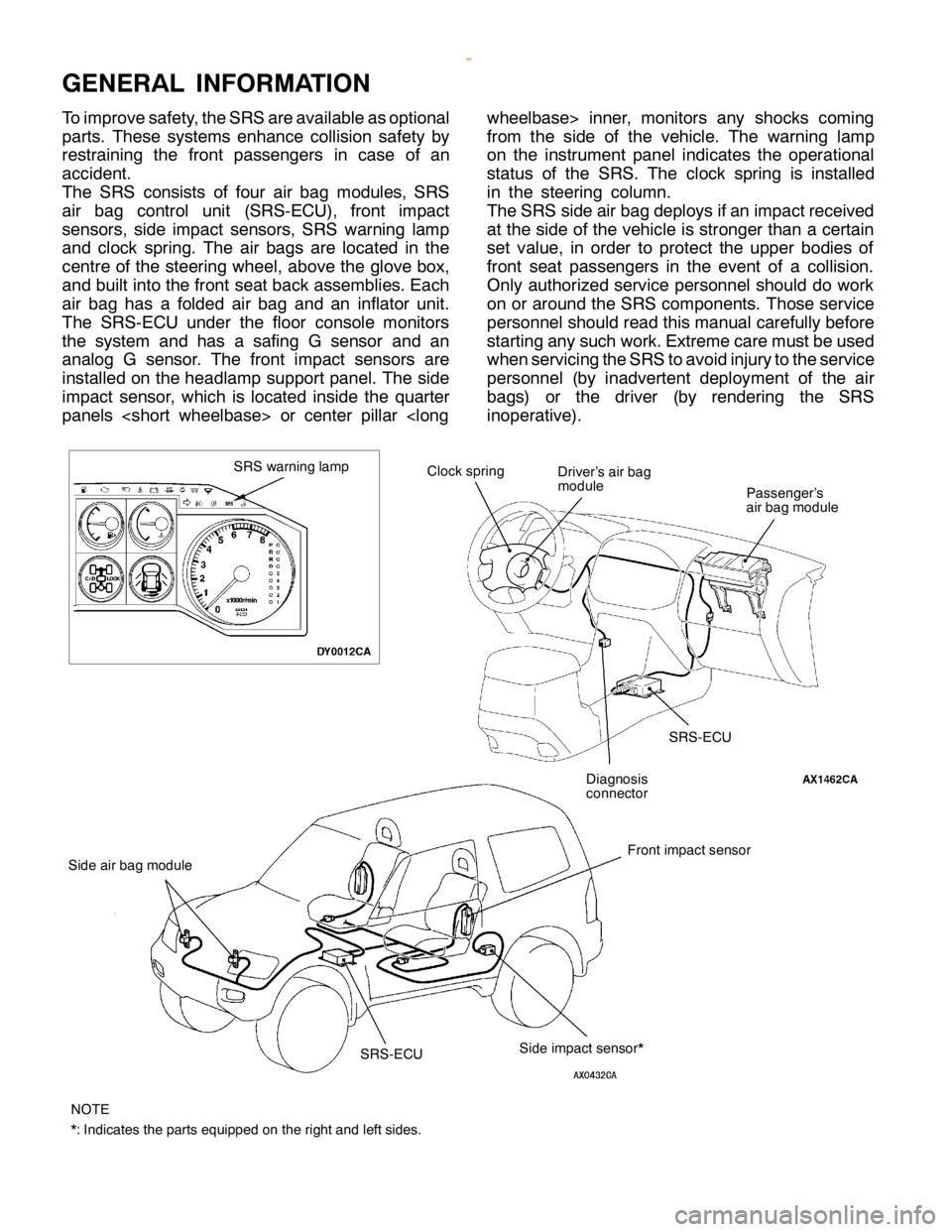

T o im pro ve sa fe ty , th e SR S are ava ila ble as optio nal

p arts . These syste m s enhance co llis io n sa fe ty by

r e str a in in g th e fr o nt passe ngers in ca se of an

a ccid ent.

T he SR S co nsis ts of fo ur air bag module s, SR S

a ir bag co ntr o l unit (S R S-E C U), fr o nt im pact

s e nso rs , sid e im pact se nso rs , SR S warn in g la m p

a nd clo ck sp rin g. The air bags are lo ca te d in th e

c e ntr e of th e ste erin g wheel, above th e glo ve box,

a nd built in to th e fr o nt se at back asse m blie s. E ach

a ir bag has a fo ld ed air bag and an in fla to r unit .

T he SR S-E C U under th e flo or co nso le monit o rs

t h e syste m and has a sa fin g G se nso r and an

a nalo g G se nso r. The fr o nt im pact se nso rs are

i n sta lle d on th e headla m p su pport panel. T he sid e

i m pact se nso r, w hic h is lo ca te d in sid e th e quarte r

p anels

f r o m th e sid e of th e ve hic le . The warn in g la m p

o n th e in str u m ent panel in dic a te s th e opera tio nal

s ta tu s of th e SR S. The clo ck sp rin g is in sta lle d

i n th e ste erin g co lu m n.

T he SR S sid e air bag deplo ys if a n im pact re ce iv e d

a t th e sid e of th e ve hic le is str o nger th an ace rta in

s e t va lu e, in ord er to pro te ct th e upper bodie s of

f r o nt se at passe ngers in th e eve nt of a co llis io n.

O nly auth oriz e d se rv ic e pers o nnelsh ould do work

o n or aro und th e SR S co m ponents . T hose se rv ic e

p ers o nnelsh ould re ad th is m anualca re fu lly befo re

s ta rtin g any su ch work . E xtr e m eca re m ust b e use d

w hen se rv ic in g th e SR S to avo id in ju ry to th e se rv ic e

p ers o nnel (b y in adve rte nt deplo ym ent of th e air

b ags) or th e driv e r (b y re nderin g th e SR S

i n opera tiv e ). C

lo ck sp rin g D

riv e r’s air bag

m odule P

asse nger’s

a ir bag m odule

S R S-E C U D

ia gnosis

c o nnecto r

N O TE

* : In dic a te s th e parts equip ped on th e rig hta nd le ft sid es.

S

R S-E C U

S

id e air bag module

Sid e im pact se nso r* F

ro nt im pact se nso r

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

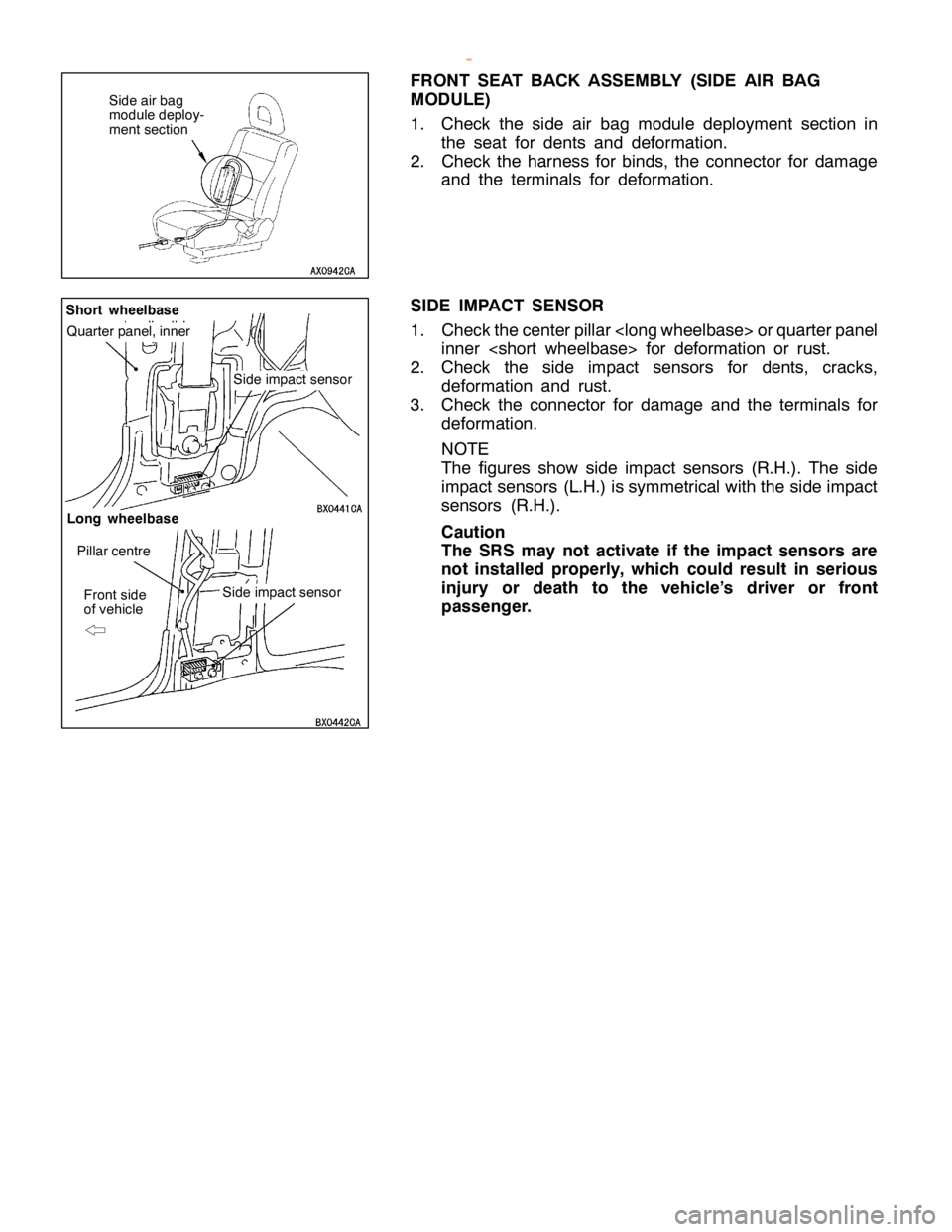

Page 1521 of 1839

P

illa r ce ntr e S

id e im pact se nso r L

ong wheelb ase Q

uarte r panel, in ner F

ro nt sid e

o fve hic le

Page 1523 of 1839

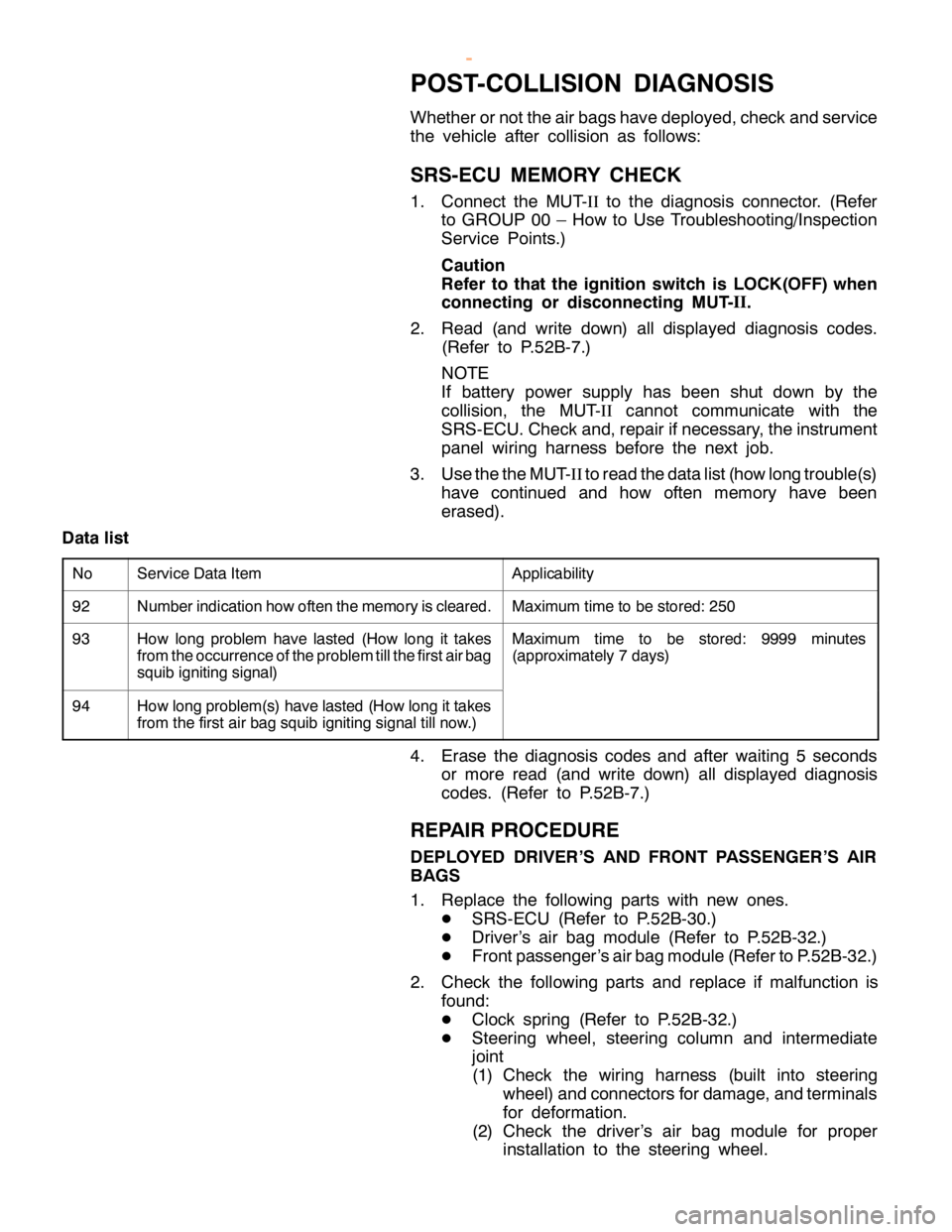

SRS -Post-collision Diagnosis52B-23

POST-COLLISION DIAGNOSIS

Whether or not the air bags have deployed, check and service

the vehicle after collision as follows:

SRS-ECU MEMORY CHECK

1. Connect the MUT-

IIto the diagnosis connector. (Refer

to GROUP 00 – How to Use Troubleshooting/Inspection

Service Points.)

Caution

Refer to that the ignition switch is LOCK(OFF) when

connecting or disconnecting MUT-II

.

2. Read (and write down) all displayed diagnosis codes.

(Refer to P.52B-7.)

NOTE

If battery power supply has been shut down by the

collision, the MUT-

IIcannot communicate with the

SRS-ECU. Check and, repair if necessary, the instrument

panel wiring harness before the next job.

3. Use the the MUT-

IIto read the data list (how long trouble(s)

have continued and how often memory have been

erased).

Data list

NoService Data ItemApplicability

92Number indication how often the memory is cleared.Maximum time to be stored: 250

93How long problem have lasted (How long it takes

from the occurrence of the problem till the first air bag

squib igniting signal)Maximum time to be stored: 9999 minutes

(approximately 7 days)

94How long problem(s) have lasted (How long it takes

from the first air bag squib igniting signal till now.)

4. Erase the diagnosis codes and after waiting 5 seconds

or more read (and write down) all displayed diagnosis

codes. (Refer to P.52B-7.)

REPAIR PROCEDURE

DEPLOYED DRIVER’S AND FRONT PASSENGER’S AIR

BAGS

1. Replace the following parts with new ones.

DSRS-ECU (Refer to P.52B-30.)

DDriver’s air bag module (Refer to P.52B-32.)

DFront passenger’s air bag module (Refer to P.52B-32.)

2. Check the following parts and replace if malfunction is

found:

DClock spring (Refer to P.52B-32.)

DSteering wheel, steering column and intermediate

joint

(1) Check the wiring harness (built into steering

wheel) and connectors for damage, and terminals

for deformation.

(2) Check the driver’s air bag module for proper

installation to the steering wheel.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

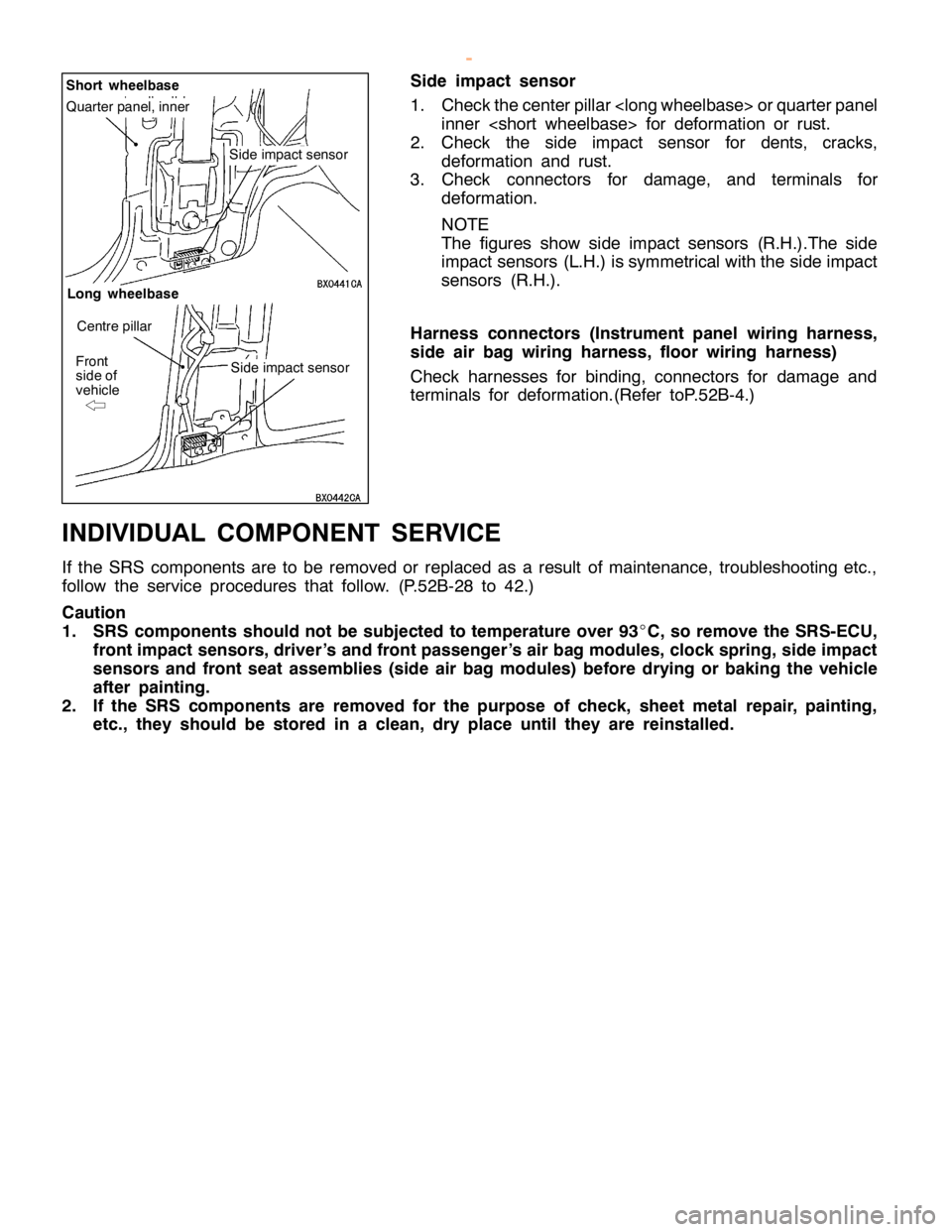

Page 1526 of 1839

S

id e im pact se nso r L

ong wheelb ase Q

uarte r panel, in ner F

ro nt

s id e of

v e hic le

Page 1527 of 1839

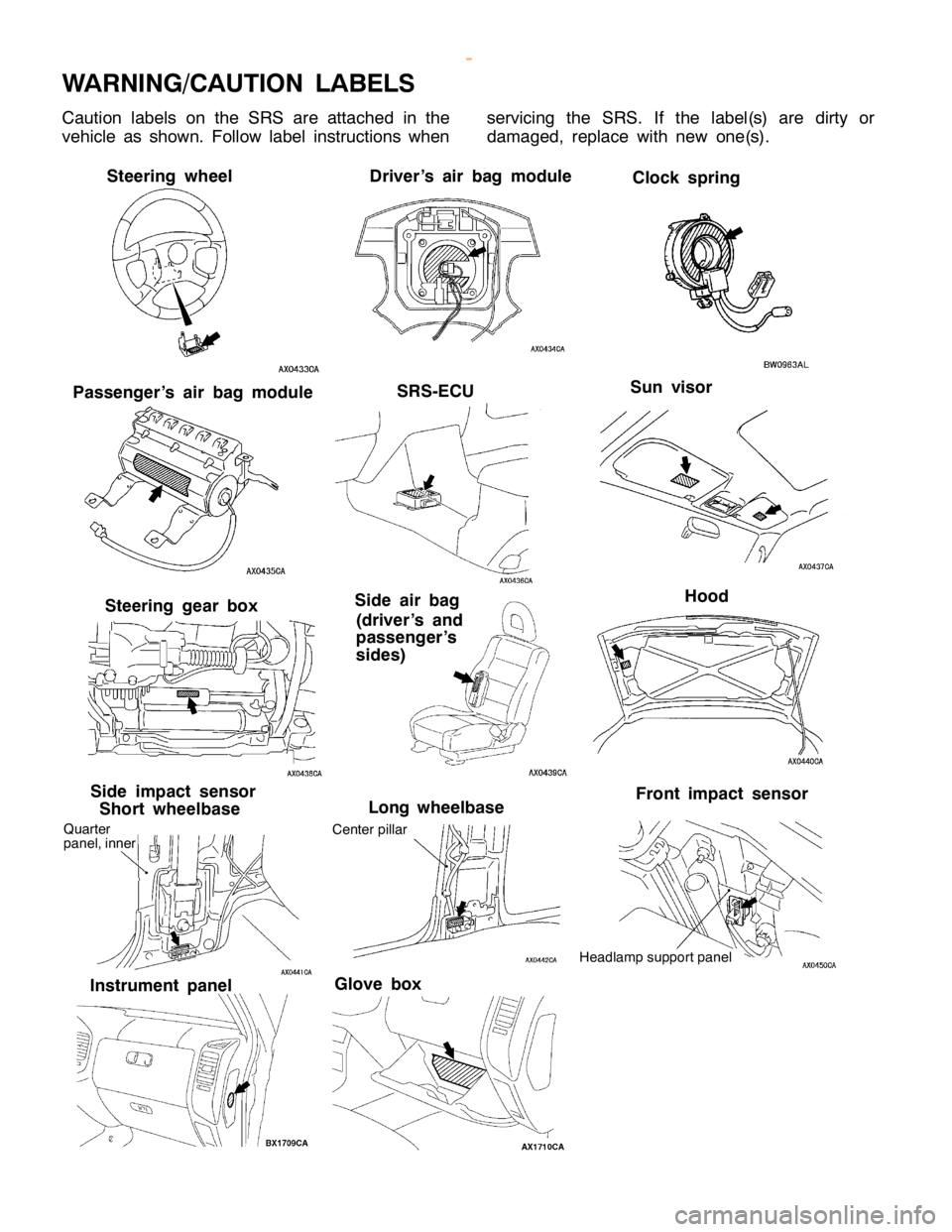

W

ARNIN G /C AUTIO N LA BELS

C autio n la bels on th e SR S are atta ch ed in th e

v e hic le as sh ow n. Follo w la bel in str u ctio ns when s

e rv ic in g th e SR S. If th e la bel( s ) are dir ty or

d am aged, re pla ce wit h new one(s ). D

riv er’s air bag module C

lo ck sp rin g P

assen ger’s air bag module S

R S-E C U S

un vis o r S

te erin g gear box

Fro nt im pact sen so r

S

id e im pact sen so r H

ood

S hort wheelb ase L

o ng wheelb ase

C ente r pilla r

Q

uarte r

p anel

, i

n ner (

d riv er’s an d

p assen ger’s

s id es) S

id e air bag

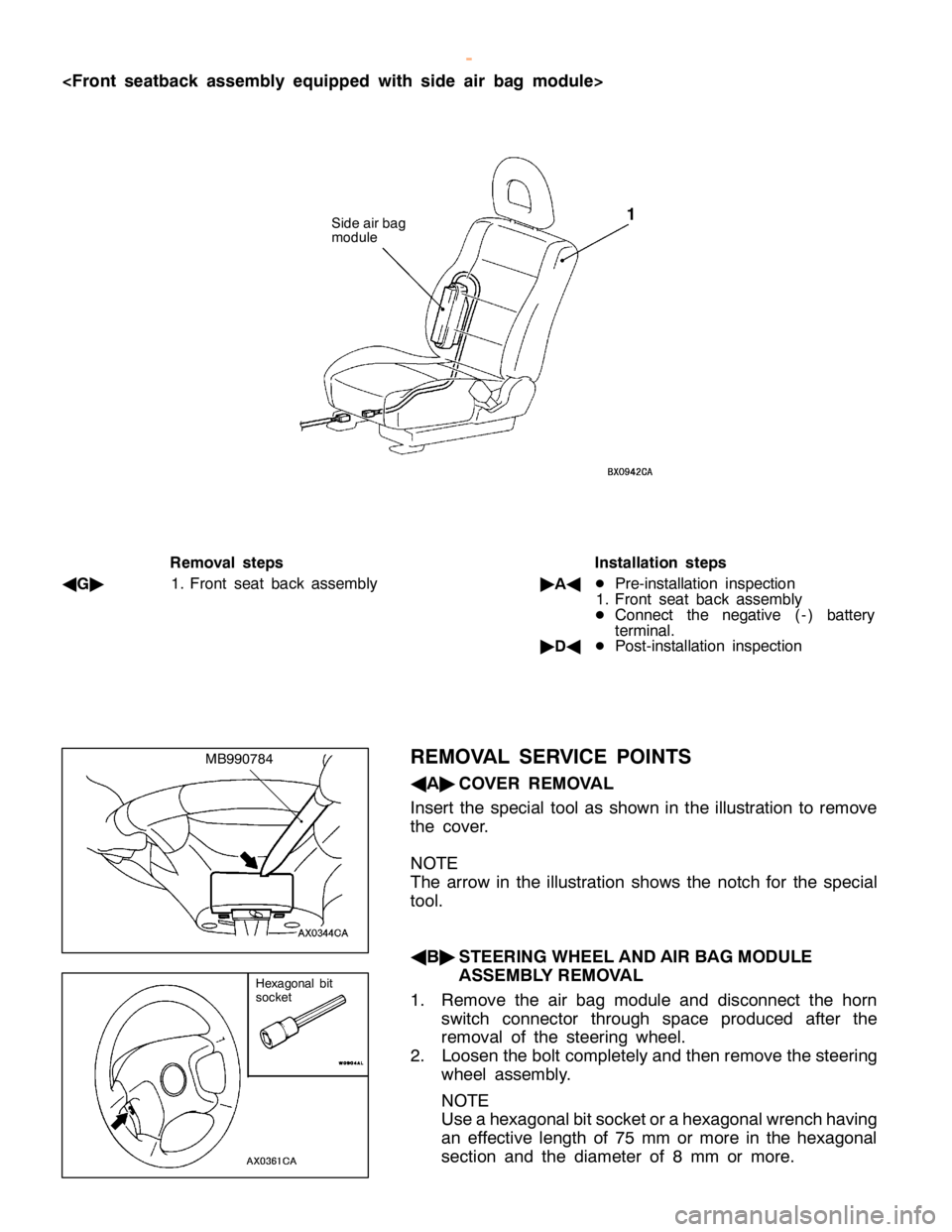

Page 1535 of 1839

1

S id e air bag

m odule

R em oval ste p s

A G"

1. Fro nt se at back asse m bly I

n sta lla tio n ste p s

" AA

D

Pre -in sta lla tio n in sp ectio n

1 . Fro nt se at back asse m bly

D Connect th e negativ e (- ) batte ry

t e rm in al.

" DA

D

Post- in sta lla tio n in sp ectio n

R EM OVA L SER VIC E PO IN TS

A A"

CO VER REM OVA L

I n se rt th e sp ecia l to ol as sh ow n in th e illu str a tio n to re m ove

t h e co ve r.

N O TE

T he arro w in th e illu str a tio n sh ow s th e notc h fo r th e sp ecia l

t o ol.

A B"

STE ER IN G WHEEL AND AIR BAG MODULE

A SSEM BLY REM OVA L

1 . Rem ove th e air bag module and dis co nnect th e horn

s w it c h co nnecto r th ro ugh sp ace pro duce d afte r th e

r e m ova l of th e ste erin g wheel.

2 . Loose n th e bolt co m ple te ly and th en re m ove th e ste erin g

w heel asse m bly .

N O TE

U se a hexa gonalb it so cke to r a hexa gonalw re nch havin g

a n eff e ctiv e le ngth of 75 mm or m ore in th e hexa gonal

s e ctio n and th e dia m ete r of 8 mm or m ore .