wheel MITSUBISHI MONTERO 2000 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1149 of 1839

WHEEL AND TYRE -Troubleshooting31-6

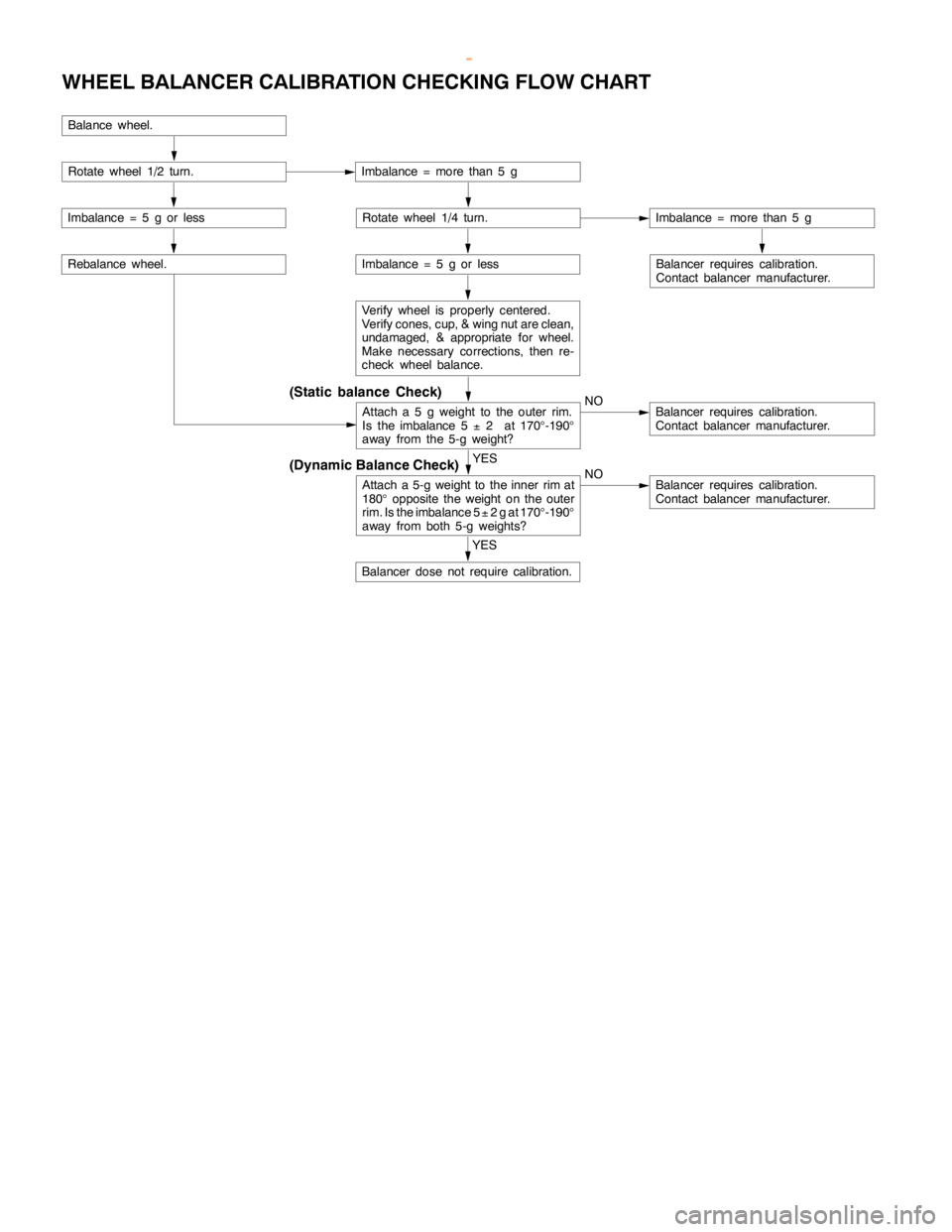

WHEEL BALANCER CALIBRATION CHECKING FLOW CHART

(Dynamic Balance Check)

(Static balance Check)

Balance wheel.

Rotate wheel 1/2 turn.Imbalance = more than 5 g

Imbalance = 5 g or lessRotate wheel 1/4 turn.Imbalance = more than 5 g

Imbalance = 5 g or less

Verify wheel is properly centered.

Verify cones, cup, & wing nut are clean,

undamaged, & appropriate for wheel.

Make necessary corrections, then re-

check wheel balance.

Attacha 5 g weight to the outer rim.

Is the imbalance 5

±2 at 170

°-190

°

away from the 5-g weight?NOBalancer requires calibration.

Contact balancer manufacturer.

Balancer requires calibration.

Contact balancer manufacturer.

YES

Attach a 5-g weight to the inner rim at

180

°opposite the weight on the outer

rim. Is the imbalance 5

±2 g at 170

°-190

°

away from both 5-g weights?NOBalancer requires calibration.

Contact balancer manufacturer.

Rebalance wheel.

YES

Balancer dose not require calibration.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1150 of 1839

O

N-V EH IC LE SER VIC E

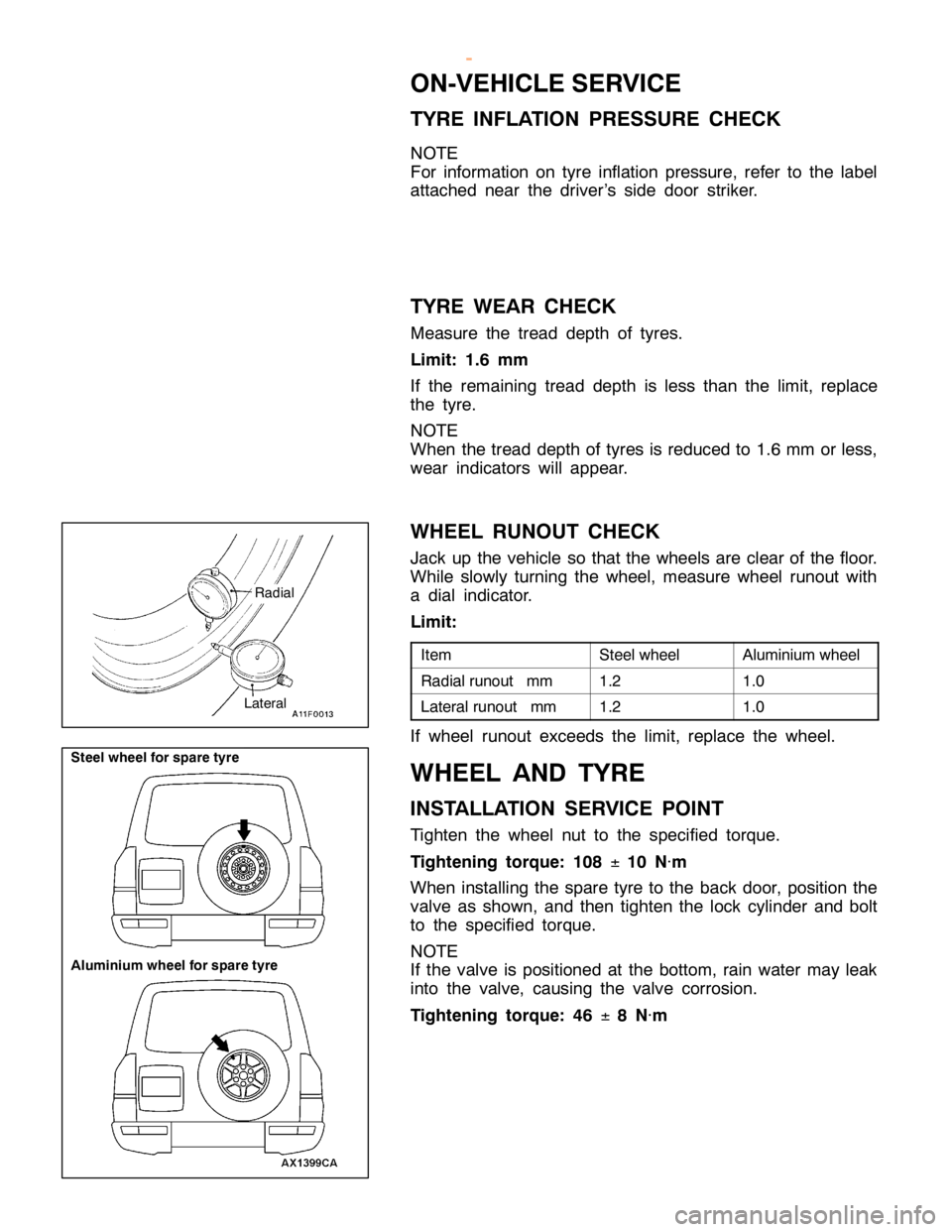

T Y R E IN FLA TIO N PR ESSU RE CHEC K

N O TE

F or in fo rm atio n on ty re in fla tio n pre ssu re , re fe r to th e la bel

a tta ch ed near th e driv e r’s sid e door str ik e r.

T Y R E WEA R CHEC K

M easu re th e tr e ad depth of ty re s.

L im it : 1.6 mm

I f th e re m ain in g tr e ad depth is le ss th an th e lim it , re pla ce

t h e ty re .

N O TE

W hen th e tr e ad depth of ty re s is re duce d to 1.6 mm or le ss,

w ear in dic a to rs will appear.

W HEEL RUNO UT CHEC K

J a ck up th e ve hic le so th at th e wheels are cle ar of th e flo or.

W hile slo w ly tu rn in g th e wheel, m easu re wheel ru nout w it h

a dia l in dic a to r.

L im it :

I te m S

te elw heel A

lu m in iu m wheel R

adia lru nout mm 1

.2 1

.0 L

ate ra lru nout mm 1

.2 1

.0 A

lu m in iu m wheelfo r sp are ty re

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1156 of 1839

4

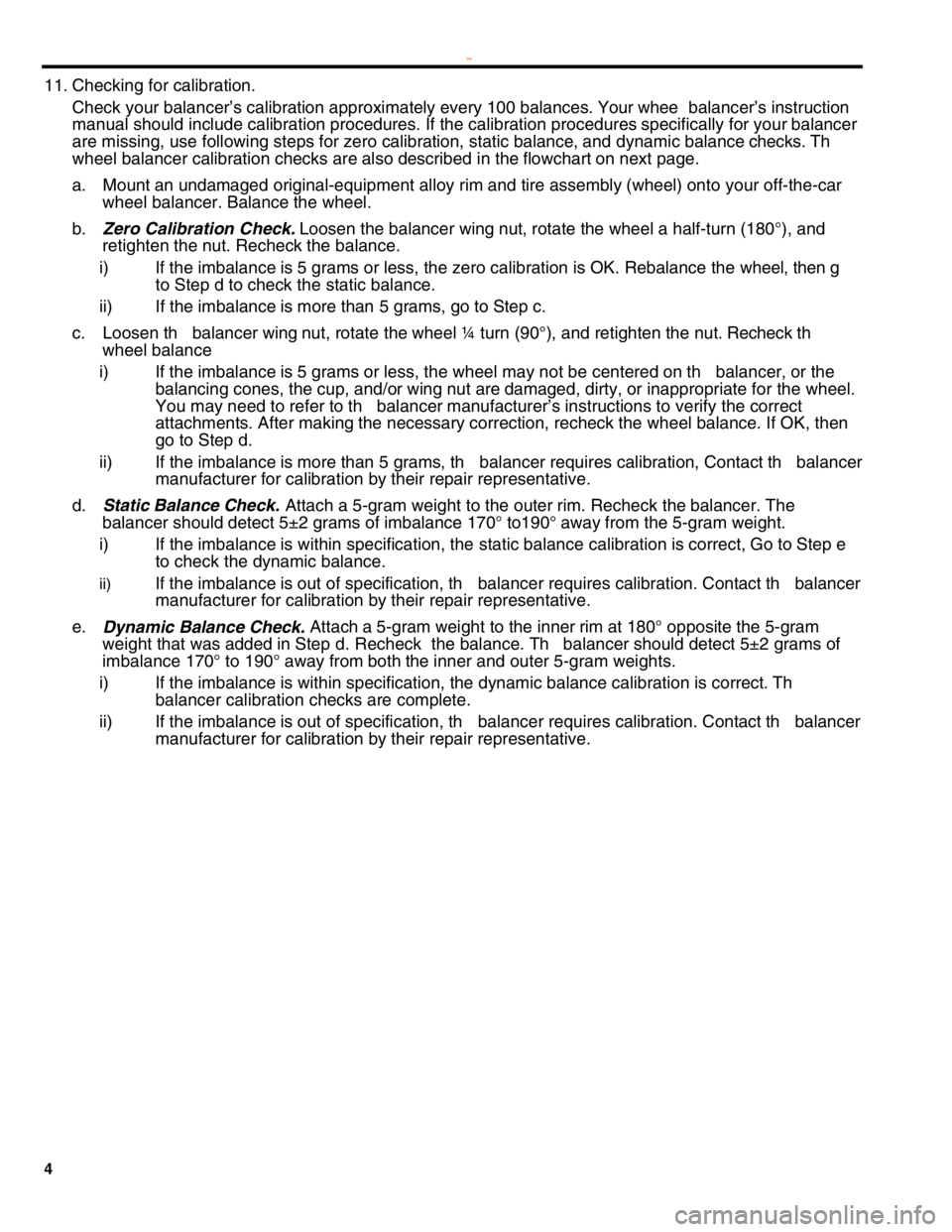

11.

Checking for calibration.

Check your balancer’s calibration approximately every 100 balances. Your whee balancer’s instruction

manual should include calibration procedures. If the calibration procedures specifically for your balancer

are missing, use following steps for zero calibration, static balance, and dynamic balance checks. Th

wheel balancer calibration checks are also described in the flowchart on next page.

a.

Mount an undamaged original-equipment alloy rim and tire assembly (wheel) onto your off-the-car

wheel balancer. Balance the wheel.

b.

Zero Calibration Check. Loosen the balancer wing nut, rotate the wheel a half-turn (180°), and

retighten the nut. Recheck the balance.

i)

If the imbalance is 5 grams or less, the zero calibration is OK. Rebalance the wheel, then g

to Step d to check the static balance.

ii)

If the imbalance is more than 5 grams, go to Step c.

c.

Loosen th balancer wing nut, rotate the wheel ¼ turn (90°), and retighten the nut. Recheck th

wheel balance

i)

If the imbalance is 5 grams or less, the wheel may not be centered on th balancer, or the

balancing cones, the cup, and/or wing nut are damaged, dirty, or inappropriate for the wheel.

You may need to refer to th balancer manufacturer’s instructions to verify the correct

attachments. After making the necessary correction, recheck the wheel balance. If OK, then

go to Step d.

ii)

If the imbalance is more than 5 grams, th balancer requires calibration, Contact th balancer

manufacturer for calibration by their repair representative.

d.

Static Balance Check. Attach a 5-gram weight to the outer rim. Recheck the balancer. The

balancer should detect 5±2 grams of imbalance 170° to190° away from the 5-gram weight.

i)

If the imbalance is within specification, the static balance calibration is correct, Go to Step e

to check the dynamic balance.

ii)

If the imbalance is out of specification, th balancer requires calibration. Contact th balancer

manufacturer for calibration by their repair representative.

e.

Dynamic Balance Check. Attach a 5-gram weight to the inner rim at 180° opposite the 5-gram

weight that was added in Step d. Recheck the balance. Th balancer should detect 5±2 grams of

imbalance 170° to 190° away from both the inner and outer 5-gram weights.

i)

If the imbalance is within specification, the dynamic balance calibration is correct. Th

balancer calibration checks are complete.

ii)

If the imbalance is out of specification, th balancer requires calibration. Contact th balancer

manufacturer for calibration by their repair representative.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1157 of 1839

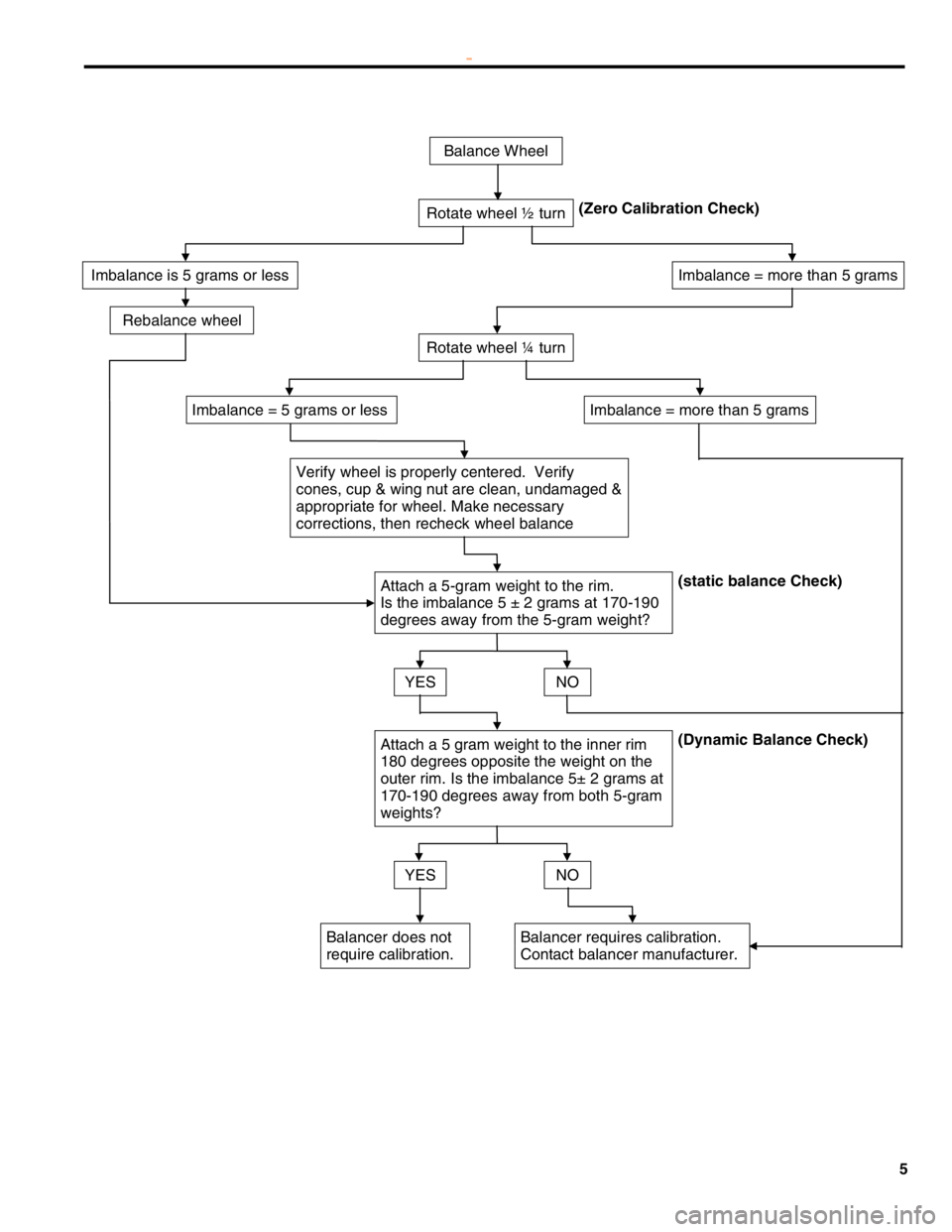

5 Balance Wheel

Rotate wheel ½ turn(Zero Calibration Check)

Imbalance is 5 grams or less Imbalance = more than 5 grams

Rebalance wheel

Rotate wheel ¼ turn

Imbalance = 5 grams or less Imbalance = more than 5 grams

Verify wheel is properly centered. Verify

cones, cup & wing nut are clean, undamaged &

appropriate for wheel. Make necessary

corrections, then recheck wheel balance

Attach a 5-gram weight to the rim.

Is the imbalance 5 ± 2 grams at 170-190

degrees away from the 5-gram weight?(static balance Check)

YES NO

Attach a 5 gram weight to the inner rim

180 degrees opposite the weight on the

outer rim. Is the imbalance 5± 2 grams at

170-190 degrees away from both 5-gram

weights?(Dynamic Balance Check)

YES NO

Balancer does not

require calibration.Balancer requires calibration.

Contact balancer manufacturer.

WHEEL BALANCER CALIBRATION CHECKS

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1165 of 1839

POWER PLANT MOUNT - No.1 Crossmember32-7

No.1 CROSSMEMBER

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and airbag module assembly, always refer to GROUP 52B

- Service Precautions, Airbag Module and Clock Spring. Also, set the front wheels so that

they are facing straight forward, and remove the ignition key. If you fail to do this, the SRS

clock spring will be damaged, causing the SRS airbag to be inoperative and serious injury.

2. *: Indicates parts which should be initially tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal

DDrive Shaft Removal

(Refer to GROUP 26.)

DDifferential Carrier and No.2 Crossmember

Assembly Removal (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DUpper Arm Removal

(Refer to GROUP 33A.)

DLower Arm Removal

(Refer to GROUP 33A.)

DStabilizer Bar Removal

(Refer to GROUP 33A.)

DEngine Oil Cooler Removal<6G7>

(Refer to GROUP 12.)

DAir Cleaner Removal<4M4>

(Refer to GROUP 15.)

DIntercooler Removal<4M4>

(Refer to GROUP 15.)

DEngine Cover Removal

(Refer to GROUP 11A - Timing Belt.)

DRadiator Removal

(Refer to GROUP 14.)

DPower Steering Fluid Draining

(Refer to GROUP 37A - On - vehicle Service.)Post - installation Operations

DDifferential Carrier and No.2 Crossmember

Assembly Installation (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DDrive Shaft Installation

(Refer to GROUP 26.)

DLower Arm Installation

(Refer to GROUP 33A.)

DUpper Arm Installation

(Refer to GROUP 33A.)

DStabilizer Bar Installation

(Refer to GROUP 33A.)

DAir Cleaner Installation<4M4>

(Refer to GROUP 15.)

DIntercooler Installation<4M4>

(Refer to GROUP 15.)

DRadiator Installation

(Refer to GROUP 14.)

DEngine Oil Cooler Installation

(Refer to GROUP 12.)

DPower Steering Fluid Supplying

(Refer to GROUP 37A - On - vehicle Service.)

DPower Steering Fluid Line Bleeding

(Refer to GROUP 37A - On - vehicle Service.)

DPress the dust cover with a finger tocheck whether

the dust cover is cracked or damaged.

DChecking Steering Wheel Position with Wheels

StraightAhead

DFront Wheel AlignmentCheck and Adjustment

(Refer to GROUP 37A - On - vehicle Service.)

DUnder Cover Installation

DEngine Cover Installation

(Refer to GROUP 11A - Timing Belt.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1170 of 1839

33A-1

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATION 1..................

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Wheel Alignment Check and Adjustment 4.......Ball Joint Dust Cover Check 6..................

UPPER ARM ASSEMBLY 7...................

SHOCK ABSORBER ASSEMBLY 10.........

LOWER ARM ASSEMBLY 13................

STABILIZER BAR 16........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1171 of 1839

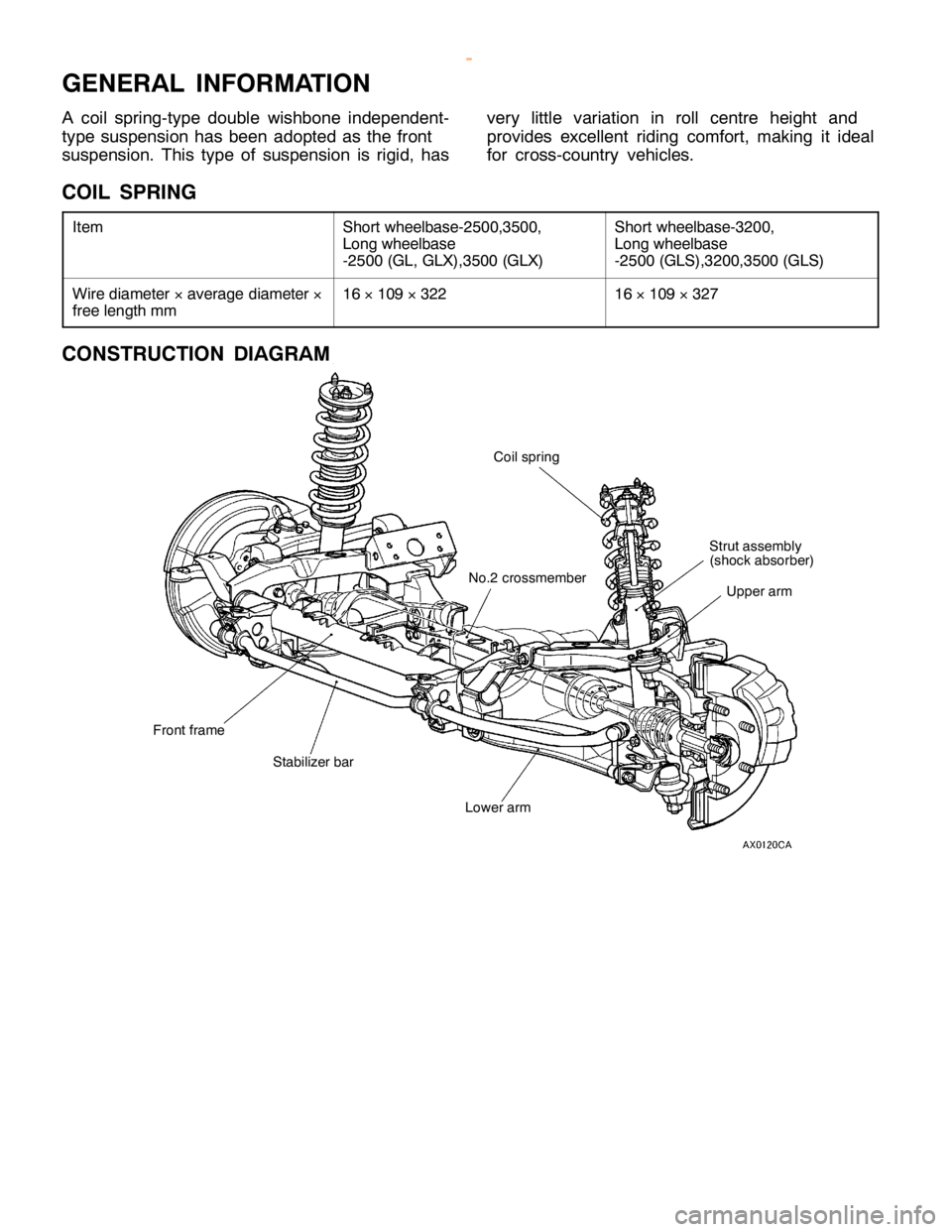

G

EN ER AL IN FO RM ATIO N

A co il sp rin g-ty p e double wis h bone in dependent-

t y p e su sp ensio n has been adopte d as th e fr o nt

s u sp ensio n. This ty p e of su sp ensio n is rig id , has v

e ry lit tle va ria tio n in ro ll ce ntr e heig ht and

p ro vid es exce lle nt rid in g co m fo rt, m akin g it id eal

f o r cro ss-c o untr y ve hic le s.

C O IL SPR IN G

I te m S

hort w heelb ase -2 500,3 500,

L ong wheelb ase

- 2 500 (G L, G LX ),3 500 (G LX ) S

hort w heelb ase -3 200,

L ong wheelb ase

- 2 500 (G LS ),3 200,3 500 (G LS ) W

ir e dia m ete r ´ ave ra ge dia m ete r ´

f r e e le ngth mm 1

6 ´ 109 ´322 1

6 ´ 109 ´327

Page 1176 of 1839

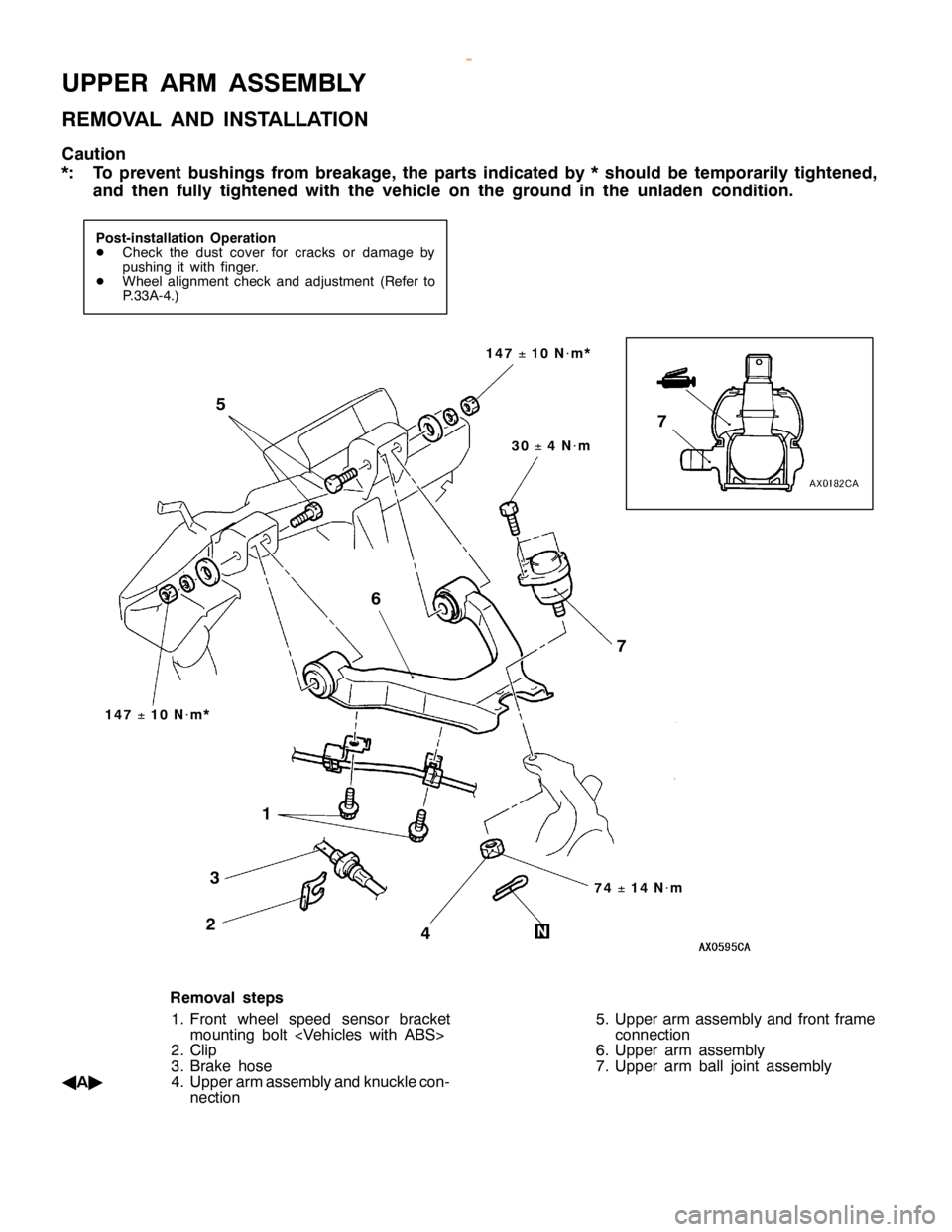

U

PPER ARM ASSEM BLY

R EM OVA L AND IN STA LLA TIO N

C au tio n

* : To pre ven t bush in gs fr o m bre akag e, th e parts in dic ate d by *sh ould be te m pora rily tig hte n ed ,

a n d th en fu lly tig hte n ed wit h th e veh ic le on th e gro und in th e unla d en co ndit io n. 3

2 15

6

71

47 ±

10 N×

m * 3

0 ±

4 N×

m

R em oval ste p s

1 . Fro nt wheel sp eed se nso r bra cke t

m ountin g bolt

2 . C lip

3 . B ra ke hose

A A"

4. U ppera rm asse m bly and kn uckle co n-

n ectio n 5

. U pper arm asse m bly and fr o nt fr a m e

c o nnectio n

6 . U pper arm asse m bly

7 . U pper arm ball jo in t asse m bly

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1189 of 1839

34-1

REAR

SUSPENSION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Wheel Alignment Check and Adjustment 4.......

Ball Joint Dust Cover Check 5..................

UPPER ARM ASSEMBLY 6...................SHOCK ABSORBER/COIL SPRING/LOWER

ARM ASSEMBLY 9...........................

STABILIZER BAR 11.........................

TOE CONTROL ARM ASSEMBLY/TOE

CONTROL TOWER BAR 13..................

TRAILING ARM ASSEMBLY 16..............

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1190 of 1839

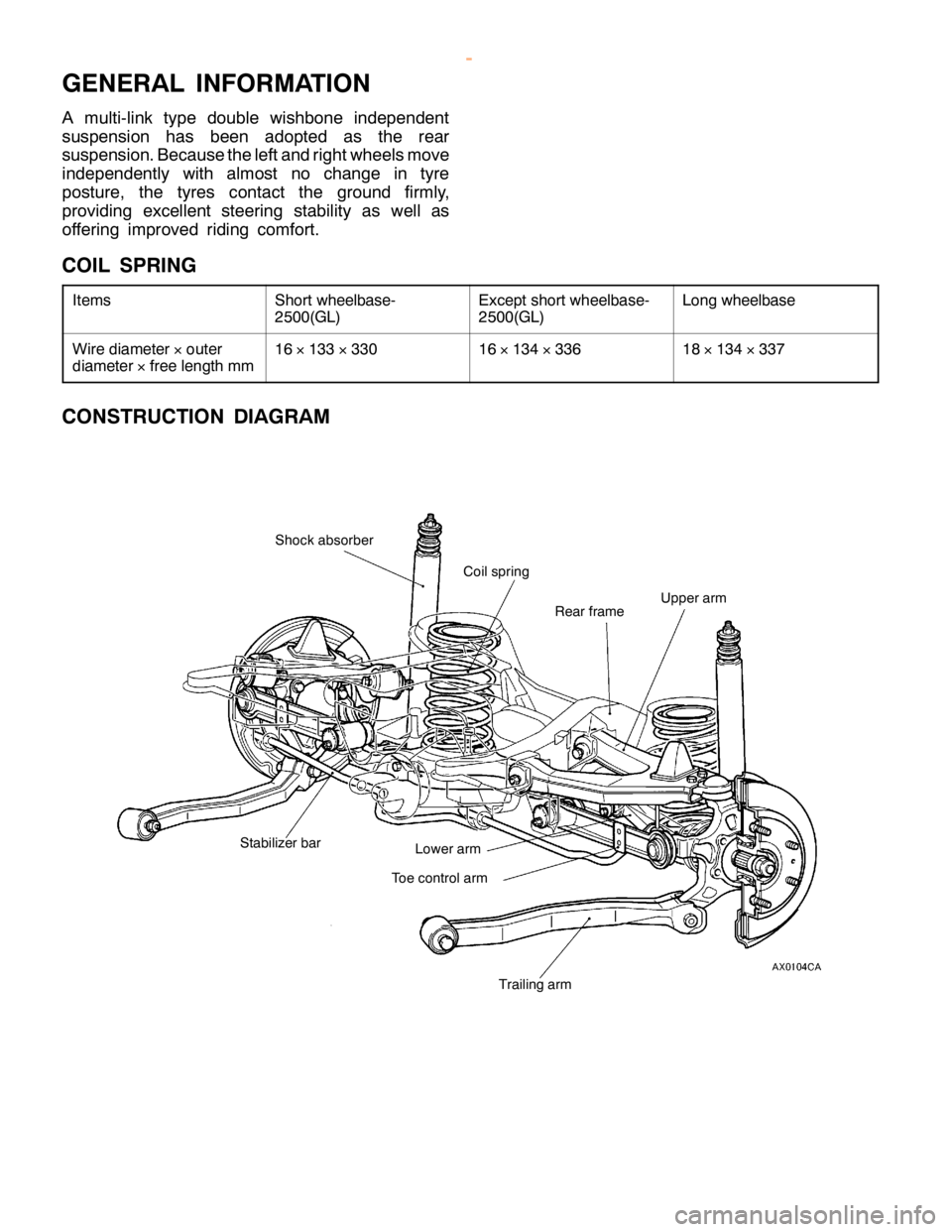

G

EN ER AL IN FO RM ATIO N

A mult i- lin k ty p e double wis h bone in dependent

s u sp ensio n has been adopte d as th e re ar

s u sp ensio n.B eca use th e le ft a nd rig htw heels m ove

i n dependently wit h alm ost no ch ange in ty re

p ostu re , th e ty re s co nta ct th e gro und fir m ly ,

p ro vid in g exce lle nt ste erin g sta bilit y as well as

o ff e rin g im pro ve d rid in g co m fo rt.

C O IL SPR IN G

I te m s S

hort w heelb ase -

2 500(G L) E

xce pt sh ort w heelb ase -

2 500(G L) L

ong wheelb ase W

ir e dia m ete r ´ oute r

d ia m ete r ´ fr e e le ngth mm 1

6 ´ 133 ´330 1

6 ´ 134 ´336 1

8 ´ 134 ´337