warning MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 343 of 1839

Page 380 of 1839

Page 384 of 1839

Page 419 of 1839

Page 464 of 1839

15

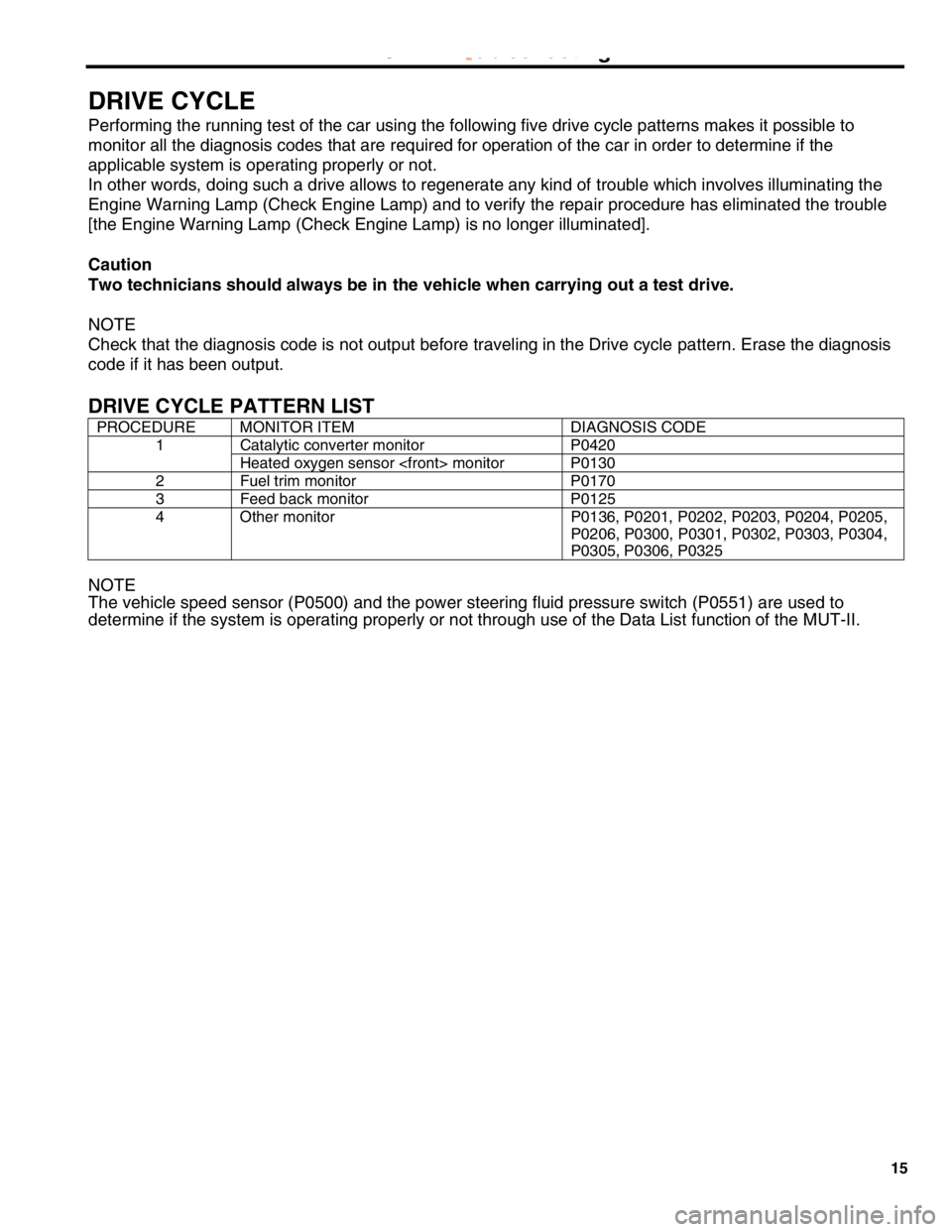

DRIVE CYCLE

Performing the running test of the car using the following five drive cycle patterns makes it possible to

monitor all the diagnosis codes that are required for operation of the car in order to determine if the

applicable system is operating properly or not.

In other words, doing such a drive allows to regenerate any kind of trouble which involves illuminating the

Engine Warning Lamp (Check Engine Lamp) and to verify the repair procedure has eliminated the trouble

[the Engine Warning Lamp (Check Engine Lamp) is no longer illuminated].

Caution

Two technicians should always be in the vehicle when carrying out a test drive.

NOTE

Check that the diagnosis code is not output before traveling in the Drive cycle pattern. Erase the diagnosis

code if it has been output.

DRIVE CYCLE PATTERN LIST

PROCEDURE MONITOR ITEM DIAGNOSIS CODE

Catalytic converter monitor P04201

Heated oxygen sensor

2 Fuel trim monitor P0170

3 Feed back monitor P0125

4 Other monitor P0136, P0201, P0202, P0203, P0204, P0205,

P0206, P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0325

NOTE

The vehicle speed sensor (P0500) and the power steering fluid pressure switch (P0551) are used to

determine if the system is operating properly or not through use of the Data List function of the MUT-II.

2001 PAJERO/MONTERO WAGON Workshop Manual 6G74

GDI - Troubleshooting

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 472 of 1839

GDI -General/General Information/Troubleshooting13A-3

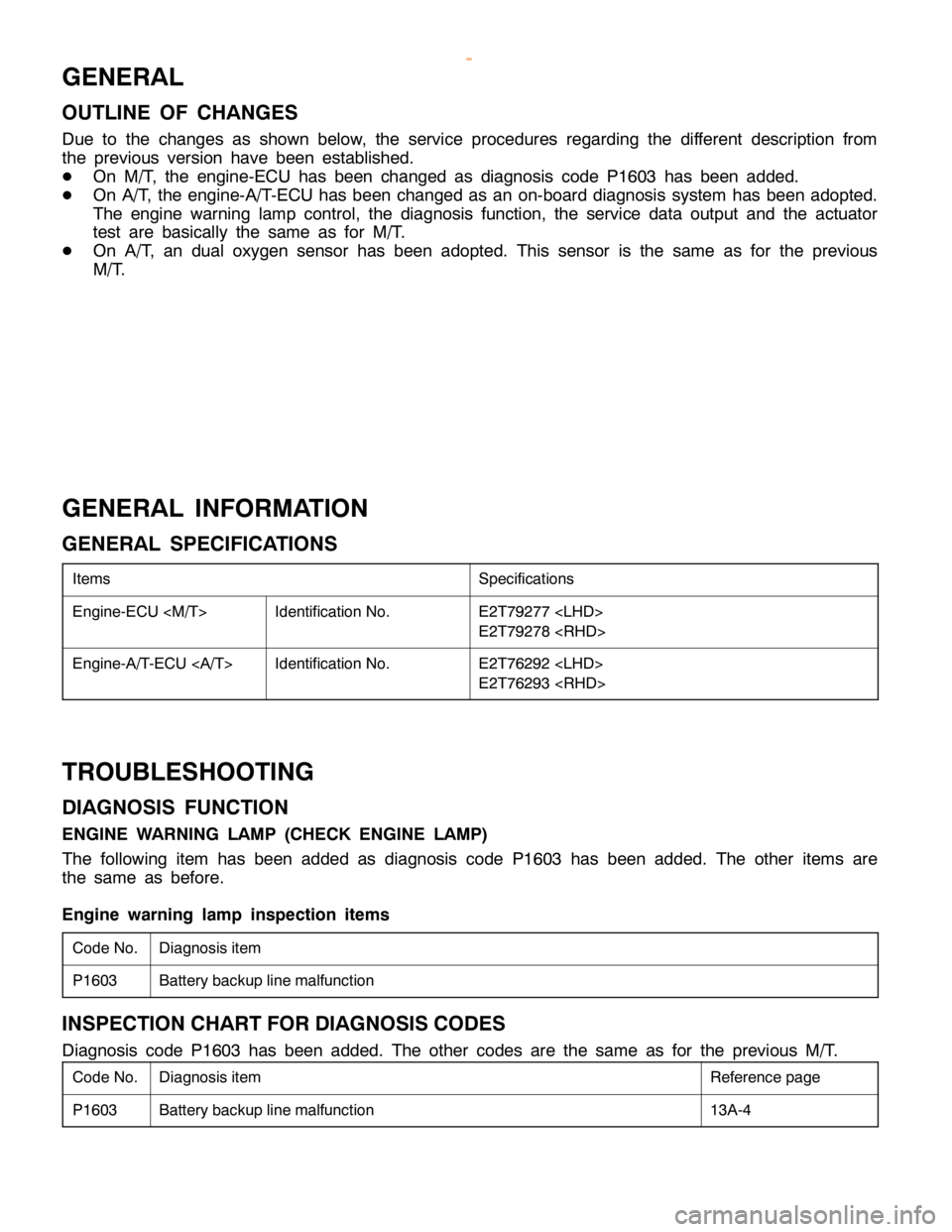

GENERAL

OUTLINE OF CHANGES

Due to the changes as shown below, the service procedures regarding the different description from

the previous version have been established.

DOn M/T, the engine-ECU has been changed as diagnosis code P1603 has been added.

DOn A/T, the engine-A/T-ECU has been changed as an on-board diagnosis system has been adopted.

The engine warning lamp control, the diagnosis function, the service data output and the actuator

test are basically the same as for M/T.

DOn A/T, an dual oxygen sensor has been adopted. This sensor is the same as for the previous

M/T.

GENERAL INFORMATION

GENERAL SPECIFICATIONS

ItemsSpecifications

Engine-ECU

E2T79278

Engine-A/T-ECU Identification No.E2T76292

E2T76293

TROUBLESHOOTING

DIAGNOSIS FUNCTION

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

The following item has been added as diagnosis code P1603 has been added. The other items are

the same as before.

Engine warning lamp inspection items

Code No.Diagnosis item

P1603Battery backup line malfunction

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis code P1603 has been added. The other codes are the same as for the previous M/T.

Code No.Diagnosis itemReference page

P1603Battery backup line malfunction13A-4

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 473 of 1839

GDI -TroubleshootingGDI -Troubleshooting13A-4

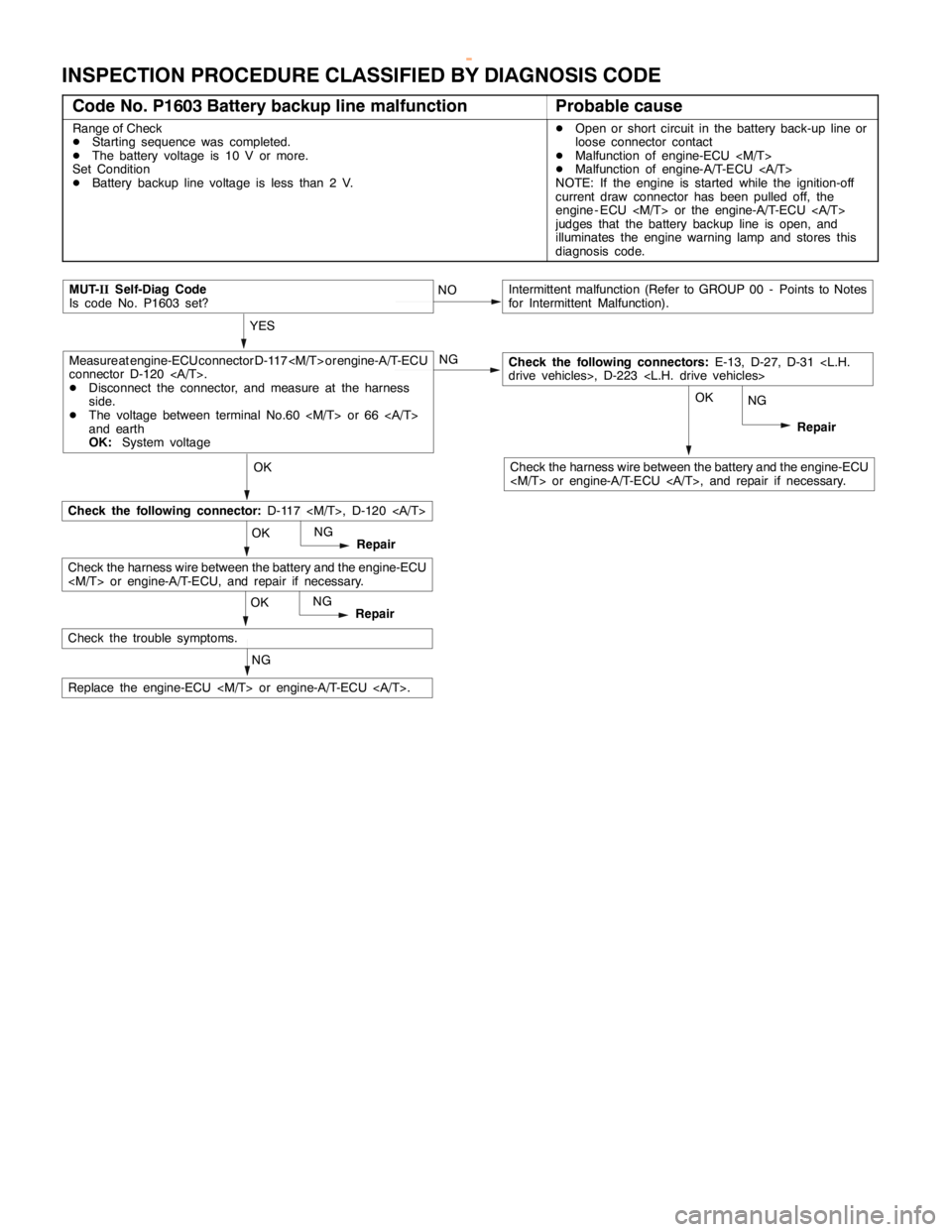

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No. P1603 Battery backup line malfunctionProbable cause

Range of Check

DStarting sequence was completed.

DThe battery voltage is 10 V or more.

Set Condition

DBattery backup line voltage is less than 2 V.DOpen or short circuit in the battery back-up line or

loose connector contact

DMalfunction of engine-ECU

DMalfunction of engine-A/T-ECU

NOTE: If the engine is started while the ignition-off

current draw connector has been pulled off, the

engine - ECU

judges that the battery backup line is open, and

illuminates the engine warning lamp and stores this

diagnosis code.

NG

Replace the engine-ECU

Check the trouble symptoms.

OKNG

Repair

Check the harness wire between the battery and the engine-ECU

OKNG

Repair

Check the harness wire between the battery and the engine-ECU

OK

NG

Repair

MUT-IISelf-Diag Code

Is code No. P1603 set?

Check the following connector:D-117

Check the following connectors:E-13, D-27, D-31

connector D-120 .

DDisconnect the connector, and measure at the harness

side.

DThe voltage between terminal No.60

and earth

OK:System voltageNG

Intermittent malfunction (Refer to GROUP 00 - Points to Notes

for Intermittent Malfunction).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 493 of 1839

DIESEL FUEL <4M4> -General Information13C-2

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine is idling after having warmed up, the throttle valve is half opened to restrict the

amount of intake air in order to reduce vibration and noise.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Fan motor relay control

The radiator fan and condenser fan operating speeds are controlled in accordance with the engine

coolant temperature and the vehicle speed.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 514 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-23

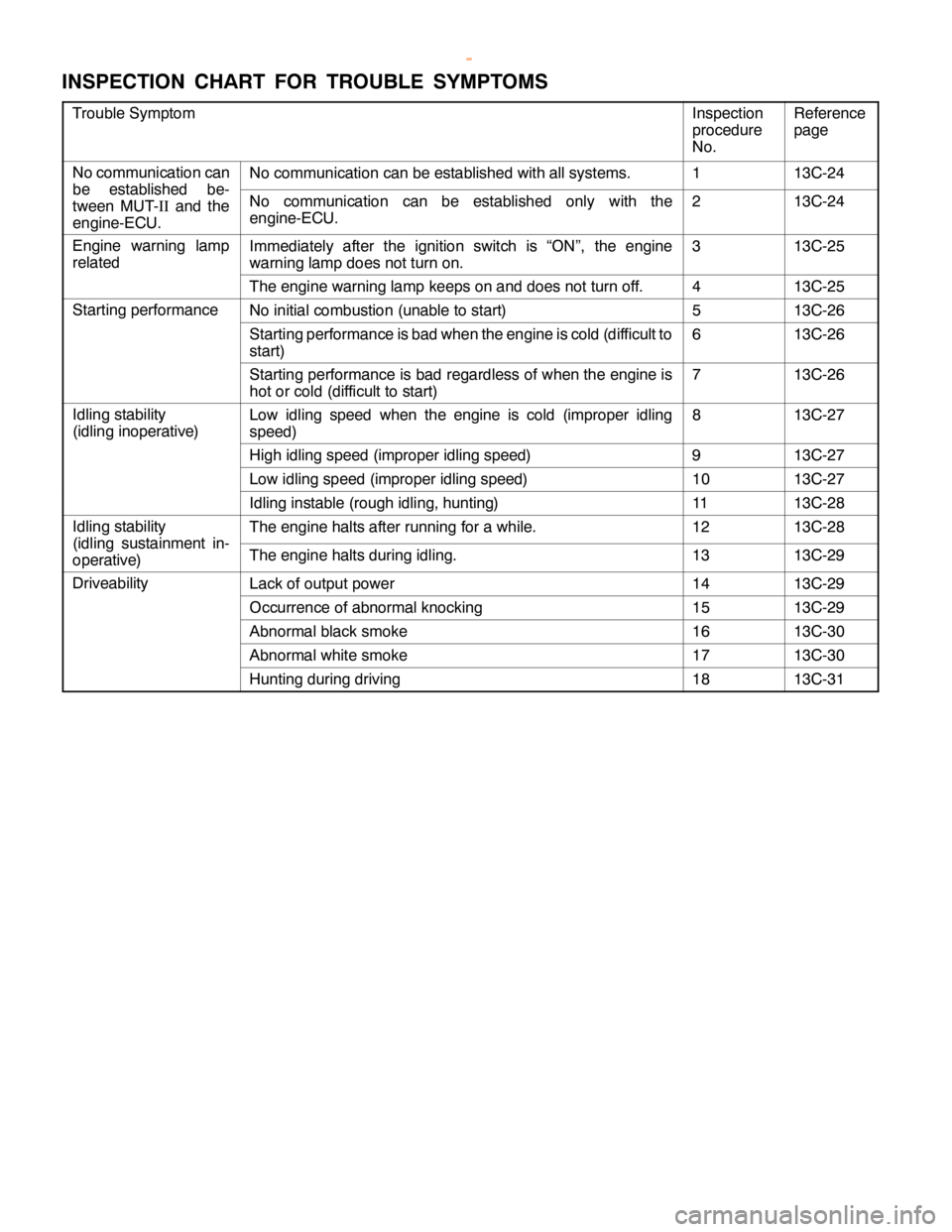

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble SymptomInspection

procedure

No.Reference

page

No communication canNo communication can be established with all systems.113C-24

be established be-

tween MUT-IIand the

engine-ECU.No communication can be established only with the

engine-ECU.213C-24

Engine warning lamp

relatedImmediately after the ignition switch is “ON”, the engine

warning lamp does not turn on.313C-25

The engine warning lamp keeps on and does not turn off.413C-25

Starting performanceNo initial combustion (unable to start)513C-26

Starting performance is bad when the engine is cold (difficult to

start)613C-26

Starting performance is bad regardless of when the engine is

hot or cold (difficult to start)713C-26

Idling stability

(idling inoperative)Low idling speed when the engine is cold (improper idling

speed)813C-27

High idling speed (improper idling speed)913C-27

Low idling speed (improper idling speed)1013C-27

Idling instable (rough idling, hunting)1113C-28

Idling stabilityThe engine halts after running for a while.1213C-28

(idling sustainment in-

operative)The engine halts during idling.1313C-29

DriveabilityLack of output power1413C-29

Occurrence of abnormal knocking1513C-29

Abnormal black smoke1613C-30

Abnormal white smoke1713C-30

Hunting during driving1813C-31

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 516 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-25

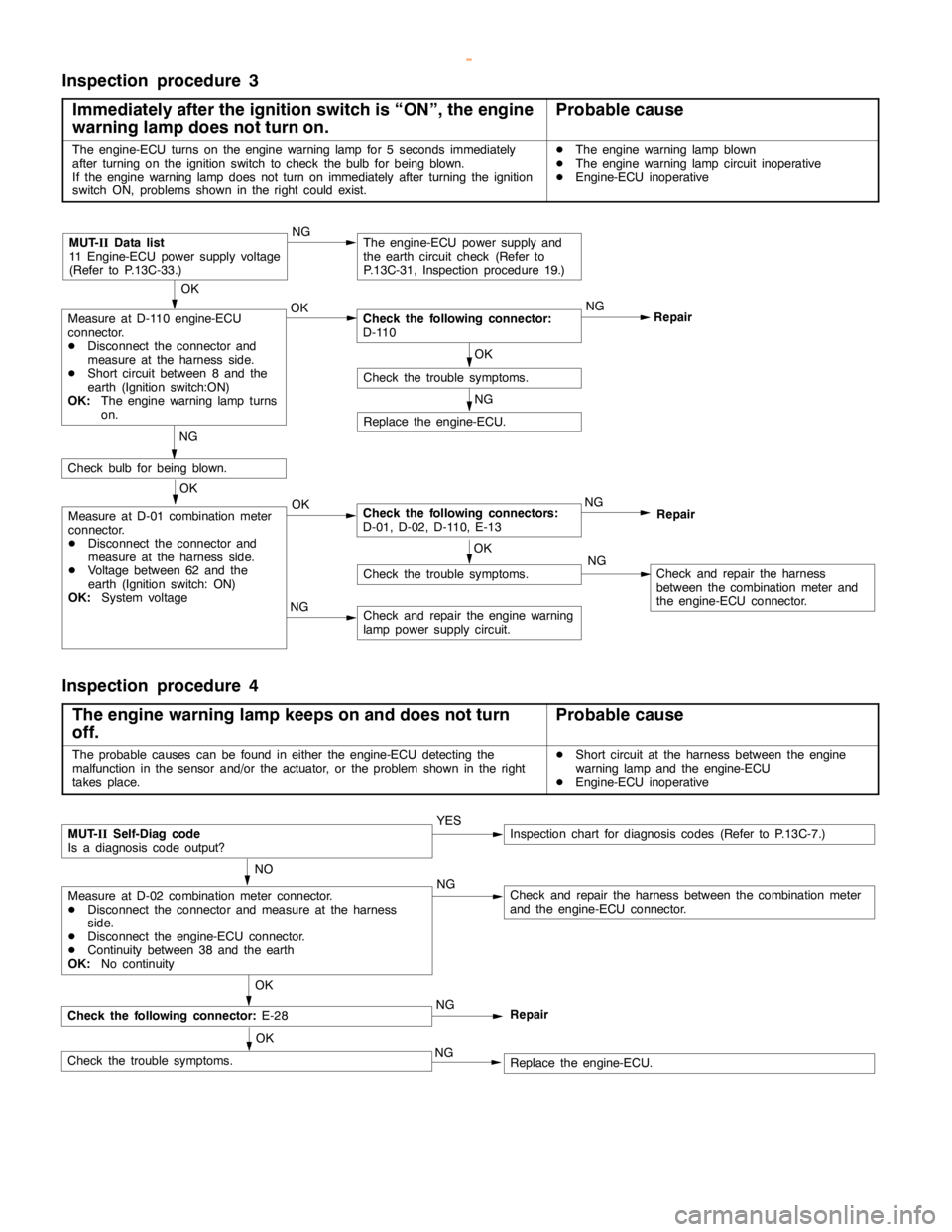

Inspection procedure 3

Immediately after the ignition switch is “ON”, the engine

warning lamp does not turn on.

Probable cause

The engine-ECU turns on theengine warning lamp for 5seconds immediately

after turning on the ignition switch to check thebulb for being blown.

If the engine warning lampdoes not turn on immediately after turning the ignition

switch ON, problems shown in the right could exist.DThe engine warning lamp blown

DThe engine warning lampcircuit inoperative

DEngine-ECU inoperative

NG

Replace the engine-ECU.

NG

Check and repair the harness

between the combination meter and

the engine-ECU connector.

NG

Check and repair theengine warning

lamppower supply circuit.

OK

Check the trouble symptoms.

OK

Measure at D-01 combination meter

connector.

DDisconnect the connector and

measure at the harness side.

DVoltage between 62 and the

earth (Ignition switch: ON)

OK:

System voltageOKCheck the following connectors:

D-01, D-02, D-110, E-13NG

Repair

NG

Checkbulb for being blown.

OK

Check the trouble symptoms.

OK

Measure at D-110 engine-ECU

connector.

DDisconnect the connector and

measure at the harness side.

DShort circuit between 8 and the

earth (Ignition switch:ON)

OK:

The engine warning lampturns

on.OKCheck the following connector:

D-110NG

Repair

MUT-

IIData list

11 Engine-ECU power supply voltage

(Refer to P.13C-33.)NGThe engine-ECU power supply and

the earth circuit check (Refer to

P.13C-31, Inspection procedure 19.)

Inspection procedure 4

The engine warning lamp keeps on and does not turn

off.

Probable cause

The probable causes can be found in either the engine-ECU detecting the

malfunction in the sensor and/or the actuator, or the problem shown in the right

takes place.DShort circuit at the harness between theengine

warning lamp and the engine-ECU

DEngine-ECU inoperative

Check the following connector:

E-28

NO

Measure at D-02 combination meter connector.

DDisconnect the connector and measure at the harness

side.

DDisconnect the engine-ECU connector.

DContinuity between 38 and the earth

OK:

No continuityNGCheck and repair the harness between the combination meter

and the engine-ECU connector.

OK

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

Check the trouble symptoms.OKReplace the engine-ECU. NGNG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk