warning MITSUBISHI MONTERO 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 526 of 1839

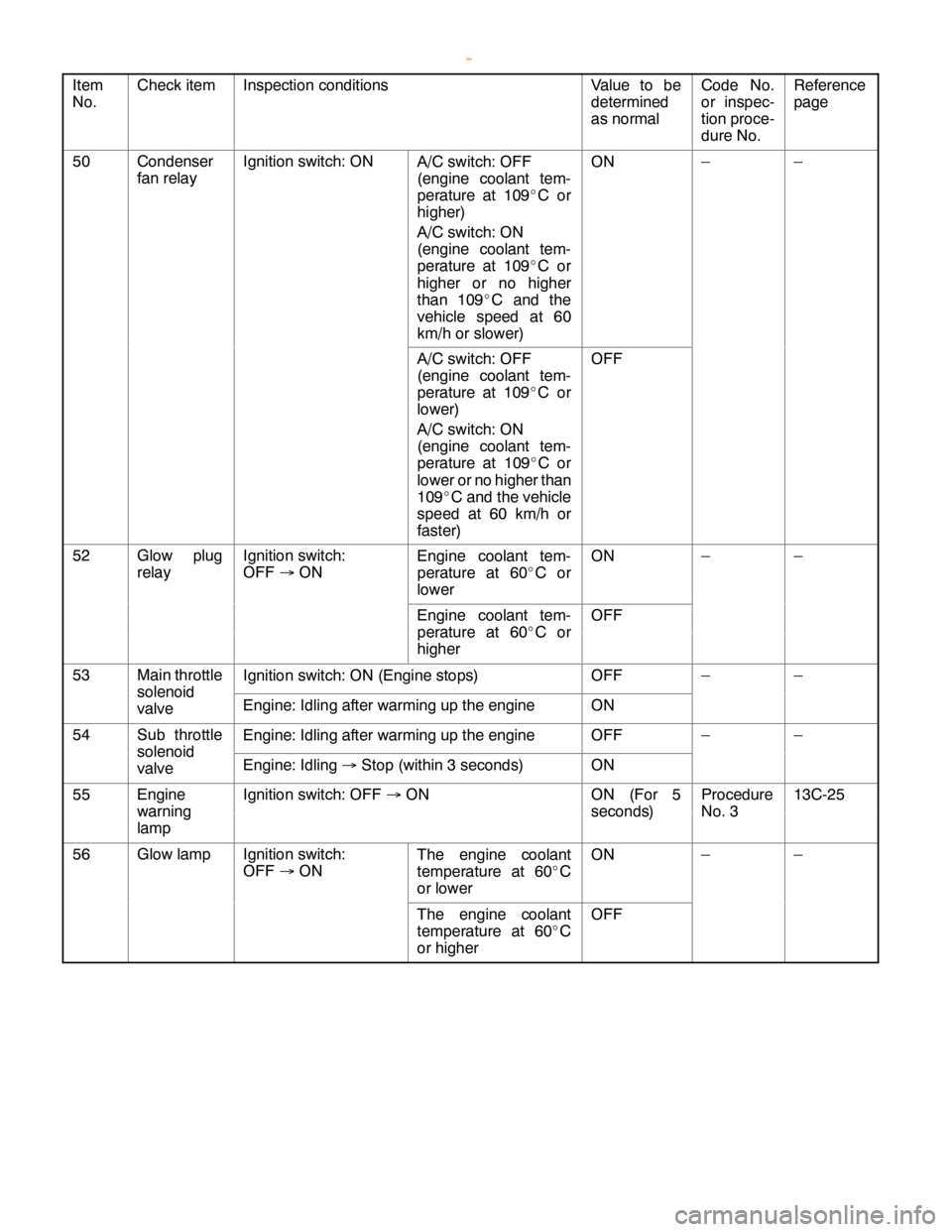

DIESEL FUEL <4M4> -Troubleshooting13C-35

Item

No.Check itemInspection conditionsValue to be

determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

50Condenser

fan relayIgnition switch: ONA/C switch: OFF

(engine coolant tem-

perature at 109_Cor

higher)

A/C switch: ON

(engine coolant tem-

perature at 109_Cor

higher or no higher

than 109_C and the

vehicle speed at 60

km/h or slower)ON––

A/C switch: OFF

(engine coolant tem-

perature at 109_Cor

lower)

A/C switch: ON

(engine coolant tem-

perature at 109_Cor

lower or no higher than

109_C and the vehicle

speed at 60 km/h or

faster)OFF

52Glow plug

relayIgnition switch:

OFF®ONEngine coolant tem-

perature at 60_Cor

lowerON––

Engine coolant tem-OFF

perature at 60_Cor

higher

53Main throttleIgnition switch: ON (Engine stops)OFF––

solenoid

valveEngine: Idling after warming up the engineON

54Sub throttleEngine: Idling after warming up the engineOFF––

solenoid

valveEngine: Idling®Stop (within 3 seconds)ON

55EngineIgnition switch: OFF®ONON (For 5Procedure13C-25

warning

lampseconds)No. 3

56Glow lampIgnition switch:

OFF®ONThe engine coolant

temperature at 60_C

or lowerON––

The engine coolant

temperature at 60_C

or higherOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 528 of 1839

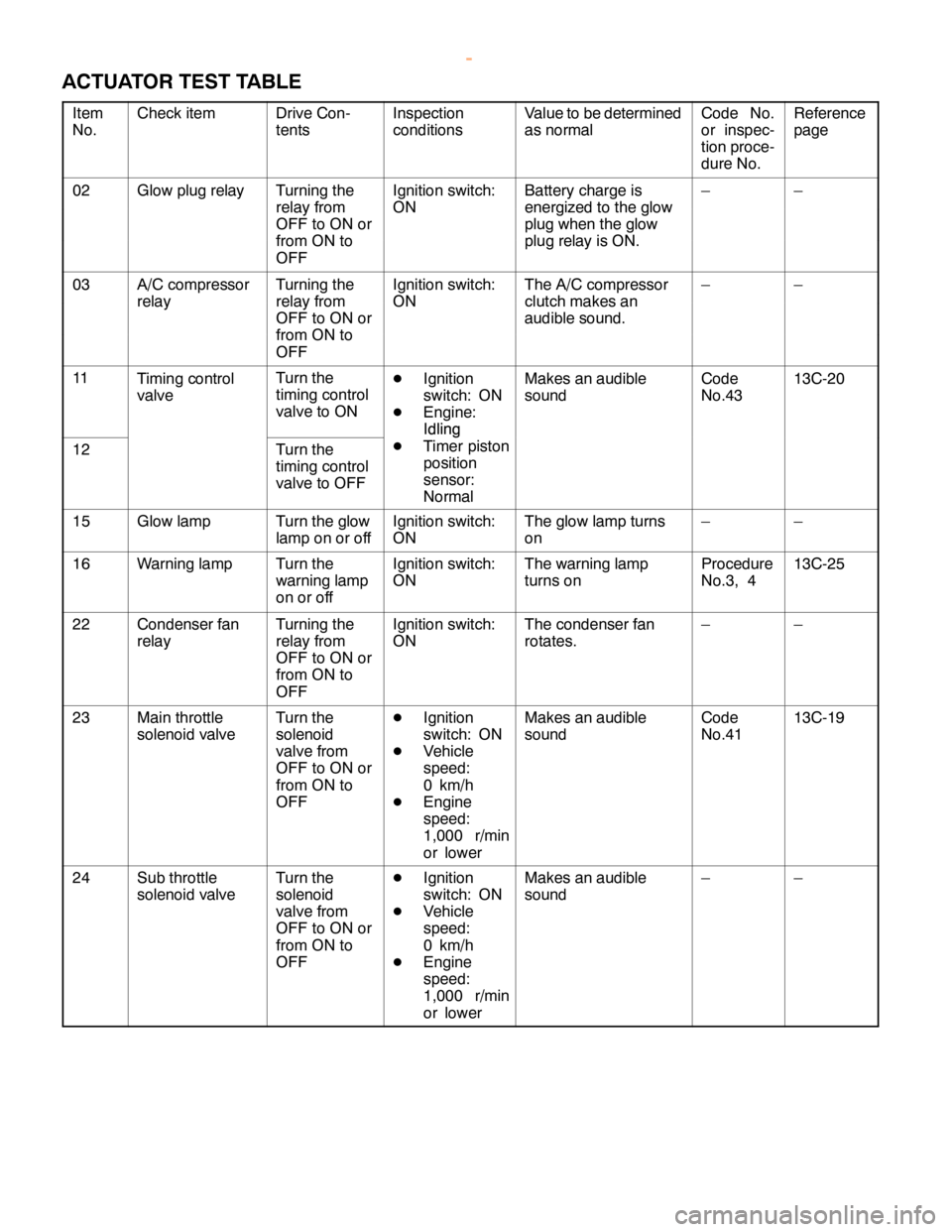

DIESEL FUEL <4M4> -Troubleshooting13C-37

ACTUATOR TEST TABLE

Item

No.Check itemDrive Con-

tentsInspection

conditionsValue to be determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

02Glow plug relayTurning theIgnition switch:Battery charge is––

relay from

OFF to ON orONenergized to the glow

plug when the glow

from ON to

OFFplug relay is ON.

03A/C compressorTurning theIgnition switch:The A/C compressor––

relayrelay from

OFF to ON orONclutch makes an

audible sound.

from ON to

OFF

11Timing control

valveTurn the

timing control

valve to ONDIgnition

switch: ON

DEngine:

IdlingMakes an audible

soundCode

No.4313C-20

12Turn the

timing control

valve to OFF

Idling

DTimer piston

position

sensor:

Normal

15Glow lampTurn the glow

lamp on or offIgnition switch:

ONThe glow lamp turns

on––

16Warning lampTurn the

warning lamp

on or offIgnition switch:

ONThe warning lamp

turns onProcedure

No.3, 413C-25

22Condenser fan

relayTurning the

relay from

OFF to ON or

from ON to

OFFIgnition switch:

ONThe condenser fan

rotates.––

23Main throttle

solenoid valveTurn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/h

DEngine

speed:

1,000 r/min

or lowerMakes an audible

soundCode

No.4113C-19

24Sub throttle

solenoid valveTurn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/h

DEngine

speed:

1,000 r/min

or lowerMakes an audible

sound––

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 590 of 1839

13E-1

MITSUBISHI STABILITY

CONTROL

(MITSUBISHI SC)

CONTENTS

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 4..............

SPECIAL TOOLS 4........................

TROUBLESHOOTING 5....................

ON-VEHICLE SERVICE 18.................

Operation Test of MITSUBISHI SC 18.........Wheel Speed Sensor (FR) Check 18..........

Vehicle Speed Sensor Check 18..............

SC-ECU* 19...............................

G SENSOR 20.............................

WHEEL SPEED SENSOR (FR) 20..........

VEHICLE SPEED SENSOR 20..............

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: front impact sensors, SRS-ECU, SRS warning lamp, air bag module, clock spring and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 595 of 1839

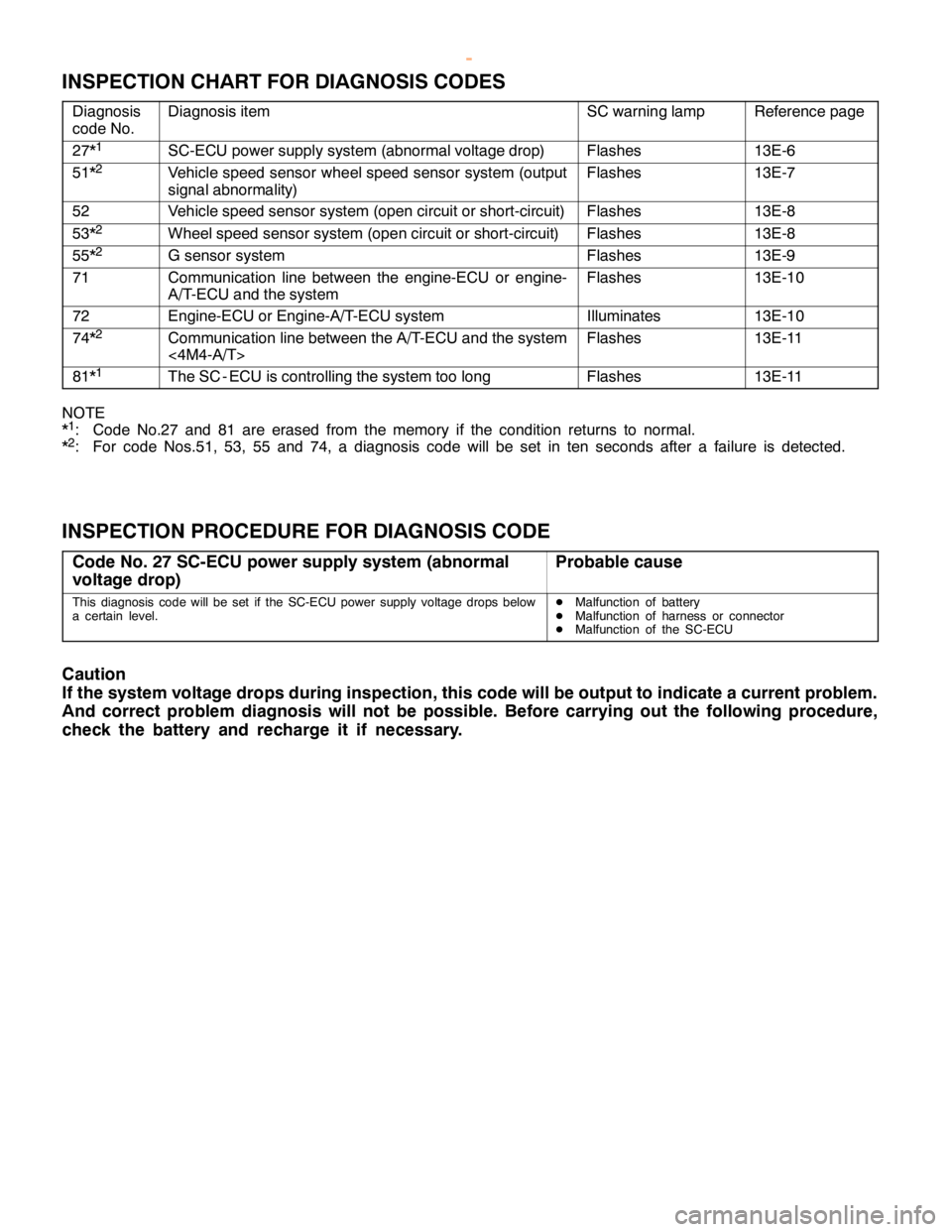

MITSUBISHI SC-Troubleshooting13E-6

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemSC warning lampReference page

27*1SC-ECU power supply system (abnormal voltage drop)Flashes13E-6

51*2Vehicle speed sensor wheel speed sensor system (output

signal abnormality)Flashes13E-7

52Vehicle speed sensor system (open circuit or short-circuit)Flashes13E-8

53*2Wheel speed sensor system (open circuit or short-circuit)Flashes13E-8

55*2G sensor systemFlashes13E-9

71Communication line between the engine-ECU or engine-

A/T-ECU and the systemFlashes13E-10

72Engine-ECU or Engine-A/T-ECU systemIlluminates13E-10

74*2Communication line between the A/T-ECU and the system

<4M4-A/T>Flashes13E-11

81*1The SC - ECU is controlling the system too longFlashes13E-11

NOTE

*1: Code No.27 and 81 are erased from the memory if the condition returns to normal.

*2: For code Nos.51, 53, 55 and 74, a diagnosis code will be set in ten seconds after a failure is detected.

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No. 27 SC-ECU power supply system (abnormal

voltage drop)Probable cause

This diagnosis code will be set if the SC-ECU power supply voltage drops below

a certain level.DMalfunction of battery

DMalfunction of harness or connector

DMalfunction of the SC-ECU

Caution

If the system voltage drops during inspection, this code will be output to indicate a current problem.

And correct problem diagnosis will not be possible. Before carrying out the following procedure,

check the battery and recharge it if necessary.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 601 of 1839

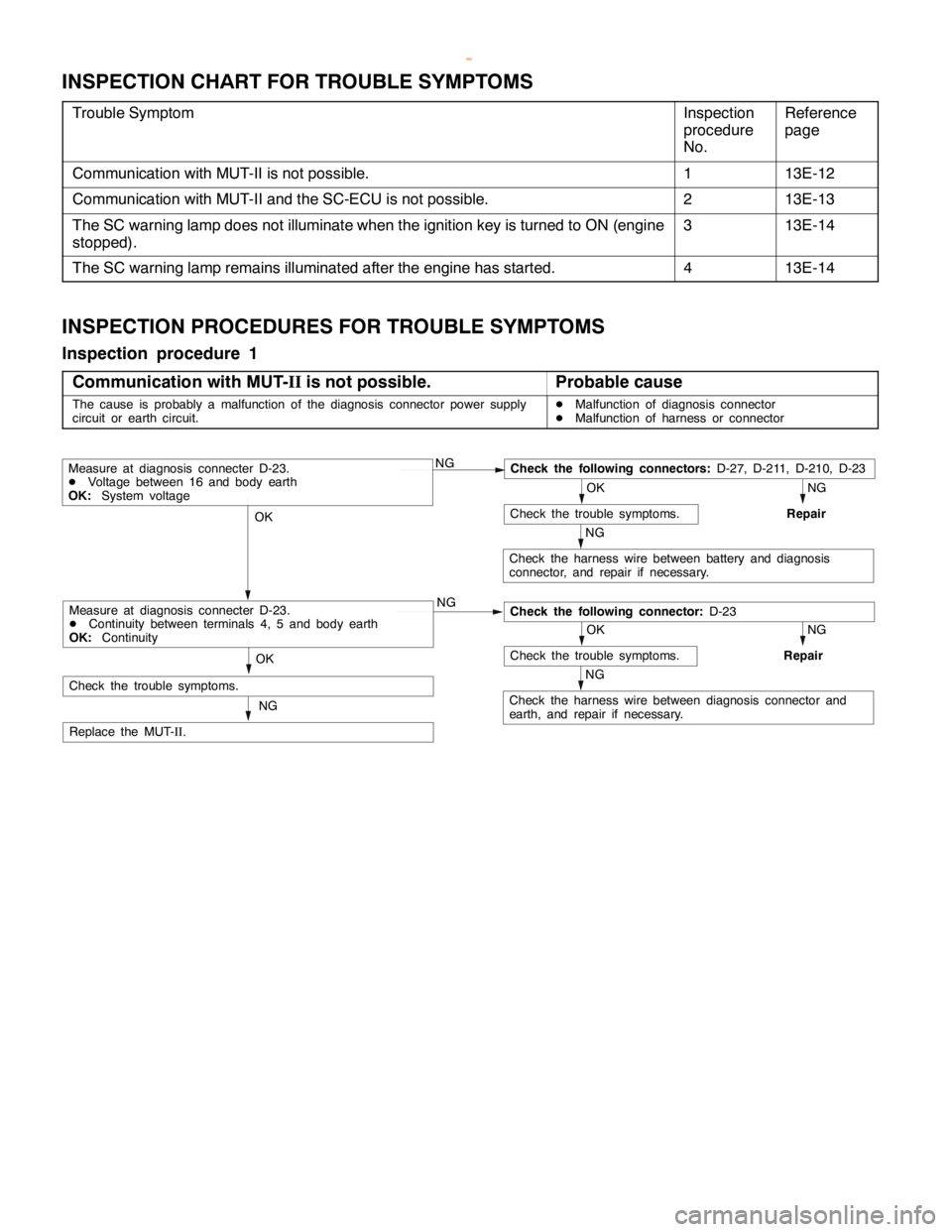

MITSUBISHI SC-Troubleshooting13E-12

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble SymptomInspection

procedure

No.Reference

page

Communication with MUT-II is not possible.113E-12

Communication with MUT-II and the SC-ECU is not possible.213E-13

The SC warning lamp does not illuminate when the ignition key is turned to ON (engine

stopped).313E-14

The SC warning lamp remains illuminated after the engine has started.413E-14

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

Communication with MUT-

IIis not possible.

Probable cause

The cause is probably a malfunction of the diagnosis connector power supply

circuit or earth circuit.DMalfunction of diagnosis connector

DMalfunction of harness or connector

NGCheck the following connectors:

D-27, D-211, D-210, D-23

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire between battery and diagnosis

connector, and repair if necessary.

OK

NG

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire between diagnosis connector and

earth, and repair if necessary.

OK

NG

Replace the MUT-

II.

Measure at diagnosis connecter D-23.

DVoltage between 16 and body earth

OK:

System voltage

Check the following connector:

D-23Measure at diagnosis connecter D-23.

DContinuity between terminals 4, 5 and body earth

OK:

Continuity

Check the trouble symptoms.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 603 of 1839

MITSUBISHI SC-Troubleshooting13E-14

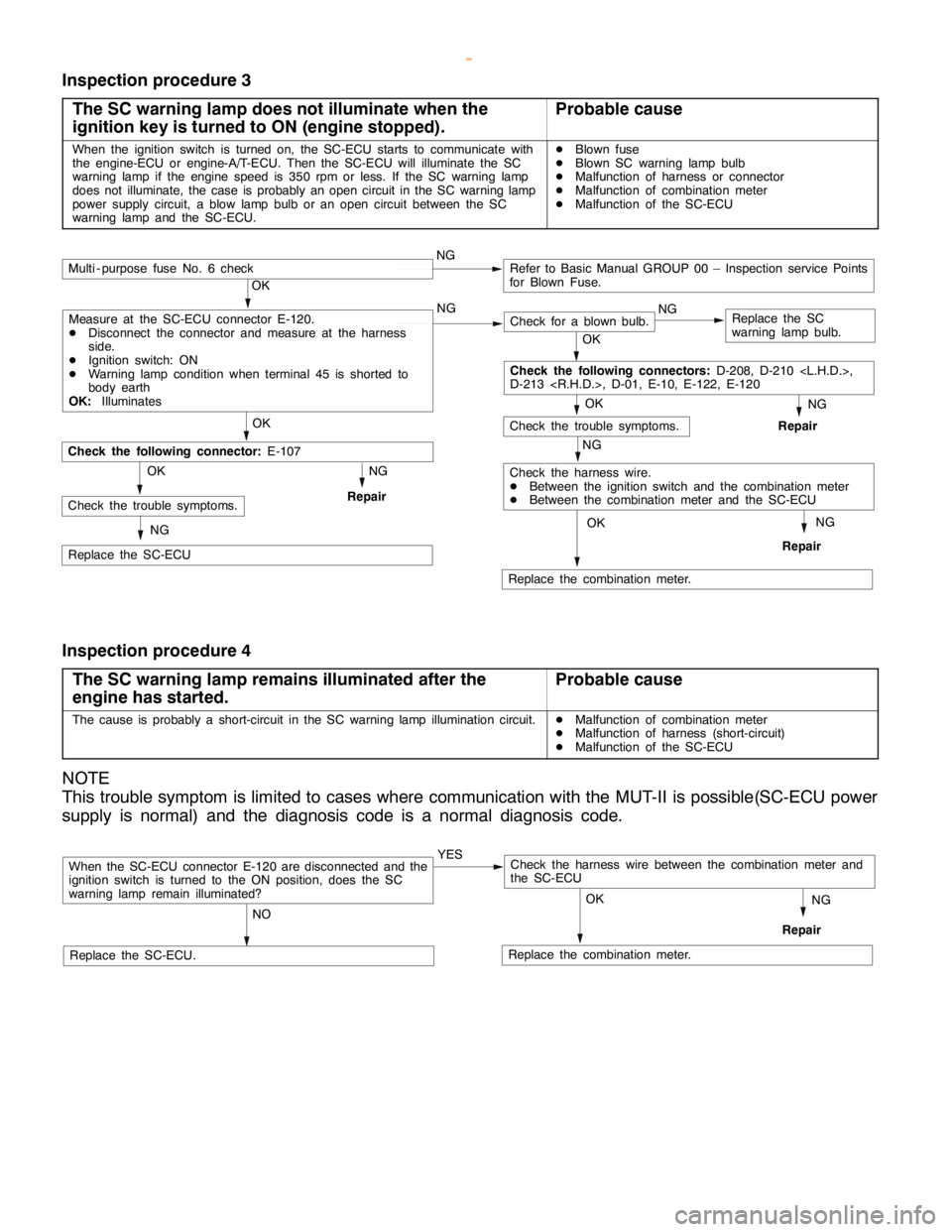

Inspection procedure 3

The SC warning lamp does not illuminate when the

ignition key is turned to ON (engine stopped).

Probable cause

When the ignition switch is turned on, the SC-ECU starts to communicate with

the engine-ECU or engine-A/T-ECU. Then the SC-ECU will illuminate the SC

warning lamp if the engine speed is 350 rpm or less. If the SC warning lamp

does not illuminate, the case is probably an open circuit in the SC warning lamp

power supply circuit, a blow lamp bulb or an open circuit between the SC

warning lamp and the SC-ECU.DBlown fuse

DBlown SC warning lamp bulb

DMalfunction of harness or connector

DMalfunction of combination meter

DMalfunction of the SC-ECU

NG

Replace the combination meter.

NG

Repair

OK

NG

Check for a blown bulb.Replace the SC

warning lamp bulb.

OK

NG

Repair

OK

Check the trouble symptoms.

Multi - purpose fuse No. 6 checkNGRefer to Basic Manual GROUP 00 – Inspection service Points

for Blown Fuse.

NG

Check the harness wire.

DBetween the ignition switch and the combination meter

DBetween the combination meter and the SC-ECU

OK

OK

Replace the SC-ECU

Check the following connector:

E-107

NG

RepairCheck the trouble symptoms.OK

NG

Check the following connectors:

D-208, D-210

D-213

Measure at the SC-ECU connector E-120.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DWarning lamp condition when terminal 45 is shorted to

body earth

OK:

Illuminates

Inspection procedure 4

The SC warning lamp remains illuminated after the

engine has started.

Probable cause

The cause is probably a short-circuit in the SC warning lamp illumination circuit.DMalfunction of combination meter

DMalfunction of harness (short-circuit)

DMalfunction of the SC-ECU

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(SC-ECU power

supply is normal) and the diagnosis code is a normal diagnosis code.

When the SC-ECU connector E-120 are disconnected and the

ignition switch is turned to the ON position, does the SC

warning lamp remain illuminated?YES

NO

Replace the SC-ECU.Replace the combination meter.

NG

Repair

OK

Check the harness wire between the combination meter and

the SC-ECU

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 612 of 1839

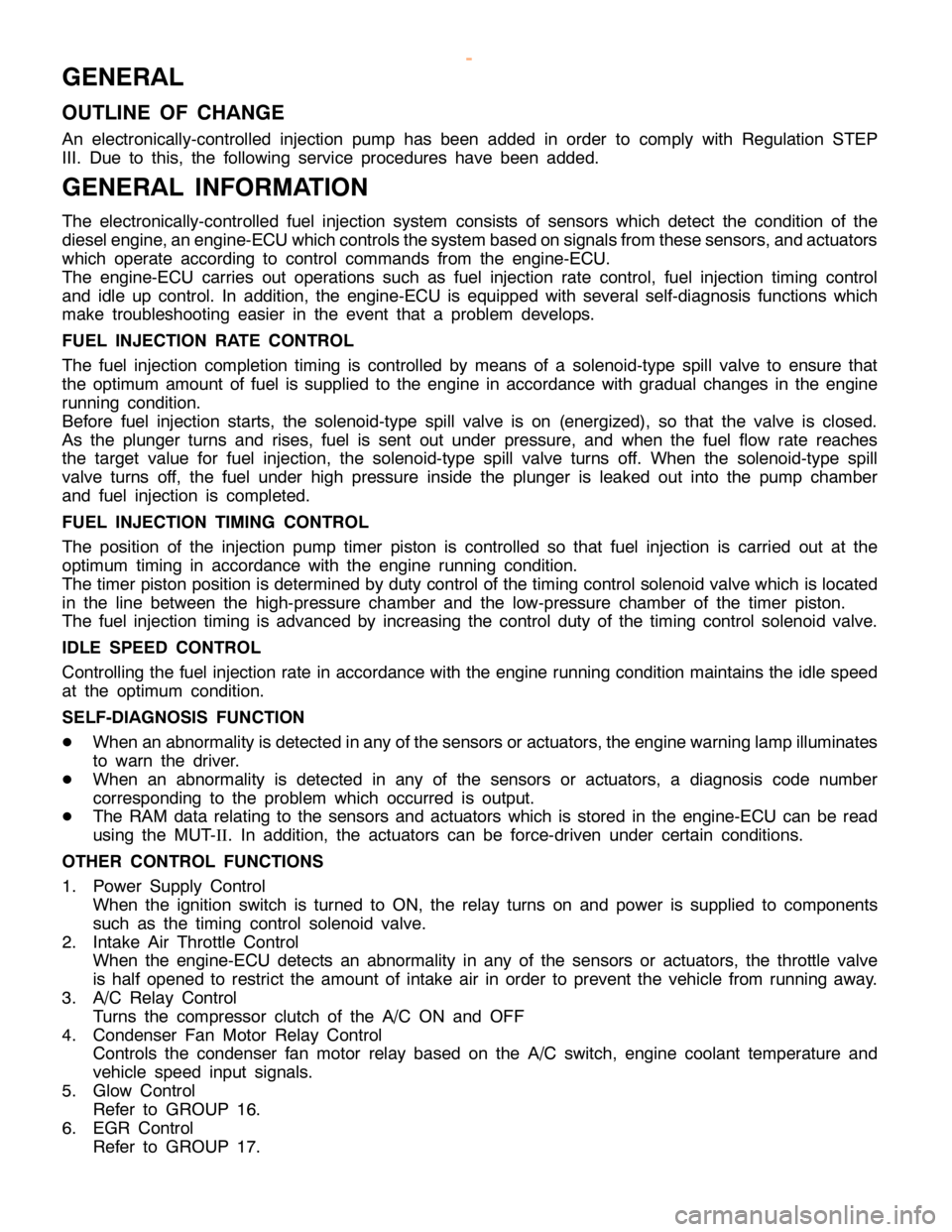

DIESEL FUEL <4D5-stepIII>-General/General Information13E-2

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 638 of 1839

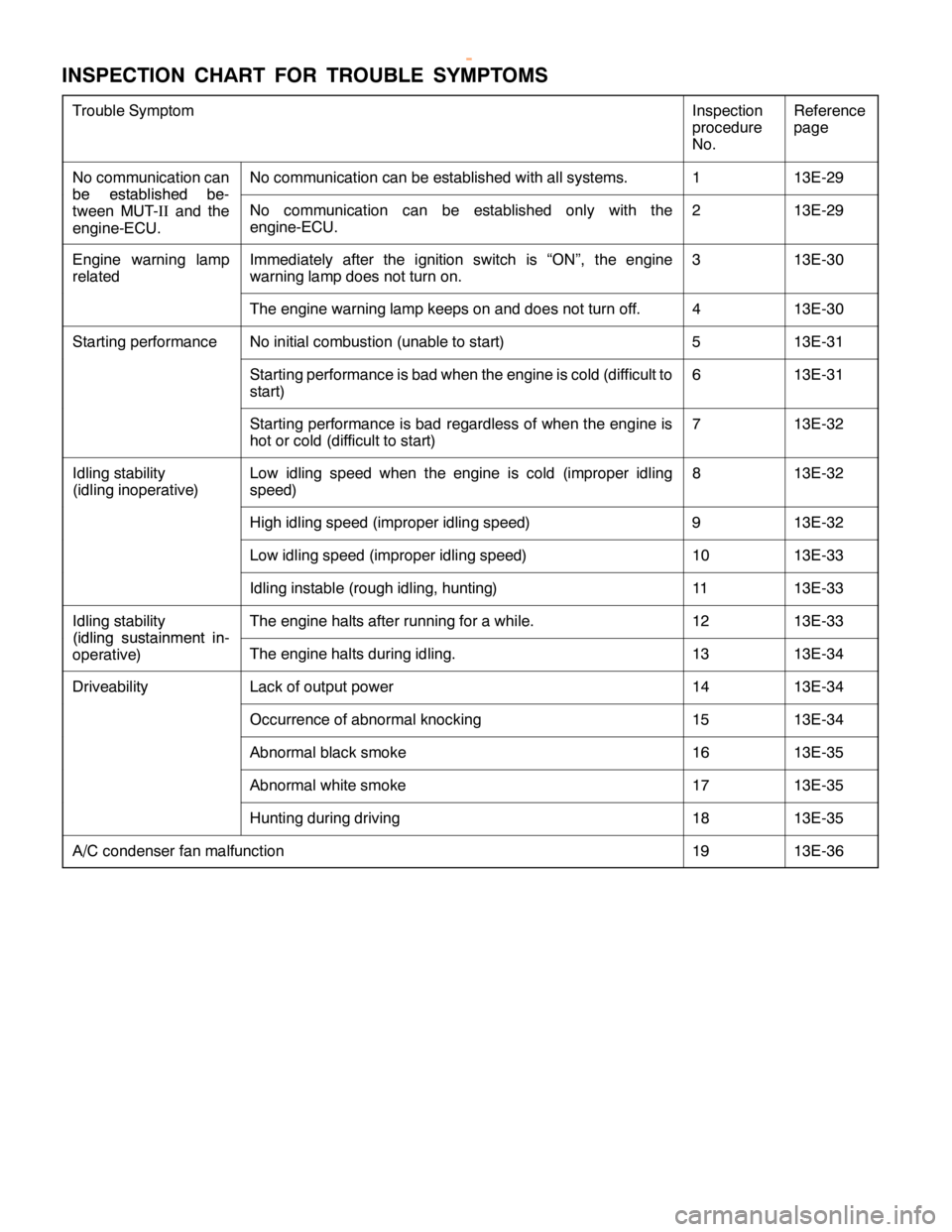

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-28

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble SymptomInspection

procedure

No.Reference

page

No communication can

beestablishedbe

No communication can be established with all systems.113E-29

beestablishedbe-

tween MUT-IIand the

engine-ECU.

No communication can be established only with the

engine-ECU.213E-29

Engine warning lamp

relatedImmediately after the ignition switch is “ON”, the engine

warning lamp does not turn on.313E-30

The engine warning lamp keeps on and does not turn off.413E-30

Starting performanceNo initial combustion (unable to start)513E-31

Starting performance is bad when the engine is cold (difficult to

start)613E-31

Starting performance is bad regardless of when the engine is

hot or cold (difficult to start)713E-32

Idling stability

(idling inoperative)Low idling speed when the engine is cold (improper idling

speed)813E-32

High idling speed (improper idling speed)913E-32

Low idling speed (improper idling speed)1013E-33

Idling instable (rough idling, hunting)1113E-33

Idling stability

(idlingsustainmentin

The engine halts after running for a while.1213E-33

(idling sustainmentin-

operative)

The engine halts during idling.1313E-34

DriveabilityLack of output power1413E-34

Occurrence of abnormal knocking1513E-34

Abnormal black smoke1613E-35

Abnormal white smoke1713E-35

Hunting during driving1813E-35

A/C condenser fan malfunction1913E-36

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 640 of 1839

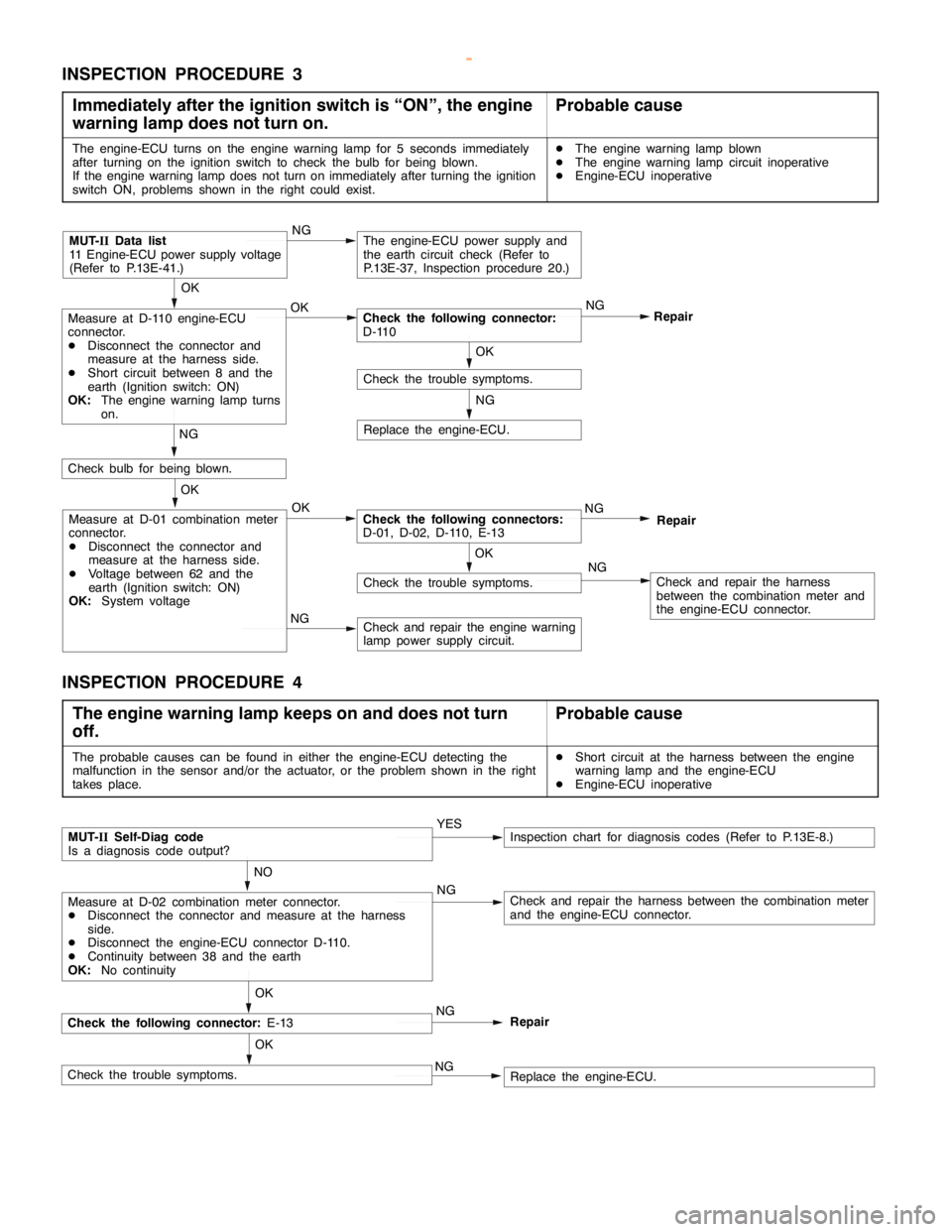

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-30

INSPECTION PROCEDURE 3

Immediately after the ignition switch is “ON”, the engine

warning lamp does not turn on.

Probable cause

The engine-ECU turns on the engine warning lamp for 5 seconds immediately

after turning on the ignition switch to check the bulb for being blown.

If the engine warning lamp does not turn on immediately after turning the ignition

switch ON, problems shown in the right could exist.DThe engine warning lamp blown

DThe engine warning lamp circuit inoperative

DEngine-ECU inoperative

NG

Replace the engine-ECU.

NG

Check and repair the harness

between the combination meter and

the engine-ECU connector.

NG

Check and repair the engine warning

lamp power supply circuit.

OK

Check the trouble symptoms.

OK

Measure at D-01 combination meter

connector.

DDisconnect the connector and

measure at the harness side.

DVoltage between 62 and the

earth (Ignition switch: ON)

OK:System voltageOKCheck the following connectors:

D-01, D-02, D-110, E-13NG

Repair

NG

Check bulb for being blown.

OK

Check the trouble symptoms.

OK

Measure at D-110 engine-ECU

connector.

DDisconnect the connector and

measure at the harness side.

DShort circuit between 8 and the

earth (Ignition switch: ON)

OK:The engine warning lamp turns

on.OKCheck the following connector:

D-110NG

Repair

MUT-IIData list

11 Engine-ECU power supply voltage

(Refer to P.13E-41.)NGThe engine-ECU power supply and

the earth circuit check (Refer to

P.13E-37, Inspection procedure 20.)

INSPECTION PROCEDURE 4

The engine warning lamp keeps on and does not turn

off.

Probable cause

The probable causes can be found in either the engine-ECU detecting the

malfunction in the sensor and/or the actuator, or the problem shown in the right

takes place.DShort circuit at the harness between the engine

warning lamp and the engine-ECU

DEngine-ECU inoperative

Check the following connector:E-13

NO

Measure at D-02 combination meter connector.

DDisconnect the connector and measure at the harness

side.

DDisconnect the engine-ECU connector D-110.

DContinuity between 38 and the earth

OK:No continuityNGCheck and repair the harness between the combination meter

and the engine-ECU connector.

OK

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

Check the trouble symptoms.OKReplace the engine-ECU. NGNG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 653 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-43

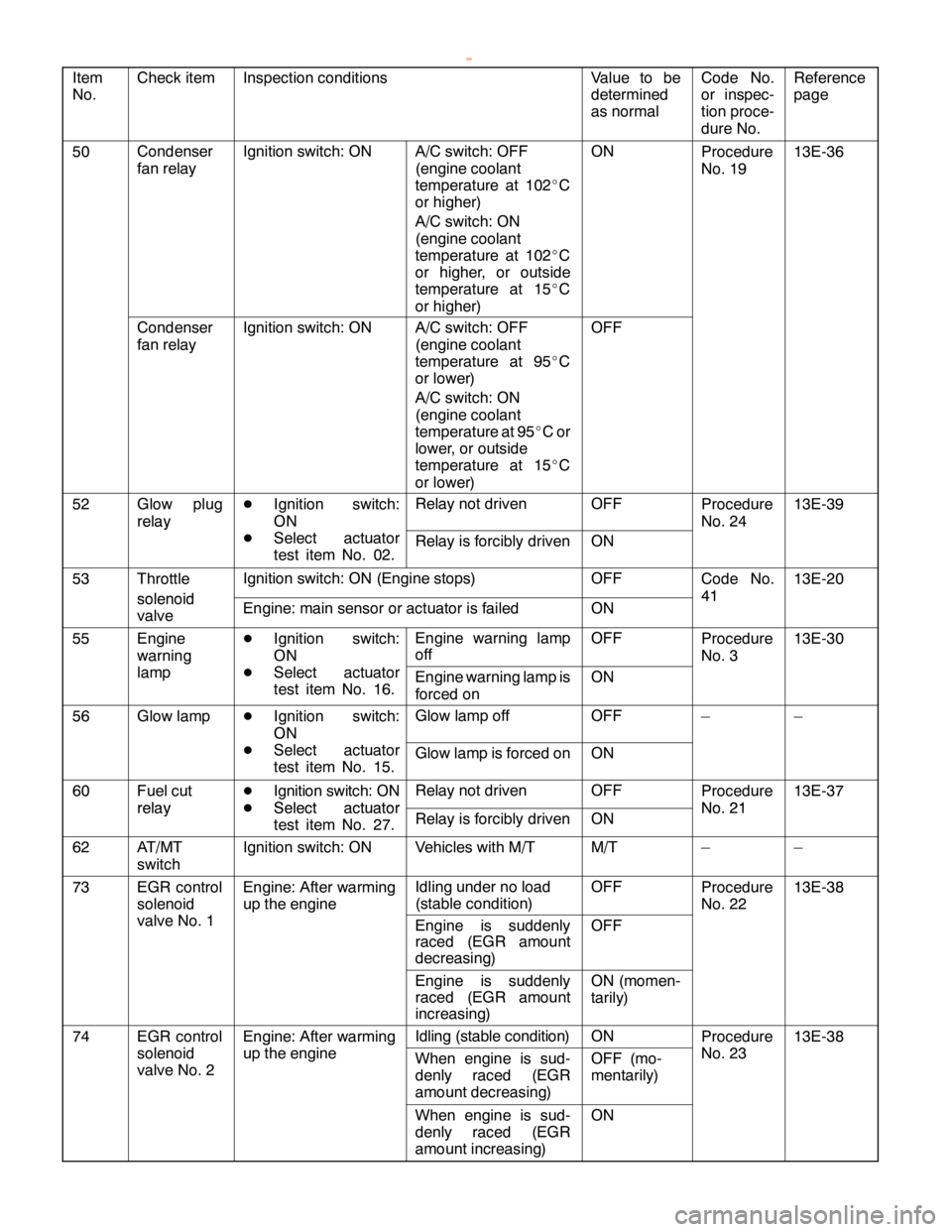

Item

No.Check itemInspection conditionsValue to be

determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

50Condenser

fan relayIgnition switch: ONA/C switch: OFF

(engine coolant

temperature at 102_C

or higher)

A/C switch: ON

(engine coolant

temperature at 102_C

or higher, or outside

temperature at 15_C

or higher)ONProcedure

No. 1913E-36

Condenser

fan relayIgnition switch: ONA/C switch: OFF

(engine coolant

temperature at 95_C

or lower)

A/C switch: ON

(engine coolant

temperature at 95_Cor

lower, or outside

temperature at 15_C

or lower)OFF

52Glow plug

relayDIgnition switch:

ONRelay not drivenOFFProcedure

No. 2413E-39

relayON

DSelect actuator

test item No. 02.Relay is forcibly drivenON

No.24

53Throttle

solenoid

Ignition switch: ON (Engine stops)OFFCode No.

41

13E-20

solenoid

valveEngine: main sensor or actuator is failedON41

55Engine

warningDIgnition switch:

ON

S

Engine warning lamp

offOFFProcedure

No. 313E-30

g

lampDSelect actuator

test item No. 16.Engine warning lamp is

forced onON

56Glow lampDIgnition switch:

ONGlow lamp offOFF––

ON

DSelect actuator

test item No. 15.Glow lamp is forced onON

60Fuel cut

relay

DIgnition switch: ON

DSelectactuator

Relay not drivenOFFProcedure

No21

13E-37

relayDSelectactuator

test item No. 27.Relay is forcibly drivenONNo.21

62AT/MT

switchIgnition switch: ONVehicles with M/TM/T––

73EGR control

solenoidEngine: After warming

up the engineIdling under no load

(stable condition)OFFProcedure

No. 2213E-38

valve No. 1

pg

Engine is suddenly

raced (EGR amount

decreasing)OFF

Engine is suddenly

raced (EGR amount

increasing)ON (momen-

tarily)

74EGR control

lid

Engine: After warming

hi

Idling (stable condition)ONProcedure

N

13E-38

solenoid

valve No. 2

gg

up the engineWhen engine is sud-

denly raced (EGR

amount decreasing)OFF (mo-

mentarily)No. 23

When engine is sud-

denly raced (EGR

amount increasing)ON

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk