belt MITSUBISHI MONTERO 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 143 of 1839

ENGINE <4M4> -General Information/Service Specifications11C-2

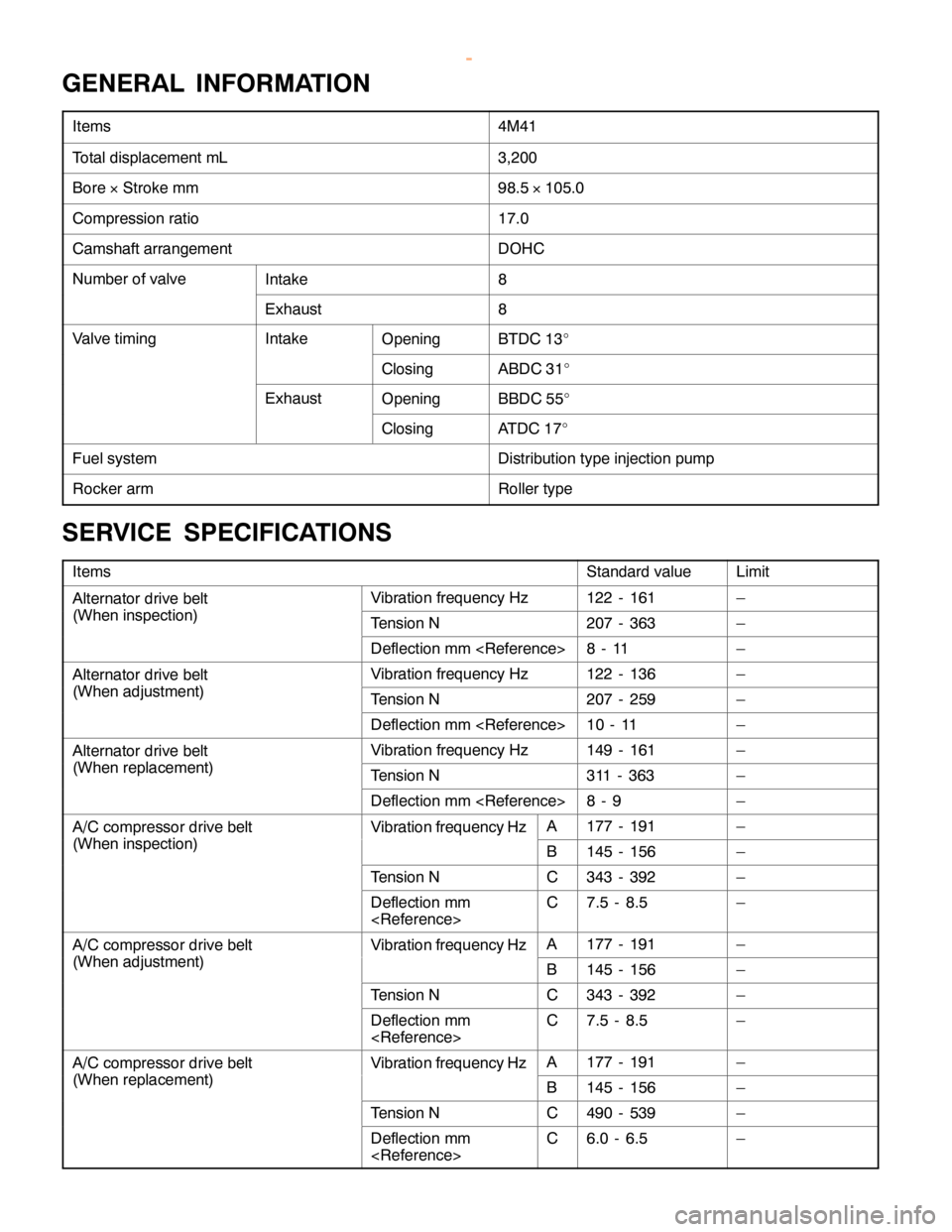

GENERAL INFORMATION

Items4M41

Total displacement mL3,200

Bore´Stroke mm98.5´105.0

Compression ratio17.0

Camshaft arrangementDOHC

Number of valveIntake8

Exhaust8

Valve timingIntakeOpeningBTDC 13_

ClosingABDC 31_

ExhaustOpeningBBDC 55_

ClosingATDC 17_

Fuel systemDistribution type injection pump

Rocker armRoller type

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Alternator drive beltVibration frequency Hz122 - 161–

(When inspection)Tension N207 - 363–

Deflection mm

Alternator drive beltVibration frequency Hz122 - 136–

(When adjustment)Tension N207 - 259–

Deflection mm

Alternator drive beltVibration frequency Hz149 - 161–

(When replacement)Tension N311 - 363–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When inspection)B145 - 156–

Tension NC343 - 392–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When adjustment)B145 - 156–

Tension NC343 - 392–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When replacement)B145 - 156–

Tension NC490 - 539–

Deflection mm

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 144 of 1839

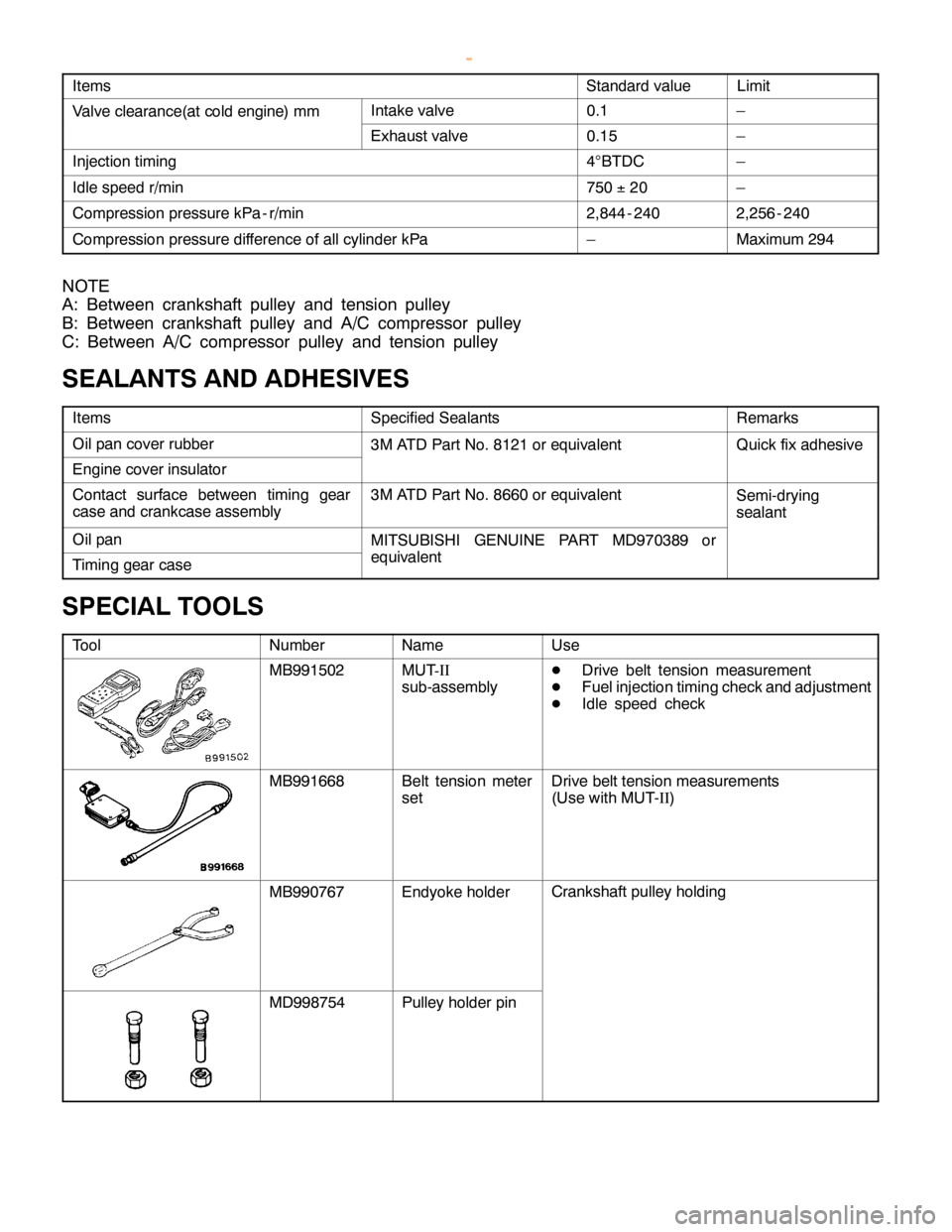

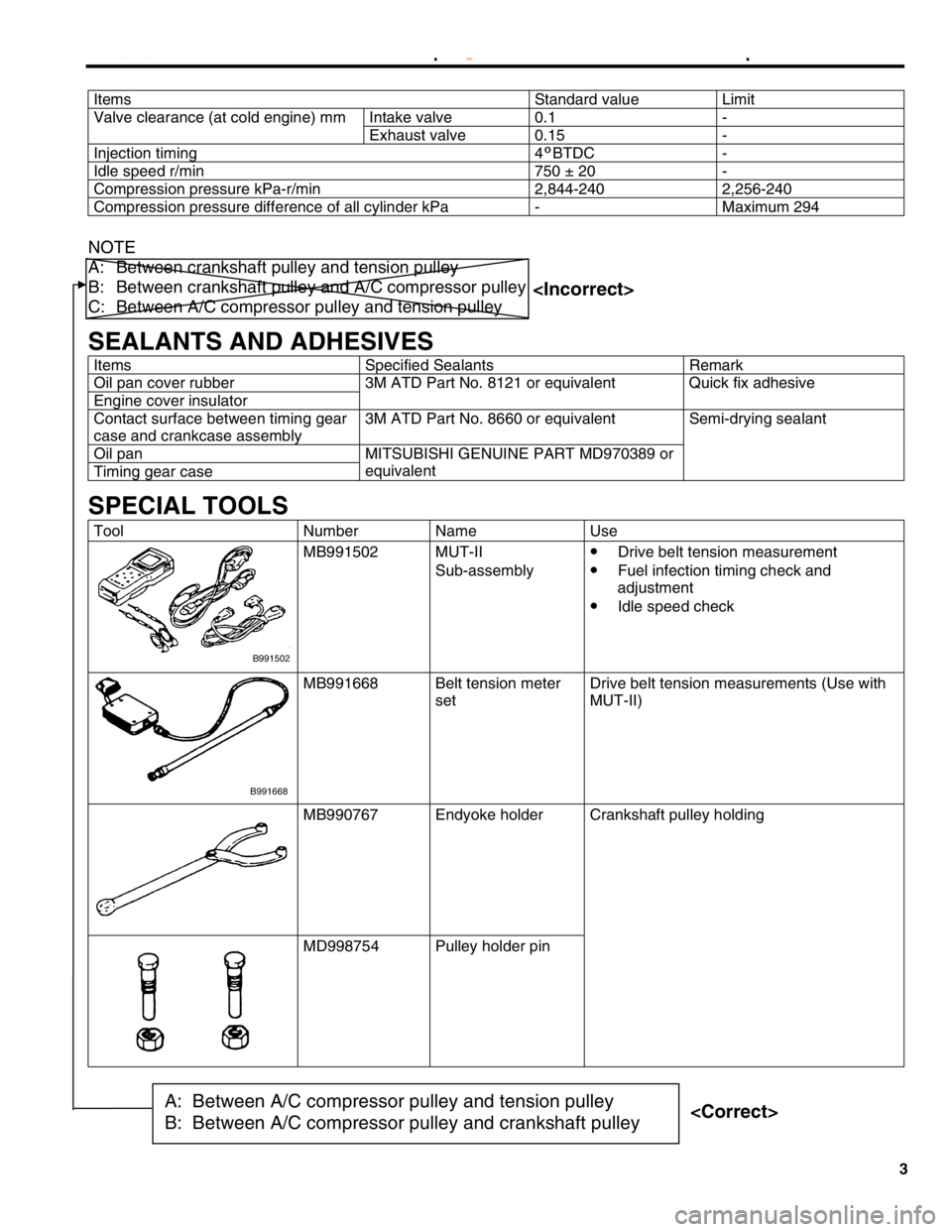

V

alv e cle ara nce (a t co ld engin e) m m I

n ta ke va lv e 0

.1 –

E

xh aust va lv e 0

.1 5 –

I

n je ctio n tim in g 4

°B TD C –

I

d le sp eed r/m in 7

50 ±20 –

C

om pre ssio n pre ssu re kP a-r/m in 2

,8 44 -2 40 2

,2 56 -2 40 C

om pre ssio n pre ssu re dif f e re nce of all cylin der kP a – M

axim um 294 S

pecif ie d Seala nts R

em ark s O

il p an co ve r ru bber 3

M AT D Part N o. 8121 or equiv a le nt Q

uic k fix adhesiv e E

ngin e co ve r in su la to r C

onta ct su rfa ce betw een tim in g gear

c a se and cra nkca se asse m bly 3

M AT D Part N o. 8660 or equiv a le nt S

em i- d ry in g

s e ala nt O

il p an M

IT S U BIS H I GEN UIN E PA R T MD970389 or T

im in g gear ca se e

quiv a le nt N

um ber N

am e U

se M

B991502 M

UT-II

s u b-a sse m bly M

B991668 B

elt te nsio n mete r

s e t D

riv e belt te nsio n measu re m ents

( U se wit h M UT-II ) M

B990767 E

ndyo ke hold er C

ra nksh aft pulle y hold in g M

D998754 P

ulle y hold er pin

Page 146 of 1839

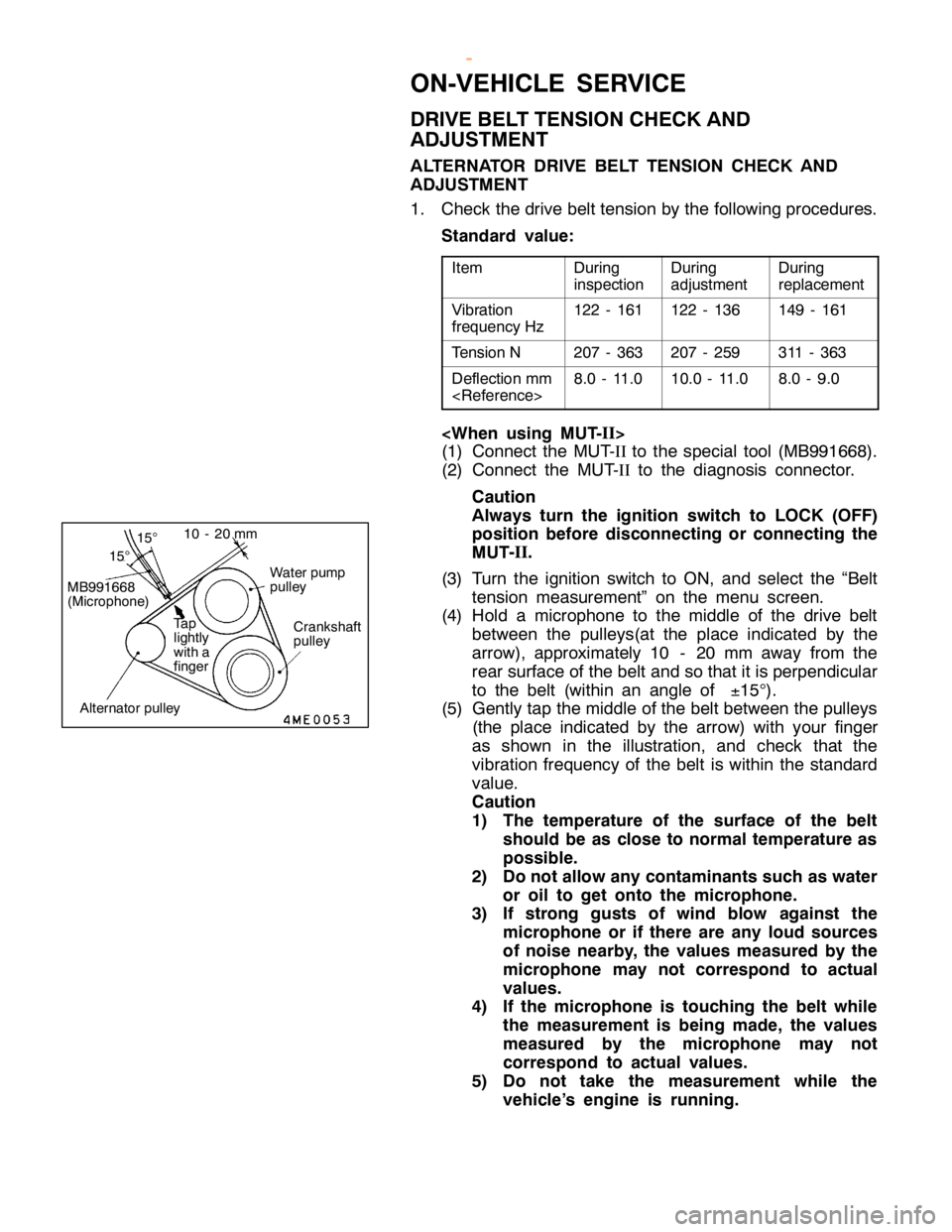

O

N-V EH IC LE SER VIC E

D RIV E BELT TE N SIO N CHEC K AND

A DJU STM EN T

A LT E R NATO R DRIV E BELT TE N SIO N CHEC K AND

A DJU STM EN T

1 . Check th e driv e belt te nsio n by th e fo llo w in g pro ce dure s.

S ta n dard valu e:

I te m D

urin g

i n sp ectio n D

urin g

a dju stm ent D

urin g

r e pla ce m ent V

ib ra tio n

f r e quency Hz 1

22 -161 1

22 -136 1

49 -161 T

e nsio n N 2

07 -363 2

07 -259 3

11 -363 D

efle ctio n mm

< R efe re nce > 8

.0 -11 .0 1

0.0 -11 .0 8

.0 -9.0 A

lt e rn ato r pulle y w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 168 of 1839

ENGINE <4M4> -Cylinder Head Gasket11C-27

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DEngine Coolant Drain and Refill

(Refer to GROUP 14 - On-vehicle Service.)

DEngine Oil Check andRefill

(Refer to GROUP 12 - On-vehicle Service.)

DFuel Line Air-bleeding

(Refer to GROUP 13C - On-vehicle Service.)

DDrive Belt TensionCheck and Adjustment

(Refer to P.11C-5.)

(Refer to P.11C-20.)

DCooling Fan and Fan Clutch Assembly Removal and

Installation (Refer to GROUP 14.)

DIntake Manifold Removal and Installation

(Refer to GROUP15.)

DTurbocharger Removal and Installation

(Refer to GROUP15.)

DExhaust Manifold Removal and Installation

(Refer to GROUP15.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 190 of 1839

2

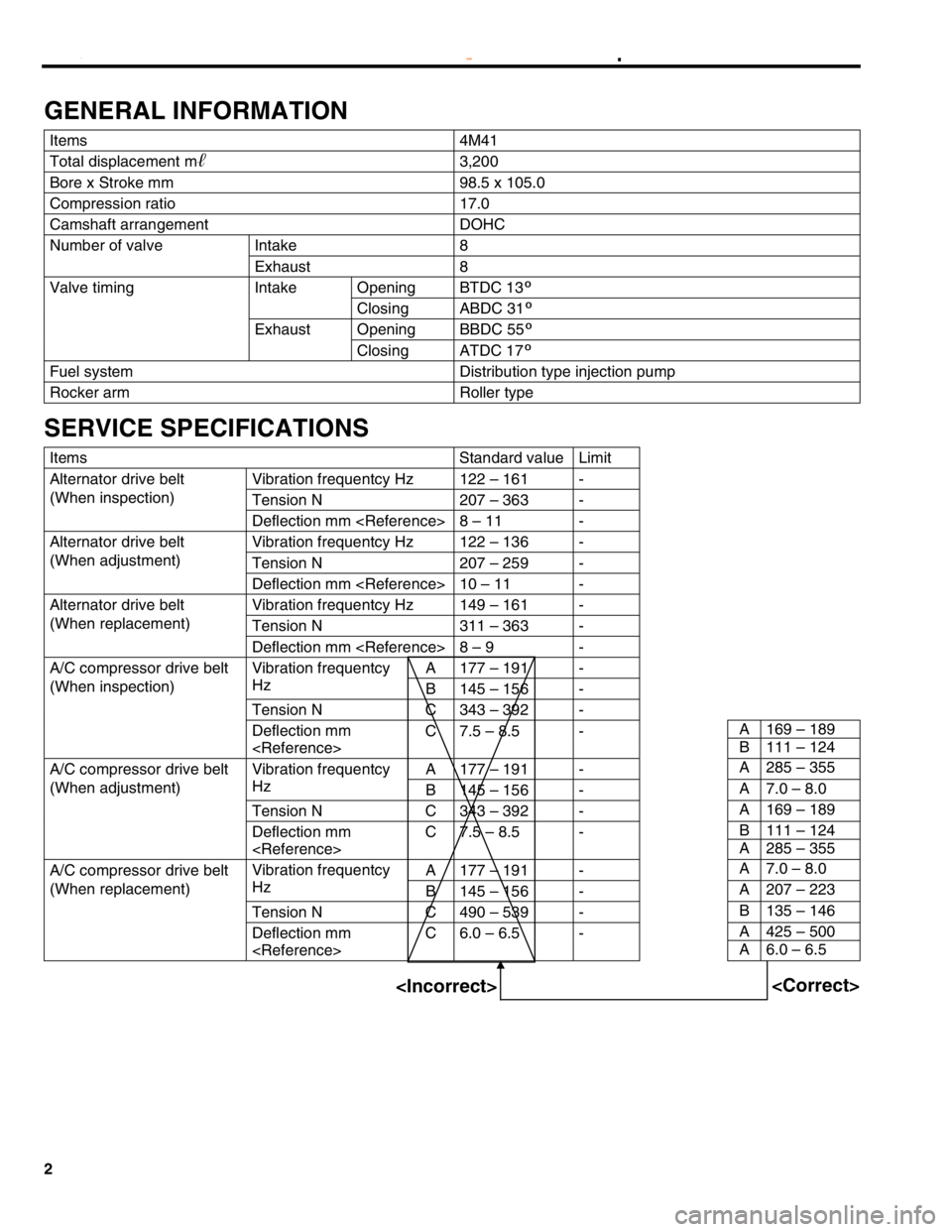

GENERAL INFORMATION

Items 4M41

Total displacement mℓ

3,200

Bore x Stroke mm 98.5 x 105.0

Compression ratio 17.0

Camshaft arrangement DOHC

Intake 8Number of valve

Exhaust 8

Opening BTDC 13ºIntake

Closing ABDC 31º

Opening BBDC 55º

Valve timing

Exhaust

Closing ATDC 17º

Fuel system Distribution type injection pump

Rocker arm Roller type

SERVICE SPECIFICATIONS

Items Standard value Limit

Vibration frequentcy Hz 122 – 161 -

Tension N 207 – 363 -

Alternator drive belt

(When inspection)

Deflection mm

Vibration frequentcy Hz 122 – 136 -

Tension N 207 – 259 -

Alternator drive belt

(When adjustment)

Deflection mm

Vibration frequentcy Hz 149 – 161 -

Tension N 311 – 363 -

Alternator drive belt

(When replacement)

Deflection mm

A 177 – 191 -Vibration frequentcy

Hz

B 145 – 156 -

Tension N C 343 – 392 -

A 169 – 189

A/C compressor drive belt

(When inspection)

Deflection mm

B 111 – 124

A 177 – 191 -A 285 – 355Vibration frequentcy

Hz

B 145 – 156 -A 7.0 – 8.0

Tension N C 343 – 392 -A 169 – 189

B 111 – 124

A/C compressor drive belt

(When adjustment)

Deflection mm

A 285 – 355

A 177 – 191 -A 7.0 – 8.0Vibration frequentcy

Hz

B 145 – 156 -A 207 – 223

Tension N C 490 – 539 -B 135 – 146

A 425 – 500

A/C compressor drive belt

(When replacement)

Deflection mm

A 6.0 – 6.5

11C-2ENGINE <4M4> - General Information/Service Specifications

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 191 of 1839

I

n ta ke v a lv e 0.1 -V

alv e c le ara nce ( a t c o ld e ng in e) m m

Exh aust v a lv e 0.1 5 -I

n je ctio n tim in g 4º

B TD C -I

d le s p ee d r /m in 750 ± 2 0 -C

om pre ssio n p re ssu re k P a-r/m in 2,8 4 4-2 40 2,2 5 6-2 40 C

om pre ssio n p re ssu re d if fe re nce o f a ll c ylin der k P a - Maxim um 2 94 O

il p an c o ve r r u bber E

ng in e c o ve r in su la to r 3

M A TD P art N o. 8 1 21 o r e qu iv a le nt Quic k fix a d hesiv e C

onta ct s u rfa ce b e tw ee n t im in g g ear

c a se a nd c ra nkca se a sse m bly 3

M A TD P art N o. 8 6 60 o r e qu iv a le nt O

il p an T

im in g g ear c a se M

IT S U BIS H I G EN UIN E P AR T M D9703 89 o r

e qu iv a le nt S

em i- d ry in g s e a la nt M

B9915 02 MUT-II

S ub-a sse m bly •

D

riv e b e lt t e nsio n m easu re m ent

• F

uel in fe ctio n tim in g c h eck a nd

a dju stm en t

• I

d le s p ee d c h eck M

B9916 68 Belt te nsio n m ete r

s e t D

riv e b e lt t e nsio n m easu re m ents ( U se w it h

M UT-II) M

B9907 67 Endyo ke h o ld er M

D99 875 4 Pulle y h old er p in C

ra nksh aft p ulle y h old in g

Page 291 of 1839

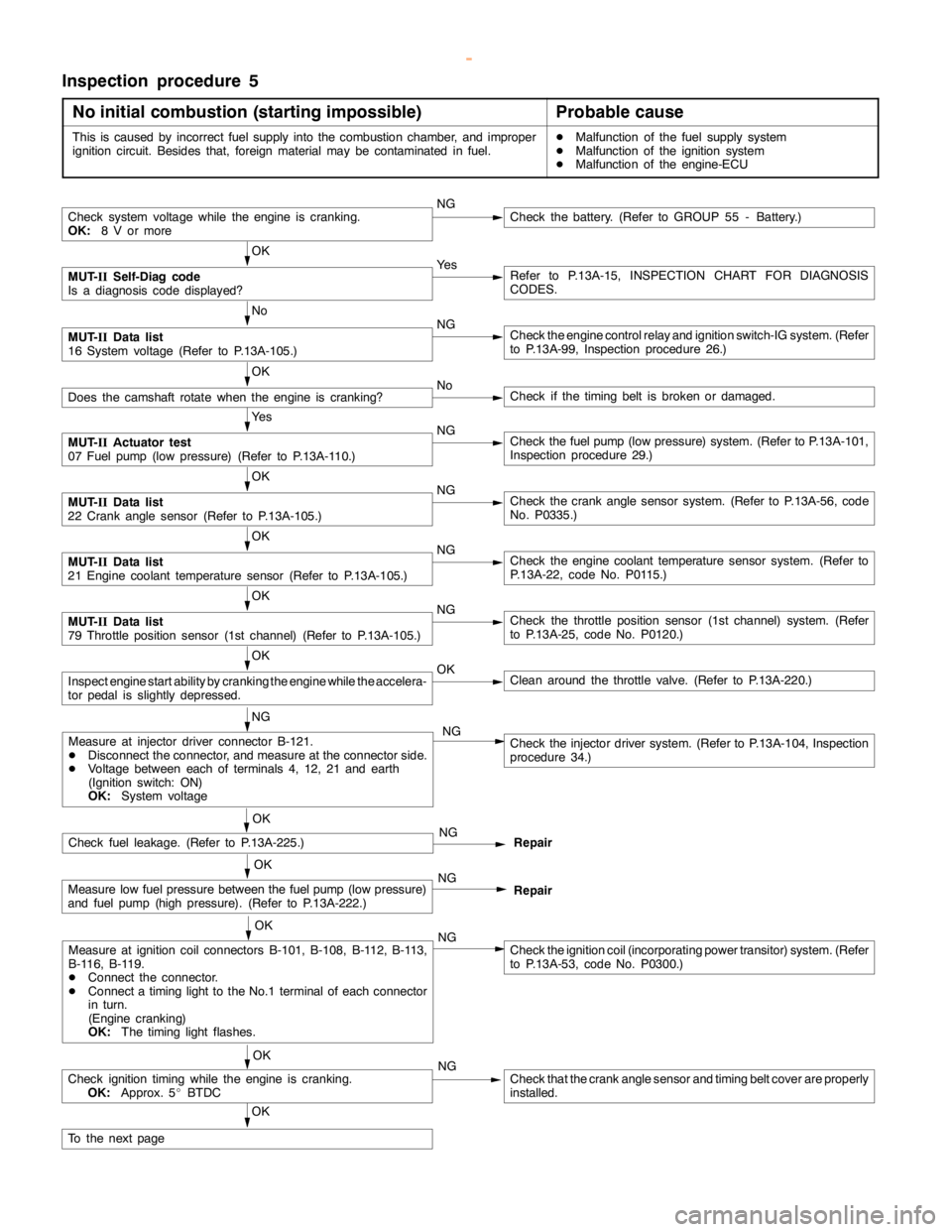

GDI -Troubleshooting

Inspection procedure 5

No initial combustion (starting impossible)

Probable cause

This is caused by incorrect fuel supply into the combustion chamber, and improper

ignition circuit. Besides that, foreign material may be contaminated in fuel.DMalfunction of the fuel supply system

DMalfunction of the ignition system

DMalfunction of the engine-ECU

Check system voltage while theengine iscranking.

OK:

8 V or moreNGCheck the battery. (Refer to GROUP 55 - Battery.)

OK

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIData list

16 System voltage (Refer to P.13A-105.)NGCheck theengine controlrelay and ignition switch-IG system. (Refer

to P.13A-99, Inspection procedure 26.)

OK

Does the camshaft rotate when theengine is cranking?NoCheck if thetiming belt isbroken ordamaged.

Ye s

MUT-

IIActuator test

07 Fuel pump(low pressure) (Refer to P.13A-110.)NGCheck the fuelpump(low pressure) system. (Refer to P.13A-101,

Inspection procedure 29.)

OK

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)NGCheck the crankanglesensor system. (Refer to P.13A-56, code

No. P0335.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor system. (Refer to

P.13A-22, code No. P0115.)

OK

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle position sensor (1st channel) system. (Refer

to P.13A-25, code No. P0120.)

OK

Inspectenginestart ability by cranking theengine while theaccelera-

tor pedal isslightly depressed.OKClean around the throttle valve. (Refer to P.13A-220.)

NG

Check fuel leakage. (Refer to P.13A-225.)NG

Repair

OK

Measure low fuel pressure between the fuelpump(low pressure)

and fuel pump (highpressure). (Refer to P.13A-222.)NG

Repair

OK

Measure at ignition coil connectors B-101, B-108, B-112, B-113,

B-116, B-119.

DConnect the connector.

DConnect atiming light to theNo.1 terminal of each connector

in turn.

(Engine cranking)

OK:

The timing lightflashes.NGCheck the ignition coil (incorporating power transitor) system. (Refer

to P.13A-53, code No. P0300.)

OK

Check ignitiontiming while the engine iscranking.

OK:

Approx. 5_BTDCNGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

To the nextpage

Measure at injector driver connector B-121.

DDisconnect the connector, and measure at the connector side.

DVoltage between each of terminals 4, 12, 21 and earth

(Ignition switch: ON)

OK:

System voltageCheck the injector driver system. (Refer to P.13A-104, Inspection

procedure 34.) NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 293 of 1839

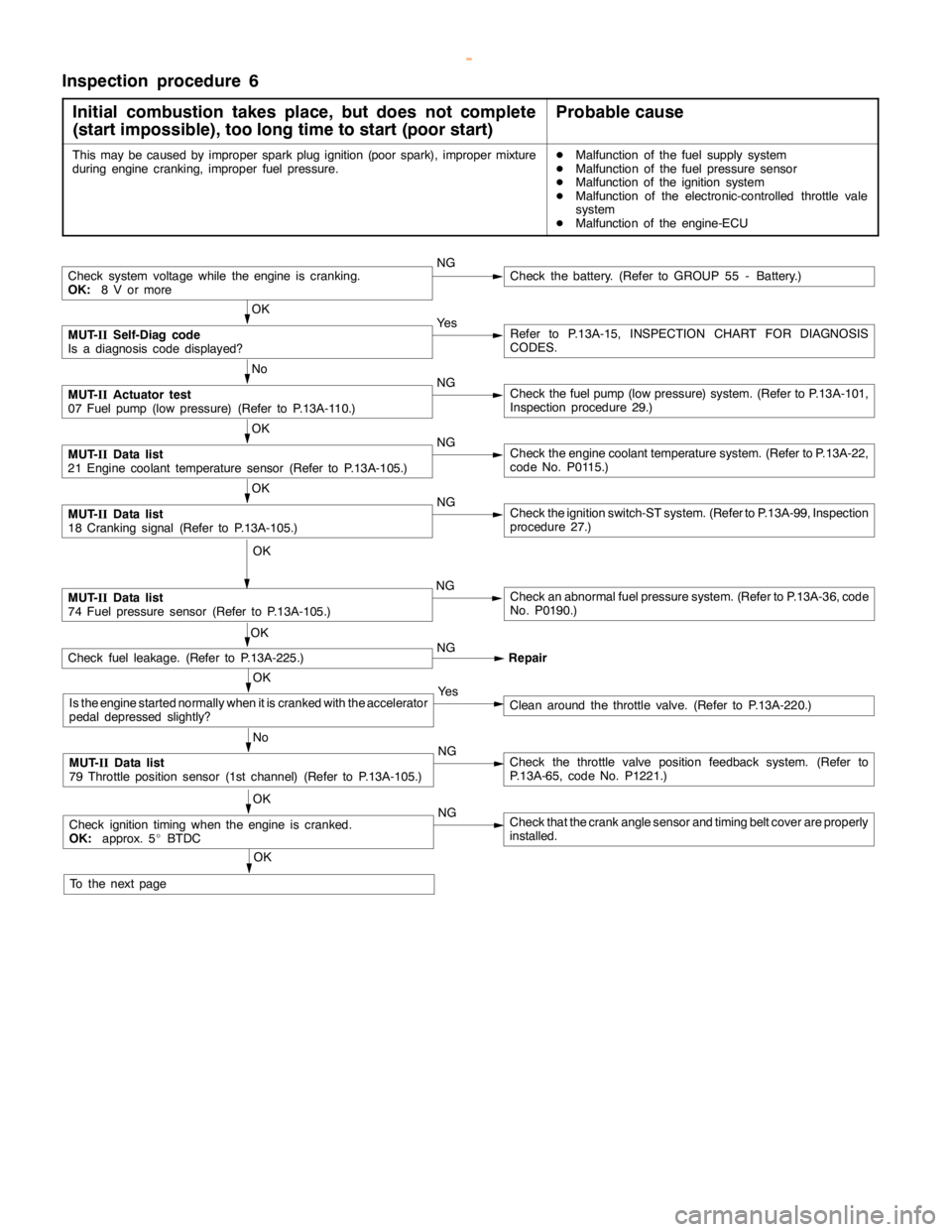

GDI -Troubleshooting

Inspection procedure 6

Initial combustion takes place, but does not complete

(start impossible), too long time to start (poor start)

Probable cause

This may be caused by improper sparkplug ignition (poorspark), improper mixture

during enginecranking, improper fuel pressure.DMalfunction of the fuel supply system

DMalfunction of the fuel pressure sensor

DMalfunction of the ignition system

DMalfunction of the electronic-controlled throttle vale

system

DMalfunction of the engine-ECU

Check system voltage while theengine iscranking.

OK:

8 V or moreNGCheck the battery. (Refer to GROUP 55 - Battery.)

OK

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIActuator test

07 Fuel pump(low pressure) (Refer to P.13A-110.)NGCheck the fuelpump(low pressure) system. (Refer to P.13A-101,

Inspection procedure 29.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesystem. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

18 Cranking signal (Refer to P.13A-105.)NGCheck the ignition switch-ST system. (Refer to P.13A-99, Inspection

procedure 27.)

OK

MUT-

IIData list

74 Fuel pressure sensor (Refer to P.13A-105.)NGCheck an abnormal fuel pressure system. (Refer to P.13A-36, code

No. P0190.)

Check fuel leakage. (Refer to P.13A-225.)NG

Repair

OK

Is the enginestarted normally when it is cranked with the accelerator

pedal depressed slightly?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

Check ignitiontimingwhen theengine iscranked.

OK:

approx. 5_BTDCNGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

To the nextpageOK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 296 of 1839

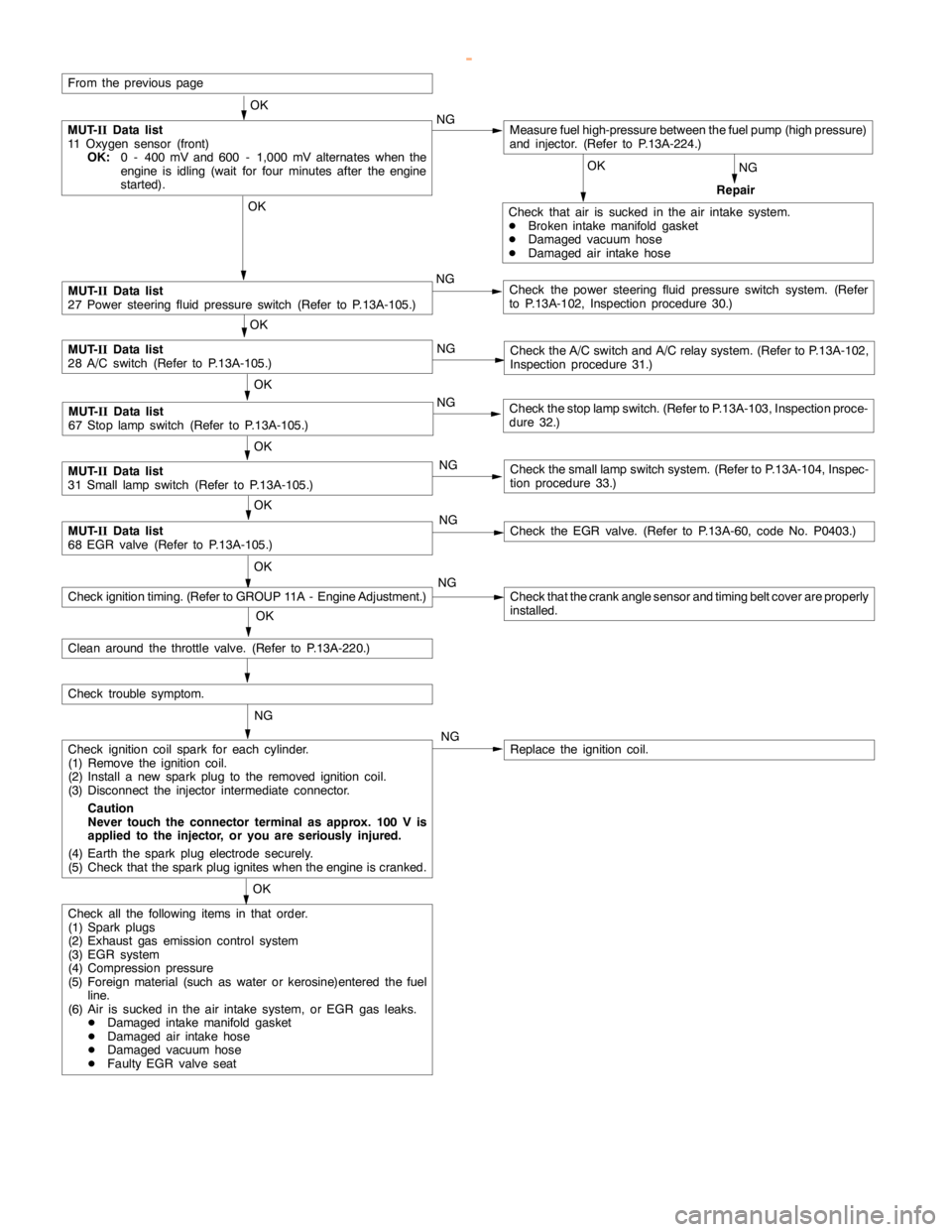

GDI -Troubleshooting

OK

Check that air is sucked in the air intake system.

DBroken intake manifold gasket

DDamaged vacuum hose

DDamaged air intake hose

From the previouspage

OK

MUT-

IIData list

27 Power steering fluid pressure switch (Refer to P.13A-105.)NGCheck the power steering fluid pressure switch system. (Refer

to P.13A-102, Inspection procedure 30.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

OK

MUT-

IIData list

67 Stoplampswitch (Refer to P.13A-105.)NGCheck the stoplampswitch. (Refer to P.13A-103, Inspection proce-

dure 32.)

OK

MUT-

IIData list

31 Small lampswitch (Refer to P.13A-105.)NGCheck the smalllampswitch system. (Refer to P.13A-104, Inspec-

tion procedure 33.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve. (Refer to P.13A-60, code No. P0403.)

OK

NG

Check that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check trouble symptom.

Check all the following items in that order.

(1) Spark plugs

(2) Exhaust gas emission control system

(3) EGR system

(4) Compression pressure

(5) Foreign material (such as water or kerosine)entered the fuel

line.

(6) Air is sucked in the air intake system, or EGR gas leaks.

DDamaged intake manifoldgasket

DDamaged air intake hose

DDamaged vacuum hose

DFaulty EGR valve seat

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).NG

NG

Repair

Measure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)

Clean around the throttle valve. (Refer to P.13A-220.)

NG

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 298 of 1839

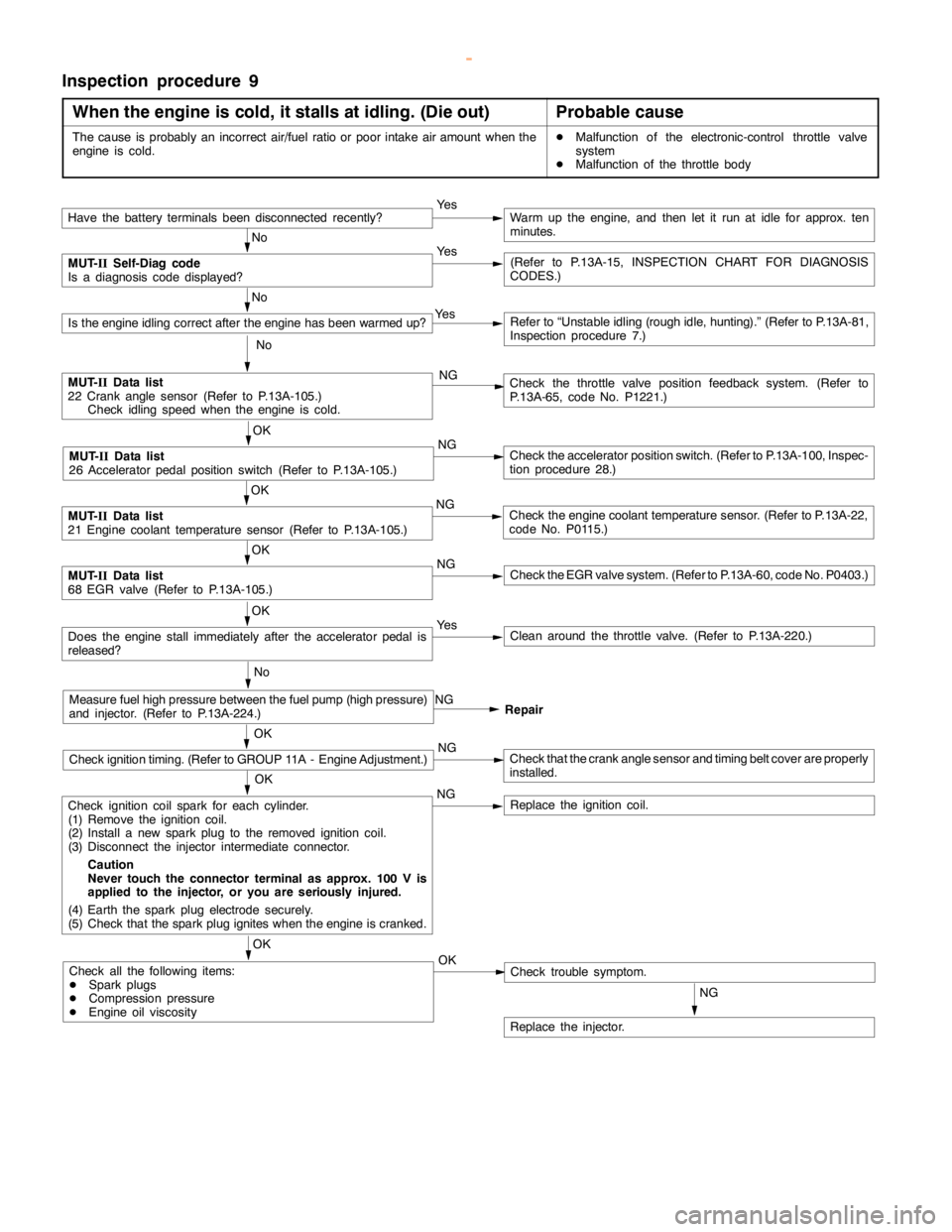

GDI -Troubleshooting

Inspection procedure 9

When the engine is cold, it stalls at idling. (Die out)

Probable cause

The cause is probably an incorrect air/fuel ratio or poor intake airamountwhen the

engine iscold.DMalfunction of the electronic-control throttle valve

system

DMalfunction of the throttle body

Have the battery terminalsbeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

Is the engine idlingcorrect after theengine has been warmed up?Ye sRefer to “Unstableidling (rough idle, hunting).”(Refer to P.13A-81,

Inspection procedure 7.)

No

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)

Checkidlingspeed when theengine iscold.NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the accelerator position switch. (Refer to P.13A-100, Inspec-

tion procedure 28.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve system. (Refer to P.13A-60, code No. P0403.)

OK

Does theenginestall immediately after the acceleratorpedal is

released?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

Measure fuel highpressure between the fuelpump (highpressure)

and injector. (Refer to P.13A-224.)NG

Repair

OK

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)NGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check all the following items:

DSpark plugs

DCompression pressure

DEngine oilviscosityNGCheck trouble symptom. OK

Replace the injector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk