MITSUBISHI MONTERO 2000 Service Repair Manual

MONTERO 2000

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57331/w960_57331-0.png

MITSUBISHI MONTERO 2000 Service Repair Manual

Trending: fog light, gearbox, power steering fluid, Jump, check oil, sport mode, fuel

Page 851 of 1839

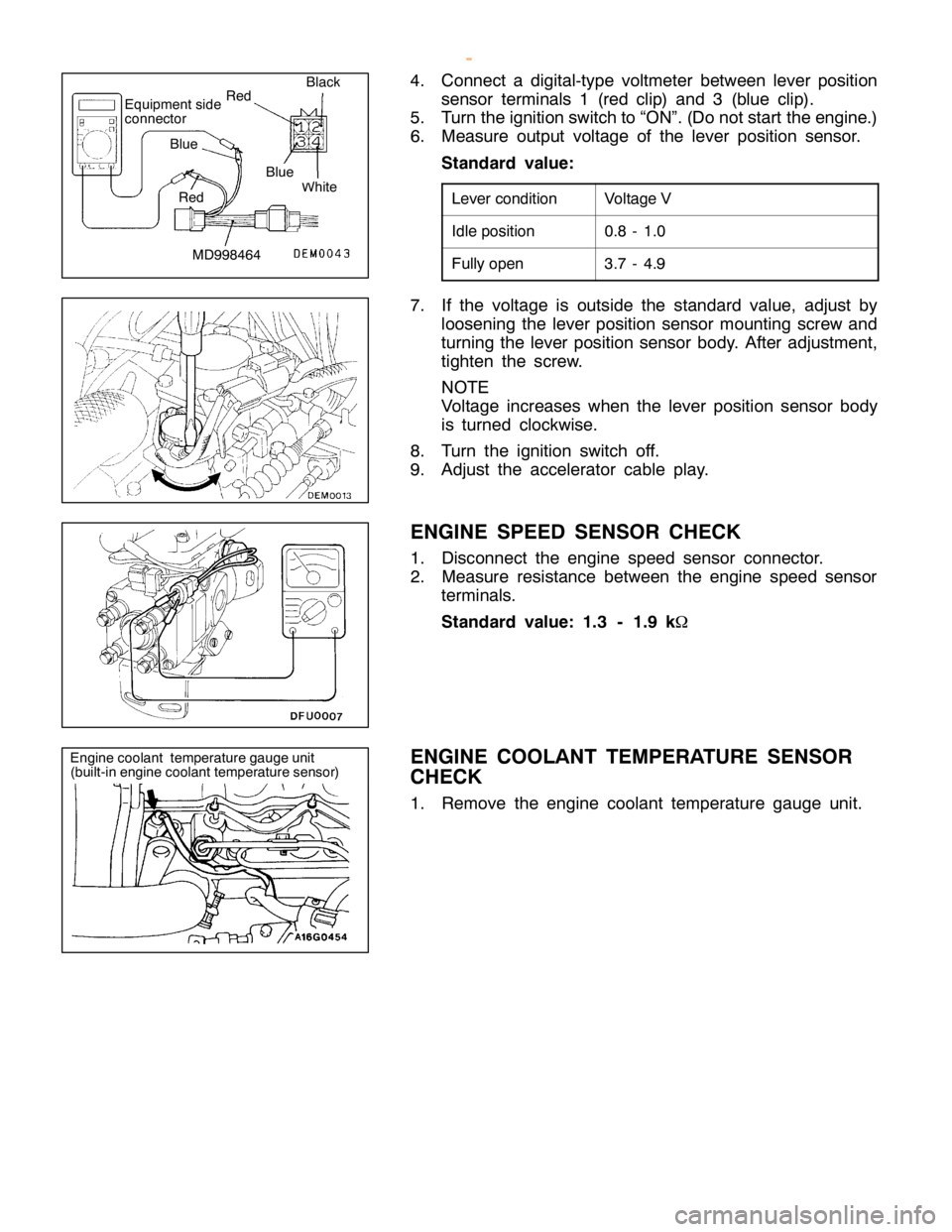

V

olt a ge V I

d le posit io n 0

.8 -1.0 F

ully open 3

.7 -4.9 M

D998464 W

hit e

R

ed B

la ck B

lu e E

ngin e co ola nt te m pera tu re gauge unit

( b uilt - in engin e co ola ntte m pera tu re se nso r)

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 852 of 1839

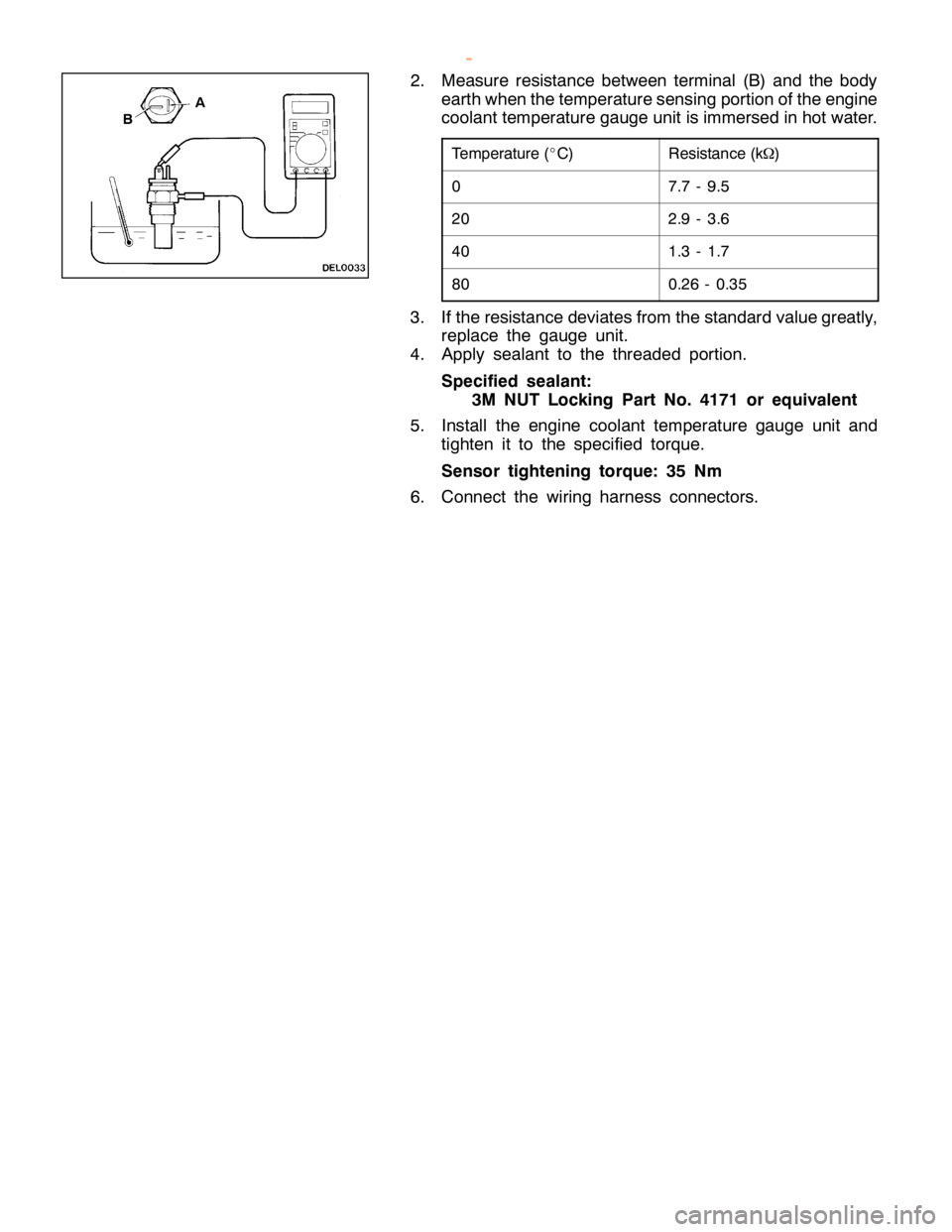

R

esis ta nce (k W ) 0 7

.7 -9.5 2

0 2

.9 -3.6 4

0 1

.3 -1.7 8

0 0

.2 6 -0.3 5

Page 853 of 1839

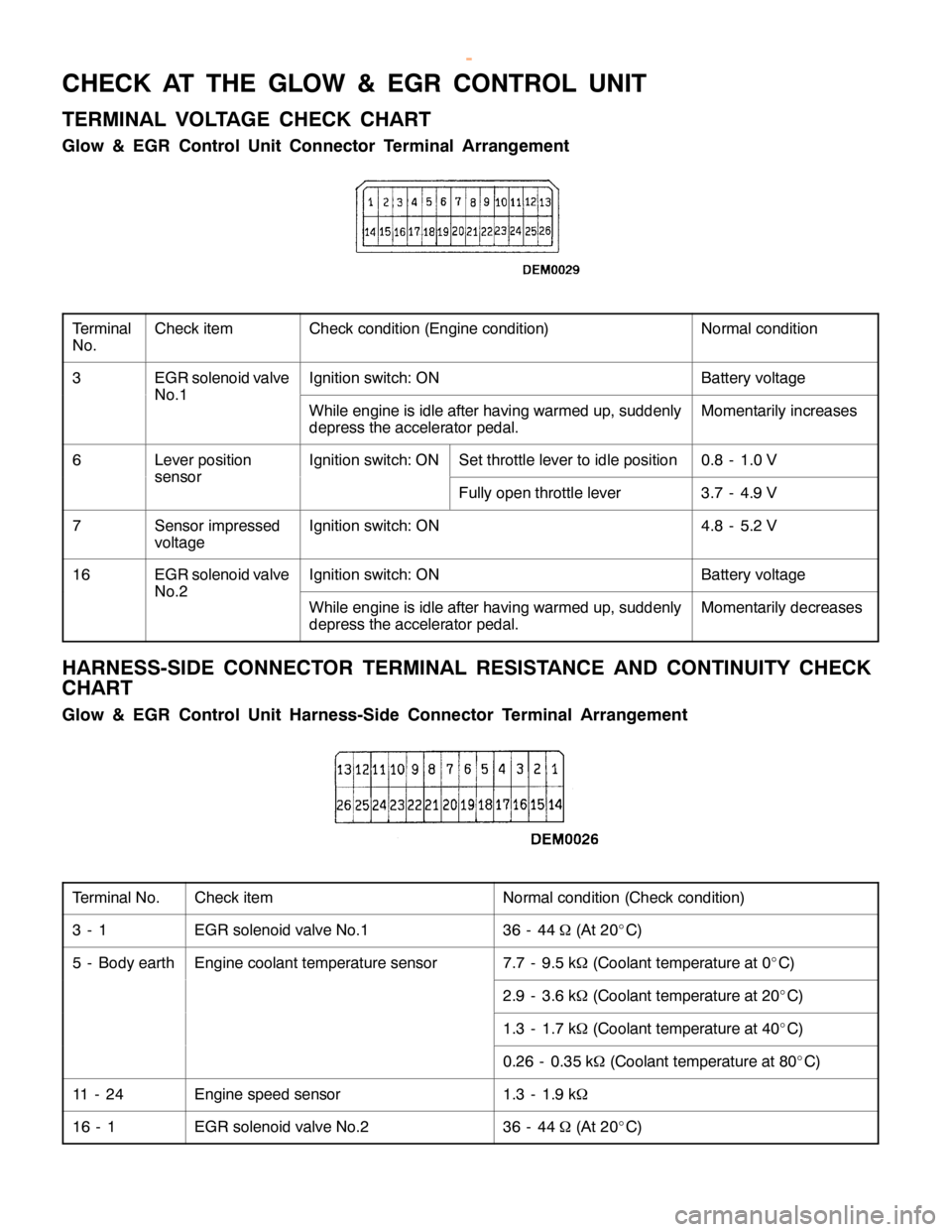

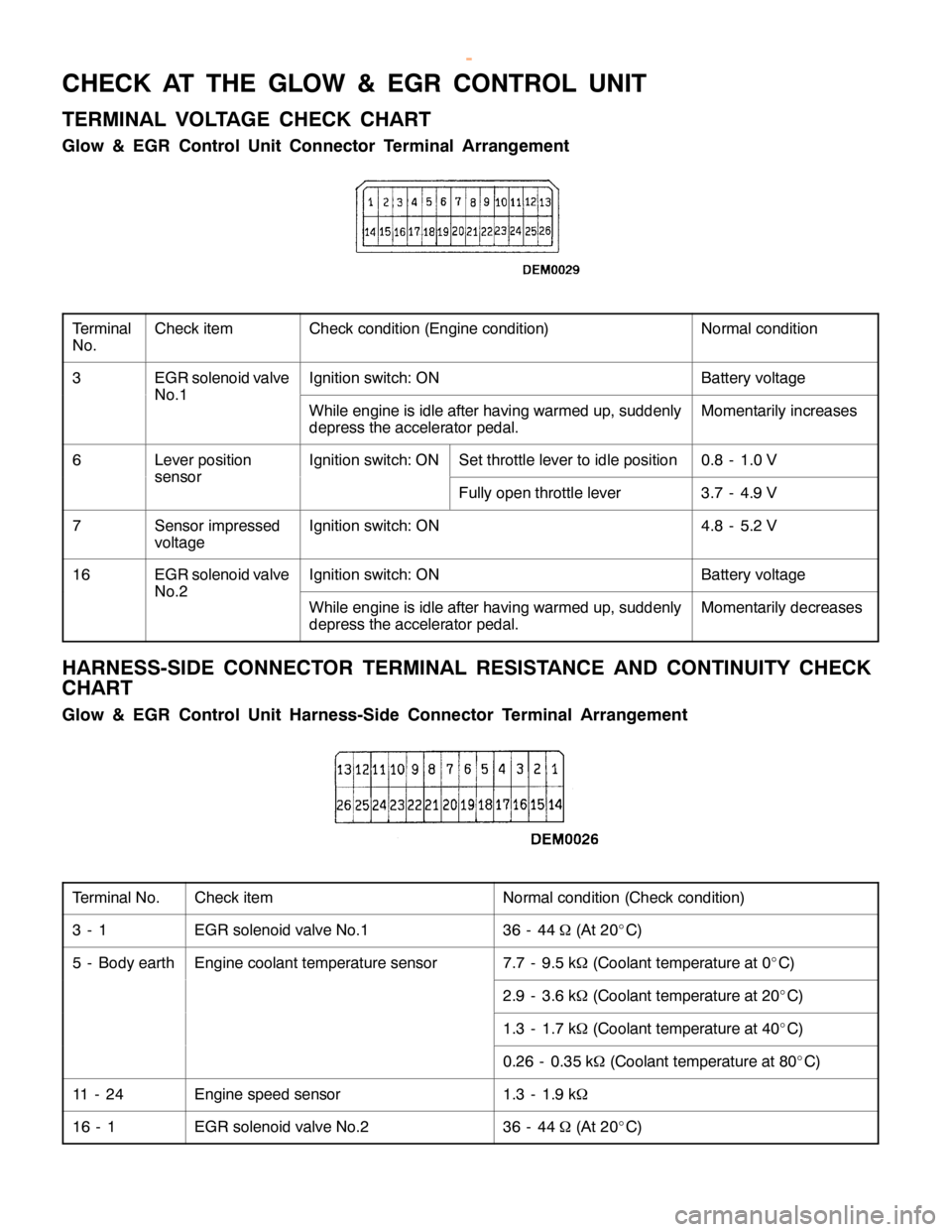

C

HEC K AT TH E GLO W &EG R CO NTR O L UNIT

T E R M IN AL VO LTA G E CHEC K CHART

G lo w &EG R Contr o l Unit Connecto r Te rm in al Arra n gem en t C

heck it e m C

heck co ndit io n (E ngin e co ndit io n) N

orm alco ndit io n 3 E

G R so le noid va lv e I

g nit io n sw it c h : O N B

atte ry vo lt a ge N

o.1 W

hile engin e is id le afte r havin g warm ed up, su ddenly

d epre ss th e acce le ra to r pedal. M

om enta rily in cre ase s 6 L

eve r posit io n I

g nit io n sw it c h :O N S

et th ro ttle le ve r to id le posit io n 0

.8 -1.0 V s

e nso r F

ully open th ro ttle le ve r 3

.7 -4.9 V 7 S

enso r im pre sse d

v o lt a ge I

g nit io n sw it c h : O N 4

.8 -5.2 V 1

6 E

G R so le noid va lv e I

g nit io n sw it c h : O N B

atte ry vo lt a ge N

o.2 W

hile engin e is id le afte r havin g warm ed up, su ddenly

d epre ss th e acce le ra to r pedal. M

om enta rily decre ase s C

heck it e m N

orm alco ndit io n (C heck co ndit io n) 3

-1 E

G R so le noid va lv e No.1 3

6 -44 W (A t20_C ) 5

-Body earth E

ngin e co ola nt te m pera tu re se nso r 7

.7 -9.5 kW (C oola nt te m pera tu re at 0_C ) 2

.9 -3.6 kW (C oola nt te m pera tu re at 20_C ) 1

.3 -1.7 kW (C oola nt te m pera tu re at 40_C ) 0

.2 6 -0.3 5 kW (C oola nt te m pera tu re at 80_C ) 1

1 -24 E

ngin e sp eed se nso r 1

.3 -1.9 kW E

G R so le noid va lv e No.2 3

6 -44 W (A t20_C )

Page 854 of 1839

ENGINE AND EMISSION CONTROL -Emission Control System

<4M4-Vehicles with EGR>17-52

EMISSION CONTROL SYSTEM <4M4-VEHICLES WITH

EGR>

GENERAL INFORMATION

The electronically-controlled EGR system and the

fuel injection timing control system (load timer)

reduce the level of exhaust gases (NO

x).

ItemsNameSpecification

Exhaust emission

control systemExhaust gas recirculation system

DEGR valve

DEGR solenoid valve No.1

DEGR solenoid valve No.2Electronically-controlled EGR system

Single type

Duty cycle solenoid valve

ON-OFFsolenoid valve

SERVICE SPECIFICATIONS

ItemsStandard value

EGR solenoid valve No.1/No. 2 resistance (at 20_C)W36 - 44

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 855 of 1839

E

G R so le n oid valv e No.1 1

7-5 3 E

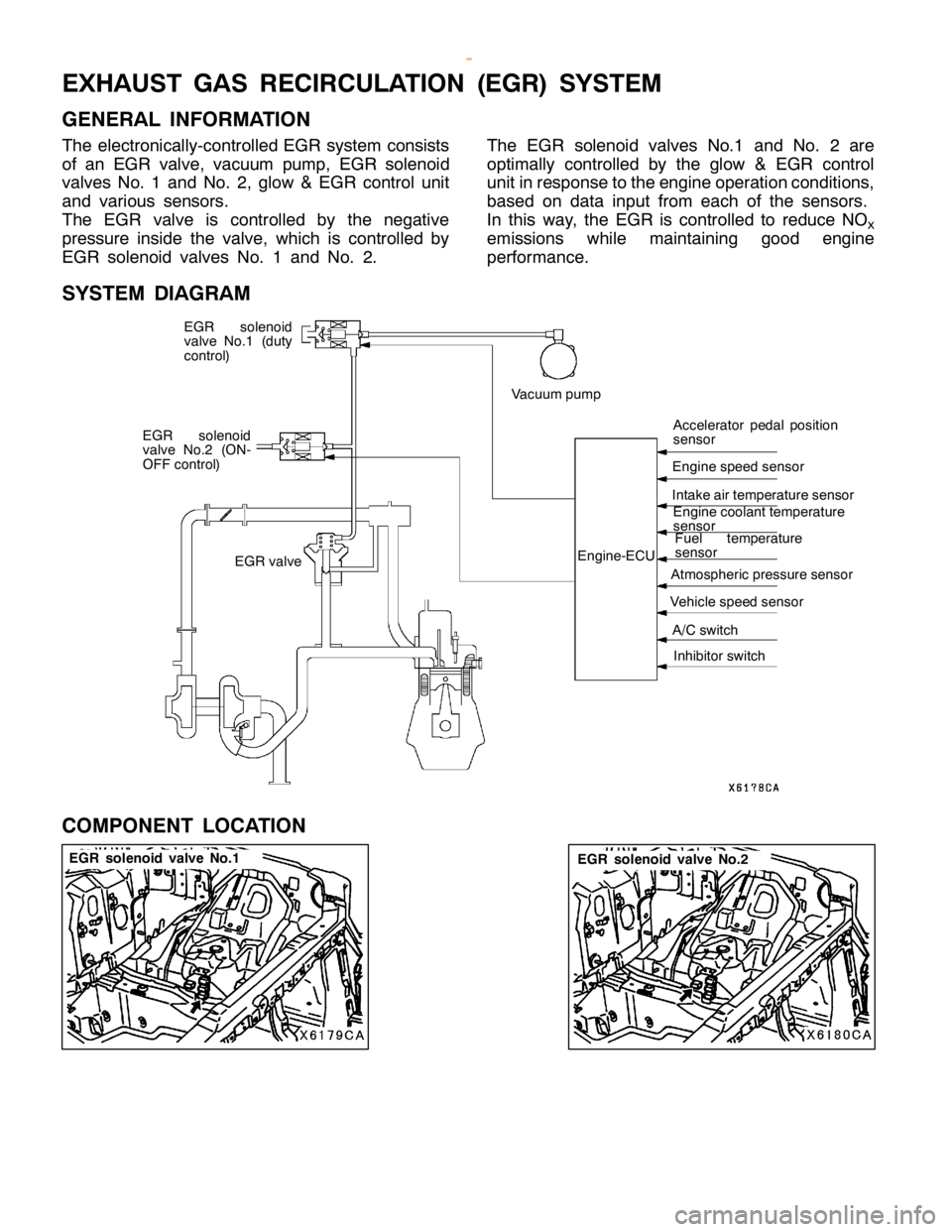

XH AUST GAS REC IR CULA TIO N (E G R) SYSTE M

G EN ER AL IN FO RM ATIO N

T he ele ctr o nic a lly -c o ntr o lle d EG R syste m co nsis ts

o f an EG R va lv e , va cu um pum p, EG R so le noid

v a lv e s No. 1 and No. 2, glo w &EG R co ntr o l unit

a nd va rio us se nso rs .

T he EG R va lv e is co ntr o lle d by th e negativ e

p re ssu re in sid e th e va lv e , whic h is co ntr o lle d by

E G R so le noid va lv e s No. 1 and No. 2. T

he EG R so le noid va lv e s No.1 and No. 2 are

o ptim ally co ntr o lle d by th e glo w &EG R co ntr o l

u nit in re sp onse to th e engin e opera tio n co ndit io ns,

b ase d on data in put fr o m each of th e se nso rs .

I n th is way, th e EG R is co ntr o lle d to re duce NO

x

e m is sio ns while main ta in in g good engin e

p erfo rm ance .

S YSTE M DIA G RAM

Page 856 of 1839

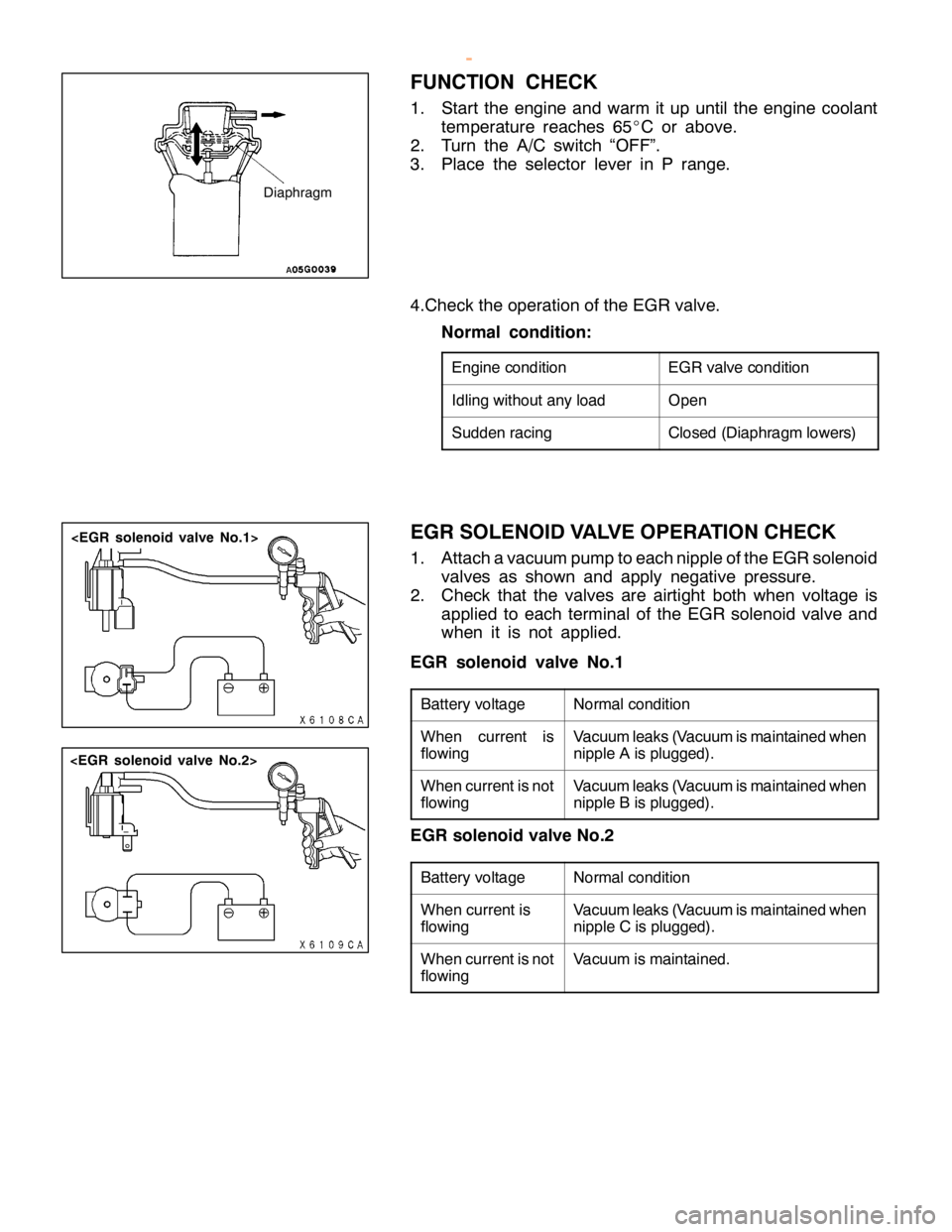

E

G R va lv e co ndit io n I

d lin g wit h out any lo ad O

pen S

udden ra cin g C

lo se d (D ia phra gm lo w ers ) N

orm alco ndit io n W

hen cu rre nt is

f lo w in g V

acu um le aks (V acu um is m ain ta in ed when

n ip ple A is plu gged). W

hen cu rre ntis not

f lo w in g V

acu um le aks (V acu um is m ain ta in ed when

n ip ple B is plu gged). N

orm alco ndit io n W

hen cu rre ntis

f lo w in g V

acu um le aks (V acu um is m ain ta in ed when

n ip ple C is plu gged). W

hen cu rre ntis not

f lo w in g V

acu um is m ain ta in ed. <

E G R so le n oid valv e No.2 >

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 857 of 1839

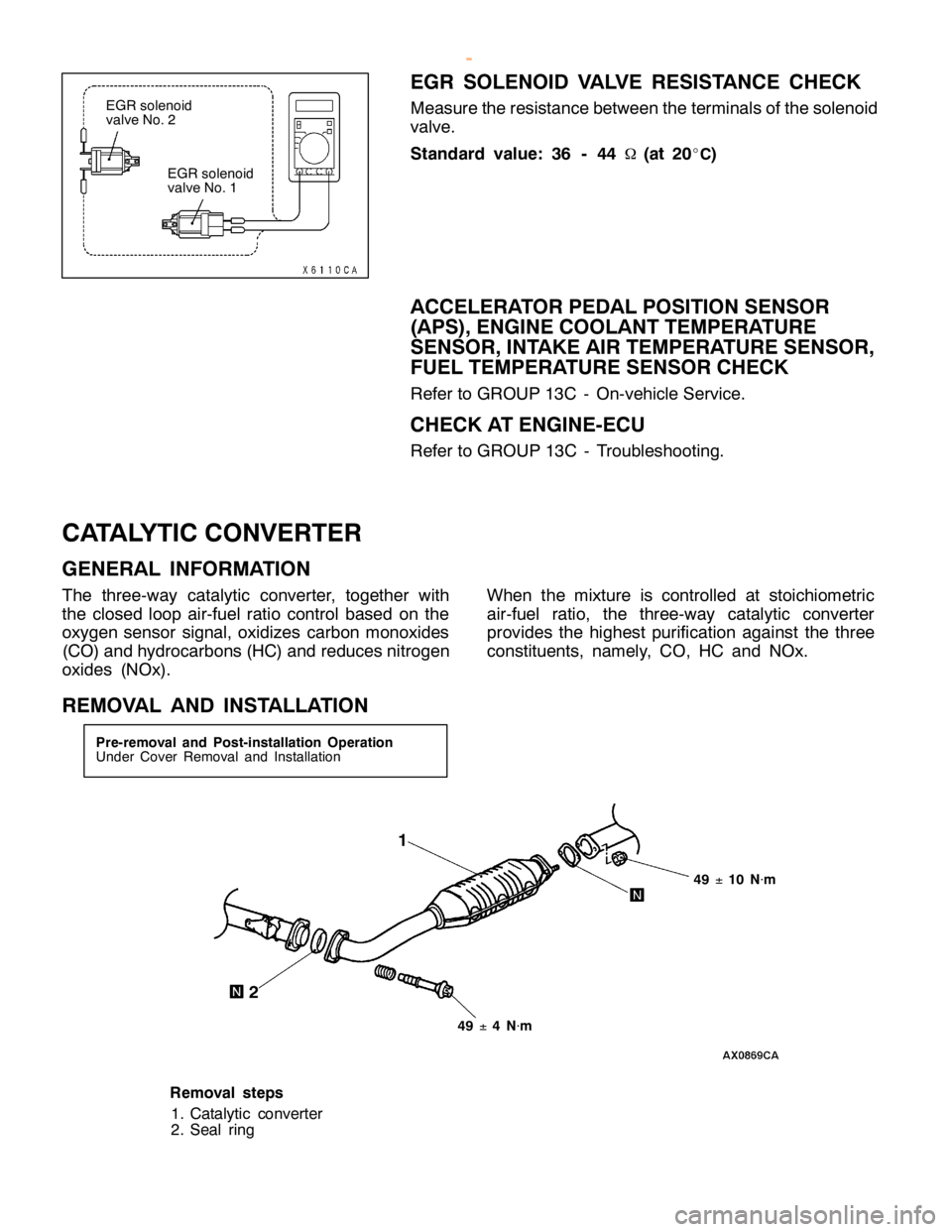

4

9 ±

10 N×

m

R em oval ste p s

1 . C ata ly tic co nve rte r

2 . S eal rin g E

G R so le noid

v a lv e No. 1

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 858 of 1839

NOTES

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 859 of 1839

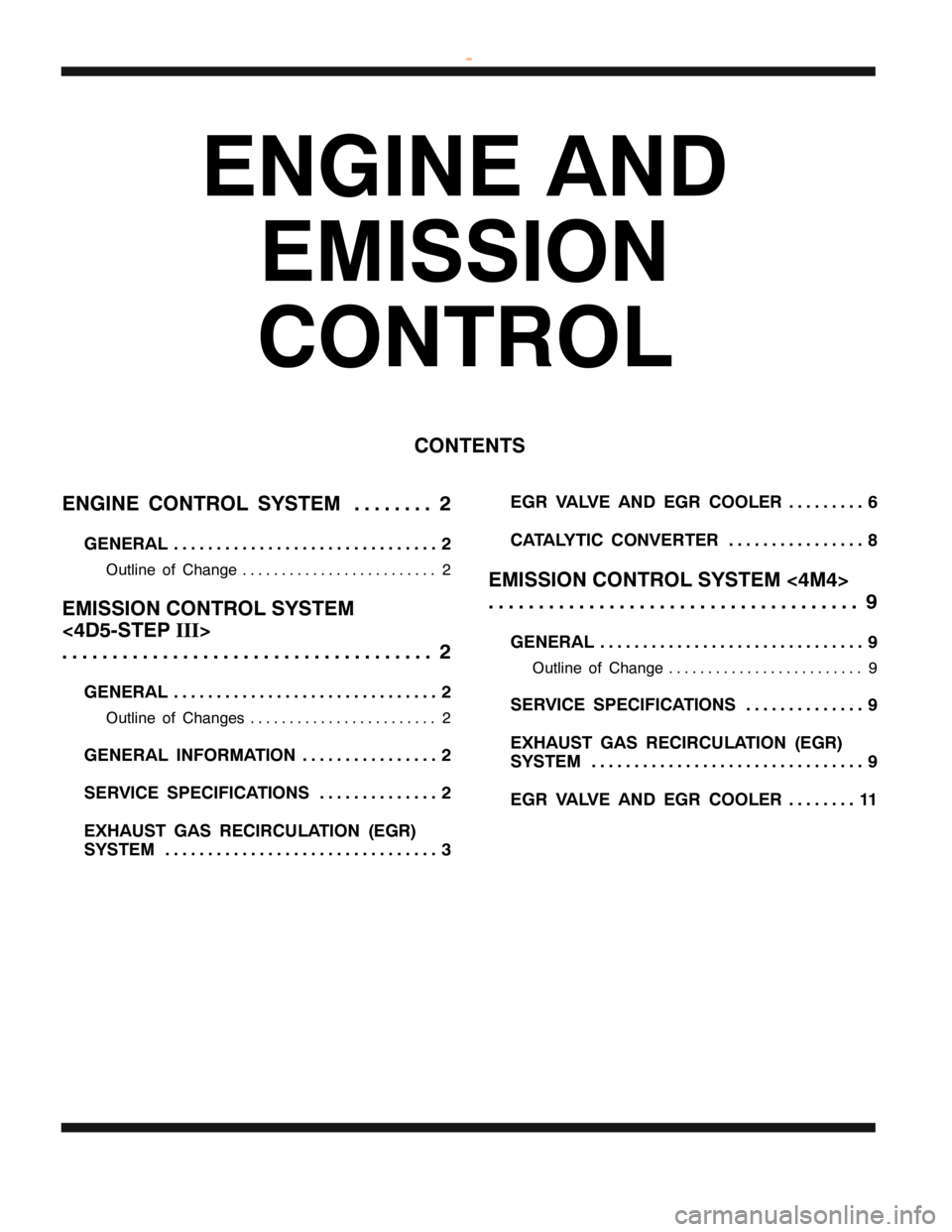

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 2........

GENERAL 2...............................

Outline of Change 2.........................

EMISSION CONTROL SYSTEM

<4D5-STEPIII>

2 .....................................

GENERAL 2...............................

Outline of Changes 2........................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2..............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 3................................EGR VALVE AND EGR COOLER 6.........

CATALYTIC CONVERTER 8................

EMISSION CONTROL SYSTEM <4M4>

9 .....................................

GENERAL 9...............................

Outline of Change 9.........................

SERVICE SPECIFICATIONS 9..............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 9................................

EGR VALVE AND EGR COOLER 11........

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 860 of 1839

ENGINE AND EMISSION CONTROL -EngineControlSystem/EmissionControl

System <4D5-Step III>17-2

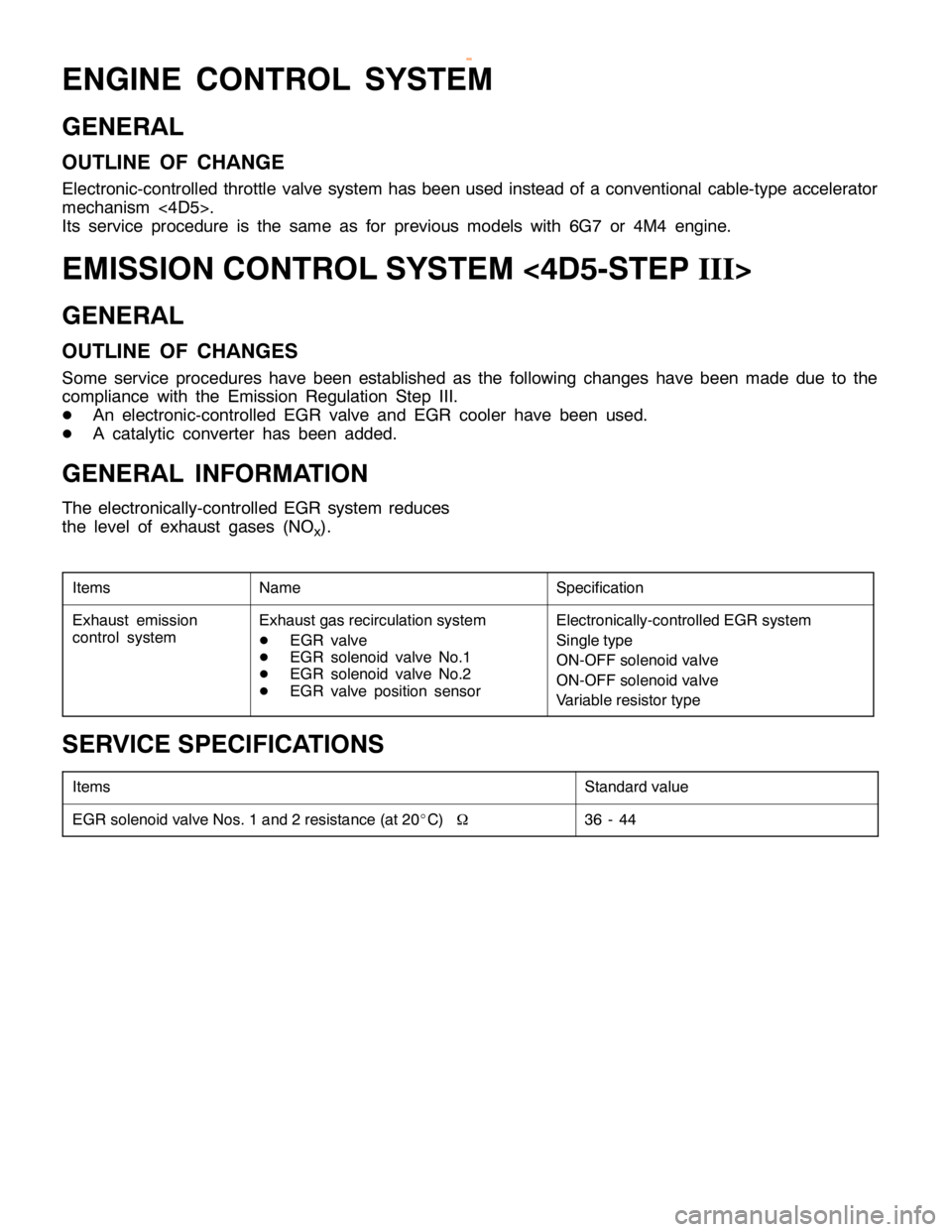

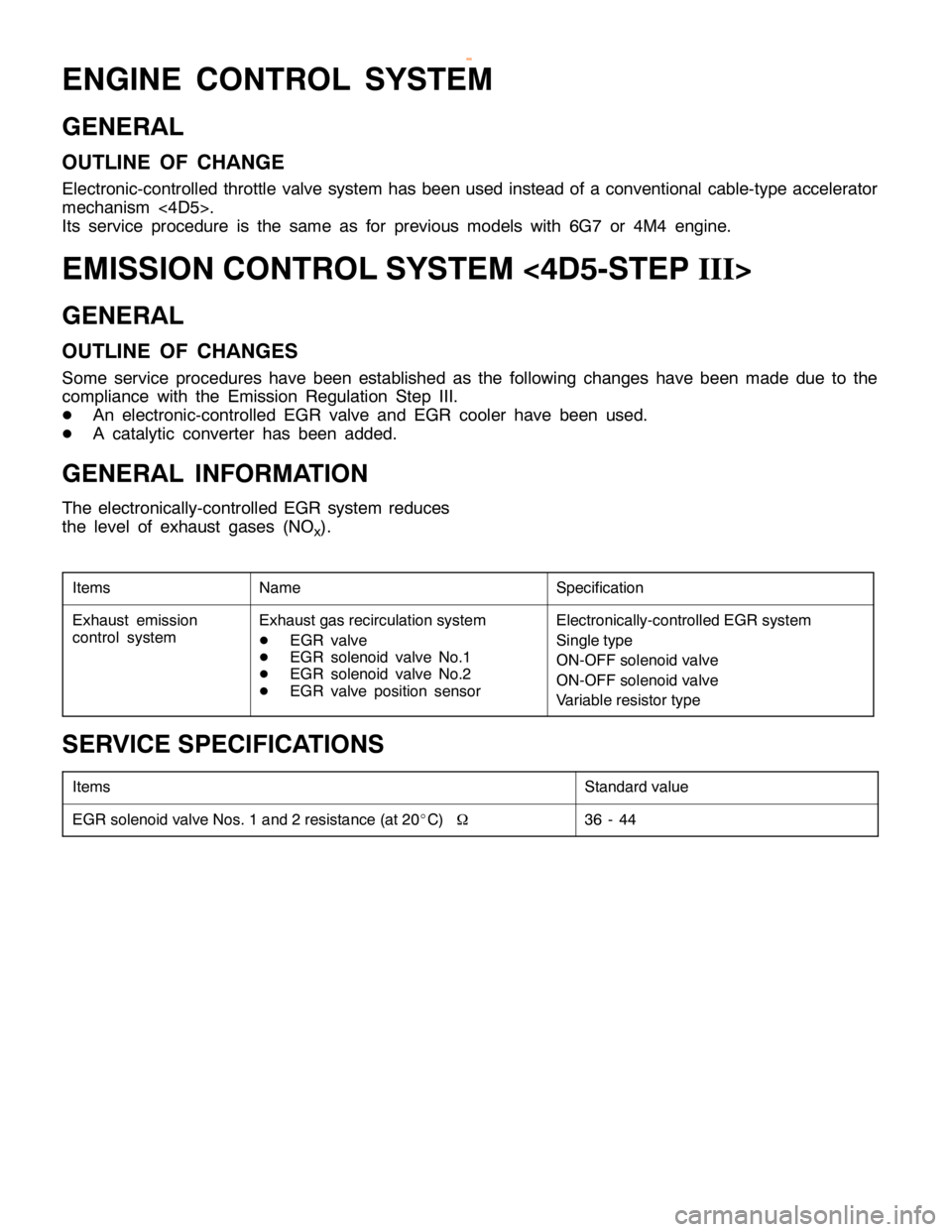

ENGINE CONTROL SYSTEM

GENERAL

OUTLINE OF CHANGE

Electronic-controlled throttle valve system has been used instead of a conventional cable-type accelerator

mechanism <4D5>.

Its service procedure is the same as for previous models with 6G7 or 4M4 engine.

EMISSION CONTROL SYSTEM <4D5-STEP

III>

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation Step III.

DAn electronic-controlled EGR valve and EGR cooler have been used.

DA catalytic converter has been added.

GENERAL INFORMATION

The electronically-controlled EGR system reduces

the level of exhaust gases (NO

x).

ItemsNameSpecification

Exhaust emission

control systemExhaust gas recirculation system

DEGR valve

DEGR solenoid valve No.1

DEGR solenoid valve No.2

DEGR valve position sensorElectronically-controlled EGR system

Single type

ON-OFF solenoid valve

ON-OFF solenoid valve

Variable resistor type

SERVICE SPECIFICATIONS

ItemsStandard value

EGR solenoid valve Nos. 1 and 2 resistance (at 20_C)Ω36 - 44

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Trending: table contents, low beam, low oil pressure, radio antenna, seat memory, checking oil, steering wheel adjustment