MITSUBISHI MONTERO 2000 Service Repair Manual

MONTERO 2000

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57331/w960_57331-0.png

MITSUBISHI MONTERO 2000 Service Repair Manual

Trending: heater, oil filter, windshield wipers, trip computer, diagram, Indicator, At mode

Page 891 of 1839

<

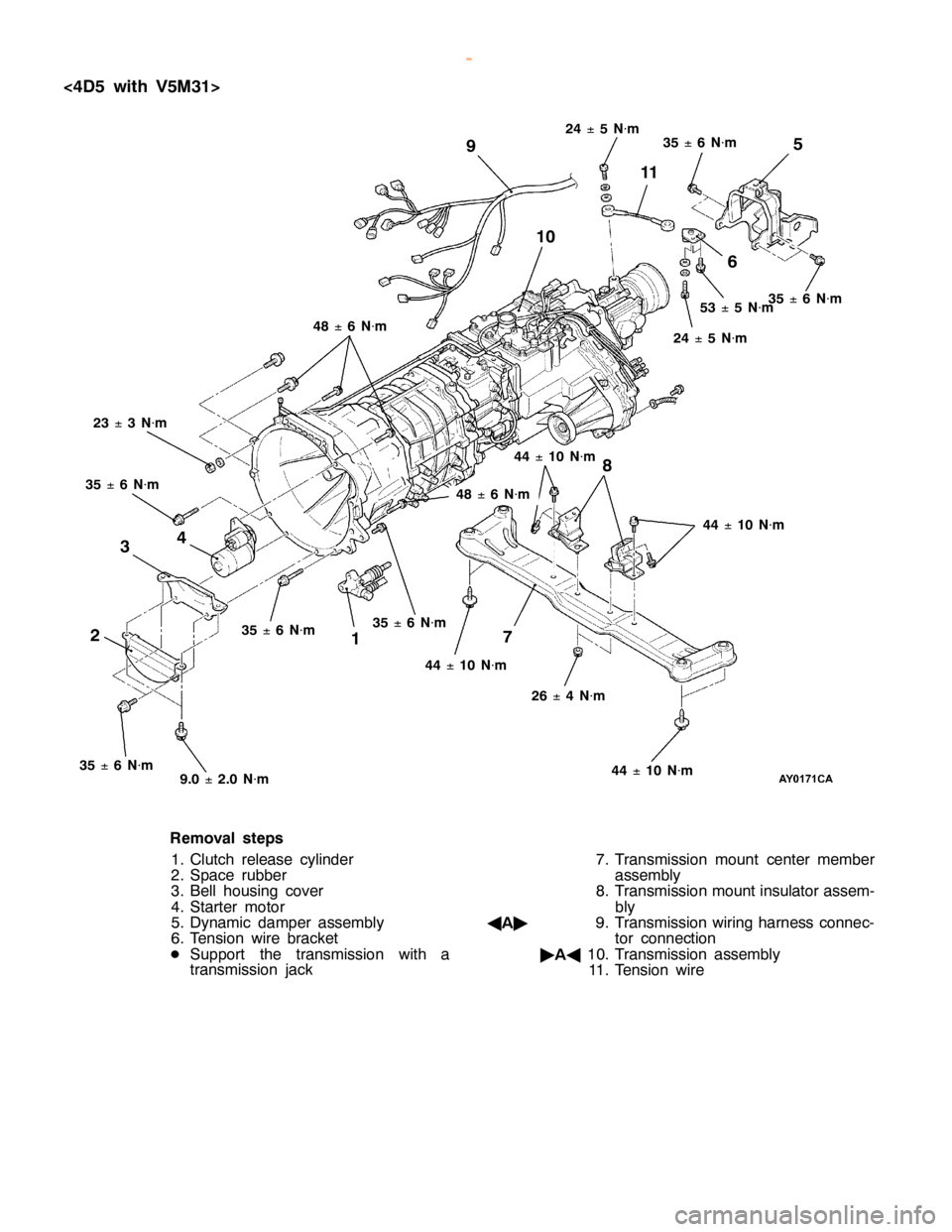

4D 5 wit h V5M 31>

5

4 4

±1

0 N

×m

4

4

±1

0 N

×m

4 4

±1

0 N

×m

44

±1

0 N

×m

2

6

±4

N

×m 3

5

±6

N

×m

3

5

±6

N

×m

2 4

±5

N

×m

5

3

±5

N

×m

2

4

±5

N

×m

3 5

±6

N

×m

3 5

±6

N

×m 3

5

±6

N

×m 4

8

±6

N

×m

2 3

±3

N

×m

9.0

±2

.0 N

×m 3

5

±6

N

×m 4

8

±6

N

×m

R em oval ste p s

1 . C lu tc h re le ase cylin der

2 . S pace ru bber

3 . B ell housin g co ve r

4 . S ta rte r m oto r

5 . D yn am ic dam per asse m bly

6 . Te nsio n wir e bra cke t

D Support th e tr a nsm is sio n wit h a

t r a nsm is sio n ja ck 7

. Tra nsm is sio n mount ce nte r m em ber

a sse m bly

8 . Tra nsm is sio n mount in su la to r asse m -

b ly

A A"

9. Tra nsm is sio n wir in g harn ess co nnec-

t o r co nnectio n

" AA

10. Tra nsm is sio n asse m bly

1 1 . Te nsio n wir e

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 892 of 1839

Page 893 of 1839

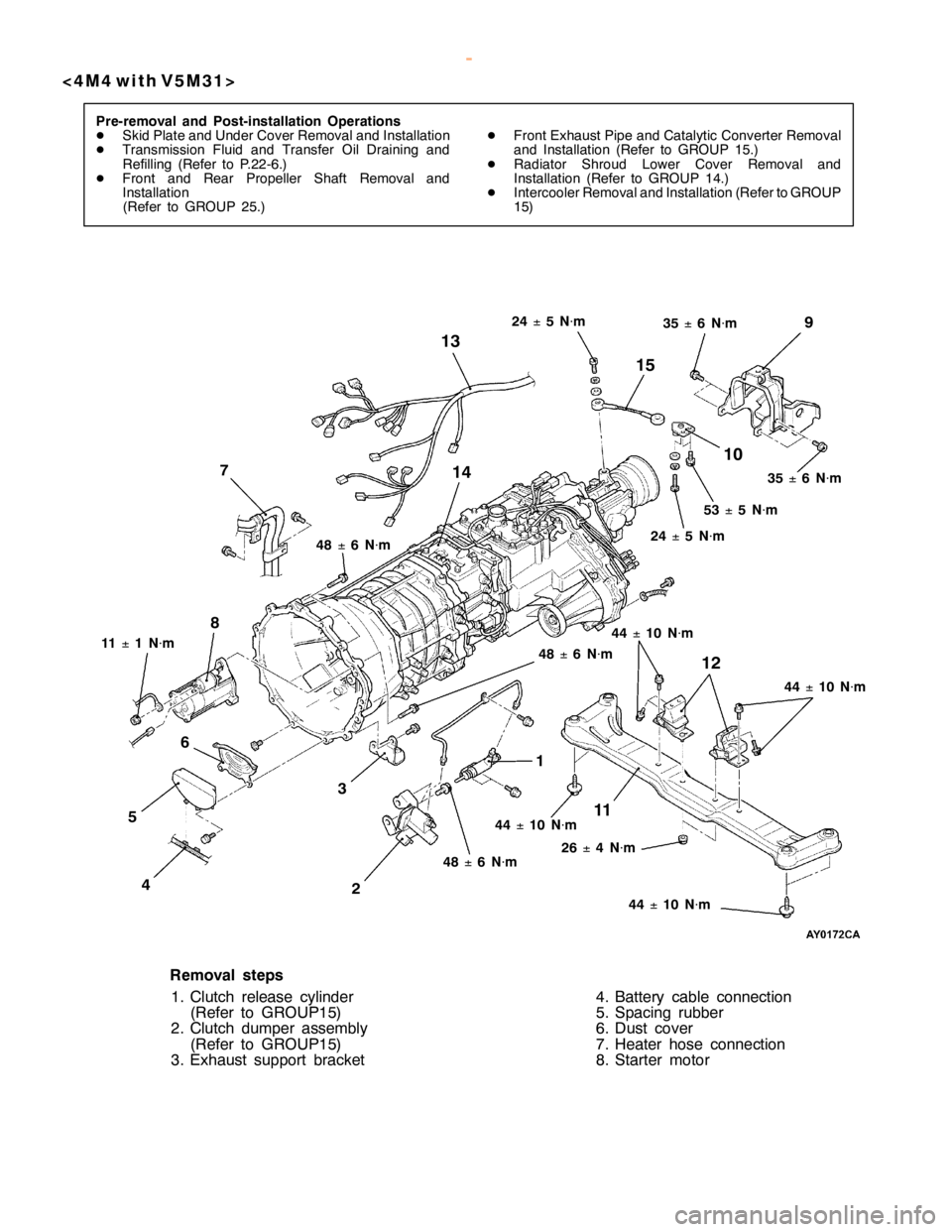

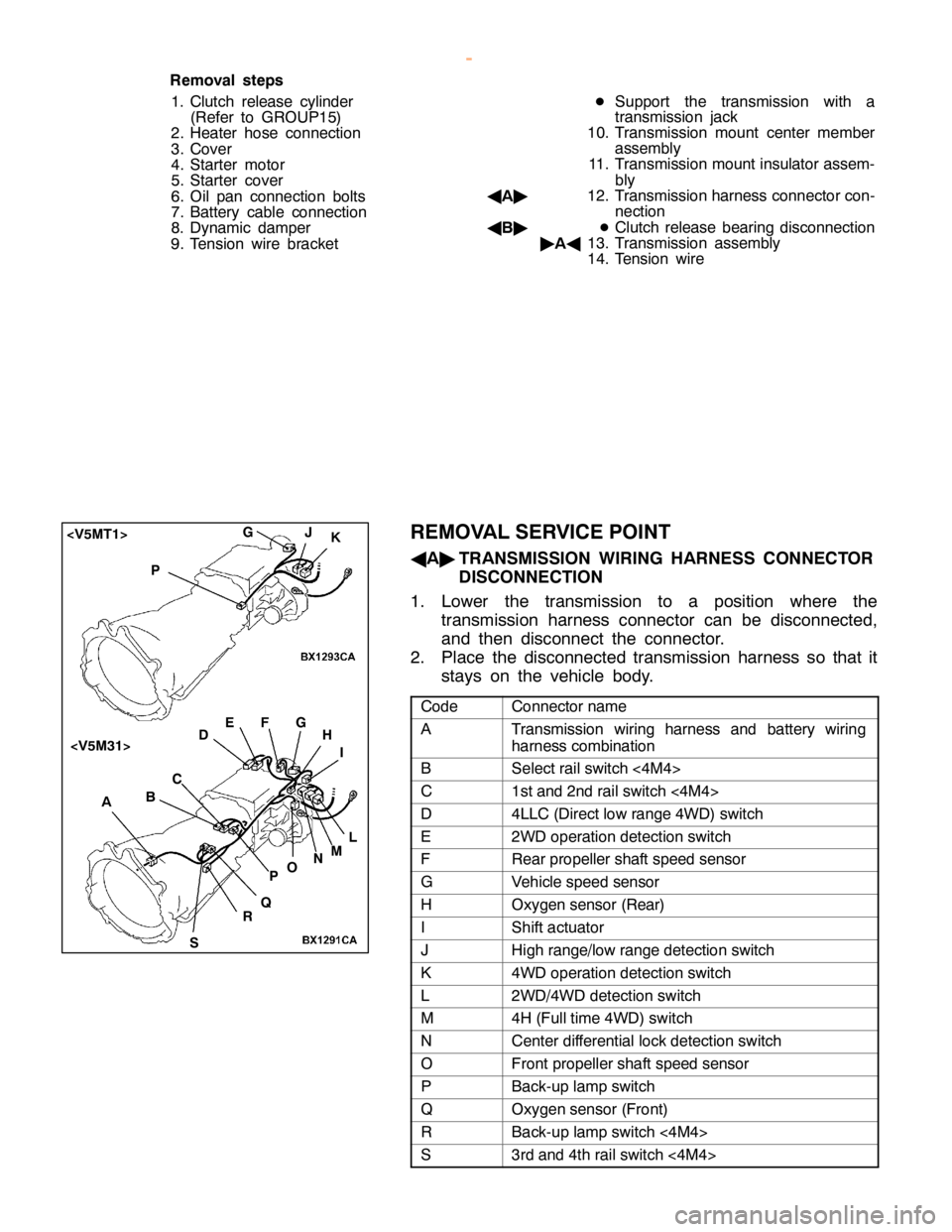

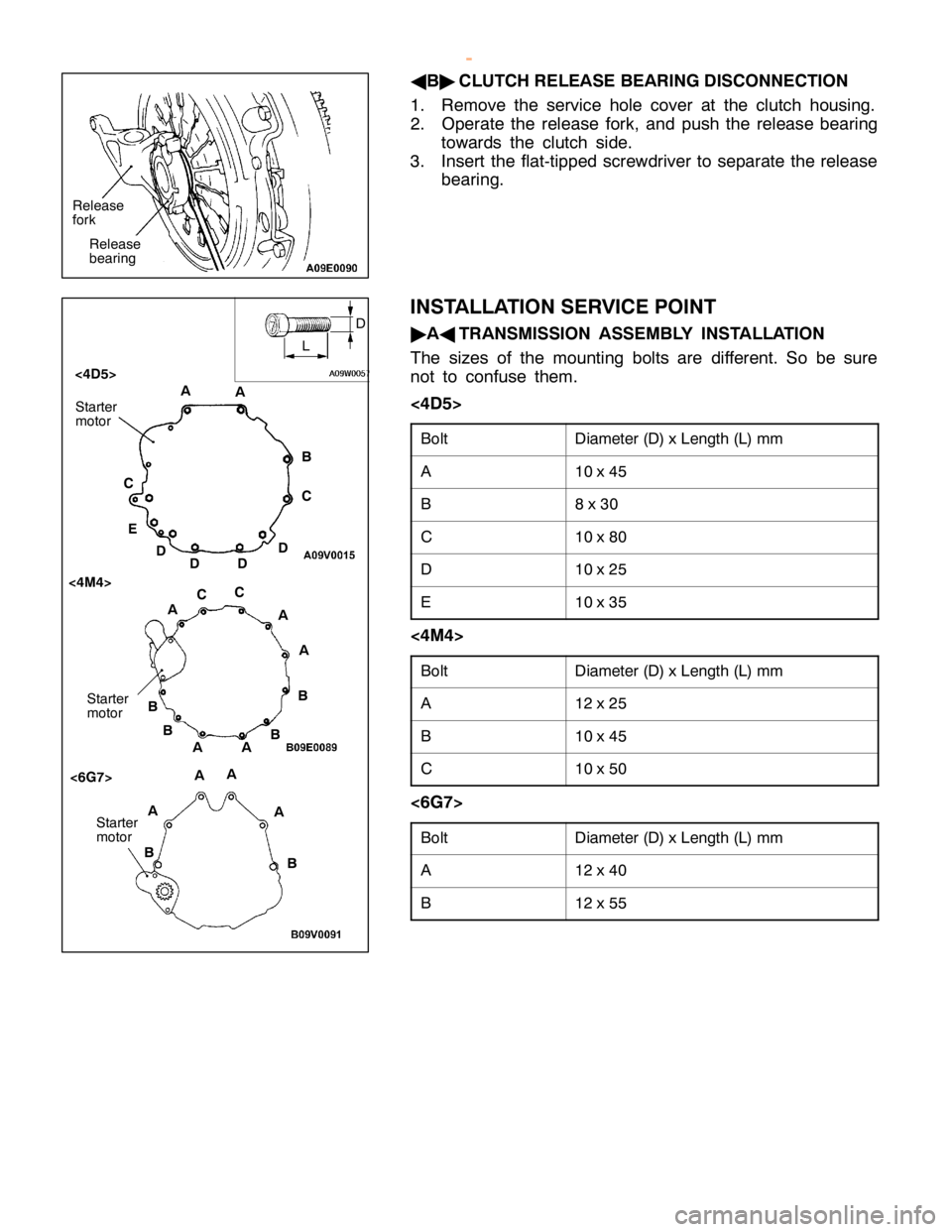

MANUAL TRANSMISSION -Transmission Assembly22-13

9. Dynamic damper

10. Tension wire bracket

DSupport the transmission with a

transmission jack

11. Transmission mount center member

assembly

12. Transmission mount insulator assem-

blyA

A"13. Transmission harness connector con-

nection

A

B"DClutch release bearing disconnection

"

AA14. Transmission assembly

15. Tension wire

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 894 of 1839

Page 895 of 1839

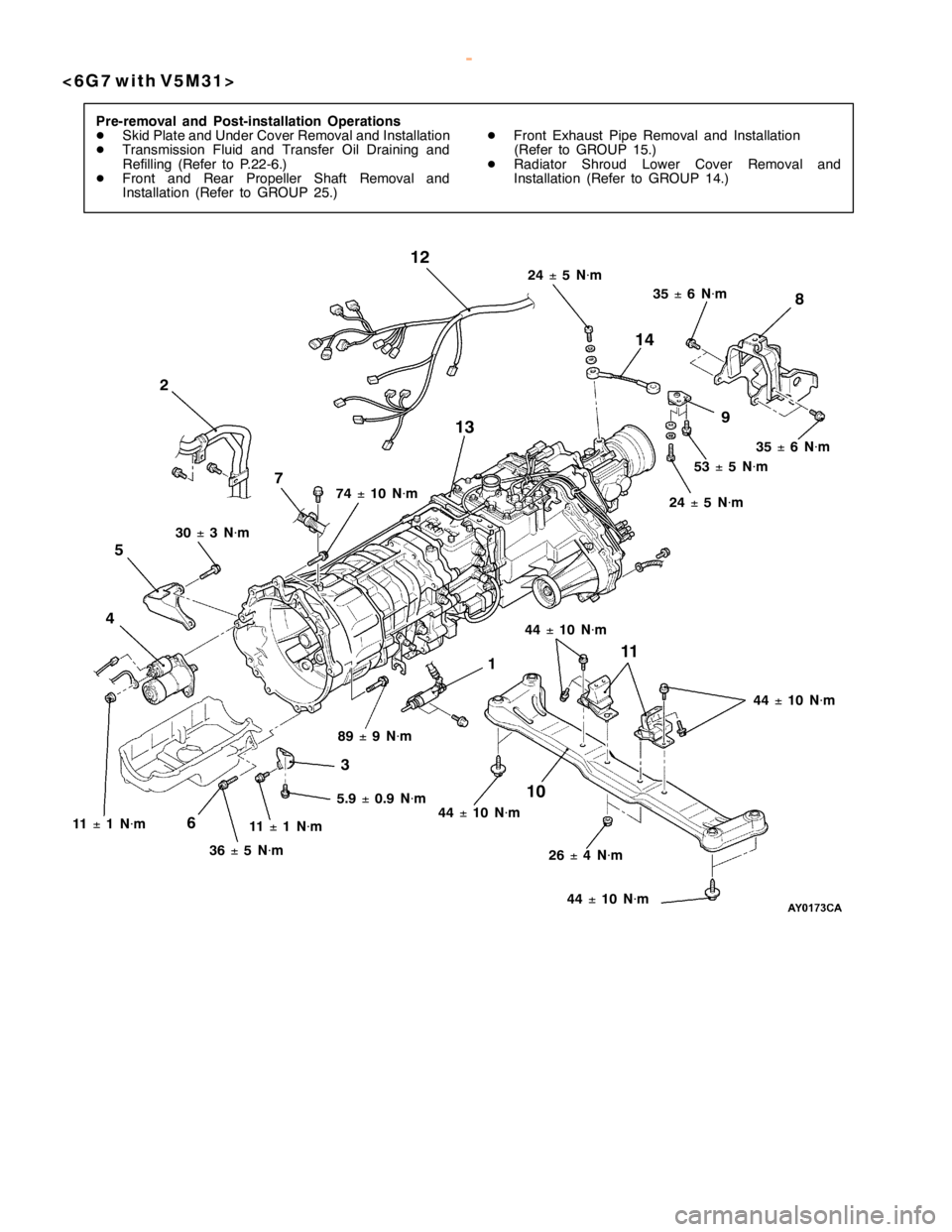

C

onnecto r nam e A T

ra nsm is sio n wir in g harn ess and batte ry wir in g

h arn ess co m bin atio n B S

ele ct ra il sw it c h <4M 4> C 1

st and 2nd ra il sw it c h <4M 4> D 4

LLC (D ir e ct lo w ra nge 4W D)sw it c h E 2

W D opera tio n dete ctio n sw it c h F R

ear pro pelle r sh aft sp eed se nso r G V

ehic le sp eed se nso r H O

xyg en se nso r (R ear) I S

hif t actu ato r J H

ig h ra nge/lo w ra nge dete ctio n sw it c h K 4

W D opera tio n dete ctio n sw it c h L 2

W D/4 W D dete ctio n sw it c h M 4

H (F ull tim e 4W D)sw it c h N C

ente r dif f e re ntia llo ck dete ctio n sw it c h O F

ro nt pro pelle r sh aft sp eed se nso r P B

ack-u p la m p sw it c h Q O

xyg en se nso r (F ro nt) R B

ack-u p la m p sw it c h <4M 4> S 3

rd and 4th ra il sw it c h <4M 4> K

O N

M L

P

Q

R

S

P J

G

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 896 of 1839

D

ia m ete r (D )x Length (L ) m m A 1

0 x45 B 8

x30 C 1

0 x80 D 1

0 x25 E 1

0 x35 D

ia m ete r (D )x Length (L ) m m A 1

2 x25 B 1

0 x45 C 1

0 x50 D

ia m ete r (D )x Length (L ) m m A 1

2 x40 B 1

2 x55 R

ele ase

b earin g <

6G 7> S

ta rte r

m oto r

S ta rte r

m oto r w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 897 of 1839

4

W D IN DIC ATO R-E C U/T R ANSFE R -E C U

R EM OVA L AND IN STA LLA TIO N

Page 898 of 1839

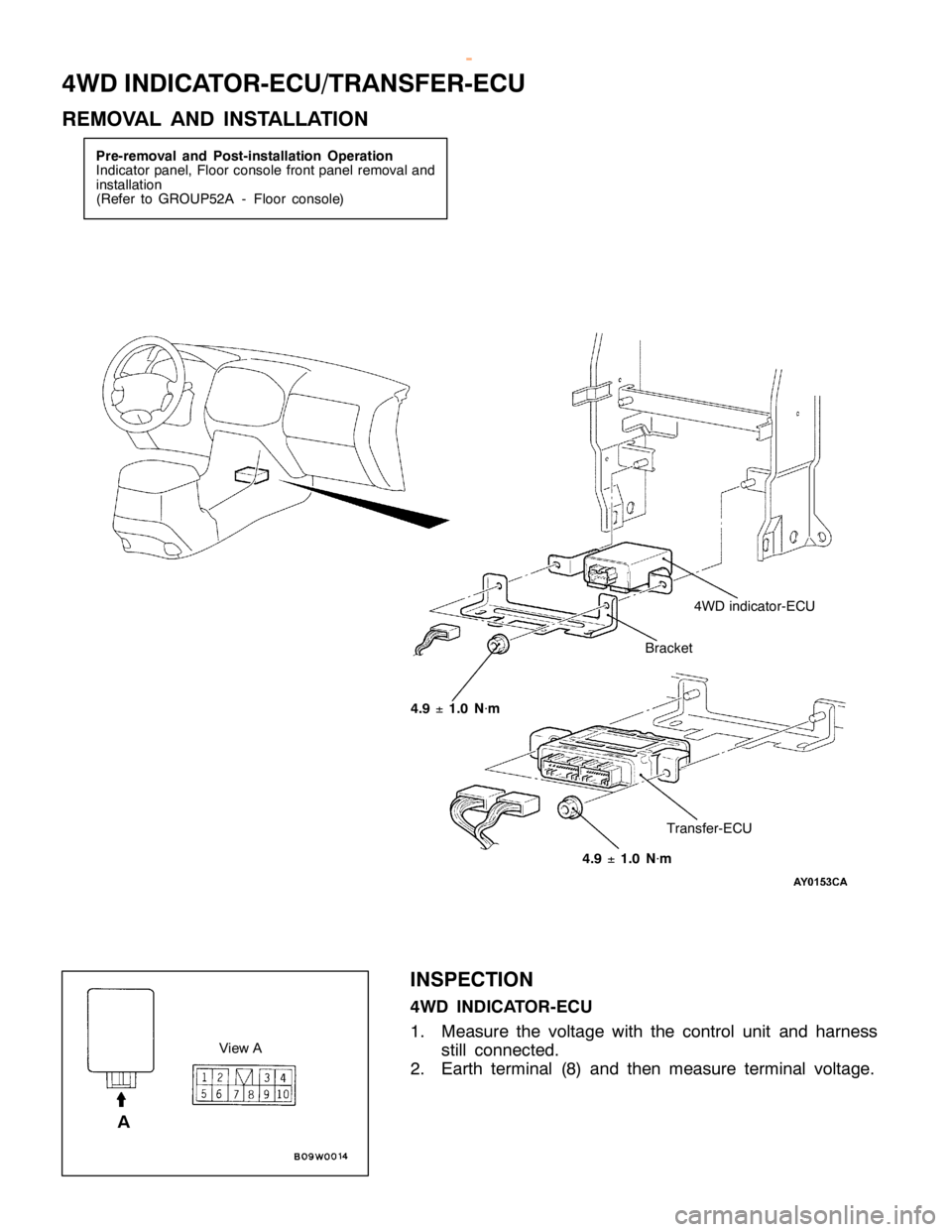

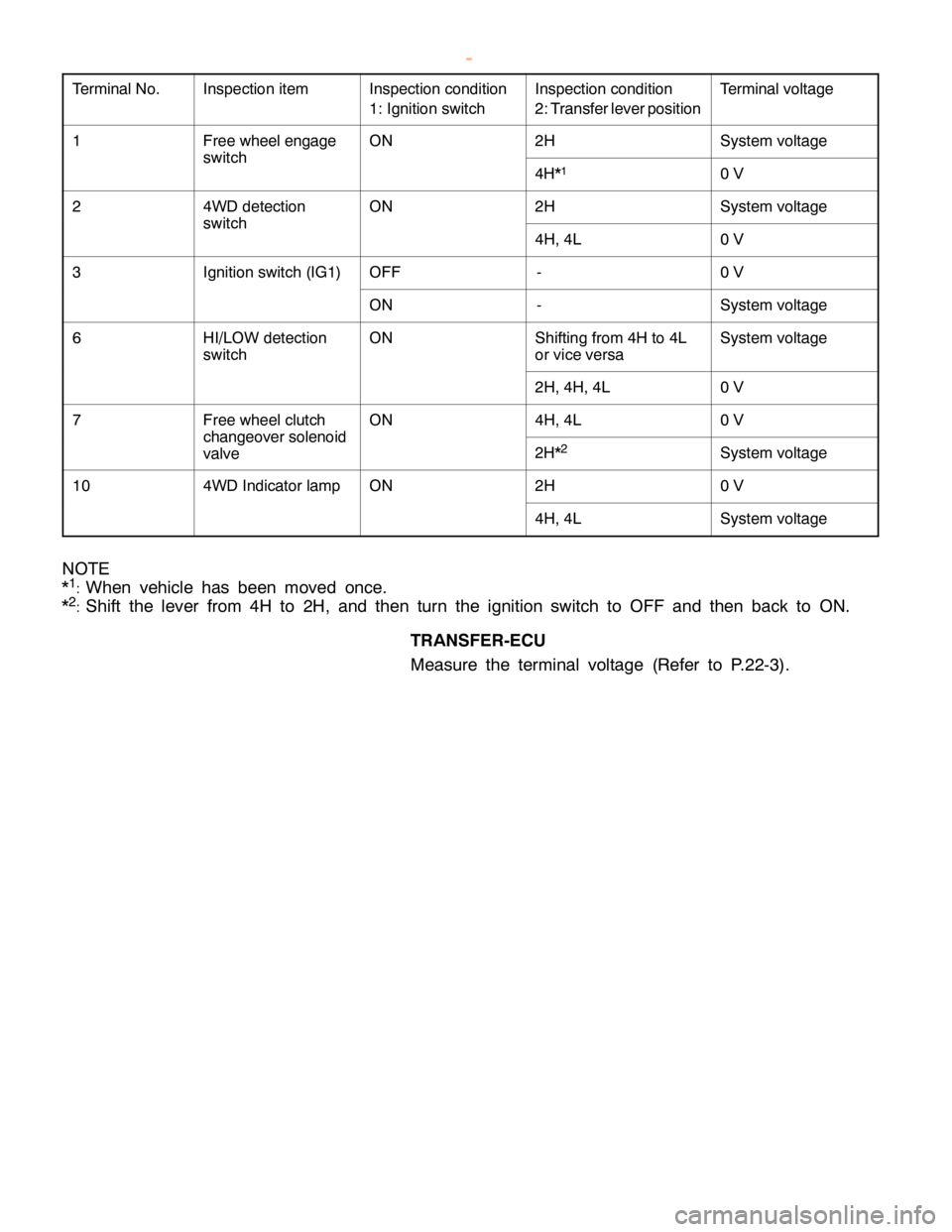

MANUAL TRANSMISSION -4WD Indicator-ECU/Transfer-ECU22-18

Terminal No.Inspection itemInspection condition

1: Ignition switchInspection condition

2: Transfer lever positionTerminal voltage

1Free wheel engageON2HSystem voltage

switch

4H*10V

24WD detectionON2HSystem voltage

switch

4H, 4L0V

3Ignition switch (IG1)OFF-0V

ON-System voltage

6HI/LOW detection

switchONShifting from 4H to 4L

or vice versaSystem voltage

2H, 4H, 4L0V

7Free wheel clutchON4H, 4L0V

changeover solenoid

valve

2H*2System voltage

104WD Indicator lampON2H0V

4H, 4LSystem voltage

NOTE

*1:When vehicle has been moved once.

*2:Shift the lever from 4H to 2H, and then turn the ignition switch to OFF and then back to ON.

TRANSFER-ECU

Measure the terminal voltage (Refer to P.22-3).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 899 of 1839

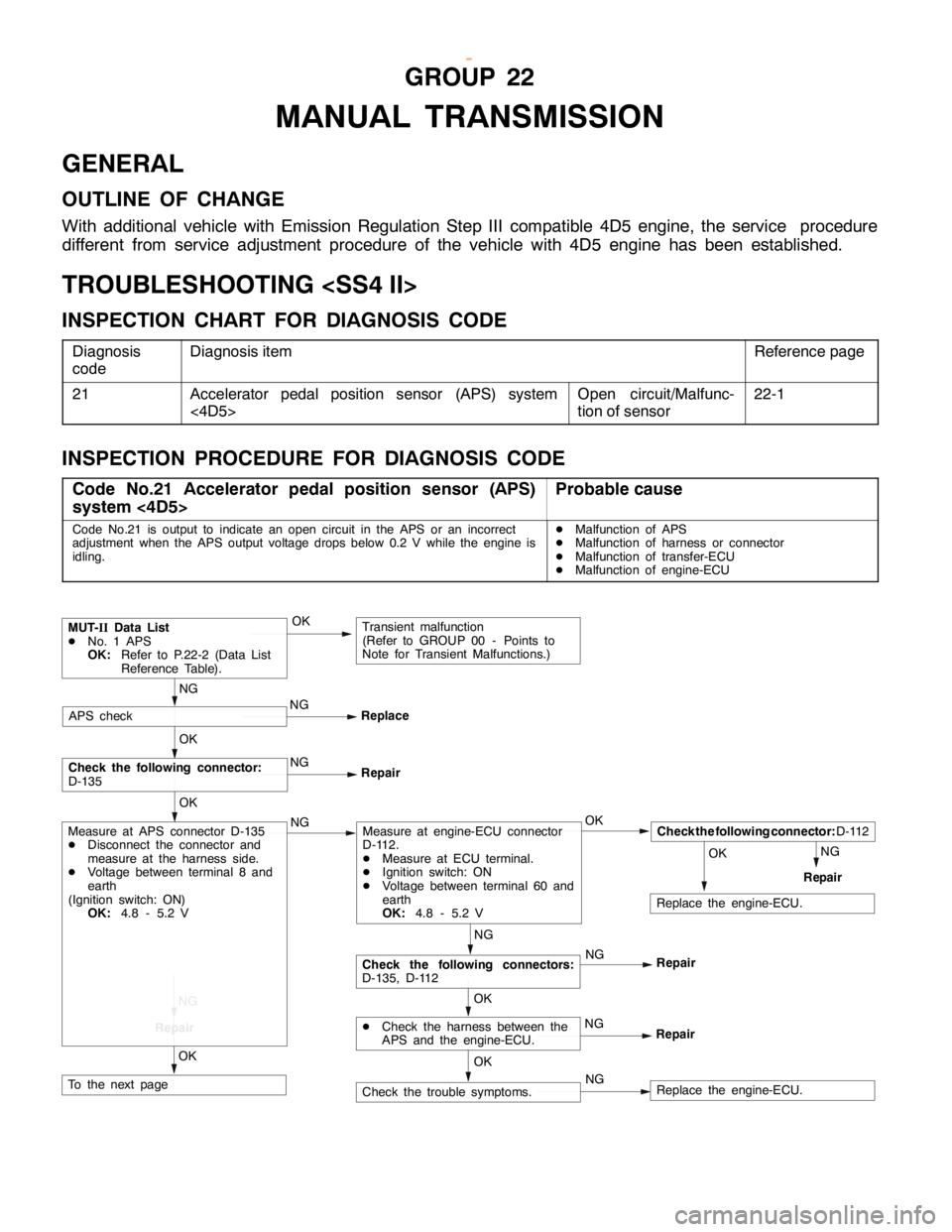

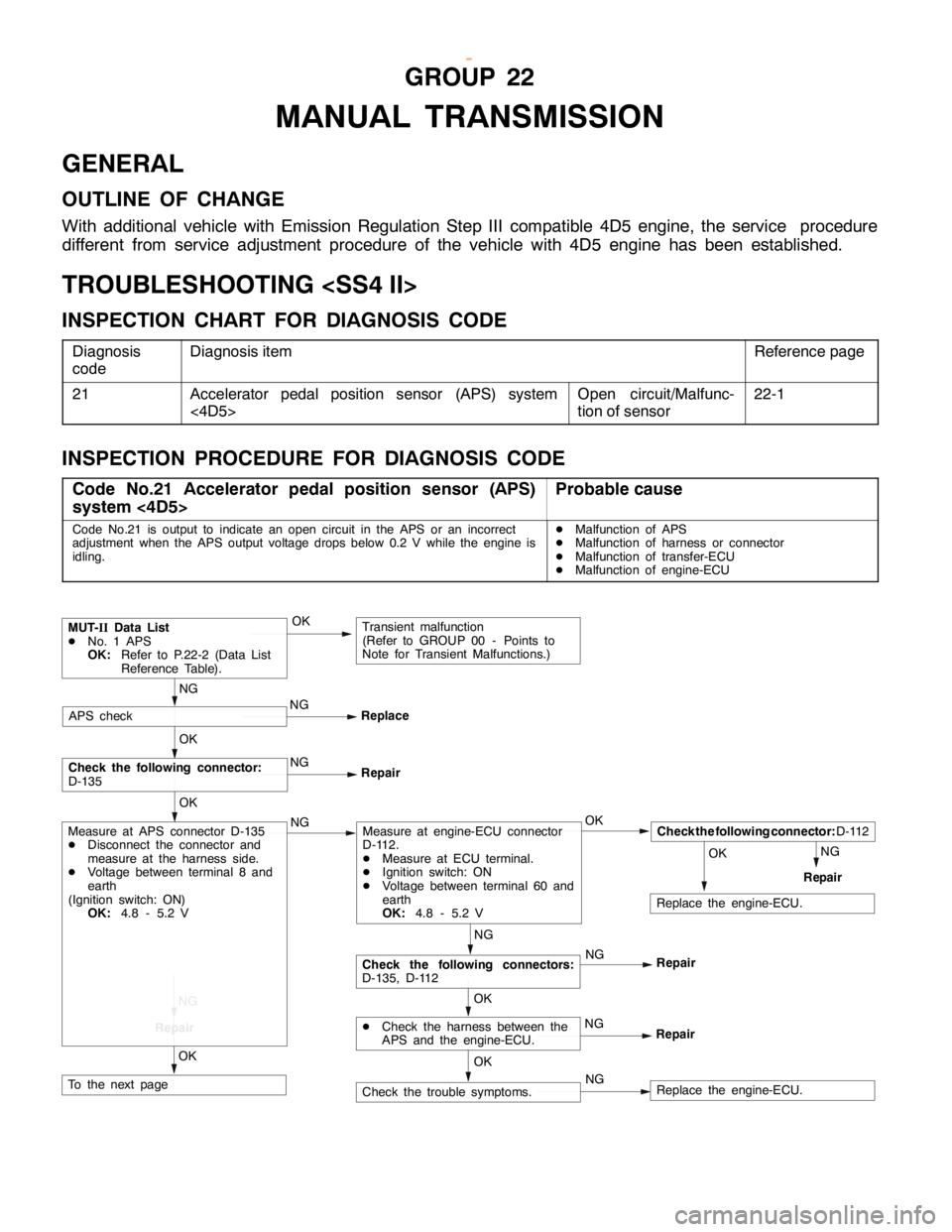

MANUAL TRANSMISSION -Gneral/Troubleshooting 22-1

GROUP 22

MANUAL TRANSMISSION

GENERAL

OUTLINE OF CHANGE

With additional vehicle with Emission Regulation Step III compatible 4D5 engine, the service procedure

different from service adjustment procedure of the vehicle with 4D5 engine has been established.

TROUBLESHOOTING

INSPECTION CHART FOR DIAGNOSIS CODE

Diagnosis

codeDiagnosis itemReference page

21Accelerator pedal position sensor (APS) system

<4D5>Open circuit/Malfunc-

tion of sensor22-1

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No.21 Accelerator pedal position sensor (APS)

system <4D5>Probable cause

Code No.21 is output to indicate an open circuit in the APS or an incorrect

adjustment when the APS output voltage drops below 0.2 V while the engine is

idling.DMalfunction of APS

DMalfunction of harness or connector

DMalfunction of transfer-ECU

DMalfunction of engine-ECU

NGNG

NG

Repair

MUT-IIData List

DNo. 1 APS

OK:Refer to P.22-2 (Data List

Reference Table).

NG

ReplaceAPS check

OK

NG

Repair

OK

Check the following connector:

D-135

OK

OK

Check the following connector:D-112

Repair

NG

Repair

NG

Repair

OK

DCheck the harness between the

APS and the engine-ECU.

OK

Check the following connectors:

D-135, D-112

Measure at engine-ECU connector

D-112.

DMeasure at ECU terminal.

DIgnition switch: ON

DVoltage between terminal 60 and

earth

OK:4.8 - 5.2 V

NGNG

NGCheck the trouble symptoms.Replace the engine-ECU.

OK

Measure at APS connector D-135

DDisconnect the connector and

measure at the harness side.

DVoltage between terminal 8 and

earth

(Ignition switch: ON)

OK:4.8 - 5.2 V

To the next page

Transient malfunction

(Refer to GROUP 00 - Points to

Note for Transient Malfunctions.)

OK

Replace the engine-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 900 of 1839

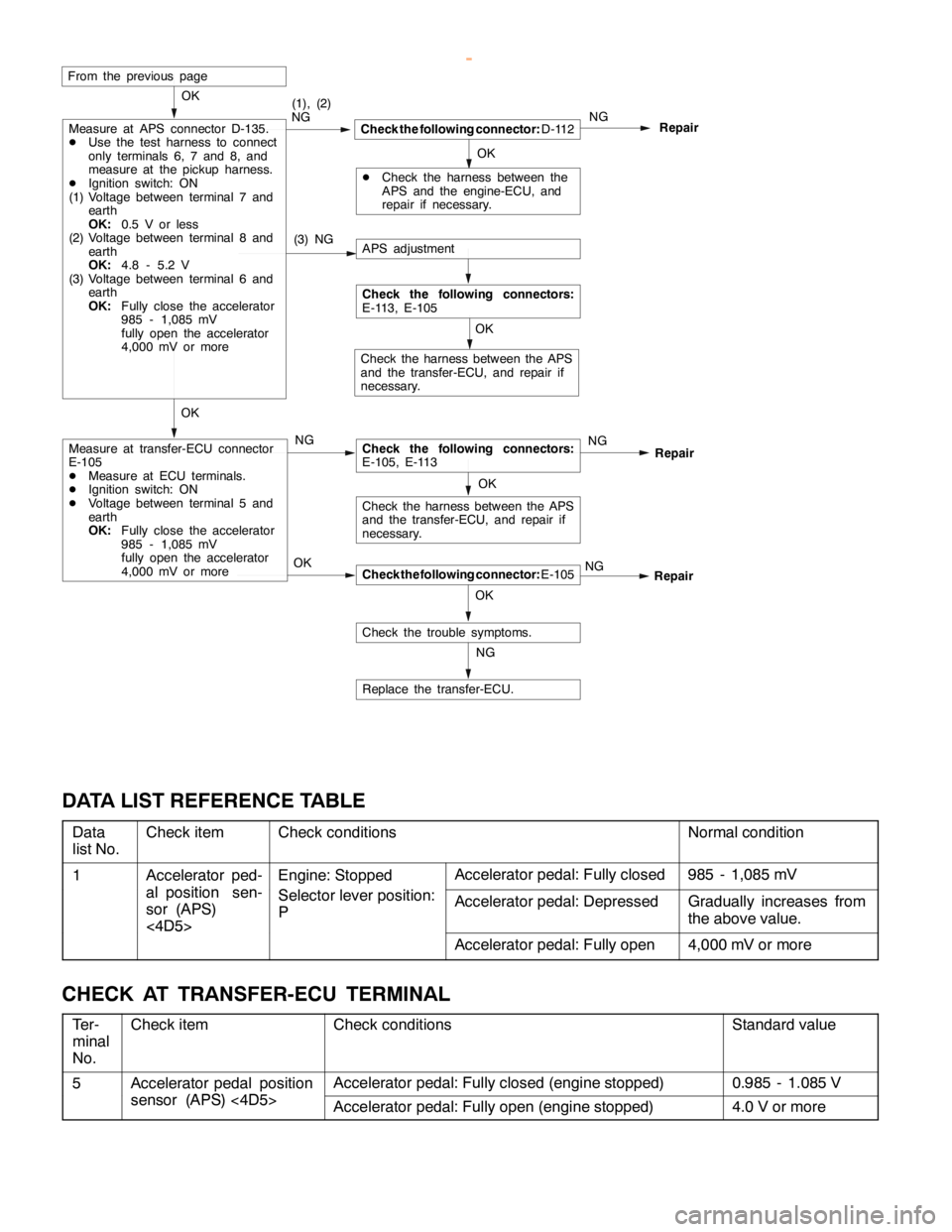

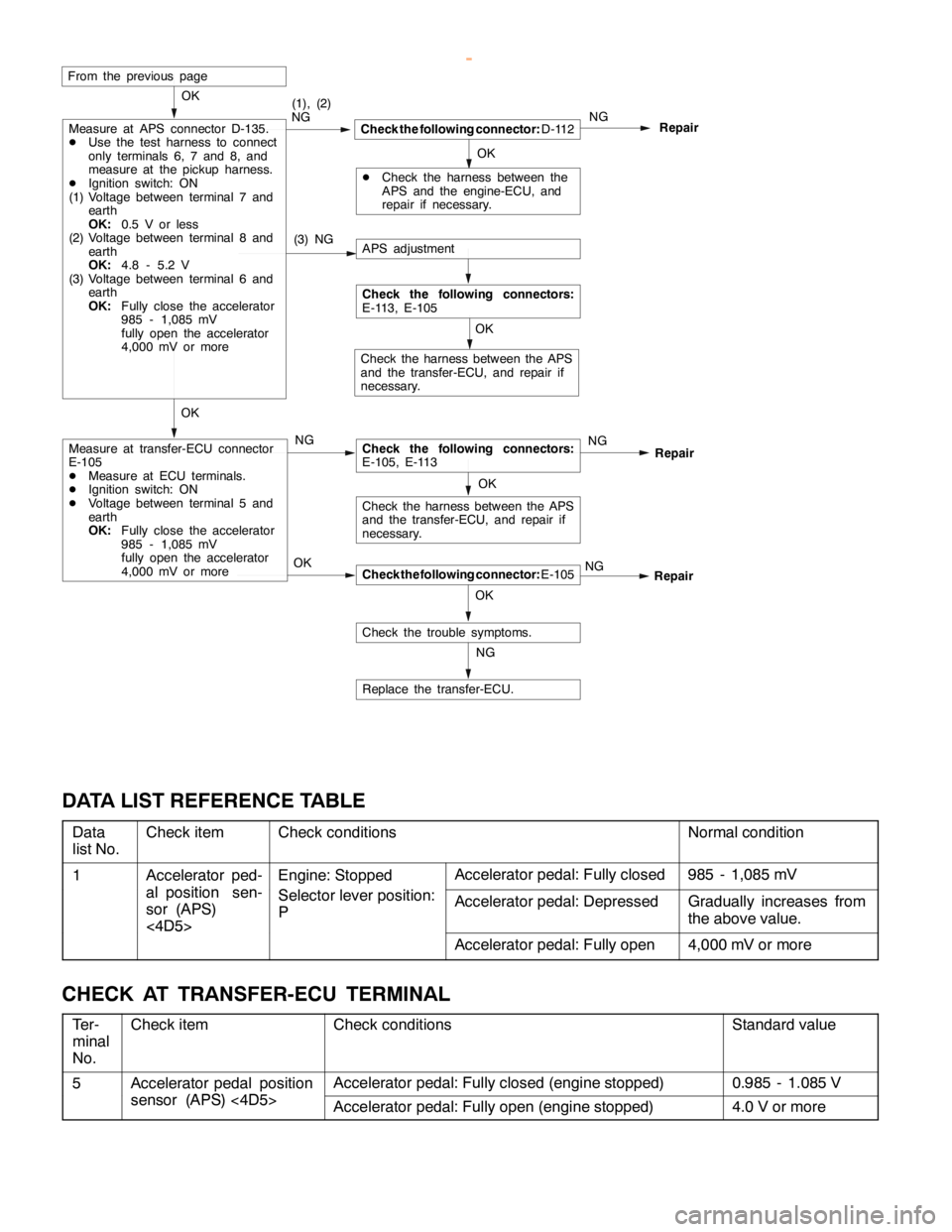

MANUAL TRANSMISSION -Troubleshooting 22-2

OKOK OK

NG

NG

NG(1), (2)

NG

Check the following connector:D-112Repair OK

DCheck the harness between the

APS and the engine-ECU, and

repair if necessary.OK

Measure at transfer-ECU connector

E-105

DMeasure at ECU terminals.

DIgnition switch: ON

DVoltage between terminal 5 and

earth

OK:Fully close the accelerator

985 - 1,085 mV

fully open the accelerator

4,000 mV or more

Check the following connector:E-105

Check the trouble symptoms.OK

Check the following connectors:

E-105, E-113 NG

Replace the transfer-ECU. OK

NGRepair

Check the harness between the APS

and the transfer-ECU, and repair if

necessary.

Check the harness between the APS

and the transfer-ECU, and repair if

necessary.

From the previous page

(3) NG

Measure at APS connector D-135.

DUse the test harness to connect

only terminals 6, 7 and 8, and

measure at the pickup harness.

DIgnition switch: ON

(1) Voltage between terminal 7 and

earth

OK:0.5 V or less

(2) Voltage between terminal 8 and

earth

OK:4.8 - 5.2 V

(3) Voltage between terminal 6 and

earth

OK:Fully close the accelerator

985 - 1,085 mV

fully open the accelerator

4,000 mV or more

APS adjustment

Check the following connectors:

E-113, E-105

Repair

DATA LIST REFERENCE TABLE

Data

list No.Check itemCheck conditionsNormal condition

1Accelerator ped-

alpositionsen

Engine: Stopped

Sllii

Accelerator pedal: Fully closed985 - 1,085 mV

al position sen-

sor (APS)

<4D5>Selector lever position:

PAccelerator pedal: DepressedGradually increases from

the above value.

<4D5>

Accelerator pedal: Fully open4,000 mV or more

CHECK AT TRANSFER-ECU TERMINAL

Ter-

minal

No.Check itemCheck conditionsStandard value

5Accelerator pedal position

(APS)4D5

Accelerator pedal: Fully closed (engine stopped)0.985 - 1.085 Vpp

sensor (APS) <4D5>Accelerator pedal: Fully open (engine stopped)4.0 V or more

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Trending: engine coolant, fuel cap, display, fuses, light, ECO mode, fuse diagram