speed sensor MITSUBISHI MONTERO 2000 Service Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 620 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-10

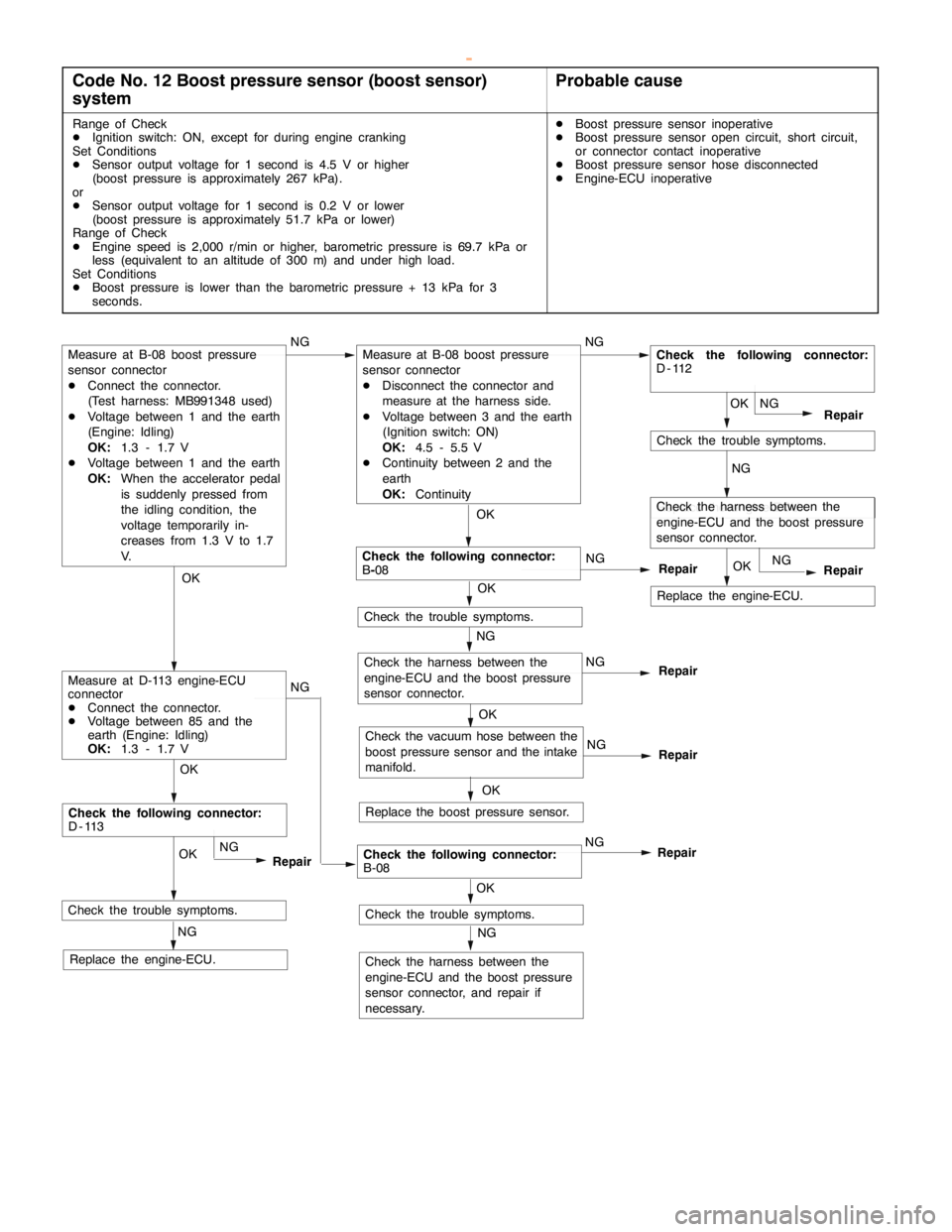

Code No. 12 Boost pressure sensor (boost sensor)

systemProbable cause

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DSensor output voltage for 1 second is 4.5 V or higher

(boost pressure is approximately 267 kPa).

or

DSensor output voltage for 1 second is 0.2 V or lower

(boost pressure is approximately 51.7 kPa or lower)

Range of Check

DEngine speed is 2,000 r/min or higher, barometric pressure is 69.7 kPa or

less (equivalent to an altitude of 300 m) and under high load.

Set Conditions

DBoost pressure is lower than the barometric pressure + 13 kPa for 3

seconds.DBoost pressure sensor inoperative

DBoost pressure sensor open circuit, short circuit,

or connector contact inoperative

DBoost pressure sensor hose disconnected

DEngine-ECU inoperative

NG

Check the trouble symptoms.

Replace the engine-ECU.

Check the following connector:

D-113

NGOK

NG

Repair

RepairOK

NG

Check the trouble symptoms.

OKOK

OK

Check the following connector:

B-08NG

Check the trouble symptoms. NG

Repair

NG

NG

Check the vacuum hose between the

boost pressure sensor and the intake

manifold.

Replace the boost pressure sensor.

OK OK OK

Repair

NG

Repair

Check the trouble symptoms.

Check the harness between the

engine-ECU and the boost pressure

sensor connector, and repair if

necessary.

NG OK

NG

RepairCheck the following connector:

B-08NG

Measure at B-08 boost pressure

sensor connector

DConnect the connector.

(Test harness: MB991348 used)

DVoltage between 1 and the earth

(Engine: Idling)

OK:1.3 - 1.7 V

DVoltage between 1 and the earth

OK:When the accelerator pedal

is suddenly pressed from

the idling condition, the

voltage temporarily in-

creases from 1.3 V to 1.7

V.

Measure at D-113 engine-ECU

connector

DConnect the connector.

DVoltage between 85 and the

earth (Engine: Idling)

OK:1.3 - 1.7 V

Check the harness between the

engine-ECU and the boost pressure

sensor connector.

Measure at B-08 boost pressure

sensor connector

DDisconnect the connector and

measure at the harness side.

DVoltage between 3 and the earth

(Ignition switch: ON)

OK:4.5 - 5.5 V

DContinuity between 2 and the

earth

OK:Continuity

Replace the engine-ECU.NGCheck the harness between the

engine-ECU and the boost pressure

sensor connector.

Replace the engine-ECU.OK

NG

Repair

Check the following connector:

D-112

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 623 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-13

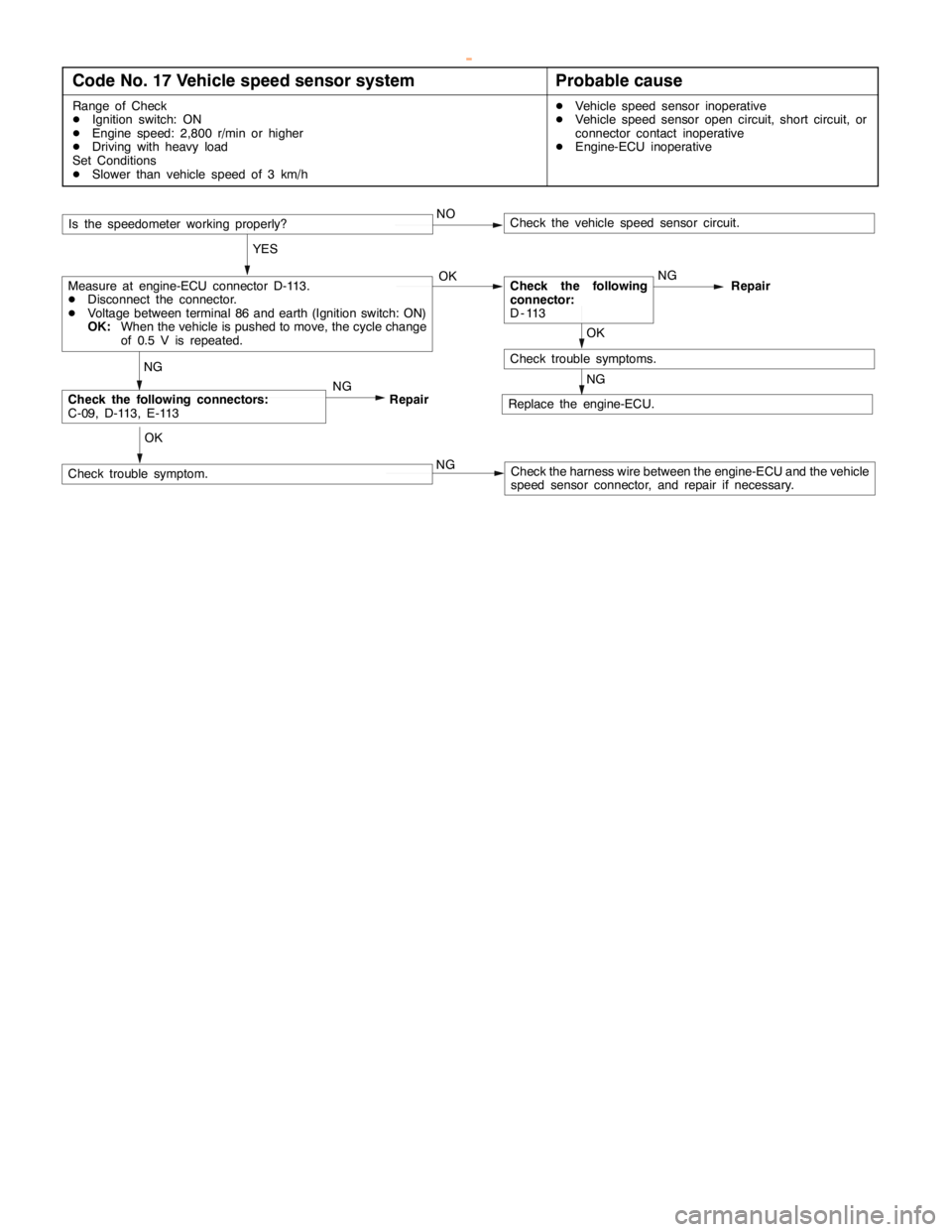

Code No. 17 Vehicle speed sensor systemProbable cause

Range of Check

DIgnition switch: ON

DEngine speed: 2,800 r/min or higher

DDriving with heavy load

Set Conditions

DSlower than vehicle speed of 3 km/hDVehicle speed sensor inoperative

DVehicle speed sensor open circuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

Replace the engine-ECU.

NG

OK

Check trouble symptoms.

NG

OK

Check trouble symptom.

NG

Check the following connectors:

C-09, D-113, E-113NG

Repair

YES

Measure at engine-ECU connector D-113.

DDisconnect the connector.

DVoltage between terminal 86 and earth (Ignition switch: ON)

OK:When the vehicle is pushed to move, the cycle change

of 0.5 V is repeated.Check the following

connector:

D-113NG

Repair

Is the speedometer working properly?NO

Check the harness wire between the engine-ECU and the vehicle

speed sensor connector, and repair if necessary.

Check the vehicle speed sensor circuit.

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 624 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-14

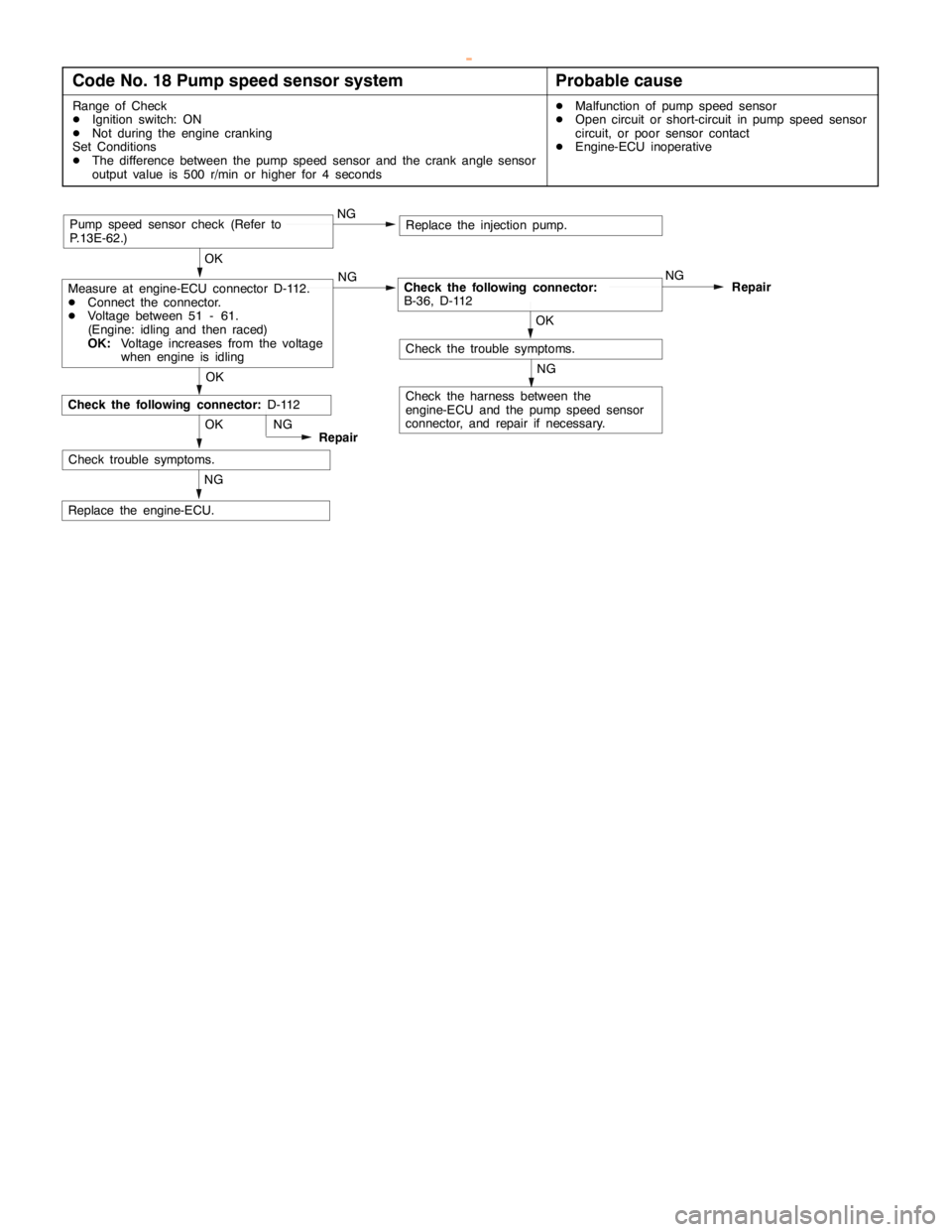

Code No. 18 Pump speed sensor systemProbable cause

Range of Check

DIgnition switch: ON

DNot during the engine cranking

Set Conditions

DThe difference between the pump speed sensor and the crank angle sensor

output value is 500 r/min or higher for 4 secondsDMalfunction of pump speed sensor

DOpen circuit or short-circuit in pump speed sensor

circuit, or poor sensor contact

DEngine-ECU inoperative

NG

Replace the engine-ECU.OK

Check trouble symptoms.NG

Repair

NG

Check the harness between the

engine-ECU and the pump speed sensor

connector, and repair if necessary.

OK

Replace the injection pump.

OK

Measure at engine-ECU connector D-112.

DConnect the connector.

DVoltage between 51 - 61.

(Engine: idling and then raced)

OK:Voltage increases from the voltage

when engine is idlingNGCheck the following connector:

B-36, D-112NG

Repair

OK

NGPump speed sensor check (Refer to

P.13E-62.)

Check the following connector:D-112

Check the trouble symptoms.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 625 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-15

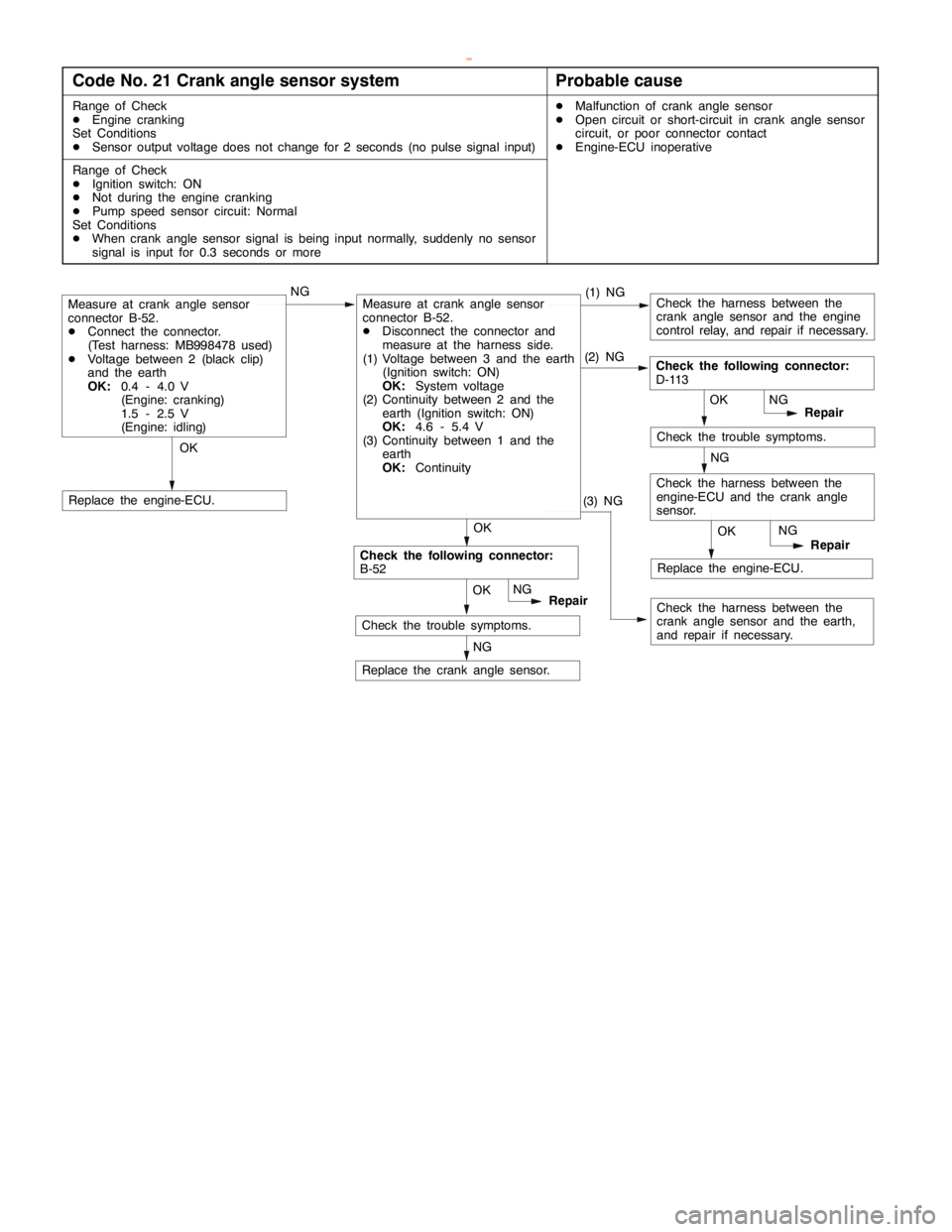

Code No. 21 Crank angle sensor systemProbable cause

Range of Check

DEngine cranking

Set Conditions

DSensor output voltage does not change for 2 seconds (no pulse signal input)DMalfunction of crank angle sensor

DOpen circuit or short-circuit in crank angle sensor

circuit, or poor connector contact

DEngine-ECU inoperative

Range of Check

DIgnition switch: ON

DNot during the engine cranking

DPump speed sensor circuit: Normal

Set Conditions

DWhen crank angle sensor signal is being input normally, suddenly no sensor

signal is input for 0.3 seconds or more

OK

Check the harness between the

crank angle sensor and the engine

control relay, and repair if necessary.

OKNG(1) NGMeasure at crank angle sensor

connector B-52.

DConnect the connector.

(Test harness: MB998478 used)

DVoltage between 2 (black clip)

and the earth

OK:0.4 - 4.0 V

(Engine: cranking)

1.5 - 2.5 V

(Engine: idling)

NG

Replace the crank angle sensor.

Replace the engine-ECU.

OKRepair

Check the following connector:

D-113

NG

OK

Repair NG

Check the harness between the

engine-ECU and the crank angle

sensor.NG

Check the trouble symptoms.

Replace the engine-ECU.

Check the harness between the

crank angle sensor and the earth,

and repair if necessary. OKRepair NG

Check the following connector:

B-52

Check the trouble symptoms.

Measure at crank angle sensor

connector B-52.

DDisconnect the connector and

measure at the harness side.

(1) Voltage between 3 and the earth

(Ignition switch: ON)

OK:System voltage

(2) Continuity between 2 and the

earth (Ignition switch: ON)

OK:4.6 - 5.4 V

(3) Continuity between 1 and the

earth

OK:Continuity(2) NG

(3) NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 651 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-41

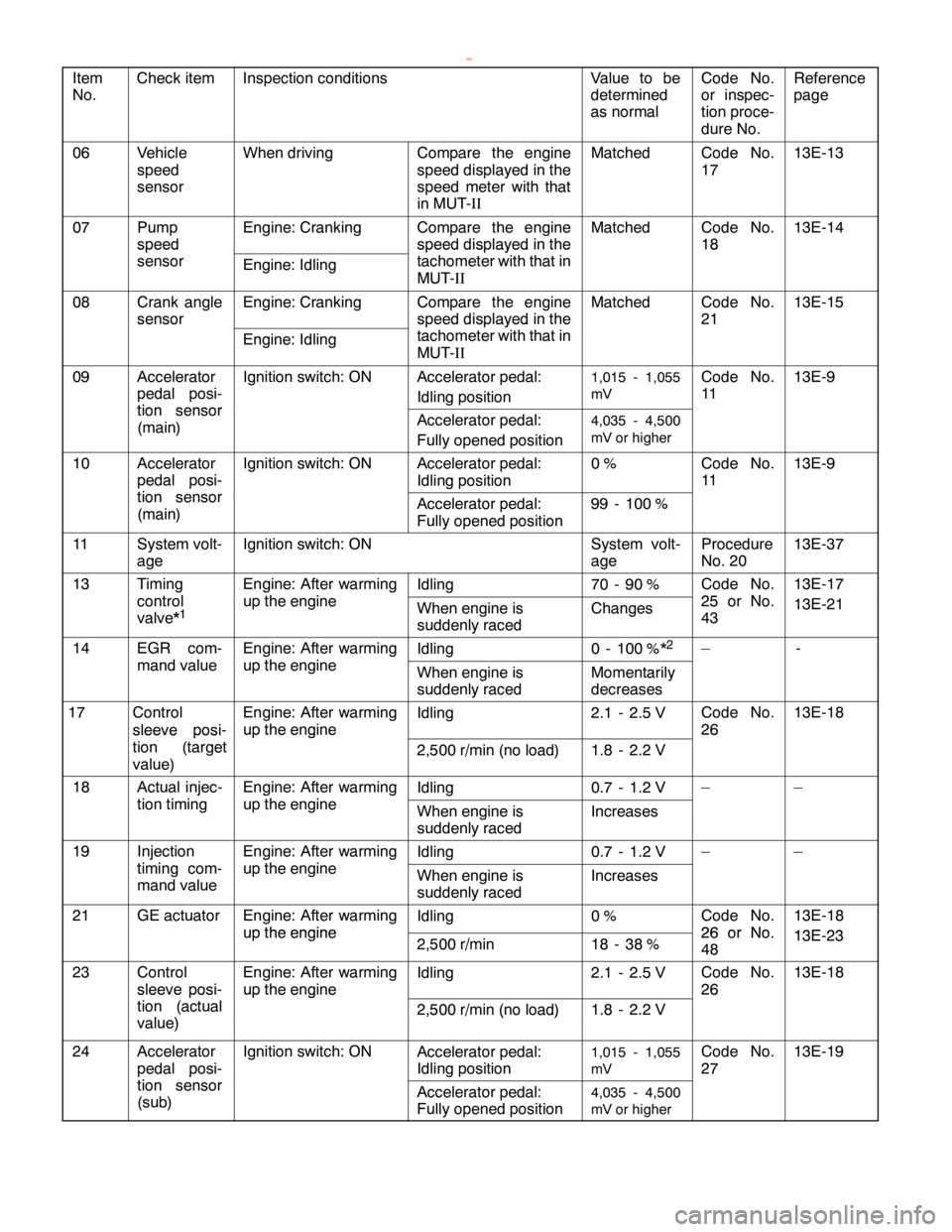

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be

determined

as normal Inspection conditions Check item

06Vehicle

speed

sensorWhen drivingCompare the engine

speed displayed in the

speed meter with that

in MUT-IIMatchedCode No.

1713E-13

07Pump

speedEngine: CrankingCompare the engine

speed displayed in theMatchedCode No.

1813E-14

speed

sensorEngine: Idling

speeddisplayedinthe

tachometer with that in

MUT-II

18

08Crank angle

sensorEngine: CrankingCompare the engine

speed displayed in theMatchedCode No.

2113E-15

sensor

Engine: Idling

speeddisplayedinthe

tachometer with that in

MUT-II

21

09Accelerator

pedal posi-

tionsensor

Ignition switch: ONAccelerator pedal:

Idling position1,015 - 1,055

mVCode No.

1113E-9

tion sensor

(main)Accelerator pedal:

Fully opened position4,035 - 4,500

mV or higher

10Accelerator

pedal posi-

ti

Ignition switch: ONAccelerator pedal:

Idling position0%Code No.

1113E-9

pp

tion sensor

(main)Accelerator pedal:

Fully opened position99 - 100 %

11System volt-

ageIgnition switch: ONSystem volt-

ageProcedure

No. 2013E-37

13Timing

tl

Engine: After warming

thi

Idling70 - 90 %Code No.

25N

13E-17g

control

valve*1

gg

up the engineWhen engine is

suddenly racedChanges25 or No.

4313E-21

14EGR com-

dl

Engine: After warming

thi

Idling0 - 100 %*2–-

mand value

gg

up the engineWhen engine is

suddenly racedMomentarily

decreases

17Control

sleeve posi-Engine: After warming

up the engineIdling2.1 - 2.5 VCode No.

2613E-18

sleeveposi

tion (target

value)

uptheengine

2,500 r/min (no load)1.8 - 2.2 V

26

18Actual injec-

titi i

Engine: After warming

thi

Idling0.7 - 1.2 V––j

tion timing

gg

up the engineWhen engine is

suddenly racedIncreases

19Injection

ti i

Engine: After warming

thi

Idling0.7 - 1.2 V––j

timing com-

mand value

gg

up the engineWhen engine is

suddenly racedIncreases

21GE actuatorEngine: After warming

uptheengine

Idling0%Code No.

26orNo

13E-18

13E 23upthe engine2,500 r/min18 - 38 %26orNo.

4813E-23

23Control

sleeve posi-Engine: After warming

up the engineIdling2.1 - 2.5 VCode No.

2613E-18

sleeveposi

tion (actual

l)

uptheengine

2,500 r/min (no load)1.8 - 2.2 V

26

(

value)2,500r/min(noload)1.82.2V

24Accelerator

pedal posi-

ti

Ignition switch: ONAccelerator pedal:

Idling position1,015 - 1,055

mVCode No.

2713E-19

pp

tion sensor

(sub)Accelerator pedal:

Fully opened position4,035 - 4,500

mV or higher

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 654 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-44

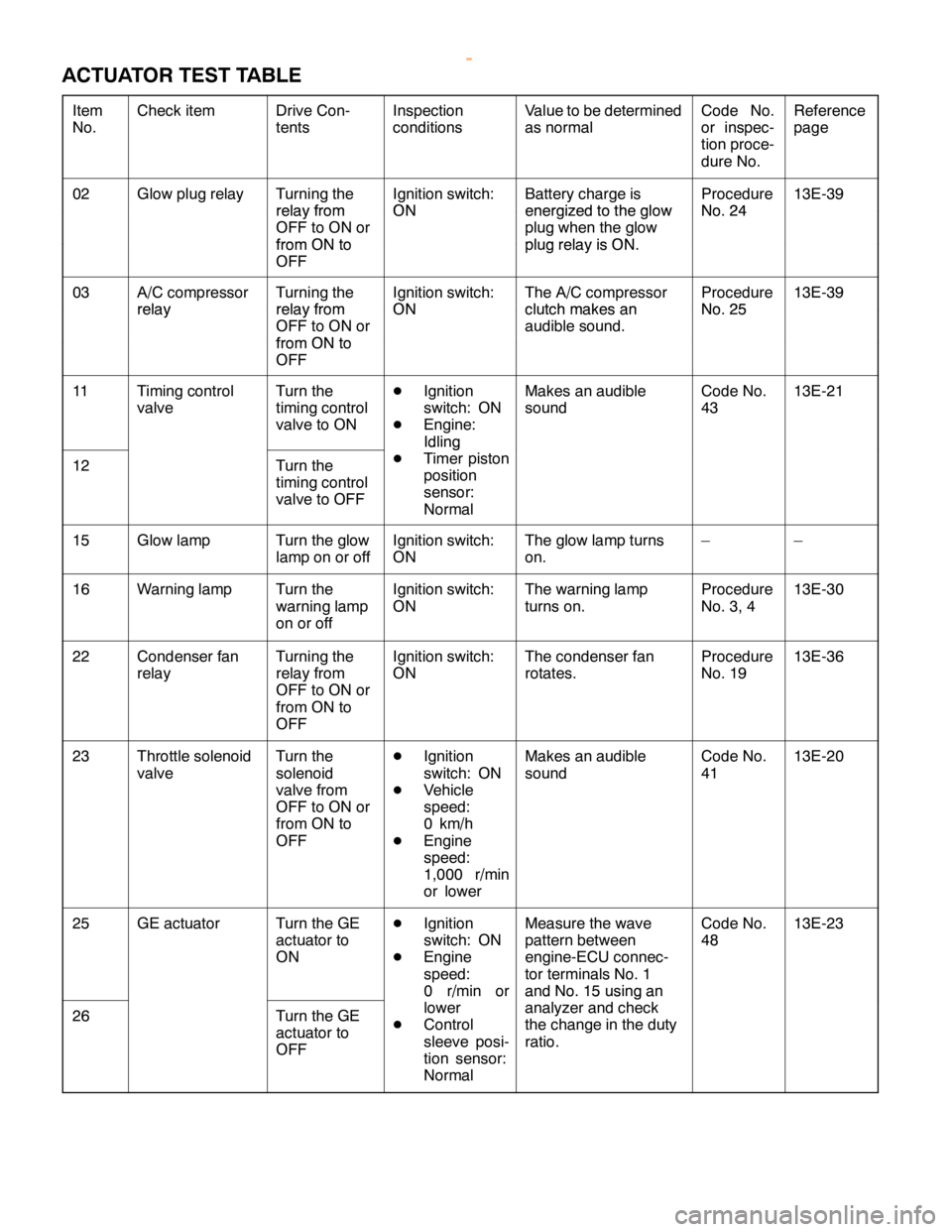

ACTUATOR TEST TABLE

Item

No.Check itemDrive Con-

tentsInspection

conditionsValue to be determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

02Glow plug relayTurning the

relayfrom

Ignition switch:

ON

Battery charge is

energizedtotheglow

Procedure

No24

13E-39

relayfrom

OFF to ON or

fromONto

ONenergizedtotheglow

plug when the glow

plugrelayisON

No.24

fromONto

OFFplug relayisON.

03A/C compressor

relay

Turning the

relayfrom

Ignition switch:

ON

The A/C compressor

clutchmakesan

Procedure

No25

13E-39

relayrelayfrom

OFF to ON or

fromONto

ONclutchmakes an

audible sound.No.25

fromONto

OFF

11Timing control

valveTurn the

timing control

valve to ONDIgnition

switch: ON

DEngine:

Idlin

g

Makes an audible

soundCode No.

4313E-21

12Turn the

timing control

valve to OFF

Idling

DTimer piston

position

sensor:

Normal

15Glow lampTurn the glow

lamp on or offIgnition switch:

ONThe glow lamp turns

on.––

16Warning lampTurn the

warning lamp

on or offIgnition switch:

ONThe warning lamp

turns on.Procedure

No. 3, 413E-30

22Condenser fan

relayTurning the

relay from

OFF to ON or

from ON to

OFFIgnition switch:

ONThe condenser fan

rotates.Procedure

No. 1913E-36

23Throttle solenoid

valveTurn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/h

DEngine

speed:

1,000 r/min

or lowerMakes an audible

soundCode No.

4113E-20

25GE actuatorTurn the GE

actuator to

ONDIgnition

switch: ON

DEngine

speed:

0 r/min orMeasure the wave

pattern between

engine-ECU connec-

tor terminals No. 1

and No. 15 using anCode No.

4813E-23

26Turn the GE

actuator to

OFF

0r/minor

lower

DControl

sleeve posi-

tion sensor:

Normal

andNo.15usingan

analyzer and check

the change in the duty

ratio.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 657 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-47

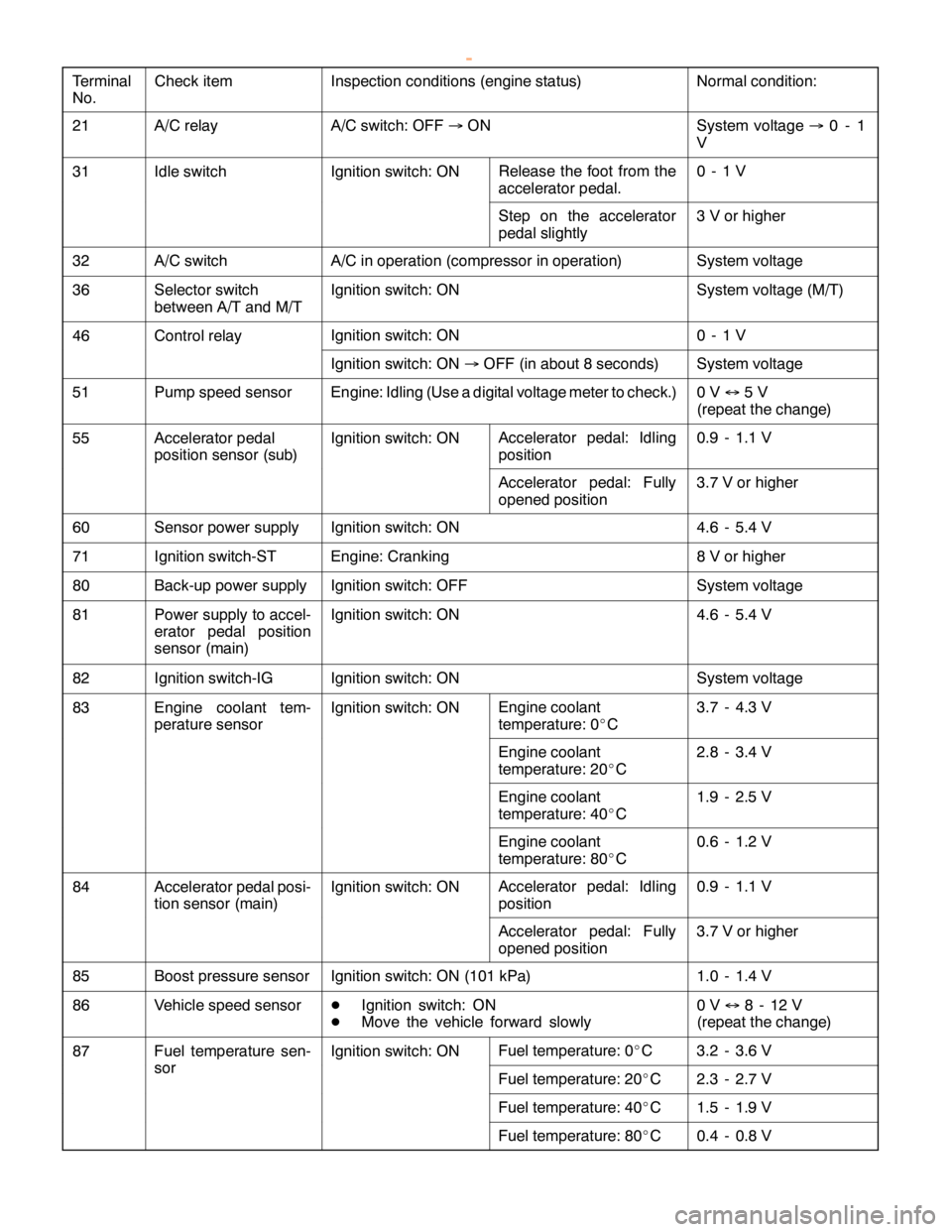

Terminal

No.Normal condition: Inspection conditions (engine status) Check item

21A/C relayA/C switch: OFF→ONSystem voltage→0-1

V

31Idle switchIgnition switch: ONRelease the foot from the

accelerator pedal.0-1V

Step on the accelerator

pedal slightly3 V or higher

32A/C switchA/C in operation (compressor in operation)System voltage

36Selector switch

between A/T and M/TIgnition switch: ONSystem voltage (M/T)

46Control relayIgnition switch: ON0-1V

Ignition switch: ON→OFF (in about 8 seconds)System voltage

51Pump speed sensorEngine: Idling (Use a digital voltage meter to check.)0V↔5V

(repeat the change)

55Accelerator pedal

position sensor (sub)Ignition switch: ONAccelerator pedal: Idling

position0.9 - 1.1 V

Accelerator pedal: Fully

opened position3.7 V or higher

60Sensor power supplyIgnition switch: ON4.6 - 5.4 V

71Ignition switch-STEngine: Cranking8 V or higher

80Back-up power supplyIgnition switch: OFFSystem voltage

81Power supply to accel-

erator pedal position

sensor (main)Ignition switch: ON4.6 - 5.4 V

82Ignition switch-IGIgnition switch: ONSystem voltage

83Engine coolant tem-

perature sensorIgnition switch: ONEngine coolant

temperature: 0_C3.7 - 4.3 V

Engine coolant

temperature: 20_C2.8 - 3.4 V

Engine coolant

temperature: 40_C1.9 - 2.5 V

Engine coolant

temperature: 80_C0.6 - 1.2 V

84Accelerator pedal posi-

tion sensor (main)Ignition switch: ONAccelerator pedal: Idling

position0.9 - 1.1 V

Accelerator pedal: Fully

opened position3.7 V or higher

85Boost pressure sensorIgnition switch: ON (101 kPa)1.0 - 1.4 V

86Vehicle speed sensorDIgnition switch: ON

DMove the vehicle forward slowly0V↔8 - 12 V

(repeat the change)

87Fuel temperature sen-

sor

Ignition switch: ONFuel temperature: 0_C3.2 - 3.6 V

sorFuel temperature: 20_C2.3 - 2.7 V

Fuel temperature: 40_C1.5 - 1.9 V

Fuel temperature: 80_C0.4 - 0.8 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 735 of 1839

INTAKE AND EXHAUST -General Information/Service Specifications/Sealant15-3

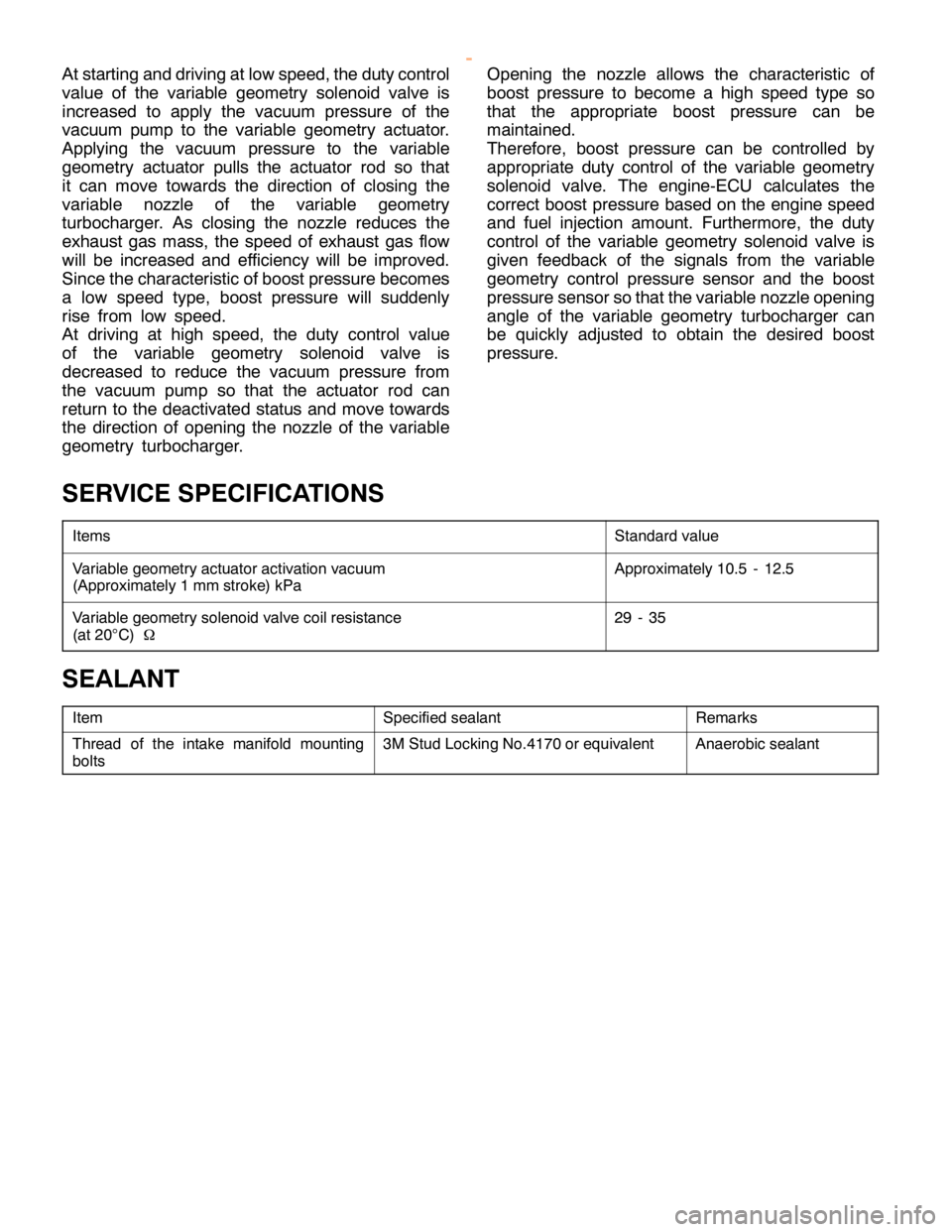

At starting and driving at low speed, the duty control

value of the variable geometry solenoid valve is

increased to apply the vacuum pressure of the

vacuum pump to the variable geometry actuator.

Applying the vacuum pressure to the variable

geometry actuator pulls the actuator rod so that

it can move towards the direction of closing the

variable nozzle of the variable geometry

turbocharger. As closing the nozzle reduces the

exhaust gas mass, the speed of exhaust gas flow

will be increased and efficiency will be improved.

Since the characteristic of boost pressure becomes

a low speed type, boost pressure will suddenly

rise from low speed.

At driving at high speed, the duty control value

of the variable geometry solenoid valve is

decreased to reduce the vacuum pressure from

the vacuum pump so that the actuator rod can

return to the deactivated status and move towards

the direction of opening the nozzle of the variable

geometry turbocharger.Opening the nozzle allows the characteristic of

boost pressure to become a high speed type so

that the appropriate boost pressure can be

maintained.

Therefore, boost pressure can be controlled by

appropriate duty control of the variable geometry

solenoid valve. The engine-ECU calculates the

correct boost pressure based on the engine speed

and fuel injection amount. Furthermore, the duty

control of the variable geometry solenoid valve is

given feedback of the signals from the variable

geometry control pressure sensor and the boost

pressure sensor so that the variable nozzle opening

angle of the variable geometry turbocharger can

be quickly adjusted to obtain the desired boost

pressure.

SERVICE SPECIFICATIONS

ItemsStandard value

Variable geometry actuator activation vacuum

(Approximately 1 mm stroke) kPaApproximately 10.5 - 12.5

Variable geometry solenoid valve coil resistance

(at 20°C)Ω29 - 35

SEALANT

ItemSpecified sealantRemarks

Thread of the intake manifold mounting

bolts3M Stud Locking No.4170 or equivalentAnaerobic sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

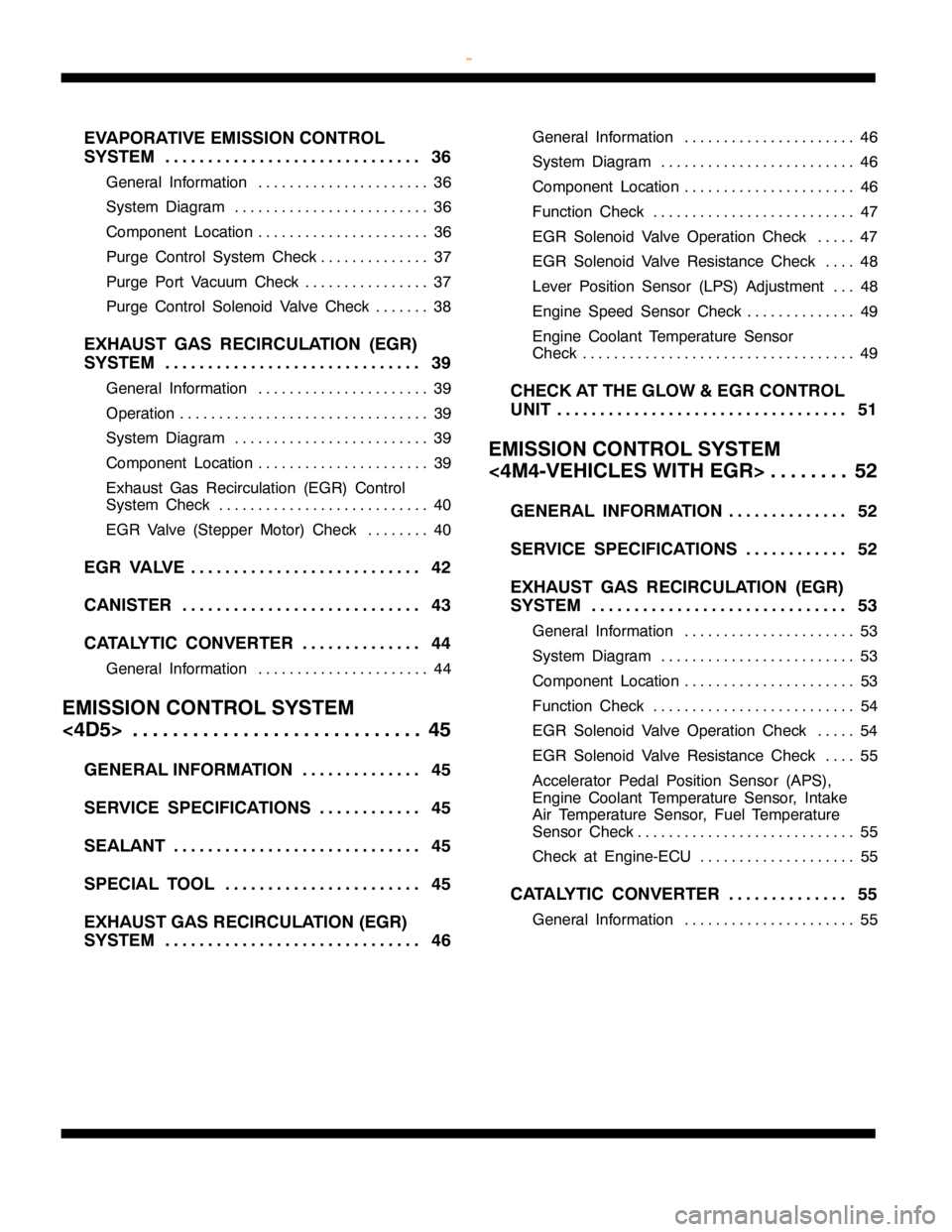

Page 804 of 1839

17-2

EVAPORATIVE EMISSION CONTROL

SYSTEM 36..............................

General Information 36......................

System Diagram 36.........................

Component Location 36......................

Purge Control System Check 37..............

Purge Port Vacuum Check 37................

Purge Control Solenoid Valve Check 38.......

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 39..............................

General Information 39......................

Operation 39................................

System Diagram 39.........................

Component Location 39......................

Exhaust Gas Recirculation (EGR) Control

System Check 40...........................

EGR Valve (Stepper Motor) Check 40........

EGR VALVE 42...........................

CANISTER 43............................

CATALYTIC CONVERTER 44..............

General Information 44......................

EMISSION CONTROL SYSTEM

<4D5> 45.............................

GENERAL INFORMATION 45..............

SERVICE SPECIFICATIONS 45............

SEALANT 45.............................

SPECIAL TOOL 45.......................

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 46..............................

General Information 46......................

System Diagram 46.........................

Component Location 46......................

Function Check 47..........................

EGR Solenoid Valve Operation Check 47.....

EGR Solenoid Valve Resistance Check 48....

Lever Position Sensor (LPS) Adjustment 48...

Engine Speed Sensor Check 49..............

Engine Coolant Temperature Sensor

Check 49...................................

CHECK AT THE GLOW & EGR CONTROL

UNIT 51..................................

EMISSION CONTROL SYSTEM

<4M4-VEHICLES WITH EGR> 52........

GENERAL INFORMATION 52..............

SERVICE SPECIFICATIONS 52............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 53..............................

General Information 53......................

System Diagram 53.........................

Component Location 53......................

Function Check 54..........................

EGR Solenoid Valve Operation Check 54.....

EGR Solenoid Valve Resistance Check 55....

Accelerator Pedal Position Sensor (APS),

Engine Coolant Temperature Sensor, Intake

Air Temperature Sensor, Fuel Temperature

Sensor Check 55............................

Check at Engine-ECU 55....................

CATALYTIC CONVERTER 55..............

General Information 55......................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 814 of 1839

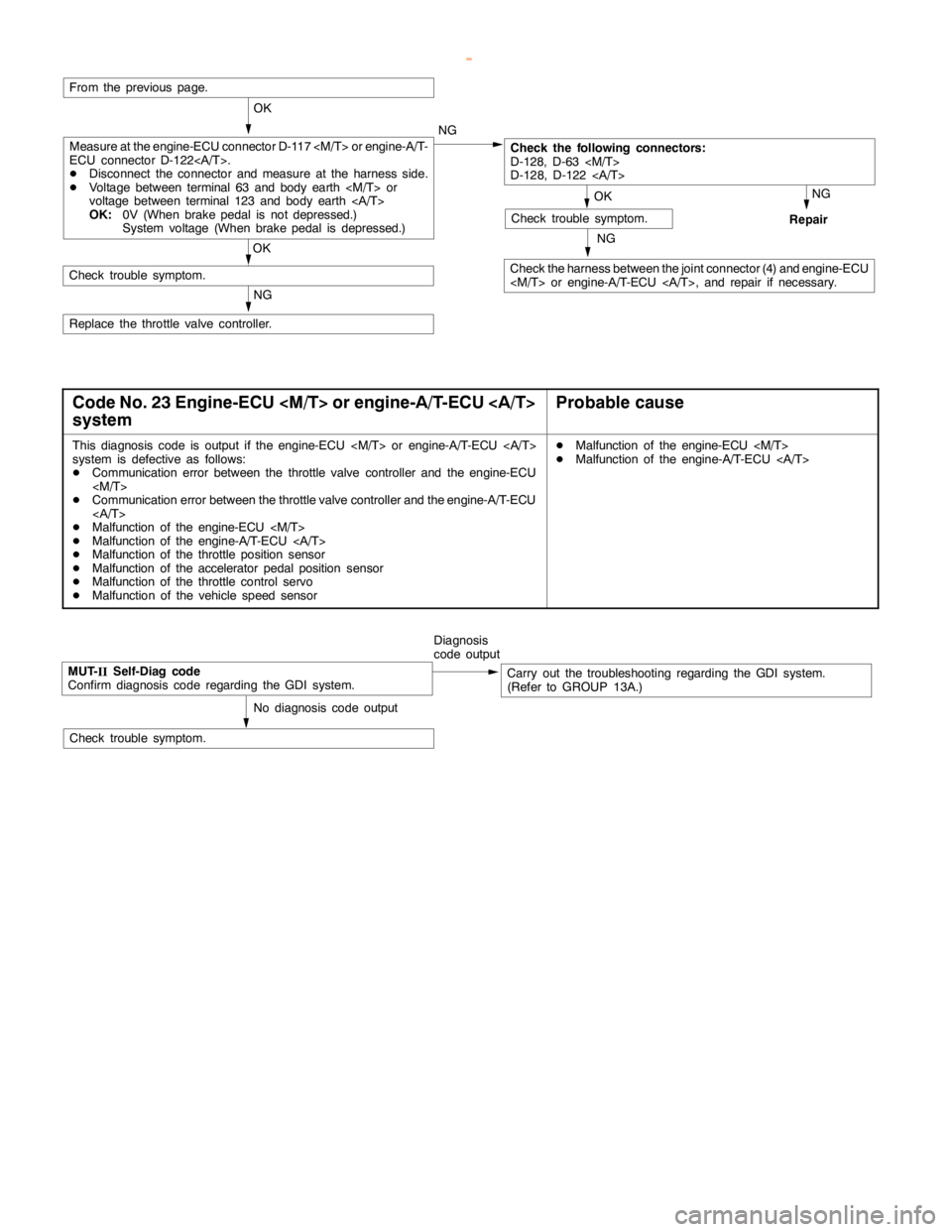

ENGINE AND EMISSION CONTROL -Auto-cruise Control System17-12

NG

Check the harness between the joint connector (4) and engine-ECU

NG

Repair

OK

Check trouble symptom.

From the previous page.

OK

Check the following connectors:

D-128, D-63

D-128, D-122

OK

Check trouble symptom.

NG

Replace the throttle valve controller.NG

Measure at the engine-ECU connector D-117

ECU connector D-122.

DDisconnect the connector and measure at the harness side.

DVoltage between terminal 63 and body earth

voltage between terminal 123 and body earth

OK:0V (When brakepedal is not depressed.)

System voltage (When brakepedal is depressed.)

Code No. 23 Engine-ECU

systemProbable cause

This diagnosis code is output if the engine-ECU

system is defective as follows:

DCommunication error between the throttle valve controller and the engine-ECU

DCommunication error between the throttle valve controller and the engine-A/T-ECU

DMalfunction of the engine-ECU

DMalfunction of the engine-A/T-ECU

DMalfunction of the throttle position sensor

DMalfunction of the accelerator pedal positionsensor

DMalfunction of the throttle control servo

DMalfunction of the vehicle speed sensorDMalfunction of the engine-ECU

DMalfunction of the engine-A/T-ECU

MUT-

IISelf-Diag code

Confirm diagnosis code regarding the GDI system.Diagnosis

code outputCarry out the troubleshooting regarding the GDI system.

(Refer to GROUP 13A.)

No diagnosis code output

Check trouble symptom.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk