charging MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 308 of 1839

GDI -Troubleshooting

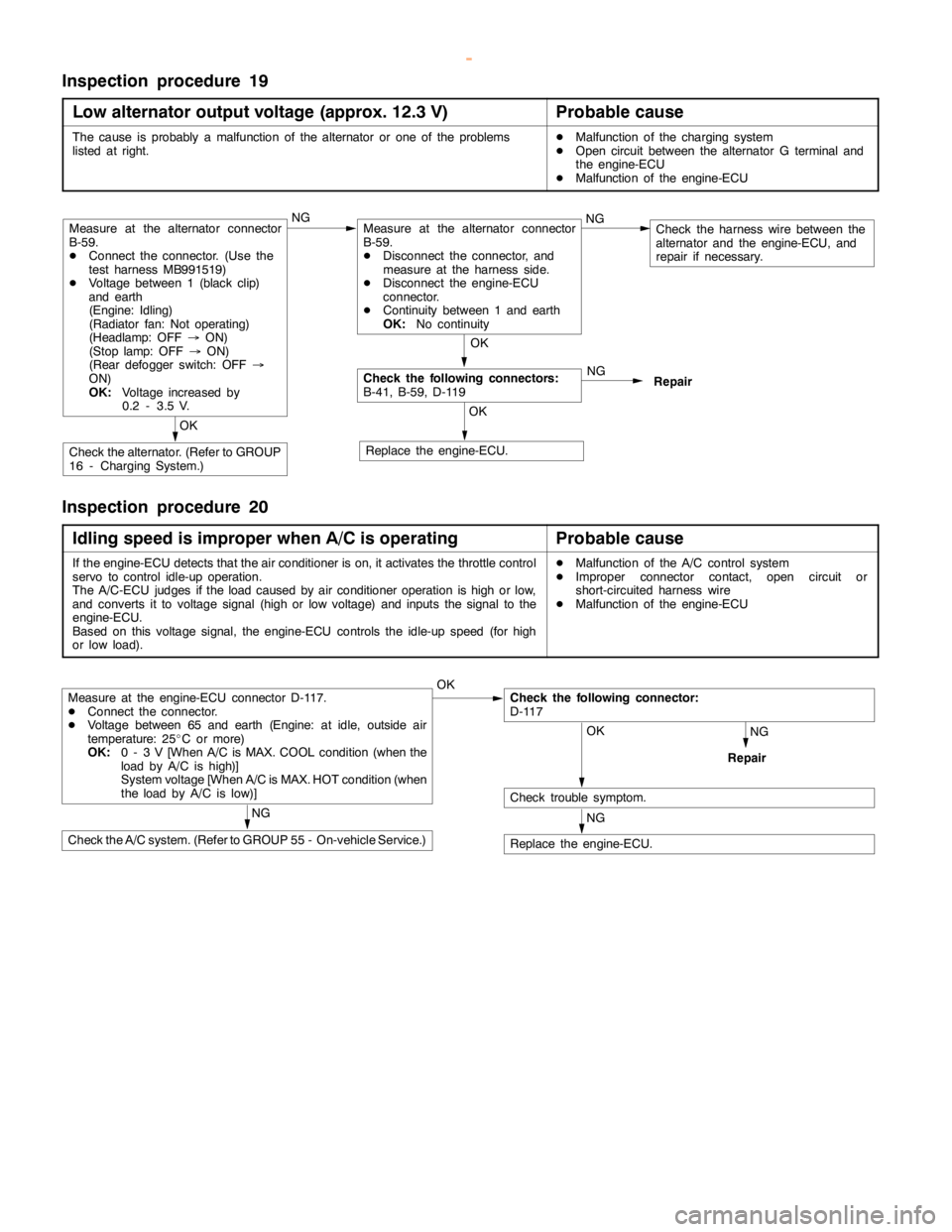

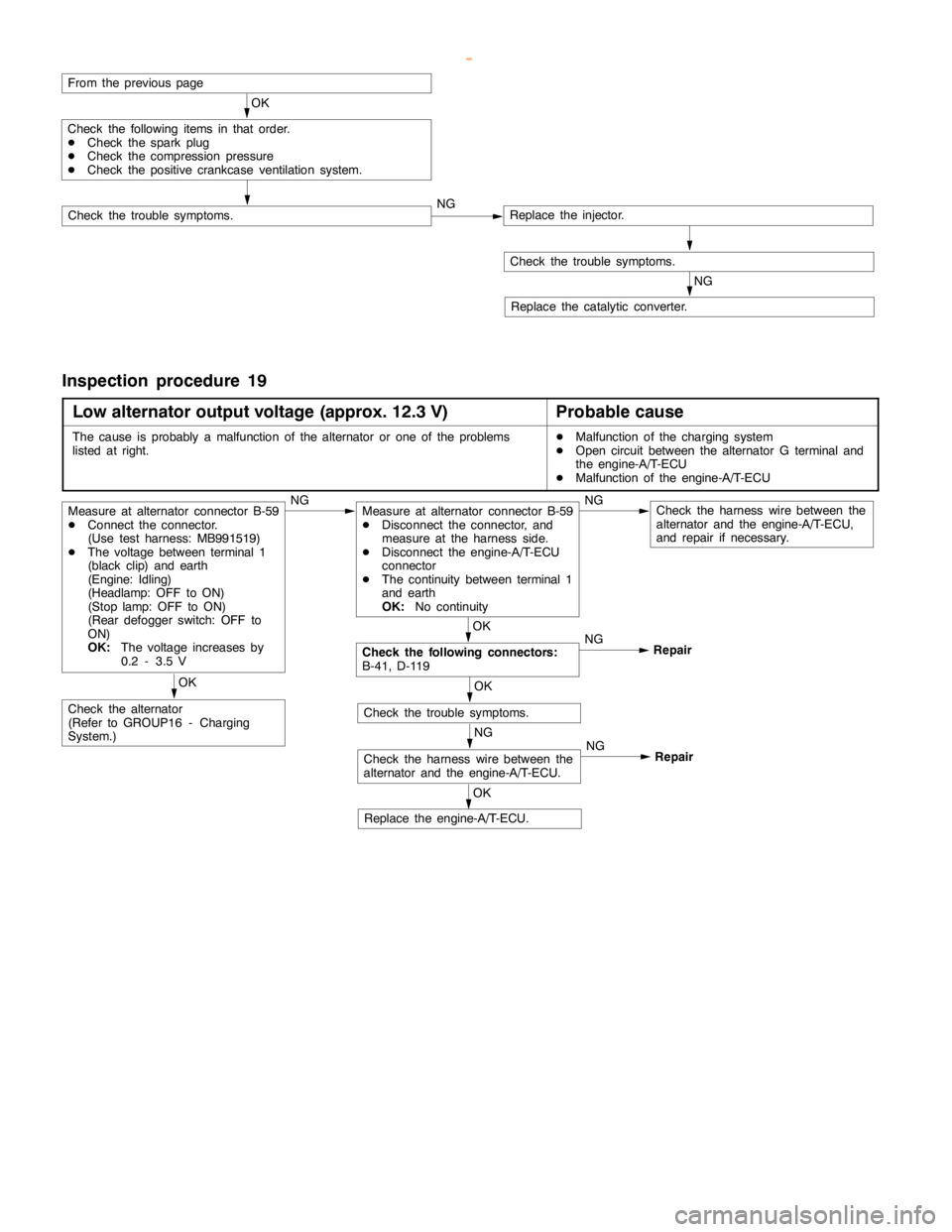

Inspection procedure 19

Low alternator output voltage (approx.12.3 V)

Probable cause

The cause is probably a malfunction of the alternator or one of the problems

listed at right.DMalfunction of the charging system

DOpen circuit between the alternator G terminal and

the engine-ECU

DMalfunction of the engine-ECU

NG

Repair

OK

Replace the engine-ECU.

OK

Check the alternator. (Refer to GROUP

16 - Charging System.)

OK

Check the following connectors:

B-41, B-59, D-119

Measure at the alternator connector

B-59.

DConnect the connector. (Use the

test harness MB991519)

DVoltage between 1 (black clip)

and earth

(Engine: Idling)

(Radiator fan: Not operating)

(Headlamp: OFF®ON)

(Stoplamp: OFF®ON)

(Rear defogger switch: OFF®

ON)

OK:

Voltage increased by

0.2 - 3.5 V.NGMeasure at the alternator connector

B-59.

DDisconnect the connector, and

measure at the harness side.

DDisconnect the engine-ECU

connector.

DContinuity between 1 and earth

OK:

No continuityNGCheck the harness wire between the

alternator and the engine-ECU, and

repair if necessary.

Inspection procedure 20

Idling speed is improper when A/C is operating

Probable cause

If the engine-ECU detects that the air conditioner is on, it activates the throttle control

servo to control idle-up operation.

The A/C-ECU judges if theloadcaused by air conditioner operation ishigh or low,

and converts it to voltage signal (high or low voltage) and inputs the signal to the

engine-ECU.

Based on this voltage signal, the engine-ECU controls the idle-up speed (forhigh

or low load).DMalfunction of the A/C control system

DImproper connector contact,opencircuit or

short-circuited harness wire

DMalfunction of the engine-ECU

NG

Repair

Measure at the engine-ECU connector D-117.

DConnect the connector.

DVoltage between 65 and earth (Engine: at idle, outside air

temperature: 25_C or more)

OK:

0 - 3 V [When A/C is MAX. COOL condition (when the

load by A/C is high)]

System voltage [When A/C is MAX. HOT condition (when

the load by A/C islow)]OKCheck the following connector:

D-117

OK

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Check the A/C system. (Refer to GROUP 55 - On-vehicle Service.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 400 of 1839

Page 707 of 1839

15-1

INTAKE AND

EXHAUST

CONTENTS

SERVICE SPECIFICATIONS 2.................

SEALANT 2..................................

SPECIAL TOOL 2............................

ON-VEHICLE SERVICE 2.....................

Intake Manifold Vacuum Check <6G7> 2.........

Turbocharger Supercharging Check <4D5> 2.....

Waste Gate Actuator Check <4D5> 3..........

Waste Gate Actuator Check <4M4> 3..........

AIR CLEANER 4.............................

INTERCOOLER<4D5, 4M4> 5.................

INTAKE MANIFOLD <6G7> 6.................

INTAKE MANIFOLD AND THROTTLE BODY

<4M4> 8.....................................EXHAUST MANIFOLD <6G7> 11..............

INTAKE MANIFOLD AND EXHAUST

MANIFOLD, TURBOCHARGER <4D5> 12...

TURBOCHARGER AND EXHAUST

MANIFOLD <4M4> 14.....................

TURBOCHARGER <4D5> 16.................

TURBOCHARGER <4M4> 19.................

EXHAUST PIPE AND MAIN MUFFLER

<6G7> 21...................................

EXHAUST PIPE AND MAIN MUFFLER

<4D5> 23...................................

EXHAUST PIPE AND MAIN MUFFLER

<4M4> 25...................................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 733 of 1839

15-1

INTAKE AND

EXHAUST

CONTENTS

GENERAL 2.................................

Outline of Changes 2...........................

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

ON-VEHICLE SERVICE 4.....................

Turbocharger Supercharging Check 4............

Supercharging Pressure Control

System Check 5...............................

Variable Geometry Actuator Check 6.............Variable Geometry Solenoid Valve Check 6.......

INTAKE MANIFOLD AND THROTTLE BODY

<4M4> 7.....................................

INTAKE MANIFOLD AND EXHAUST

MANIFOLD, THROTTLE BODY AND

TURBOCHARGER <4D5> 10..................

TURBOCHARGER AND EXHAUST

MANIFOLD <4M4> 12........................

EXHAUST PIPE AND MAIN MUFFLER

<4D5> 14....................................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 749 of 1839

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3..............

SPECIAL TOOL 4.........................

ON-VEHICLE SERVICE 5..................

Alternator Output Line Voltage Drop Test 5....

Output Current Test 6.......................

Regulated Voltage Test 8....................

Waveform Check Using An Analyzer 11.......

ALTERNATOR 13.........................

STARTING SYSTEM 23................

GENERAL INFORMATION 23..............

SERVICE SPECIFICATIONS 24............

STARTER MOTOR 24.....................

IGNITION SYSTEM 37.................

GENERAL INFORMATION 37..............

SERVICE SPECIFICATIONS 38............

SPECIAL TOOL 38.......................

ON-VEHICLE SERVICE 38................

Ignition Coil (With Built-in Power Transistor)

Check 38...................................

Spark Plug Check and Cleaning 39...........

Ignition Failure Sensor Check 40.............

Camshaft Position Sensor Check, Crank angle

Sensor Check, Detonation Sensor Check 40...

IGNITION COIL <6G7> 41.................

CRANKSHAFT ANGLE SENSOR

<6G7> 42................................

CAMSHAFT POSITION SENSOR

<6G7> 42................................

DETONATION SENSOR <6G7> 43.........

GLOW SYSTEM 44....................

GENERAL INFORMATION 44..............

SERVICE SPECIFICATIONS 45............

ON-VEHICLE SERVICE 45................

Self-regulating Glow System Check 45........

Glow & EGR Control Unit Check 48..........

Engine ECU Check 49.......................

Glow Plug Relay Check 50..................

Glow Plug Check 51........................

Engine Coolant Temperature Sensor

Check 51...................................

GLOW PLUG 52..........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 758 of 1839

ENGINE ELECTRICAL -Charging System16-10

14. If the voltage reading conforms to the value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

15. After the test, lower the engine speed to the

idle speed.

16. Turn the ignition switch off.17. Remove the tachometer or the MUT-II.

18. Disconnect the negative battery cable.

19. Disconnect the ammeter and voltmeter.

20. Connect the alternator output wire to the

alternator “B” terminal.

21. Remove the special tool, and return the

connector to the original condition.

22. Connect the negative battery cable.

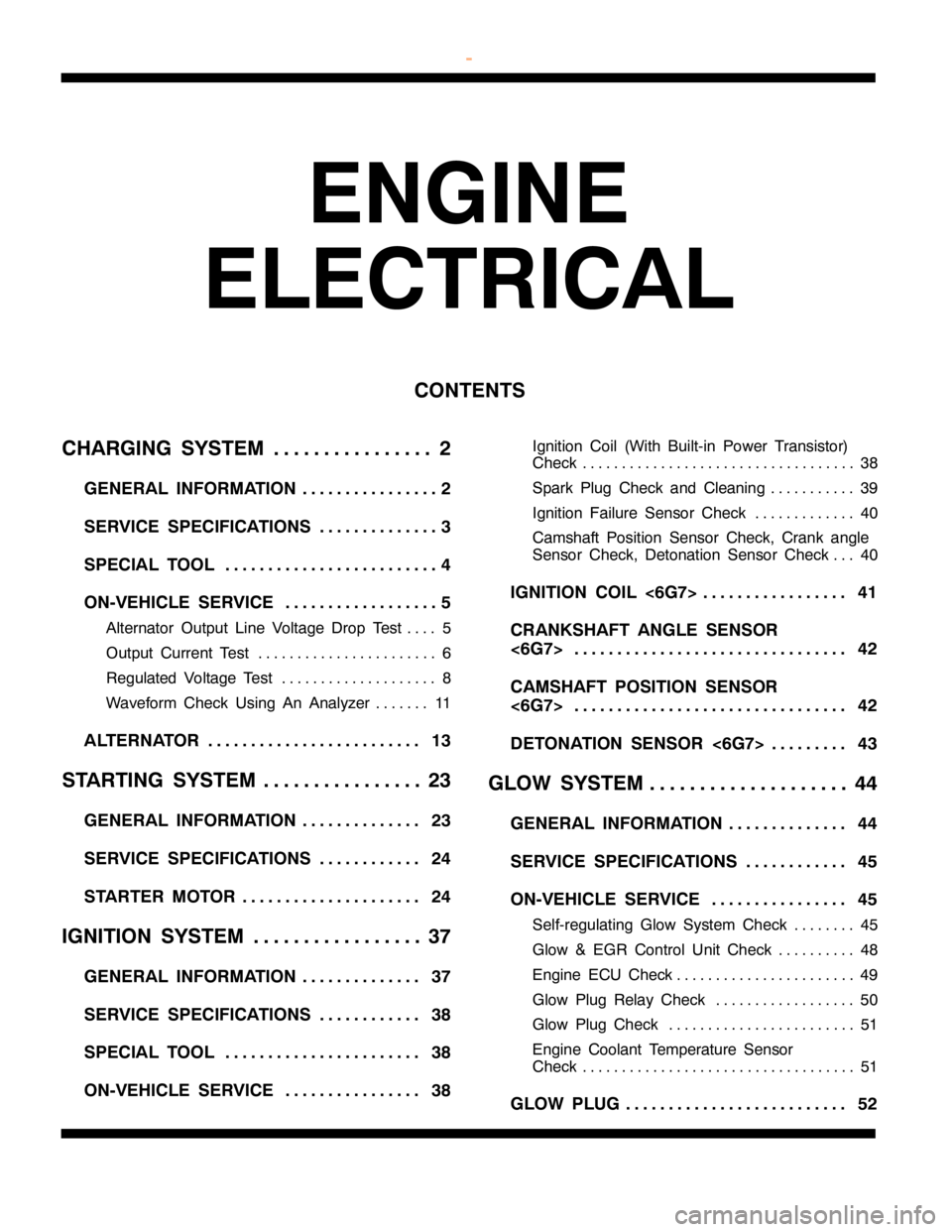

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient temperature_

CVoltage V

Terminal “S”-2014.2 - 15.4

2013.9 - 14.9

6013.4 - 14.6

8013.1 - 14.5

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1572 of 1839

54A-2

CHASSIS

ELECTRICAL

CONTENTS

BATTERY 4

..............................

SERVICE SPECIFICATIONS 4..................

ON-VEHICLE SERVICE 4......................

Electrolyte Level and Specific Gravity Check 4..

Charging 5.................................

Battery Test 5...............................

IGNITION SWITCH AND IMMOBILIZER

SPECIAL TOOLS 6............................

TROUBLESHOOTING 6........................

IGNITION SWITCH AND

IMMOBILIZER-ECU 11.........................

IGNITION SWITCH AND IMMOBILIZER

<4D56> 14...............................

SPECIAL TOOLS 14...........................

TROUBLESHOOTING 14.......................

IGNITION SWITCH AND IMMOBILIZER-ECU

19 ............................................

COMBINATION METER 23................

SERVICE SPECIFICATIONS 23.................

SEALANTS 24................................

SPECIAL TOOLS 24...........................

TROUBLESHOOTING 24.......................

ON-VEHICLE SERVICE 30.....................

Speedometer Check 30......................

Tachometer Check 30........................

Fuel Gauge Unit Check 31....................Engine Coolant Temperature Gauge Unit Check

32 .........................................

COMBINATION METER 33.....................

HEADLAMP ASSEMBLY 36...............

SERVICE SPECIFICATIONS 36.................

SPECIAL TOOLS 36...........................

TROUBLESHOOTING 36.......................

ON-VEHICLE SERVICE 36.....................

Headlamp Aiming Adjustment 36..............

Luminance Measurement 38..................

Headlamp Bulb Replacement 39...............

HEADLAMP ASSEMBLY 40....................

FOG LAMPS 41..........................

SERVICE SPECIFICATIONS 41.................

SPECIAL TOOLS 41...........................

TROUBLESHOOTING 41.......................

ON-VEHICLE SERVICE 41.....................

Fog Lamp Aiming Check 41...................

FOG LAMPS 44...............................

SIDE TURN-SIGNAL LAMPS 45...........

SPECIAL TOOLS 45...........................

SIDE TURN-SIGNAL LAMPS 46................

ROOM LAMP 46.........................

TROUBLESHOOTING 46.......................

CONTINUED ON NEXT PAGE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1575 of 1839

CHASSIS ELECTRICAL-Battery54A-5

CHARGING

1. Remove the battery from the vehicle.

2. The normal charging current is a value in amperes which is 1/10th of the battery capacity. If the

battery needs to be charged rapidly because of reasons such as time limitations, the maximum charging

current for rapid charging is the battery capacity expressed as an ampere value.

Battery typeCapacity (5-hour rate)Normal charging currentRapid charging current

75D2354 A5.4 A54 A

80D2658 A5.8 A58 A

95D3170 A7.0 A70 A

3. Determine when charging is finished.

DWhen the specific gravity of the battery electrolyte is constantly within 1.250 - 1.290 for a continuous

period of one hour or more

DWhen the voltage per cell during charging is 2.5 - 2.8 V constantly for a continuous period of one hour

or more

Caution

1. The battery plugs should be removed during charging.

2. The battery electrolyte level may rise and overflow from the battery during charging.

3. Explosions may occur if the battery is brought close to naked flames during charging.

4. Be careful to avoid tasks that might produce sparks or other danger while the battery is charging.

5. After charging is complete, replace the battery plugs, pour water over the battery to rinse

away any sulphuric acid, and let the battery stand to dry.

6. Charge the battery in a well-ventilated location.

7. Do not let the battery electrolyte temperature rise above approximately 45

°C (approximately

55

°C during rapid charging).

BATTERY TEST

Test procedure

OK

NG

Replace

Re-test

OK

Normal

(1) Connect a battery tester to the battery.

(2) Apply aloadwith the specified current to the battery.(Refer

to Table 1.)

(3) After measuring the battery voltage after 15 seconds,

remove the loadcurrent.

(4) Compare the measurement value with the specified

minimum voltage.(Refer to Table 2.)

OK:Higher than the minimum voltage

Measure the battery discharge voltage.

OK:12.4 V or more (specific gravity 1.240)NGCharge the battery at 5 A (constant current charging). (Refer

to Table 1.)

(1) Turn on the headlamps for 15 seconds.

(2) Turn off the headlamps and let the battery stand for 2

minutes to allow the battery voltage to stabilise.

(3) Disconnect the battery cables.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1748 of 1839

55A-2

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS 3.................

LUBRICANTS 3..............................

TROUBLESHOOTING

TROUBLESHOOTING

ON-VEHICLE SERVICE 9.....................

Refrigerant Level Test through Performance Test 9.

Magnetic Clutch Test 10.........................

Receiver Drier Test 10..........................

Compressor Drive Belt Adjustment 10.............

Dual Pressure Switch Check 10..................

Charging 11...................................

Performance Test 15............................

Front Blower Relay and Rear Blower Relay

Continuity Check 18............................

Continuity Check of A/C Compressor Relay and

Condernser Fan Relay 18.......................

PTC Heater Relay Continuity Check 19...........

Idle-up Operation Check

Vacuum Actuator Check

Idle-up Solenoid Valve Check 21.................

Clean Air Filter Replacement Procedure 22........

FRONT A/C 23..............................

Air Conditioner Control Panel Assembly and

A/C Switch 23.................................

Heater Unit and Blower Assembly 26.............

Blower Motor and Resistor 29....................

Inside/Outside Air Changeover Damper Motor 30...

Automatic Compressor-ECU and

Air Thermo Sensor Assembly 31.................

REAR HEATER AND REAR COOLER 32.....

Rear A/C Switch, Front Rear Fan Switch 32.......

Rear A/C Control Unit 34........................

Rear Heater Unit 34............................

Rear Heater Unit and Rear Blower Assembly 37....

HEAT SWITCH 40...........................

COMPRESSOR 41...........................

CONDENSER ASSEMBLY AND

CONDENSER FAN 45........................

REFRIGERANT LINE 47.....................

ENGINE COOLANT TEMPERATURE SWITCH

51 ..........................................

IDLE-UP SYSTEM 53........................

DUCTS 54..................................

VENTILATION 56............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1763 of 1839

HEATER, AIR CONDITIONER AND VENTILATION - On-vehicle Service55A-17

REFRIGERANT LEAK REPAIR

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system. (See procedure.)

2. Charge the system with approximately one

pound of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

6. Replace receiver drier.

Caution

Replacement filter-drier units must be

sealed while in storage. The drier used in

these units will saturate water quickly upon

exposure to the atmosphere. When

installing a drier, have all tools and supplies

ready for quick reassembly to avoid keeping

the system open any longer than necessary.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are

produced in the system when it is operating.

Extreme care must be exercised to make sure that

all connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair

or replacement of lines or components. The

following precautions must be observed. The

system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use

the correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter

of the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that

they are at least 80 mm from the exhaust manifold.

It is good practice to inspect all flexible hose lines

at least once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or

any other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets,

or a loose clutch assembly. Verify accessory drive

belt tension (power steering or alternator).

Improper accessory drive belt tension can cause

a misleading noise when the compressor is

engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure),

restrict air flow through condenser. Install

manifold gauge set to make sure discharge

pressure doesn’t exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt.

Check to assure clutch coil is tight (no rotation

or wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge. (See “Charging

System”.)

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retorque. Repeat Step 1.

7. If noise continues, replace compressor and

repeat Step 1.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk