heater MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 46 of 1839

3 MSB-00E00-505

3. Details:

Contents of Attachment are to be added to GROUP 00 (GENERAL).

PRECAUTIONS BEFORE SERVICE

LEARNING FUNCTION OF GDI ENGINE

1. Purpose

On the GDI engine equipped cars, when replacement of the ECU (for engine control) or resetting

of the battery* has been performed, an idle learning function of the ECU (for engine control) will

be required.

The idle learning function will be completed by running the engine at idle by the following procedure.

NOTE:

*: Disconnection of ECU (for engine control) battery backup power supply (disconnection of battery

terminals or ECU connectors)

2. Idle Learning Procedure

(1) Start the engine, and warm up the engine until its coolant temperature reaches 85°C or higher.

When the engine coolant temperature is 85°C or higher, you have only to turn the ignition

switch to the ON position.

(2) Turn the ignition switch to the LOCK (OFF) position, and stop the engine.

(3) After lapse of ten or more seconds, restart the engine.

(4) Run the engine at idle for ten minutes under the following conditions.

DTransmission: Neutral (P range for automatic transmission)

DAir conditioner and heater: Not operational

DEngine coolant temperature: 83°C or higher

(5) Stop the engine.

(6) Restart the engine, and run it at idle for ten minutes under the following condition.

DTransmission: Neutral (P range for automatic transmission)

DAir conditioner: Operational (Temperature set at “maximum cool”, fan at high speed, and

windows fully opened)

DEngine coolant temperature: 83°C or higher

(7) Repeat steps (5) and (6).

NOTE:

1) When the atmospheric temperature is 20°C or more and the air conditioner has continuously

been operated, step (7) may be omitted.

2) During idling operation of the engine in steps (4) and (6), when engine operation switches

from lean operation to stoichiometric operation, engine stall can occur. In this case, clean the

throttle body (throttle valve) thoroughly, and then repeat step (1) and the subsequent steps.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 226 of 1839

GDI -Troubleshooting

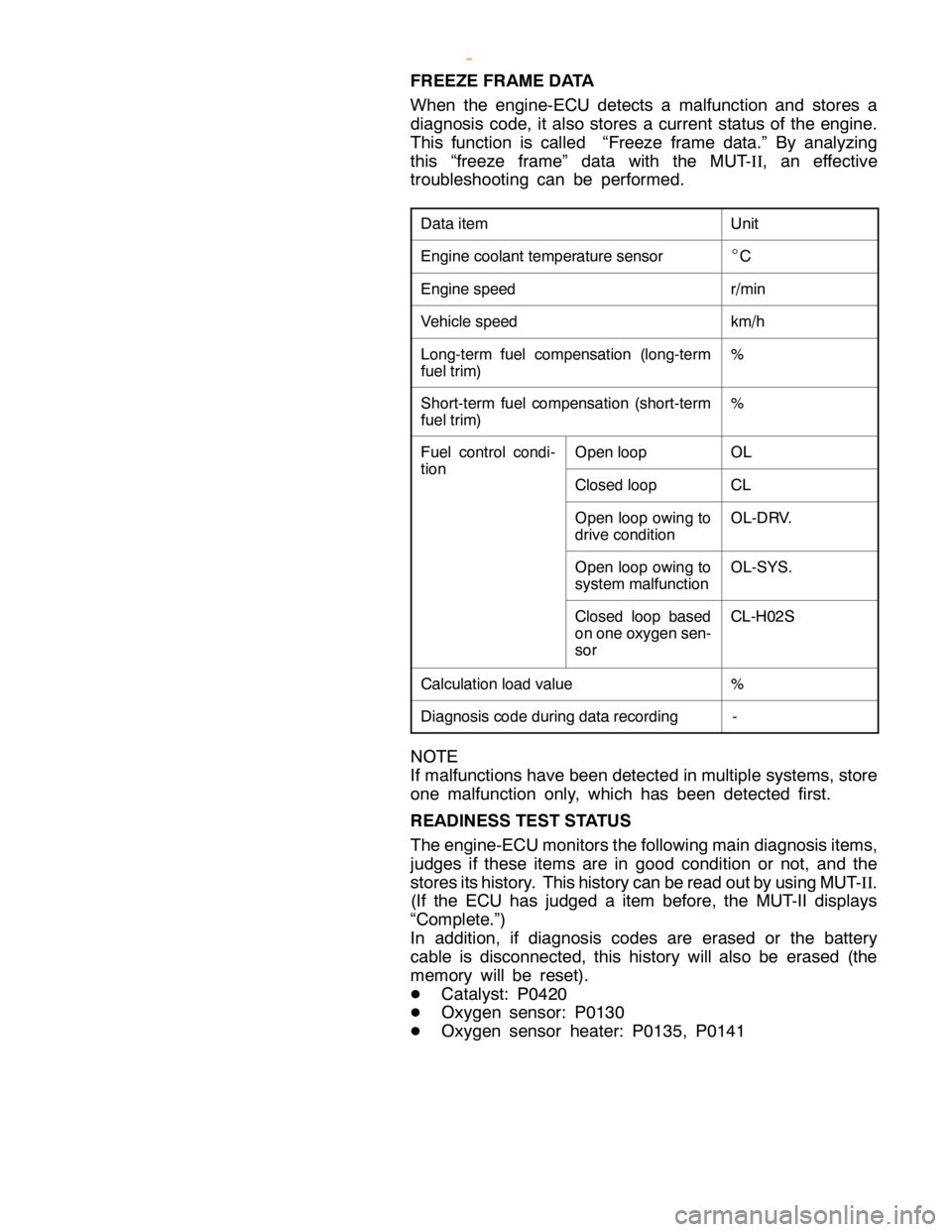

FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a

diagnosis code, it also stores a current status of the engine.

This function is called “Freeze frame data.” By analyzing

this “freeze frame” data with the MUT-II, an effective

troubleshooting can be performed.

Data itemUnit

Engine coolant temperature sensor_C

Engine speedr/min

Vehicle speedkm/h

Long-term fuel compensation (long-term

fuel trim)%

Short-term fuel compensation (short-term

fuel trim)%

Fuel control condi-Open loopOL

tion

Closed loopCL

Open loop owing to

drive conditionOL-DRV.

Open loop owing to

system malfunctionOL-SYS.

Closed loop based

on one oxygen sen-

sorCL-H02S

Calculation load value%

Diagnosis code during data recording-

NOTE

If malfunctions have been detected in multiple systems, store

one malfunction only, which has been detected first.

READINESS TEST STATUS

The engine-ECU monitors the following main diagnosis items,

judges if these items are in good condition or not, and the

stores its history. This history can be read out by using MUT-II.

(If the ECU has judged a item before, the MUT-II displays

“Complete.”)

In addition, if diagnosis codes are erased or the battery

cable is disconnected, this history will also be erased (the

memory will be reset).

DCatalyst: P0420

DOxygen sensor: P0130

DOxygen sensor heater: P0135, P0141

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 229 of 1839

GDI -Troubleshooting

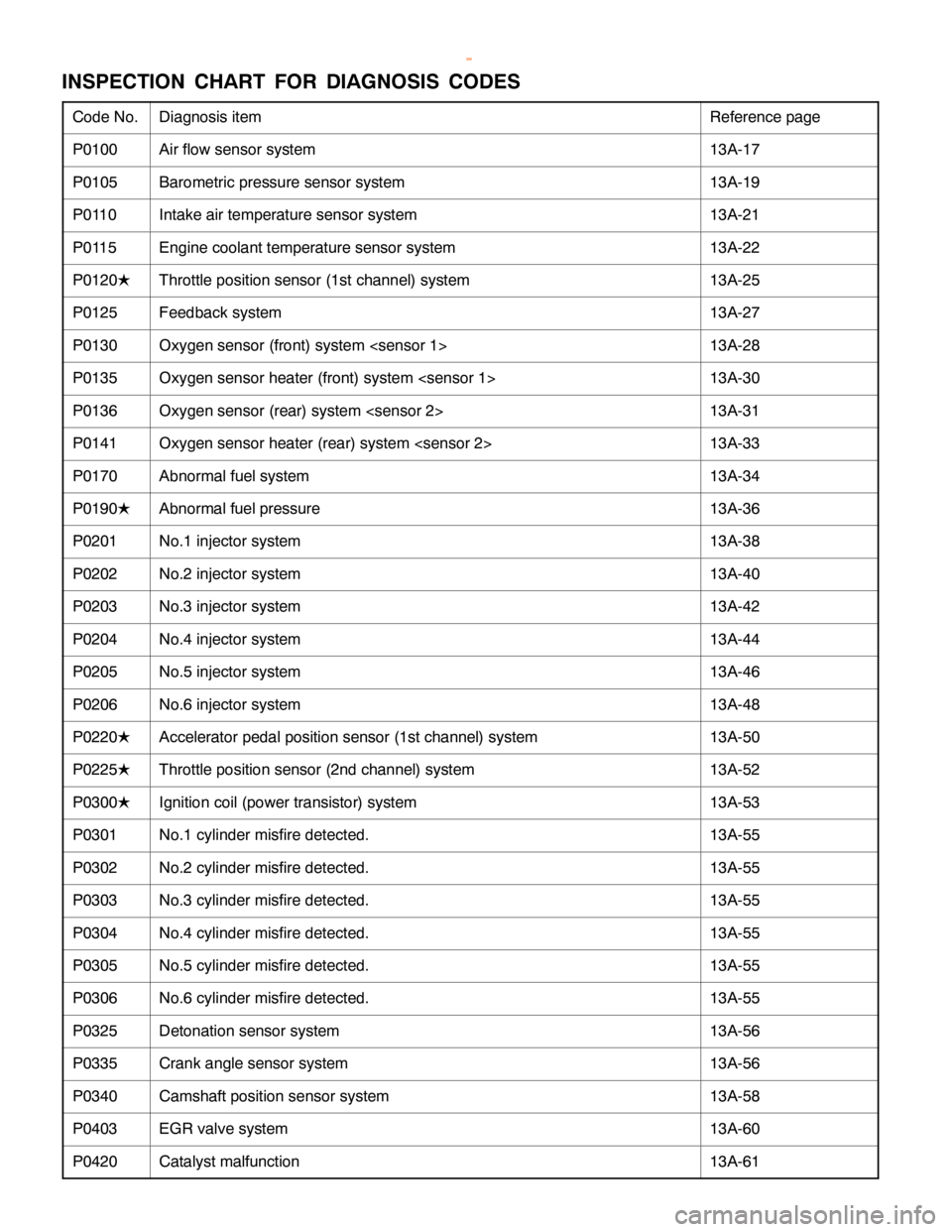

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference page

P0100Air flow sensor system13A-17

P0105Barometric pressure sensor system13A-19

P0110Intake air temperature sensor system13A-21

P0115Engine coolant temperature sensor system13A-22

P0120LThrottle position sensor (1st channel) system13A-25

P0125Feedback system13A-27

P0130Oxygen sensor (front) system

P0135Oxygen sensor heater (front) system

P0136Oxygen sensor (rear) system

P0141Oxygen sensor heater (rear) system

P0170Abnormal fuel system13A-34

P0190LAbnormal fuel pressure13A-36

P0201No.1 injector system13A-38

P0202No.2 injector system13A-40

P0203No.3 injector system13A-42

P0204No.4 injector system13A-44

P0205No.5 injector system13A-46

P0206No.6 injector system13A-48

P0220LAccelerator pedal position sensor (1st channel) system13A-50

P0225LThrottle position sensor (2nd channel) system13A-52

P0300LIgnition coil (power transistor) system13A-53

P0301No.1 cylinder misfire detected.13A-55

P0302No.2 cylinder misfire detected.13A-55

P0303No.3 cylinder misfire detected.13A-55

P0304No.4 cylinder misfire detected.13A-55

P0305No.5 cylinder misfire detected.13A-55

P0306No.6 cylinder misfire detected.13A-55

P0325Detonation sensor system13A-56

P0335Crank angle sensor system13A-56

P0340Camshaft position sensor system13A-58

P0403EGR valve system13A-60

P0420Catalyst malfunction13A-61

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 244 of 1839

GDI -Troubleshooting

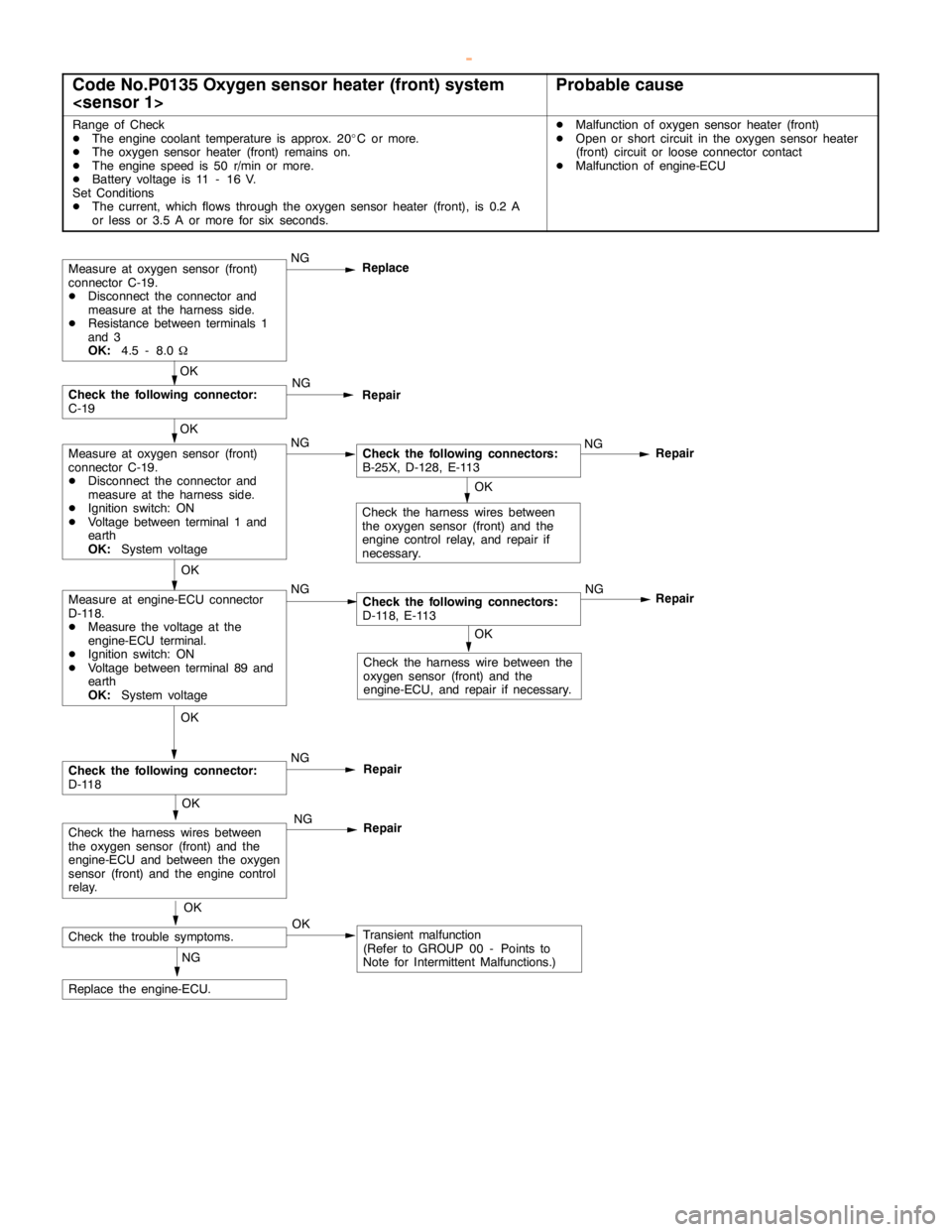

Code No.P0135 Oxygen sensor heater (front) system

Range of Check

DThe engine coolant temperature is approx. 20_C or more.

DThe oxygen sensor heater (front) remains on.

DThe enginespeed is 50 r/min or more.

DBattery voltage is 11 - 16 V.

Set Conditions

DThe current, which flows through the oxygen sensor heater (front), is 0.2 A

or less or 3.5 A or more for six seconds.DMalfunction of oxygen sensor heater (front)

DOpen or short circuit in the oxygen sensor heater

(front) circuit or loose connector contact

DMalfunction of engine-ECU

OK

Check the harness wire between the

oxygen sensor (front) and the

engine-ECU, and repair if necessary.

Repair

OK

Measure at engine-ECU connector

D-118.

DMeasure the voltage at the

engine-ECU terminal.

DIgnition switch: ON

DVoltage between terminal 89 and

earth

OK:

System voltageNGCheck the following connectors:

D-118, E-113NG

OK

Check the harness wires between

the oxygen sensor (front) and the

engine controlrelay, and repair if

necessary.

Measure at oxygen sensor (front)

connector C-19.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 1

and 3

OK:

4.5 - 8.0WNG

Replace

Repair

OK

Measure at oxygen sensor (front)

connector C-19.

DDisconnect the connector and

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal 1 and

earth

OK:

System voltageNGCheck the following connectors:

B-25X, D-128, E-113NG

OK

Check the following connector:

C-19NG

Repair

OK

Check the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.) NG

Replace the engine-ECU.

OK

Check the following connector:

D-118NG

Repair

OK

Check the harness wires between

the oxygen sensor (front) and the

engine-ECU and between the oxygen

sensor (front) and theengine control

relay.NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 247 of 1839

GDI -Troubleshooting

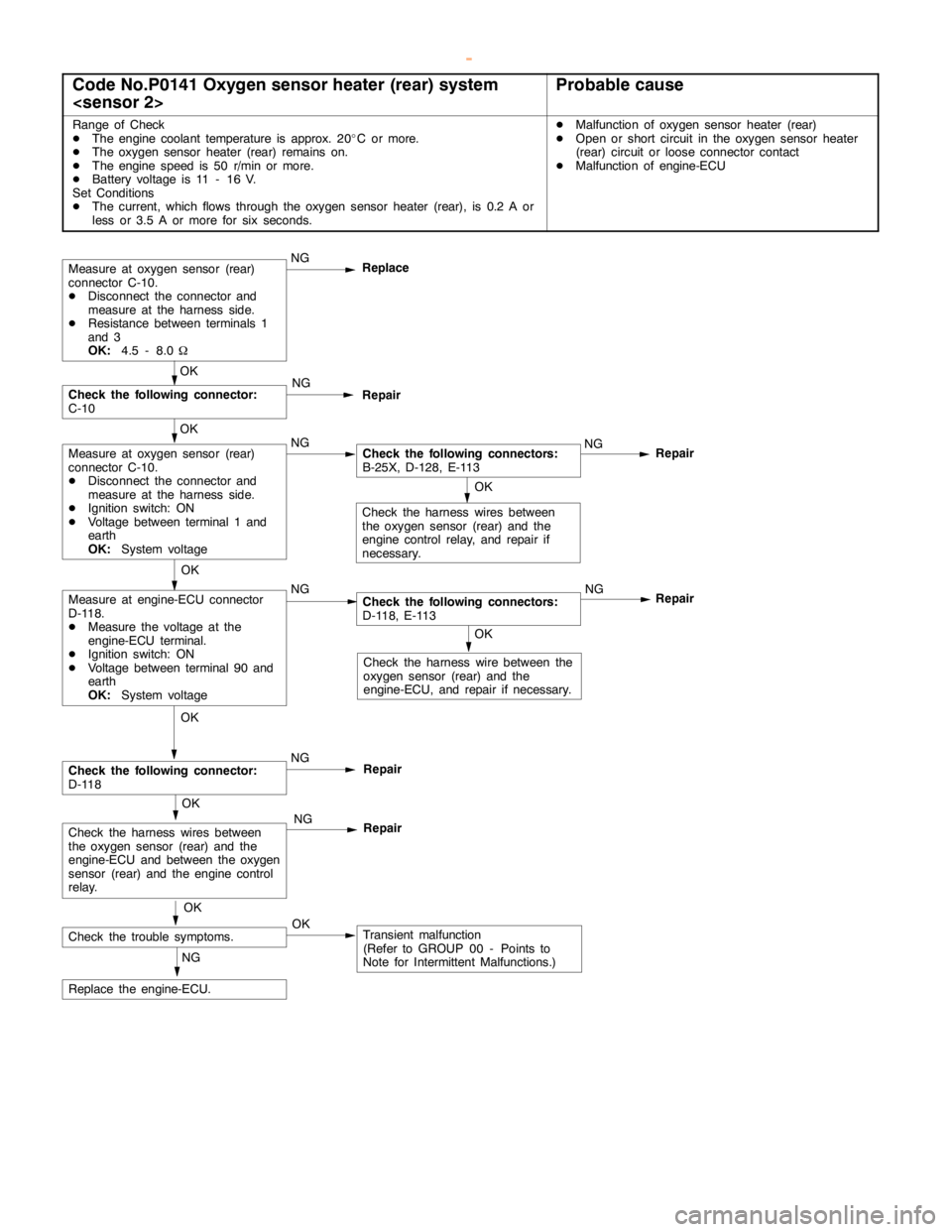

Code No.P0141 Oxygen sensor heater (rear) system

Range of Check

DThe engine coolant temperature is approx. 20_C or more.

DThe oxygen sensor heater (rear) remains on.

DThe enginespeed is 50 r/min or more.

DBattery voltage is 11 - 16 V.

Set Conditions

DThe current, which flows through the oxygen sensor heater (rear), is 0.2 A or

less or 3.5 A or more for six seconds.DMalfunction of oxygen sensor heater (rear)

DOpen or short circuit in the oxygen sensor heater

(rear) circuit or loose connector contact

DMalfunction of engine-ECU

OK

Check the harness wire between the

oxygen sensor (rear) and the

engine-ECU, and repair if necessary.

Repair

OK

Measure at engine-ECU connector

D-118.

DMeasure the voltage at the

engine-ECU terminal.

DIgnition switch: ON

DVoltage between terminal 90 and

earth

OK:

System voltageNGCheck the following connectors:

D-118, E-113NG

OK

Check the harness wires between

the oxygen sensor (rear) and the

engine controlrelay, and repair if

necessary.

Measure at oxygen sensor (rear)

connector C-10.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 1

and 3

OK:

4.5 - 8.0WNG

Replace

Repair

OK

Measure at oxygen sensor (rear)

connector C-10.

DDisconnect the connector and

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal 1 and

earth

OK:

System voltageNGCheck the following connectors:

B-25X, D-128, E-113NG

OK

Check the following connector:

C-10NG

Repair

OK

Check the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.) NG

Replace the engine-ECU.

OK

Check the following connector:

D-118NG

Repair

OK

Check the harness wires between

the oxygen sensor (rear) and the

engine-ECU and between the oxygen

sensor (rear) and theengine control

relay.NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 328 of 1839

GDI -Troubleshooting

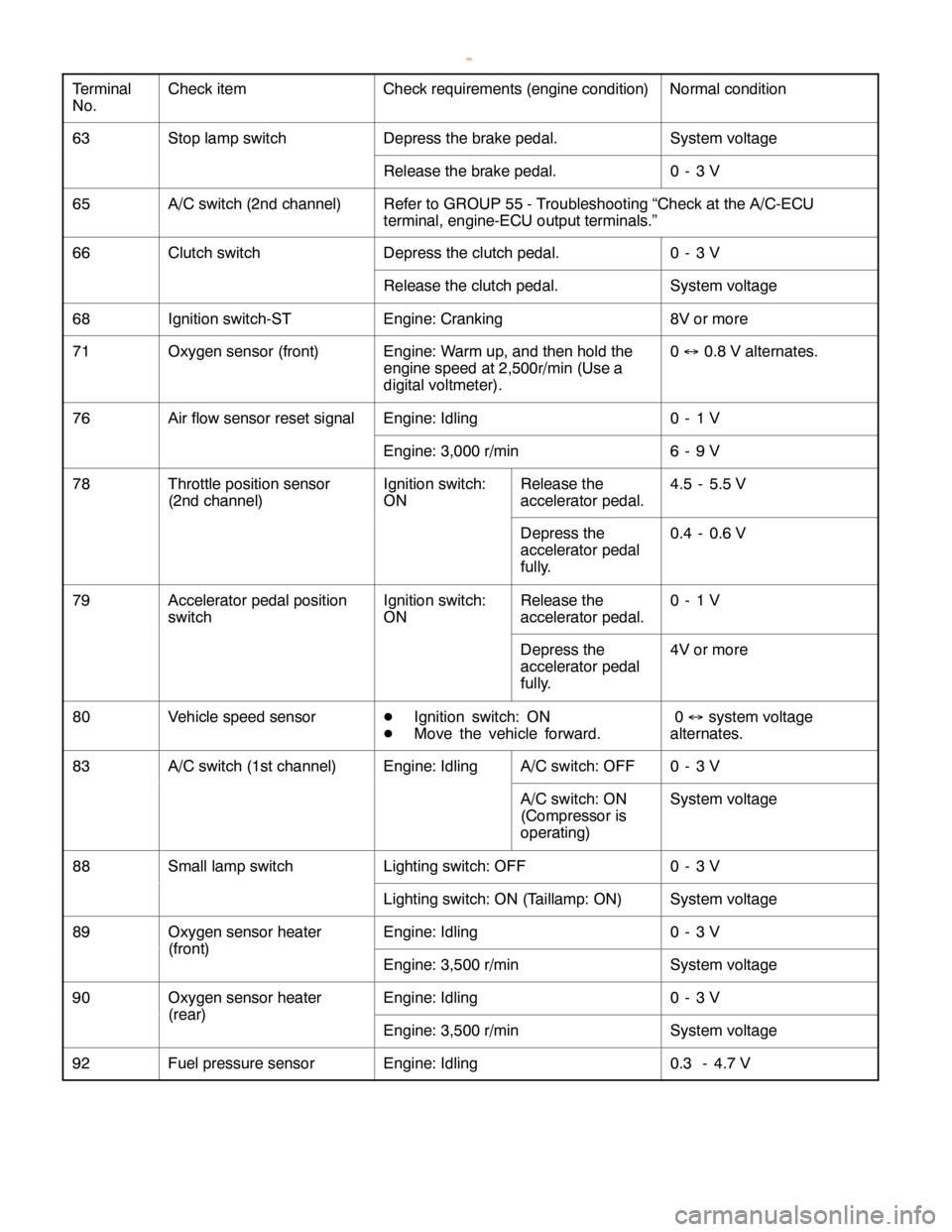

Terminal

No.Normal condition Check requirements (engine condition) Check item

63Stop lamp switchDepress the brake pedal.System voltage

Release the brake pedal.0-3V

65A/C switch (2nd channel)Refer to GROUP 55 - Troubleshooting “Check at the A/C-ECU

terminal, engine-ECU output terminals.”

66Clutch switchDepress the clutch pedal.0-3V

Release the clutch pedal.System voltage

68Ignition switch-STEngine: Cranking8V or more

71Oxygen sensor (front)Engine: Warm up, and then hold the

engine speed at 2,500r/min (Use a

digital voltmeter).0«0.8 V alternates.

76Air flow sensor reset signalEngine: Idling0-1V

Engine: 3,000 r/min6-9V

78Throttle position sensor

(2nd channel)Ignition switch:

ONRelease the

accelerator pedal.4.5 - 5.5 V

Depress the

accelerator pedal

fully.0.4 - 0.6 V

79Accelerator pedal position

switchIgnition switch:

ONRelease the

accelerator pedal.0-1V

Depress the

accelerator pedal

fully.4V or more

80Vehicle speed sensorDIgnition switch: ON

DMove the vehicle forward.0«system voltage

alternates.

83A/C switch (1st channel)Engine: IdlingA/C switch: OFF0-3V

A/C switch: ON

(Compressor is

operating)System voltage

88Small lamp switchLighting switch: OFF0-3V

Lighting switch: ON (Taillamp: ON)System voltage

89Oxygen sensor heaterEngine: Idling0-3V

(front)

Engine: 3,500 r/minSystem voltage

90Oxygen sensor heaterEngine: Idling0-3V

(rear)

Engine: 3,500 r/minSystem voltage

92Fuel pressure sensorEngine: Idling0.3 - 4.7 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

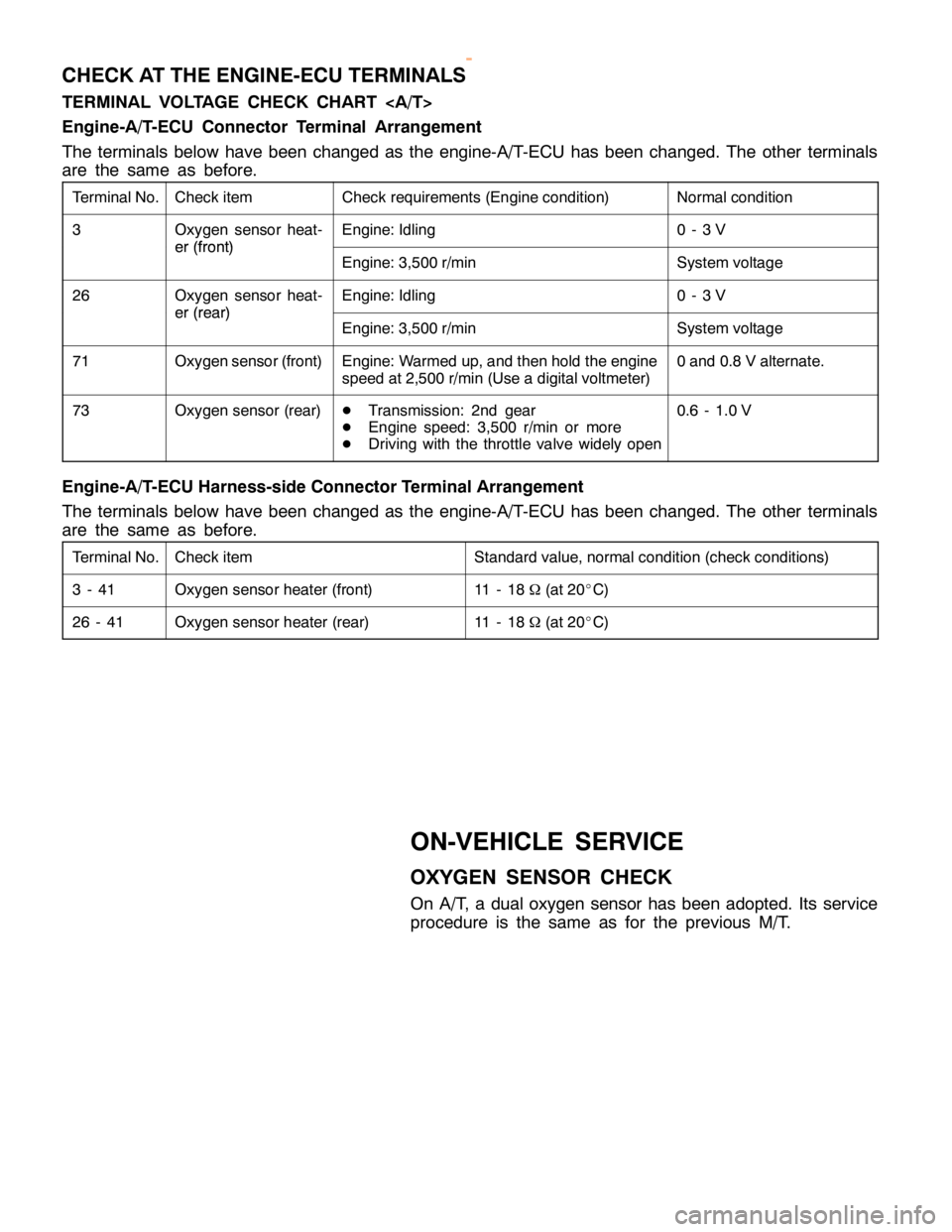

Page 476 of 1839

Page 527 of 1839

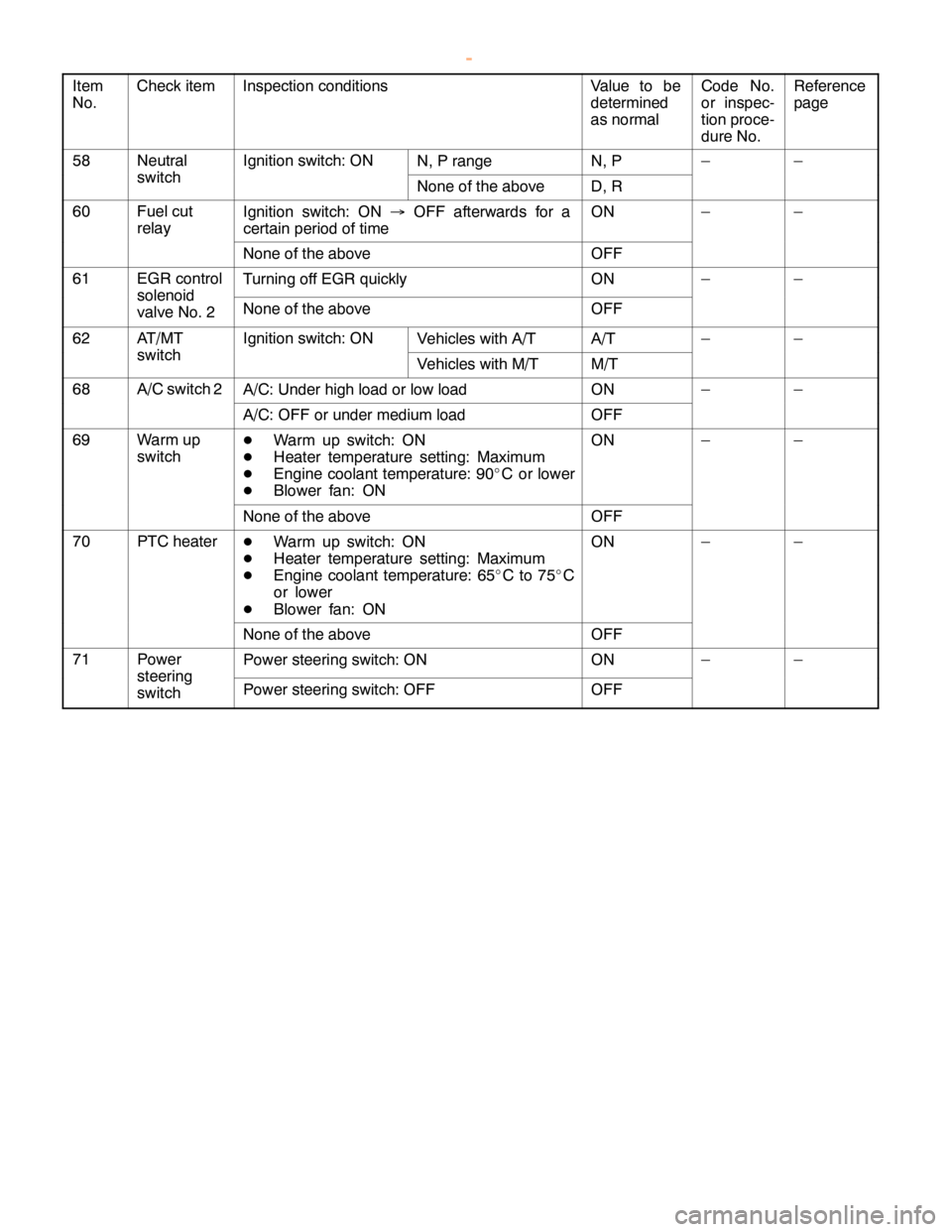

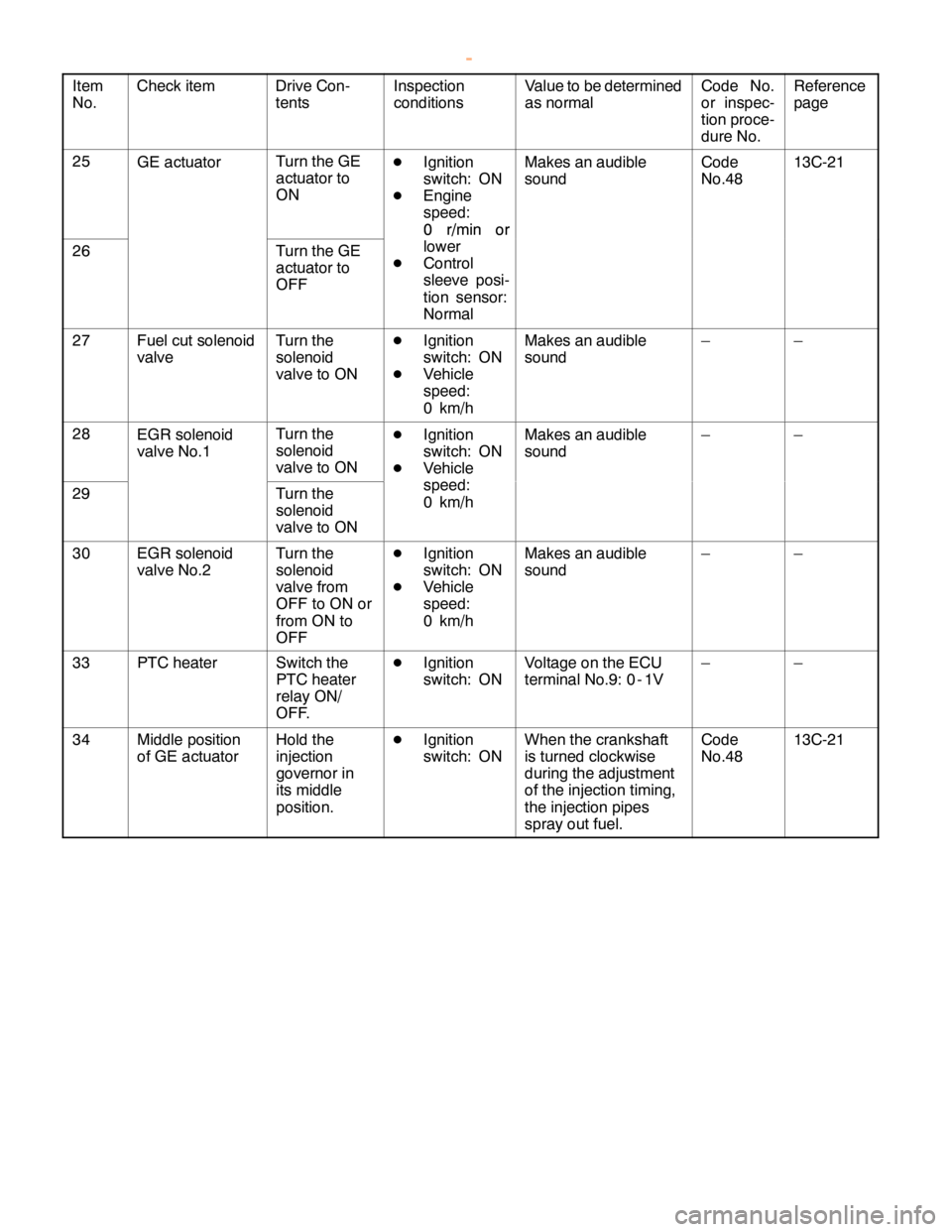

DIESEL FUEL <4M4> -Troubleshooting13C-36

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be

determined

as normal Inspection conditions Check item

58NeutralIgnition switch: ONN, P rangeN, P––

switchNone of the aboveD, R

60Fuel cut

relayIgnition switch: ON®OFF afterwards for a

certain period of timeON––

None of the aboveOFF

61EGR controlTurning off EGR quicklyON––

solenoid

valve No. 2None of the aboveOFF

62AT/MTIgnition switch: ONVehicles with A/TA/T––

switchVehicles with M/TM/T

68A/C switch 2A/C: Under high load or low loadON––

A/C: OFF or under medium loadOFF

69Warm up

switchDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 90_C or lower

DBlower fan: ONON––

None of the aboveOFF

70PTC heaterDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 65_Cto75_C

or lower

DBlower fan: ONON––

None of the aboveOFF

71PowerPower steering switch: ONON––

steering

switchPower steering switch: OFFOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 529 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-38

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be determined

as normal Inspection

conditions Drive Con-

tents Check item

25GE actuatorTurn the GE

actuator to

ONDIgnition

switch: ON

DEngine

speed:

0 r/min orMakes an audible

soundCode

No.4813C-21

26Turn the GE

actuator to

OFF

0 r/min or

lower

DControl

sleeve posi-

tion sensor:

Normal

27Fuel cut solenoid

valveTurn the

solenoid

valve to ONDIgnition

switch: ON

DVehicle

speed:

0 km/hMakes an audible

sound––

28EGR solenoid

valve No.1Turn the

solenoid

valve to ONDIgnition

switch: ON

DVehicleMakes an audible

sound––

29Turn the

solenoid

valve to ONspeed:

0 km/h

30EGR solenoid

valve No.2Turn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/hMakes an audible

sound––

33PTC heaterSwitch the

PTC heater

relay ON/

OFF.DIgnition

switch: ONVoltage on the ECU

terminal No.9: 0 - 1V––

34Middle position

of GE actuatorHold the

injection

governor in

its middle

position.DIgnition

switch: ONWhen the crankshaft

is turned clockwise

during the adjustment

of the injection timing,

the injection pipes

spray out fuel.Code

No.4813C-21

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 679 of 1839

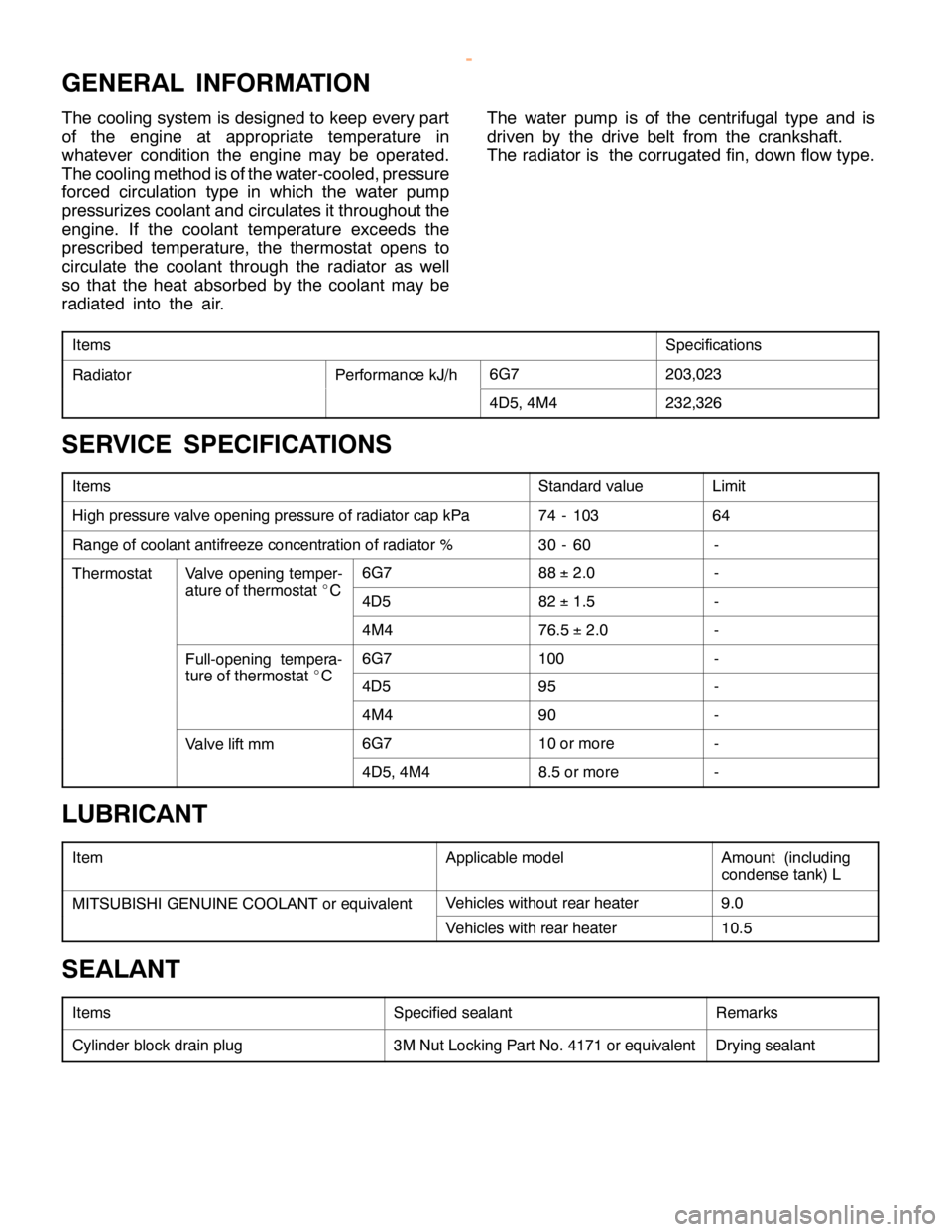

ENGINE COOLING -General Information/

Service Specifications/Lubricant/Sealant14-2

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

ItemsSpecifications

RadiatorPerformance kJ/h6G7203,023

4D5, 4M4232,326

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

High pressure valve opening pressure of radiator cap kPa74 - 10364

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temper-6G788±

2.0-

ature of thermostat_

C4D582±

1.5-

4M476.5±

2.0-

Full-opening tempera-6G7100-

ture of thermostat_

C4D595-

4M490-

Valve lift mm6G710 or more-

4D5, 4M48.5 or more-

LUBRICANT

ItemApplicable modelAmount (including

condense tank) L

MITSUBISHI GENUINE COOLANT or equivalentVehicles without rear heater9.0

Vehicles with rear heater10.5

SEALANT

ItemsSpecified sealantRemarks

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk