MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: glove box, checking oil, set clock, open hood, oil temperature, power steering, coolant level

Page 1241 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL Transaxle

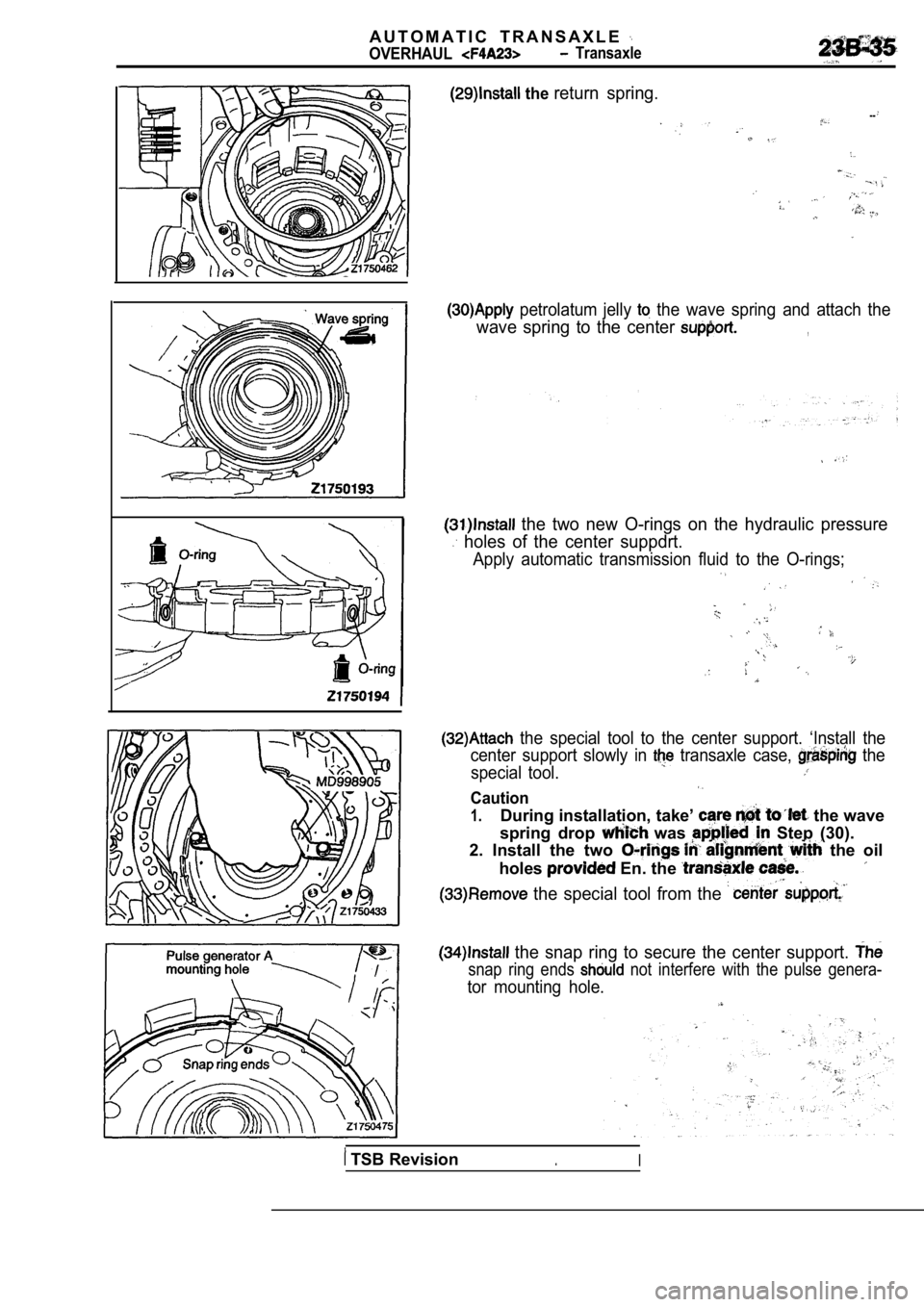

the return spring.

--

petrolatum jelly the wave spring and attach the

wave spring to the center ,

the two new O-rings on the hydraulic pressure

holes of the center suppdrt.

Apply automatic transmission fluid to the O-rings;

the special tool to the center support. ‘Install the

center support slowly in

transaxle case, the

special tool.

Caution

1.During installation, take’ the wave

spring drop

was Step (30).

2. Install the two

the oil

holes

En. the

the special tool from the

the snap ring to secure the center support.

snap ring ends not interfere with the pulse genera-

tor mounting hole.

TSB Revision.I

Page 1242 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL Transaxle

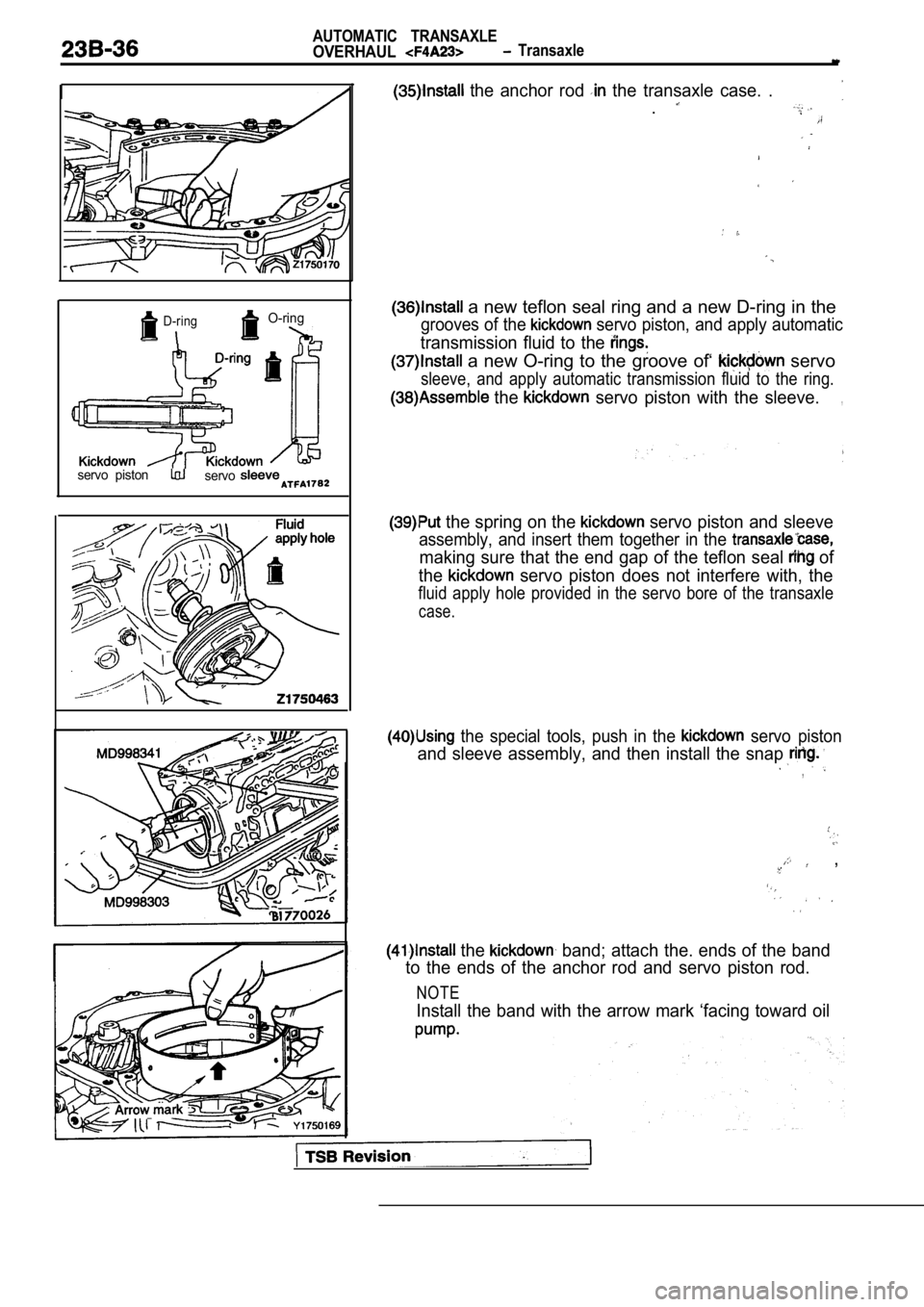

D-ringO-ring

servo pistonservo

the anchor rod the transaxle case. .

.

a new teflon seal ring and a new D-ring in the

grooves of the servo piston, and apply automatic

transmission fluid to the

a new O-ring to the groove of‘ servo

sleeve, and apply automatic transmission fluid to the ring.

the servo piston with the sleeve.,

the spring on the servo piston and sleeve

assembly, and insert them together in the

making sure that the end gap of the teflon seal of

the

servo piston does not interfere with, the

fluid apply hole provided in the servo bore of the transaxle

case.

the special tools, push in the servo piston

and sleeve assembly, and then install the snap

,

,

the band; attach the. ends of the band

to the ends of the anchor rod and servo piston rod.

NOTE

Install the band with the arrow mark ‘facing toward oil

Page 1243 of 2103

AUTOMATIC

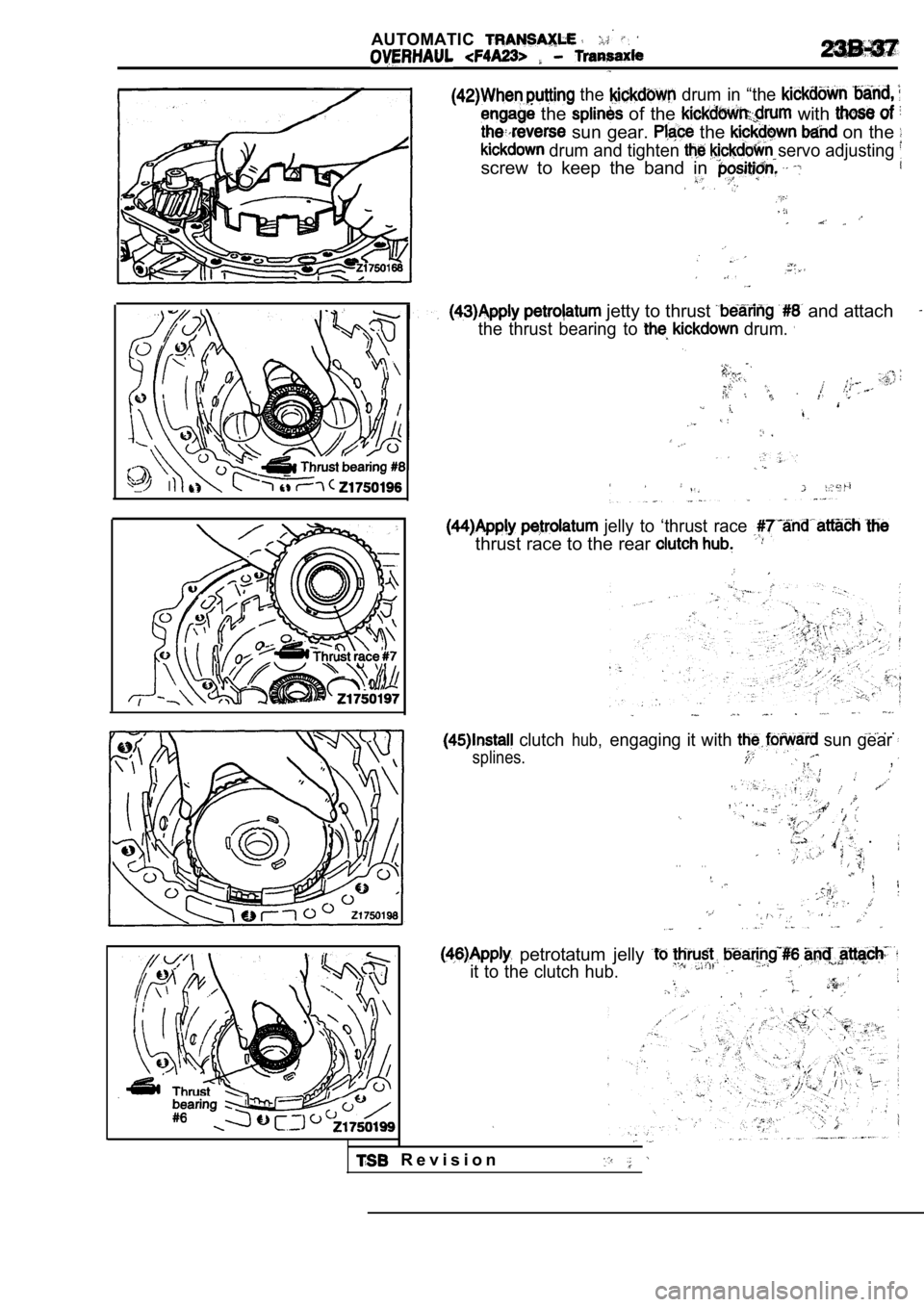

the drum in “the

the of the with

sun gear. the on the

drum and tighten servo adjusting

screw to keep the band in

jetty to thrust and attach

the thrust bearing to drum.

jelly to ‘thrust race

thrust race to the rear

clutch

splines.hub,

. .engaging it with sun gear

,

, . .

, .

. .. .

petrotatum jelly

it to the clutch hub.

R e v i s i o n

Page 1244 of 2103

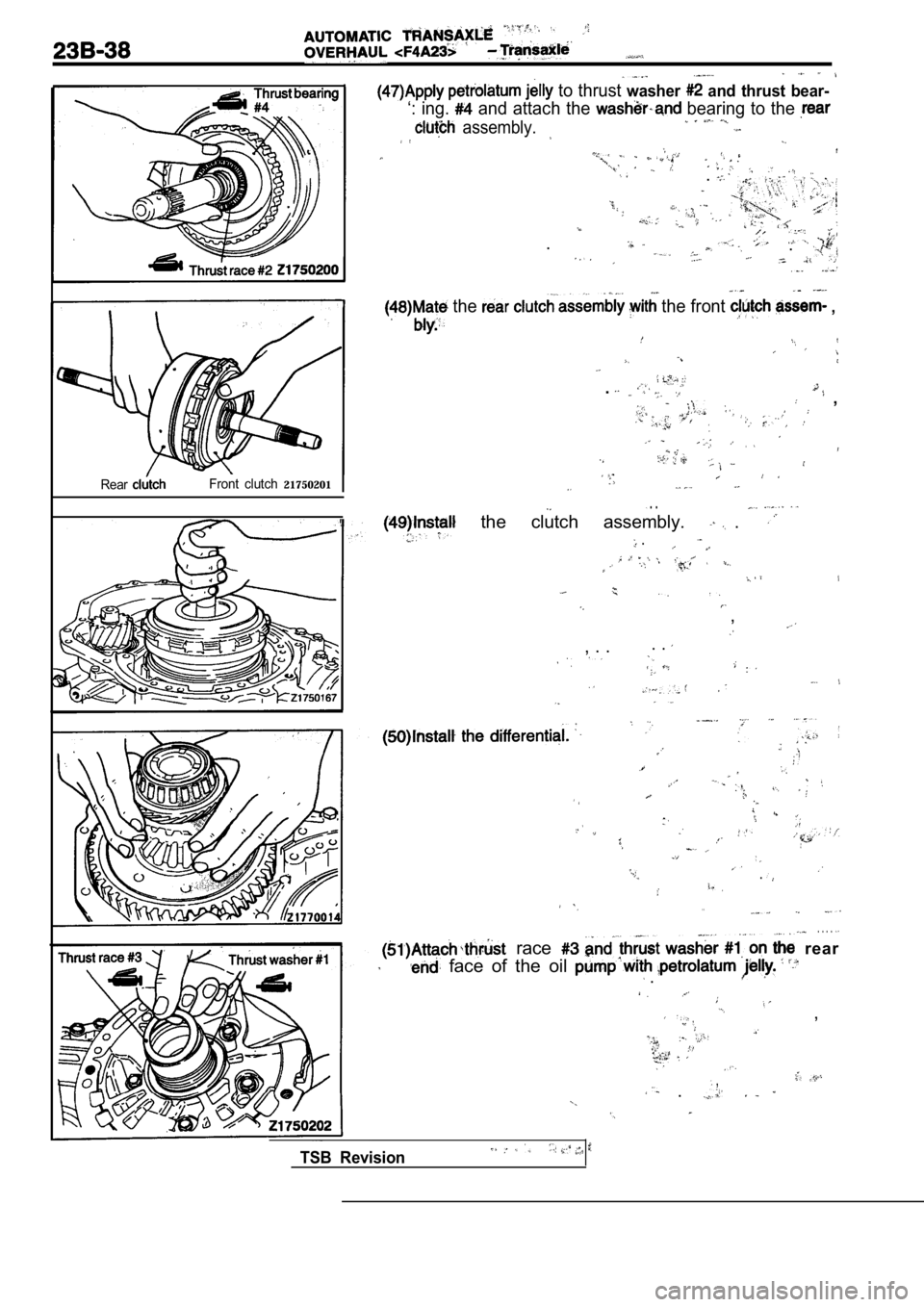

RearFront clutch 21750201

to thrust washer and thrust bear-

‘: ing. and attach the bearing to the

assembly.

.

. .

the the front ,

. ,

. .

the clutch assembly. .

.

,

. . , . .

.

. .

. . . .

race rear

face of the oil .

,

,. .

TSB Revision

Page 1245 of 2103

A U T O M A T I C

O V E R H A U L

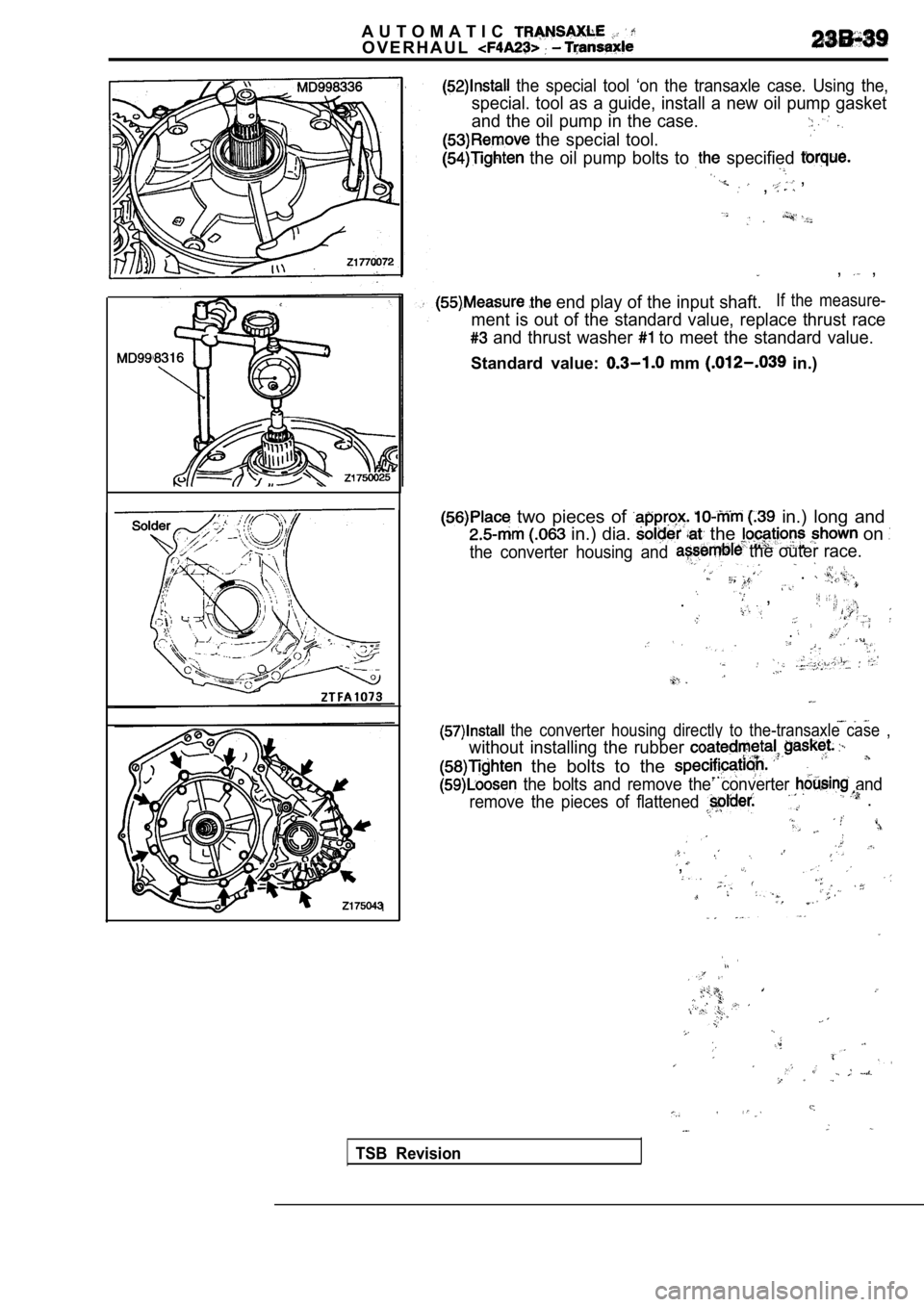

the special tool ‘on the transaxle case. Using the,

special. tool as a guide, install a new oil pump gasket

and the oil pump in the case.

the special tool.

the oil pump bolts to specified

,

,

, ,

1

end play of the input shaft.If the measure-

ment is out of the standard value, replace thrust r ace

and thrust washer to meet the standard value.

Standard value: mm in.)

two pieces of in.) long and

in.) dia. the on

the converter housing and the outer race.

.

,.

.

the converter housing directly to the-transaxle ca se ,

without installing the rubber

the bolts to the

the bolts and remove the’ converter and

remove the pieces of flattened

.

,

TSB Revision

Page 1246 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL. .

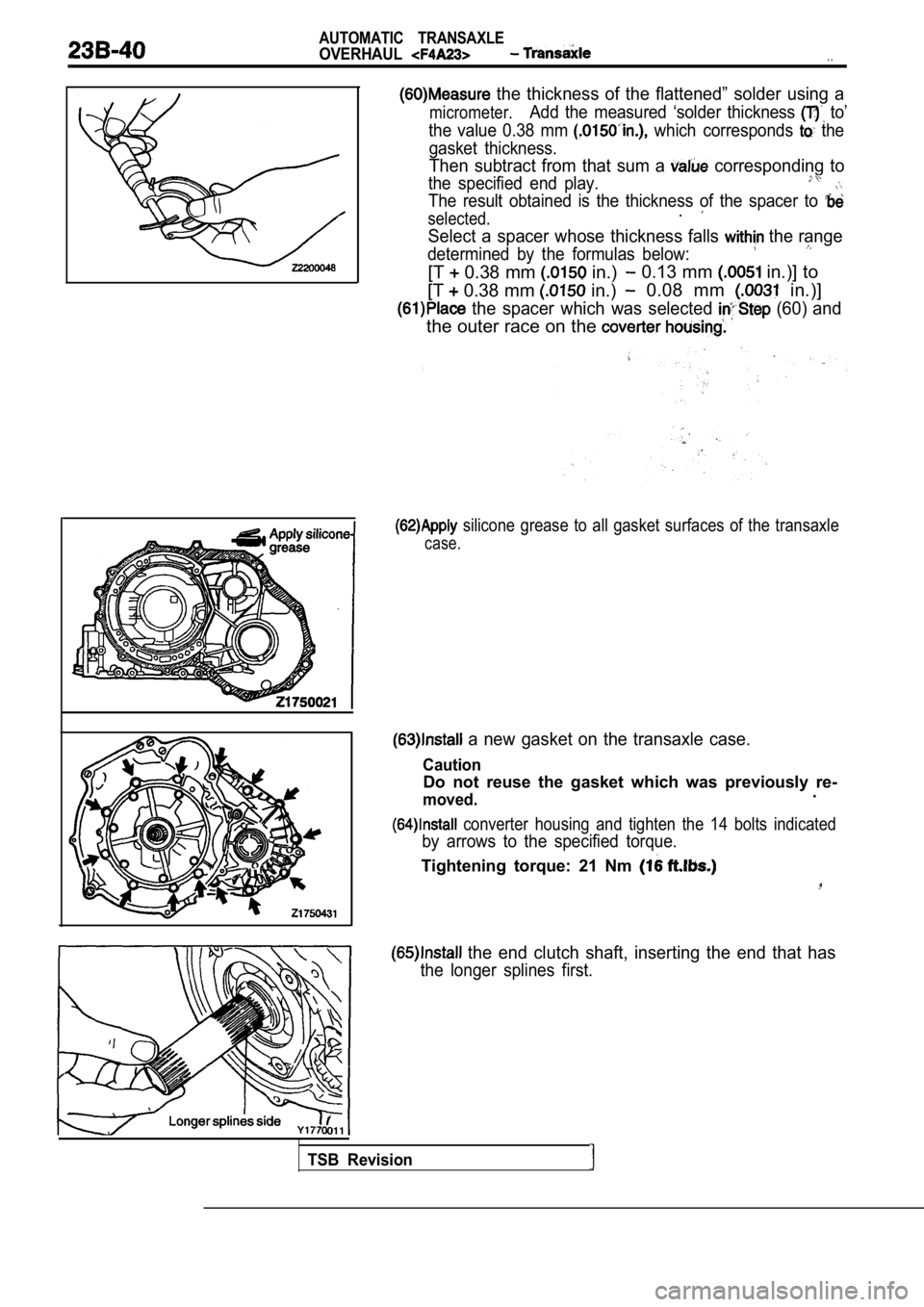

the thickness of the flattened” solder using a

micrometer.Add the measured ‘solder thickness to’

the value 0.38 mm

which corresponds the

gasket thickness.

Then subtract from that sum a corresponding to

the specified end play.

The result obtained is the thickness of the spacer to

selected..

Select a spacer whose thickness falls the range

determined by the formulas below:

[T 0.38 mm in.) 0.13 mm in.)] to

[T

0.38 mm in.) 0.08 mm in.)]

the spacer which was selected (60) and

the outer race on the

silicone grease to all gasket surfaces of the tran saxle

case.

a new gasket on the transaxle case.

Caution

Do not reuse the gasket which was previously re-

moved..

converter housing and tighten the 14 bolts indicat ed

by arrows to the specified torque.

Tightening torque: 21 Nm

the end clutch shaft, inserting the end that has

the longer splines first.

TSB Revision

Page 1247 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL Transaxle

Thrust bearing .

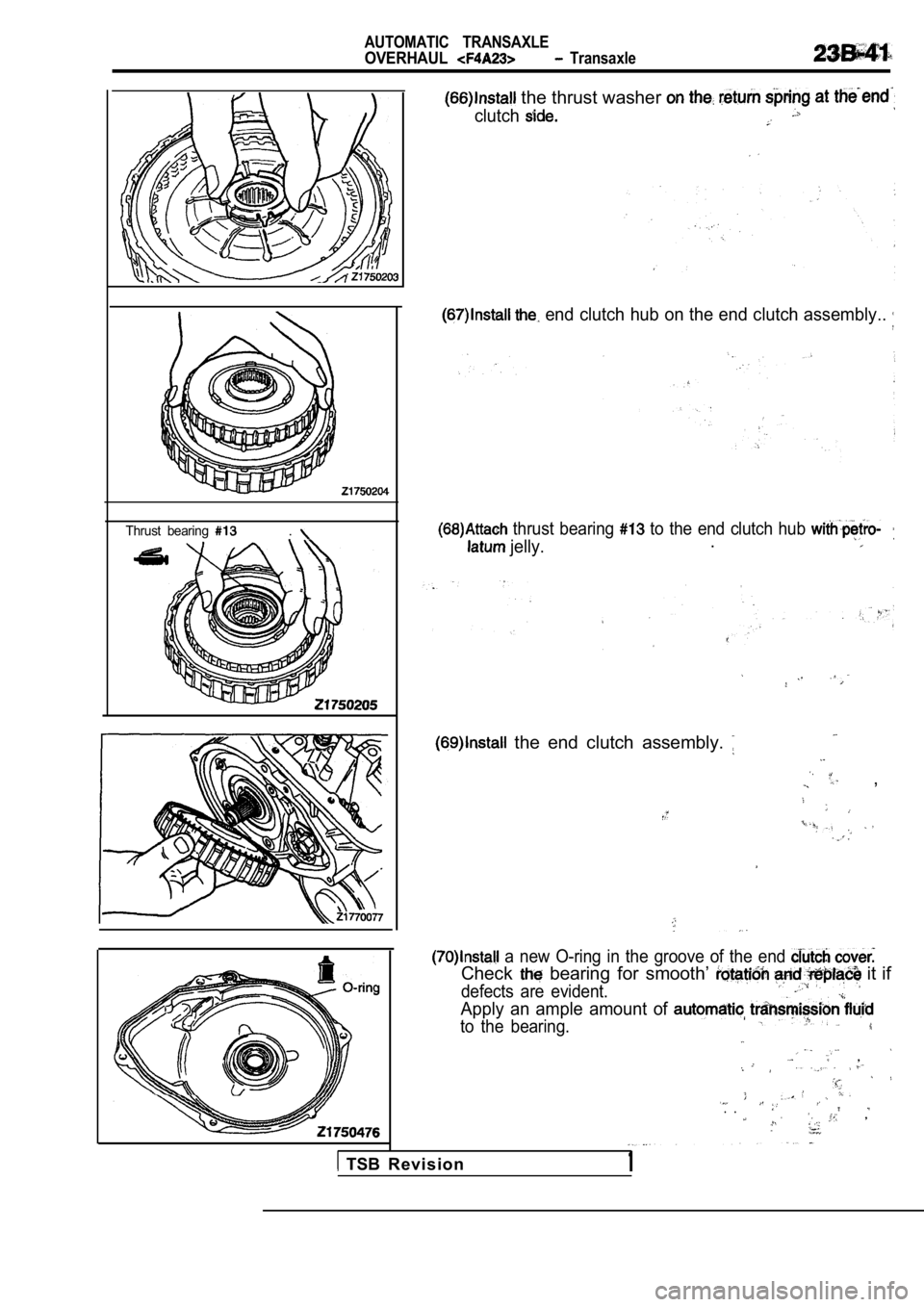

the thrust washer

clutch

end clutch hub on the end clutch assembly..

thrust bearing to the end clutch hub

jelly..

the end clutch assembly.

,

a new O-ring in the groove of the end

Check bearing for smooth’ it if

defects are evident.

Apply an ample amount of

to the bearing.

,

. .. ,

TSB R e v i s i o n1

Page 1248 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL . .

Manual control

shaft

O-ring

groove

Set screw

,

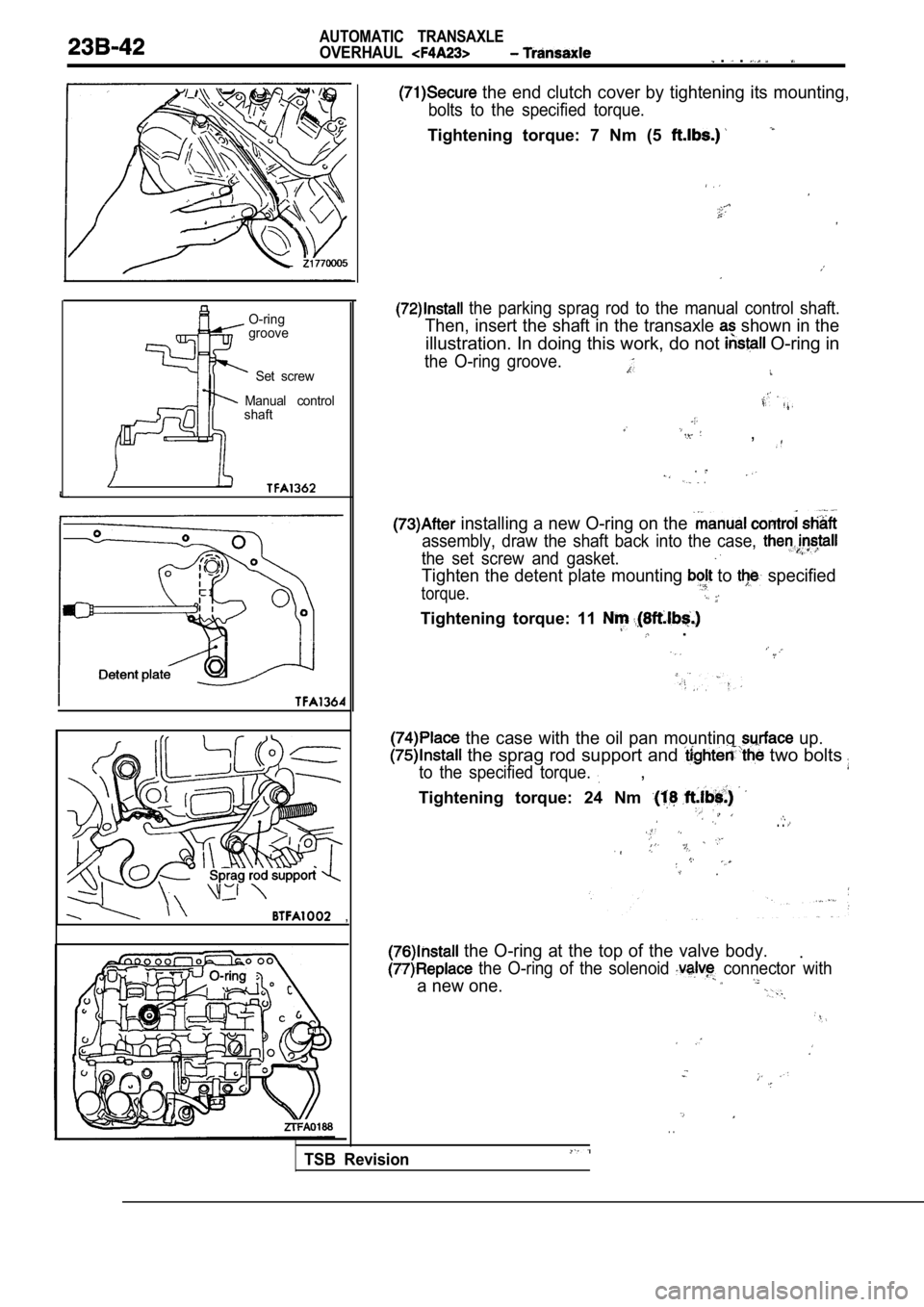

the end clutch cover by tightening its mounting,

bolts to the specified torque.

Tightening torque: 7 Nm (5

the parking sprag rod to the manual control shaft.

Then, insert the shaft in the transaxle shown in the

illustration. In doing this work, do not O-ring in

the O-ring groove.

,

installing a new O-ring on the

assembly, draw the shaft back into the case,

the set screw and gasket.

Tighten the detent plate mounting to specified

torque.

Tightening torque: 11 .

the case with the oil pan mounting up.

the sprag rod support and two bolts

to the specified torque. ,

Tightening torque: 24 Nm

. .

the O-ring at the top of the valve body..

the O-ring of the solenoid connector with

a new one.

. .

TSB Revision

Page 1249 of 2103

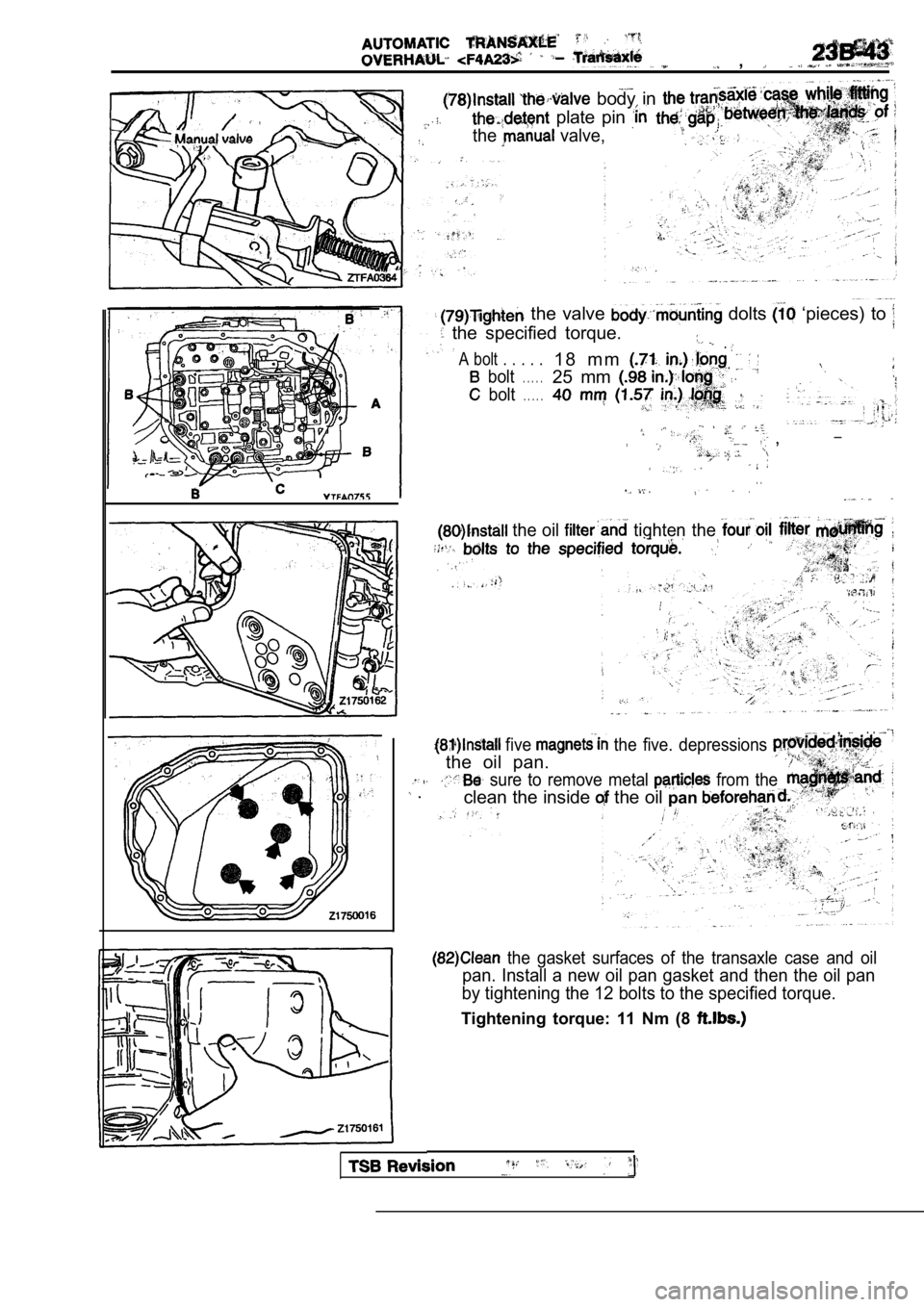

,

body in

plate pin

the valve,

the valve dolts ‘pieces) to

the specified torque.

A bolt . . . . .

.

bolt

1 8 m m

. . . . .

bolt

25 mm

. . . . .

__ ,

. .

the oil tighten the

five the five. depressions

, . .

the oil pan.

sure to remove metal from the .clean the inside the oil pan

the gasket surfaces of the transaxle case and oil

pan. Install a new oil pan gasket and then the oil pan

by tightening the 12 bolts to the specified torque.

Tightening torque: 11 Nm (8

Page 1250 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

I

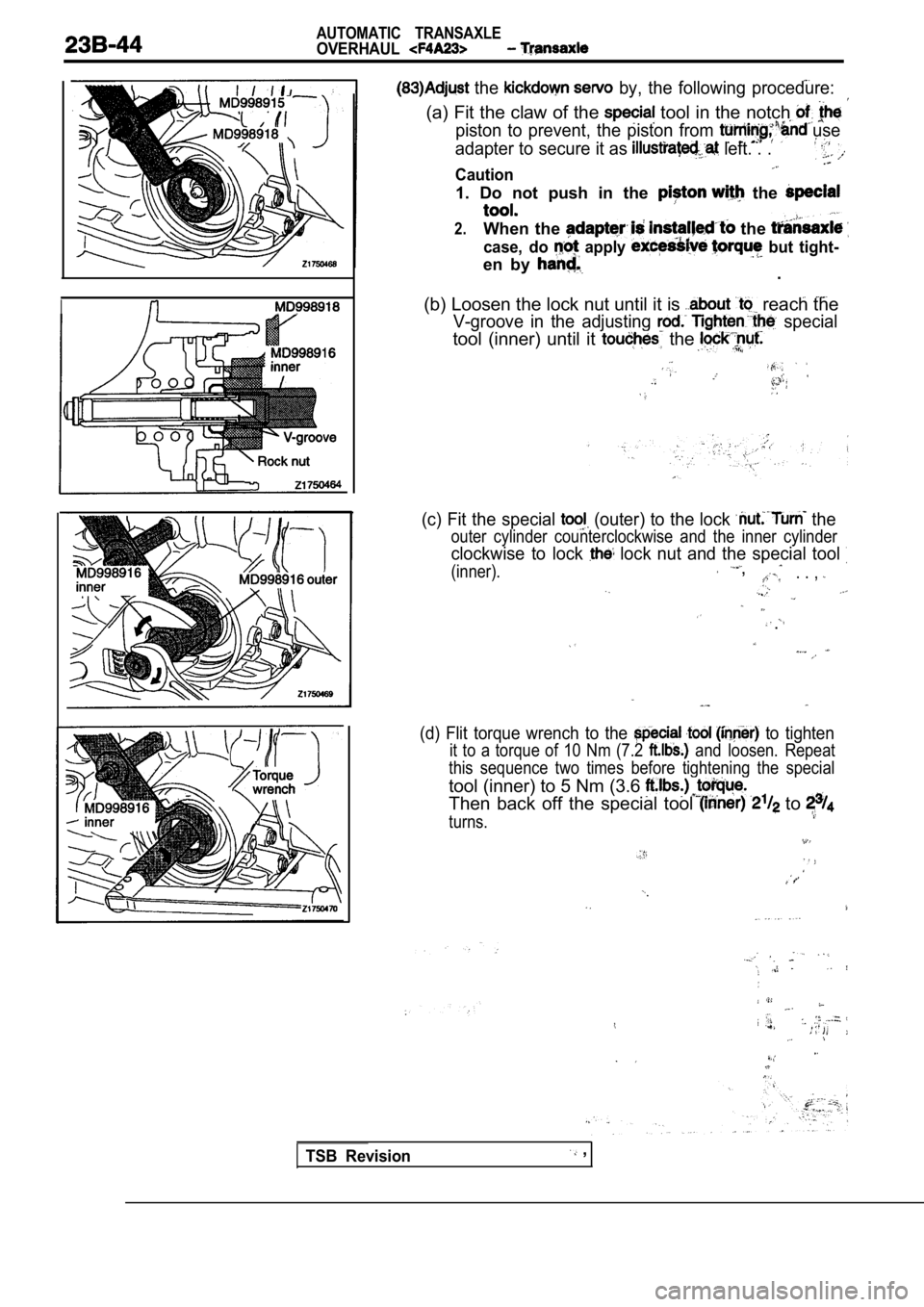

the by, the following procedure:

(a) Fit the claw of the tool in the notch

piston to prevent, the piston from use

adapter to secure it as

left. . .

Caution

1. Do not push in the the

2.When the the

case, do apply but tight-

en by .

(b) Loosen the lock nut until it is reach the

V-groove in the adjusting special

tool (inner) until it the

(c) Fit the special (outer) to the lock the

outer cylinder counterclockwise and the inner cylin der

clockwise to lock lock nut and the special tool

(inner). ,. . ,

.

(d) Flit torque wrench to the to tighten

it to a torque of 10 Nm (7.2 and loosen. Repeat

this sequence two times before tightening the speci al

tool (inner) to 5 Nm (3.6

Then back off the special tool to

turns.

TSB Revision ,

Trending: wiper fluid, spark plugs, oil filter, hood release, roof rack, tire size, change wheel