MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: turn signal, brake sensor, trunk, radiator cap, horn, water pump, fuel type

Page 1231 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL

I

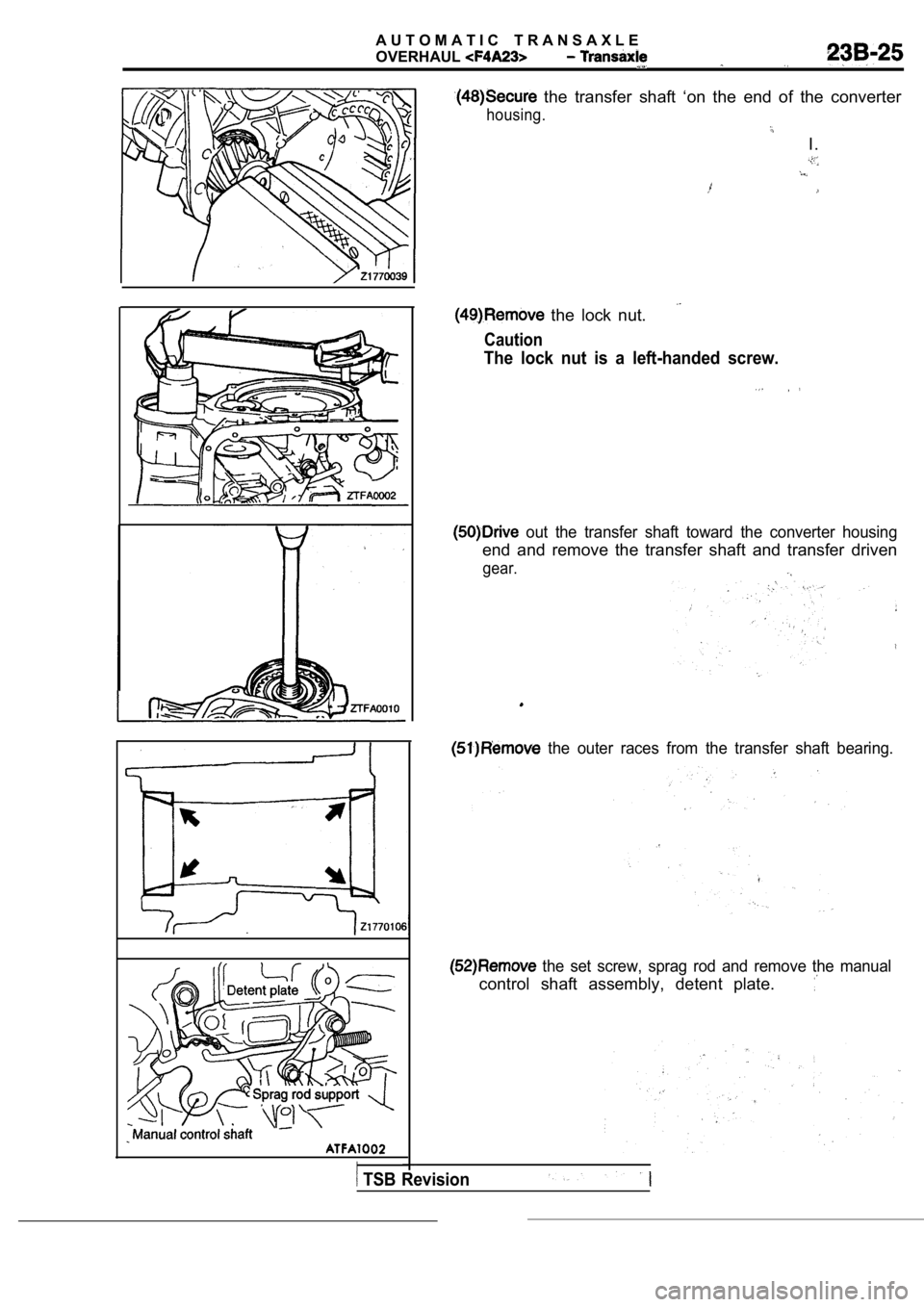

the transfer shaft ‘on the end of the converter

housing.

I .

the lock nut.

Caution

The lock nut is a left-handed screw.

out the transfer shaft toward the converter housing

end and remove the transfer shaft and transfer driv en

gear.

the outer races from the transfer shaft bearing.

the set screw, sprag rod and remove the manual

control shaft assembly, detent plate.

TSB Revision

Page 1232 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL

Oil pump side

Pressure spring

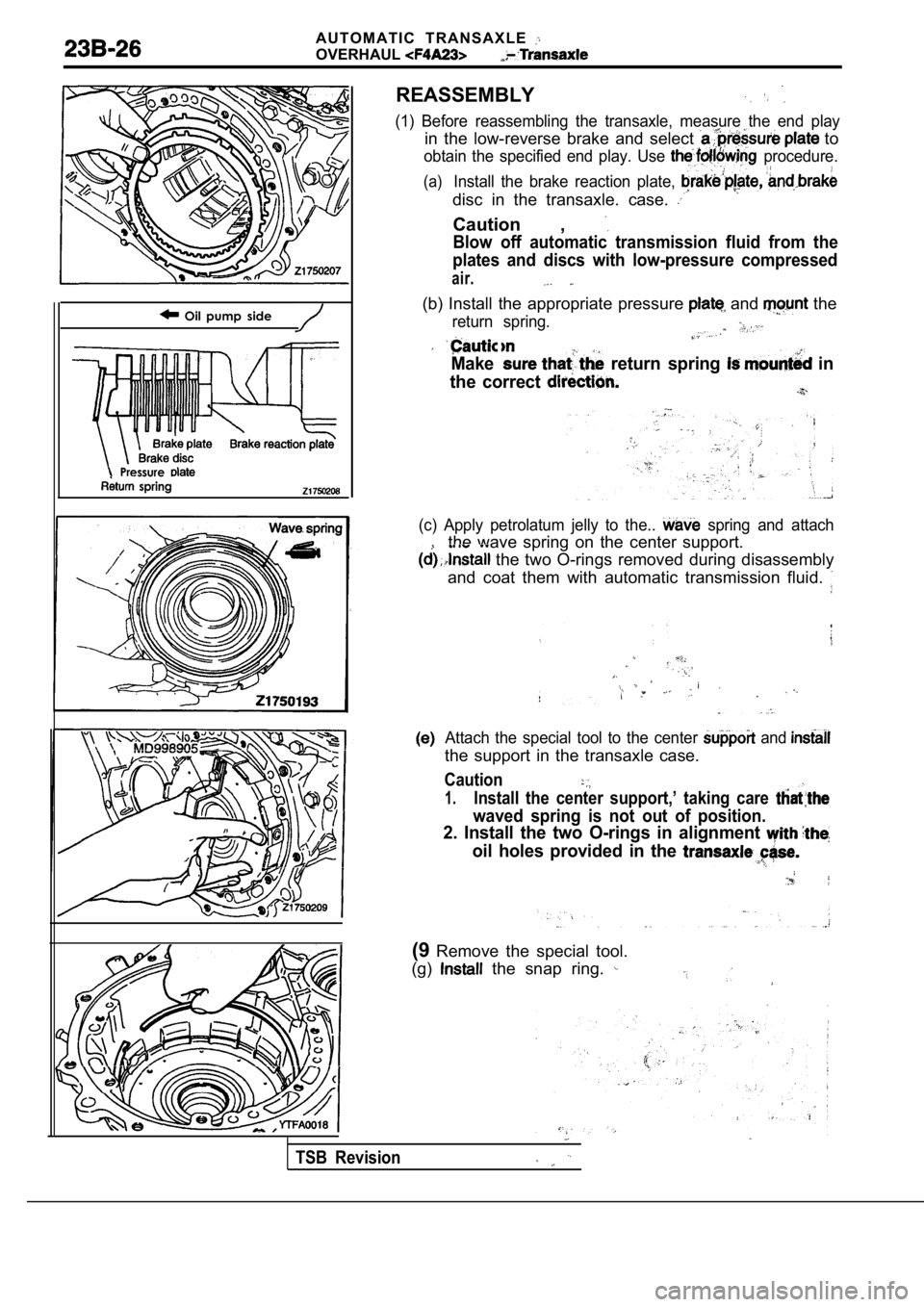

REASSEMBLY

(1) Before reassembling the transaxle, measure the end play

in the low-reverse brake and select to

obtain the specified end play. Use procedure.

(a)Install the brake reaction plate,

disc in the transaxle. case.

Caution ,

Blow off automatic transmission fluid from the

plates and discs with low-pressure compressed

air.

(b) Install the appropriate pressure and the

return spring.

Make return spring in

the correct

(c) Apply petrolatum jelly to the.. spring and attach

the wave spring on the center support.

the two O-rings removed during disassembly

and coat them with automatic transmission fluid.

i .

Attach the special tool to the center and

the support in the transaxle case.

Caution

1.Install the center support,’ taking care

waved spring is not out of position.

2. Install the two O-rings in alignment

oil holes provided in the

(9 Remove the special tool.

(g)

the snap ring.

TSB Revision

Page 1233 of 2103

A U T O M A T I C

OVERHAUL

8

Idler

shaft

hole 3

Brake

reaction

plate

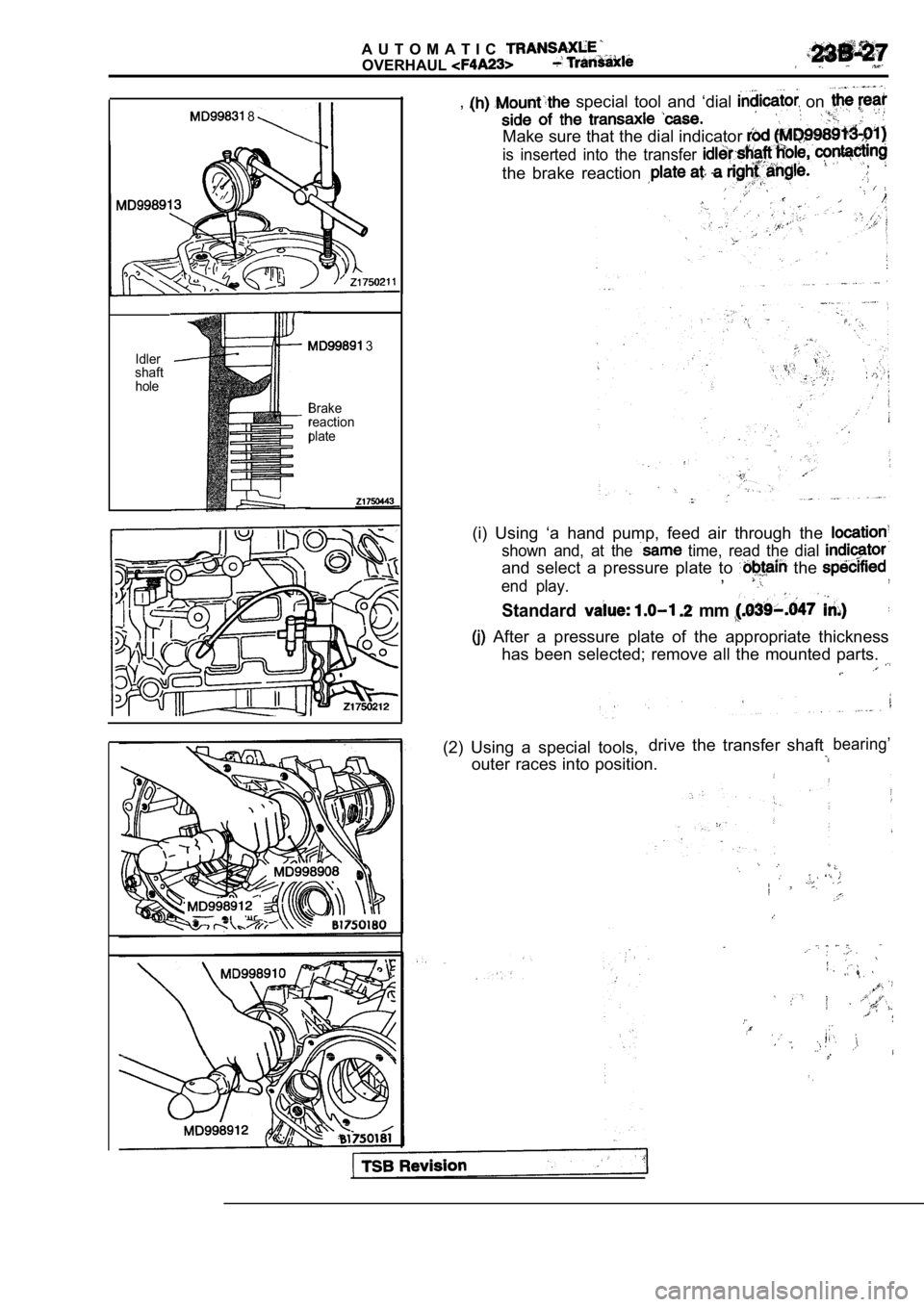

, special tool and ‘dial on

Make sure that the dial indicator

is inserted into the transfer

the brake reaction

(i) Using ‘a hand pump, feed air through the

shown and, at the time, read the dial

and select a pressure plate to the

end play.,

Standard mm

After a pressure plate of the appropriate thicknes s

has been selected; remove all the mounted parts.

(2) Using a special tools, drive the transfer shaftbearing’

outer races into position.

Page 1234 of 2103

AUTOMATIC TRANSAXLEOVERHAUL Transaxle

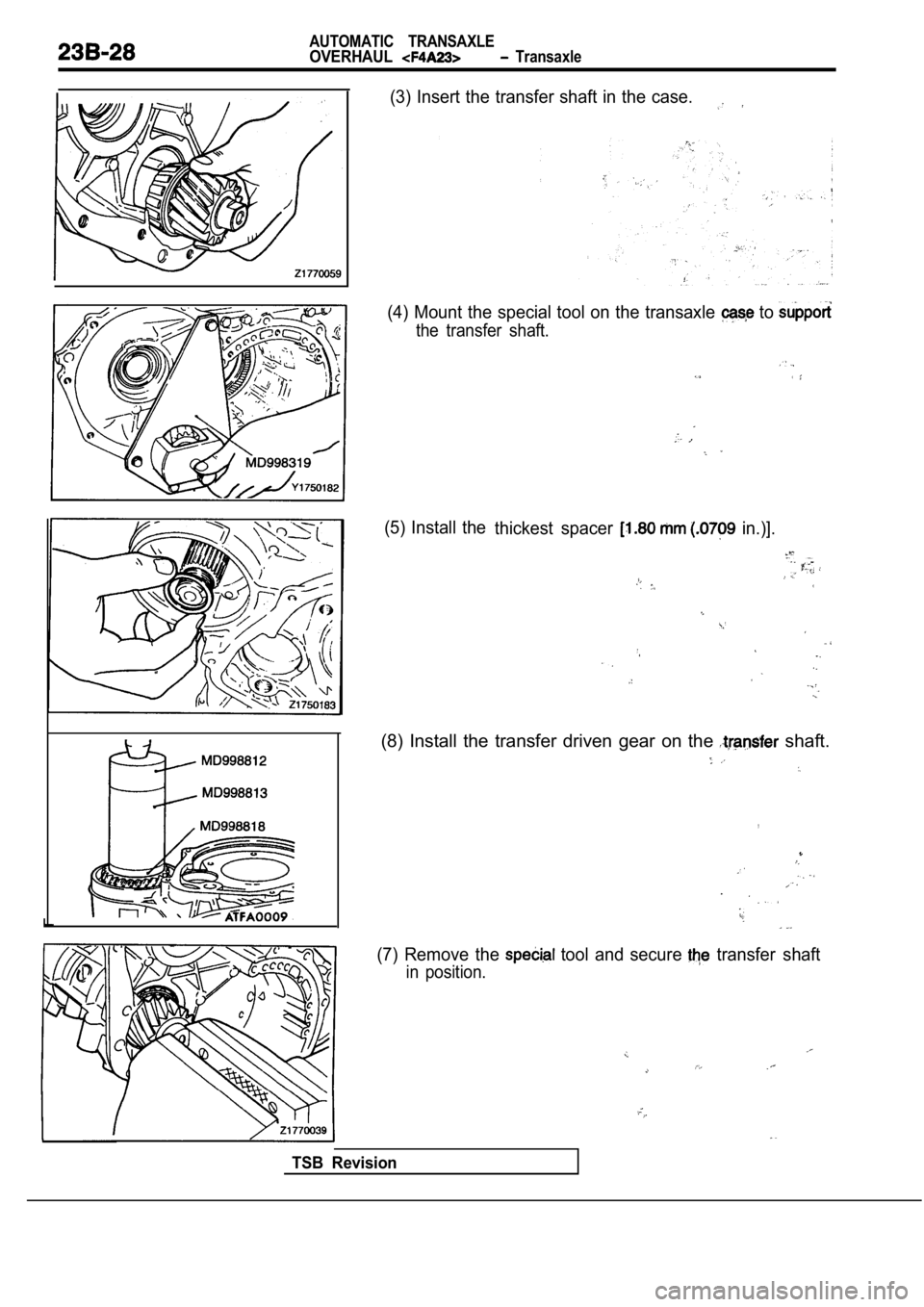

(3) Insert the transfer shaft in the case.

(4) Mount the special tool on the transaxle to

the transfer shaft.

(5) Install thethickest spacer in.)].

(8) Install the transfer driven gear on the shaft.

,

(7) Remove the tool and secure transfer shaft

in position.

TSB Revision

Page 1235 of 2103

AUTOMATIC TRANSAXLE

O V E R H A U L

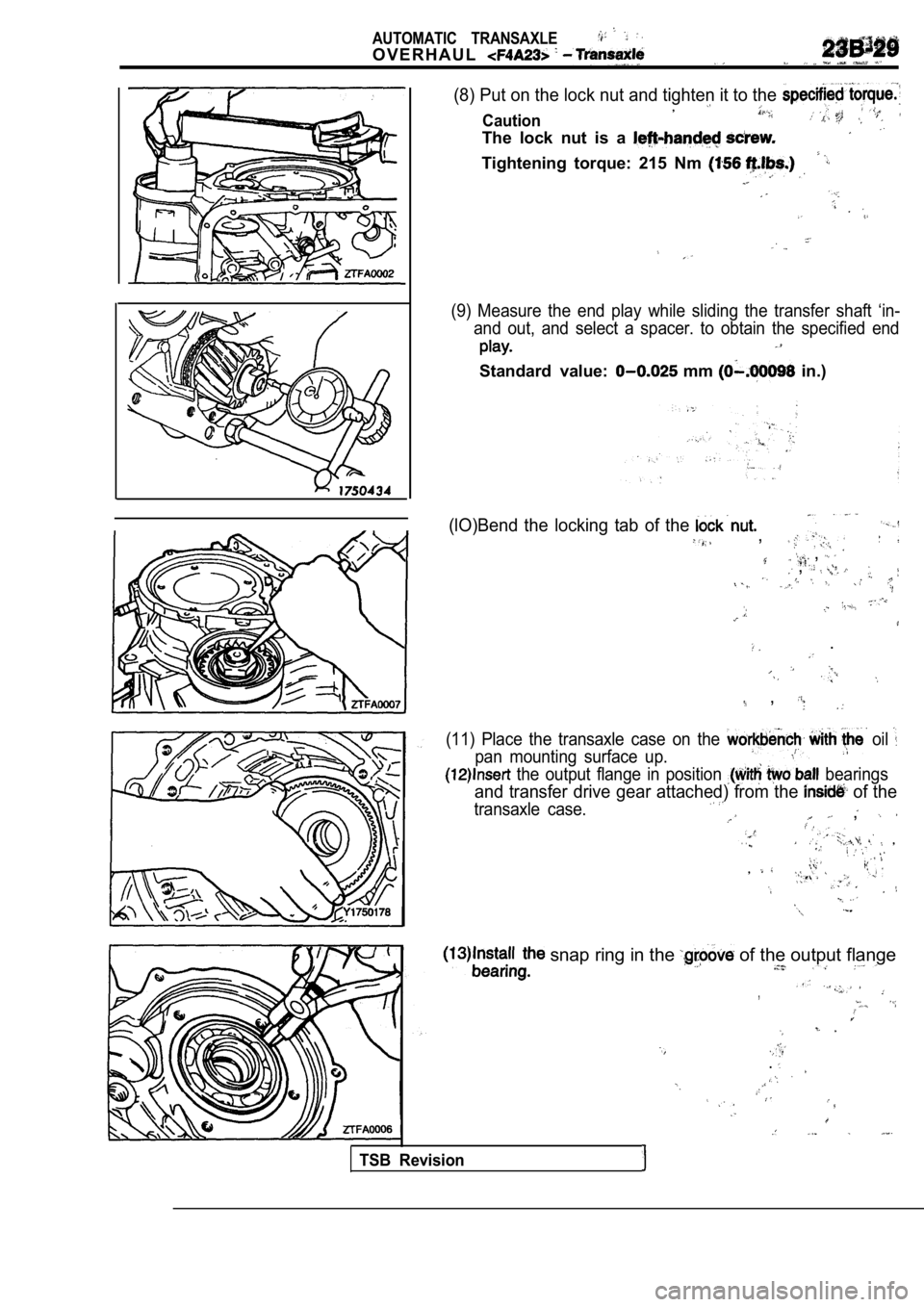

(8) Put on the lock nut and tighten it to the

Caution,

The lock nut is a

Tightening torque: 215 Nm

(9) Measure the end play while sliding the transfer shaft ‘in-

and out, and select a spacer. to obtain the specifi ed end

Standard value: mm in.)

(lO)Bend the locking tab of the ,

, ,

.

,

(11) Place the transaxle case on the oil

pan mounting surface up.

the output flange in position bearings

and transfer drive gear attached) from the of the

transaxle case. ,

. . ,

,

snap ring in the of the output flange

.

,

.

TSB Revision

Page 1236 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL Transaxle

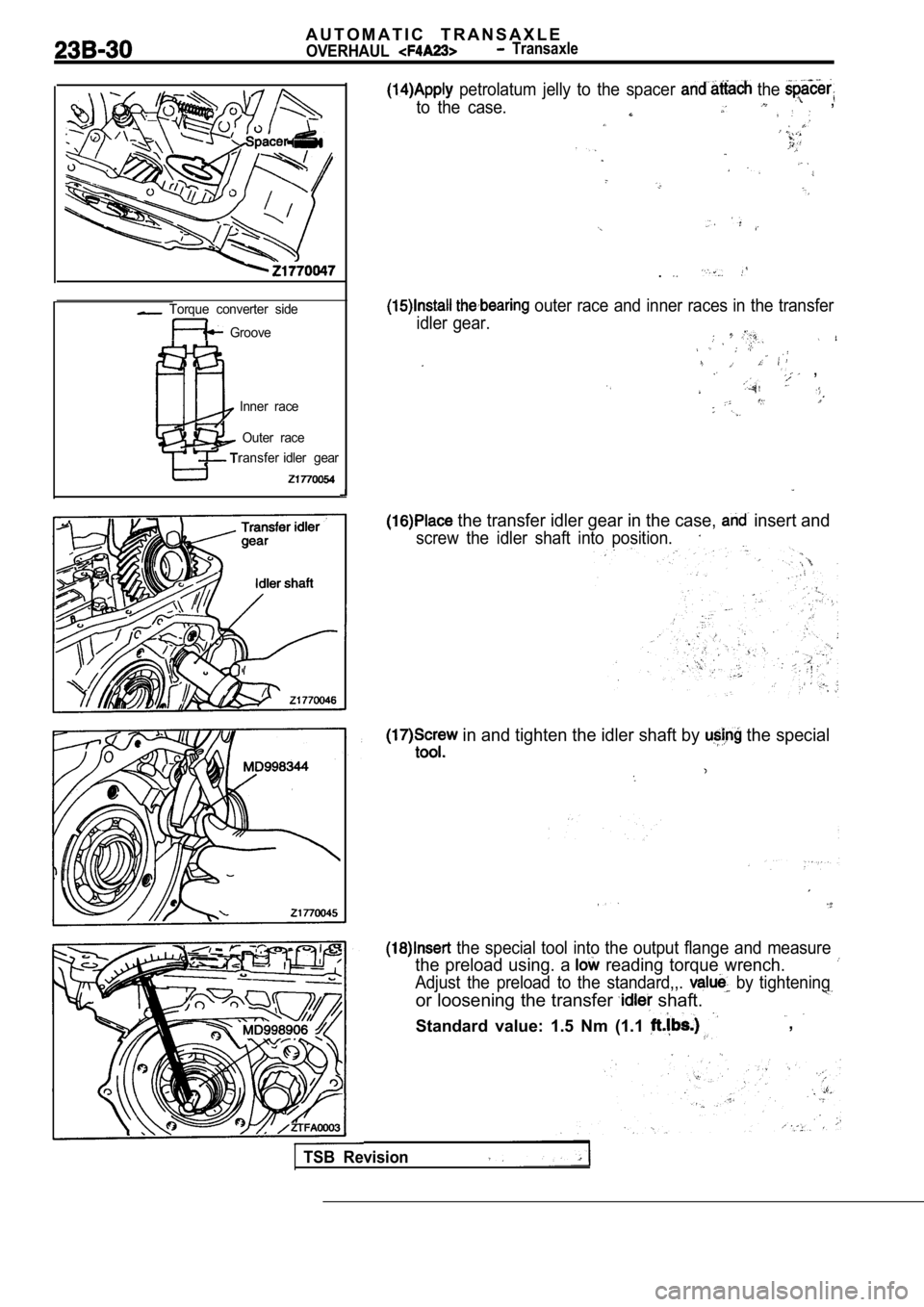

Torque converter side

GrooveInner raceOuter race

ransfer idler gear

petrolatum jelly to the spacer the

to the case. ,

.

outer race and inner races in the transfer

idler gear.

,

the transfer idler gear in the case, insert and

screw the idler shaft into position.

in and tighten the idler shaft by the special

the special tool into the output flange and measur e

the preload using. a reading torque wrench.

Adjust the preload to the standard,,. by tightening

or loosening the transfer shaft.

Standard value: 1.5 Nm (1.1 ,

TSB Revision

Page 1237 of 2103

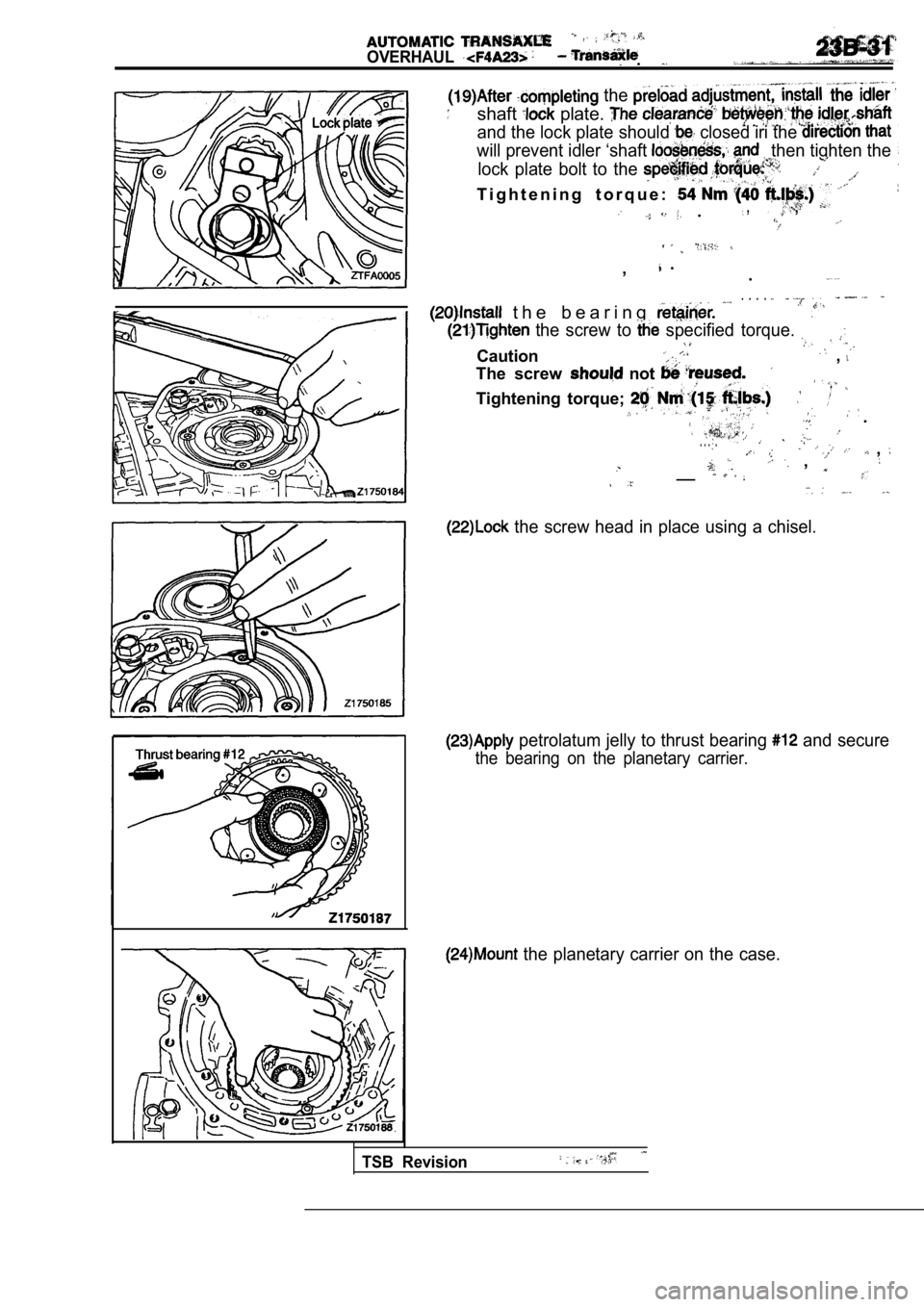

OVERHAUL.

the

shaft plate.

and the lock plate should closed iri the

will prevent idler ‘shaft then tighten the

lock plate bolt to the

T i g h t e n i n g t o r q u e :

. , ,

, . .

t h e b e a r i n g

. . . .

the screw to specified torque.

Caution,

The screw not

Tightening torque;

.

. . . . , , __

the screw head in place using a chisel.

petrolatum jelly to thrust bearing and secure

the bearing on the planetary carrier.

the planetary carrier on the case.

TSB Revision

Page 1238 of 2103

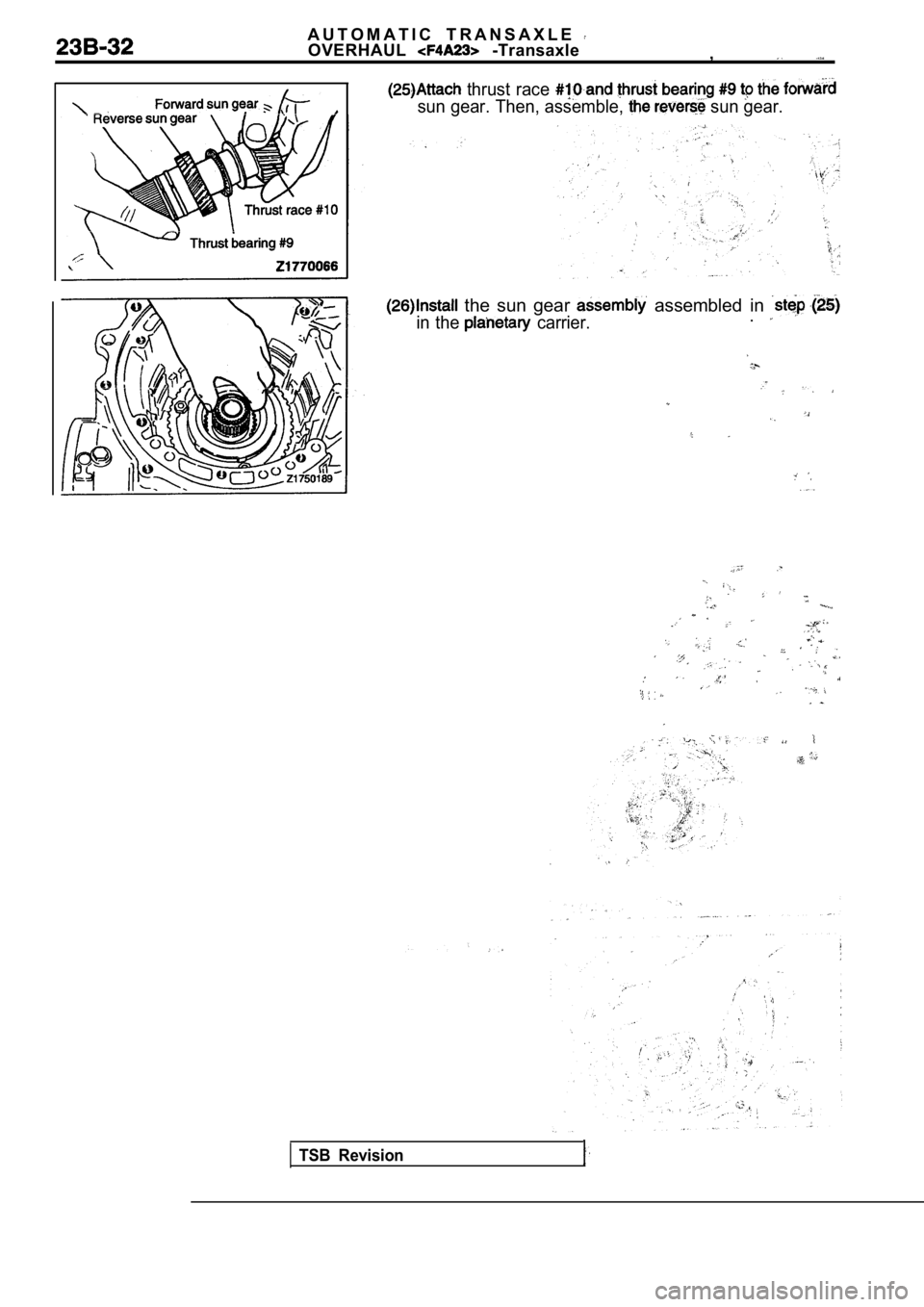

A U T O M A T I C T R A N S A X L E

OVERHAUL -Transaxle,

thrust race

sun gear. Then, assemble, sun gear.

the sun gear assembled in

in the carrier..

TSB Revision

Page 1239 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

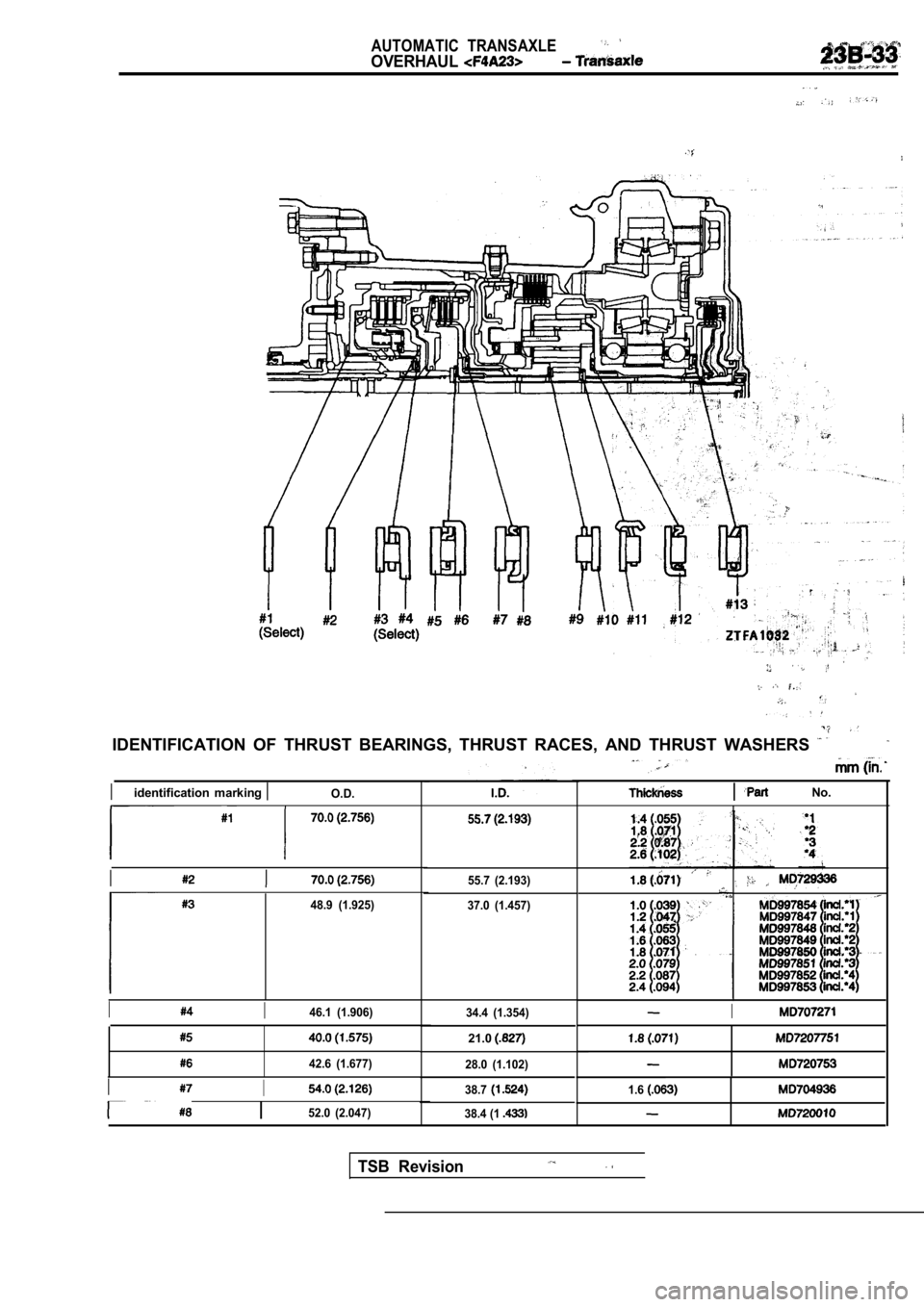

IDENTIFICATION OF THRUST BEARINGS, THRUST RACES, AND THRUST WASHERS

Iidentification marking O.D.

I

48.9 (1.925)

II46.1 (1.906)

42.6 (1.677)

II

I52.0 (2.047)55.7 (2.193)

37.0 (1.457)

34.4 (1.354)

21.0

28.0 (1.102)

38.7

38.4 (1

No.

I

1.6

TSB Revision

Page 1240 of 2103

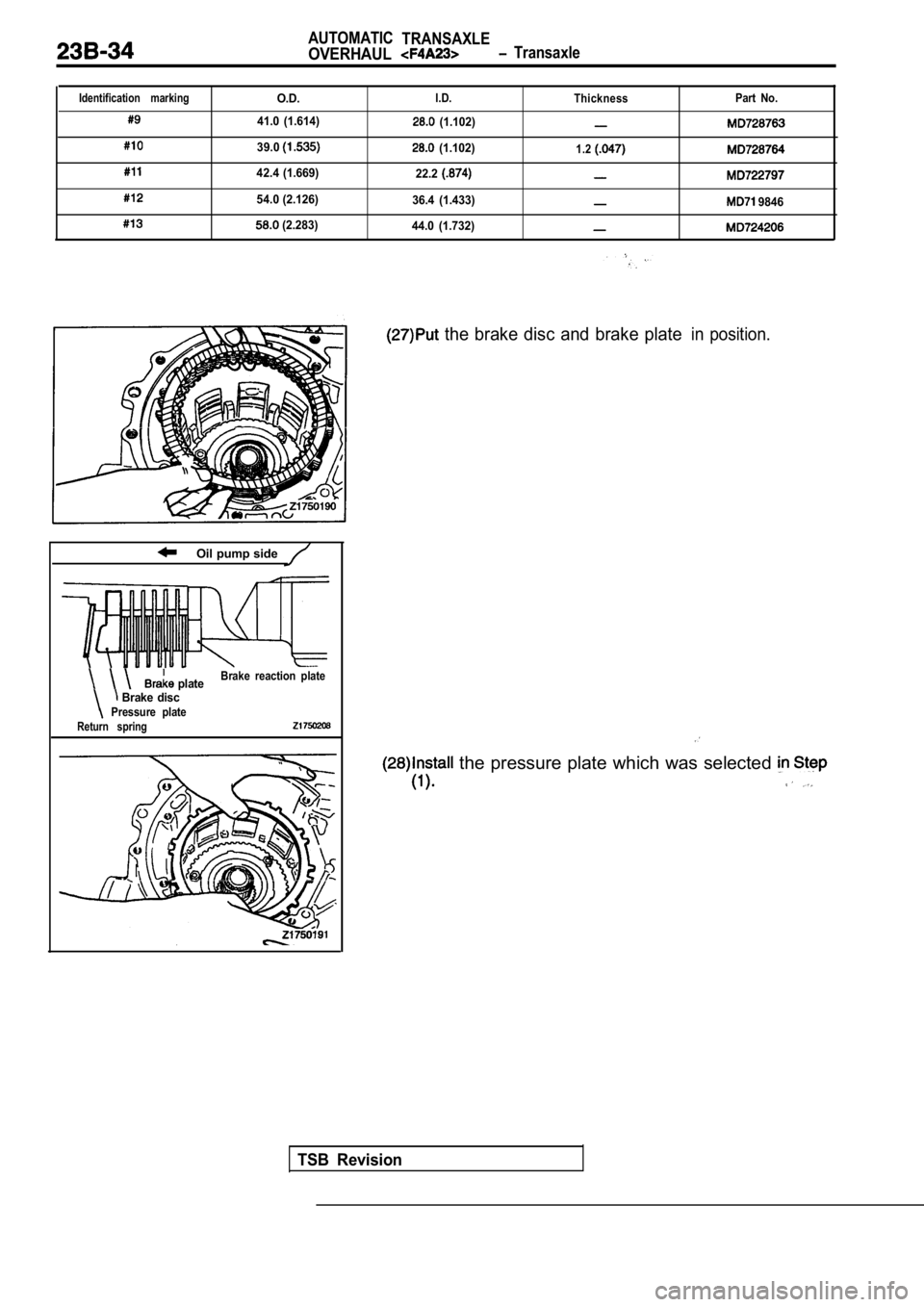

Identification marking

AUTOMATICTRANSAXLE

OVERHAUL Transaxle

O.D.I.D. Thickness Part No.

41.0 (1.614) (1.102)

39.0 (1.102)1.2

42.4 (1.669)

22.2

54.0 (2.126)36.4 (1.433) 9846

(2.283)44.0 (1.732)

Oil pump side

plateBrake reaction plate

Brake discPressure plateReturn spring

the brake disc and brake platein position.

the pressure plate which was selected

TSB Revision

Trending: wipers, hood open, door lock, heater, cruise control, child lock, open hood