engine oil MITSUBISHI SPYDER 1990 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 87 of 2103

ENGINE Oil and

Oil pan side

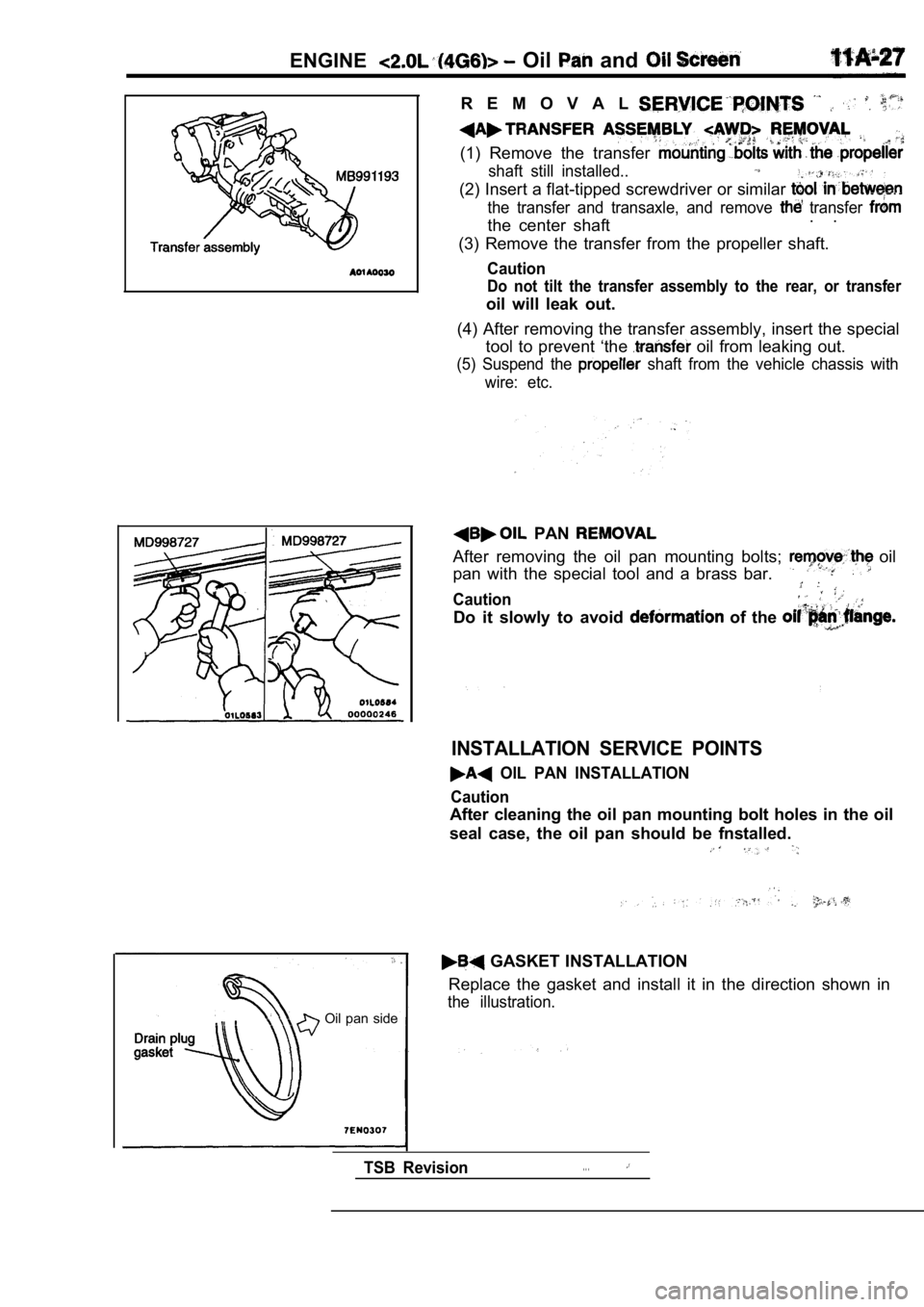

R E M O V A L

(1) Remove the transfer

shaft still installed..

(2) Insert a flat-tipped screwdriver or similar

the transfer and transaxle, and remove transfer

the center shaft. .

(3) Remove the transfer from the propeller shaft.

Caution

Do not tilt the transfer assembly to the rear, or t ransfer

oil will leak out.

(4) After removing the transfer assembly, insert th e special

tool to prevent ‘the

oil from leaking out.

(5) Suspend the shaft from the vehicle chassis with

wire: etc.

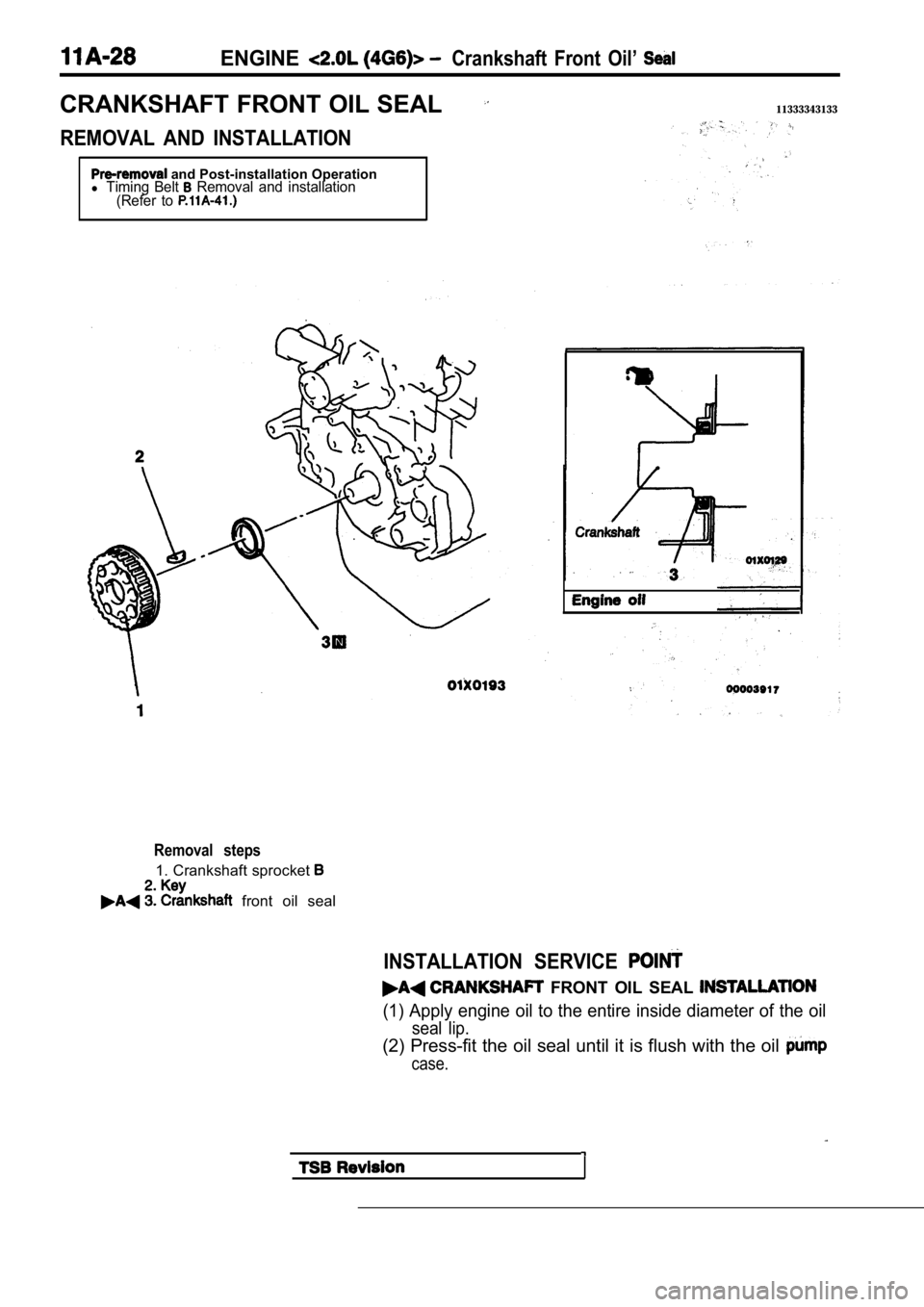

PAN

After removing the oil pan mounting bolts; oil

pan with the special tool and a brass bar.

Caution

Do it slowly to avoid of the

INSTALLATION SERVICE POINTS

OIL PAN INSTALLATION

Caution

After cleaning the oil pan mounting bolt holes in t he oil

seal case, the oil pan should be fnstalled.

GASKET INSTALLATION

Replace the gasket and install it in the direction shown in

the illustration.

TSB Revision. . .

Page 88 of 2103

ENGINECrankshaft Front Oil’

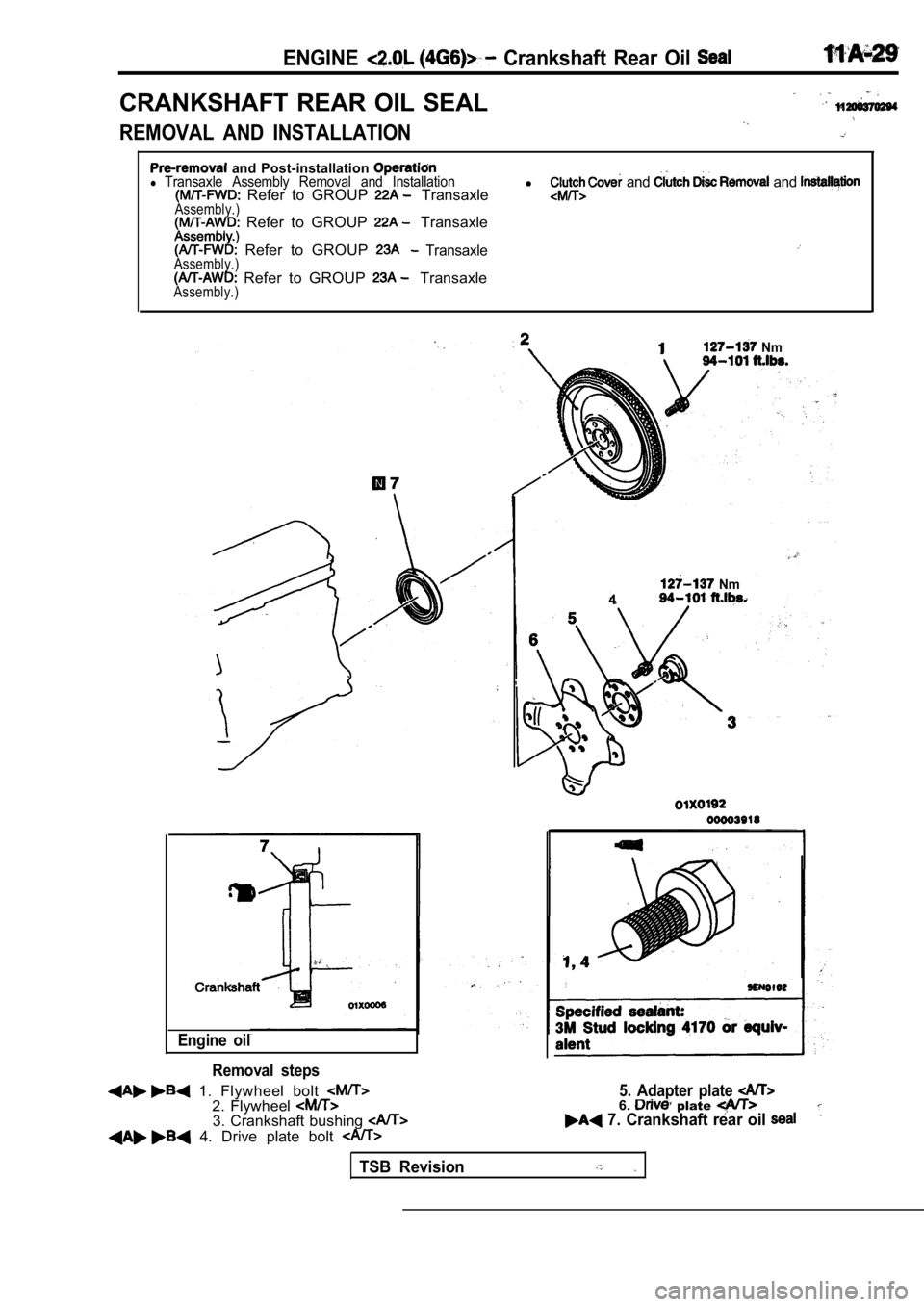

CRANKSHAFT FRONT OIL SEAL11333343133

REMOVAL AND INSTALLATION

and Post-installation Operationl Timing Belt Removal and installation

(Refer to

Removal steps

1. Crankshaft sprocket

front oil seal

INSTALLATION SERVICE

FRONT OIL SEAL

(1) Apply engine oil to the entire inside diameter of the oil

seal lip.

(2) Press-fit the oil seal until it is flush with the oil

case.

Page 89 of 2103

ENGINE Crankshaft Rear Oil

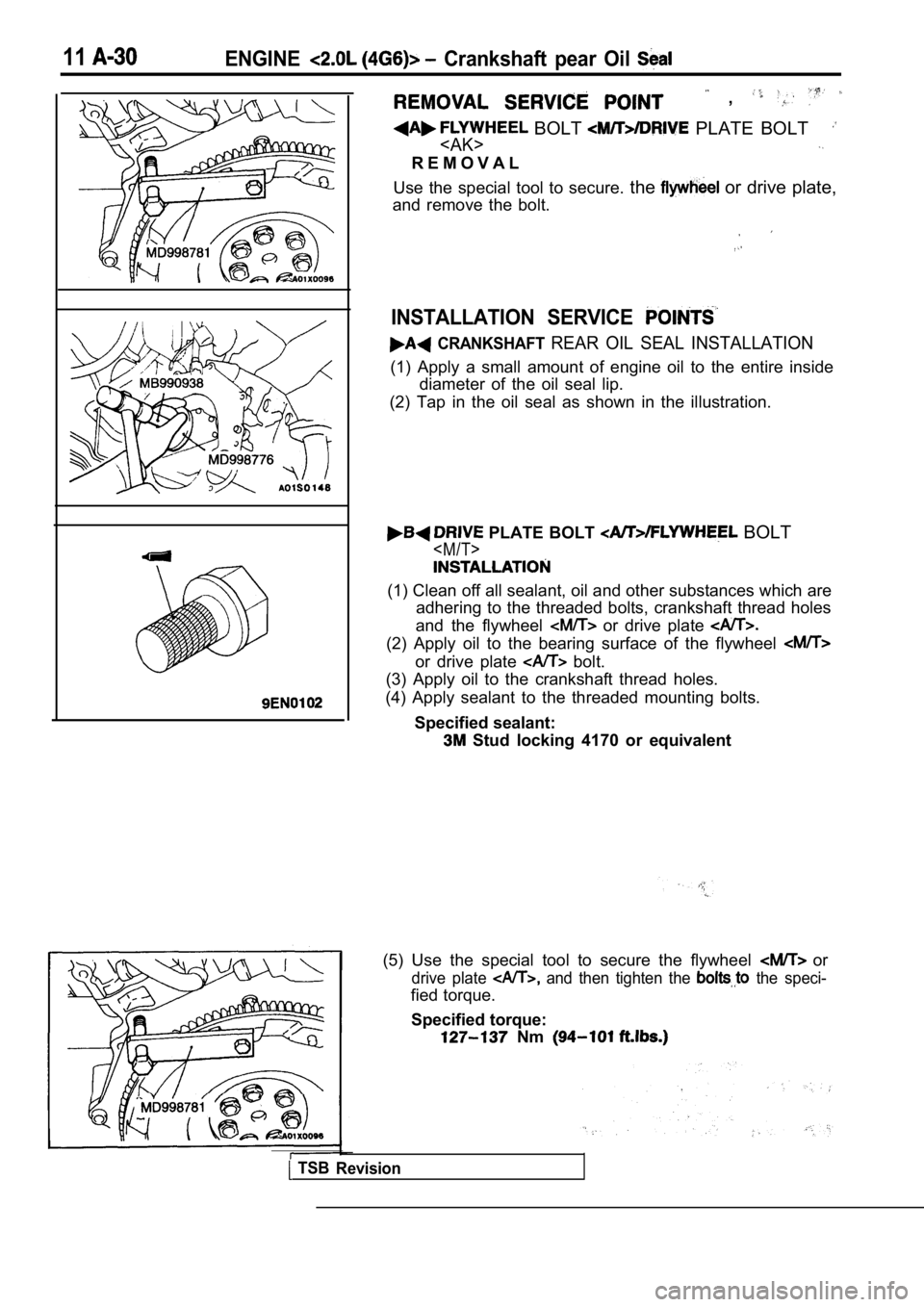

CRANKSHAFT REAR OIL SEAL

REMOVAL AND INSTALLATION

and Post-installation l Transaxle Assembly Removal and Installation Refer to GROUP TransaxleAssembly.)

l and and

Refer to GROUP TransaxleAssembl Refer to GROUP TransaxleAssembly.) Refer to GROUP TransaxleAssembly.)

Nm

Engine oilRemoval steps

1. Flywheel bolt 2. Flywheel 3. Crankshaft bushing

4. Drive plate bolt

Nm4

5. Adapter plate 6. plate 7. Crankshaft rear oil

TSB Revision

Page 90 of 2103

11ENGINE Crankshaft pear Oil

,

BOLT PLATE BOLT

R E M O V A L

Use the special tool to secure. the

or drive plate,

and remove the bolt.

INSTALLATION SERVICE

CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small amount of engine oil to the entir e inside

diameter of the oil seal lip.

(2) Tap in the oil seal as shown in the illustratio n.

PLATE BOLT BOLT

(1) Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread h oles

and the flywheel

or drive plate

(2) Apply oil to the bearing surface of the flywhee l

or drive plate bolt.

(3) Apply oil to the crankshaft thread holes.

(4) Apply sealant to the threaded mounting bolts.

Specified sealant:

Stud locking 4170 or equivalent

TSB Revision

(5) Use the special tool to secure the flywheel or

drive plate and then tighten the the speci-

fied torque.

Specified torque:

Nm

Page 91 of 2103

ENGINE Cylinder Head

CYLINDER HEAD GASKET

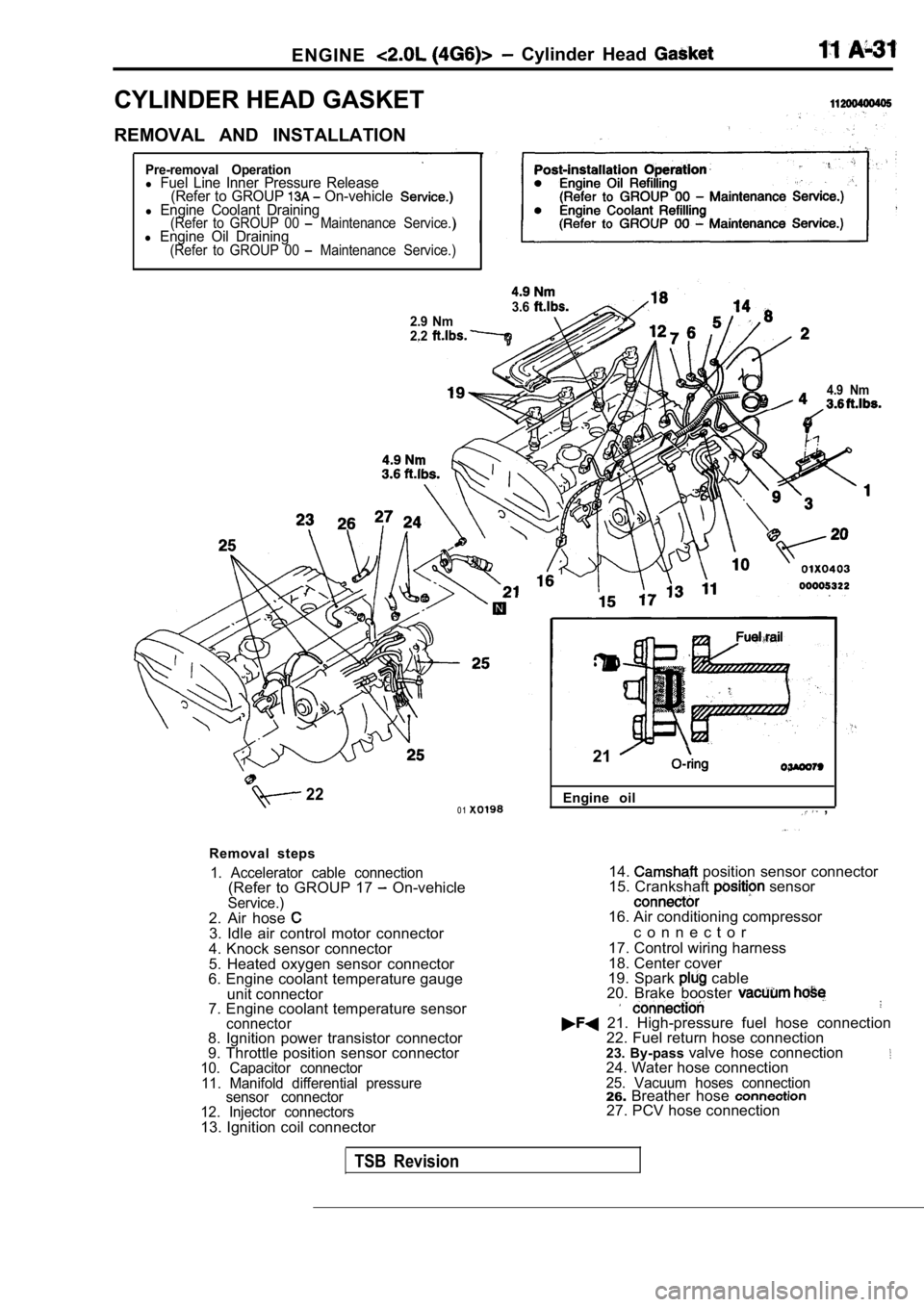

REMOVAL AND INSTALLATION

Pre-removal Operationl Fuel Line Inner Pressure Release(Refer to GROUP On-vehiclel Engine Coolant Draining(Refer to GROUP 00 Maintenance Service.)l Engine Oil Draining(Refer to GROUP 00 Maintenance Service.)

3.62.9 Nm

2.2

4.9 Nm

220 1

Removal steps

1. Accelerator cable connection(Refer to GROUP 17 On-vehicleService.)2. Air hose 3. Idle air control motor connector

4. Knock sensor connector

5. Heated oxygen sensor connector

6. Engine coolant temperature gauge

unit connector

7. Engine coolant temperature sensor

connector8. Ignition power transistor connector

9. Throttle position sensor connector

10. Capacitor connector

11. Manifold differential pressure sensor connector

12. Injector connectors

13. Ignition coil connector Engine oil

,

21

14. position sensor connector

15. Crankshaft sensor

16. Air conditioning compressor

c o n n e c t o r

17. Control wiring harness

18. Center cover

19. Spark

cable

20. Brake booster

21. High-pressure fuel hose connection 22. Fuel return hose connection

23. By-pass valve hose connection

24. Water hose connection25. Vacuum hoses connection26.Breather hose 27. PCV hose connection

TSB Revision

Page 93 of 2103

ENGINE Cylinder Head Gasket,

Intake sideFront of

engine

Exhaust side

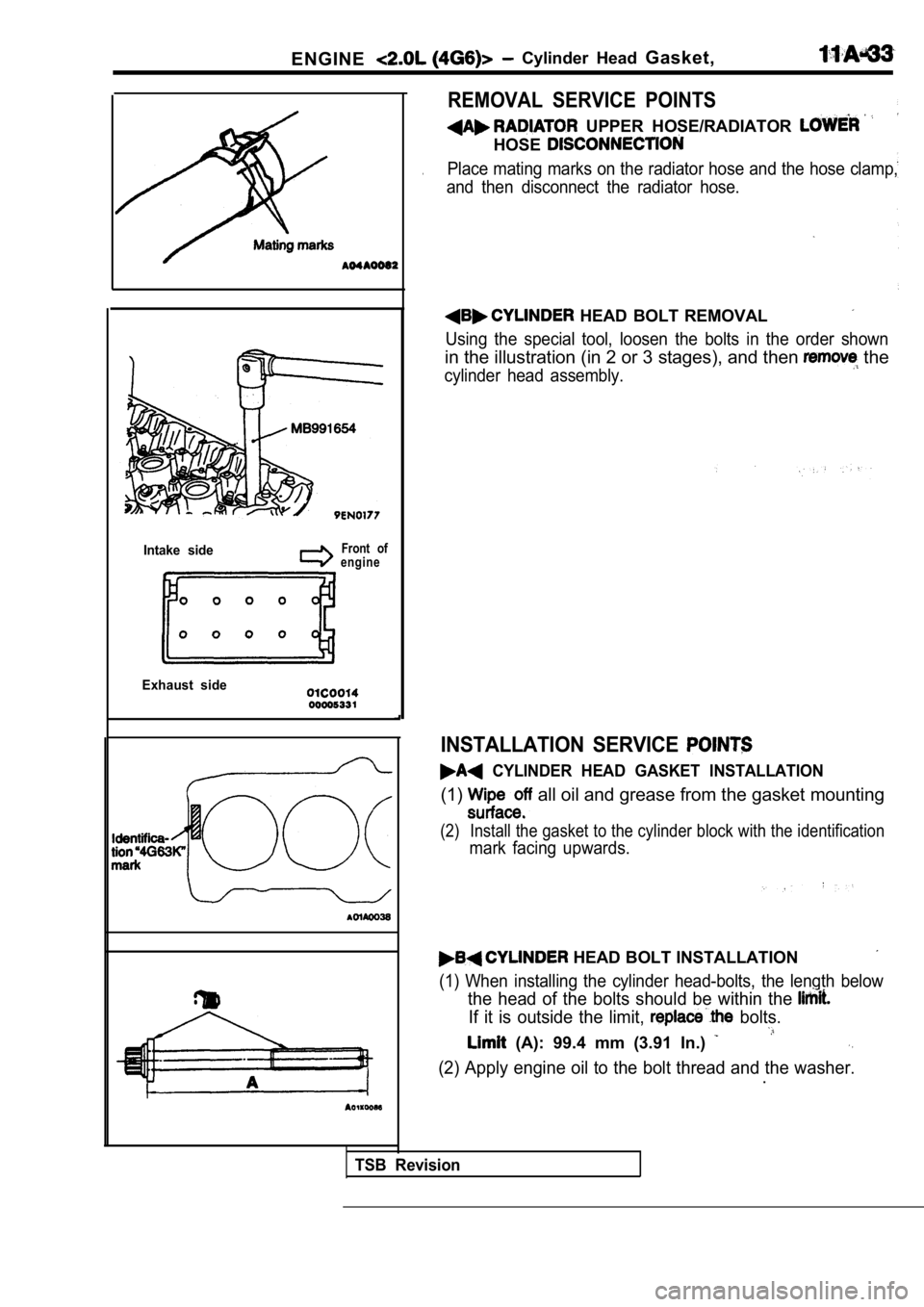

REMOVAL SERVICE POINTS

UPPER HOSE/RADIATOR

HOSE

.Place mating marks on the radiator hose and the hos e clamp,

and then disconnect the radiator hose.

HEAD BOLT REMOVAL

Using the special tool, loosen the bolts in the ord er shown

in the illustration (in 2 or 3 stages), and then the

cylinder head assembly.

INSTALLATION SERVICE

CYLINDER HEAD GASKET INSTALLATION

(1) all oil and grease from the gasket mounting

(2) Install the gasket to the cylinder block with the identification

mark facing upwards.

HEAD BOLT INSTALLATION

(1) When installing the cylinder head-bolts, the le ngth below

the head of the bolts should be within the

If it is outside the limit, bolts.

(A): 99.4 mm (3.91 In.)

(2) Apply engine oil to the bolt thread and the was her..

TSB Revision

Page 94 of 2103

ENGINE H e a d

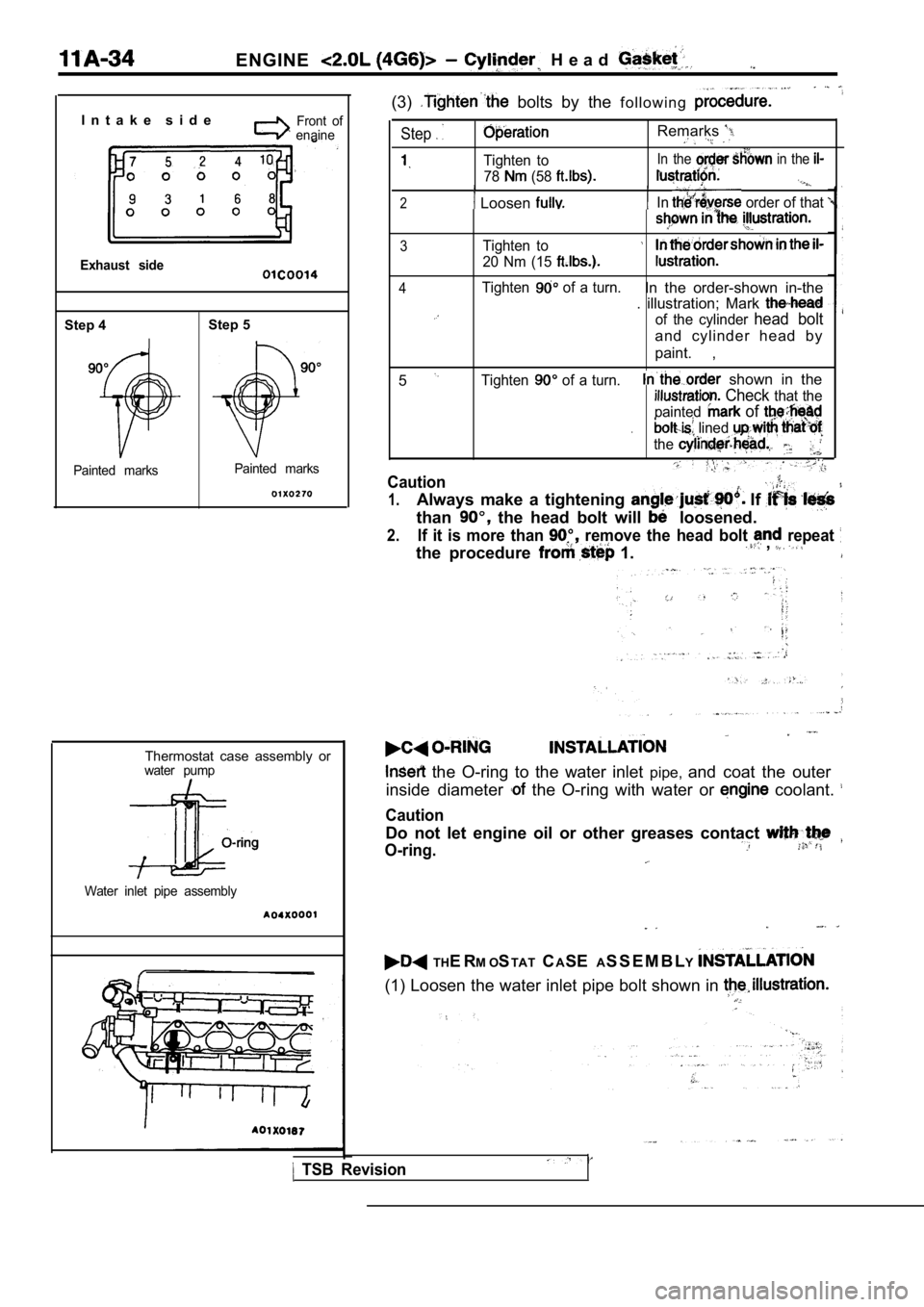

I n t a k e s i d eFront of

enaine

Exhaust side

Step 4

I

Painted marks

Step 5

Painted marks

Thermostat case assembly orwater pump

Water inlet pipe assembly

(3) bolts by the f o l l o w i n g

Step

Tighten to

78

(58

Remarks

In the in the

2 Loosen In order of that

3Tighten to

20 Nm (15

4Tighten of a turn.In the order-shown in-the

. illustration; Mark

of the cylinder head bolt

and cylinder head by

paint. ,

5

Tighten of a turn. shown in the

Check that the

painted

of

. lined

the

Caution

1.Always make a tightening If

than the head bolt will loosened.

2.If it is more than remove the head bolt repeat

the procedure 1. ,

the O-ring to the water inlet pipe,and coat the outer

inside diameter

the O-ring with water or coolant.

Caution

Do not let engine oil or other greases contact

O-ring.

TH E R M OSTAT CASE AS S E M B L Y

(1) Loosen the water inlet pipe bolt shown in

TSB Revision

Page 95 of 2103

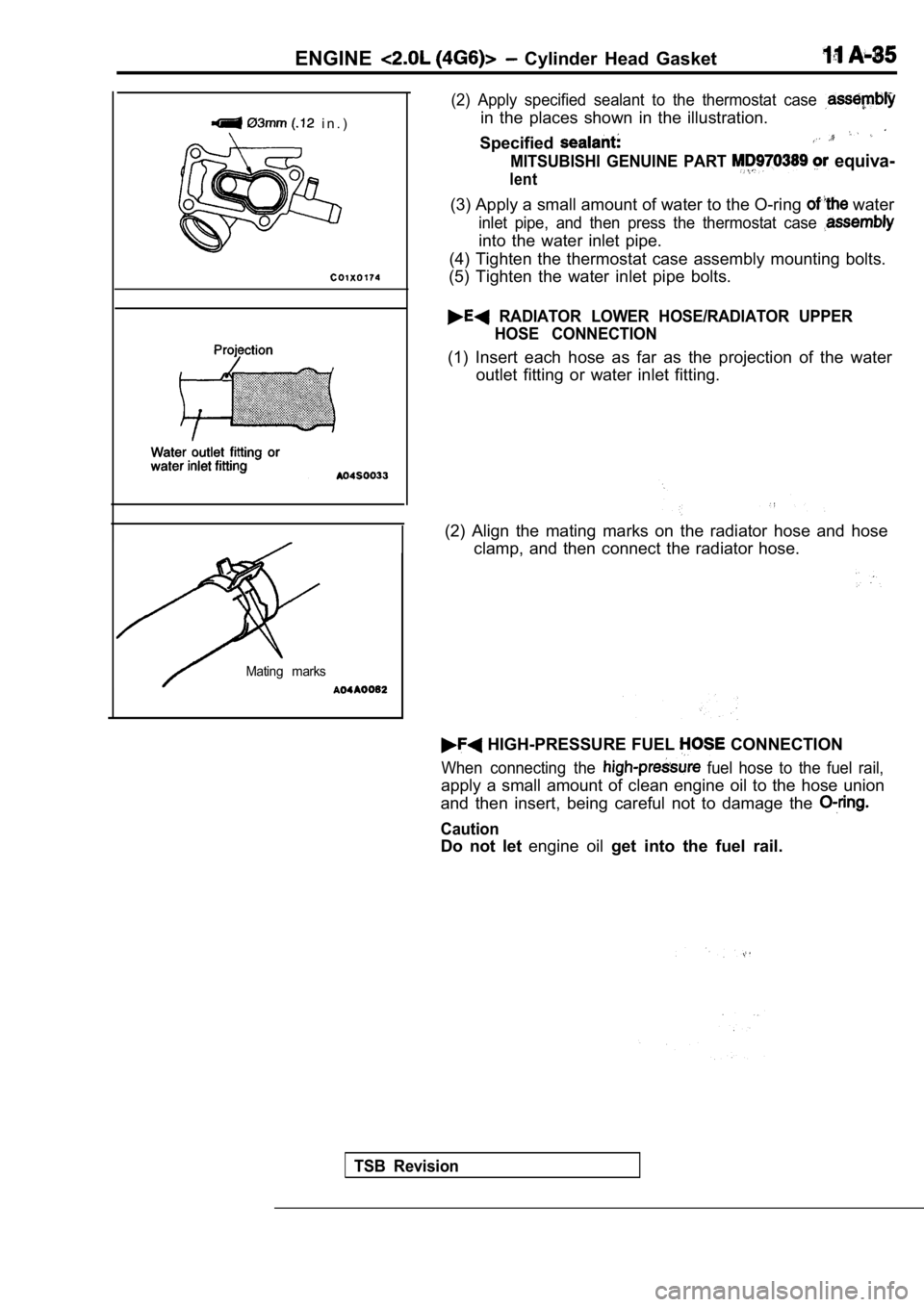

ENGINE Cylinder Head Gasket

i n . )

Mating marks

(2) Apply specified sealant to the thermostat case

in the places shown in the illustration.

Specified

MITSUBISHI GENUINE PART equiva-

lent

(3) Apply a small amount of water to the O-ring water

inlet pipe, and then press the thermostat case

into the water inlet pipe.

(4) Tighten the thermostat case assembly mounting b olts.

(5) Tighten the water inlet pipe bolts.

RADIATOR LOWER HOSE/RADIATOR UPPER HOSE CONNECTION

(1) Insert each hose as far as the projection of th e water

outlet fitting or water inlet fitting.

(2) Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

HIGH-PRESSURE FUEL CONNECTION

When connecting the fuel hose to the fuel rail,

apply a small amount of clean engine oil to the hos e union

and then insert, being careful not to damage the

Caution

Do not let engine oil get into the fuel rail.

TSB Revision

Page 98 of 2103

ENGINE Timing Belt

,Set pin

I

Timing marksCylinder had

Itop surface

Crankshaft

sprocket

60 mm

60 mm

(2.36 in.)

(2.36 in.)

or more

or more in.) in.)

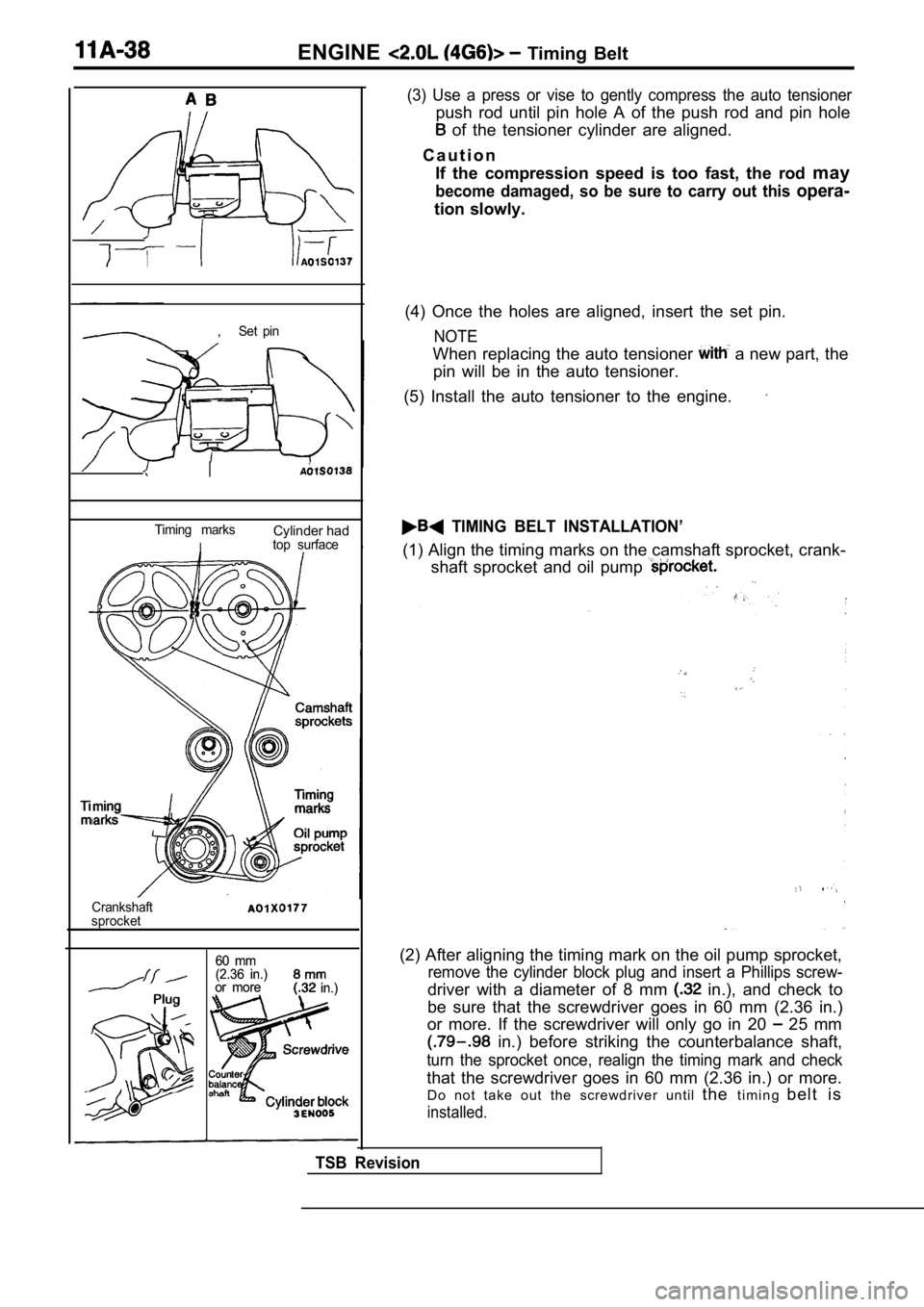

(3) Use a press or vise to gently compress the auto tensioner

push rod until pin hole A of the push rod and pin hole

of the tensioner cylinder are aligned.

C a u t i o n If the compression speed is too fast, the rod may

become damaged, so be sure to carry out this opera-

tion slowly.

(4) Once the holes are aligned, insert the set pin.

NOTE

When replacing the auto tensioner a new part, the

pin will be in the auto tensioner.

(5) Install the auto tensioner to the engine.

TIMING BELT INSTALLATION’

(1) Align the timing marks on the camshaft sprocket , crank-

shaft sprocket and oil pump

(2) After aligning the timing mark on the oil pump sprocket,

remove the cylinder block plug and insert a Phillips screw-

driver with a diameter of 8 mm in.), and check to

be sure that the screwdriver goes in 60 mm (2.36 in .)

or more. If the screwdriver will only go in 20

25 mm

in.) before striking the counterbalance shaft,

turn the sprocket once, realign the timing mark and check

that the screwdriver goes in 60 mm (2.36 in.) or mo re.

Do not take out the screwdriver until thet i m i n g b e l t i s

installed.

TSB Revision

Page 99 of 2103

E N G I N E

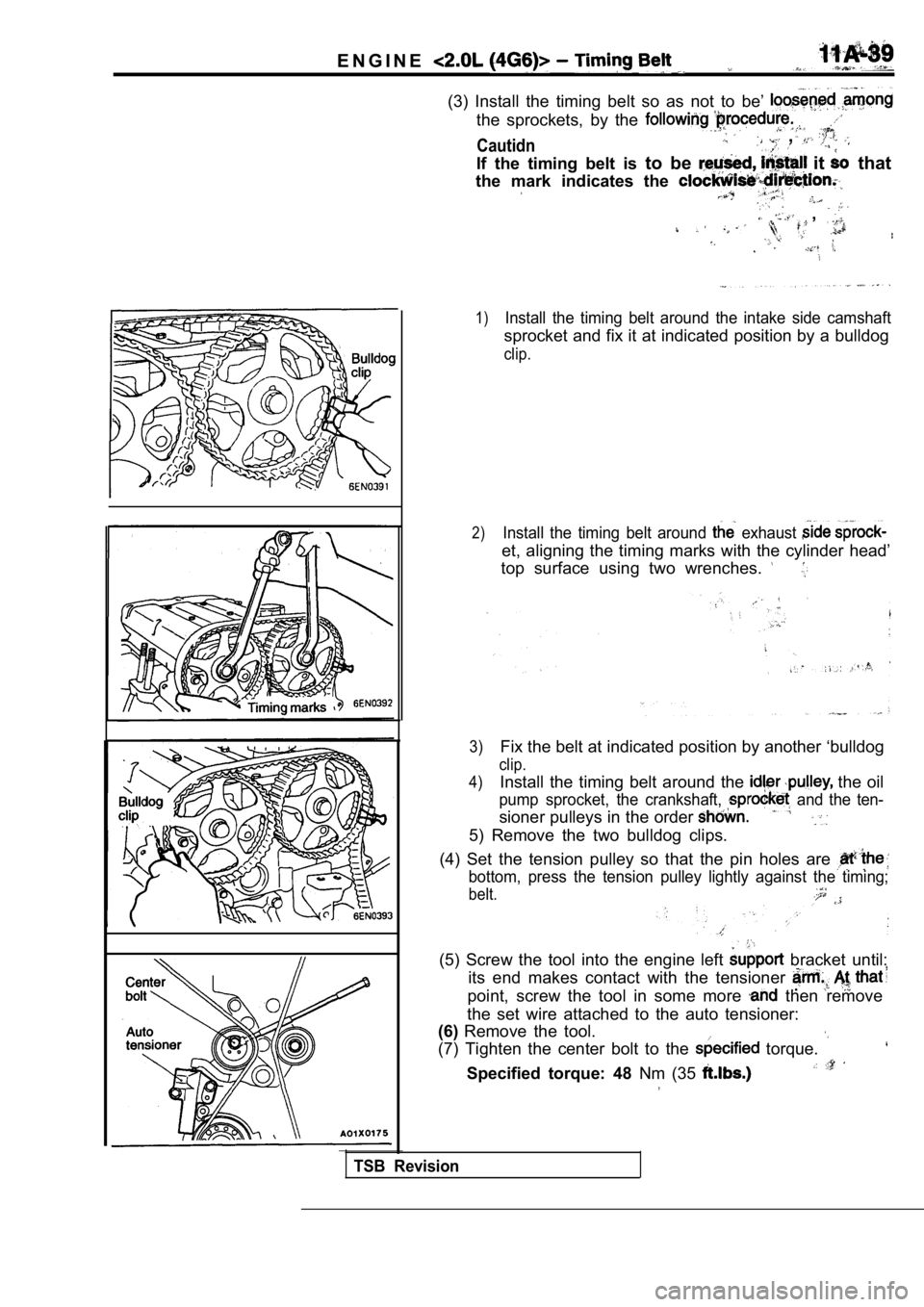

(3) Install the timing belt so as not to be’

the sprockets, by the

Cautidn ,

If the timing belt is to be it that

the mark indicates the

,

1)Install the timing belt around the intake side cams haft

sprocket and fix it at indicated position by a bulldog

clip.

2)Install the timing belt around exhaust

et, aligning the timing marks with the cylinder hea d’

top surface using two wrenches.

3)Fix the belt at indicated position by another ‘bull dog

clip.

4)

Install the timing belt around the the oil

pump sprocket, the crankshaft, and the ten-

sioner pulleys in the order

5) Remove the two bulldog clips.

(4) Set the tension pulley so that the pin holes ar e

bottom, press the tension pulley lightly against the timing;

belt.

(5) Screw the tool into the engine left bracket until:

its end makes contact with the tensioner

point, screw the tool in some more then remove

the set wire attached to the auto tensioner:

(6) Remove the tool.

(7) Tighten the center bolt to the

torque.

Specified torque: 48 Nm (35

TSB Revision