MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 741 of 2103

CONTENTS

AUTO-CRUISE CONTROL SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

AUTO-CRUISE CONTROL* . . . . . . . . . . . . . . 40

GENERAL INFORMATION . . . . . . . . . . . . . . . . 7

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . 33

Auto-cruise Control Cable Check and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Auto-cruise Control Component Check . . . . . 37

Auto-cruise Control System Operation Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

SERVICE SPECIFICATIONS . . . . . . . . . . . . . 8

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING

ENGINE (NON-TURBO)> . . . . . . . . . . . 9

TROUBLESHOOTING

(TURBO) AND ENGINE> . . . . .

EMISSION CONTROL’ SYSTEM

. . . . .

CATALYTIC . . . . . . . . . . . . . .

General Information . . . . . . . . . . . . . . . . . . 57

EVAPORATIVE EMISSION .

SYSTEM. . . . . . . . . . . . . . . .

Air Conditioning . . . . . . . . . . . . . . . . . . . 52

Component Location

. . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor

Intake Air Temperature Sensor . . . . . . . . . . . . 52

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRA INT SYSTEM (SRS) EQUIPPED

WARNING!

(1) Improper serviceor maintenance of any component of the or any SRS-related can to injuryorcleathtoservicepersonnel (from inadvertentfiring the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly rev iew this manual, and especially its GROUP

Restraint System (SRS) and GROUP 00 Maintenance Service, before any service or maintenance of any

componentof the SRS or any SRS-related component.

NOTEJhe includes the following components: warning light, air bag module, clock components (that may have to be removed/installed in connection with or areIndicated in the table of contents by an asterisk

Page 742 of 2103

17-2

Evaporative Emission Canister/Air Filter/

Evaporative Emission Ventilation Solenoid

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Evaporative Emission Purge Solenoid

Check. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

General Information. . .. . .. . . . . . . . . . . . . . .

Purge Control System Check. . . . . . . . . . . . .

Purge Port Vacuum Check. . . . . . . . . . . . . . . .51

EXHAUST GAS (EGR)

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Component Location. . . . . . . . . . . . . . . . . . . . .54

EGR Port Vacuum Check. . . . . . . . . . . . . . . . .56

EGR System Check. . . . . . . . . . . . . . . . . . . . . .55

EGR Valve Check. . . . . . . . . . . . . . . . . . . . . . . .55

Electric EGR Transducer Solenoid Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

General Information. . . . . . . . . . . . . . . . . . . . . .54

GENERAL INFORMATION. . . . . . . . . . . . . . .44

POSITIVE CRANKCASE VENTILATION

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Component Location. . . . . . . . . . . . . . . . . . . . .48

Crankcase Ventilation System Check. . . . . .49

General Information. . . . . . . . . . . . . . . . . . . . . .48

Positive Crankcase Ventilation Valve

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

SERVICE SPECIFICATIONS. . . . . . . . . . . . .45

TROUBLESHOOTING’

. . . . . . . . . . . . . . . . . . .45

VACUUM HOSES. . . . . . . . . . . . . . . . . . . . . ..4 8

Vacuum Circuit Diagram. . . . . . . . . . . . . . . . . .47

Vacuum Hose Routing

. . . . . . . . . . . . . . . . . . . .46

CONTROL SYSTEM

ENGINE (TURBO) AND

ENGINE>. . . . . . . . . . . . . . . . . . . . . 6 0

CATALYTIC CONVERTER. . . . . . . . . . . . . . .89

General Information. . . . . . . . . . . . . . . . . . . . . .89

EVAPORATIVE EMISSION CONTROL

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69’

Air Conditioning Switch

. . . . . . . . . . . . . . . . . . .77

Component Location Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

Component Location Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70

Evaporative Emission Canister/Fuel Tank

Pressure Relief Valve/Purge Control Valve

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Evaporative Emission Purge Solenoid

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

General Information Engine (Turbo)> G e n e r a l I n f o r m a t i o n

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .70

Purge Control System Check

. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .71

Purge Control ‘System

(Purge Flow Check) Engine>. . . . . . .73

Purge Control Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purge Port Vacuum Check. . . . . . . . . . . . . . . .75

Volume Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . .77

RECIRCULATION (EGR)

.... . .. . . . . . . . . . . . . . . . . . . . . . . .81

Component Location. . . . . . . . . . . . . . . . . . . . .82

EGR Port Vacuum Check . . . . . . . . . . . . . . . . .86

EGR Solenoid Check Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

87

EGR Solenoid Check Engine>. . . . . .

EGR System Check . . . . . . . . . . . . . . . . . .

EGR Valve Check. . . . . . . . . . . . .. . .

General Information... . . . . . . . . . . . . .....81

Vacuum Control Valve Check

. . . . . . . . .

.......................................

POSITIVE CRANKCASE VENTILATION

SYSTEM

. . . . . . . ... . .. . . . . . . . . . . . . . . . . 65

Component Location. . . . . . . . . . . . .. . . . . . . . .66

Crankcase Ventilation. System . .67

General Information

. . . .. . . . . ... . ........

Positive Crankcase Ventilation Valve

Check. . . . . . . . . . . . . . . . . . . . . ... . ............

SERVICE SPECIFICATIONS. .. . . . . . . . . 60

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . . .

. . .. .

HOSES

. . . . ..

. . . . . . . . . . . . . . . . . . . . .,

Circuit Diagram.. . . . . . . . . . . . . . . . . . ,

Vacuum Hose Routing. . . . . . . ...... . . . 6 1

ENGINE CONTROL

3

ACCELERATOR

......

GENERAL INFORMATION . . . . . .. . . . . . . . . .3

ON-VEHICLE SERVICE. . . . . . . . . . . .4

Accelerator Cable Check and

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATION. . . . . . . . . . . . . . .3

. ... . . . . ...3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

Page 743 of 2103

ENGINE AND EMISSION CONTROL Engine Control System

GENERAL INFORMATION

A c a b l e - t y p e a c c e l e r a t o r m e c h a n i s m a n d asuspended-type pedal have been adopted.

SERVICE SPECIFICATION

I Item Standard valueI

Accelerator cable play mm (in.)

TROUBLESHOOTING

Symptom Probable cause Remedy

Throttle valve will notMisadjusted accelerator cable

Adjust

fully open or close Misadjusted auto-cruise control cable Adjust

Broken return spring

Replace

Throttle lever malfunction Replace I

Accelerator pedal op-

Accelerator pedal wrongly tightened Repair

eration not smooth (over acceleration)

accelerator cable. Repair

Accelerator cable requires lubrication Lubricate or replace

Revision

Page 744 of 2103

ENGINE AND EMISSION CONTROL Engine Control

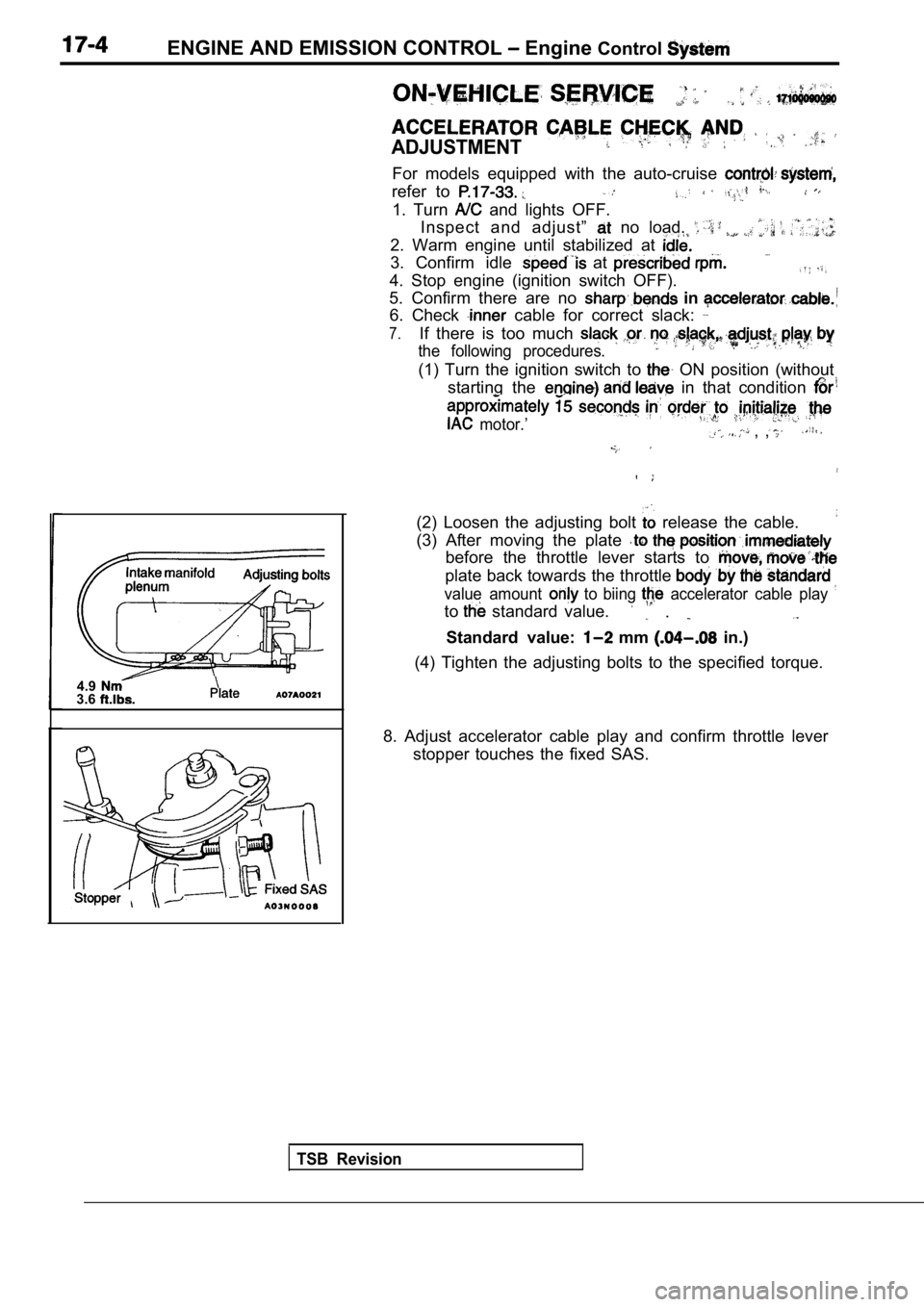

ADJUSTMENT

For models equipped with the auto-cruise

refer to

1. Turn and lights OFF.

Inspect and adjust”

no load.

2. Warm engine until stabilized at

3. Confirm idle at

4. Stop engine (ignition switch OFF).

5. Confirm there are no in

6. Check cable for correct slack:

7.If there is too much

the following procedures.

(1) Turn the ignition switch to ON position (without

starting the

in that condition

motor.’ , ,

4.93.6

TSB Revision

(2) Loosen the adjusting bolt release the cable.

(3) After moving the plate

before the throttle lever starts to

plate back towards the throttle

value amount to biing accelerator cable play

to standard value. .

Standard value: mm in.)

(4) Tighten the adjusting bolts to the specified to rque.

8. Adjust accelerator cable play and confirm thrott le lever

stopper touches the fixed SAS.

Page 745 of 2103

ENGINE AND EMISSION CONTROL

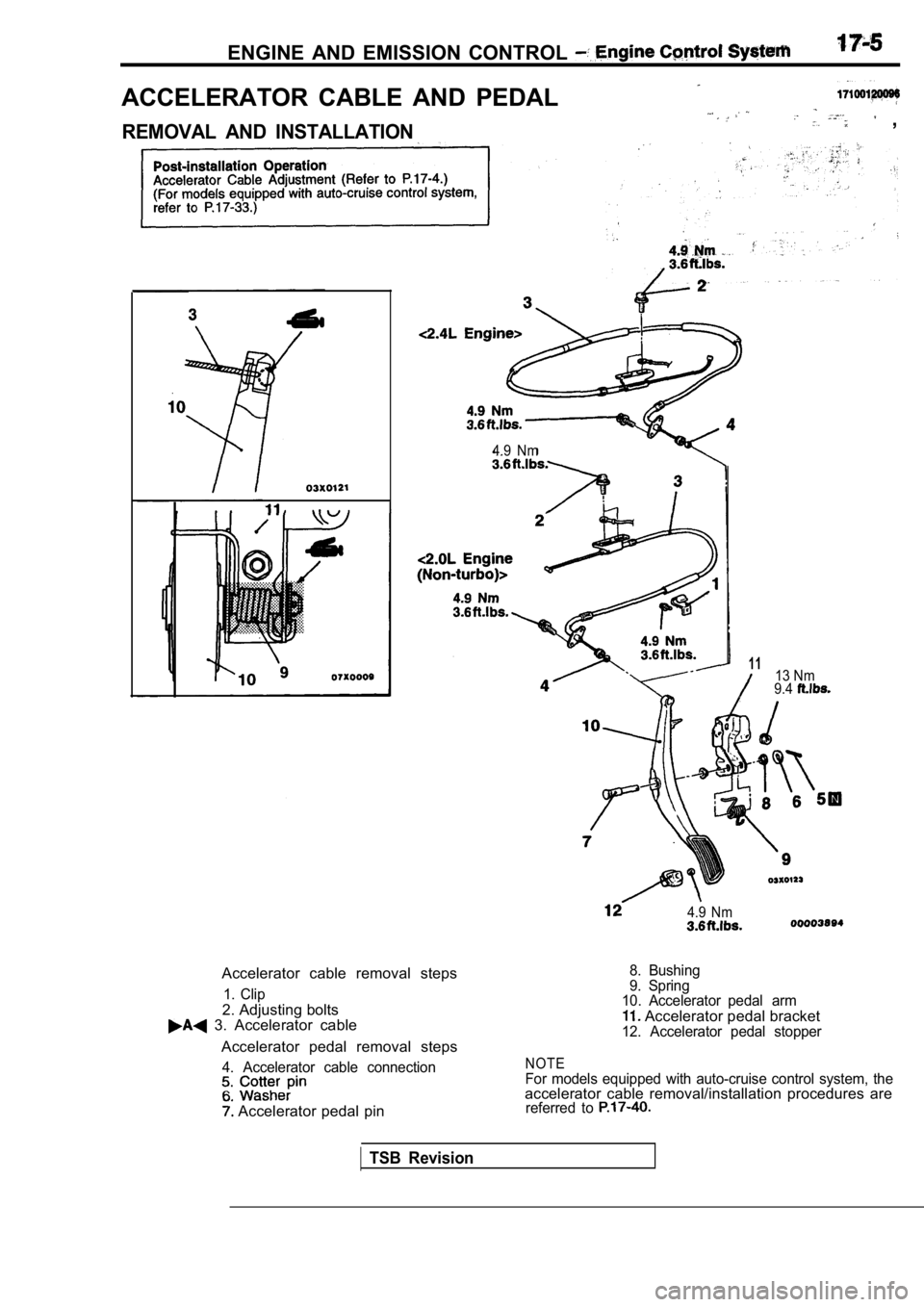

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATION ,

4.9 Nm

Accelerator cable removal steps

1. Clip

2. Adjusting bolts 3. Accelerator cableAccelerator pedal removal steps

4. Accelerator cable connection

Accelerator pedal pin

1113 Nm

9.4

4.9 Nm

8. Bushing

9. Spring

10. Accelerator pedal arm

Accelerator pedal bracket12. Accelerator pedal stopper

NOTEFor models equipped with auto-cruise control system , theaccelerator cable removal/installation procedures arereferred to

TSB Revision

Page 746 of 2103

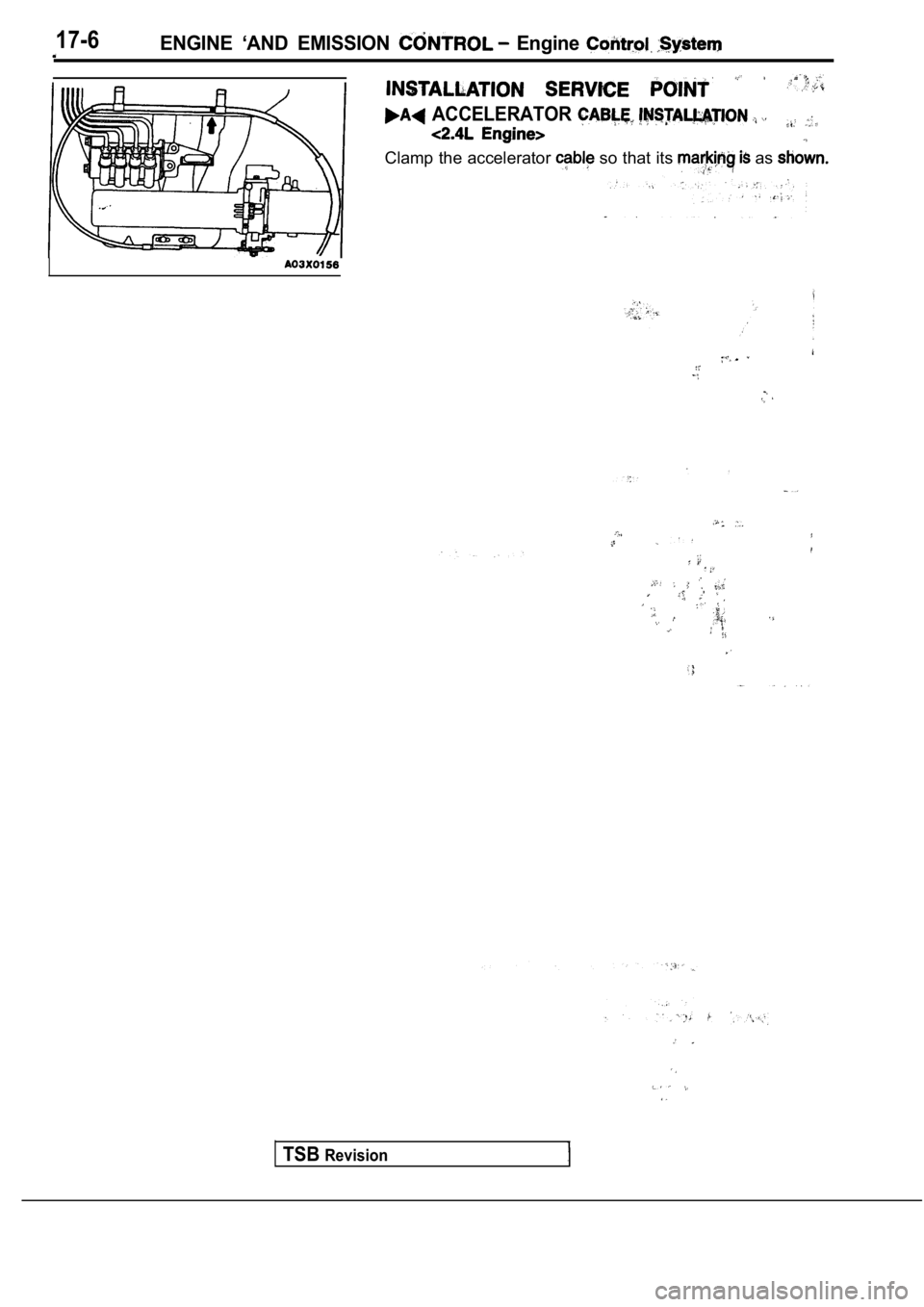

17-6ENGINE ‘AND EMISSION Engine

ACCELERATOR

Clamp the accelerator so that its as

I

TSBRevision

Page 747 of 2103

AND EMISSION CONTROL Auto-cruise Control System

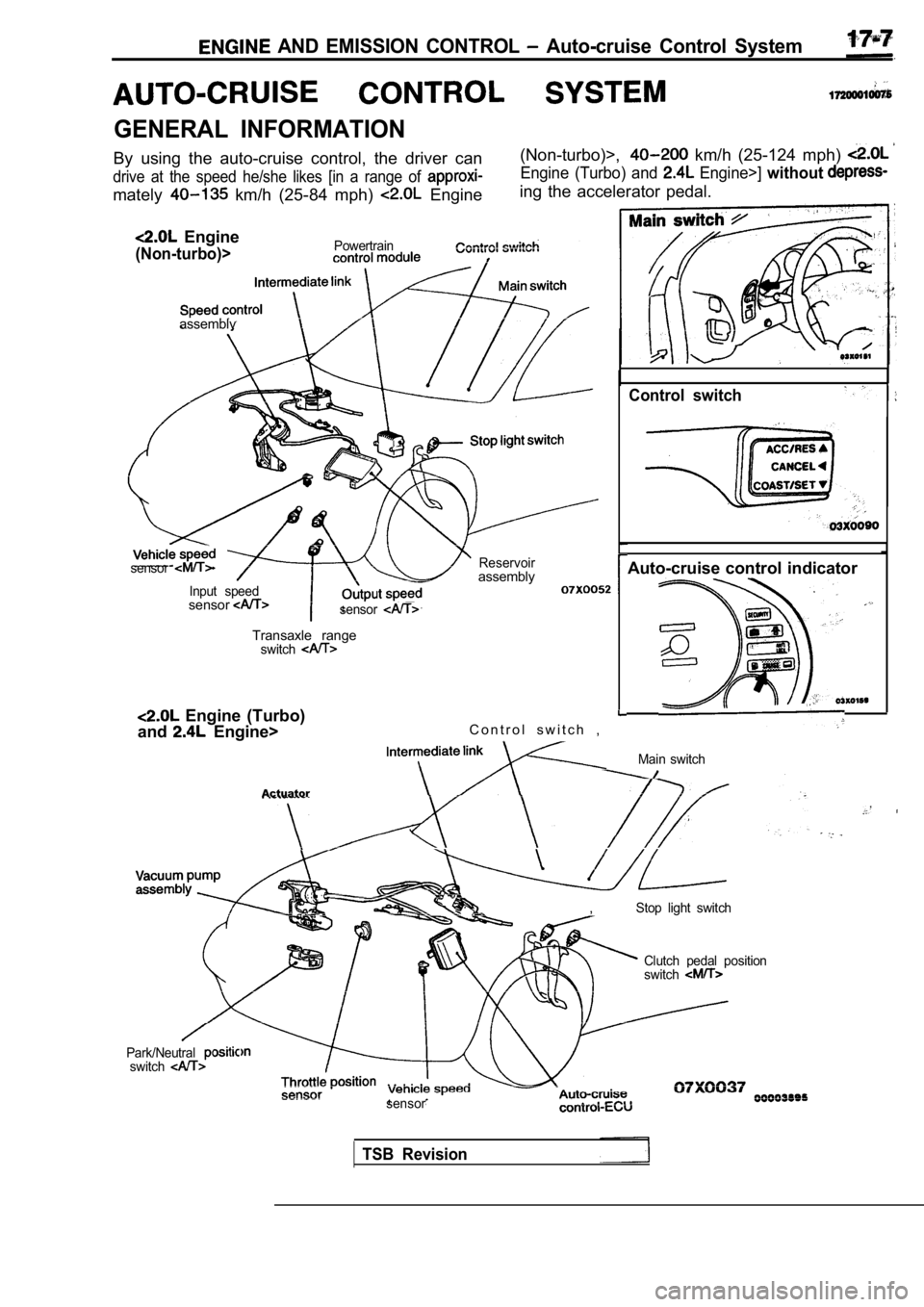

GENERAL INFORMATION

By using the auto-cruise control, the driver can

drive at the speed he/she likes [in a range of

mately km/h (25-84 mph) Engine

Engine

(Non-turbo)>Powertrain

(Non-turbo)>, km/h (25-124 mph)

Engine (Turbo) and Engine>] without

ing the accelerator pedal.

assemblv

sensor

Input speedsensorsensor

Control switch

Reservoirassembly

Transaxle rangeswitch

Engine (Turbo)

and

Engine> C o n t r o l s w i t c h ,.

Actuator

Auto-cruise control indicator

Main switch

,Stop light switch

Park/Neutralswitch

Clutch pedal position

switch

sensor

TSB Revision

Page 748 of 2103

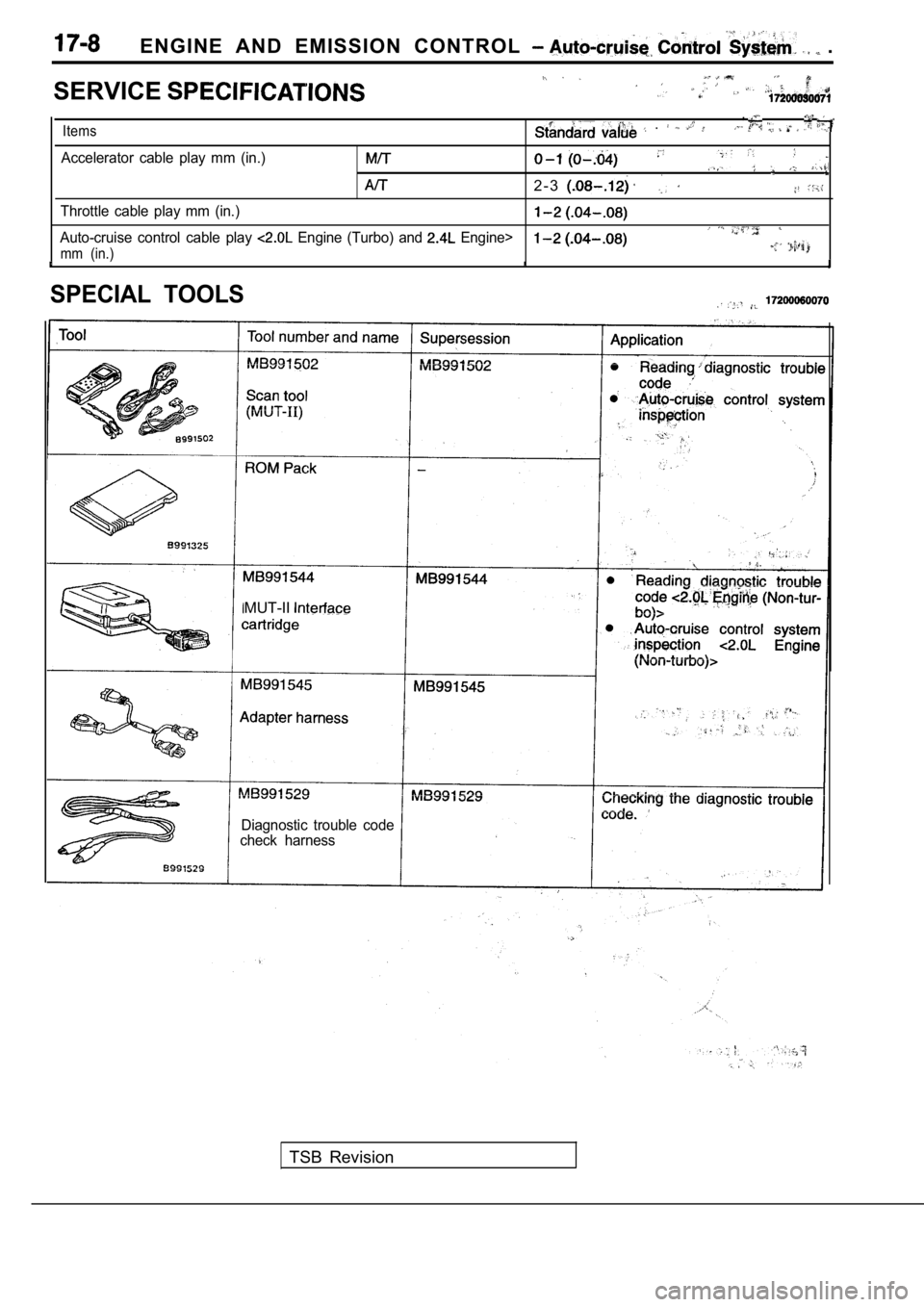

E N G I N E A N D E M I S S I O N C O N T R O L .

SERVICE

,

Items .

Accelerator cable play mm (in.)

2 - 3

Throttle cable play mm (in.)

Auto-cruise control cable play Engine (Turbo) and Engine>

mm (in.)

SPECIAL TOOLS

MUT-II

Diagnostic trouble code

check harness

TSB Revision

Page 749 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise Control

TROUBLESHOOTING ENGINE (NON-TURBO)>

DIAGNOSTIC TROUBLESHOOTING FLOW

Reoccurs not reoccur

No diagnostic troubleDiagnostic troubleNo diagnostic

code or can’t code displayed

with scan tool

NOTE

Before carrying out trouble diagnosis, check all th e following items.

Is the vacuum hose correctly installed and undamag ed?

2. Are the auto-cruise, accelerator, and throttle c ables routed correctly?

3. Do the link assembly and cables move smoothly?

4. Is the play of each cable within its standard va lue?

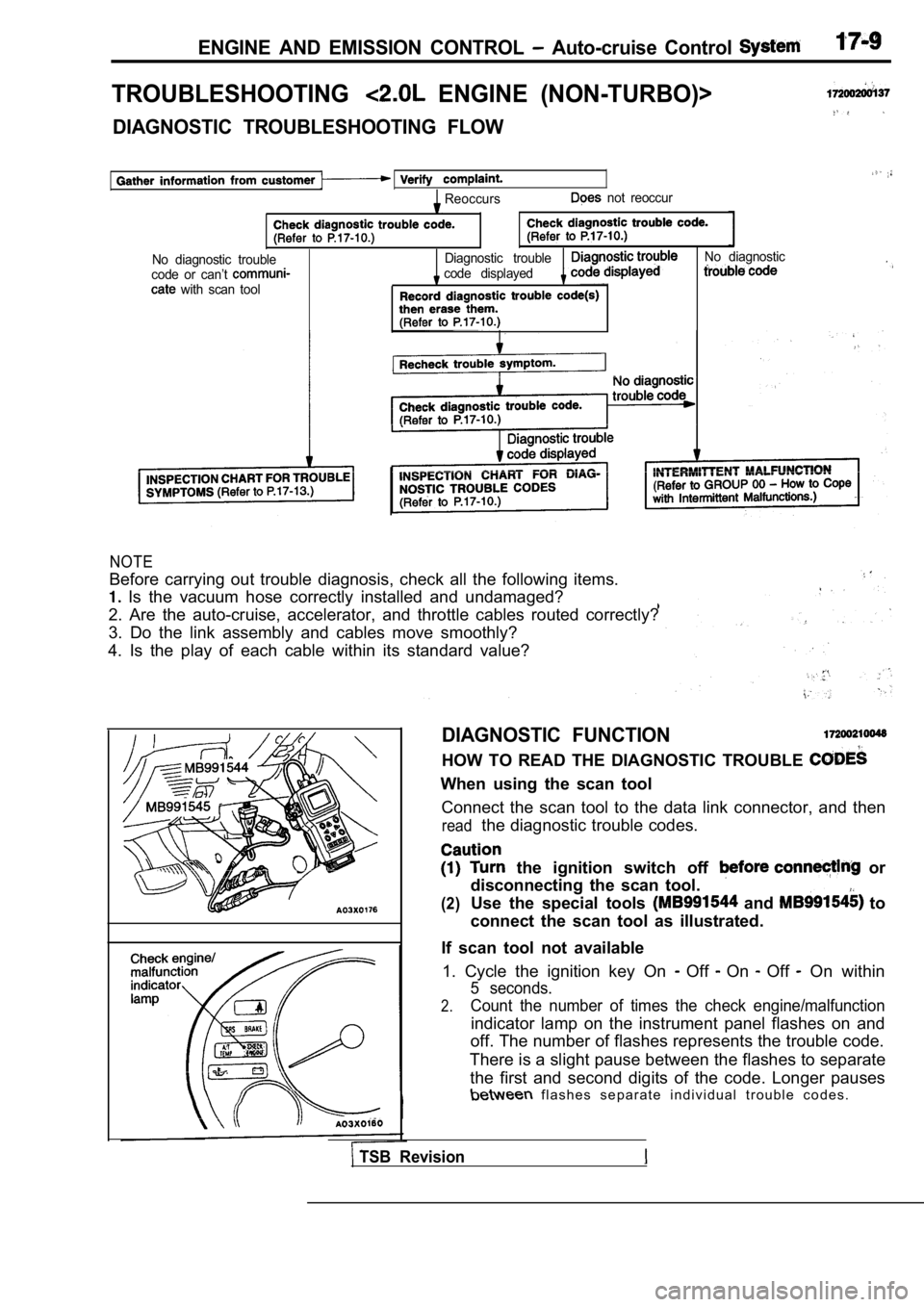

DIAGNOSTIC FUNCTION

HOW TO READ THE DIAGNOSTIC TROUBLE

When using the scan tool

Connect the scan tool to the data link connector, a nd then

readthe diagnostic trouble codes.

the ignition switch off or

disconnecting the scan tool.

(2)Use the special tools and to

connect the scan tool as illustrated.

If scan tool not available 1. Cycle the ignition key On

Off On Off On within

5 seconds.

2.Count the number of times the check engine/malfunct ion

indicator lamp on the instrument panel flashes on and

off. The number of flashes represents the trouble c ode.

There is a slight pause between the flashes to sepa rate

the first and second digits of the code. Longer pau ses

f l a s h e s s e p a r a t e i n d i v i d u a l t r o u b l e c o d e s .

TSB Revision

Page 750 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise

ERASING DIAGNOSTIC TROUBLE CODES .

the scan tool

Connect the scan tool to the data link connector, then, erase the diagnostic trouble codes according

to scan tool instruction.

the scan tool

1. Remove the battery cable from the battery terminal for 10 seconds or more, then, reconnect

the cable.

2. After the engine has warmed up, run it at idle f or about 15 minutes.

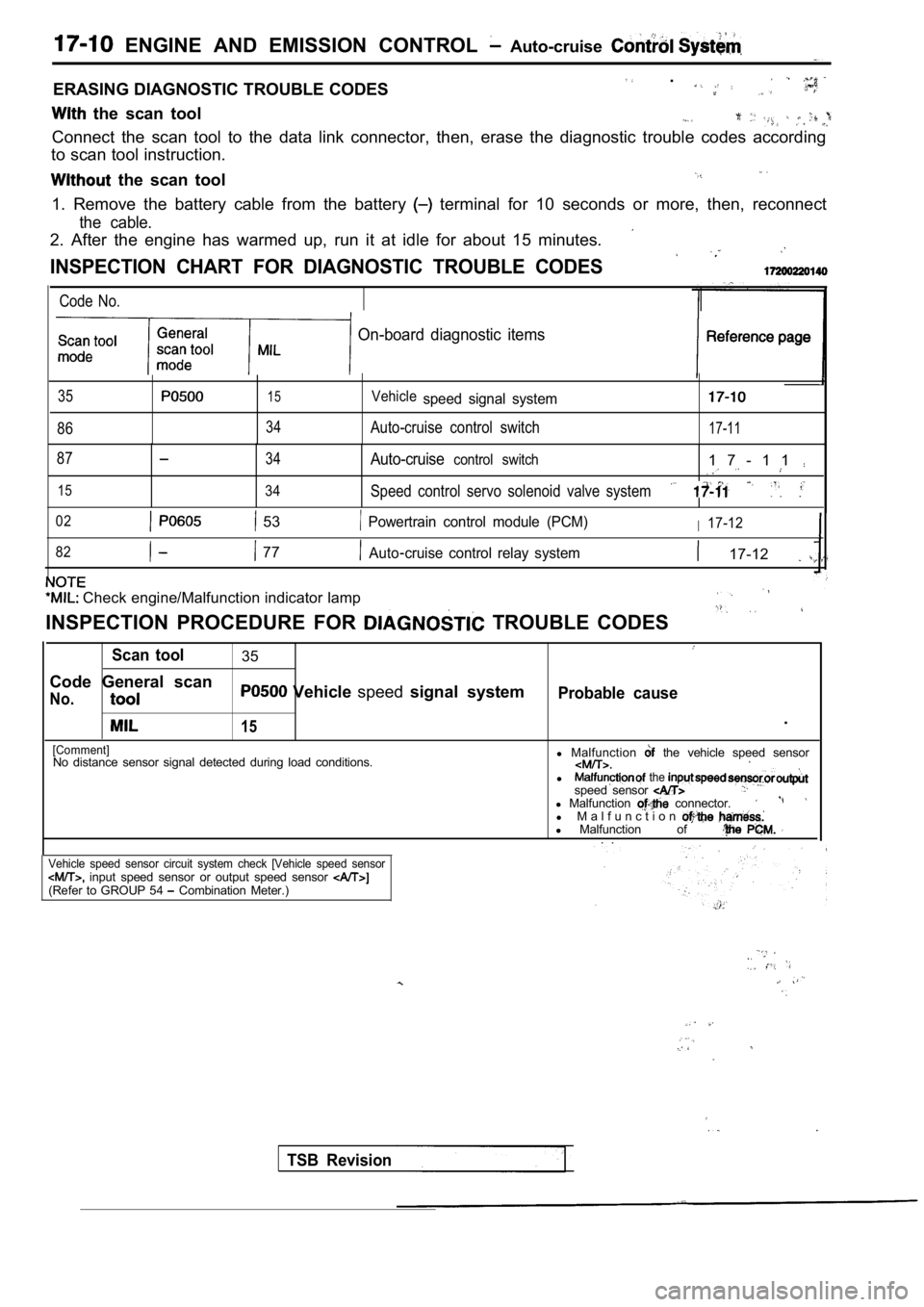

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

Code No.

On-board diagnostic items

35

86

15

34

Vehiclespeed signal system

Auto-cruise control switch17-11

87

15

34

34

Auto-cruisecontrol switch1 7 - 1 1

Speed control servo solenoid valve system

02 53 Powertrain control module (PCM)I17-12

82

77Auto cruise control relay system 17-12

Check engine/Malfunction indicator lamp

INSPECTION PROCEDURE FOR TROUBLE CODES

Scan tool35

Code General scan

No. Vehicle speedsignal systemProbable cause

15.

[Comment]No distance sensor signal detected during load cond itions.l

Malfunction the vehicle speed sensor

l the speed sensor l Malfunction connector.l M a l f u n c t i o nl Malfunction of . .

Vehicle speed sensor circuit system check [Vehicle speed sensor input speed sensor or output speed sensor (Refer to GROUP 54 Combination Meter.)

TSB Revision