ESP MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1623 of 2103

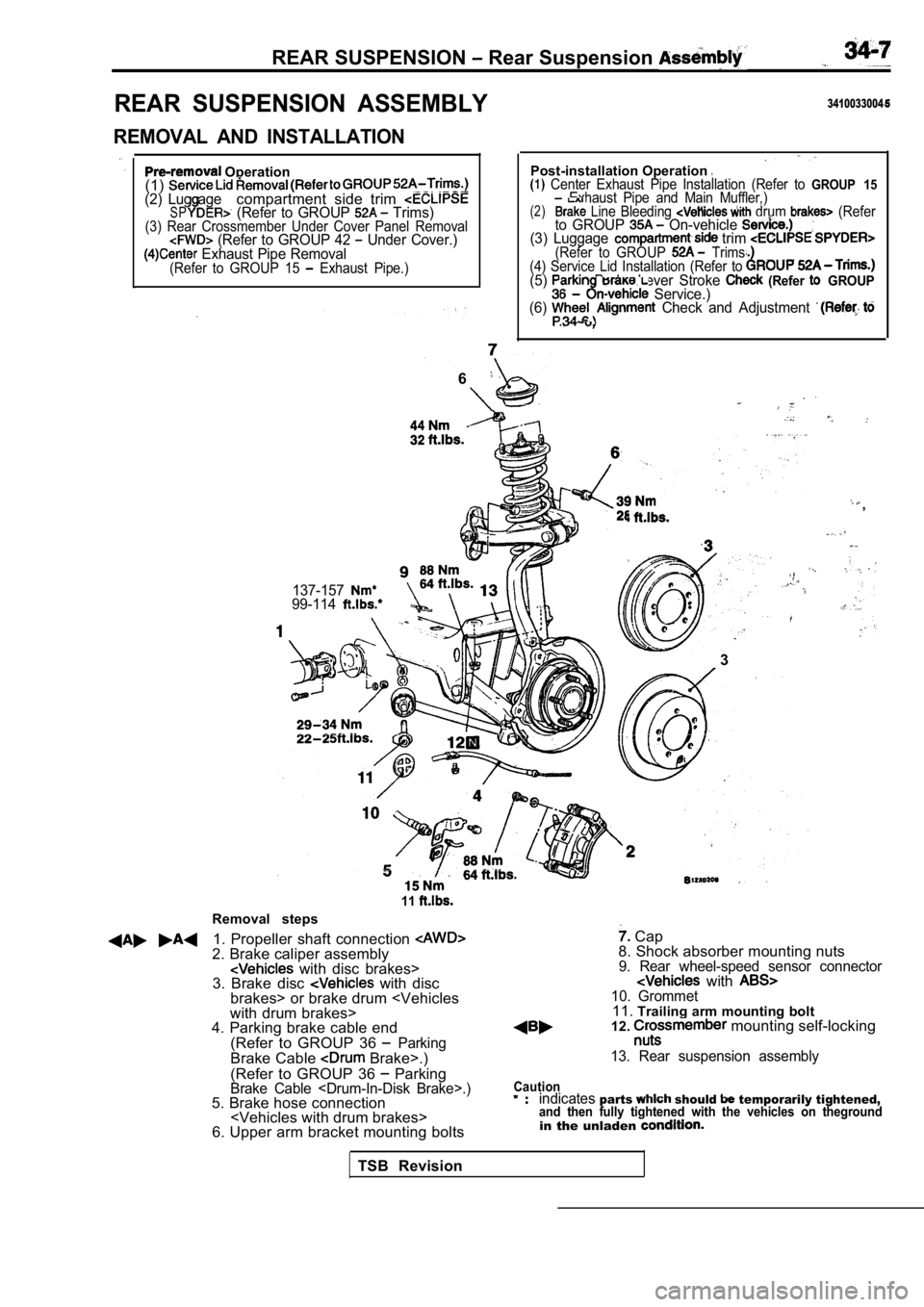

REAR SUSPENSION Rear Suspension

REAR SUSPENSION ASSEMBLY

REMOVAL AND INSTALLATION

Operation

(1)

(2) Lug agecompartment side trim SP (Refer to GROUP Trims)(3) Rear Crossmember Under Cover Panel Removal (Refer to GROUP 42 Under Cover.) Exhaust Pipe Removal(Refer to GROUP 15 Exhaust Pipe.)

3410033004

Post-installation Operation Center Exhaust Pipe Installation (Refer to GROUP 15Exhaust Pipe and Main Muffler,)(2) Line Bleeding drum (Referto GROUP On-vehicle (3) Luggage trim (Refer to GROUP Trims.

(4) Service Lid Installation (Refer to

(5) Brake Lever Stroke (Refer GROUP Service.)

(6) Check and Adjustment .

6

,

137-15799-114

.

l. .

3

Removal steps

11

1. Propeller shaft connection 2. Brake caliper assembly with disc brakes>

3. Brake disc with disc

brakes> or brake drum

4. Parking brake cable end

(Refer to GROUP 36

ParkingBrake Cable Brake>.)

(Refer to GROUP 36

ParkingBrake Cable

6. Upper arm bracket mounting bolts

Cap

8. Shock absorber mounting nuts

9. Rear wheel-speed sensor connector with 10. Grommet11. Trailing arm mounting bolt

12. mounting self-locking

13. Rear suspension assembly

Cautionindicatesparts should temporarily tightened,and then fully tightened with the vehicles on thegr oundin the unladen

TSB Revision

Page 1624 of 2103

REAR SUSPENSION Rear Suspension Assembly .

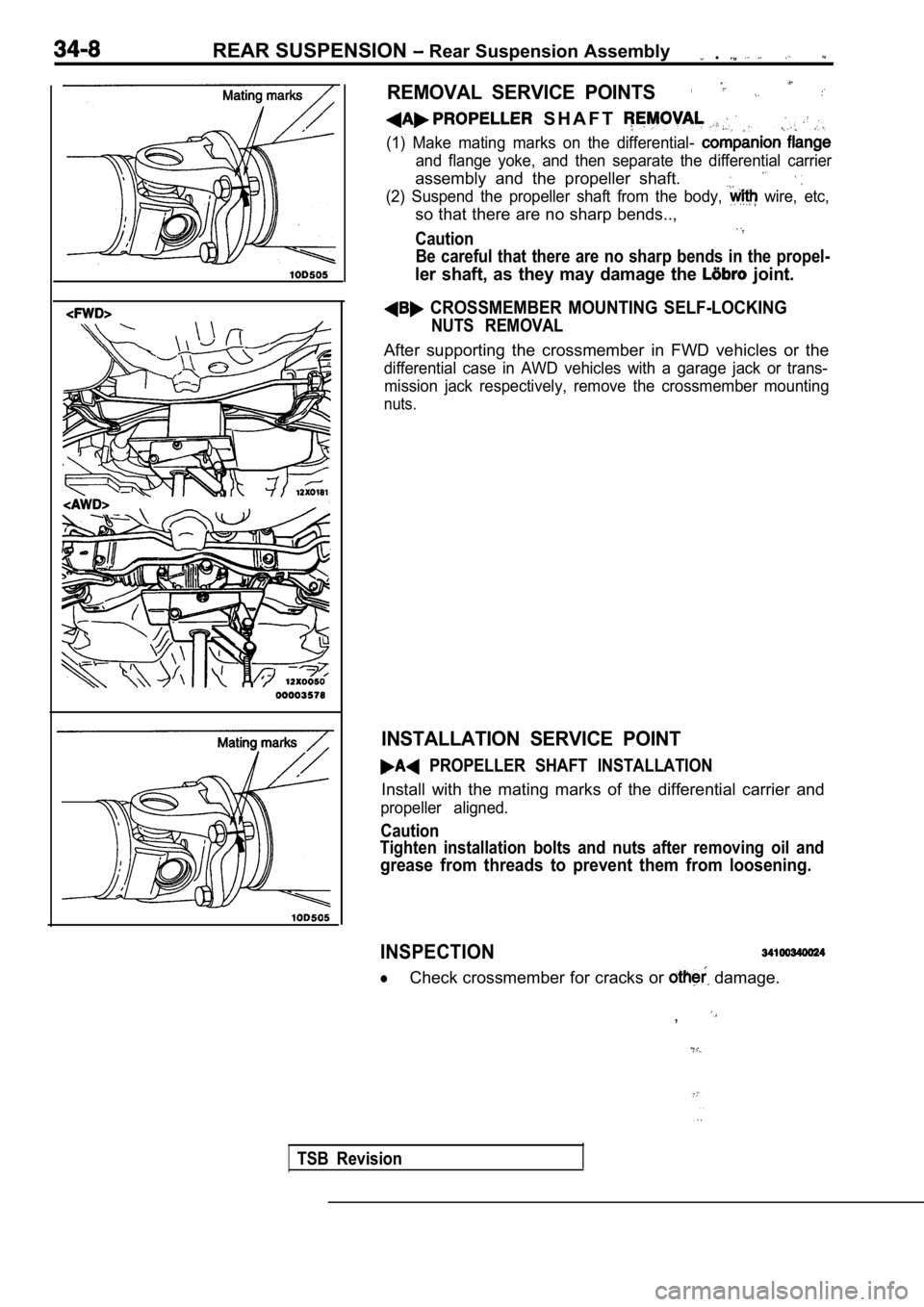

REMOVAL SERVICE POINTS

S H A F T

(1) Make mating marks on the differential-

and flange yoke, and then separate the differential carrier

assembly and the propeller shaft.

(2) Suspend the propeller shaft from the body, wire, etc,

so that there are no sharp bends..,

Caution

Be careful that there are no sharp bends in the pro pel-

ler shaft, as they may damage the joint.

CROSSMEMBER MOUNTING SELF-LOCKING

NUTS REMOVAL

After supporting the crossmember in FWD vehicles or the

differential case in AWD vehicles with a garage jack or trans-

mission jack respectively, remove the crossmember m ounting

nuts.

INSTALLATION SERVICE POINT

PROPELLER SHAFT INSTALLATION

Install with the mating marks of the differential carrier and

propeller aligned.

Caution

Tighten installation bolts and nuts after removing oil and

grease from threads to prevent them from loosening.

INSPECTION

lCheck crossmember for cracks or damage.

,

TSB Revision

Page 1695 of 2103

ABS Troubleshooting

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES’

Check according to the inspection chart that is appropriate for diagnostic trouble code.

Diagnostic

Inspection item Diagnostic contentDetection

trouble

code No.

11Right front wheel speed sensor

12Left front wheel speed sensor

13Right rear wheel speed sensor

14Left rear wheel speed sensor

15Wheel speed sensor system

16Power supply system

21Right front wheel speed sensor

22Left front wheel speed sensor

23 Right rear wheel speed sensor

24Left rear wheel speed sensor

38Stop light switch system

Right front solenoid valve system

42Left front solenoid valve system

43 Rear solenoid valve system

51Valve relay system

53Motor relay or motor system Open circuit

A,

Abnormal output signal El.

Abnormal battery posi-A,t i v e v o l t a g e

Excessive gap

or short circuit

Open circuit or ON A,

function

No response to sole-

A, valve drive signal

Valve relay OFF failureA,

Motor relay OFF failure

and motor drive failure

ABS-ECU Malfunction in

ECU (program maze,

etc.)

Detection conditions

A: During system check immediately after starting

When driving

TSB Revision

page

Page 1709 of 2103

ABS

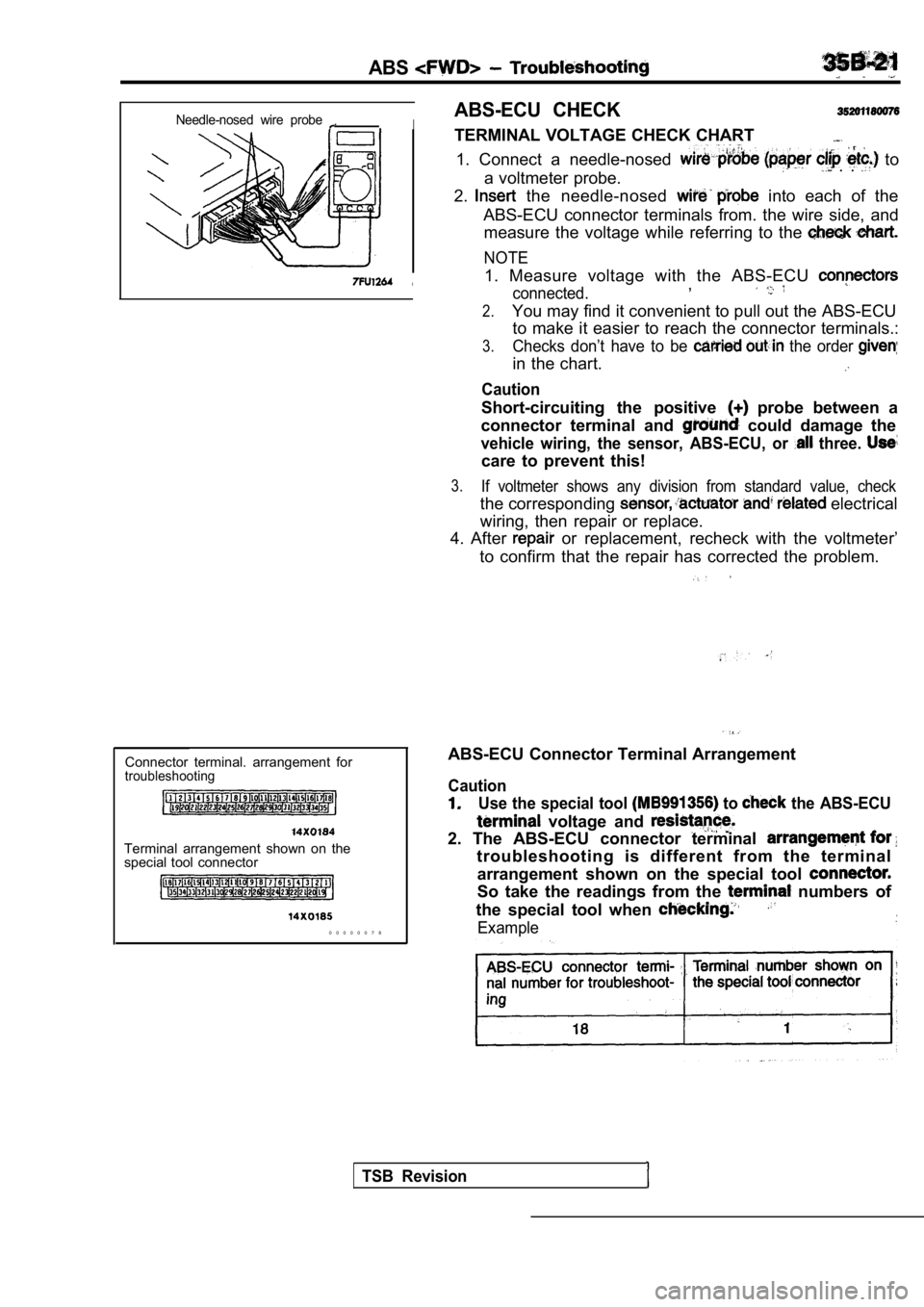

Needle-nosed wire probe .I

I

Connector terminal. arrangement for

troubleshooting

Terminal arrangement shown on the

special tool connector

0 0 0 0 0 0 7 8

ABS-ECU CHECK

TERMINAL VOLTAGE CHECK CHART

1. Connect a needle-nosed to

a voltmeter probe. . .

2. the needle-nosed into each of the

ABS-ECU connector terminals from. the wire side, an d

measure the voltage while referring to the

NOTE

1. Measure voltage with the ABS-ECU

connected.,

2.You may find it convenient to pull out the ABS-ECU to make it easier to reach the connector terminals. :

3.Checks don’t have to be the order

in the chart.

Caution

Short-circuiting the positive probe between a

connector terminal and

could damage the

vehicle wiring, the sensor, ABS-ECU, or three.

care to prevent this!

3.If voltmeter shows any division from standard value , check

the corresponding electrical

wiring, then repair or replace.

4. After

or replacement, recheck with the voltmeter’

to confirm that the repair has corrected the proble m.

ABS-ECU Connector Terminal Arrangement

Caution

Use the special tool to the ABS-ECU

voltage and

2. The ABS-ECU connector terminal

troubleshooting is different from the terminal

arrangement shown on the special tool

So take the readings from the numbers of

the special tool when

Example

TSB Revision

Page 1711 of 2103

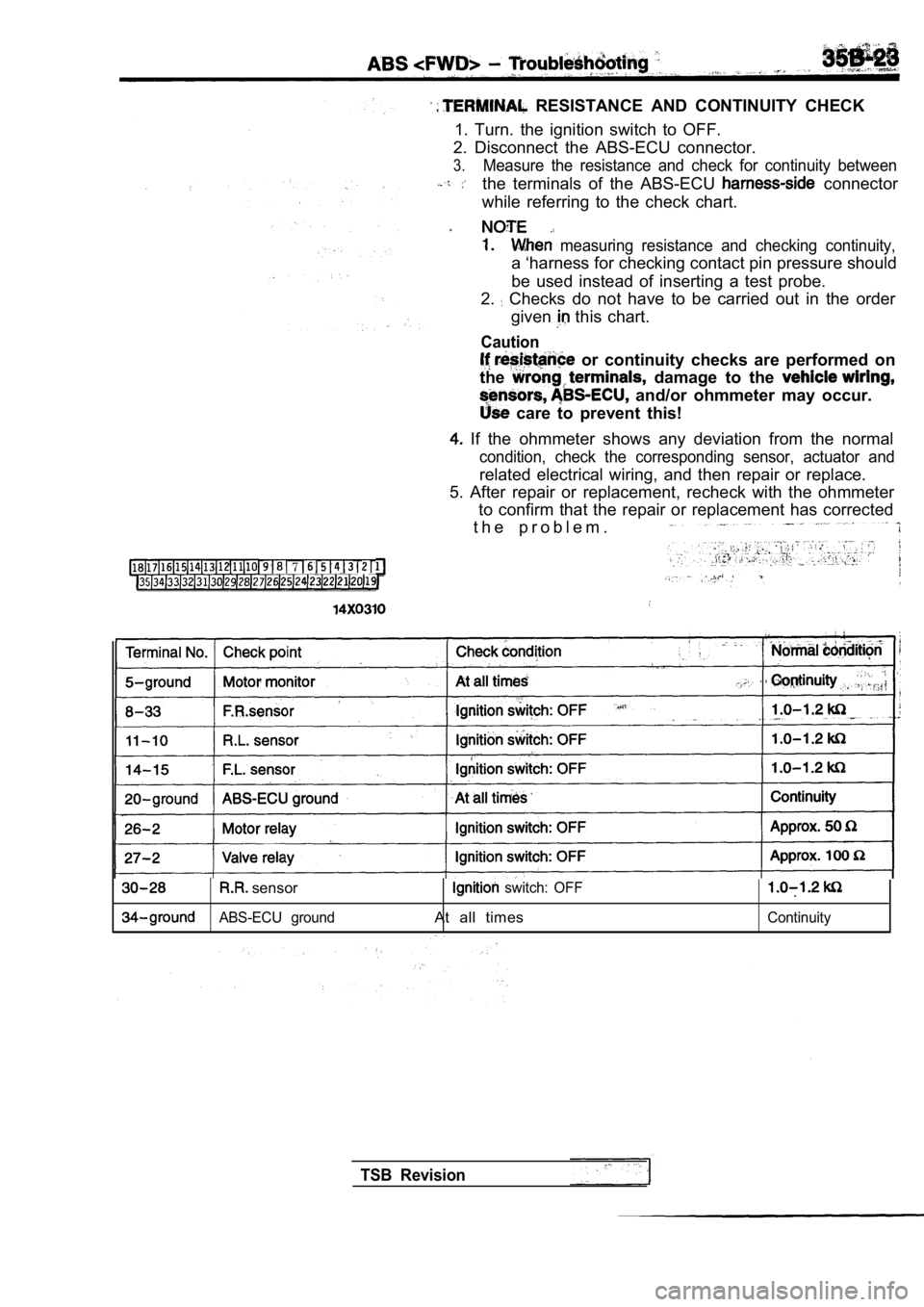

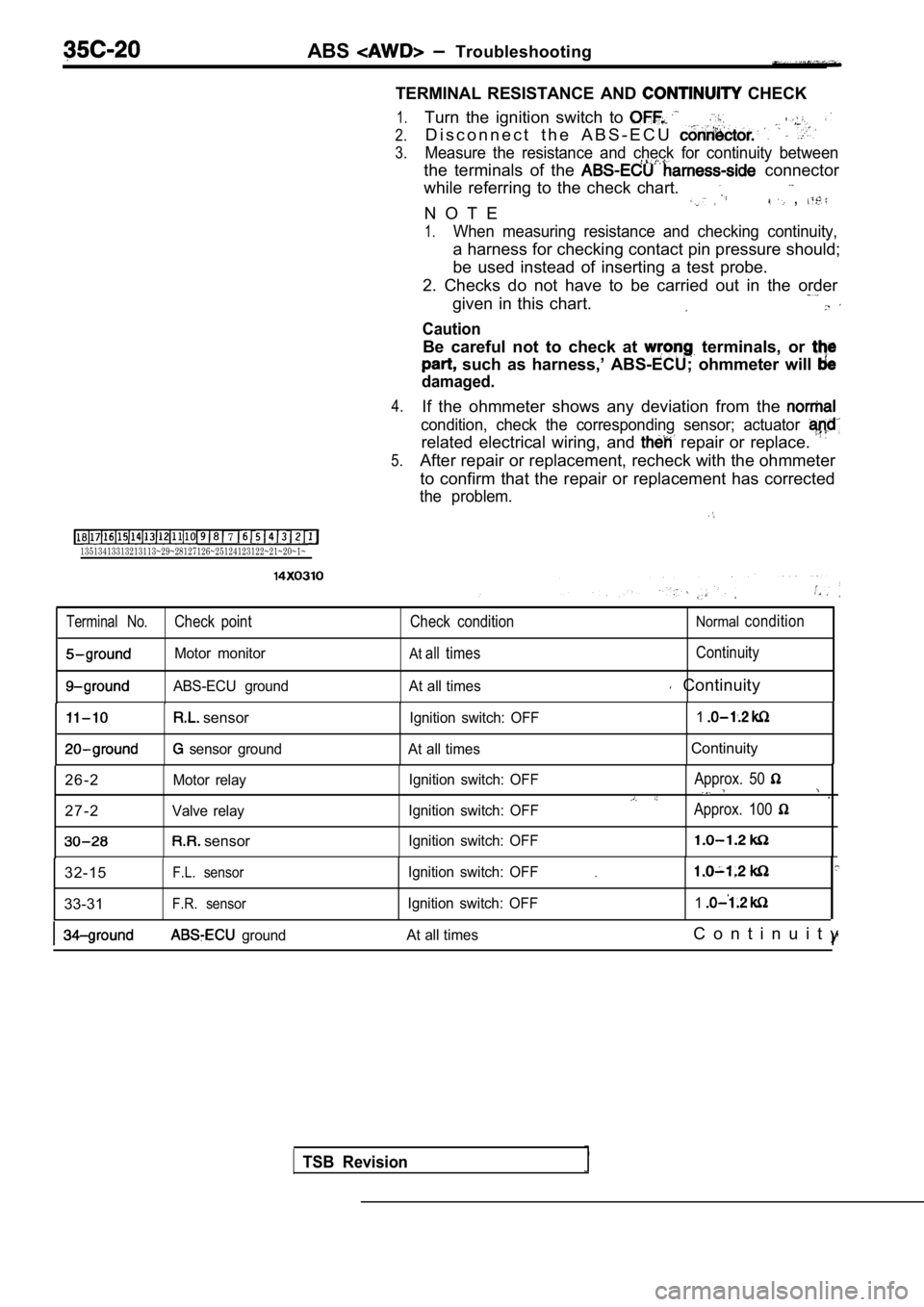

RESISTANCE AND CONTINUITY CHECK

1. Turn. the ignition switch to OFF.

2. Disconnect the ABS-ECU connector.

3.Measure the resistance and check for continuity bet ween

the terminals of the ABS-ECU connector

while referring to the check chart.

measuring resistance and checking continuity,

a ‘harness for checking contact pin pressure should

be used instead of inserting a test probe.

2.

Checks do not have to be carried out in the order

given

this chart.

Caution

or continuity checks are performed on

the

damage to the

and/or ohmmeter may occur.

care to prevent this!

If the ohmmeter shows any deviation from the norma l

condition, check the corresponding sensor, actuator and

related electrical wiring, and then repair or replace.

5. After repair or replacement, recheck with the oh mmeter

to confirm that the repair or replacement has corre cted

t h e p r o b l e m .

7

sensor switch: OFF

ABS-ECU groundAt all timesContinuity

TSB Revision

Page 1713 of 2103

Service

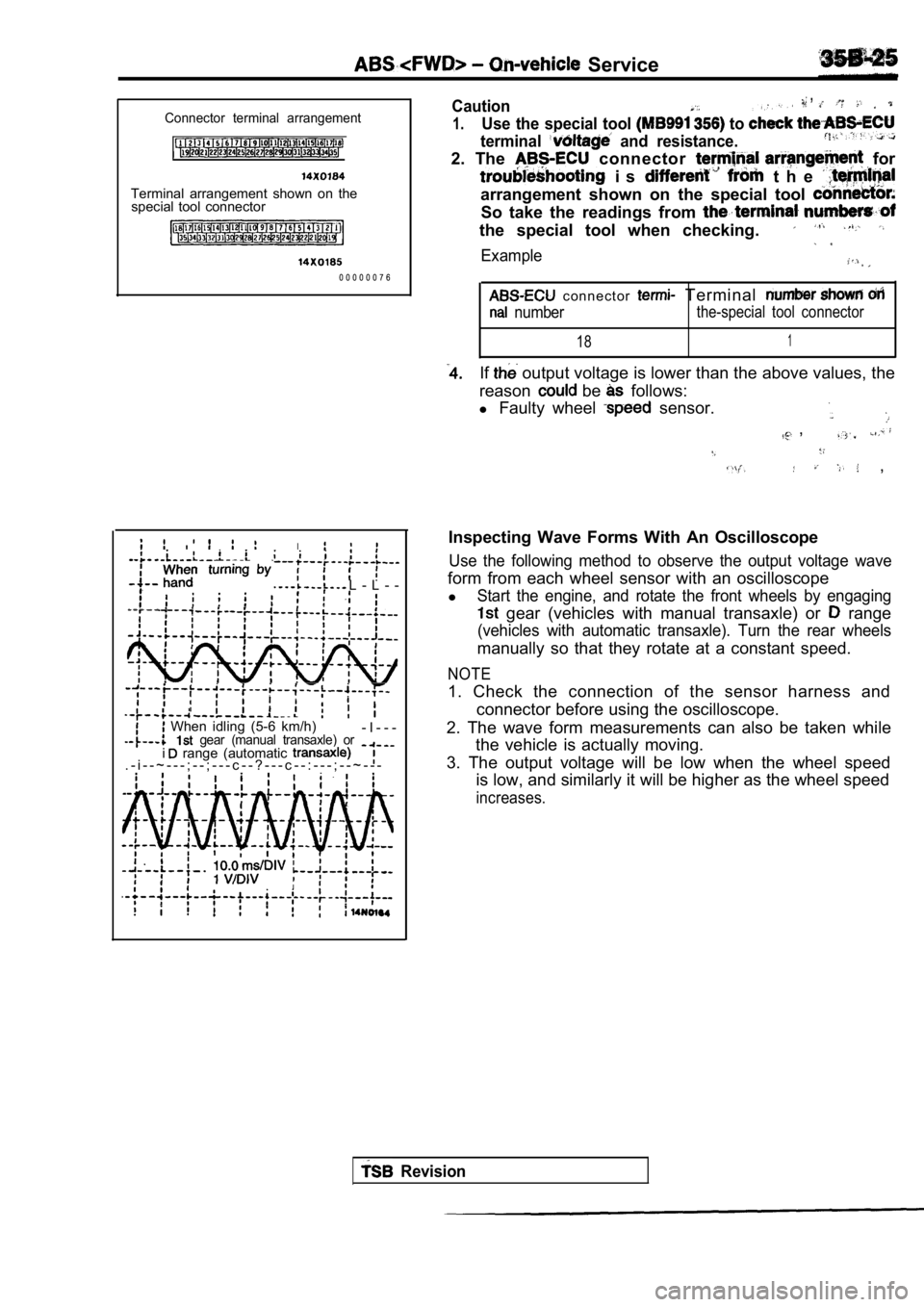

Connector terminal arrangement

Terminal arrangement shown on thespecial tool connector

0 0 0 0 0 0 7 6

L - L - -

,

I

When idling (5-6 km/h) gear (manual transaxle) or- I - - -

. - i - - ~ - - - ; - - ; - - - c - - ? - - - c - - : - - - ; - - ~ - - - i range (automatic

,Caution,

1.Use the special tool to

terminal and resistance.

2. The connector for

i s t h e

arrangement shown on the special tool

So take the readings from

the special tool when checking.

Example

c o n n e c t o r Terminal

numberthe-special tool connector

181

If output voltage is lower than the above values, the

reason

be follows:

l Faulty wheel

sensor.

,

,

Inspecting Wave Forms With An Oscilloscope

Use the following method to observe the output volt age wave

form from each wheel sensor with an oscilloscope

l

Start the engine, and rotate the front wheels by en gaging

gear (vehicles with manual transaxle) or range

(vehicles with automatic transaxle). Turn the rear wheels

manually so that they rotate at a constant speed.

NOTE

1. Check the connection of the sensor harness and

connector before using the oscilloscope.

2. The wave form measurements can also be taken whi le

the vehicle is actually moving.

3. The output voltage will be low when the wheel sp eed

is low, and similarly it will be higher as the whee l speed

increases.

Revision

Page 1736 of 2103

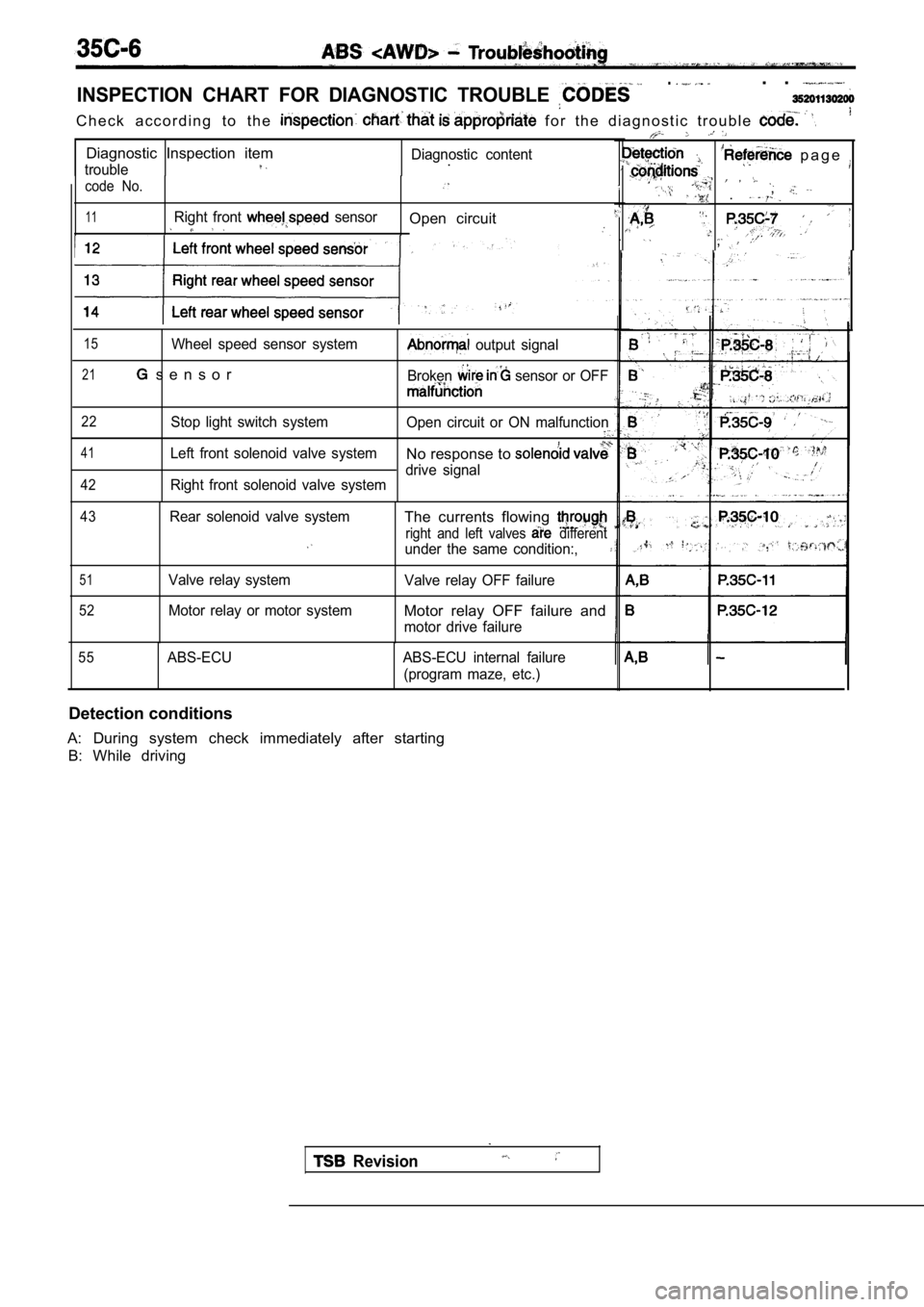

INSPECTION CHART FOR DIAGNOSTIC TROUBLE

.. .

C h e c k a c c o r d i n g t o t h e f o r t h e d i a g n o s t i c t r o u b l e

Diagnostic Inspection item

troubleDiagnostic content. p a g e

code No. .

,

11Right front sensorOpen circuit

.,

15Wheel speed sensor system

21 s e n s o r

output signal

Broken

sensor or OFF

22

41

42

Stop light switch system Open circuit or ON malfunction

Left front solenoid valve systemNo response to

Right front solenoid valve systemdrive signal

43

51

52

Rear solenoid valve system

Valve relay system

Motor relay or motor system

The currents flowing

right and left valves different

under the same condition:,

Valve relay OFF failure

Motor relay OFF failure and

motor drive failure

55ABS-ECU ABS-ECU internal failure

(program maze, etc.)

Detection conditions

A: During system check immediately after starting B: While driving

Revision

Page 1748 of 2103

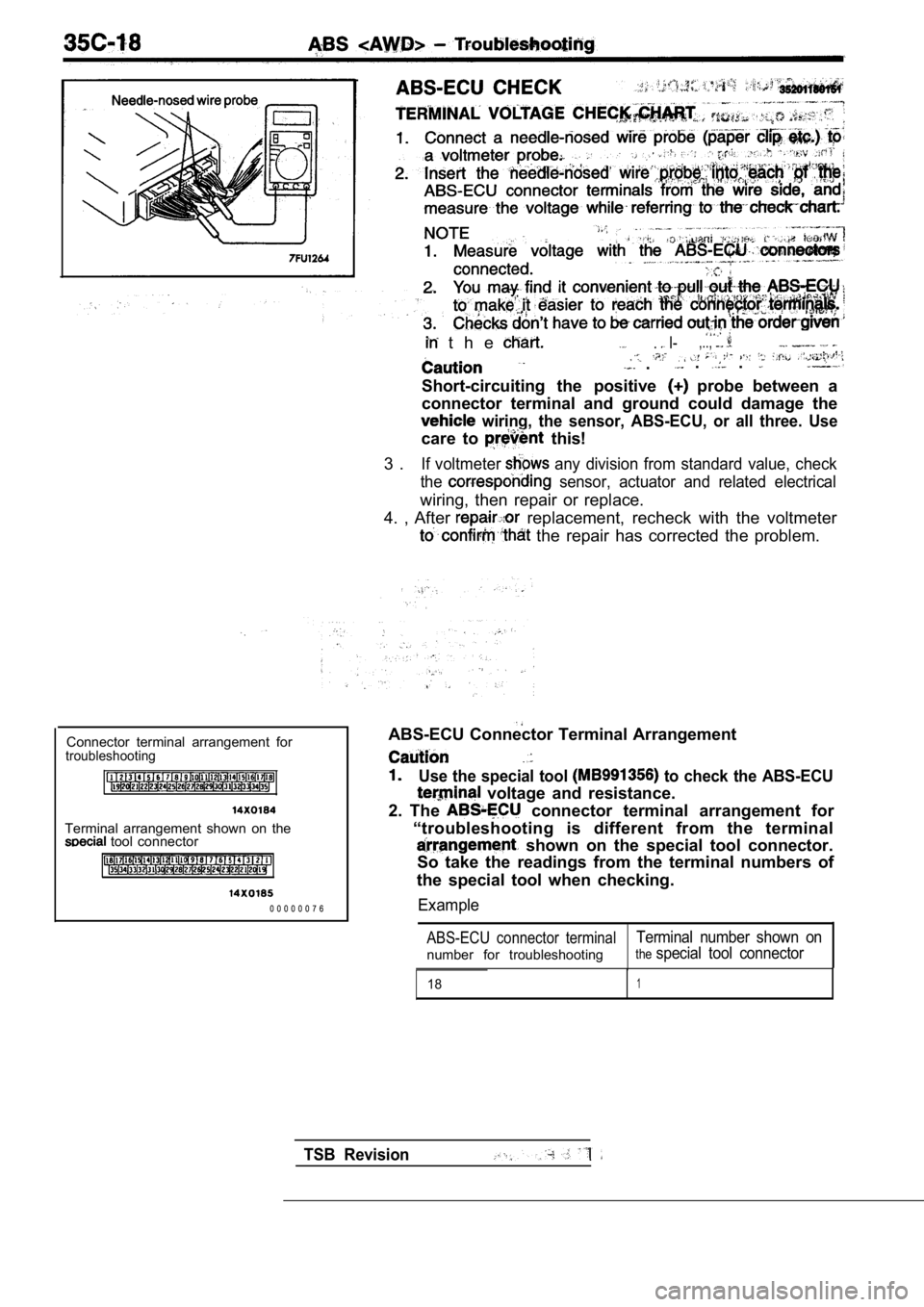

t h e . I-,..,

.. .

Short-circuiting the positive probe between a

connector terminal and ground could damage the

wiring, the sensor, ABS-ECU, or all three. Use

care to this!

3 .

If voltmeter any division from standard value, check

the

sensor, actuator and related electrical

wiring, then repair or replace.

4. , After

replacement, recheck with the voltmeter

the repair has corrected the problem.

Connector terminal arrangement for

troubleshooting

Terminal arrangement shown on the tool connector

0 0 0 0 0 0 7 6 ABS-ECU Connector Terminal Arrangement

Use the special tool to check the ABS-ECU

voltage and resistance.

2. The

connector terminal arrangement for

“troubleshooting is different from the terminal

shown on the special tool connector.

So take the readings from the terminal numbers of

the special tool when checking.

Example

ABS-ECU connector terminalTerminal number shown on

number for troubleshootingthespecial tool connector

181

TSB Revision

Page 1750 of 2103

ABS Troubleshooting

TERMINAL RESISTANCE AND

CHECK

7 13513413313213113~29~28127126~25124123122~21~20~1~

1.

2.

3.

4.

5.

Turn the ignition switch to

D i s c o n n e c t t h e A B S - E C U

Measure the resistance and check for continuity bet ween

the terminals of the connector

while referring to the check chart.

N O T E

,

1.When measuring resistance and checking continuity,

a harness for checking contact pin pressure should;

be used instead of inserting a test probe.

2. Checks do not have to be carried out in the orde r

given in this chart.

Caution

Be careful not to check at terminals, or

such as harness,’ ABS-ECU; ohmmeter will

damaged.

If the ohmmeter shows any deviation from the

condition, check the corresponding sensor; actuator

related electrical wiring, and repair or replace.

After repair or replacement, recheck with the ohmmeter

to confirm that the repair or replacement has corre cted

the problem.

Terminal No.Check point Check conditionNormalcondition

Motor monitorAtall timesContinuity

ABS-ECU ground At all times Continuity

sensor

sensor groundIgnition switch: OFF

1At all timesContinuity

2 6 - 2

Motor relay

2 7 - 2Valve relay

sensor

Ignition switch: OFF

Ignition switch: OFF

Ignition switch: OFFApprox. 50

Approx. 100

32-15F.L. sensor

33-31F.R. sensor

Ignition switch: OFF

Ignition switch: OFF.

1

ground At all timesC o n t i n u i t y

I’

TSB Revision

Page 1763 of 2103

CONTENTS

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . 2PARKING BRAKE LEVER*. . . . . . . . . . . . . . . . . . 6

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 4

PARKING BRAKE CABLE

. . . . . . . . , . .5

7Parking Brake Lever Stroke

Check and. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adjustment . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . .

4

PARKING BRAKE CABLE

BRAKE>*. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .8‘SERVICE SPECIFICATIONS . . . . . . . . . . . . . . 3

PARKING BRAKE DRUM . . . . . . . . . . . . . . . . . . 10

TROUBLESHOOTING. . . . . . . . . . . . .

3

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRA INT SYSTEM EQUIPPED VEHICLES

WARNING!

(1)Improperservice or maintenance of any component of the or any component, can lead to inadvertent firingofthealr renderingthe inoperative).(2) Service or maintenance of any component or component must be performed only at an authorized dealer. MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP Supplemental

Restraint System and GROUP 00 Maintenance Service before beginning any service o r of anycomponent of the or any component.

NOTEThe SRS includes the following SRS warning light, air bag module, clock spring and interconnecting wiring. SRS-related components (that may have to be in connection SRS service or maintenance) are

.. . . indicated the ot contents by an asterisk