tires MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1548 of 2103

REAR AXLE Troubleshooting

TROUBLESHOOTING

AXLE SHAFT

SymptomProbable causeRemedy

Noise while wheels are Brake drag

rotatingReplace

Bent axle shaft

Worn or scarred axle shaft bearing

Grease leakage Worn or damaged oil seal

Malfunction of bearing seal

Symptom

Noise Probable cause

Wear, play or seizure of ball joint Remedy

Replace

Excessive drive shaft spline looseness

DIFFERENTIAL (LIMITED SLIP DIFFERENTIAL)

SymptomProbable cause

Remedy

Abnormal noise during

driving or gear chang-Excessive drive gear backlash

Adjust

ing”’Insufficient drive pinion preload

II II

Abnormal noise

when cornering Excessive differential gear backlash

Worn spline of a side gear

Loose companion flange self-locking nut

Damaged differential gears

Damaged pinion shaft Adjust or replace

Replace

Retighten or replace

Replace

TSB Revision

Gear

Insufficient gear oil quantity

Improper drive gear tooth contact adjustmentReplenish

Adjust or replace

Incorrect drive gear backlash Adjust

I II

IImproper drive pinion preload adjustment

NOTE

l l:In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the

universal joint of the propeller shaft, the axle sh afts, the wheel bearings, etc. Before disassembling any parts,

take all possibilities into consideration and confi rm the source of the noise.

l 2: Noise from the engine, muffler vibration, transa xle, propeller shaft, wheel bearings, tires, body, etc., is easily

mistaken as being caused by malfunctions in the dif ferential carrier components. Be extremely careful and attentive

when performing the driving test, etc.

Test methods to confirm the source of the abnormal noise include: coasting, acceleration, constant speed

raising the rear wheels on a jack, etc. Use the met hod most appropriate to the circumstances.

driving,

Page 1549 of 2103

R E A R

Symptom

Gear noise**

Gear oil leakage

The limited slip

differential does not

function (on snow, mud, ice, etc.)

NOTE

Noise from the engine, muffler vibration, transaxl e, propeller shaft, wheel bearings, tires, body, etc., is easily

mistaken as being caused by malfunctions in the dif ferential carrier components. Be extremely careful and attentive

when performing the driving test, etc.

Test methods to confirm the source of the abnormal include: coasting, speed

raising the rear wheels on a -jack, etc. Use the me thod most appropriate to the

In the event of seizure, disassemble and replace the parts involved, and also be sure to check for any irregularities and repair or replace as

l 4:In addition to disassembling and replacing the failed parts, be sure to check all components forirregularities

and repair or replace as necessary.

Probable cause Remedy

Damaged, broken, and/or seized

ofReplace

the drive gear and drive pinion

‘Damaged, broken, and/or seized drive pinion bear- ings

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oil

Insufficient gear oil quantity

R e p l e n i s h

Worn or damaged front oil seal, OFan improperly Replace,

installed oil seal

Damaged gasket

Loose companion flange self-locking nut

Loose filler or drain plug Retighten or apply

‘Clean or replaceClogged or damaged vent plug

Insufficient drive

backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear

oil

Insufficient gear oil quantity

Incorrect drive gear backlash

Insufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

drive gear clamping bolts

The limited slip device is damaged Adjust

Replace

Replenish

Adjust

Retighten

Disassemble, check the functioning

and replace the damaged parts

TSB Revision

Page 1588 of 2103

WHEEL AND TIRE

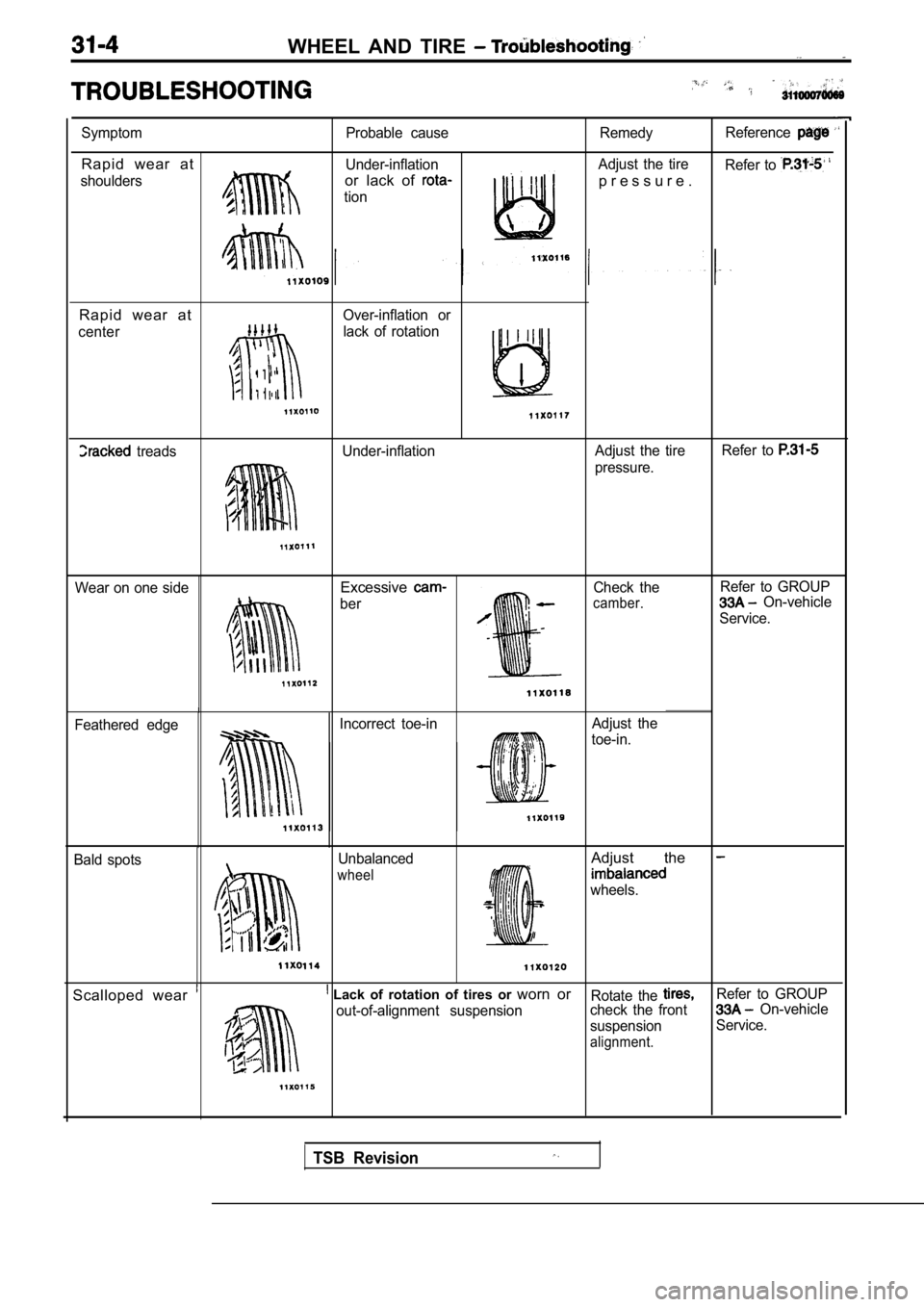

Symptom

Rapid wear at

shouldersProbable cause

Under-inflationor lack of

tion

Remedy Reference

Adjust the tire

Refer to

p r e s s u r e .

Rapid wear at

Over-inflation or

center

lack of rotation

I

treads Under-inflation Adjust the tireRefer to

pressure.

Wear on one side

Excessive

ber Check thecamber.

Refer to GROUP On-vehicle

Service.

Feathered edge Incorrect toe-in

Adjust the

toe-in.

Bald spots Unbalanced

wheel

Adjust the

wheels.

Scalloped wear Lack of rotation of tires or

worn orRotate the Refer to GROUP

out-of-alignment suspension check the front On-vehicle

suspension Service.

alignment.

TSB Revision

Page 1589 of 2103

WHEEL AND TIRE On-vehicle Service/Wheel and Tire

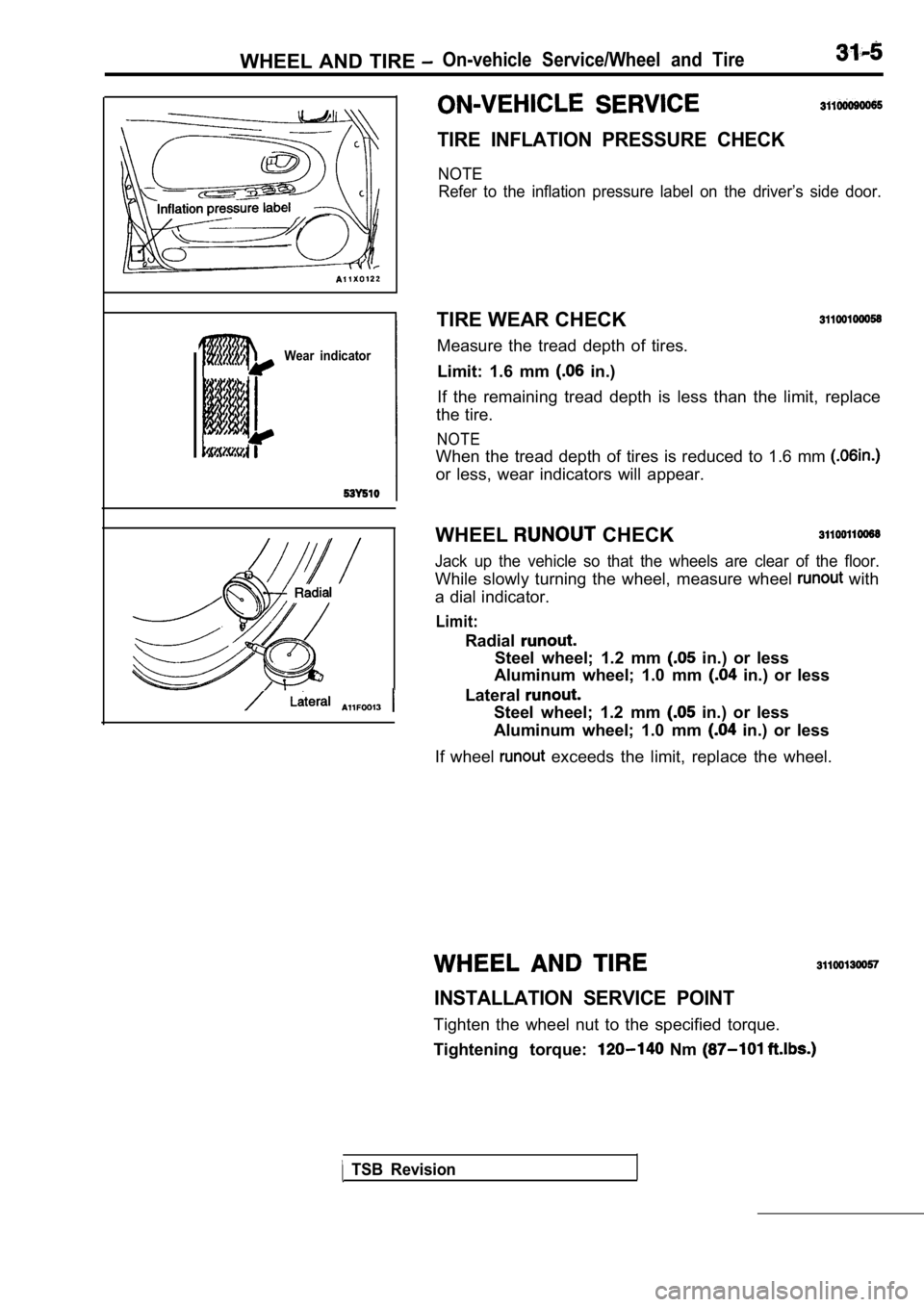

Wear indicator

TIRE INFLATION PRESSURE CHECK

NOTERefer to the inflation pressure label on the driver ’s side door.

TIRE WEAR CHECK

Measure the tread depth of tires.

Limit: 1.6 mm

in.)

If the remaining tread depth is less than the limit , replace

the tire.

NOTE

When the tread depth of tires is reduced to 1.6 mm

or less, wear indicators will appear.

WHEEL

CHECK

Jack up the vehicle so that the wheels are clear of the floor.

While slowly turning the wheel, measure wheel with

a dial indicator.

Limit:

Radial

Steel wheel; 1.2 mm in.) or less

Aluminum wheel; 1.0 mm

in.) or less

Lateral

Steel wheel; 1.2 mm in.) or less

Aluminum wheel; 1.0 mm

in.) or less

If wheel

exceeds the limit, replace the wheel.

INSTALLATION SERVICE POINT

Tighten the wheel nut to the specified torque.

Tightening torque:

Nm

TSB Revision

Page 1602 of 2103

FRONT SUSPENSION General Information

GENERAL INFORMATION

The front suspension is of a multi-link constructionby mounting the upper arm in a higher position

with two lower arms which create the ideal virtual than the tires, excellent steering stability and ride

kingpin axis for the suspension system. In addition ,comfort are obtained.

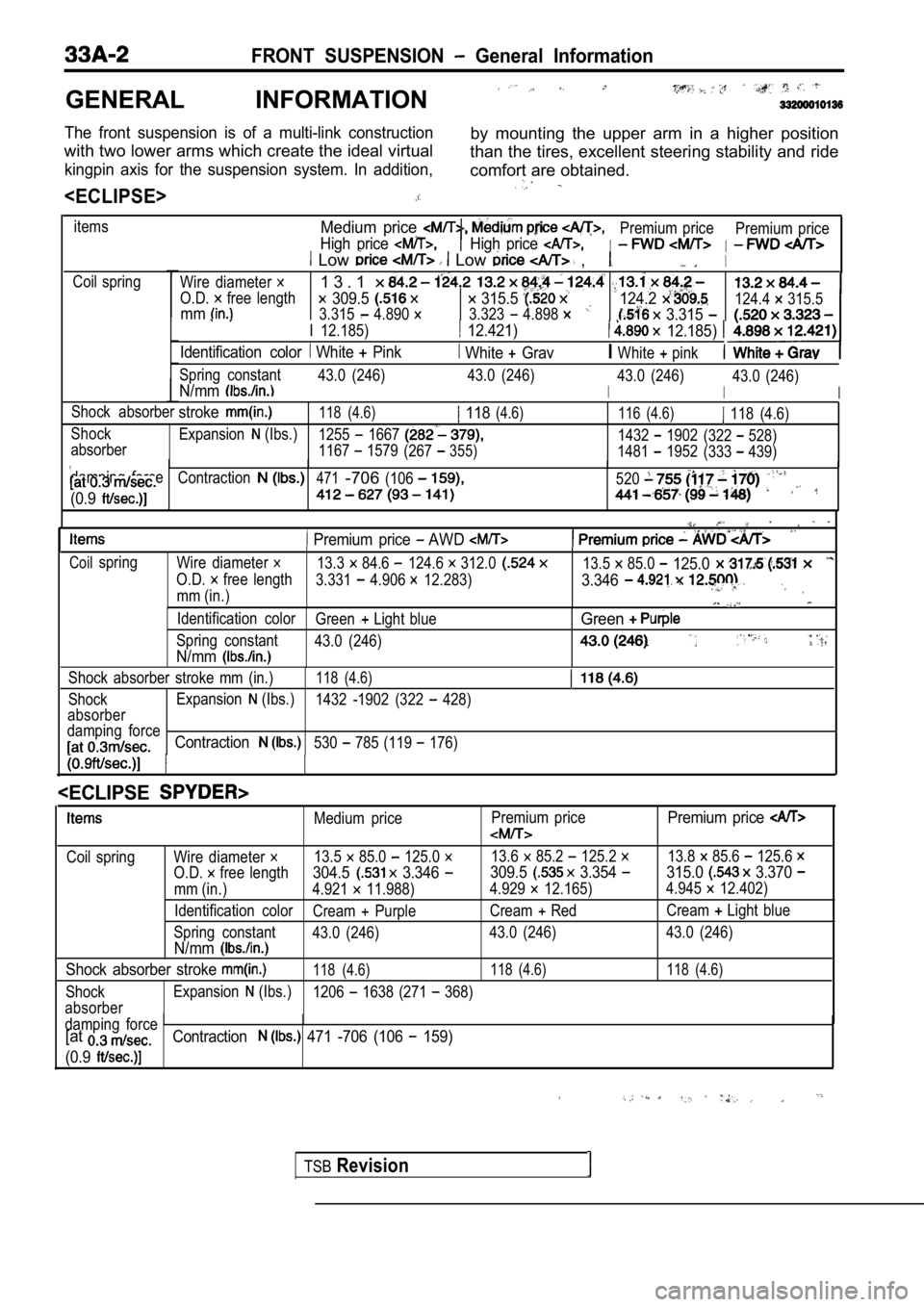

itemsMedium price

High price

Premium price

I

Premium priceHigh price I Low Low ,I

Coil spring

Wire diameter

O.D. free length

1 3 . 1

309.5 315.5 mm3.315 4.890 3.323 4.898

124.2

3.315

I 12.185) 12.421) 12.185)

Identification color White Pink White GravIWhite pink

124.4 315.5

Spring constant 43.0 (246) 43.0 (246)

I

43.0 (246)N/mmI

43.0 (246)

I

Shock absorberstroke118 (4.6) 118(4.6)116 (4.6) 118 (4.6)

Shock Expansion

(Ibs.)1255 16671432 1902(322 528)

absorber 1167 1579(267355)1481 1952 (333 439)

damping force

Contraction471-706(106520

(0.9

Premium price AWD

Coilspring Wire diameter 13.3 84.6 124.6 312.013.5 85.0 125.0

O.D. free length 3.331 4.906 12.283)3.346

mm (in.)

Identification color Green Light blueGreen

Spring constant43.0 (246)

N/mm

Shock absorber stroke mm (in.)118 (4.6)

ShockExpansion (Ibs.)

1432 -1902 (322 428)

absorber

damping force

Contraction530 785 (119 176)

Medium price Premium pricePremium price

Coil spring Wire diameter 13.5 85.0 125.0 13.6 85.2 125.2 13.8 85.6 125.6

O.D. free length304.5 3.346 309.5 3.354 315.0 3.370

mm (in.) 4.921 11.988)

4.929 12.165)4.945 12.402)

Identification color Cream

PurpleCream RedCream Light blue

Spring constant 43.0 (246) 43.0 (246) 43.0 (246)

N/mm

Shock absorber stroke 118 (4.6) 118 (4.6) 118 (4.6)

ShockExpansion (Ibs.)

1206 1638 (271 368)

absorber

damping force

[atContraction 471 -706 (106 159)

(0.9

Page 1604 of 2103

FRONT __

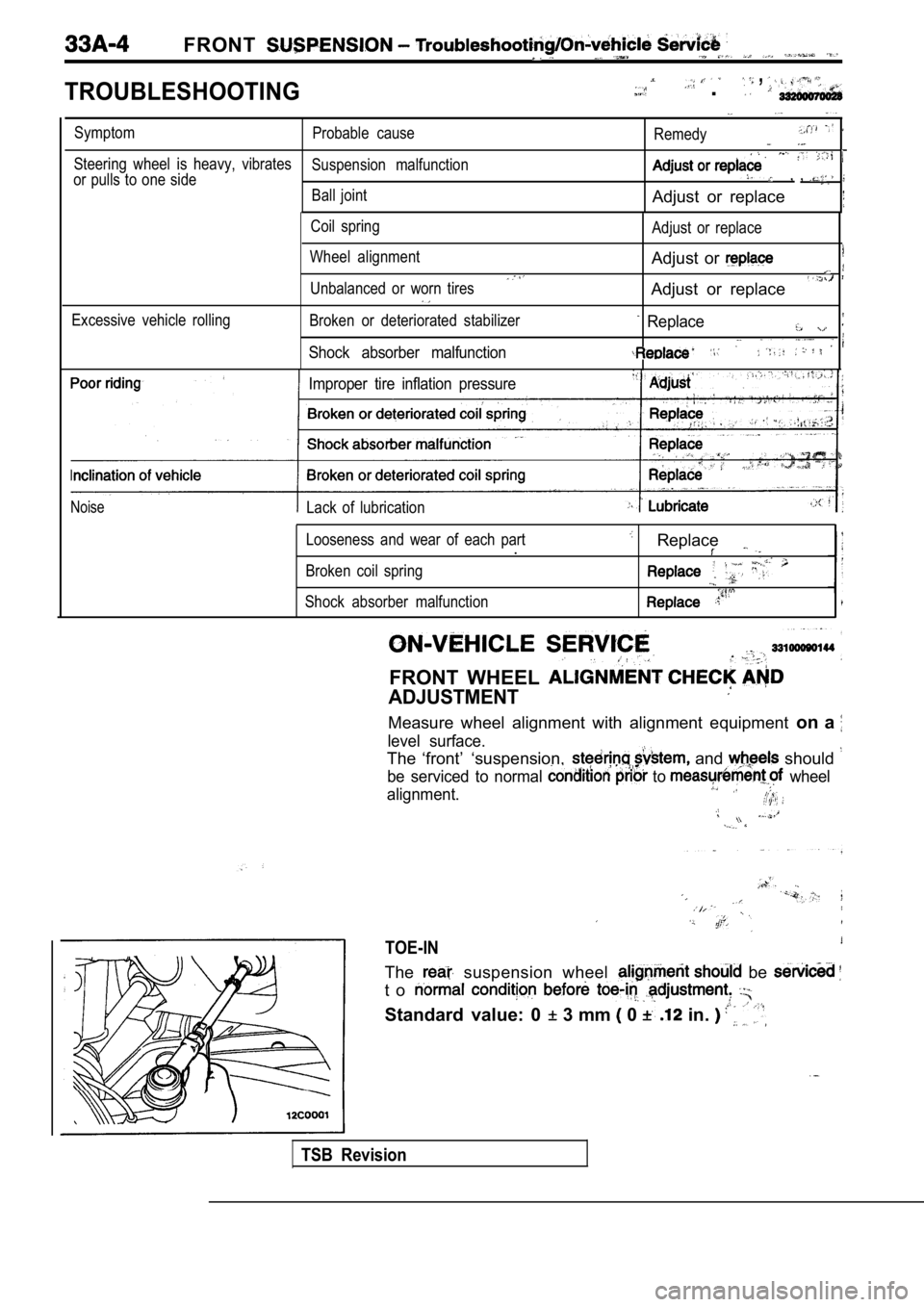

TROUBLESHOOTING

, .

SymptomProbable cause

Remedy

Steering wheel is heavy, vibratesSuspension malfunction

or pulls to one side, ,

Ball jointAdjust or replace

Coil spring

Wheel alignment

Unbalanced or worn tires Adjust or replace

Adjust or

Adjust or replace

Excessive vehicle rollingBroken or deteriorated stabilizer

Shock absorber malfunction

Replace

Improper tire inflation pressure

NoiseLack of lubrication

Looseness and wear of each part

.

Broken coil spring

Shock absorber malfunction

Replace

FRONT WHEEL

ADJUSTMENT

Measure wheel alignment with alignment equipment on a

level surface.

The ‘front’ ‘suspension, and should

be serviced to normal to wheel

alignment.

TOE-IN

The suspension wheel be

t o

Standard value: 0 3 mm 0 in.

TSB Revision

Page 1692 of 2103

ABS

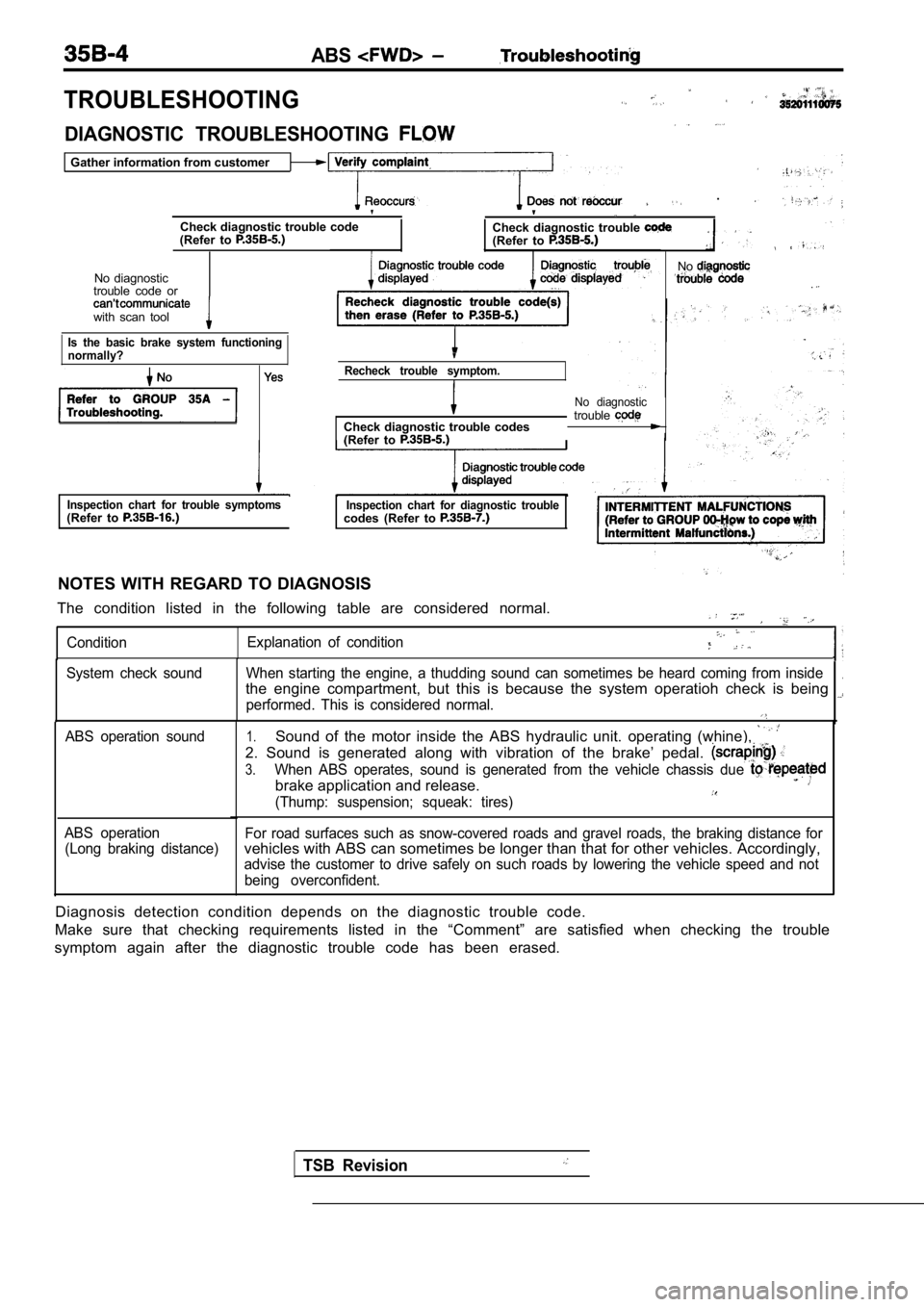

TROUBLESHOOTING

DIAGNOSTIC TROUBLESHOOTING

Gather information from customer

.

Check diagnostic trouble code

(Refer to Check diagnostic trouble (Refer to

No diagnostic

trouble code or

with scan tool

Is the basic brake system functioning

normally?

Recheck trouble symptom.

Check diagnostic trouble codes

(Refer to

No diagnostictrouble

Inspection chart for trouble symptoms(Refer to Inspection chart for diagnostic troublecodes (Refer to

NOTES WITH REGARD TO DIAGNOSIS

The condition listed in the following table are con sidered normal.

ConditionExplanation of condition

No

.

TSB Revision

System check sound When starting the engine, a thudd

ing sound can sometimes be heard coming from inside.the engine compartment, but this is because the system operatioh check is being

performed. This is considered normal.

ABS operation sound

ABS operation (Long braking distance)1.Sound of the motor inside the ABS hydraulic unit. o perating (whine),

2. Sound is generated along with vibration of the b rake’ pedal.

3.When ABS operates, sound is generated from the vehi cle chassis due

brake application and release.

(Thump: suspension; squeak: tires)

For road surfaces such as snow-covered roads and gravel roads, the braking distance forvehicles with ABS can sometimes be longer than that for other vehicles. Accordingly,

advise the customer to drive safely on such roads by lowering the vehicle speed and not

being overconfident.

Diagnosis detection condition depends on the diagno stic trouble code.

Make sure that checking requirements listed in the “Comment” are satisfied when checking the trouble

symptom again after the diagnostic trouble code has been erased.

Page 1734 of 2103

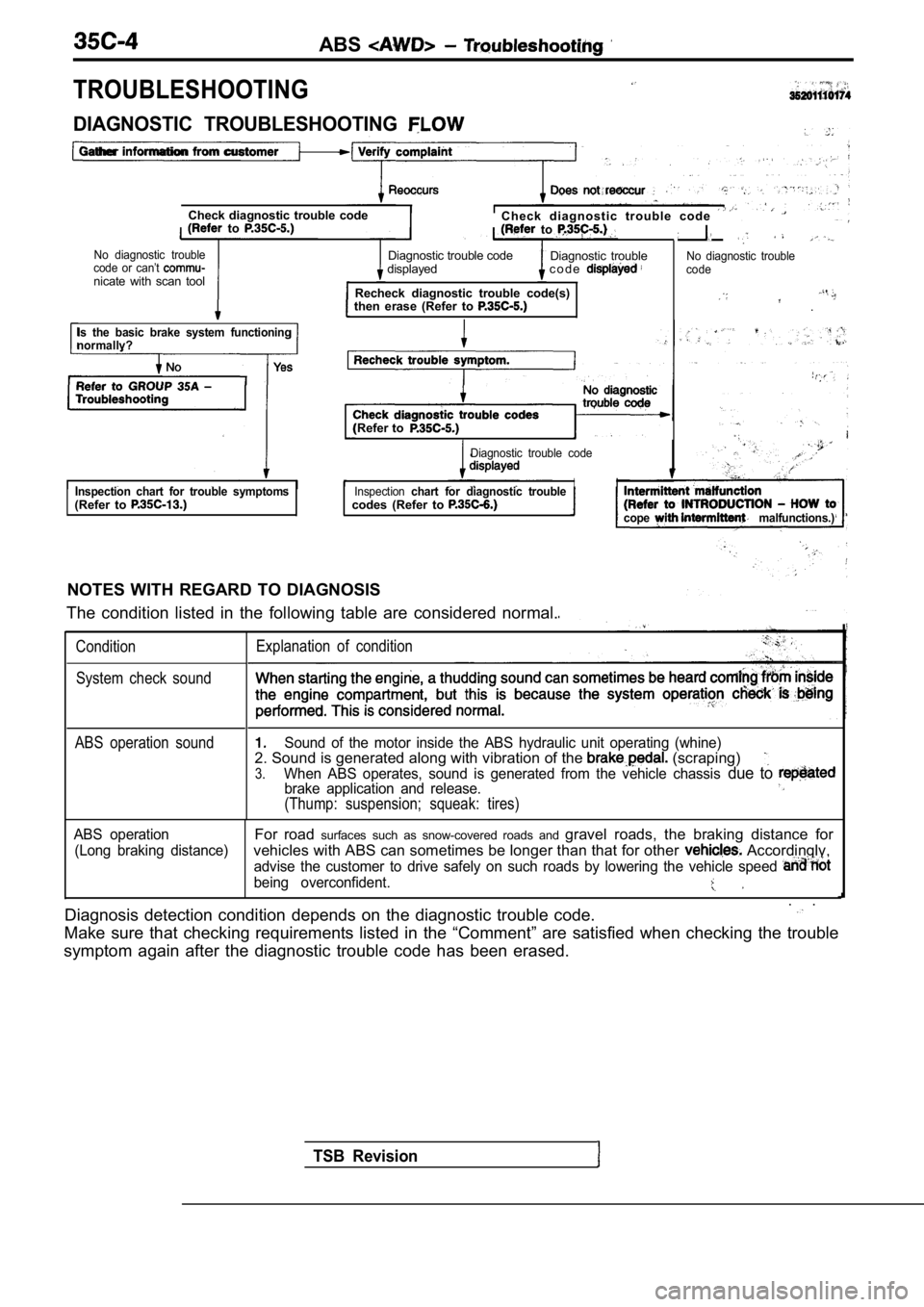

ABS

TROUBLESHOOTING

Check diagnostic trouble codeC h e c k d i a g n o s t i c t r o u b l e c o d e to to

No diagnostic troubleDiagnostic trouble codecode or can’t Diagnostic trouble

displayed c o d e

nicate with scan tool Recheck diagnostic trouble code(s)

then erase (Refer to

No diagnostic trouble

code

.

DIAGNOSTIC TROUBLESHOOTING

Gather information from customer

Is the basic brake system functioning

normallv?

(Refer to

Diagnostic trouble code

Inspection chart for trouble symptoms(Refer to Inspectionchart for diagnostic troubleII

codes (Refer to

cope malfunctions.)

NOTES WITH REGARD TO DIAGNOSIS

The condition listed in the following table are con sidered normal.

ConditionExplanation of condition

System check sound

TSB Revision

ABS operation soundSound of the motor inside the ABS hydraulic unit op erating (whine)2. Sound is generated along with vibration of the (scraping)

3.When ABS operates, sound is generated from the vehi cle chassis due to brake application and release.

(Thump: suspension; squeak: tires)

ABS operationFor road surfaces such as snow-covered roads and gravel roads, the braking distance for

(Long braking distance)vehicles with ABS can sometimes be longer than that for other Accordingly,

advise the customer to drive safely on such roads by lowering the vehicle speed

being overconfident.

. .

Diagnosis detection condition depends on the diagno stic trouble code.

Make sure that checking requirements listed in the “Comment” are satisfied when checking the trouble

symptom again after the diagnostic trouble code has been erased.

Page 2039 of 2103

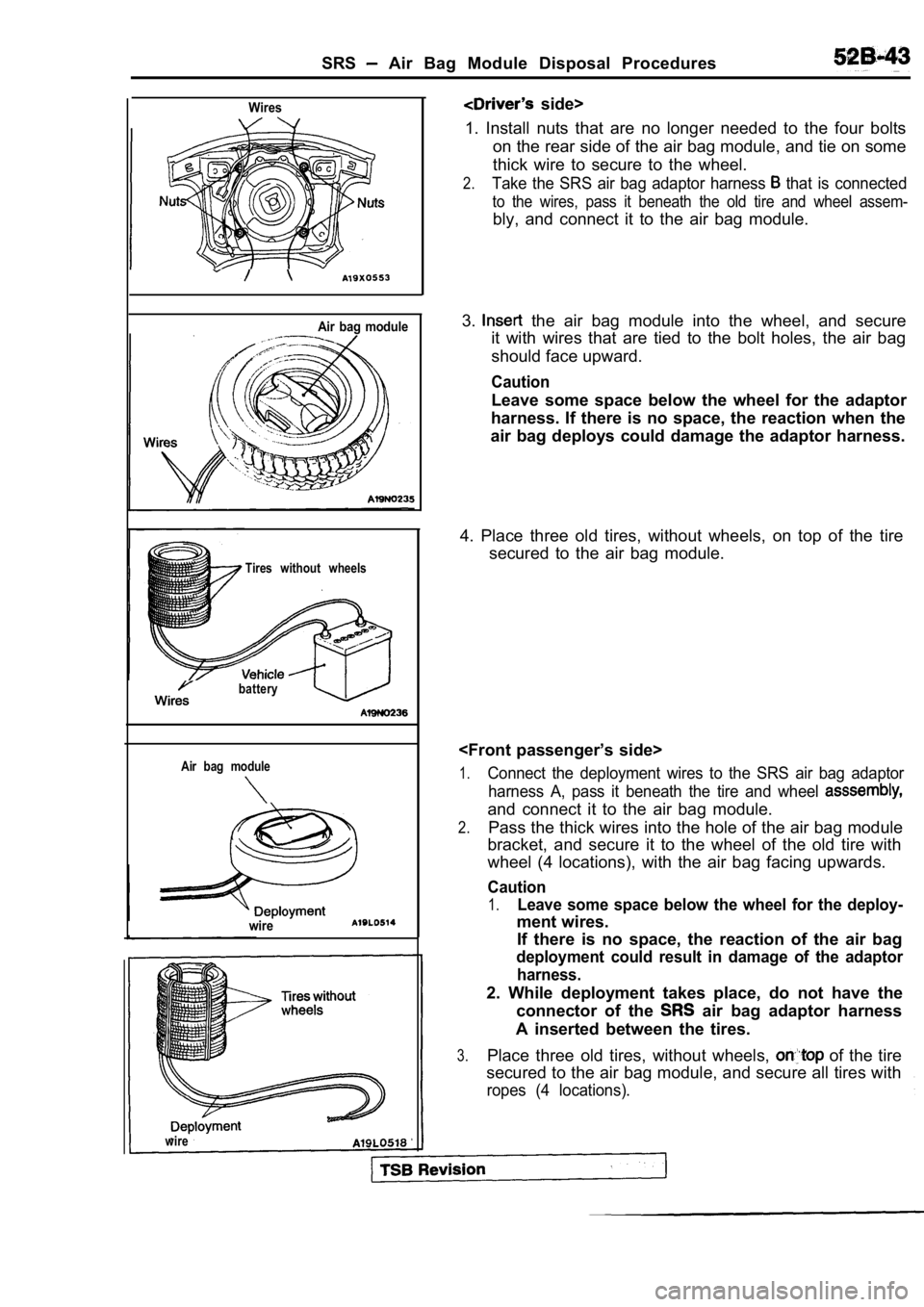

SRS Air Bag Module Disposal Procedures

Wires

Air bag module

Tires without wheels

battery

Air bag module

wire

side>

1. Install nuts that are no longer needed to the fo ur bolts

on the rear side of the air bag module, and tie on some

thick wire to secure to the wheel.

2.Take the SRS air bag adaptor harness that is connected

to the wires, pass it beneath the old tire and whee l assem-

bly, and connect it to the air bag module.

3.

the air bag module into the wheel, and secure

it with wires that are tied to the bolt holes, the air bag

should face upward.

Caution

Leave some space below the wheel for the adaptor

harness. If there is no space, the reaction when th e

air bag deploys could damage the adaptor harness.

4. Place three old tires, without wheels, on top of the tire

secured to the air bag module.

1.Connect the deployment wires to the SRS air bag ada ptor

harness A, pass it beneath the tire and wheel

and connect it to the air bag module.

2.Pass the thick wires into the hole of the air bag m odule

bracket, and secure it to the wheel of the old tire with

wheel (4 locations), with the air bag facing upward s.

Caution

1.Leave some space below the wheel for the deploy-

ment wires.

If there is no space, the reaction of the air bag

deployment could result in damage of the adaptor

harness.

2. While deployment takes place, do not have the connector of the

air bag adaptor harness

A inserted between the tires.

3.Place three old tires, without wheels, of the tire

secured to the air bag module, and secure all tires with

ropes (4 locations).

wire