oil NISSAN 300ZX 1984 Z31 Automatic Transmission Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 55 of 99

![NISSAN 300ZX 1984 Z31 Automatic Transmission Owners Manual ASSEMBLY ~

Total

end play

Totql end play = [B - 0 1 mm (0.004 in)] - C

Specified total end play:

0 25 - 0.50 mm

(0.0098 - 0.0197 in)

Total end play can be adjusted with bearing race

Avail NISSAN 300ZX 1984 Z31 Automatic Transmission Owners Manual ASSEMBLY ~

Total

end play

Totql end play = [B - 0 1 mm (0.004 in)] - C

Specified total end play:

0 25 - 0.50 mm

(0.0098 - 0.0197 in)

Total end play can be adjusted with bearing race

Avail](/img/5/563/w960_563-54.png)

ASSEMBLY ~

Total

end play

Totql end play = [B - 0 1 mm (0.004 in)] - C

Specified total end play:

0 25 - 0.50 mm

(0.0098 - 0.0197 in)

Total end play can be adjusted with bearing race

Available oil pump cover bearing race

Thickness rnm (in)

1 2 (0 0471

1

4 (0055)

16 (0.0631

18 (0071)

20

(0 079)

22

(00871

Pan number

31556-X0100 31556-XOlO1

31 556-X0102

31 556-XO103

31 556-XO104

31 556-XO105

17 Install brake band, band strut, and band servo.

Lubricate servo O-rings before installing

SAT066

18 Install and torque the retainer bolts. Loosen

piston stem.

,GG91060000

19 Finger tighten brake band servo piston stem

enough to prevent brake band and

strut from

falling out

Do not adjust brake band at this time.

SAT068

20 Apply vaseline to bearing race and thrust

washer, then mount them

on drum support

e- Bearing race

SA1573

AT-55

Page 56 of 99

ASSEMBLY

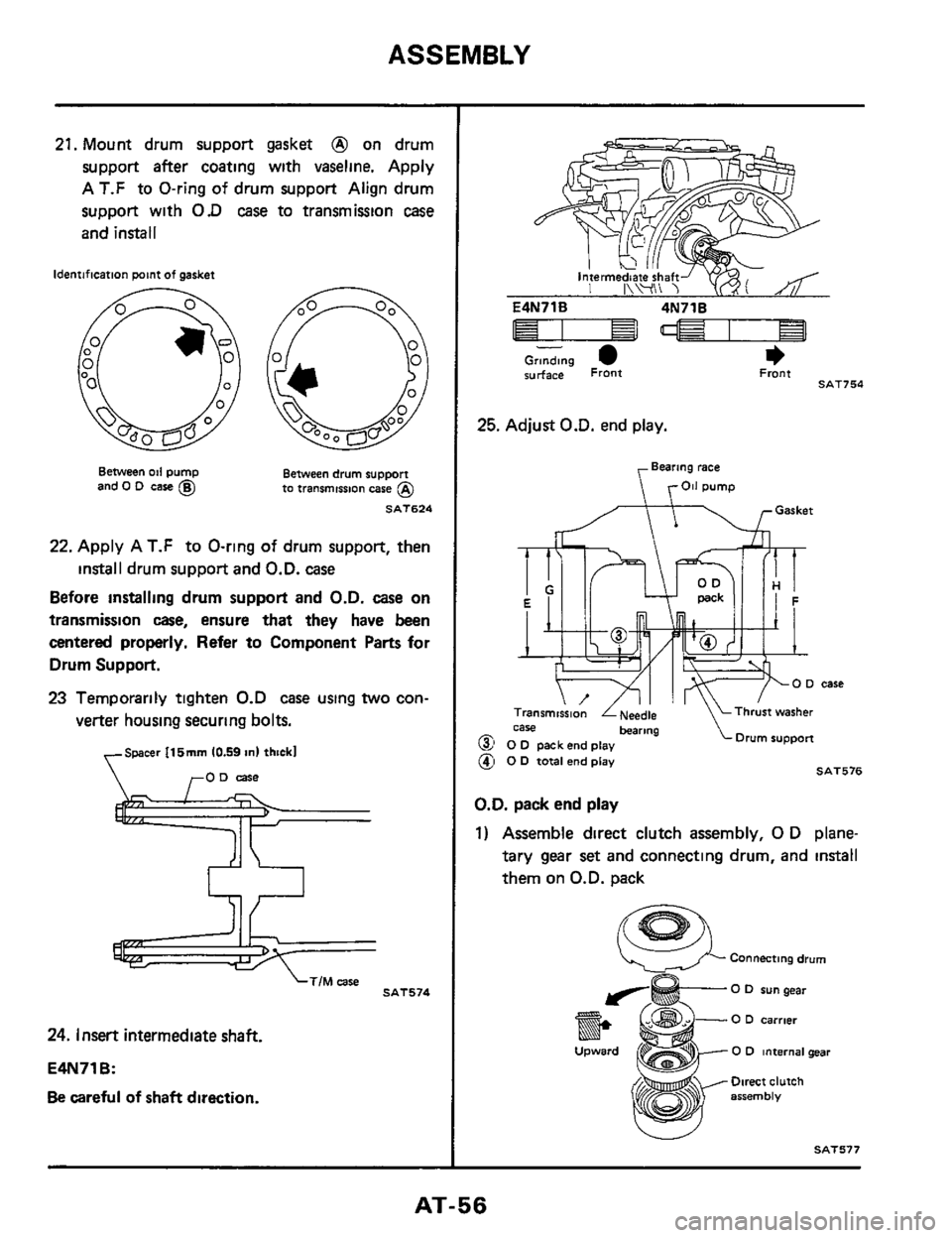

21. Mount drum support gasket @ on drum

support

after coating with vaseline. Apply

A

T.F to O-ring of drum support Align drum

support with

0.D case to transmission case

and install

identification point of gasket

Between 011 pump and 0 0 case @ Between drum SUPPOR to transmission care (@

SAT624

22. Apply A T.F to O-ring of drum support, then

Before installing drum support and O.D. case on

transmission

case, ensure that they have been

centered properly. Refer to Component

Parts for

Drum Support.

23 Temporarily tighten 0.D case using two con-

install drum support and O.D. case

verter housing securing bolts.

Spacer 115mm 10.59 in) thick1

rOD case

I I

\TIM Case SAT574

24. Insert intermediate shaft.

E4N71 B:

Be careful of shaft direction.

I-

*

-

Grinding surface Front Front SAT754

25. Adjust O.D. end play.

Bearing race

Oil pump

Gasket

bearing Drum suppon case

@I 0 0 pack end play

@ 0 D total end play SAT576

O.D. pack end play

1) Assemble direct clutch assembly, 0 D plane-

tary gear

set and connecting drum, and install

them on

O.D. pack

Connecting drum

- 0 0 run gear

-0 D carrier

0 0 internal gear

Direct clutch assembly

SAT577 u

AT-56

Page 57 of 99

ASSEMBLY

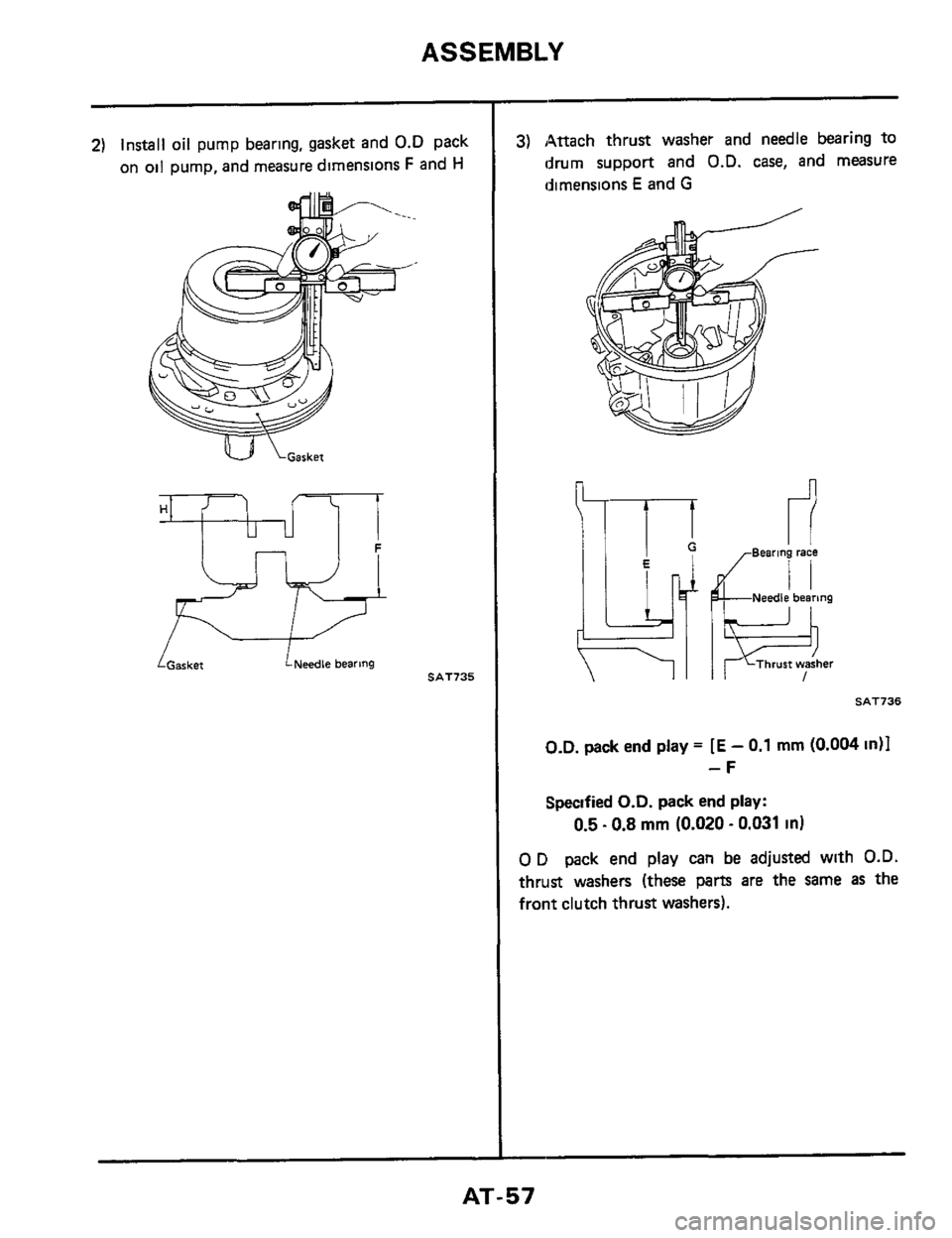

2) Install oil pump bearing, gasket and 0.D pack

on

oil pump, and measure dimensions F and H

w LGarker LNeedle bearing SAT735

3) Attach thrust washer and needle bearing to

drum support and O.D. case, and measure

dimensions

E and G

I1 Bearing race

Needle bearing

SAT736

D.D. pack end play = [E - 0.1 mm (0.004 in)]

-F

Specified O.D. pack end play:

0.5 - 0.8 mm (0.020 - 0.031 in)

0 D pack end play can be adjusted with O.D.

thrust washers (these parts are the same as the

front clutch thrust washers).

AT-57

Page 59 of 99

ASSEMBLY

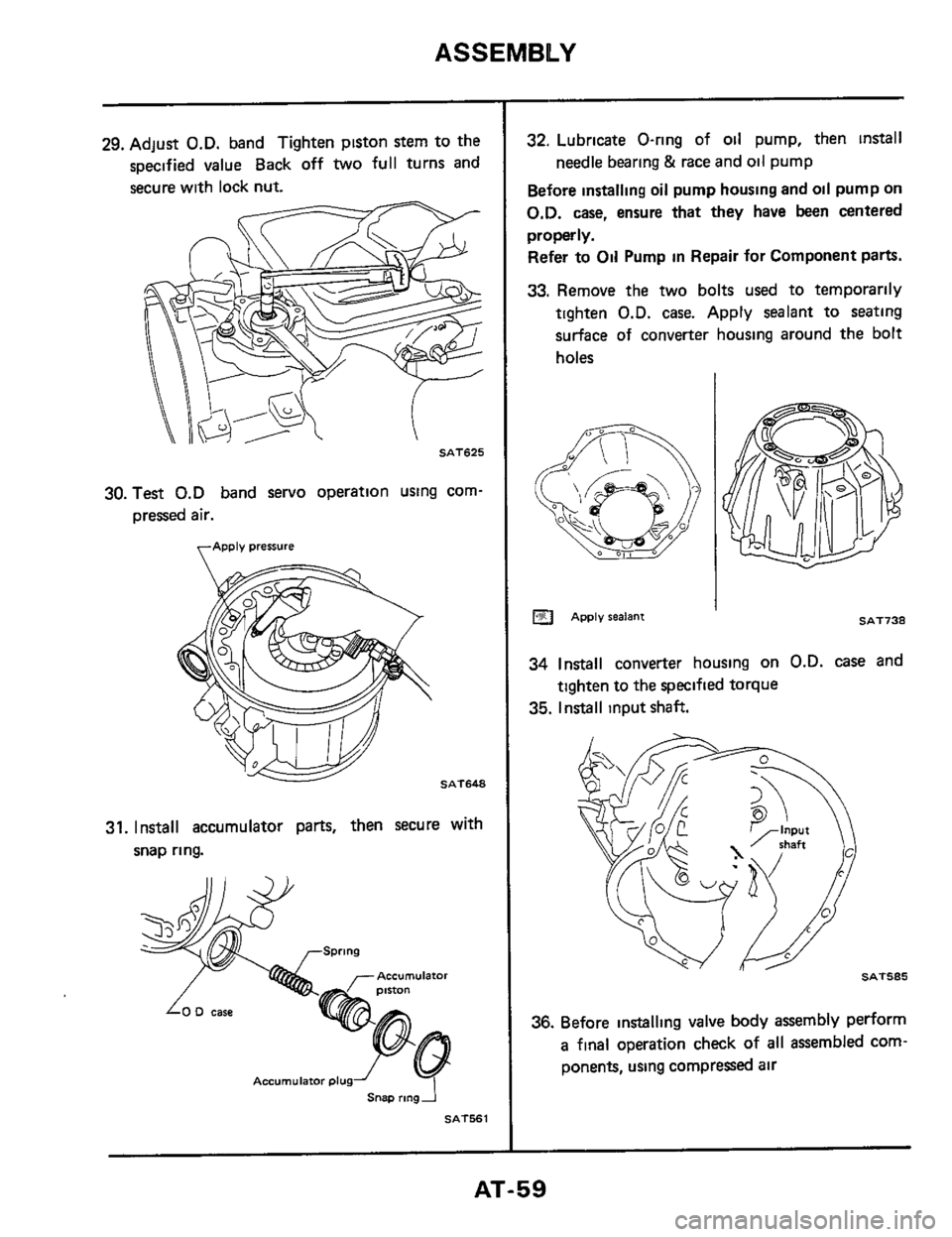

29. Adjust O.D. band Tighten piston stem to the

specified value Back off

two full turns and

secure with lock nut.

SAT625

30. Test 0.D band servo operation using corn-

pressed air.

apply pressure

SAT648

31. Install accumulator parts, then secure with

snap ring.

ACCUmUlafOr

Accumulator plug

Snap rmgi

SAT561

32. Lubricate O-ring of oil pump, then install

Before installing oil pump housing and oil pump on

O.D. case, ensure that they have been centered

properly.

Refer to Oil Pump in Repair for Component parts.

33. Remove the two bolts used to temporarily

tighten

O.D. case. Apply sealant to seating

surface

of converter housing around the bolt

holes

needle bearing & race and oil pump

APPIV sealant SAT738

34 Install converter housing on O.D. case and

35. Install input shaft.

tighten to the specified torque

.. SAT585

36. Before installlng valve body assembly perform

a final operation check of all assembled com-

ponents, using compressed air

AT-59

Page 61 of 99

ASSEMBLY

290 (1 142)

29 5 (1 161)

30 0 (1 1811

30 5 (1 201)

31 0 (1 220)

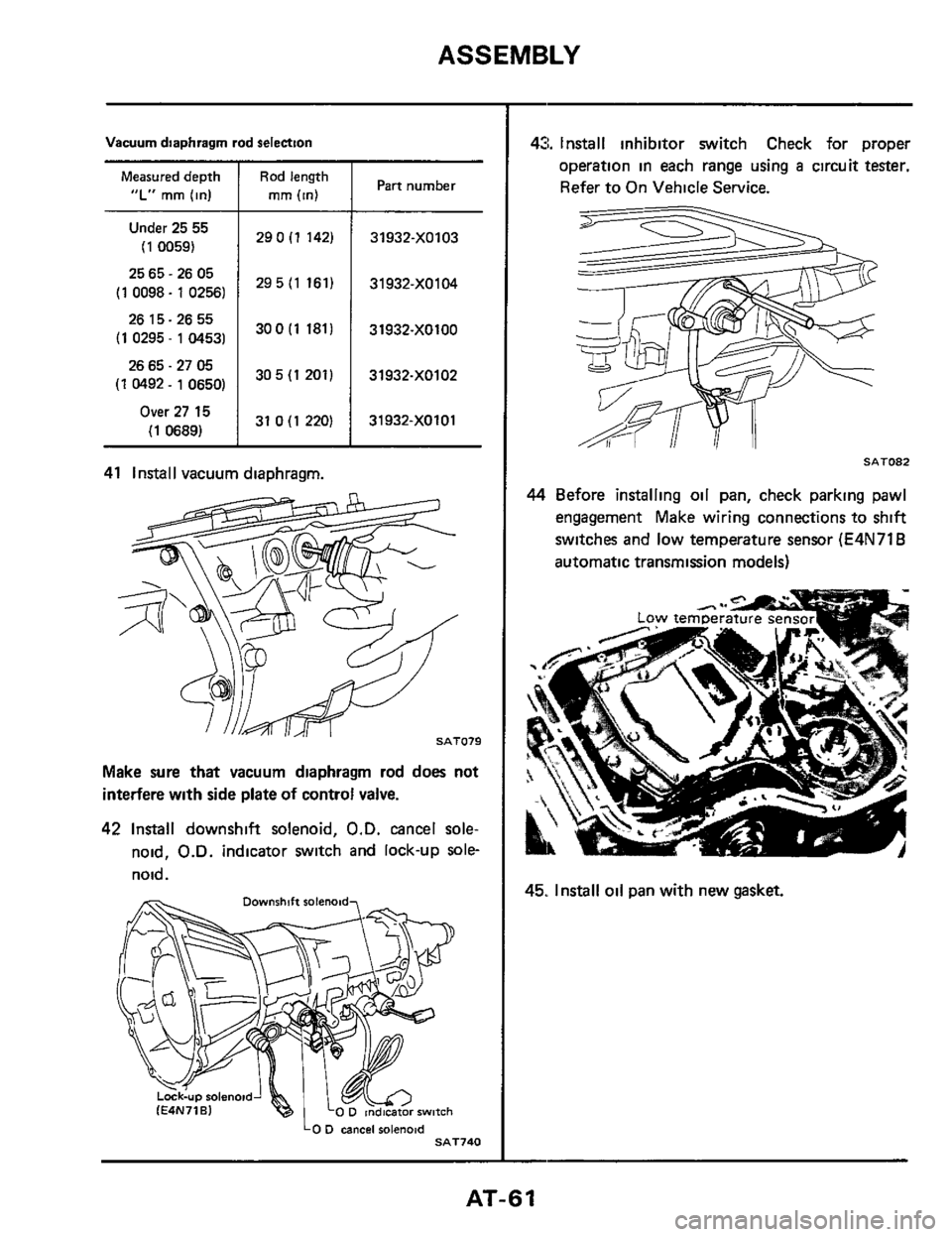

Vacuum diaphragm rod selection

31932-XO103

31932-X0104

31932-XOlOO

31932-X0102

31932-XOlOl

Measured depth

“L” mm (in)

Under 25 55

(1 0059)

25 65

- 26 05

(1

0098 - 1 02561

2615-2655

(1 0295 - 1 04531

26 65.27 05

(1 0492

- 1 0650)

Over 27 15

(1 0689)

Rod length

mm (in) Part number

41 Install vacuum diaphragm.

Make sure that vacuum diaphragm rod does not

interfere with side plate

of control valve.

42 Install downshift solenoid, O.D. cancel sole-

noid, O.D. indicator switch and lock-up sole-

noid.

LO D csncei rolenoid SAT740

43. Install inhibitor switch Check for proper

operation in each range using

a circuit tester.

Refer to On Vehicle Service.

Y li

SAT082

44 Before installing oil pan, check parking pawl

engagement Make wiring connections to shift

switches and low temperature sensor

(E4N71B

automatic transmission models)

45. Install oil pan with new gasket.

-

AT-61

Page 62 of 99

ASSEMBLY

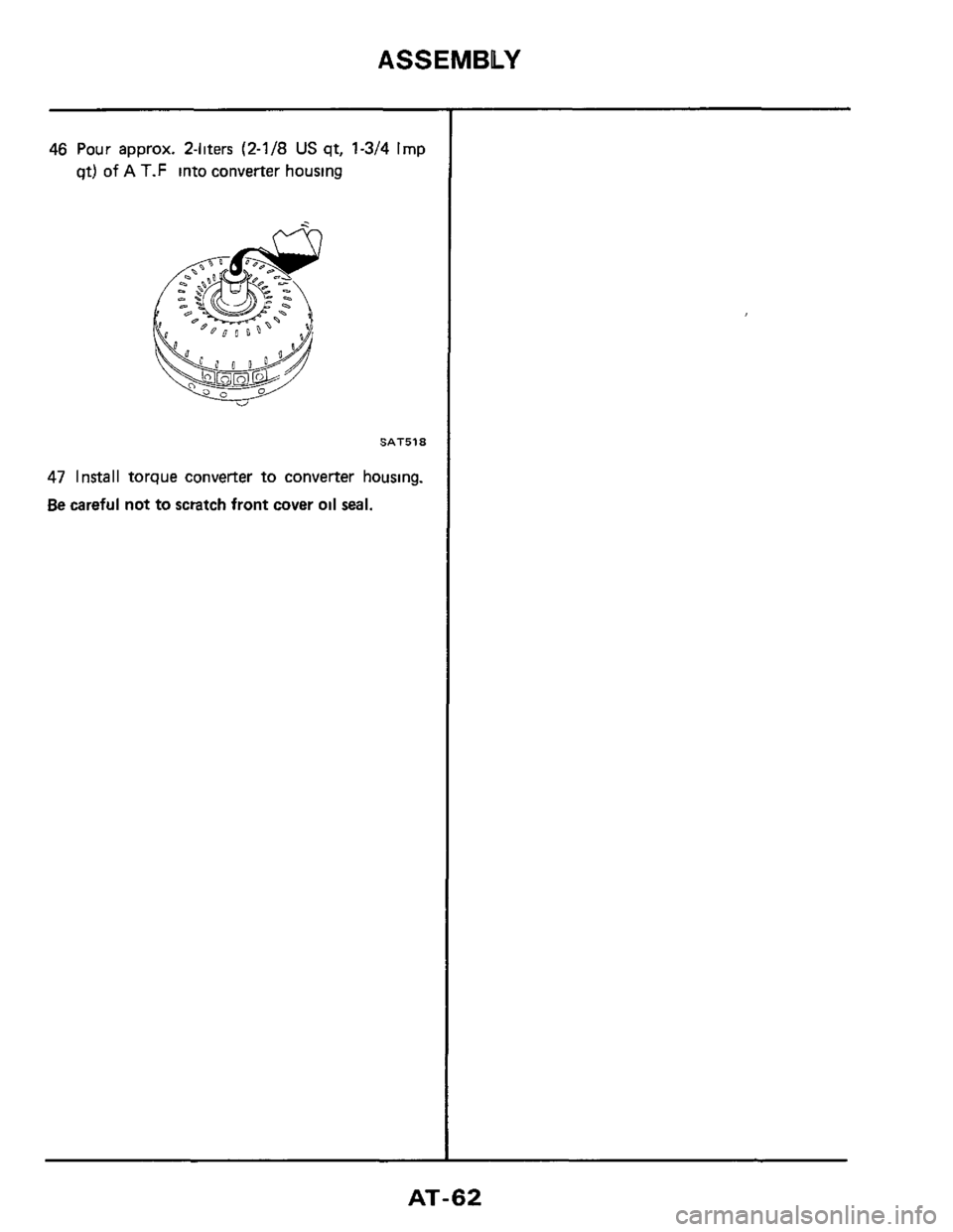

46 Pour approx. 2-liters (2-1/8 US qt, 1-3/4 Imp

qt) of A T.F into converter housing

SAT518

47 Install torque converter to converter housing.

Be careful not to scratch front cover oil seal.

AT-62

Page 76 of 99

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Lock-up Control Unit (Cont'd)

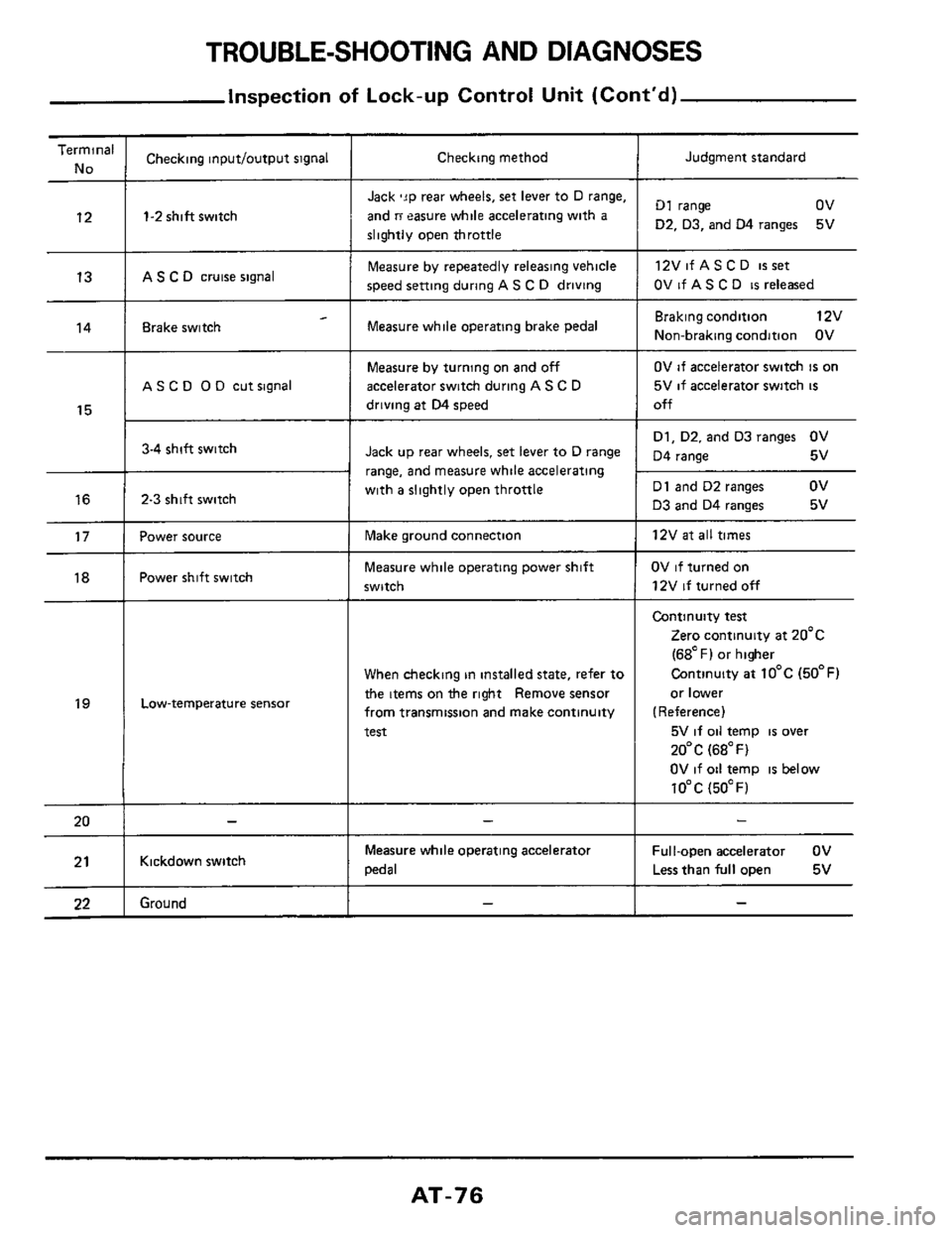

Terminal

No

12

13

14

15

16

17

18

19

20

21

22

___

Checking inputloutput signal

1-2 shift switch

AS C D cruise signal

- Brake switch

A S C 0 0 D cut signal

3-4 shift switch

2-3 shift switch

Power source

Power shift switch

Low-temperature sensor

Kickdown switch

Ground

Checking method

Jack 'JP rear wheels, set lever to D range,

and

ri easure while accelerating with a

slightly open throttle

Measure by repeatedly releasing vehicle

speed setting during

AS C D driving

Measure while operating brake pedal

Measure by turning on and off

accelerator switch during A S C D

driving at D4 speed

Jack up rear wheels, set lever to D range

range,

and measure while accelerating

with

a slightly open throttle

Make ground connection

Measure while operating power shift

switch

When checking in installed state, refer to

the items on the right Remove sensor

from transmission and make continuity

test

Measure while operating acceleratoi

pedal

Judgment standard

D1 range ov

D2. D3, and 04 ranges

12VifASCD

isset

OV if AS C D is released

5V

Braking condition 12v

Non-braking condition OV

OV if accelerator switch is on

5V

if accelerator switch is

off

D1, D2. and D3 ranges OV

D4 range 5v

D1 and D2 ranges

ov

D3 and D4 ranges 5v

12V

at all times

OV if turned on

12V

if turned off

Continuity test

Zero continuity at 20'c

(68OF) or higher

Continuity

at 10°C (50°F)

or lower

(Reference)

5V

if oil temp is over

20°C (68°F)

OV if oil temp

is below

10°C (5OOF)

Ful I-open accelerator OV

Less than

full open 5v

AT-76

Page 91 of 99

TROUBLE-SHOOTING AND DIAGNOSES

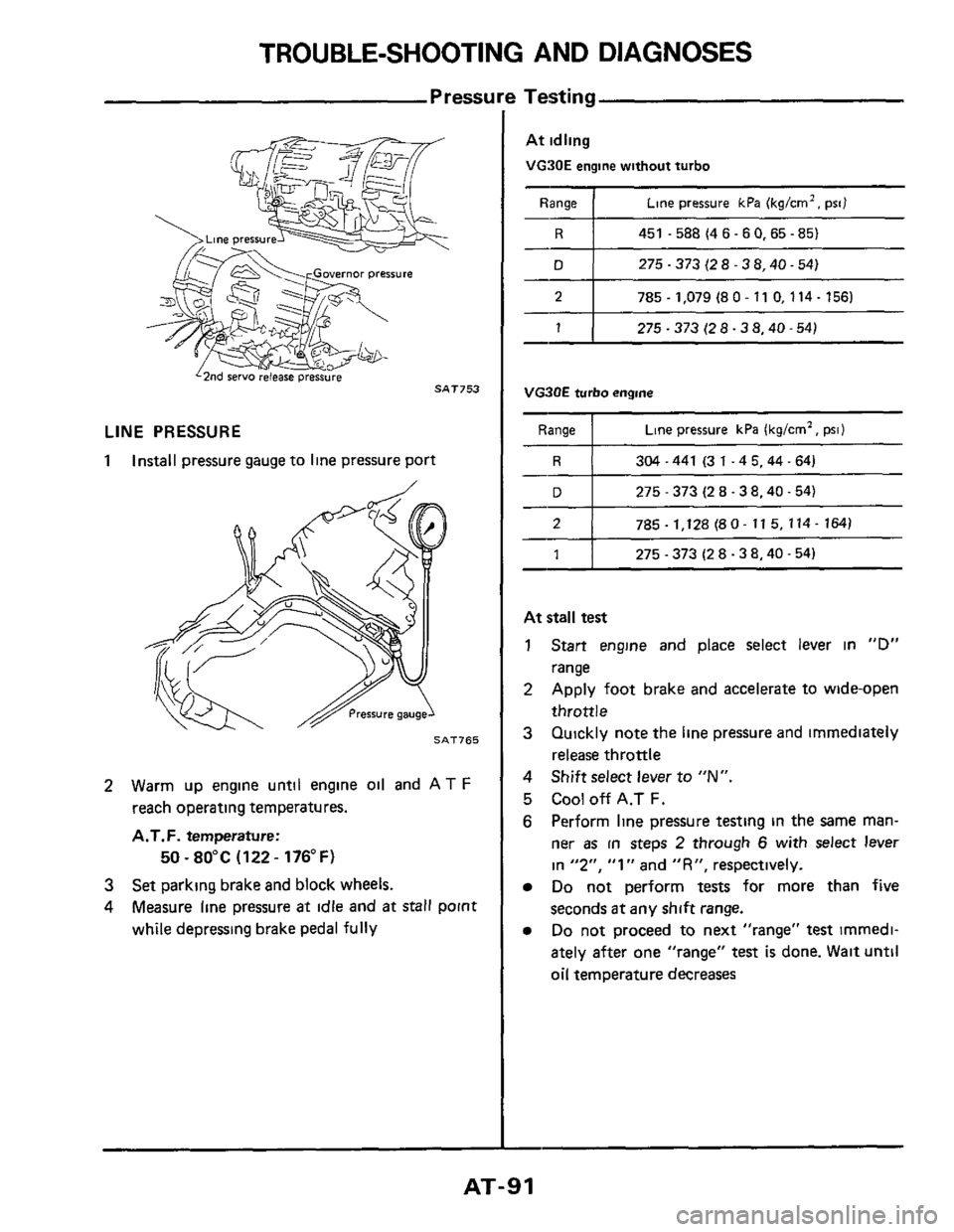

Pressure Testing ~ ~~

2

LINE PRESSURE

1 Install

pressure gauge to line pressure port

785 - 1,128 (8 0- 11 5, 114- 164)

SAT765

1

2 Warm up engine until engine oil and AT F

reach operating temperatures.

A.T.F. temperature:

3 Set parking brake and block wheels.

4 Measure line pressure at idle and at stall point

while depressing brake pedal

fully

50 ~ 80°C (122 - 176°F)

275 - 373 (2 8.3 8.40.54)

At idling

VG90E engine without turbo

Range 1 Line pressure kPa (kg/crn2. psi)

R I 451 -588(46-60,65-85)

D 1 275-373(28-38.40-54)

2 I 785.1,079 (80- 11 0,114- 156)

1 1 275-373(28-38.40-54)

VG3OE turbo engine

Range Line pressure kPa (kg/cm2, psi)

304-441 (31-45.44-64)

275

- 373 (2 8.38.40.54)

At stall test

1 Start engine and place select lever in "D"

range

2 Apply foot brake and accelerate to wide-open

throttle

3 Quickly note the line pressure and immediately

release throttle

4 Shift select lever to "N".

5 Cool off A.T F.

6 Perform line pressure testing in the same man-

ner as in steps 2 through 6 with select lever

in

"2". "1" and "R", respectively.

Do not perform tests for more than five

seconds

at any shift range.

Do not proceed to next "range" test imrnedi-

ately after one "range"

test is done. Wait until

oil temperature decreases

AT-91

Page 92 of 99

TROUBLE-SHOOTING AND DIAGNOSES

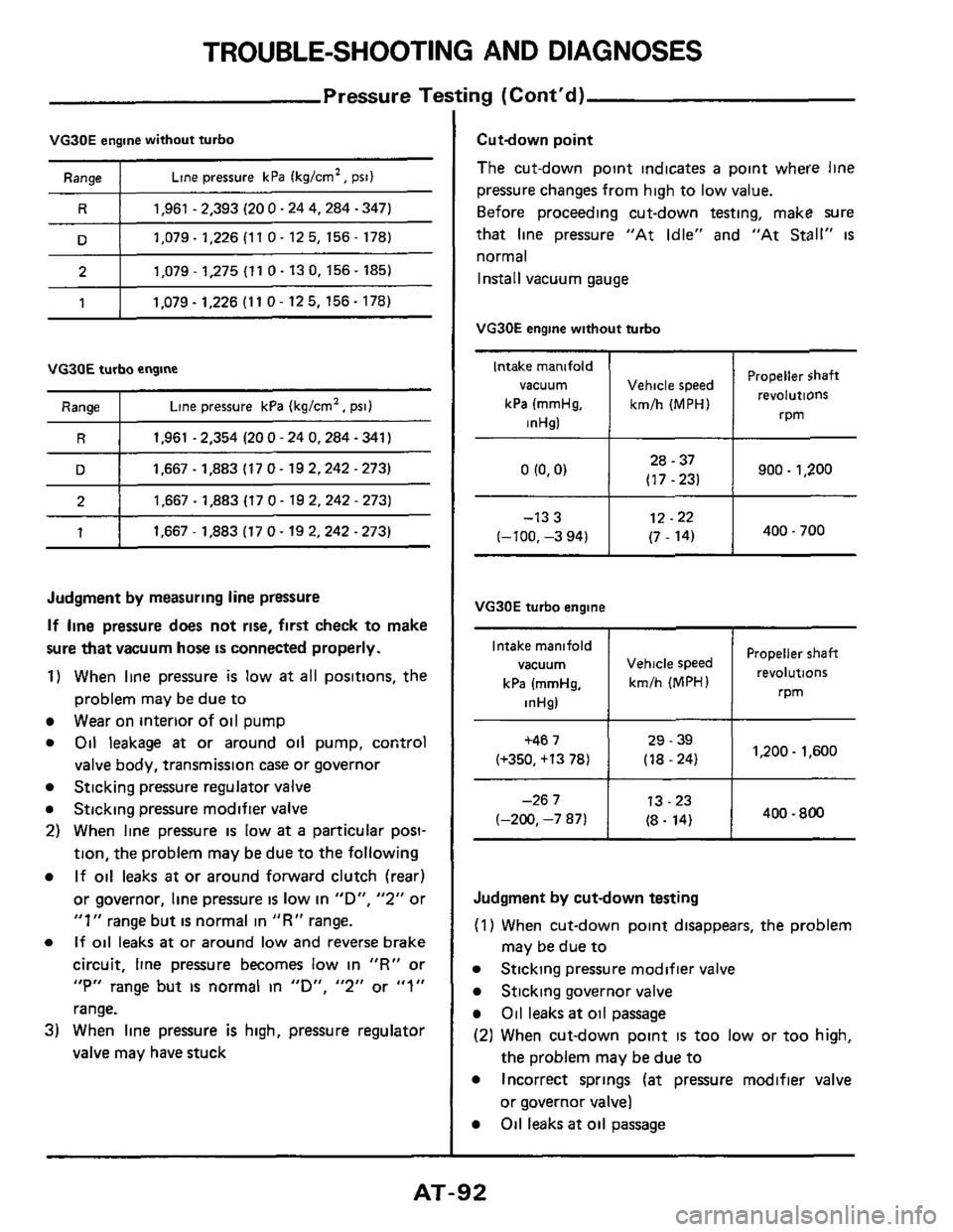

Pressure Testing (Cont'd)

Intake manifold

vacuum

kPa (mmHg,

inHsl

VG30E engine without turbo

Propeller $haft

Vehicle speed revolutions

kmlh (MPH)

rpm

Range I Line pressure kPa (kglcm', psi)

Intake manifold

vacuum

kPa (mrnHg.

inHg) ~

R I 1,961 - 2,393

(20 0.24 4,284 .347)

Propeller shaft Vehicle speed

kmlh (MPH) revolutions

rpm

D I 1.079-1,226(110-125,156-178)

2 I 1,079 - 1,275 (11 0.13 0, 156 - 185)

1 I 1,079 - 1,226 (1 1 0 - 12 5, 156 - 178)

VG30E turbo engine

Range I Line pressure kPa (kgtcm', psi)

R I 1,961 - 2,354 (20 0 - 24 0,284 - 341)

D I 1,667 - 1,883 (17 0- 19 2,242 -273)

2 I 1.667-1,883(170-192,242-273)

1 I 1.667-1.8831170-192.242-273)

Judgment by measuring line pressure

If line pressure does not rise, first check to make

sure that vacuum

hose is connected properly.

1) When line pressure is low at all positions, the

problem may be due to

Wear on interior of oil pump

Oil leakage at or around oil pump, control

valve body, transmission case or governor

Sticking pressure regulator valve

Sticking pressure modifier valve

2) When line pressure is low at a particular posi-

tion, the problem may be due to the following

If oil leaks at or around forward clutch (rear)

or governor, line pressure

is low in "D", "2" or

"1" range but is normal in "R" range.

If oil leaks at or around low and reverse brake

circuit, line pressure becomes low in

"R" or

"P" range but IS normal in "D", "2" or "1"

range.

3) When line pressure is high, pressure regulator

valve may have stuck

Cutdown point

The cut-down point indicates

a point where line

pressure changes from high to low value.

Before proceeding cut-down testing, make sure

that line pressure "At Idle" and "At

Stall'' is

normal

Install vacuum gauge

VG30E engine without turbo

28 - 37

o(o'o) I (17-231 I 900- 1,200

12.22

(7 - 14) I 400-700 (-100. -133 -3 94) I

VG30E turbo engine

+467 I 29 - 39 1,200- 1,600 (+350, +13 78) (18 - 24)

13.23

(-200,

-267 -7 871 I (8. 14) 400 - 800

Judgment by cut-down testing

(1) When cut-down point disappears, the problem

Sticking pressure modifier valve

Sticking governor valve

Oil leaks at oil passage

(2) When cut-down point is too low or too high,

the problem may be due to

Incorrect springs (at pressure modifier valve

or governor valve)

Oil leaks at oil passage

may be due to

AT-92

Page 95 of 99

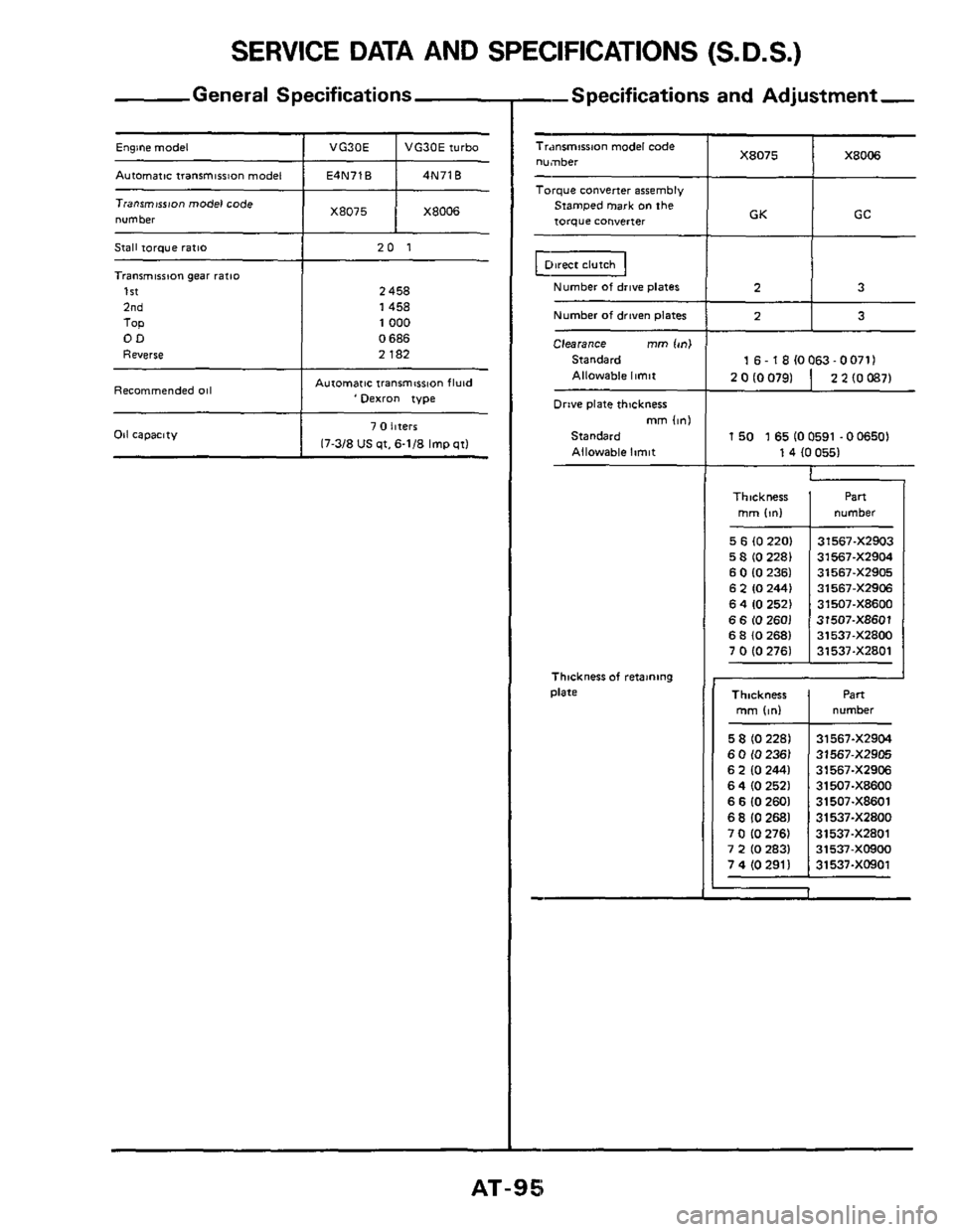

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

General Specifications

X8075 Engine model ~ I VG30E t VG30Eiurbo X8006 -

Autamatictranrmirrion model I E4N71B I 4N71B ~~

Stall torque ratlo

Transmission gear ratio

1st

2nd

TOP OD

Reverse

Recommended 011

1 X8075 1 X8006 Tianrmwon model code

number ~

20 1

2 458

1458

1000

0 686

2 182

Aurornar~c lranmwon fluid 'oexro" type

2 0 IO 0791

Oil capacity

2 2 (0 0871

7 0 hferr

17-3/8 US qt, 6-1/8 Imp qtl

5 6 (0 220)

5 8 (0 2281

6 0 (0 2361 6 2 IO 2441

6 4 10 2521

6 6 10 2601 6 8 (0 2681

7 0 (0 2761

--Specifications and Adjustment,

31567-XZ903

31567-XZ904

31567-XZ905

31567-XZ906

31507-X86W

31507-X8601

31537-XZ800

31537-XZ801

Tr.msmirrmn model code number

Torque converter assembly

Srarnped mark on the

torque COnYerter

Number of drive plates

Number of driven plates

Clearance rnm Ion1

Standard Allowable limit

Drive plate thickness mm (in1

Standard

Allowable limit

Thlcknesr of retamng

Dlate

1 GC GK

1 50 1 65 (0 0591 .O 06501

1 4 (0 0551

Thickness I numbel Part

mrn Iml

Thickness number

AT-95