NISSAN 300ZX 1984 Z31 Brake System Workshop Manual

Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 21, PDF Size: 0.54 MB

Page 1 of 21

BRAKE SYSTEM

P 7- I

SECTION BR

CONTENTS

BRAKE HYDRAULIC LINE ..

BRAKE PEDAL. . . ..

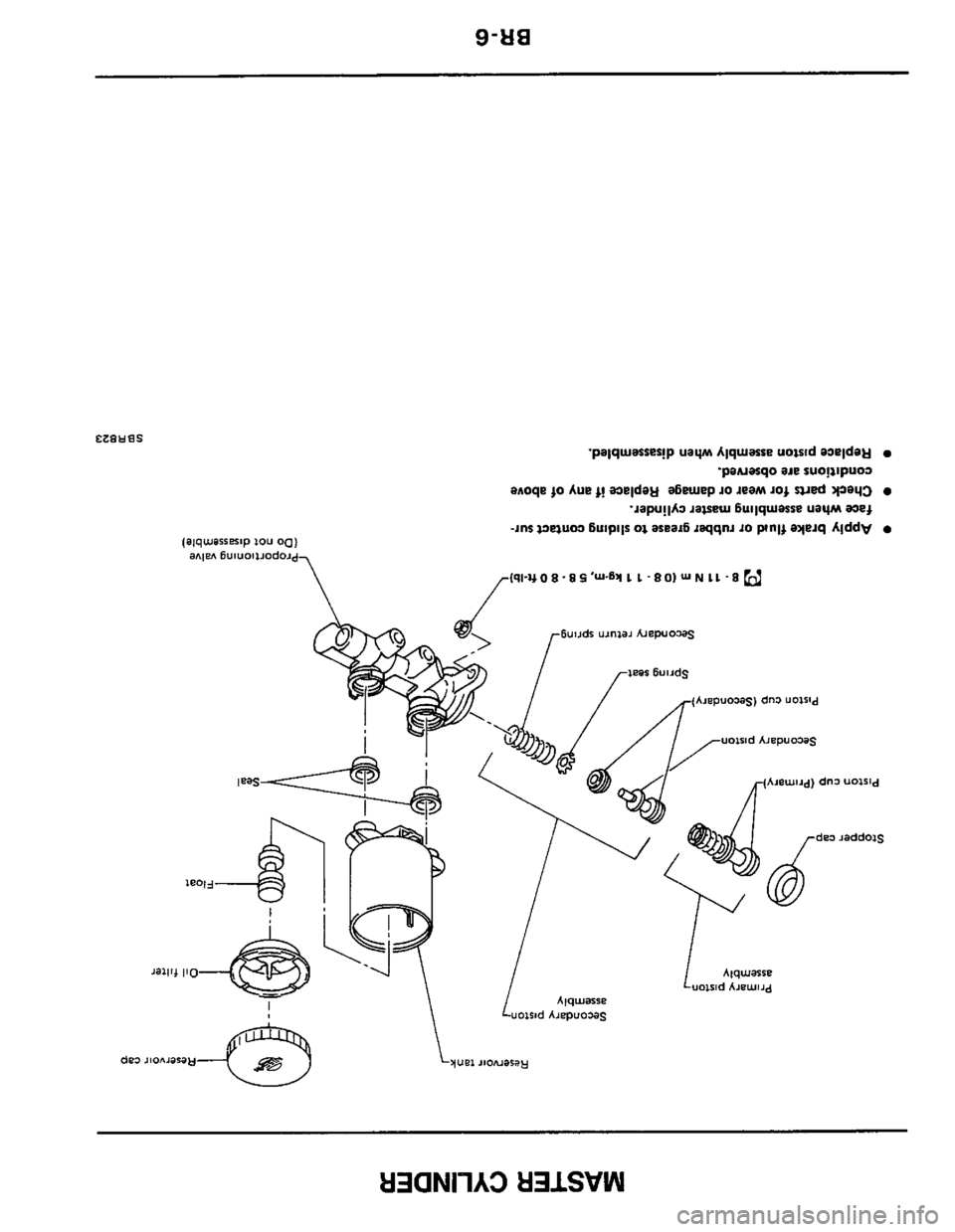

MASTER CYLINDER .

BRAKE BOOSTER

FRONT DISC BRAKE (CL28VA, CL28VB) - Rotor

REAR DISC BRAKE (CL14H, CL14HB) - Callper

PARKING BRAKE

SERVICE DATA AND SPECIFICATIONS

6 D.S)

SPECIAL SERVICE TOOL

FRONT DISC BRAKE (CL28VA, CL28VB) - Caliper

REAR DISC BRAKE - Rotor ..

.. .. .. BR- 2

. BR- 4

BR- 6

BR- 7

BR- 9

. . . BR-11

.. BR-12

BR-16

. .. . BR-17

. BR-19

.. . .. BR-21

Page 2 of 21

BRAKE HYDRAULIC LINE

rn Recommended fluid is brake fluid "DOT 3".

Do not reuse drained brake fluid

Be careful not to splash brake fluid on painted areas

Front brake lCL28VA. CL28VB)

rFlare nut

7

7

Rear brake lCL14H. CL14HB)

7 0 15- 18 I1 5- 18.11.131

@@.A

Three-way connector I1 5. 1 8, 11 - 131

Flare nut 15-18 I1 5- 18.11 -13)

\Flare nut

0 15.18 I1 5.18.11.13)

WARNING

Clean pad and shoe dust using a dust

collector after

cleaning with waste cloth

Primary llne - Secondary lone

N m lkg-m,ft Ibl

SBR821

Bleeding Procedure

Precautions

Carefully monitor brake fluid level at master

cylinder during bleeding operation.

Bleed air according to the following pro-

cedure

Left rear caliper @ -t Right rear caliper @

-t Right front caliper @ -f Left front caliper

Connect a transparent vinyl tube to air bleeder

valve of caliper.

U SBRSOS

BR-2

Page 3 of 21

BRAKE HYDRAULIC LINE

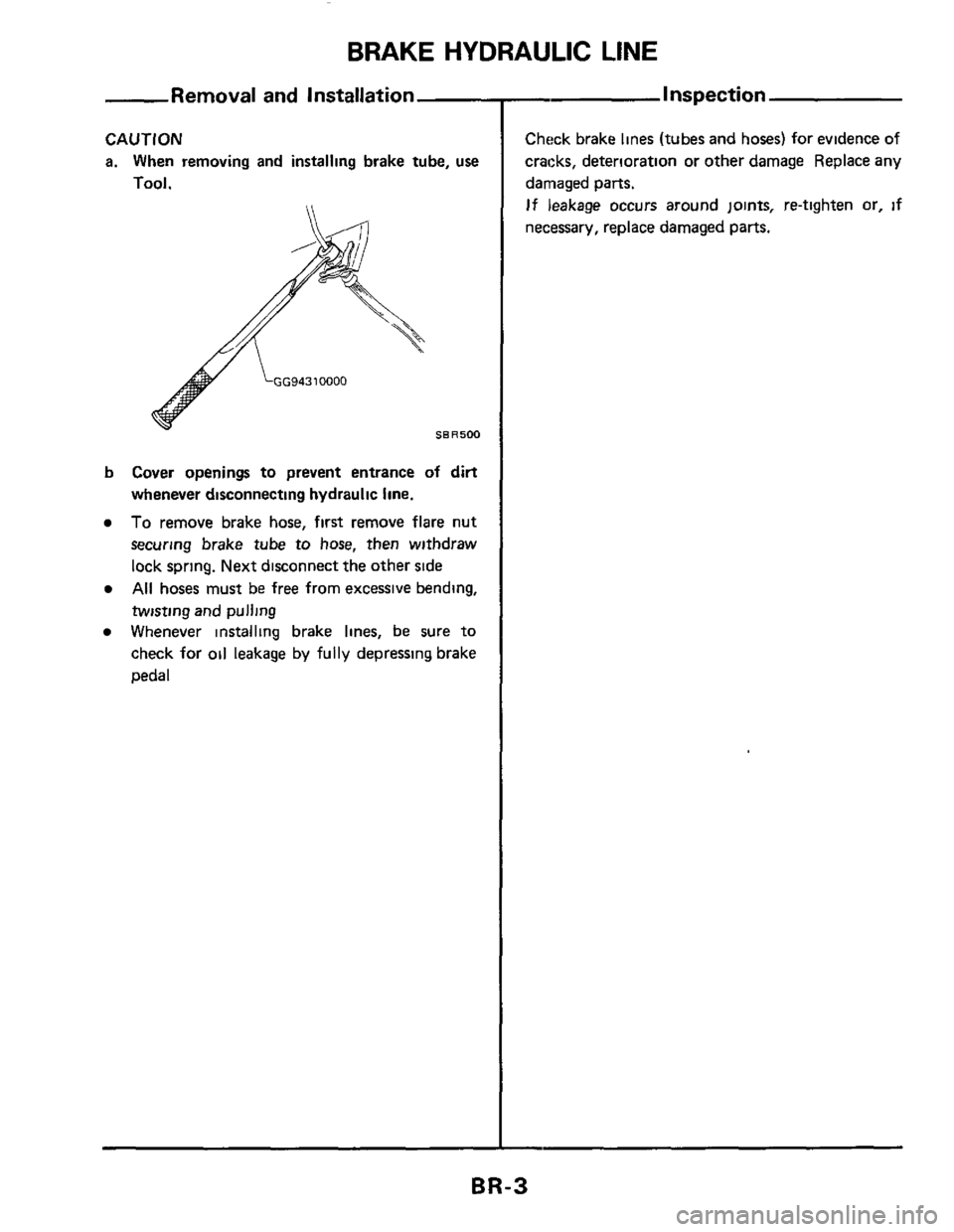

Removal and Installation

CAUTION

a. When removing and installing brake tube, use

Tool.

b Cover openings to prevent entrance of dirt

whenever disconnecting hydraulic line.

To remove brake hose, first remove flare nut

securing brake

tube to hose, then withdraw

lock spring. Next disconnect the other side

All hoses must be free from excessive bending,

twisting and pulling

Whenever installing brake lines, be sure to

check for

oil leakage by fully depressing brake

pedal

- Inspection

Check brake lines (tubes and hoses) for evidence of

cracks, deterioration or other damage Replace any

damaged

parts.

If leakage occurs around joints, retighten or, if

necessary, replace damaged parts.

BR-3

Page 4 of 21

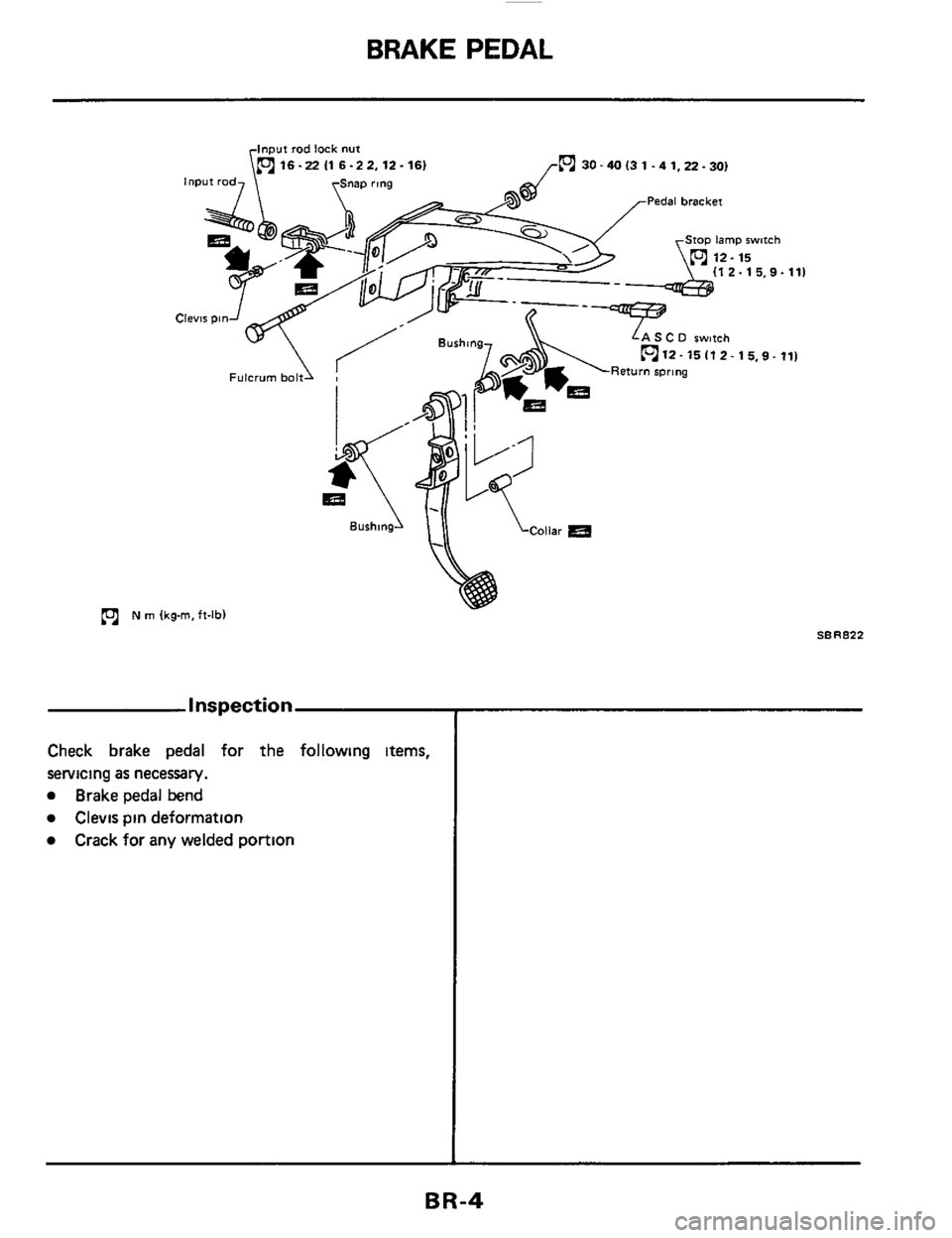

BRAKE PEDAL

Input rod lock nut

30-40 I3 1.4 1,ZZ- 30)

Pedal bracket

Stop lamp switch

I1 2. 15,9- 111

N rn lkg-m, ft-lb)

Inspection

Check brake pedal for the following items,

servicing

as necessary.

Brake pedal bend

Clevis pin deformation

Crack for any welded portion

SBR822

BR-4

Page 5 of 21

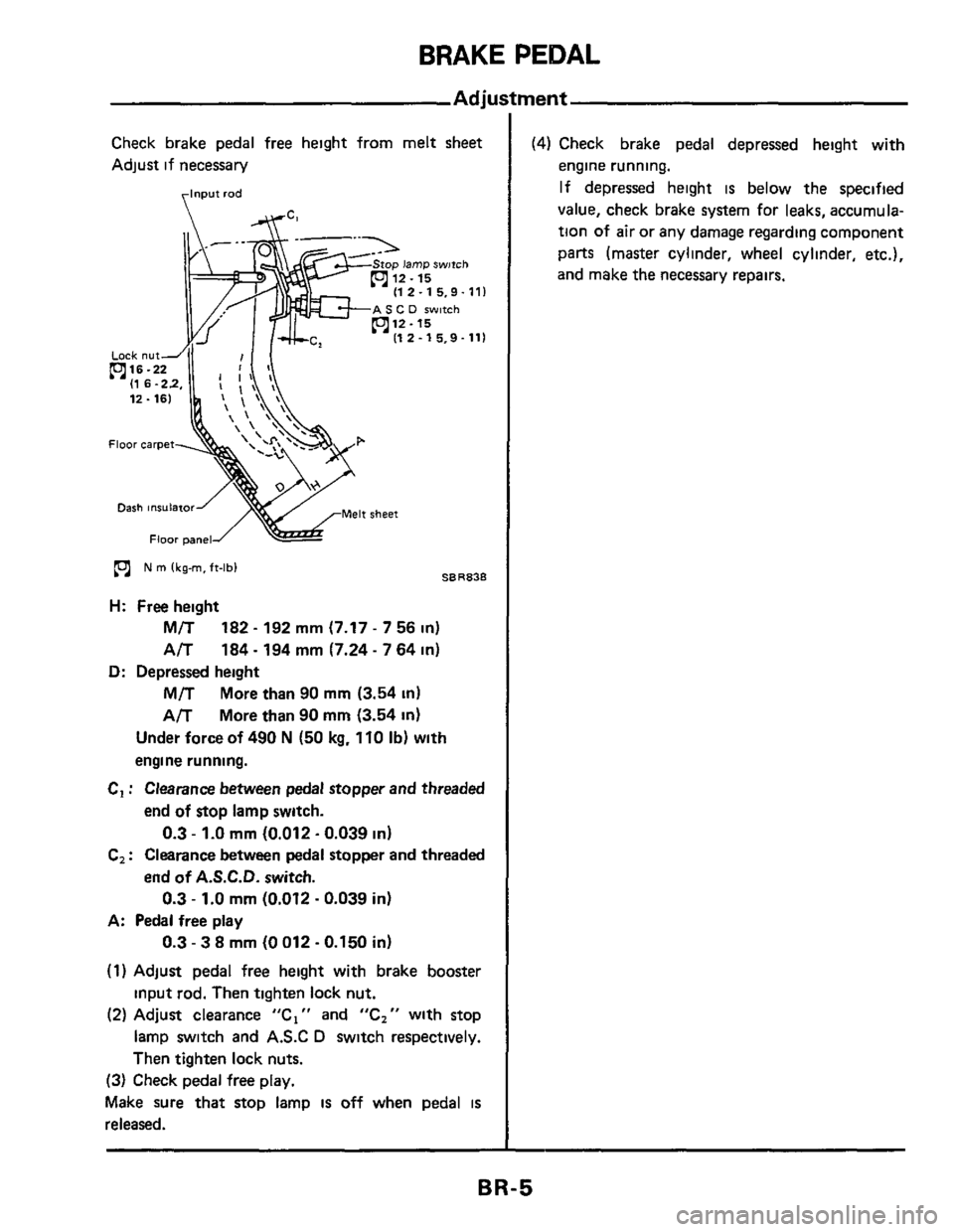

BRAKEPEDAL

Adjustment

Check brake pedal free height from melt sheet

Adjust

if necessary

I1 2.15.9- 111

AS C D switch

I /-k I1 2 - 1 5,9.111

Dash insulator

N m 1kg-m. ft-lbl

sheet

SERE38

H: Free height

M/T

A/T

D: Depressed height

M/T

A/T

I82 - 192 mm (7.17 - 7 56 in)

184 - 194 mm (7.24 - 7 64 in)

More than

90 mm (3.54 in)

More than 90 mm (3.54 in)

Under force of 490 N (50 kg. 110 Ib) with

engine running.

C, : Clearance between pedal stopper and threaded

end

of stop lamp switch.

Cz : Clearance between pedal stopper and threaded

end of A.S.C.D. switch.

0.3 - 1.0 mm (0.012 ~ 0.039 in)

0.3 - 1.0 mm (0.012 - 0.039 in)

0.3 - 3 8 mm (0 012 - 0.150 in)

A: Pedal free play

(1) Adjust pedal free height with brake booster

input rod. Then tighten lock nut.

(2) Adjust clearance "C1" and "C2" with stop

lamp switch and A.S.C

D switch respectively.

Then tighten lock nuts.

(3) Check pedal free play.

Make sure that

stop lamp is off when pedal is

released.

(4) Check brake pedal depressed height with

engine running.

If depressed height

is below the specified

value, check brake system for leaks, accumula-

tion of

air or any damage regarding component

parts (master cylinder, wheel cylinder, etc.),

and make the necessary repairs.

BR-5

Page 6 of 21

I

I

t13aNllA3 t131SVW

Page 7 of 21

BRAKE BOOSTER

Operating Check

Depress brake pedal several times with engine

off, then check that there

is not change in

pedal stroke

Depress brake pedal, then

start engine. If pedal

goes down slightly, operation

is normal

Airtight Check

Start engine, then stop it in one or two minutes.

Depress brake pedal several times slowly. If

pedal goes further down the

first time, but

gradually

rises after second or third time, the

booster

is airtight.

Depress brake pedal while engine

is running,

then stop

it with pedal depressed. If there is

no change in pedal stroke after holding pedal

for thirty seconds, brake booster

is airtight

--Removal and Installation

(9116-22 (1 6 -2 2.12.16

(91 8. 11 (0 8. 1.1,5.8.8.01 1

8 - 11 (0 8 - 1 1,5.8.8.01

SBR831 (c1 N rn (kg-m, ft-lbl

BR-7

Page 8 of 21

BRAKE BOOSTER

Inspection

HOSES AND CONNECTORS

0 Check condition of vacuum hoses and con-

0 Check vacuum hoses and check valve for air

nections.

tightness

68R832

CHECK VALVE

0 When pressure is applied to the brake booster

side of check valve and valve does not open,

replace check valve with

a new one.

Manlfold %de Brake booster ride

S8R846

OUTPUT ROD LENGTH

PV servo cannot be adjusted as output rod thread

portion

is secured by adhesive

Adjustment

INPUT ROD LENGTH

Adjust length by turning Clevis.

Length "B":

140 mm (5.51 in1

BR-8

Page 9 of 21

FRONT DISC BRAKE (CL28VA, CL28VB) - Caliper

CAUTION:

When cylinder body

IS open, do not depress brake

pedal, or piston

w~ll pop out.

1. Remove pin bolt.

SBR~

Toraue member fixing bolt- rWear indicator

2. Open cylinder body upward. Then remove pad

retainer, and Inner and outer shims

SBR825

Be careful not to damage piston boot or get oil on

rotor. Always replace shims in replacing pads.

/ / /rlnner~hm [9) 72 - 97 (7 3.9 9,53.721

Sub p~n =@ to rildlng portion

Rubber bushing

Retainer bushing Pin boot1 hetamer boot

=@ P B c IPOI~ ~utyl Cupryrill grease or rhcone-based grease Pomt =@ Rubber grease point I Always replace when disassembled (c1 N m Ikg-rn. ft-lbl

SEI3824

Page 10 of 21

FRONT DISC BRAKE (CL28VA, CL28VB) - Caliper

Removal and Installation

Remove torque member fixing bolts and brake

hose connector

SBR839

Disassembly

Push out piston with dust seal using compressed

air

SER772

Inspection

CAUTION: Use brake fluid to clean. Never

use mineral oil

CYLINDER BODY

a Check inside surface of cylinder for score, rust,

wear, damage or presence of foreign materials.

If any of the above conditions

are observed,

replace cylinder body.

Minor damage from rust of foreign materials

may be eliminated by polishing surface with

a

fine emery paper. Replace cylinder body if

necessary.

a

PISTON

Check piston for score, rust, wear, damage or

presence of foreign materials. Replace if any of

the above conditions are observed.

CAUTl ON :

Piston sliding surface IS plated. Do not polish with

emery paper even if rust

or foreign materials IS

stuck to sliding surface.

PIN, PIN BOLT, RETAINER BOOT, RUBBER

BUSHING, RETAINER BUSHING, AND

PIN

BOOT

Check for wear, cracks or other damage. Replace

if any of the above conditions are observed

0

0

Properly secure dust seal.

a

With dust seal fitted to piston, insert dust seal

into groove on cylinder body and install piston.

Pay attention to piston

seal direction.

y000t n

PlStO"

Plrron seal

ULdU

LCvlinder body SBR574

BR-10