transmission NISSAN 300ZX 1984 Z31 Automatic Transmission Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 2 of 99

DESCRIPTION OF E4N71B

I

The Model E4N71B automatic transmission is the

latest addition to Niaan's lineup

of transmissions.

This transmission

is based on the model L4N71B

(mounted on the 1983 model 810), and can pro-

vide lockup of

all forward speeds (1st to 4th speed)

by electronic control.

By use of a microcomputer, the electronic-control-

led lockup system permits lockup of

all forward

speeds (1st to 4th speed)

Either shifting pattern ("standard" or "power")

is

automatically selected by programs set in the

lockup control unit depending on the speed

at

which the accelerator pedal is depressed These

programs are

set in response to the vehicle speed

and throttle position

rlnhibitor switch \Lockup control unit

/;?\I!

LPower Shift switch and mdtcator

Stop lamp rwlrch

\Kickdown switch

Downshift solenoid

Shift switch and low temperature sensor

Throttle valve rwitchl 0 indicator

Lockup solenoid 0 D cancel solenoid

SAT7M

AT-2

Page 4 of 99

GENERAL SERVICE NOTICE

Repai

Before proceeding with disassembly, thorough-

ly clean the outside of the transmission It IS

important to prevent the internal parts of the

transmission from becoming contaminated by

dirt or other foreign matter.

Disassembly should

be done in a clean work

area. Use

a nylon cloth or paper towel for wiping

parts clean. Common

shop rags can leave lint

that might interfere with the transmission's

operation.

When disassembling parts, be sure to place

them in order

in parts rack so they can be put

back in the unit

in their proper positions

All parts should be carefully cleaned with a

general purpose, non.flammable solvent before

inspection or reassembly.

Gaskets,

seals, and O-rings should be replaced.

It is also very important to perform functional

tests whenever it is designated.

The valve body contains many precision parts

Contri

CONTROL VALVE UPPER BODY

3rd4th shift valve7

Pressure I

Uotes

and requires extreme care when parts are

removed and serviced. Place removed parts on

a parts rack so they can be put back in the

valve body in the same positions and

se-

quences. Care will also prevent springs and

small parts from becoming scattered or

lost

Before assembly, apply a coat of recommended

A

T.F. to all parts Vaseline may be applied to

O-rings and

seals. Do not use any grease.

Care should be taken to avoid damaging

O-rings, seals and

gaskets when assembling

Abbreviations used throughout this section stand

for the following.

A.T.F. ... Automatic transmission fluid

D, ........ Drive range 1st gear

D, .... ... Drive range 2nd gear

D, . . ... Drive range 3rd gear

D4 ........ Drive range 4th gear

0.D . .... Overdrive

1, ....... . 1 range 2nd gear

1, . . .... 1 range lstgear

Valve

Vacuum throttle valve

f rThrottle back-up valve

1st 2nd shift valve

2nd3rd shift valve

Second lock valve -i

SAT742

AT-4

Page 6 of 99

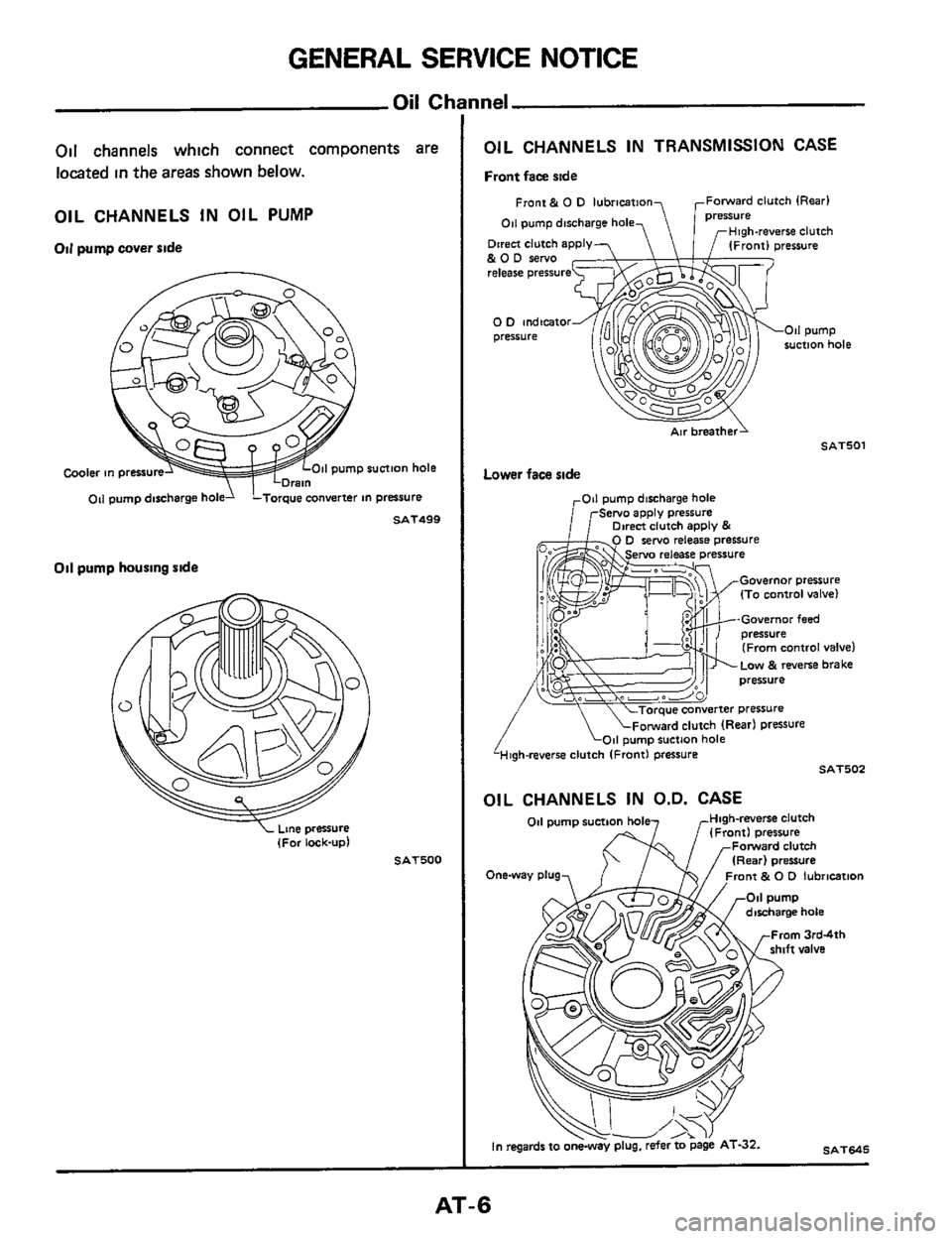

GENERAL SERVICE NOTICE

Oil Channel

Oil channels which connect components are

located in the

areas shown below.

OIL CHANNELS IN OIL PUMP

Oil pump cover ride

11 pump suction hole Cooler in pressure

011 pump discharge hold LTorque converter in pressure

Oil pump housing ride

ne oressure

SAT499

SAT500

OIL CHANNELS IN TRANSMISSION CASE

Front face rlde

Front & 0 D lubrication Forward clutch (Rear1

gh-reverse clutch

011 pump discharge hole

Direct clutch apply &OD sew0 release pressure

0 0 indicator pressure

SAT501

Lower face side

Governor pressure (To control valve)

Governor feed

(From control

valve)

LOW & reverse brake

High-reverse clutch IFrontl pressure SAT502

ii

OIL CHANNELS IN O.D. CASE

011 pump suction hole Hlgh-reverse clutch (Front1 pressure

Forward clutch

(Rear) Oresure

ront & 0 D lubrication

SAT645 In regards to oneway plug. refer to page AT-32.

AT-6

Page 7 of 99

GENERAL SERVICE NOTICE

I (Cont'd) Oil Cham

OIL CHANNELS IN DRUM SUPPORT OIL CHANNELS IN CONVERTER HOUSING

To lock-up ~ontrol valve

rDrain (E4N71Bl

clutch (Front)

Forward clutch

clutch pressure Front & 0 0 lubrmtmn

SAT706

3peration Mechanic:

In the E4N71B and 4N71B automatic transmission, each part operates as shown in the following table at

each gear select position

'arking

pawl

Htgh-

'everse

Front) Forward clutch (Rear) 0 D band servo Direct

clutch Range -

Release

ON ON

1 Reverse 1 ON 1 ION) ON

+-

ON I

I Neutral I ON I (ON) ON

T-

ON

-

ON

-

ON

ON

JT

I ION

'34

(0 D 1 ON I ON

Second I ON I (ON) ON

1 ON I (ON) 12

(Second) ON ON I ON

ON ord ON I I ON

The low & reverse brake IS applied In "1 I" range to prevent free wheeling when coasting and allows engine braking.

AT-7

Page 10 of 99

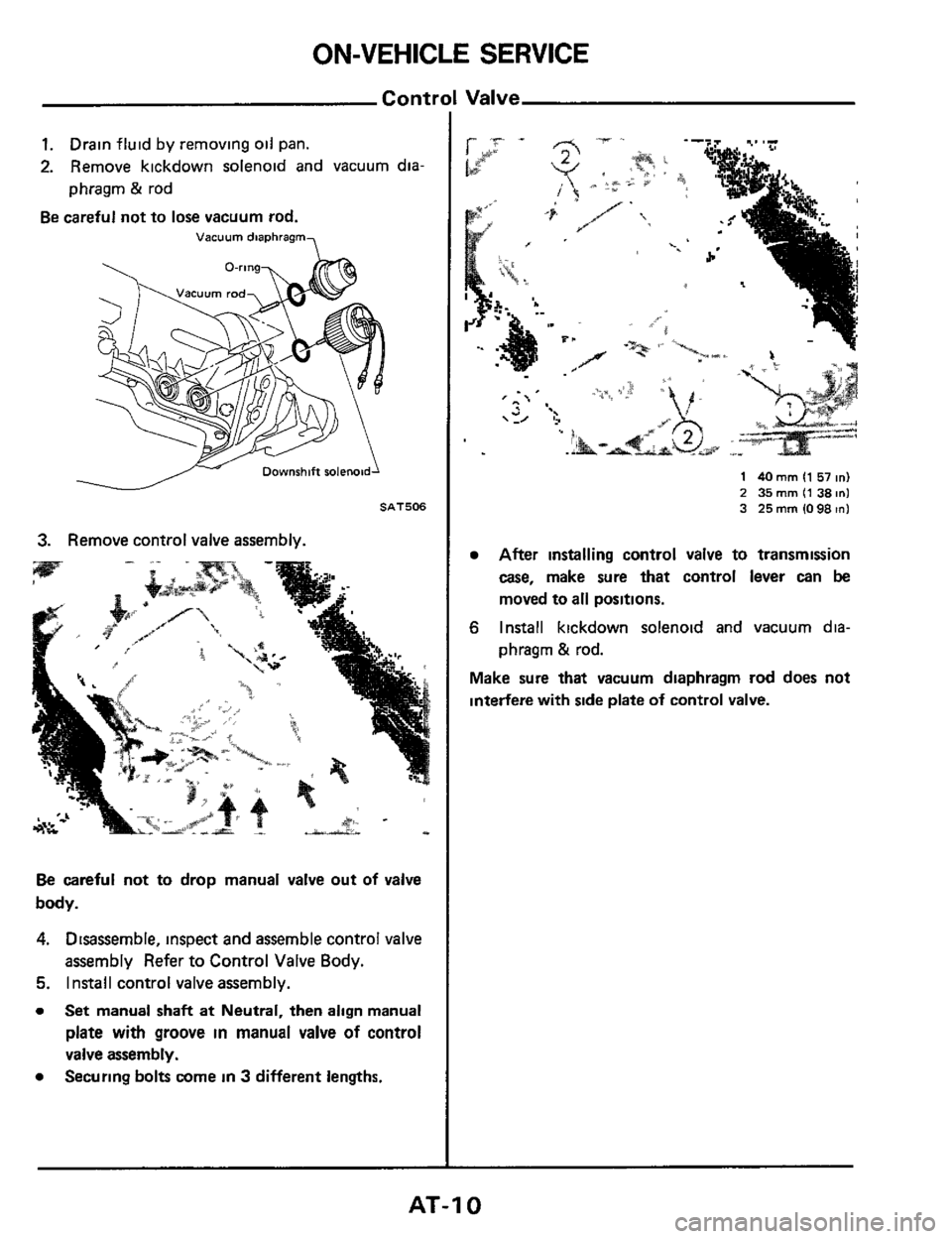

ON-VEHICLE SERVICE

Contrl

1. Drain fluid by removing oil pan.

2. Remove kickdown solenoid and vacuum dia

phragm

23 rod

Be careful not to lose vacuum rod.

Vacuum diaphragm

SAT506

3. Remove control valve assembly.

Be careful not to drop manual valve out of valve

body.

4. Disassemble, inspect and assemble control valve

assembly Refer to Control Valve Body.

5. Install control valve assembly.

0 Set manual shaft at Neutral, then align manual

plate with groove in manual valve of control

valve assembly.

Securing bolts come

in 3 different lengths. 0

1 40 mm I1 51 in) 2 35 mm (1 38 in1 3 25mm1098mI

After installing control valve to transmission

case, make sure that control lever can be

moved to all positions.

6 Install kickdown solenoid and vacuum dia-

phragm

& rod.

Make sure that vacuum diaphragm rod does not

interfere with side plate

of control valve.

AT-I 0

Page 14 of 99

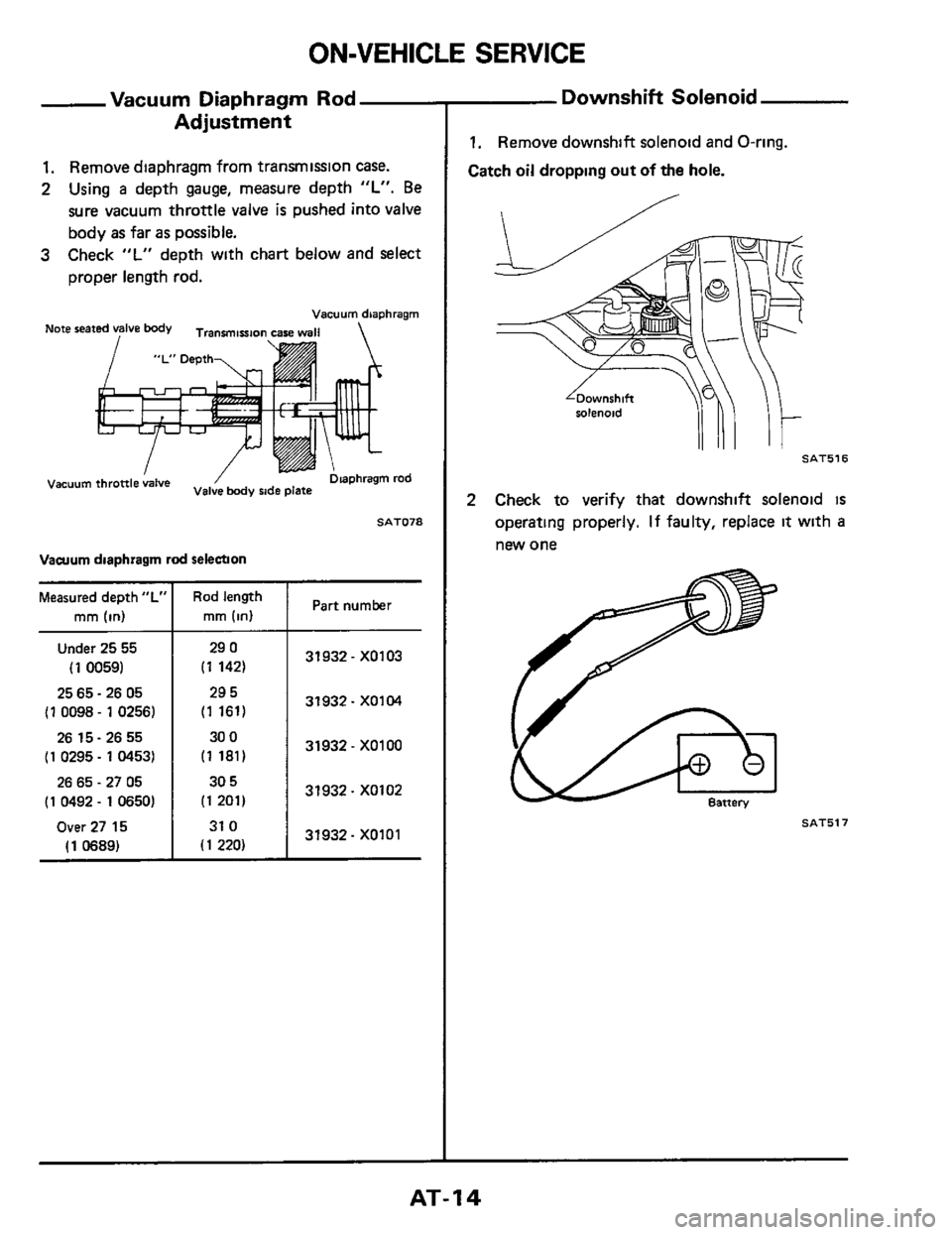

Vacuum Diaphragm Rod

Adjustment

1. Remove diaphragm from transmission case.

2 Using a depth gauge, measure depth "L". Be

sure vacuum throttle valve is pushed into valve

body

as far as possible.

3 Check "L" depth with chart below and select

proper length rod.

Measured depth "L"

mm (in)

Under 25 55

(1 0059)

25 65

- 26 05

(1 0098

- 1 0256)

26 15

- 26 55

(1 0295 - 1 0453)

26 65

- 27 05

(1 0492 - 1 0650)

Over 27 15

(1 0689)

Vacuum diaphragm

Rod length

mm (in)

29 0

(1 142)

29 5

(1 161)

30

0

(1 181)

30 5

(1 201)

31

0

(1 220)

Vacuum diaphragm

I1

rod

SAT078

Part number

31932- X0103

31932 - XO104

31932- XOlOO

31932- X0102

31932. XOlOl

Downshift Solenoid

1. Remove downshift solenoid and O-ring.

Catch

oil dropping out of the hole.

SAT516

2 Check to verify that downshift solenoid is

operatmg properly. If faulty, replace it with a

new one

SAT517

AT-I4

Page 15 of 99

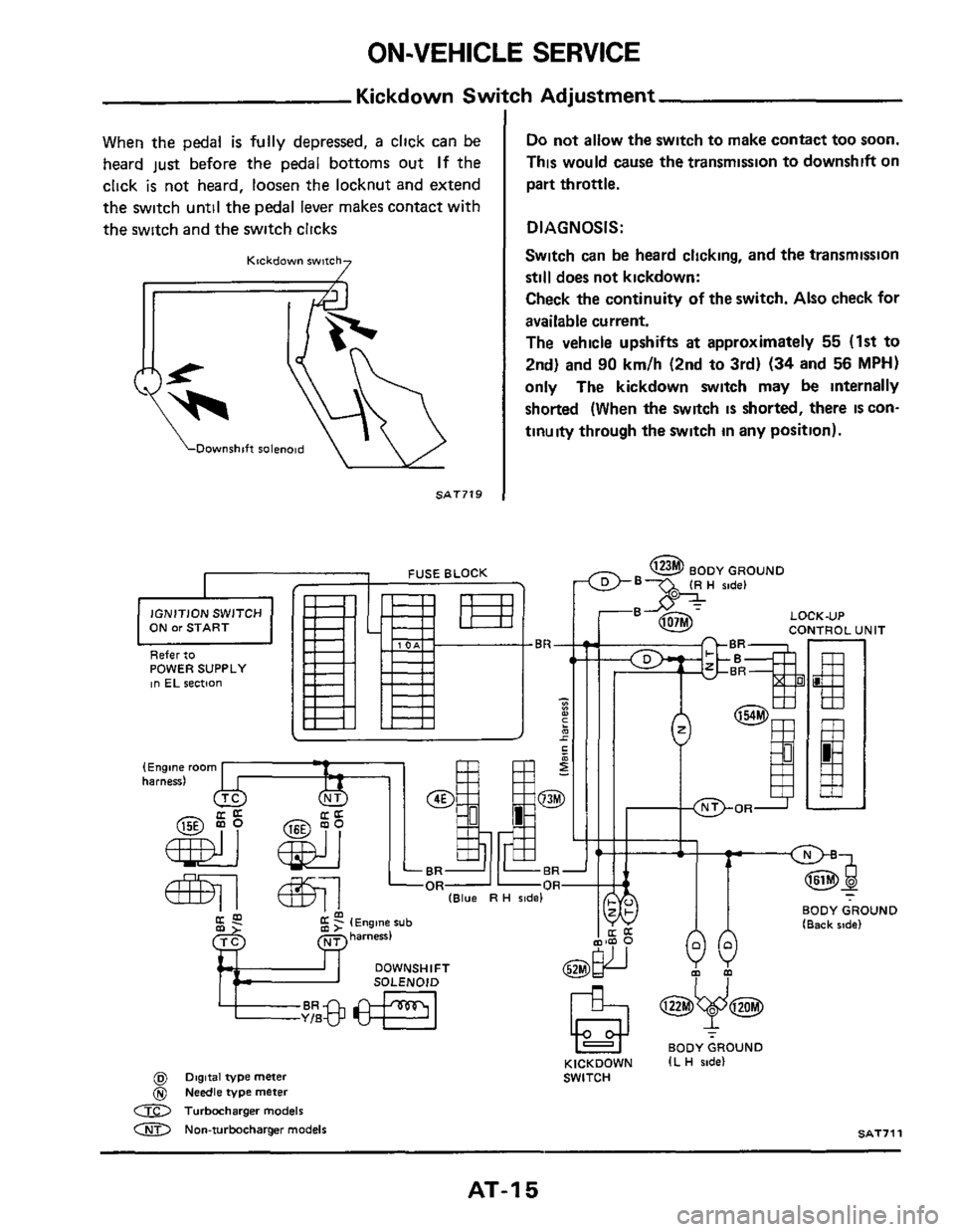

ON-VEHICLE SERVICE

Kickdown Switch Adjustment

When the pedal is fully depressed, a click can be

heard just before the pedal bottoms out

If the

click

is not heard, loosen the locknut and extend

the switch until the pedal lever makes contact with

the switch and the switch clicks

Kickdown switch 7

F$i& Downshift solenold

qi& Downshift solenold

SAT719

Do not allow the switch to make contact too soon.

This would cause the transmission to downshift on

part throttle.

DIAGNOSIS:

Switch can be heard clicking, and the transmission

still does not kickdown:

Check the continuity of the switch.

Also check for

available current.

The vehicle upshifts

at approximately 55 (1st to

2nd) and

90 kmlh (2nd to 3rd) (34 and 56 MPH)

only The kickdown switch may be internally

shorted (When the switch

is shorted, there IS con-

tinuity through the switch in any position).

AT-I 5

Page 18 of 99

REMOVAL AND INSTALLATION

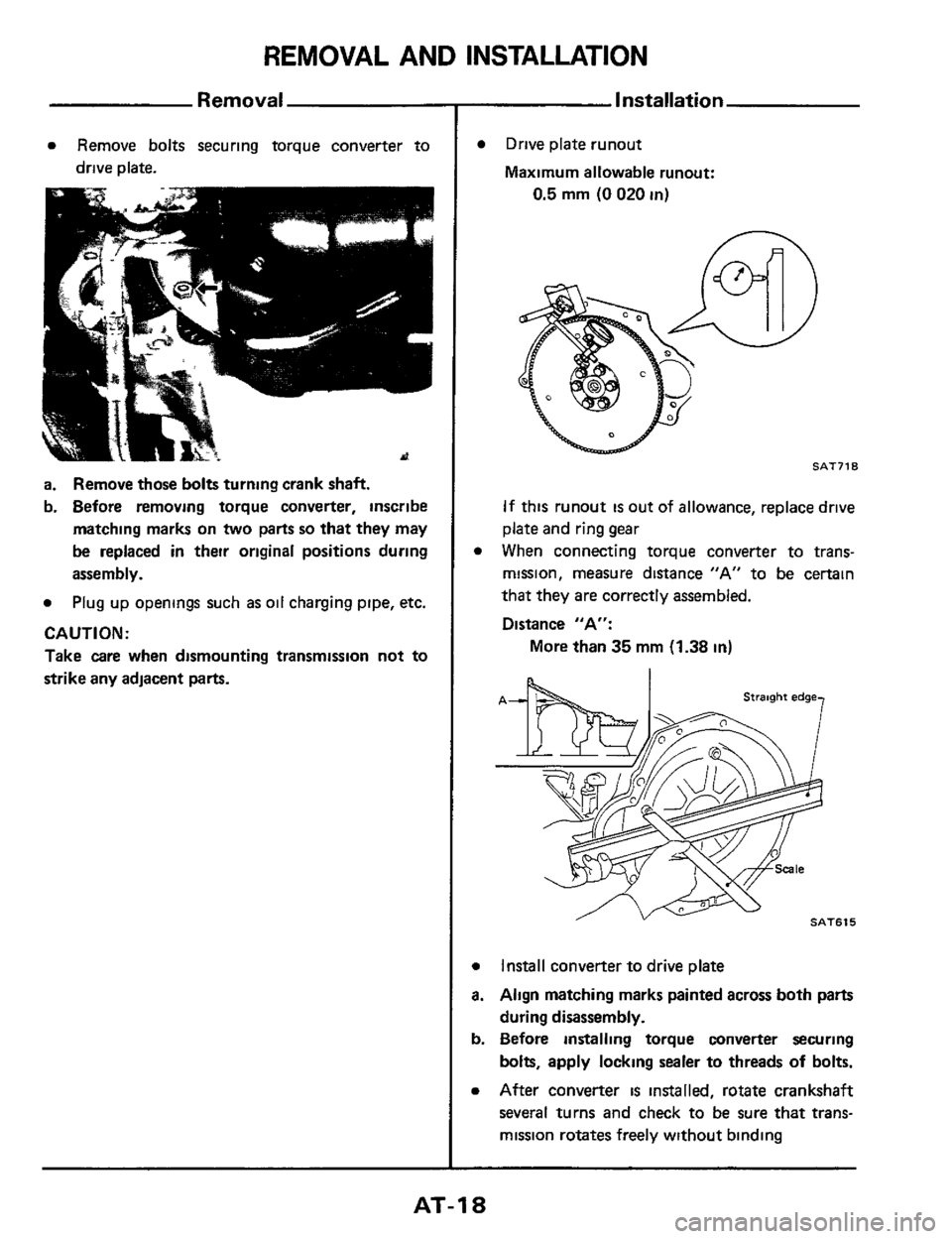

Removal

a Remove bolts securing torque converter to

drive plate.

a. Remove those bolts turning crank shaft.

b. Before removing torque converter, inscribe

matching marks on

two parts so that they may

be replaced in their original positions during

assembly.

a Plug up openings such as oil charging pipe, etc.

CAUTl ON :

Take care when dismounting transmission not to

strike any adjacent

parts.

Installation

0

a

a.

b.

a

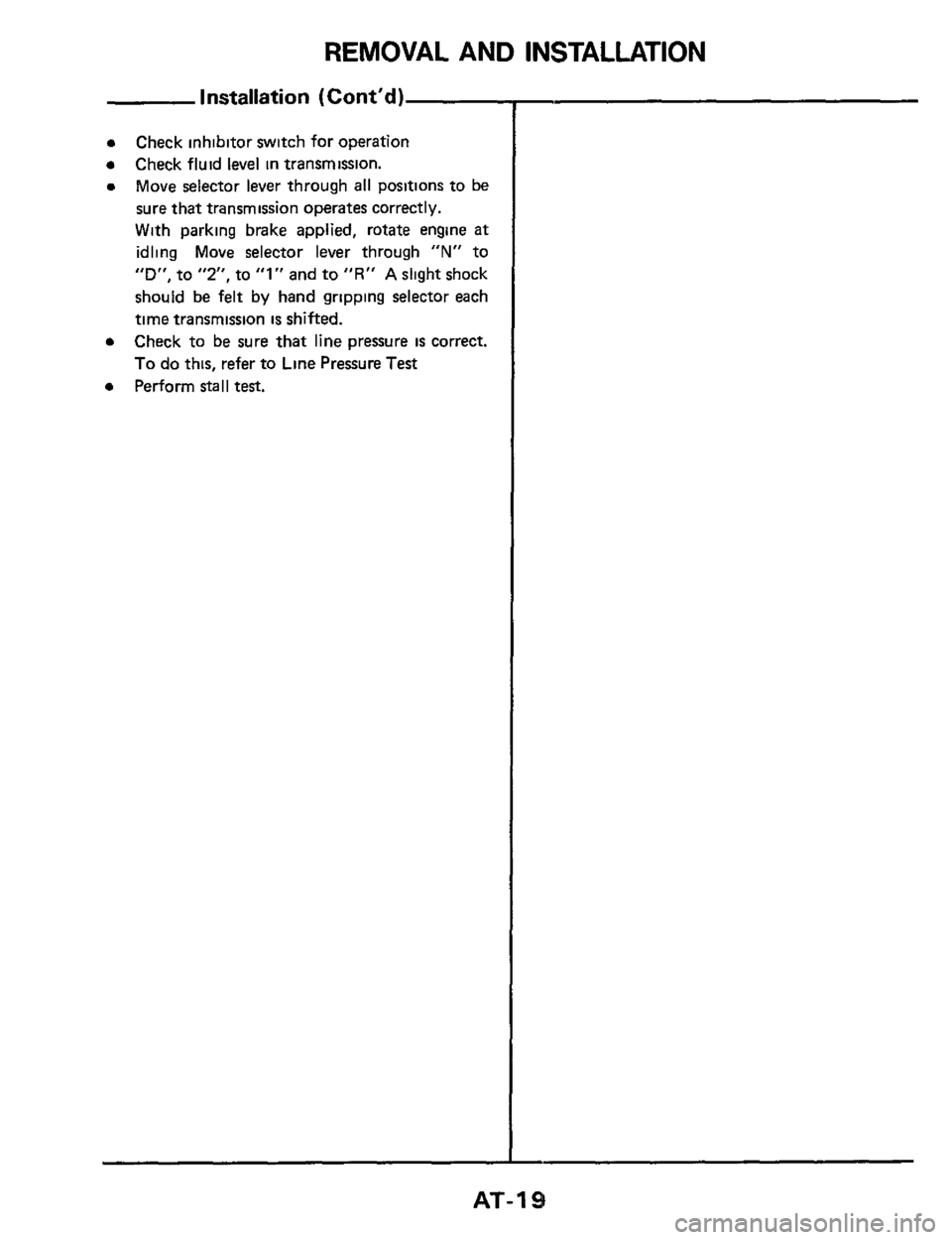

Drive plate runout

Maximum allowable runout:

0.5 mm (0 020 in)

n

SAT718

If this runout is out of allowance, replace drive

plate and ring gear

When connecting torque converter to trans-

mission, measure distance "A" to be certain

that they are correctly assembled.

Distance "A":

More than

35 mm (1.38 in)

Install converter to drive plate

Align matching marks painted across both parts

during disassembly.

Before installing torque converter securing

bolts, apply locking sealer to threads

of bolts.

After converter is installed, rotate crankshaft

several turns and check to be sure that trans-

mission rotates freely without binding

AT-I 8

Page 19 of 99

REMOVAL AND INSTALLATION

installation (Cont'd)

Check inhibitor switch for operation

Check fluid level

in transmission.

Move selector lever through

all positions to be

sure that transmission operates correctly.

With parking brake applied, rotate engine

at

idling Move selector lever through "N" to

"D", to "2". to "1" and to "R" A slight shock

should

be felt by hand gripping selector each

time transmission

is shifted.

Check to be sure

that line pressure is correct.

To do this, refer to Line Pressure Test

Perform stall test.

AT-I 9,

Page 53 of 99

ASSEMBLY

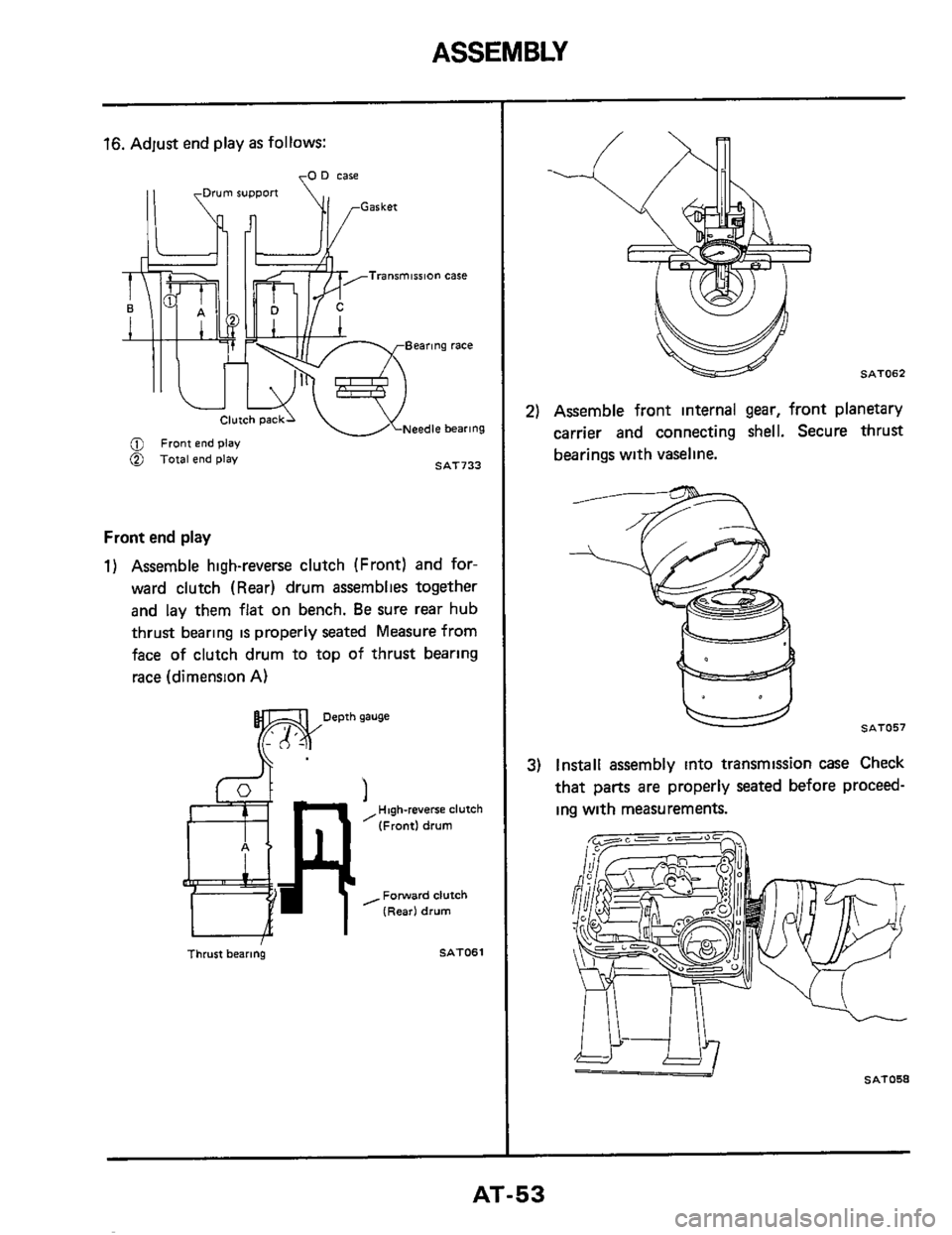

16. Adjust end play as follows:

rO 0 case

SAT733 5 Total end play

Front end play

1) Assemble high-reverse clutch (Front) and for-

ward clutch (Rear) drum assemblies together

and lay them

flat on bench. Be sure rear hub

thrust bearing

is properly seated Measure from

face of clutch drum to top

of thrust bearing

race (dimension A)

Hgh-reverse clutch

(Front) drum

,Forward clutch

(Rear1 drum

Thrust bearing 4 SAT061

SAT062

2) Assemble front internal gear, front planetary

carrier and connecting shell. Secure thrust

bearings with vaseline.

L4 SAT057

3) Install assembly into transmission case Check

that

parts are properly seated before proceed-

ing with measurements.

SAT058

AT-53