Turbo NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 1 of 79

ENGINE FUEL &

- EMISSION - CONTROL SYSTEM

SECTION EFaEC

CONTENTS

PRECAUTIONS ..

COMPONENT PARTS LOCATION

ECCS DIAGRAM

. . .

ECCS CHART ..

ECC.S WIRING DIAGRAM . . ..

FUEL FLOW SYSTEM DESCRIPTION .

AIR FLOW SYSTEM DESCRIPTION ....

E C C S. DESCRIPTION . . . . ...

DIAGNOSTIC PROCEDURE . ..

SE LF-D I AGNOSIS ..

..

.. ..

..

..

..

...

ELECTRONfC CONTROL SYSTEM INSPECTION

MIXTURE RATIO FEEDBACK SYSTEM INSPECTION

. ,

FUEL SYSTEM INSPECTION

TURBOCHARGER

. ... ..

INJECTOR COOLING FAN (VG30ET) .

PRESSURE REGULATOR CONTROL

CRANKCASE EMISSION CONTROL SYSTEM

. . . .

EXHAUST EMISSION CONTROL SYSTEM . . ...

EVAPORATIVE EMISSION CONTROL SYSTEM . . .

SERVICE DATA AND SPECIFICATIONS (S DS). . . . . . .

. . EF&EC- 2

. EF&EC- 3

EF & EC- 4

EF&EC- 6

EF&EC- 8

.. EF & EC-10

EF

& EC-11

, EF&EC-13

EF

& EC-28

EF

& EC-35

EF

& EC43

EF & EC-60

EF

& EC-63

EF

& EC-66

EF

& EC-69

EF

& EC-72

. . EF & EC-74

EF

& EC-75

, EF&EC-76

EF & EC-79

Page 4 of 79

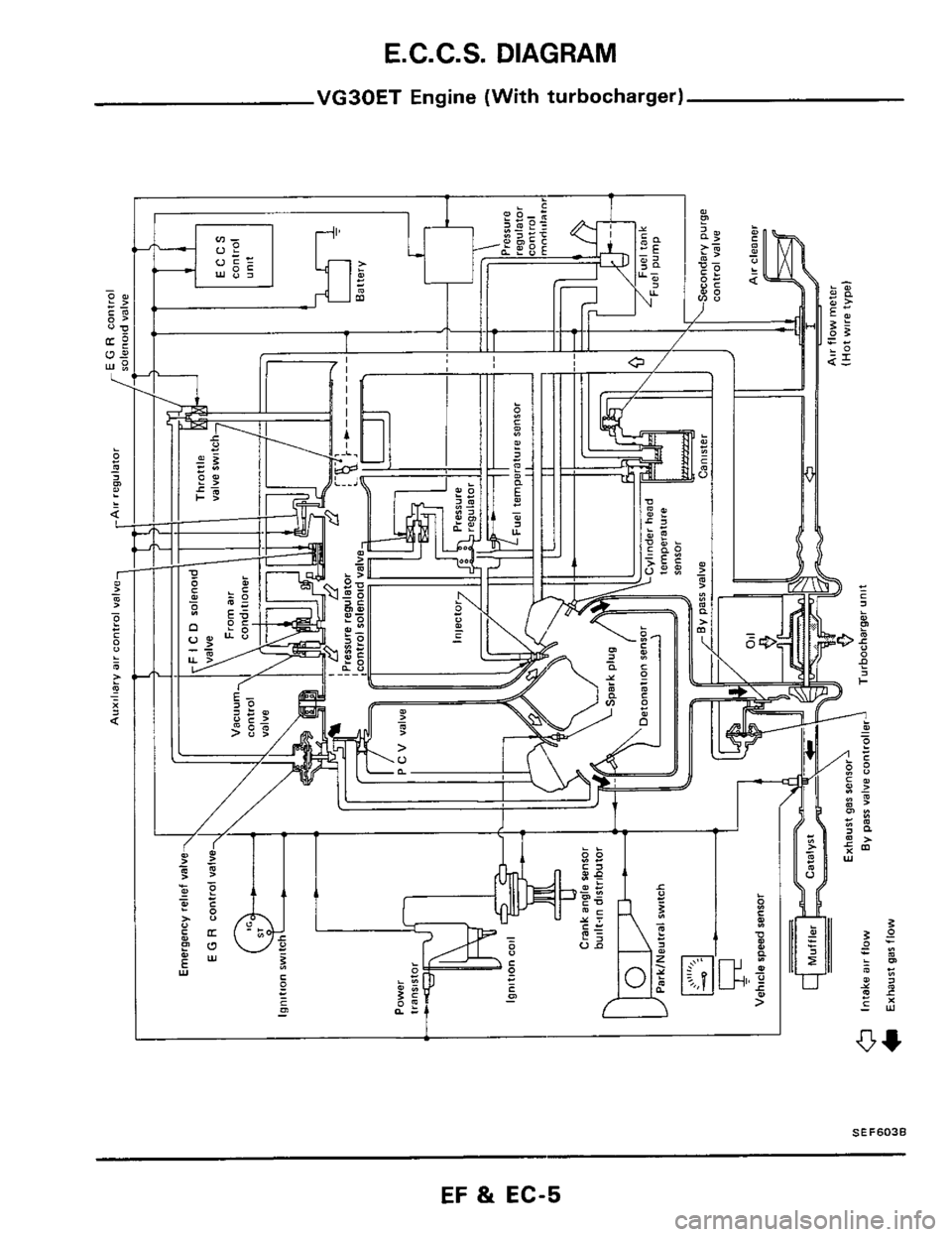

E. C.C. S. DIAGRAM

VG30E Engine (Without turbocharger)

SEF602B

EF & EC-4

Page 5 of 79

E.C.C.S. DIAGRAM

VG30ET Engine (With turbocharger)

L

SEF603B

EF & EC-5

Page 6 of 79

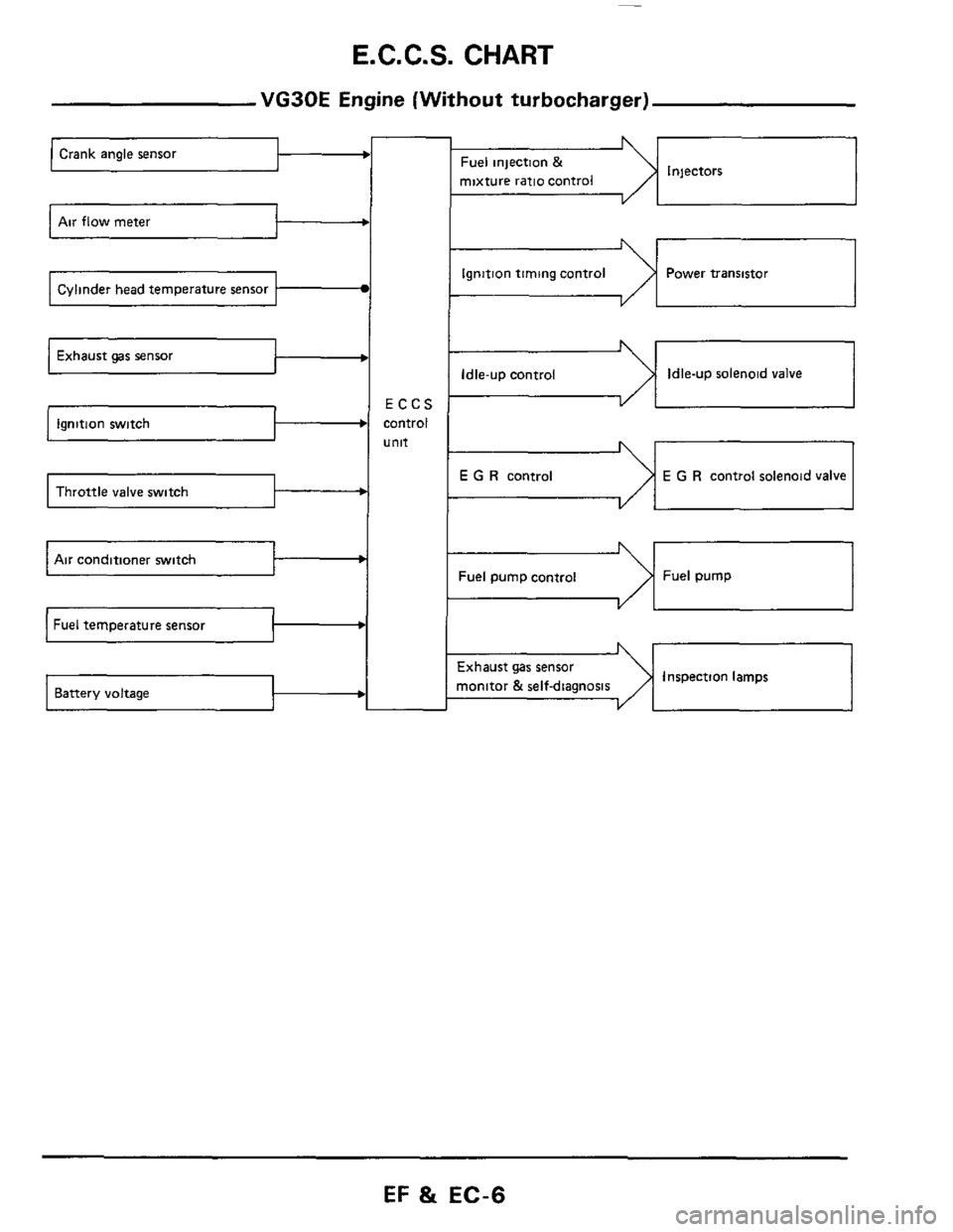

E.C.C.S. CHART

Exhaust gas sensor t

b

Throttle valve switch -b

VG30E Engine (Without turbocharger)

ECCS

control

unit

Crank angle sensor

%el pump control Fuel pump

Air conditioner switch 1 t

Battery voltage

- I

Injectors Fuel injection &

mixture ratio control

VI 1

1

Ignition timing control Power transistor

Idle-up control Idle-up solenoid valve

E G R control E G R control solenoid valve

-1 I

Inspection lamps ixhaust gas sensor

nonitor

& self-diamosis

EF & EC-6

Page 7 of 79

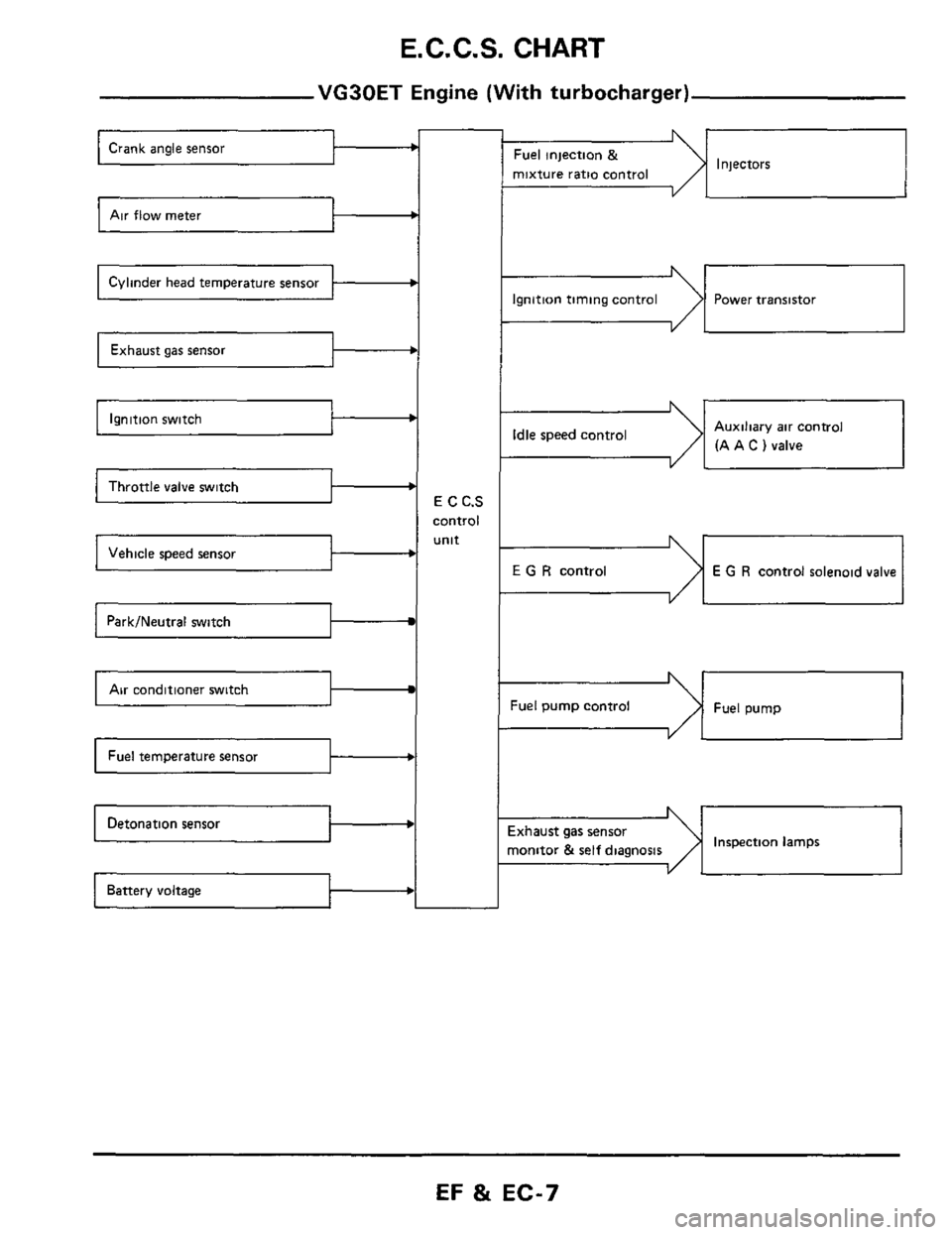

E. C. C.S. CHART

VG30ET Engine (With turbocharger)

Air flow meter c

Cylinder head temperature sensor b

b

Ignition switch b

Throttle valve switch I b

b

Park/Neutral switch

Air conditioner switch I

b

E C C.S

control

unit

b

Injectors Fuel injection &

mixture ratio control

--I

Ignition timing control Power transistor

-dI Auxiliary air control

(A A

C ) valve Idle speed control

I YL

E G R control E G R control solenoid valve

Fuel pump control Fuel pump

Inspection lamps ixhaust gas sensor

nonitor

& self diagnosis I

EF & EC-7

Page 11 of 79

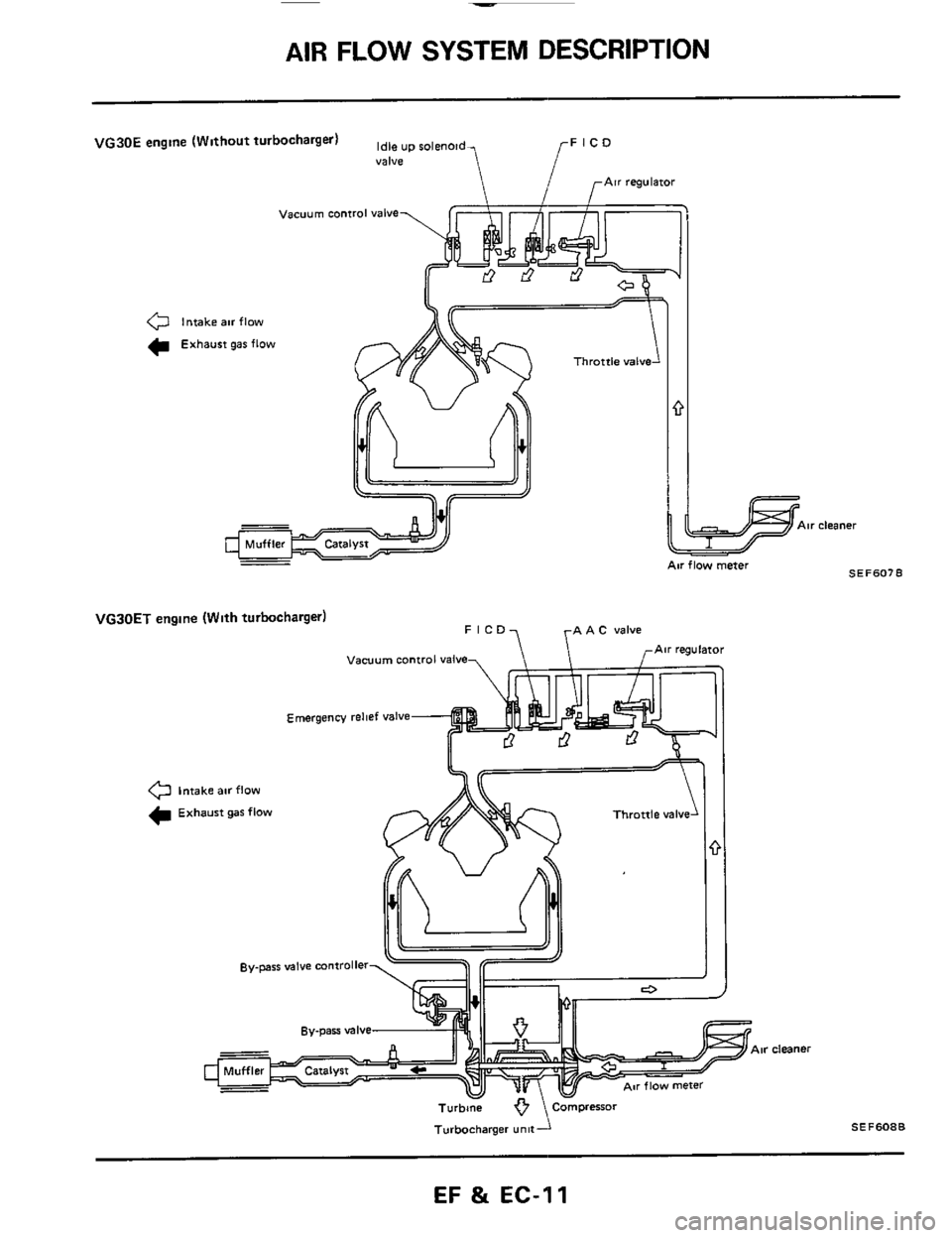

AIR FLOW SYSTEM DESCRIPTION

Air cleaner

VG30E engine (Without turbocharger) up roleno,,, FlCD

r

Valve

0 Intake air flow

C Exhaust gar flow

VGJOET engine (With turbocharger)

Vacuum control valve

Emergency relief valve

0 Intake air flow

Exhaust gar flow

cleaner

Turbbne

Turbocharger - unit- \Compresor SE F 608 B

EF & EC-11

Page 12 of 79

AIR FLOW SYSTEM DESCRIPTION

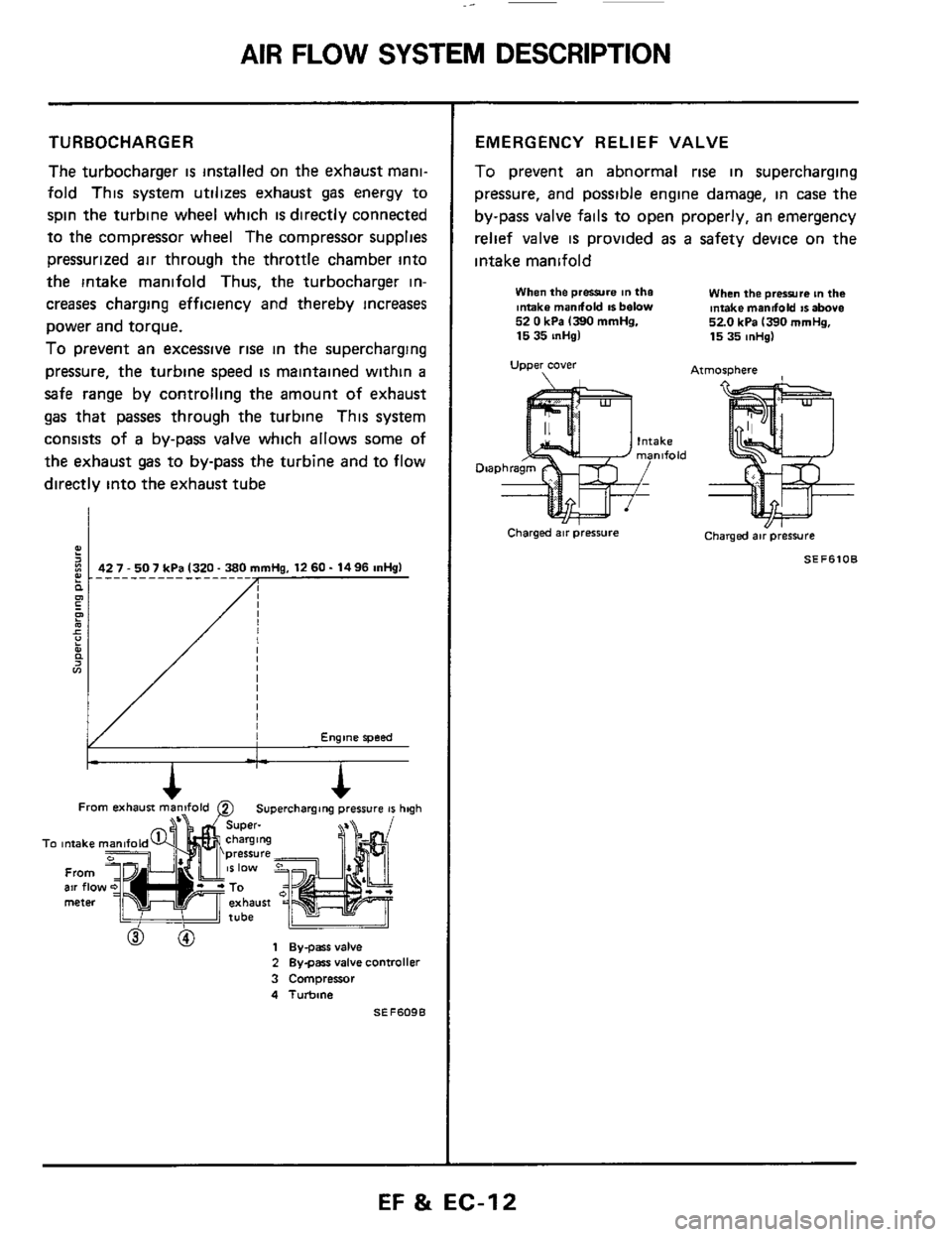

TURBOCHARGER

The turbocharger is installed on the exhaust mani-

fold This system utilizes exhaust gas energy to

spin the turbine wheel which

is directly connected

to the compressor wheel The compressor supplies

pressurized air through the throttle chamber into

the intake manifold Thus, the turbocharger in-

creases charging efficiency and thereby increases

power and torque.

To prevent an excessive rise in the supercharging

pressure, the turbine speed

is maintained within a

safe range by controlling the amount of exhaust

gas that passes through the turbine This system

consists of

a by-pass valve which allows some of

the exhaust gas to by-pass the turbine and to flow

directly into the exhaust tube

Engine speed

From b==iF exhausi man2fold 0 Superchargang pressure 41 hqh

To intake

From air flo meter

h

To intake

From air flo meter

2 Bygars valve controller

3 Compressor

4 Turbine

SEF609B

EMERGENCY RELIEF VALVE

To prevent an abnormal rise in supercharging

pressure, and possible engine damage, in case

the

by-pass valve fails to open properly, an emergency

relief valve

is provided as a safety device on the

intake manifold

When the prwre in the Intake mandold IS below 52 0 kPa 1390 mmHg. 15 35 inHgl

Upper cover

When the prerrura tn the intake mandold IS above 520 kPa 1390 mrnHg, 15 35 mHg)

Atmosphere

Charged air pressure Charged air pressure

SEF6lOB

EF & EC-12

Page 30 of 79

DIAGNOSTIC PROCEDURE

Driveabil

1. Inspect engine and E C C.S. for air leaks,

proper electrical connections, etc

1) Check all hoses and ducts for air leaks

2) Check air cleaner for clogging

3) Check harness connectors for proper connec-

tions

4) Check ignition wiring

5) Check gaskets for leaks at all air intake com-

ponents

6) Check E G.R valve operation

7) Check air regulator operation

2 Perform E C C S self-diagnosis

Follow the procedure in E CCS SELF-

DIAGNOSIS (Page EF & EC-35)

3 Check idle speed and ignition timing

a. Prepare the following conditions:

Headlampswitch' OFF

Heater blower: OFF

Air conditioner switch: OFF

Front wheel (Power steering model):

KEEP STRAIGHT AHEAD

b. Warm engine to operating temperature.

Check

and adjust as follows

[VG30E engine (Without turbocharger)]

1) Stop engine and disconnect idle-up solenoid

valve harness connector

Idle-up solenoid

2) Start engine and race engine two or three times

under no-load, then run engine

at idle speed

(Cont'd)

3) Check idle speed

M/T & A/T (in "D" position)

700250 rpm at sea level

650250 rpm at high altitude condition

If necessary, adjust to the specified

speed by

turning idle speed adjusting screw

I, SEF6456

4) Stop engine and connect idle-up solenoid valve

harness connector

5) Start engine and check ignition timing with

a

timing light

20ai2" B.T.D.C.

If necessary, adjust ignition

timing by turning

distributor

[VG30ET engine (With turbocharger)]

1) Race engine two or three times under no-load,

then run engine at idle speed

2) Check idle speed.

M/T: 70W50rpm

A/T: 650k50 rpm (in "D" position)

EF & EC-30

Page 33 of 79

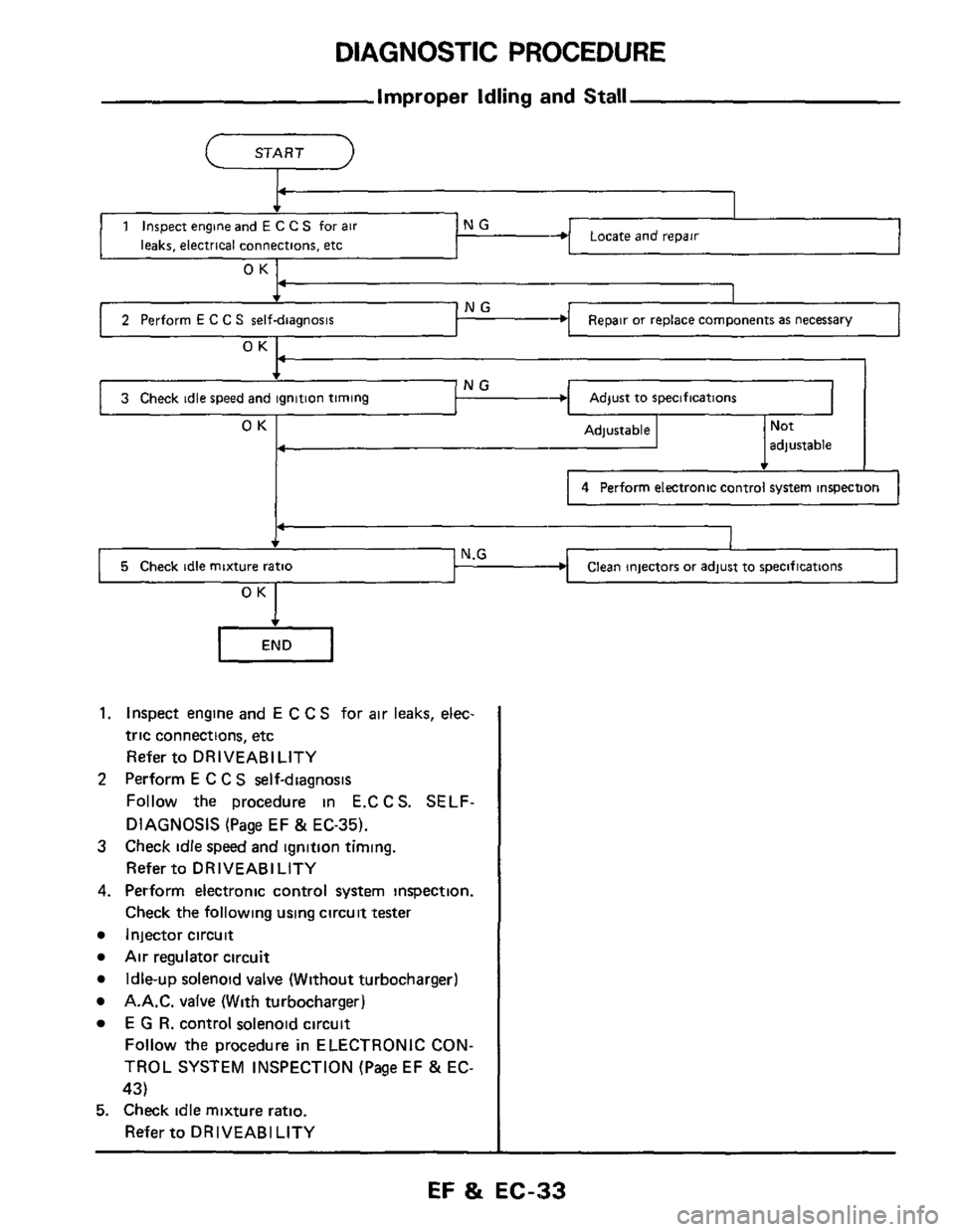

DIAGNOSTIC PROCEDURE

5 Check idle mixture ratio

Improper Idling and Stall

START 2

N.G Clean injectors or adjust to specifications

Locare ano repair

1

NG 4 I

2 Perform E C C S self-diagnosis Repair or replace components as necessary J OK

Adjust to specifications NG 3 Check idle speed and ignition timing

OK Adjustable adjustable

4 Perform electronic control system inspection

OK I

1. Inspect engine and E C C S for air leaks, elec-

tric connections, etc

Refer to DRIVEABILITY

Perform

E C C S self-diagnosis

Follow the procedure in E.CCS. SELF-

DIAGNOSIS

(Page EF & EC-35).

3 Check idle speed and ignition timing.

Refer to DRIVEABILITY

4. Perform electronic control system inspection.

Check the following using circuit tester

Injector circuit

Air regulator circuit

A.A.C. valve (With turbocharger)

2

Idle-up solenoid valve (Without turbocharger)

E G R. control solenoid circuit

Follow the procedure in ELECTRONIC CON-

TROL SYSTEM INSPECTION (Page EF

& EC-

43)

Refer to DRIVEABILITY

5. Check idle mixture ratio.

EF & EC-33

Page 50 of 79

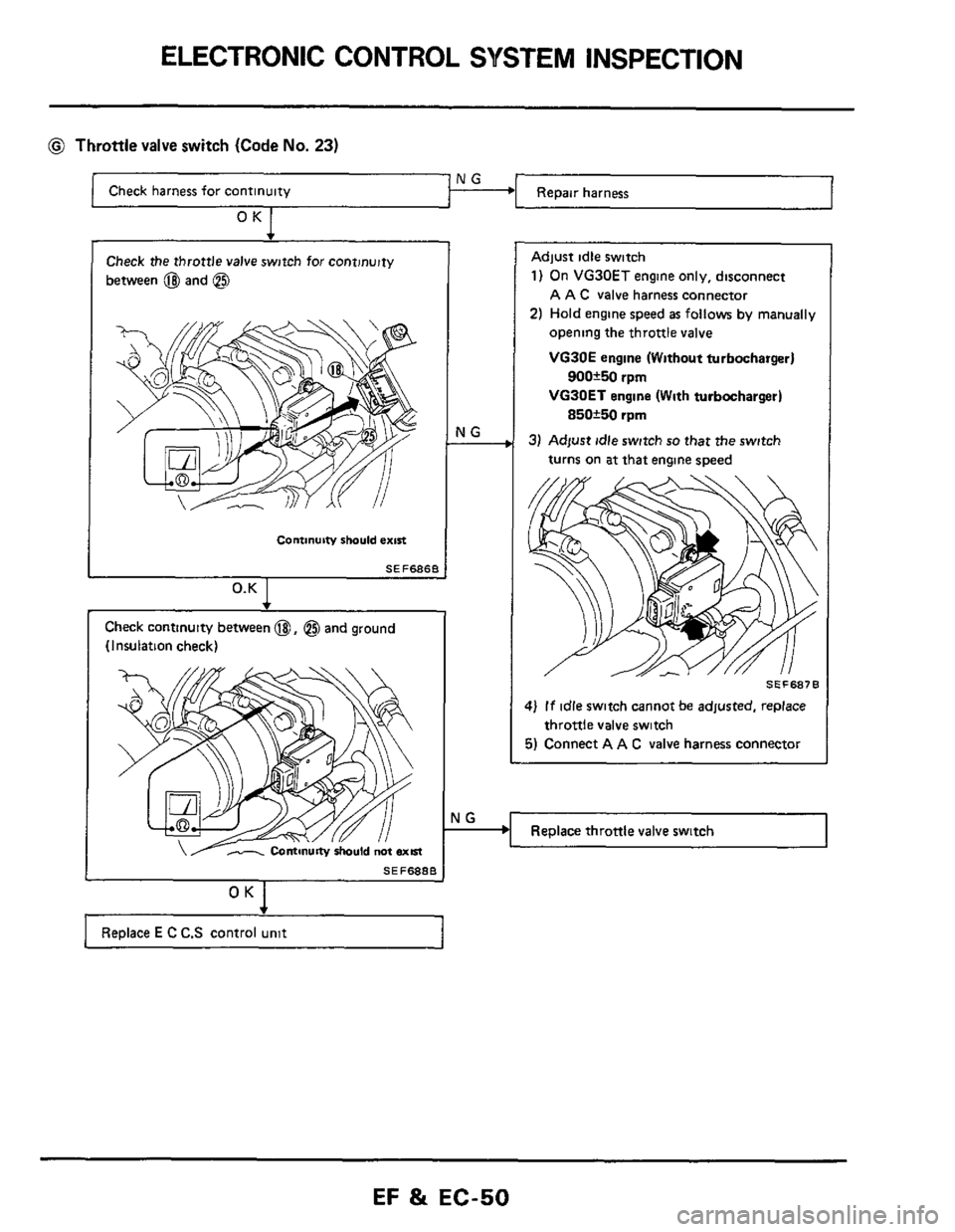

ELECTRONIC CONTROL SYSTEM INSPECTION

@ Throttle valve switch (Code No. 23)

Check harness for continuity

OK 1

Check the throttle valve switch for continuity

between

@ and @

Continuitv should exin

SEF686B

0.K I

Check continuity between @, @$ and ground

(Insulation check)

SEF6888

+

Replace E C C.S control unit

rlG

Adjust idle switch

1) On VG30ET engine only, disconnect

A A C

valve harness connector

2) Hold engine speed as follows by manually

opening the throttle

valve

VG30E engine (Without turbocharger)

VG30ET engine (With turbocharger)

3) Adfust idle switch so that the switch

900+50 rpm

850*50 rpm

turns on at that engine speed

SEF687B

1) If idle switch cannot be adjusted, replace

5) Connect A A C valve harness connector

throttle valve switch

Replace throttle valve switch

EF 81 EC-50