cylinder head NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 7 of 79

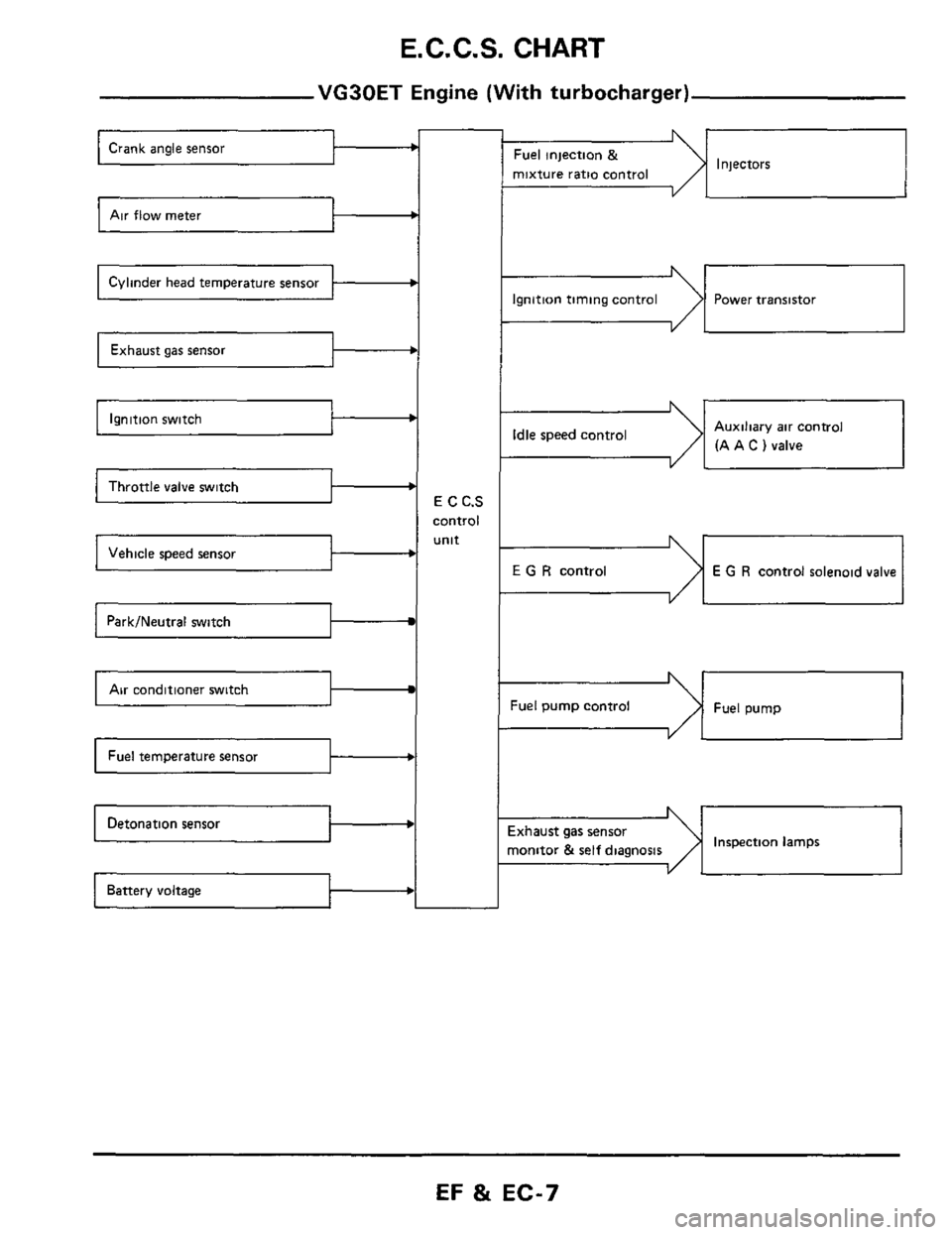

E. C. C.S. CHART

VG30ET Engine (With turbocharger)

Air flow meter c

Cylinder head temperature sensor b

b

Ignition switch b

Throttle valve switch I b

b

Park/Neutral switch

Air conditioner switch I

b

E C C.S

control

unit

b

Injectors Fuel injection &

mixture ratio control

--I

Ignition timing control Power transistor

-dI Auxiliary air control

(A A

C ) valve Idle speed control

I YL

E G R control E G R control solenoid valve

Fuel pump control Fuel pump

Inspection lamps ixhaust gas sensor

nonitor

& self diagnosis I

EF & EC-7

Page 15 of 79

E. C. C. S. DESCRIPTION

E.C.C.S. Corn1

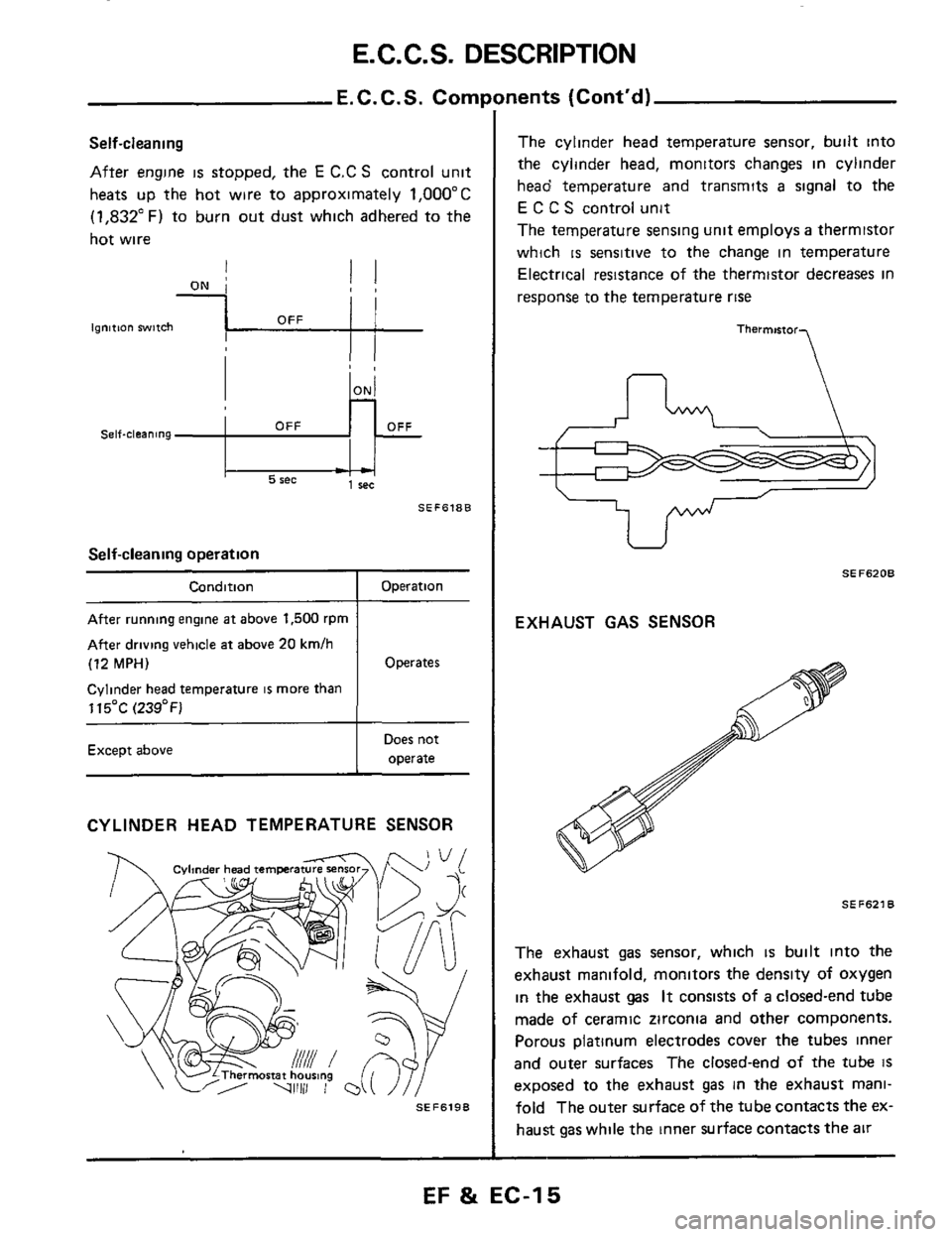

Self-cleaning

After engine is stopped, the E C.C S control unit

heats up the hot wire to approximately

1,OOO"C

(1,832"F) to burn out dust which adhered to the

hot wire

- - 1 rec 5 rec

SEF618B

Self-cleaning operation

Condition _____~ ~

After running engine at above 1,500 rpm

After driving vehicle at above

20 kmlh

(12 MPH)

Cylinder head temperature is more than

115OC

(239°F)

Except above

Operation

Operates

Does not

operate

CYLINDER HEAD TEMPERATURE SENSOR

SEF6198

nents (Cont'd)

The cylinder head temperature sensor, built into

the cylinder head, monitors changes in cylinder

head temperature and transmits

a signal to the

E C C S control unit

The temperature sensing unit employs

a thermistor

which

is sensitive to the change in temperature

Electrical resistance

of the thermistor decreases in

response to the temperature

rise

Thermmor

U

SEF6208

EXHAUST GAS SENSOR

SEF621

The exhaust gas sensor, which is built into the

exhaust manifold, monitors the density

of oxygen

in the exhaust gas It consists of a closed-end tube

made

of ceramic zirconia and other components.

Porous platinum electrodes cover the tubes inner

and outer surfaces The closed-end

of the tube IS

exposed to the exhaust gas in the exhaust mani-

fold The outer surface

of the tube contacts the ex-

haust

gas while the inner surface contacts the air

EF & EC-15

Page 20 of 79

E.C.C.S. DESCRIPTION

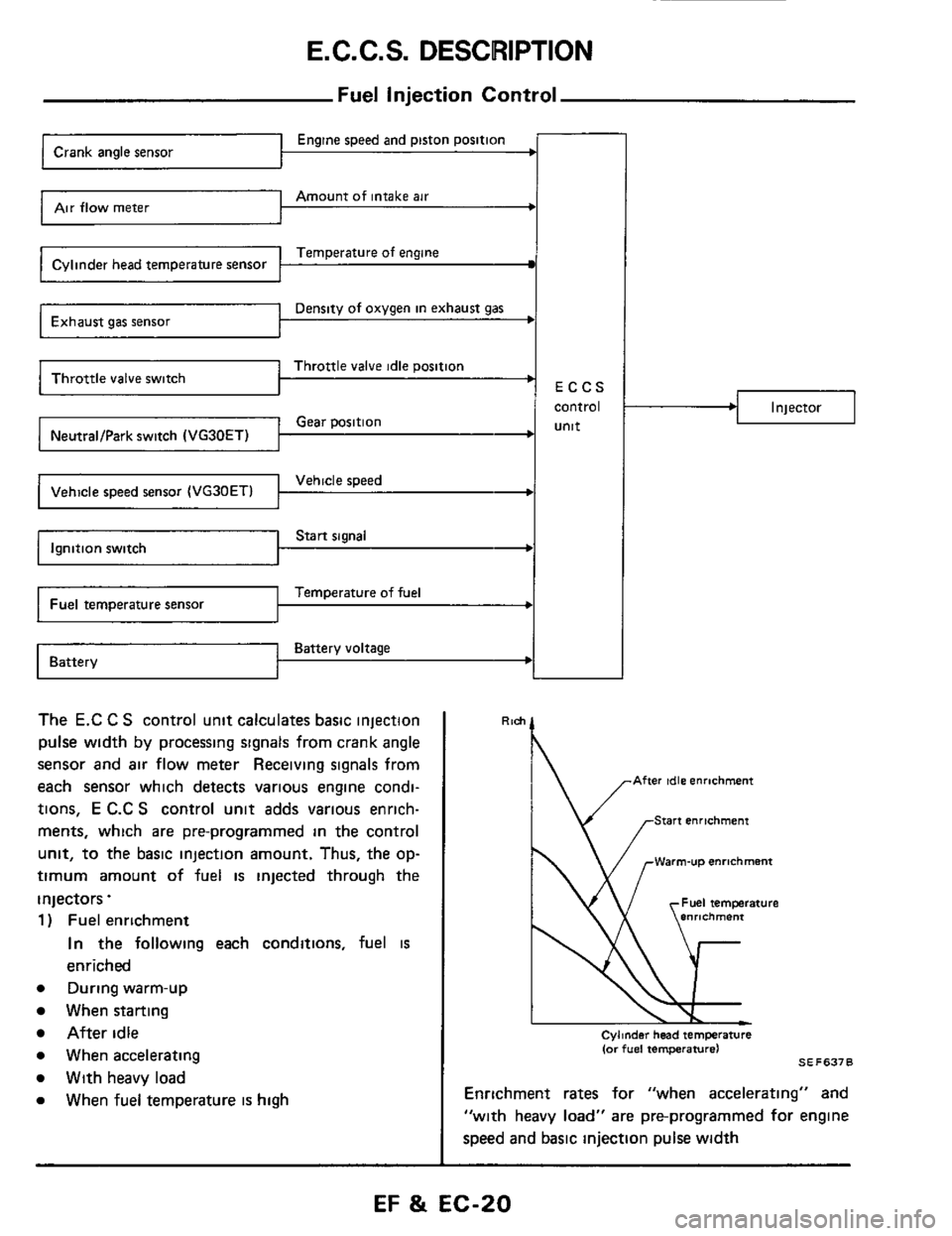

Fuel Injection Control

Temperature of engine Cylinder head temperature sensor

Density of oxygen in exhaust gas Exhaust gas sensor

Throttle valve idle position ' Throttle valve switch

Engine speed and piston position

Amount of intake air Air flow meter

ECCS

I I

I

control

Gear position unit NeutraVPark switch (VG30ET) I I

Vehicle speed

Start signal

Temperature of fuel

Battery voltage Battery

The E.C C S control unit calculates basic injection

pulse

width by processing signals from crank angle

sensor and air flow meter Receiving signals from

each sensor which detects various engine condi-

tions,

E C.C S control unit adds various enrich-

ments, which are pre-programmed

in the control

unit, to the basic injection amount. Thus, the op-

timum amount of fuel is injected through the

injectors.

1 ) Fuel enrichment

In the following each conditions, fuel is

enriched

e During warm-up

When starting

After idle

e When accelerating

e With heavy load

e When fuel temperature is high

.I Injector

Rlch

' \/ .-Warm-u~ enrichment

Cylmder head temperature (or fuel temperature1 SE F637 0

Enrichment rates for "when accelerating" and

"with heavy load" are pre-programmed for engine

speed and basic injection pulse

width

EF & EC-20

Page 22 of 79

E.C.C.S. DESCRIPTION

-Fuel injection Control (Cont'd)-

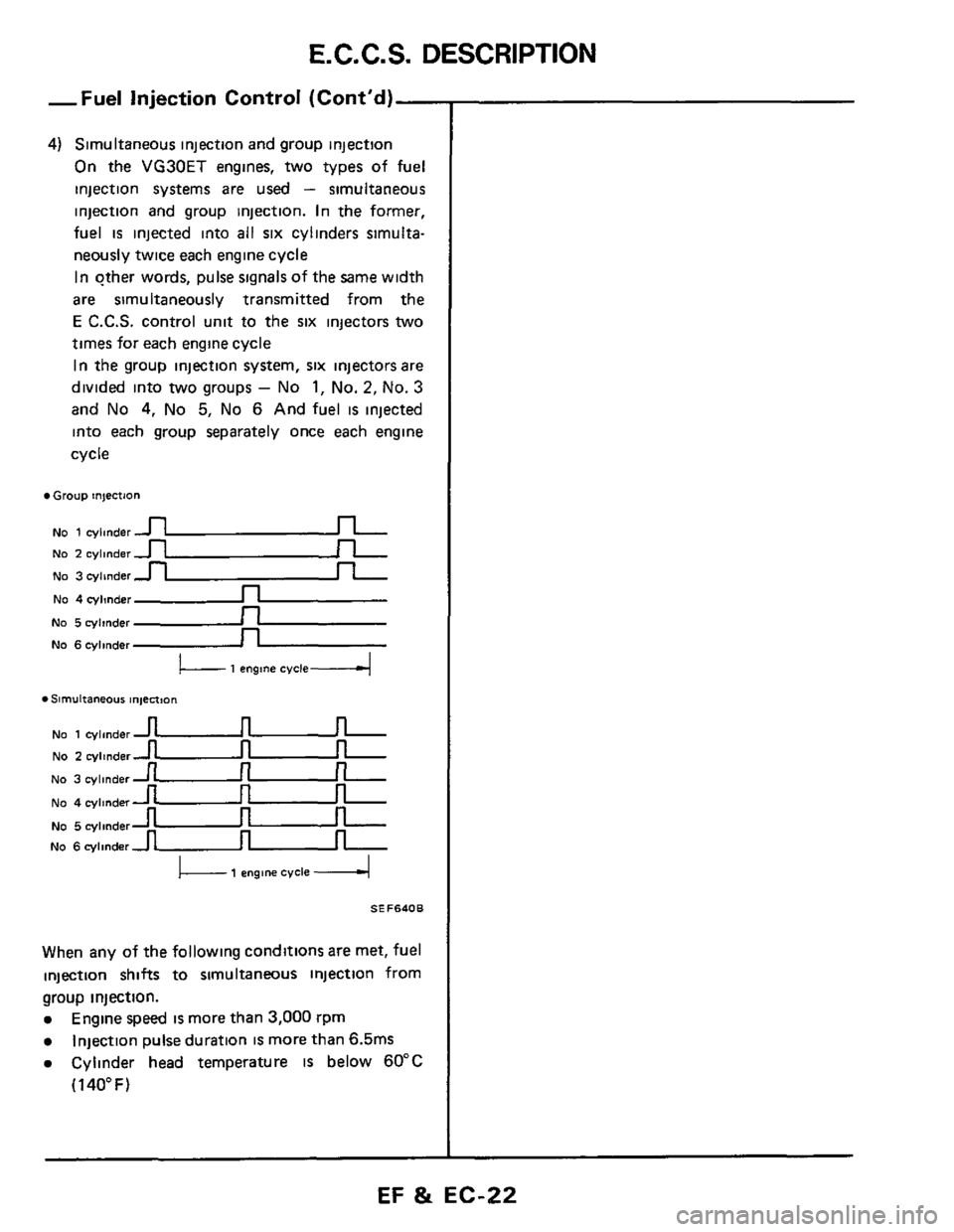

4) Simultaneous injection and group injection

On the VG30ET engines, two types of fuel

injection systems

are used - simultaneous

injection and group injection. In the former,

fuel is injected into all six cylinders simulta-

neously twice each engine cycle

In other words, pulse signals

of the same width

are simultaneously transmitted from the

E C.C.S. control unit to the six injectors two

times for each engine cycle

In the group injection system, six injectors are

divided into

two groups - No 1, No. 2, No. 3

and No 4, No 5, No 6 And fuel is injected

into each group separately once each engine

cycle

Group injection

NO 1 cylmder u

No 5 cylinder n

No 6cylinder _n

No 1 cylinder u

NO 2 cylinder -

u

u

u

u

NO 2 cylinder-

No 3 cylinder -

No 4 cylmdern

L- 1 engine cvcle4

. Slrnultaneous ln,ect,On

No 3 cylinder

No 4 cylinder

No 5 cylinder

No 6 cylinder

I 1 engm cycle I

SEF640B

When any of the following conditions are met, fuel

injection shifts to simultaneous injection from

group injection.

Engine speed is more than 3,000 rpm

Injection pulse duration is more than 6.5ms

Cylinder head temperature IS below 60°C

(1 40" F)

EF & EC-22

Page 23 of 79

E. C. C. S. DESCRIPTION

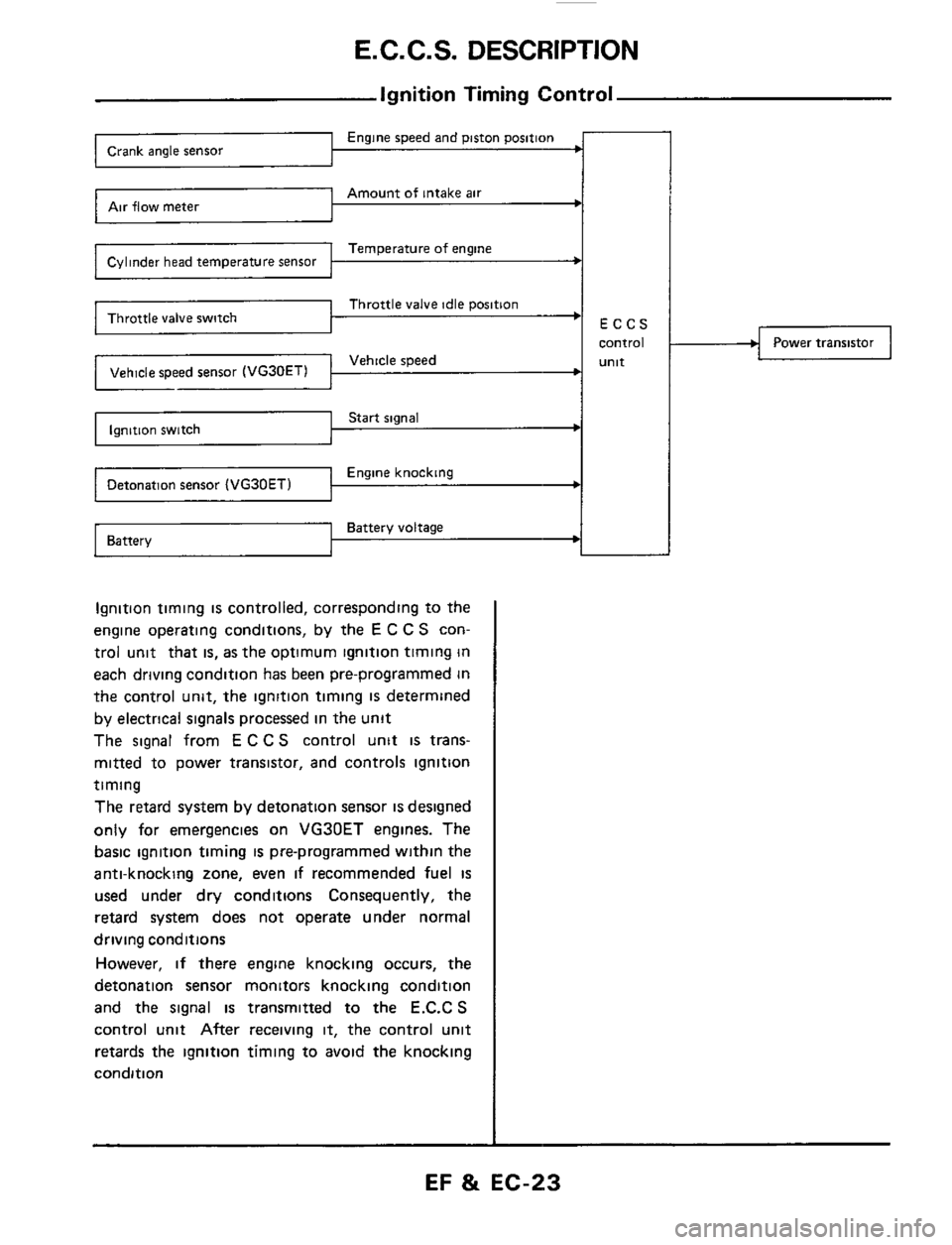

Ignition Timing Control

Engine speed and piston position Crank angle sensor

Amount of intake air Air flow meter

Temperature of engine Cylinder head temperature sensor

Throttle valve idle position

Vehicle speed Vehicle speed sensor (VG30ETl 1 I I

Start signal Ignition switch

Engine knocking Detonation sensor

Battery voltage Battery ~

Ignition

timing is controlled, corresponding to the

engine operating conditions, by the

E C C S con-

trol unit that

is, as the optimum ignition timing in

each driving condition has been pre-programmed in

the control unit, the ignition timing

IS determined

by electrical signals processed in the unit

The signal from

E C C S control unit is trans-

mitted to power transistor, and controls ignition

timing

The retard system by detonation sensor

is designed

only for emergencies on VG30ET engines. The

basic ignition timing

is pre-programmed within the

anti-knocking zone, even

if recommended fuel is

used under dry conditions Consequently, the

retard system does not operate under normal

driving conditions

However,

if there engine knocking occurs, the

detonation sensor monitors knocking condition

and the signal is transmitted to the E.C.C S

control unit After receiving it, the control unit

retards the ignition timing to avoid the knocking

condition

Power transistor

EF & EC-23

Page 25 of 79

E. C. C. S. DESCRIPTION

Start signal ’ Ignition switch

Throttle valve idle position

Neutral position t

Battery voltage Battery

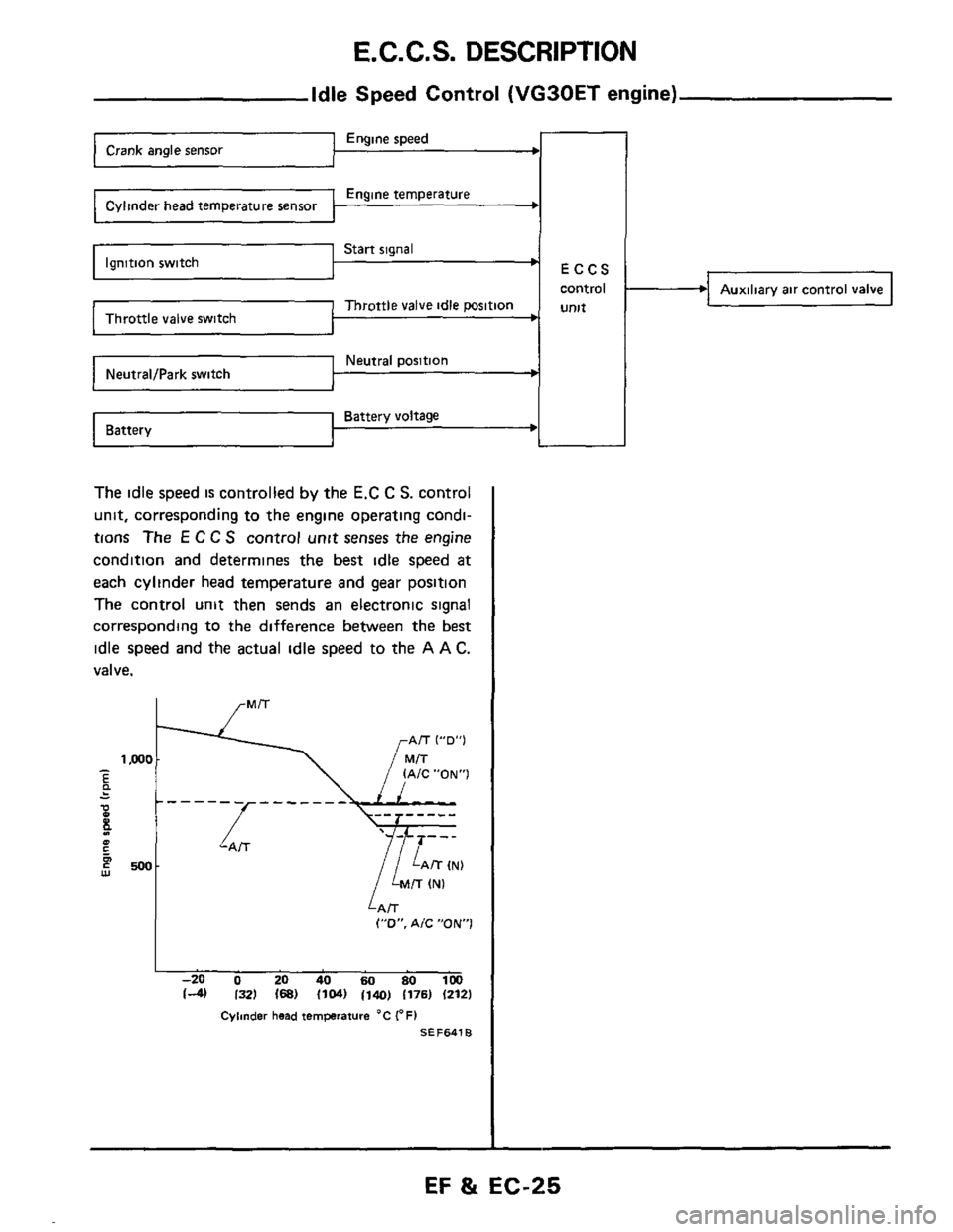

Idle Speed Control (VG30ET engine)

Engine speed

Engine temperature

ECCS

control

Unlt

-

The idle speed is controlled by the E.C C S. control

unit, corresponding to the engine operating condi-

tions

The E C C S control unit senses the engine

condition and determines the best idle speed

at

each cylinder head temperature and gear position

The control unit then sends an electronic signal

corresponding

to the difference between the best

idle speed and the actual idle speed to the A A C.

valve.

I

,/ lAiC”ON”1 -‘I E .. -

P - 0 E 4 1 - - - -L- - - - - - lZN)

500 w

LAiT (”0”. A/C ”ON1

I -20 0 20 40 60 80 1M) 14) I321 168) 11041 1140) 1176) (212)

Cylinder head ternprature “C (OF1

SEF641B

Auxiliary air control valve

EF & EC-25

Page 35 of 79

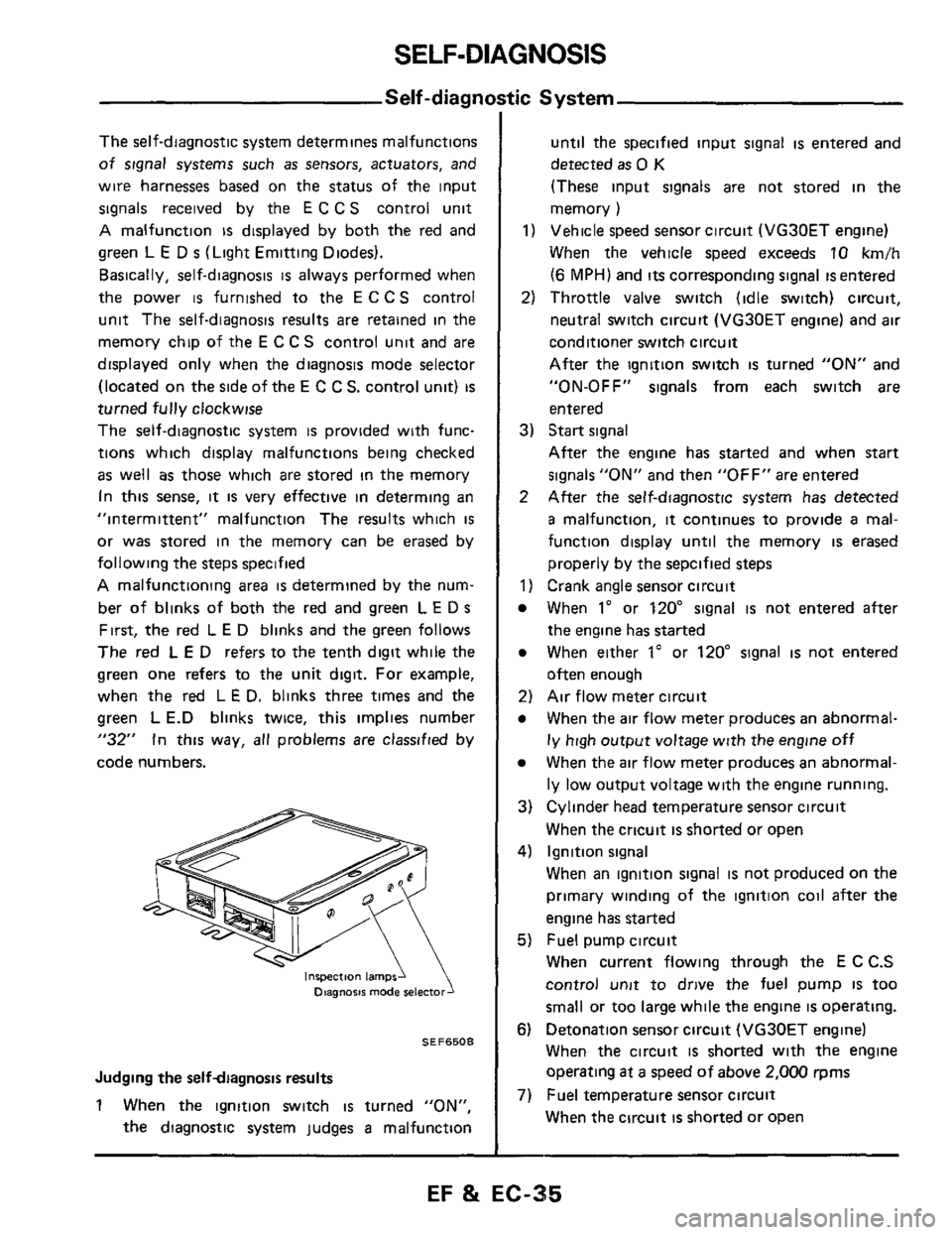

SELF-DIAGNOSIS

Self-diagni

The self-diagnostic system determines malfunctions

of signal systems such as sensors, actuators, and

wire harnesses based on the status of the input

signals received by the

E C C S control unit

A malfunction is displayed by both the red and

green

L E D s (Light Emitting Diodes).

Basically, self-diagnosis

is always performed when

the power

is furnished to the E C C S control

unit The self-diagnosis results

are retained in the

memory chip of the

E C C S control unit and are

displayed only when the diagnosis mode selector

(located on

the side of the E C C S. control unit) is

turned fully clockwise

The self-diagnostic system

is provided with func-

tions which display malfunctions being checked

as well as those which are stored in the memory

In

this sense, it is very effective in determing an

"intermittent" malfunction The results which

is

or was stored in the memory can be erased by

following the steps specified

A malfunctioning area is determined by the num-

ber of blinks of both the

red and green L E D s

First, the red L E D blinks and the green follows

The red L E D refers to the tenth digit while the

green

one refers to the unit digit. For example,

when the red L

E D. blinks three times and the

green

L E.D blinks twice, this implies number

"32" In this way, all problems are classified by

code numbers.

inspection lamps1 Diagnosis mode

SEF6508

Judging the selfdiagnosis results

1 When the ignition switch is turned "ON",

the diagnostic system judges

a malfunction

tic System

until the specified input signal is entered and

detected

as 0 K

(These input signals are not stored in the

memory

)

1) Vehicle speed sensor circuit (VG30ET engine)

When the vehicle speed exceeds

10 km/h

(6 MPH) and its corresponding signal is entered

2) Throttle valve switch (idle switch) circuit,

neutral switch circuit (VG30ET engine) and

air

conditioner switch circuit

After the ignition switch

is turned "ON" and

"ON-OFF"

signals from each switch are

entered

3) Start signal

After the engine has started and when start

signals "ON" and then "OFF" are entered

2 After the self-diagnostic system has detected

a malfunction, it continues to provide a mal-

function display until the memory

is erased

properly by the sepcified steps

1) Crank angle sensor circuit

When 1" or 120" signal is not entered after

the engine has started

When either 1" or 120" signal is not entered

often enough

2) Air flow meter circuit

When the air flow meter produces an abnormal-

ly high output voltage with the engine off

When the air flow meter produces an abnormal-

ly low output voltage with the engine running.

3) Cylinder head temperature sensor circuit

When the cricuit

is shorted or open

4) Ignition signal

When an ignition signal

is not produced on the

primary winding of the ignition coil after

the

engine has started

5) Fuel pump circuit

When current flowing through the E

C C.S

control

unit to drive the fuel pump IS too

small or too large while the engine

is operating.

6) Detonation sensor circuit (VG30ET engine)

When the circuit

is shorted with the engine

operating

at a speed of above 2,000 rpms

When the circuit is shorted or open

7) Fuel temperature sensor circuit

EF & EC-35

Page 39 of 79

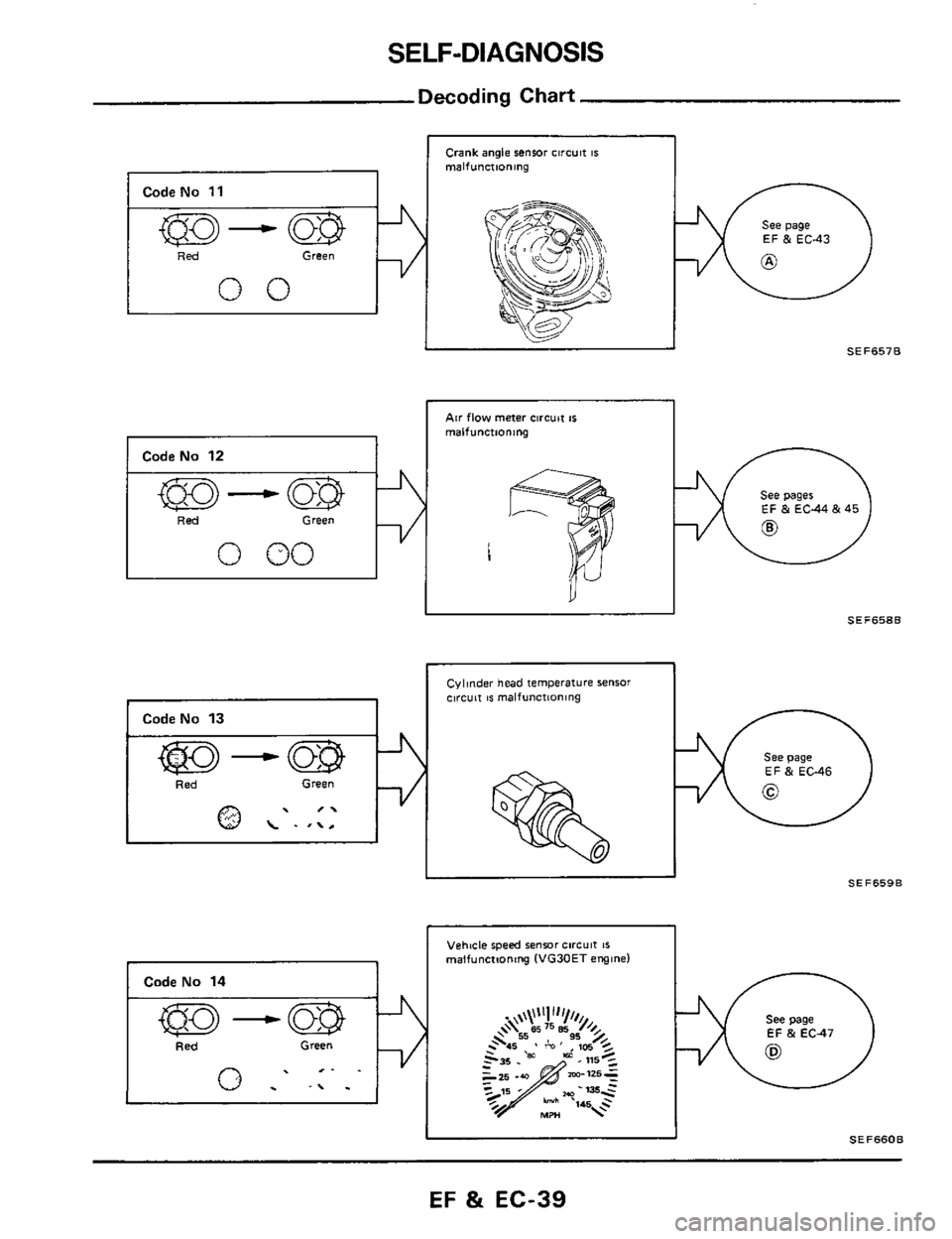

SELF-DIAGNOSIS

Decoding Chart

I Code No 11

I ked Green

00

1 CodeNo 12

I 'Red Green

0 00

Crank angle sensor circuit IS malfunctioning

Air flow meter circuit IS

malfunctioning 1

See page

EF & EC43

SEF6578

EF & EC44 & 45

1

SEF658B II

I CodeNo 13 I

Cylinder head temperature sensor clrcuit IS malfunctioning

See page EF & EC-46

SEF659B II

Vehtcle speed sensor circuit IS malfunctioning (VG30ET engine)

See page

EF & EC47

Id SEF660B

EF & EC-39

Page 46 of 79

ELECTRONIC CONTROL SYSTEM INSPECTION

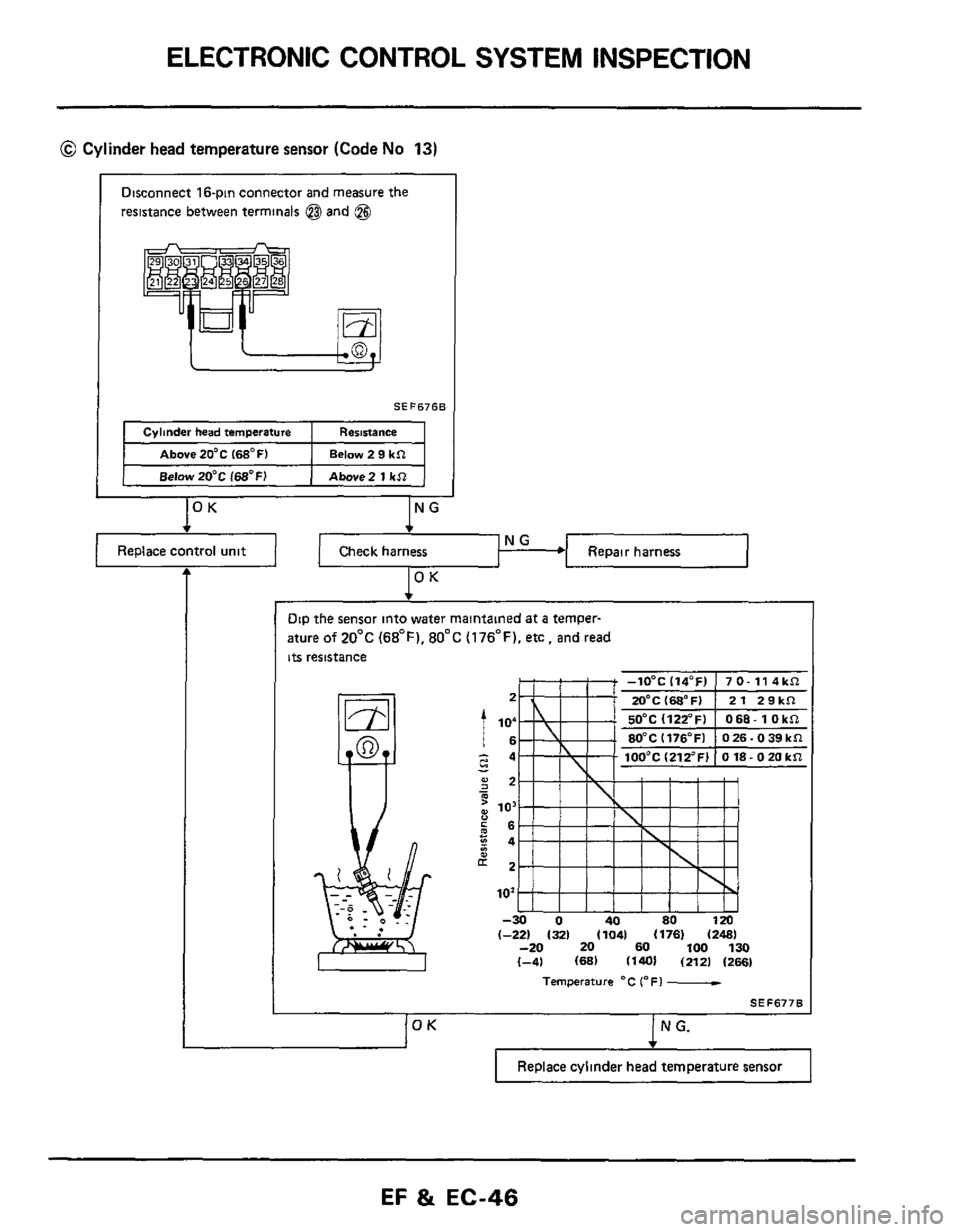

@ Cylinder head temperature sensor (Code No 13)

Disconnect 16-pin connector and measure the

resistance between terminals @and

@$

Dip the sensor into water maintained at a temper-

ature

of 20°C (68°F). 80°C (176°F). etc, and read

its resistance

2

I lo; - - c4

- ;2

c 66

g2

m : io3 u

z4 *

102

-30 0 40 80 120 (-221 I321 (1041 11781 (2481 -20 20 60 100 130 (-41 (681 (1401 (2121 (2661

Temperature "C (OF) -

SEF677B

(OK I N G.

Replace cylinder head temperature sensor

EF & EC-46

Page 61 of 79

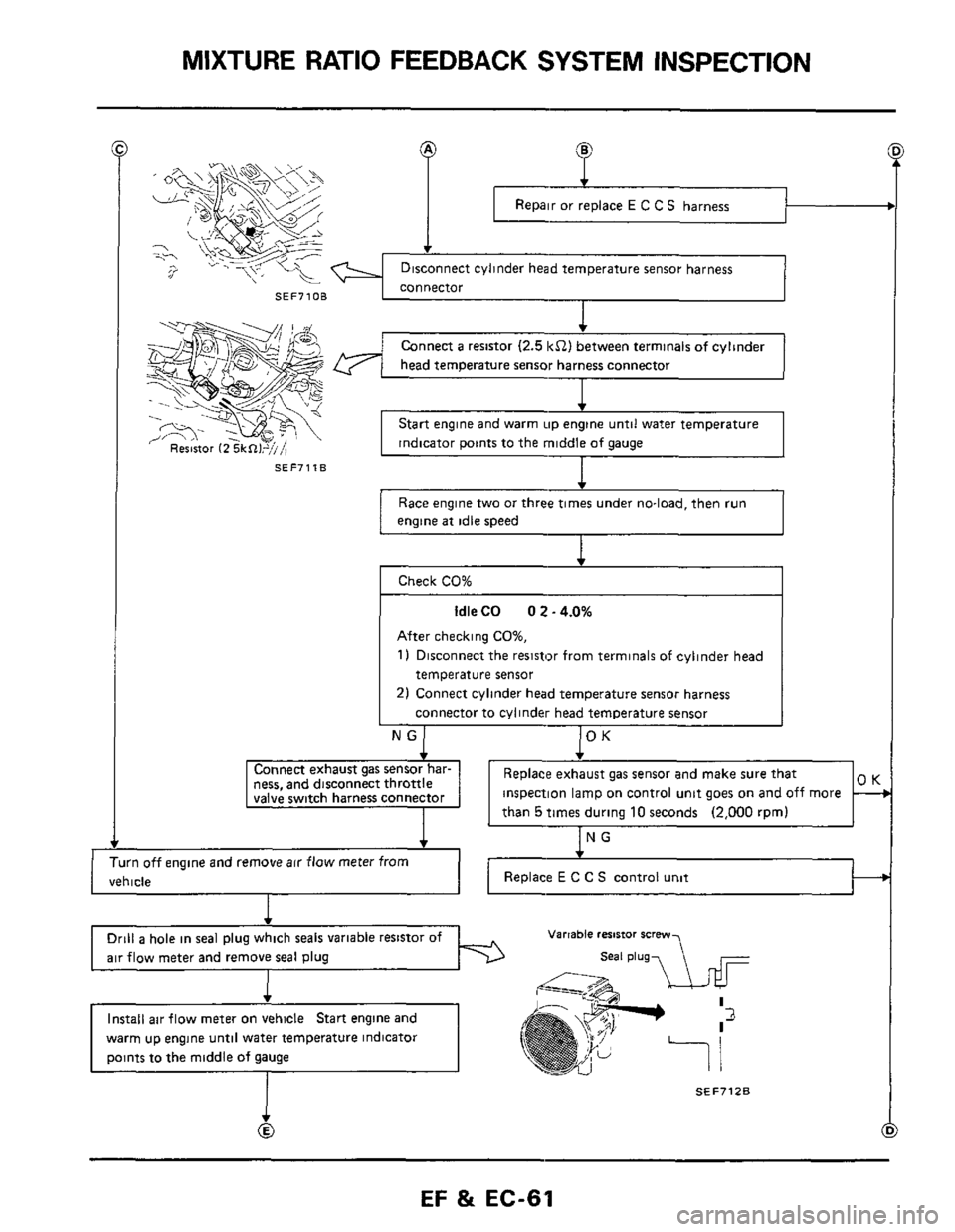

MIXTURE RATIO FEEDBACK SYSTEM INSPECTION

Repair or replace E C C S harness

SEF71OB

SEF7118

f

Connect a resistor (2.5 kS2) between terminals of cylinder

head temperature sensor harness connector

I

Start engine and warm up engine until water temperature

indicator points to the middle

of gauge

Race engine two or three times under no-load. then run

engine

at idle speed

After checking CO%,

1) Disconnect the resistor from terminals of cylinder head

temperature sensor

2) Connect cylinder head temperature sensor harness

connector to cylinder head temperature sensor

ness, and disconnect throttle inspection lamp on control unit goes on and off more

I

Turn off engine and remove air flow meter from

vehicle ~~

Drill a hole

in seal plug which seals variable resistor of

air flow meter and remove seal plug

warm up engine until water temperature indicator

Varrable resistor scmw

SEF7128