engine NISSAN 300ZX 1984 Z31 Engine Fuel And Emission Control System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 79, PDF Size: 2.15 MB

Page 1 of 79

ENGINE FUEL &

- EMISSION - CONTROL SYSTEM

SECTION EFaEC

CONTENTS

PRECAUTIONS ..

COMPONENT PARTS LOCATION

ECCS DIAGRAM

. . .

ECCS CHART ..

ECC.S WIRING DIAGRAM . . ..

FUEL FLOW SYSTEM DESCRIPTION .

AIR FLOW SYSTEM DESCRIPTION ....

E C C S. DESCRIPTION . . . . ...

DIAGNOSTIC PROCEDURE . ..

SE LF-D I AGNOSIS ..

..

.. ..

..

..

..

...

ELECTRONfC CONTROL SYSTEM INSPECTION

MIXTURE RATIO FEEDBACK SYSTEM INSPECTION

. ,

FUEL SYSTEM INSPECTION

TURBOCHARGER

. ... ..

INJECTOR COOLING FAN (VG30ET) .

PRESSURE REGULATOR CONTROL

CRANKCASE EMISSION CONTROL SYSTEM

. . . .

EXHAUST EMISSION CONTROL SYSTEM . . ...

EVAPORATIVE EMISSION CONTROL SYSTEM . . .

SERVICE DATA AND SPECIFICATIONS (S DS). . . . . . .

. . EF&EC- 2

. EF&EC- 3

EF & EC- 4

EF&EC- 6

EF&EC- 8

.. EF & EC-10

EF

& EC-11

, EF&EC-13

EF

& EC-28

EF

& EC-35

EF

& EC43

EF & EC-60

EF

& EC-63

EF

& EC-66

EF

& EC-69

EF

& EC-72

. . EF & EC-74

EF

& EC-75

, EF&EC-76

EF & EC-79

Page 2 of 79

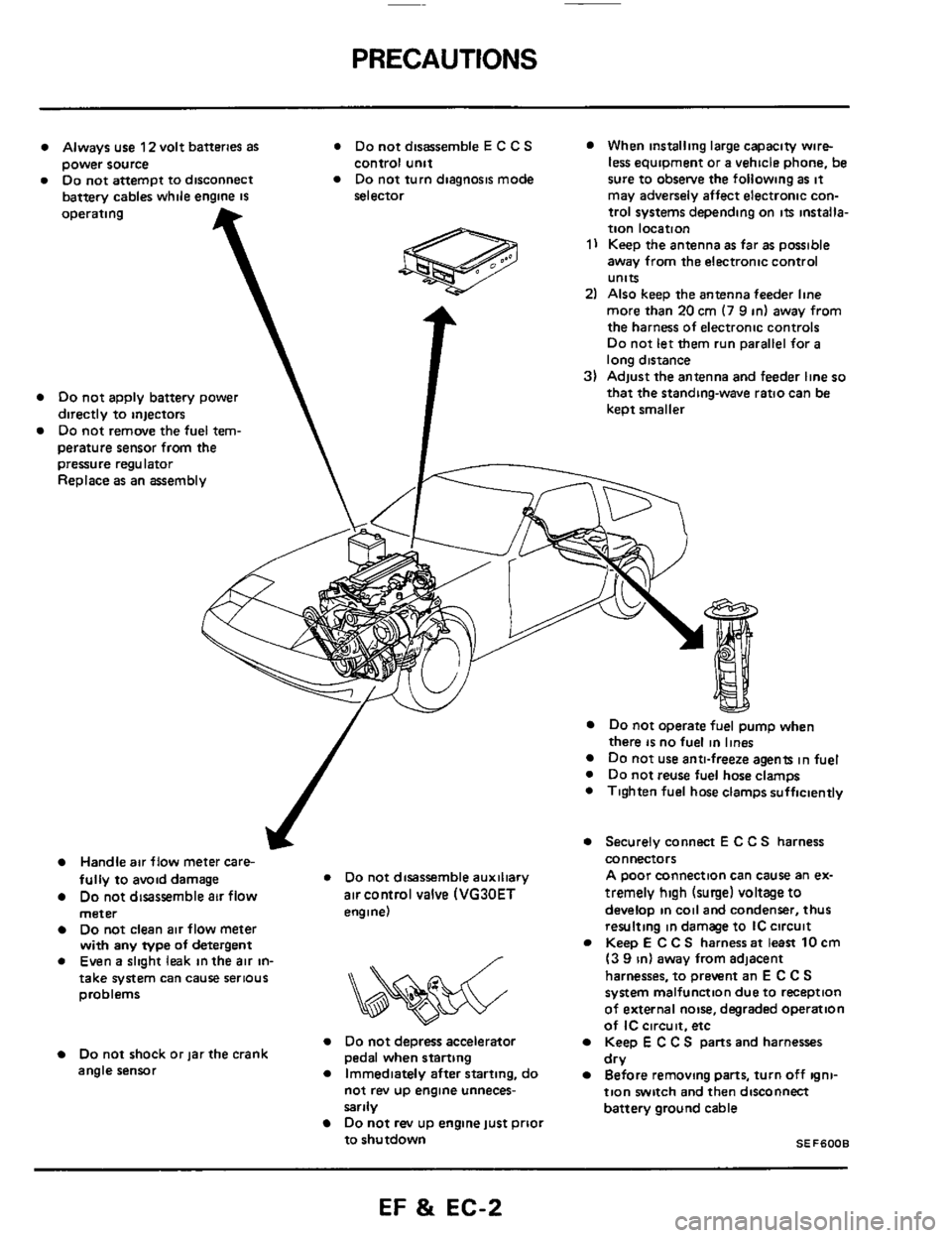

PRECAUTIONS

Always use 12 volt batteries as * Do not disassemble E C C S When installing large capacity wire-

Do not attempt to disconnect Do not turn diagnosis mode sure to obsetve the following as it power source

battery cables while engine

IS

control unit

selector less equipment or a vehicle phone, be

may adversely affect electronic con-

operating

Do not apply battery power

directly to injectors

Do not remove the fuel tem-

perature sensor from

the T

pressure regulator

Replace as an assembly

trol systems depending on its installa-

tion location

1) Keep the antenna as far as possible

away from the electronic control

units

2) Also keep the antenna feeder line

more than

20 cm (7 9 in) away from

the harness of electronic controls

Do not let them run parallel for a

long distance

3) Adjust the antenna and feeder line so

that the standing-wave ratio can be

keot smaller

J

Handle air flow meter care-

fully to avoid damage * Do not disassemble auxiliary

Do not disassemble air flow air control valve (VG30ET

meter engine)

Do not clean air flow meter

with any type of detergent

0 Even a slight leak in the air in- /

&&%$$?&

take system can cause serious

problems

Do not depress accelerator Do not shock or jar the crank

angle sensor

Immediately after starting, do

pedal when starting

not rev

up engine unneces-

sarily

Do not rev up engine just prioi

to shutdown

Do not operate fuel pump when

there is no fuel in lines Do not use anti-freeze agents in fuel

0 Do not reuse fuel hose clamps

0 Tighten fuel hose clamps sufficiently

Securely connect E C C S harness

connectors

A poor connection can cause an ex-

tremely

high (surge) voltage to

develop in coil and condenser, thus

resulting in damage to IC circuit

Keep

E C C S harness at least 10 cm

(3 9 in) away from adjacent

harnesses, to prevent an

E C C S

system malfunction due to reception

of external noise, degraded operation

of

IC circuit. etc

Keep E C C S parts and harnesses

Before removing parts, turn off igni-

tion switch and then disconnect

battery ground cable dry

SEF6008

EF & EC-2

Page 3 of 79

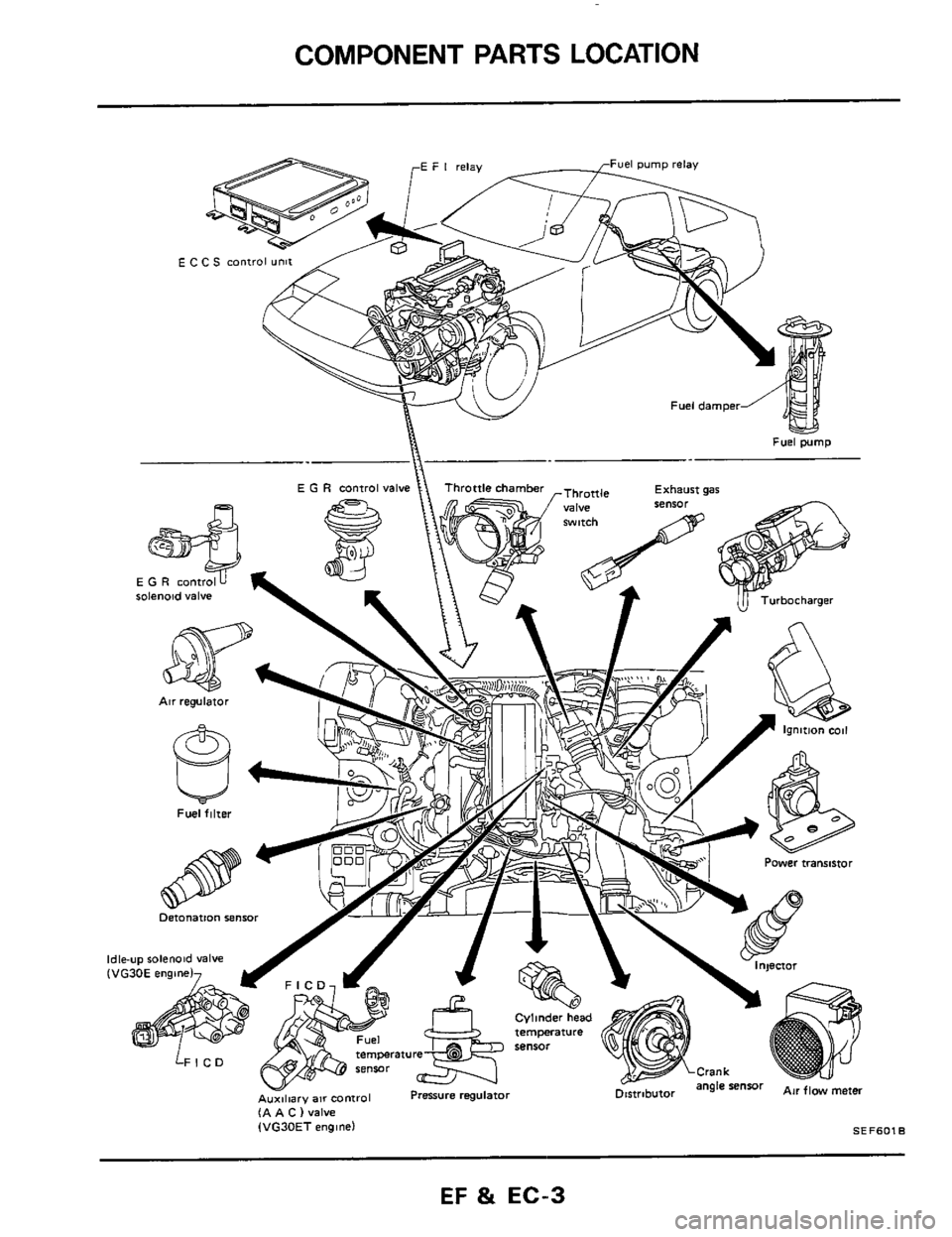

COMPONENT PARTS LOCATION

E C C S conlr01 unit

IA A C (valve (VG30ET engine) SEFBOlB

EF & EC-3

Page 4 of 79

E. C.C. S. DIAGRAM

VG30E Engine (Without turbocharger)

SEF602B

EF & EC-4

Page 5 of 79

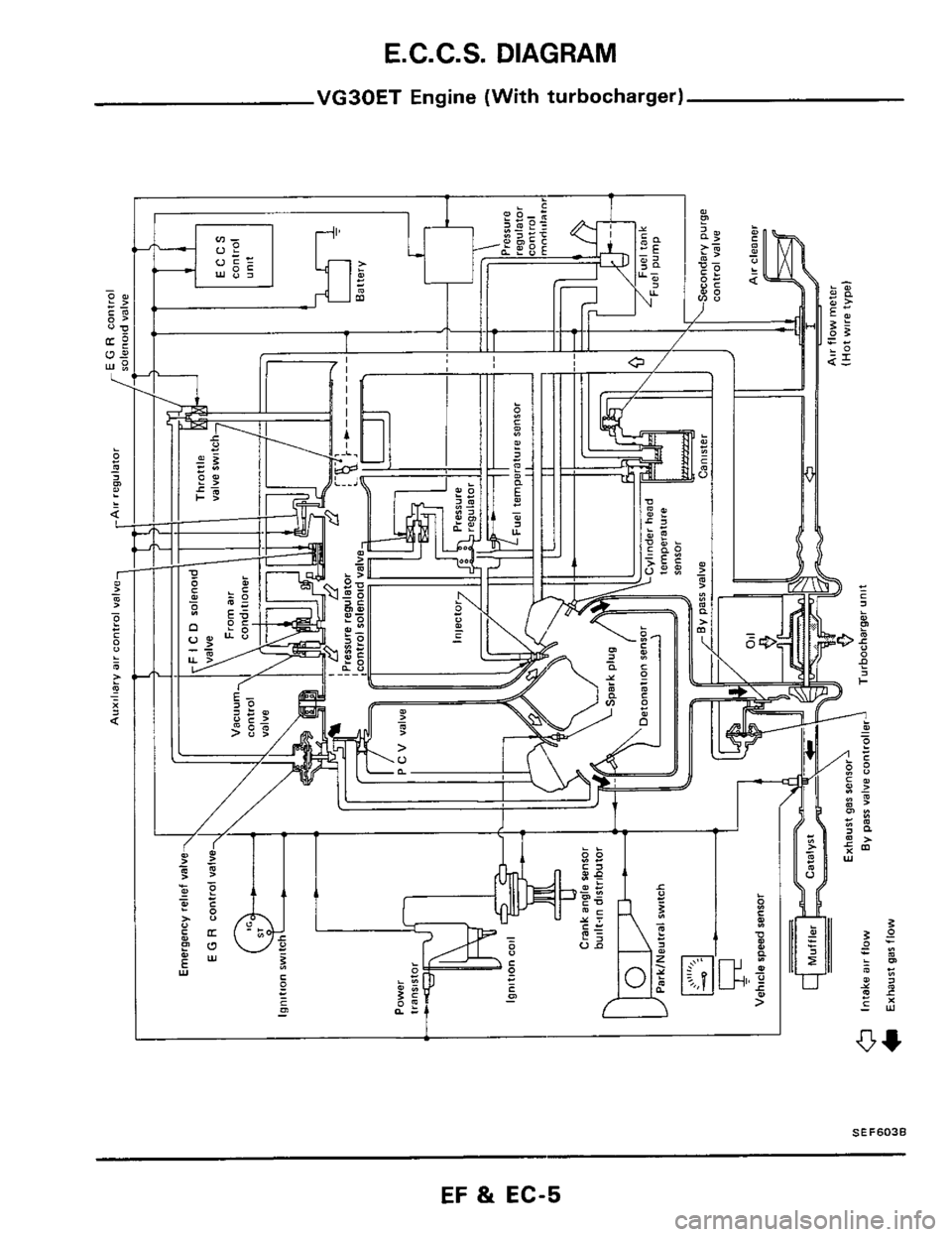

E.C.C.S. DIAGRAM

VG30ET Engine (With turbocharger)

L

SEF603B

EF & EC-5

Page 6 of 79

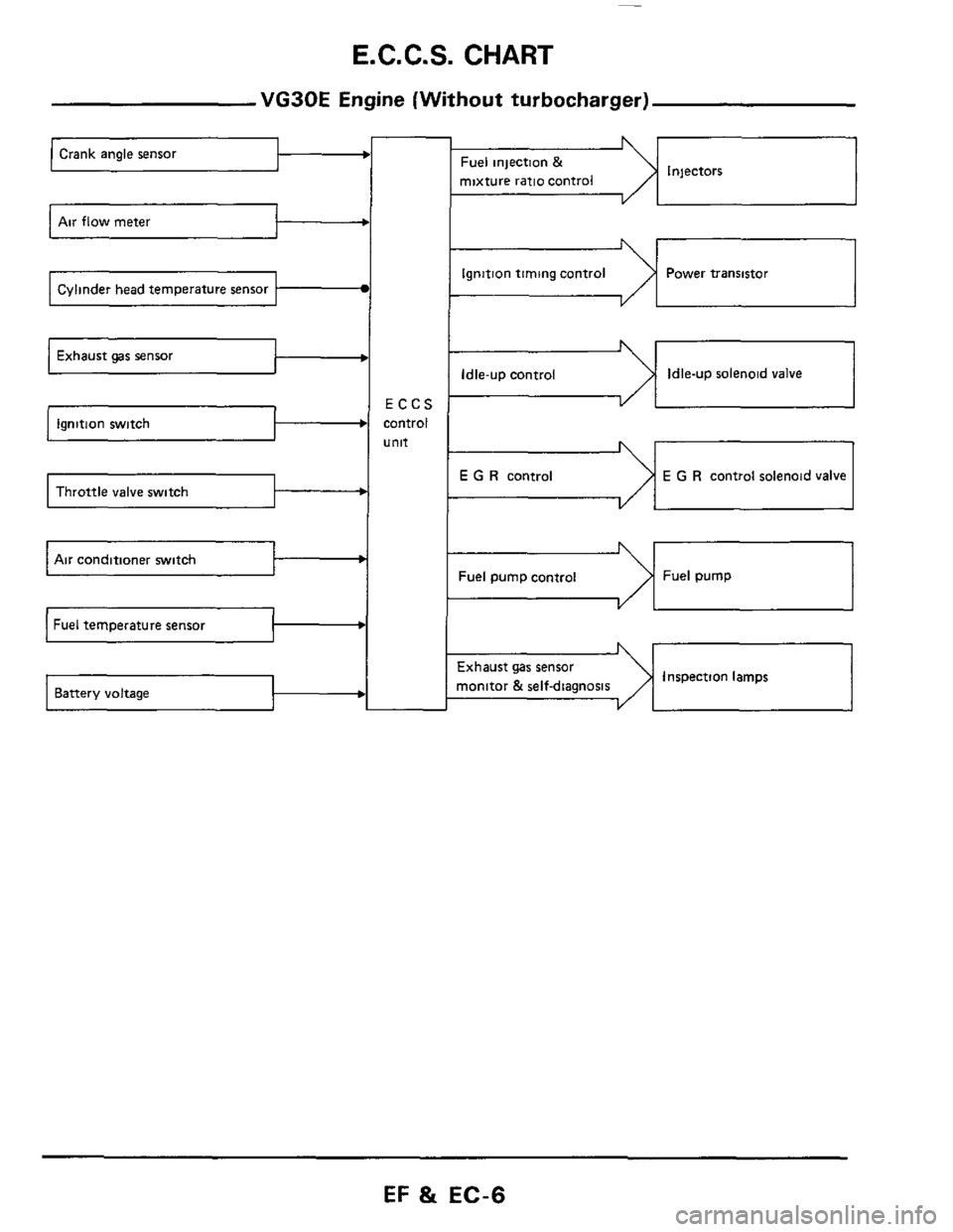

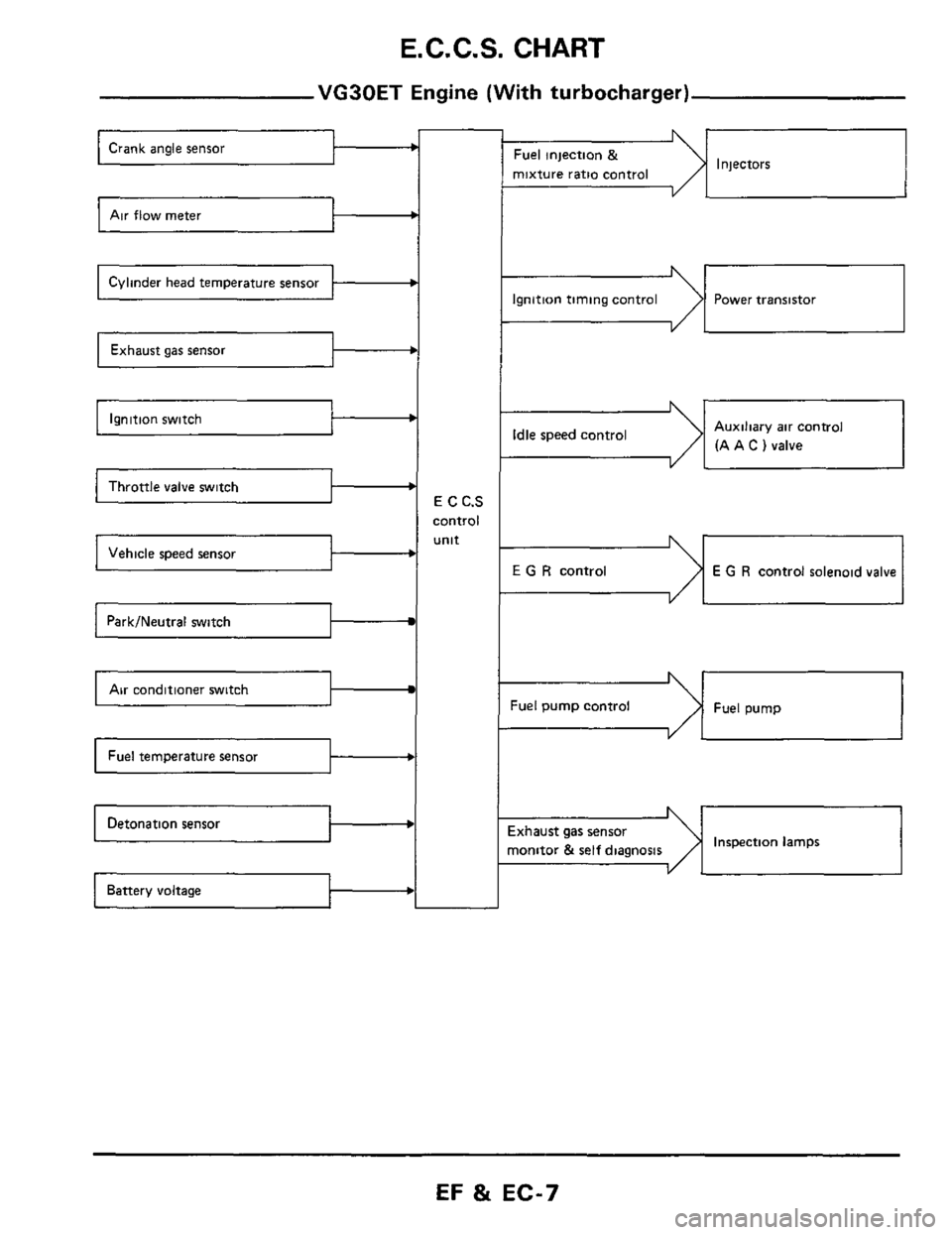

E.C.C.S. CHART

Exhaust gas sensor t

b

Throttle valve switch -b

VG30E Engine (Without turbocharger)

ECCS

control

unit

Crank angle sensor

%el pump control Fuel pump

Air conditioner switch 1 t

Battery voltage

- I

Injectors Fuel injection &

mixture ratio control

VI 1

1

Ignition timing control Power transistor

Idle-up control Idle-up solenoid valve

E G R control E G R control solenoid valve

-1 I

Inspection lamps ixhaust gas sensor

nonitor

& self-diamosis

EF & EC-6

Page 7 of 79

E. C. C.S. CHART

VG30ET Engine (With turbocharger)

Air flow meter c

Cylinder head temperature sensor b

b

Ignition switch b

Throttle valve switch I b

b

Park/Neutral switch

Air conditioner switch I

b

E C C.S

control

unit

b

Injectors Fuel injection &

mixture ratio control

--I

Ignition timing control Power transistor

-dI Auxiliary air control

(A A

C ) valve Idle speed control

I YL

E G R control E G R control solenoid valve

Fuel pump control Fuel pump

Inspection lamps ixhaust gas sensor

nonitor

& self diagnosis I

EF & EC-7

Page 10 of 79

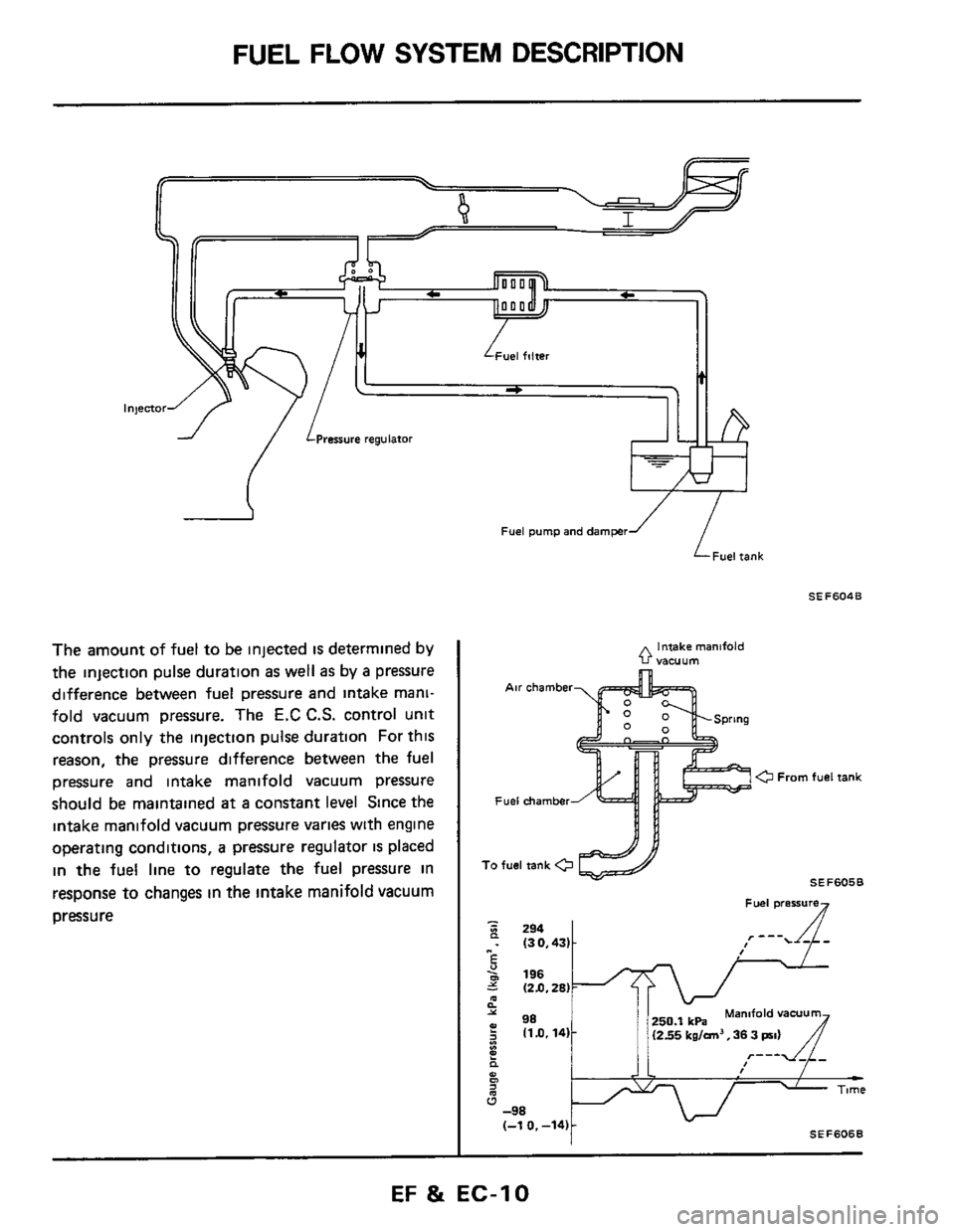

FUEL FLOW SYSTEM DESCRIPTION

The amount of fuel to be injected is determined by

the injection pulse duration

as well as by a pressure

difference between fuel pressure and intake mani-

fold vacuum pressure. The

E.C C.S. control unit

controls only the injection pulse duration For this

reason,

the pressure difference between the fuel

pressure and intake manifold vacuum pressure

should be maintained

at a constant level Since the

intake manifold vacuum pressure varies with engine

operating conditions,

a pressure regulator IS placed

in the fuel line to regulate the fuel pressure in

response to changes

in the intake manifold vacuum

pressure

Fuel pump and damper

’ iFueirank

SEF604B

intake manifold 0 vacuum

a From fuel tank

Fuel chamber

SEF605B

Fuel presswe

EF & EC-10

Page 11 of 79

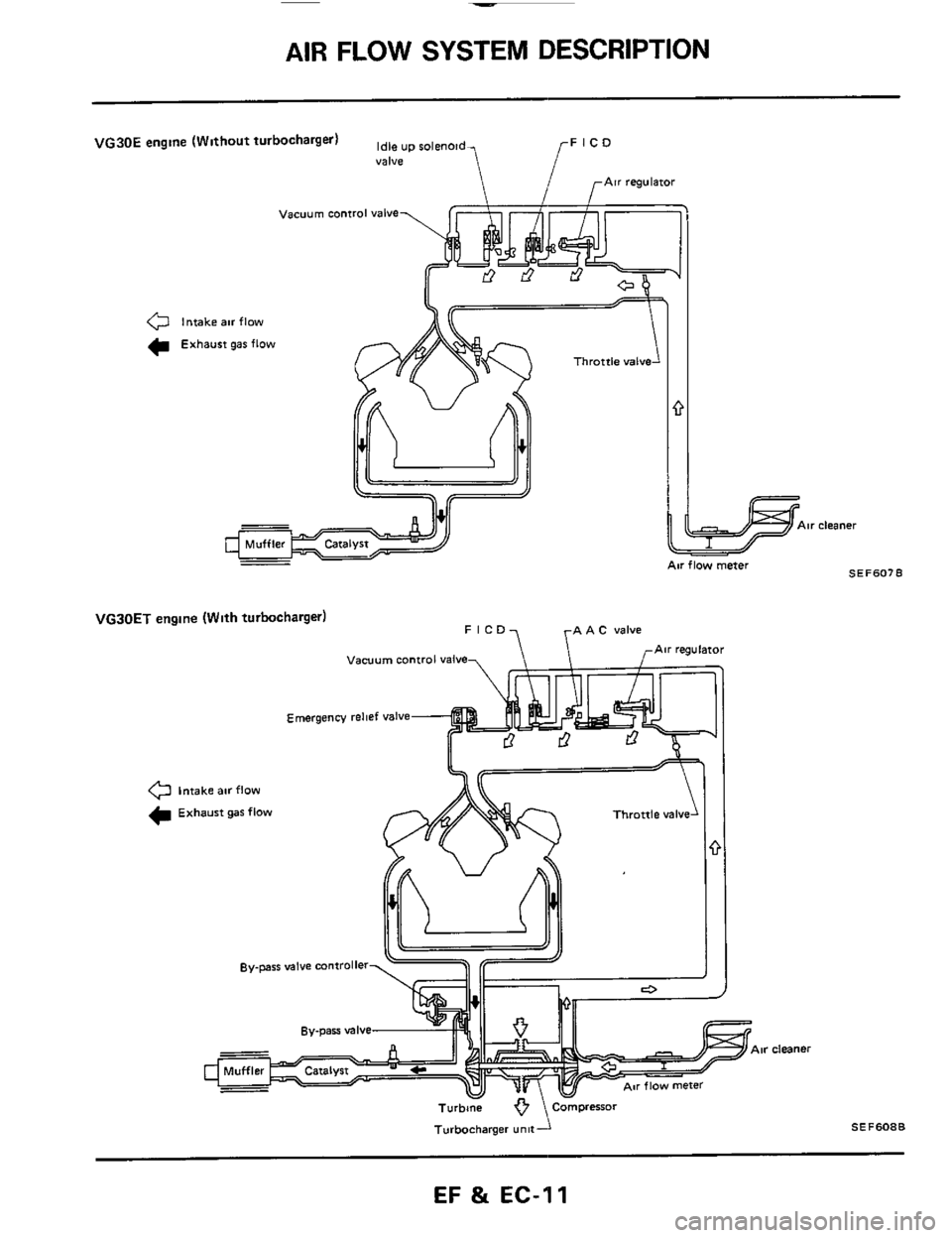

AIR FLOW SYSTEM DESCRIPTION

Air cleaner

VG30E engine (Without turbocharger) up roleno,,, FlCD

r

Valve

0 Intake air flow

C Exhaust gar flow

VGJOET engine (With turbocharger)

Vacuum control valve

Emergency relief valve

0 Intake air flow

Exhaust gar flow

cleaner

Turbbne

Turbocharger - unit- \Compresor SE F 608 B

EF & EC-11

Page 12 of 79

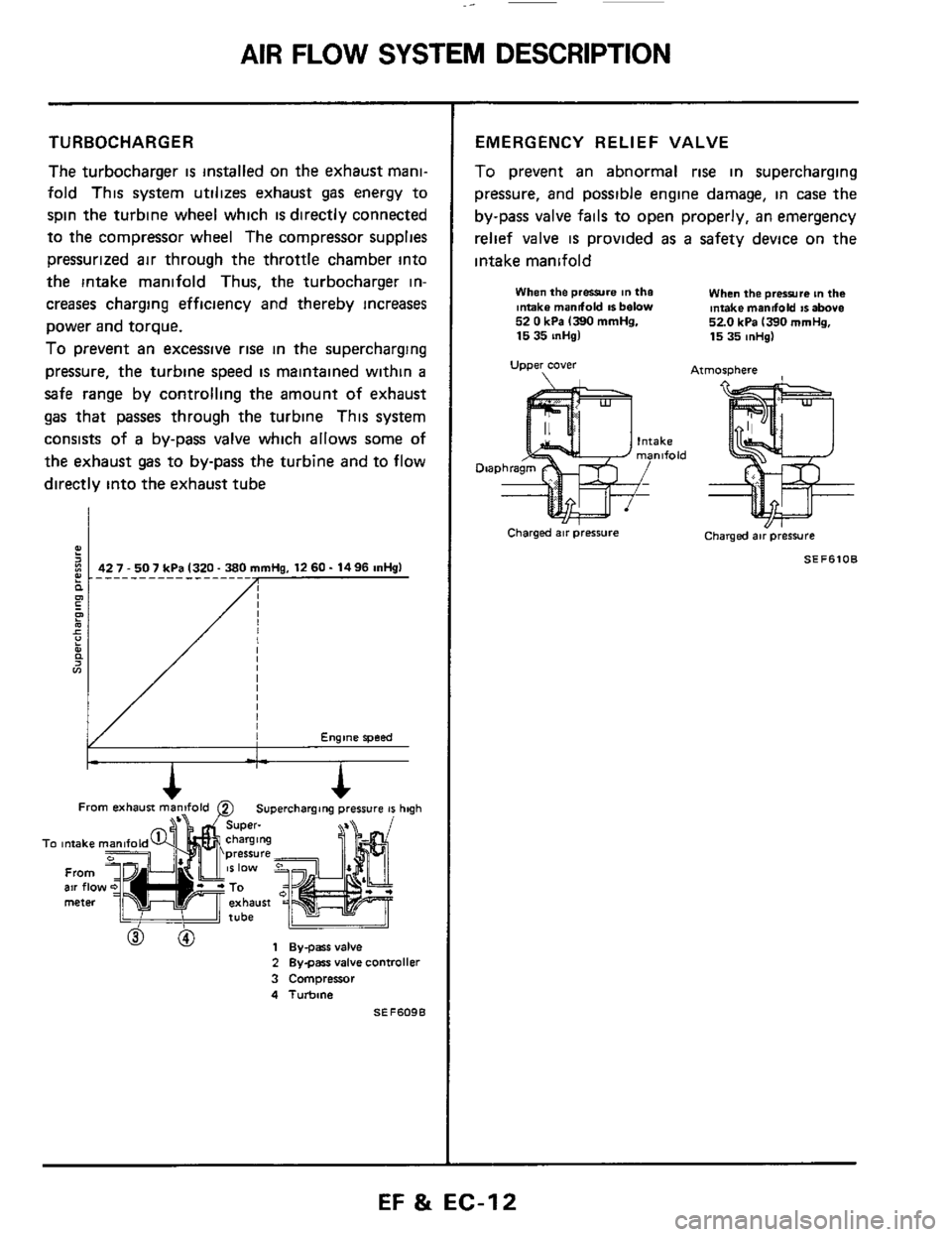

AIR FLOW SYSTEM DESCRIPTION

TURBOCHARGER

The turbocharger is installed on the exhaust mani-

fold This system utilizes exhaust gas energy to

spin the turbine wheel which

is directly connected

to the compressor wheel The compressor supplies

pressurized air through the throttle chamber into

the intake manifold Thus, the turbocharger in-

creases charging efficiency and thereby increases

power and torque.

To prevent an excessive rise in the supercharging

pressure, the turbine speed

is maintained within a

safe range by controlling the amount of exhaust

gas that passes through the turbine This system

consists of

a by-pass valve which allows some of

the exhaust gas to by-pass the turbine and to flow

directly into the exhaust tube

Engine speed

From b==iF exhausi man2fold 0 Superchargang pressure 41 hqh

To intake

From air flo meter

h

To intake

From air flo meter

2 Bygars valve controller

3 Compressor

4 Turbine

SEF609B

EMERGENCY RELIEF VALVE

To prevent an abnormal rise in supercharging

pressure, and possible engine damage, in case

the

by-pass valve fails to open properly, an emergency

relief valve

is provided as a safety device on the

intake manifold

When the prwre in the Intake mandold IS below 52 0 kPa 1390 mmHg. 15 35 inHgl

Upper cover

When the prerrura tn the intake mandold IS above 520 kPa 1390 mrnHg, 15 35 mHg)

Atmosphere

Charged air pressure Charged air pressure

SEF6lOB

EF & EC-12