remove seats NISSAN 300ZX 1984 Z31 Propeller Shaft And Differential Carrier Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 15, PDF Size: 0.66 MB

Page 5 of 15

~

~ DIFFERENTIAL

CARRIER (Tvw R200)

5 Extract drive piruon from carrier

using

a press Take out drive pinion

together with red bearing inner race,

bearing spacer and adjusting washer

6 Remove

od seal

Note Oil seal must not be reused

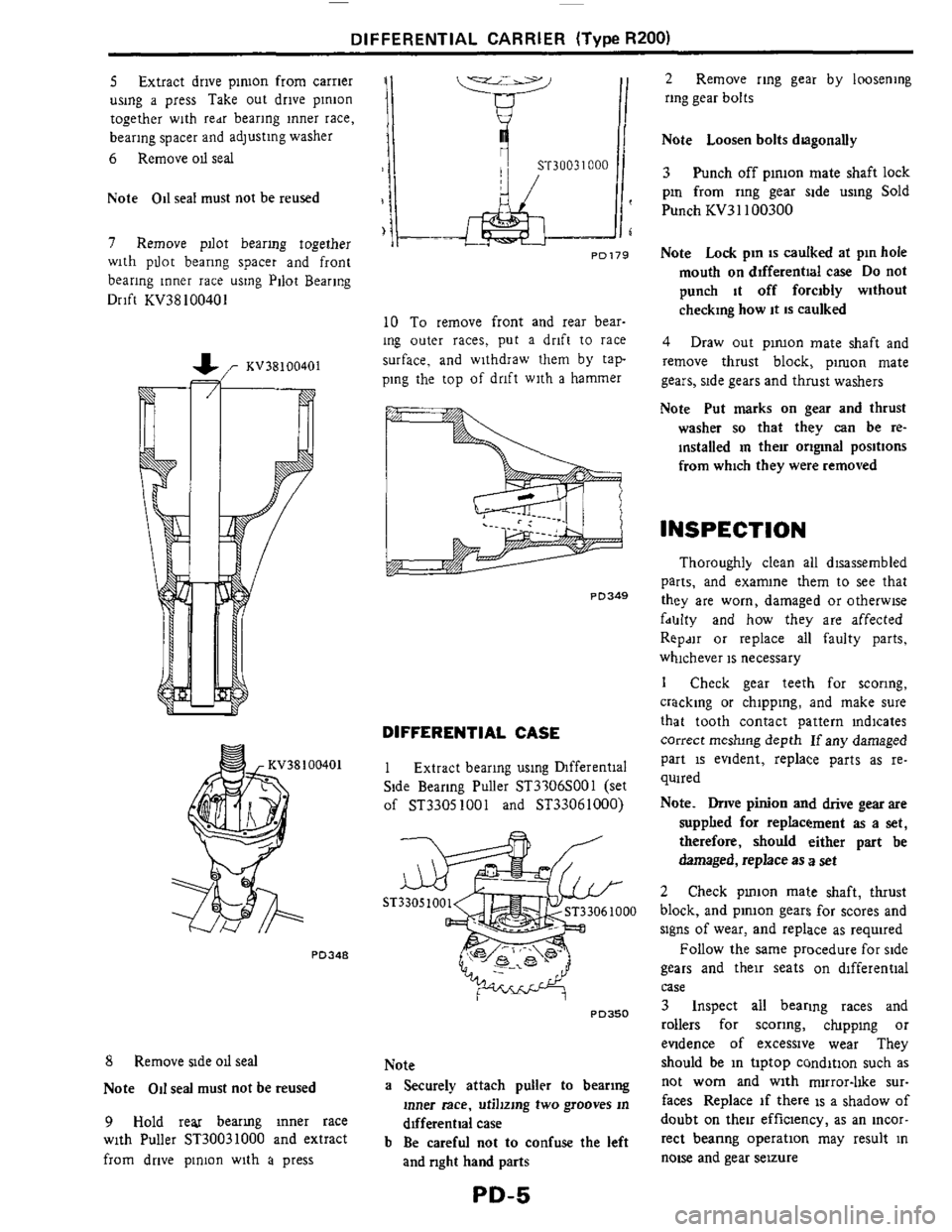

7 Remove pdot bearmg together

with pdot bearing spacer and front

bearing inner race using Pilot Bearing

Drift KV38100401

KV38100401

PD348

8 Remove side od seal

Note Oil seal must

not be reused

9 Hold rear bearmg inner race

with Puller ST30031000 and extract

from drive pinion with

a press

PO179 PO179

10 To remove front and rear bear-

ing outer races, put a drift to race

surface, and withdraw them by tap

ping the top of drift with

a hammer

P D 349

DIFFERENTIAL CASE

1 Extract bearing using Differential

Side Bearing Puller ST3306S001 (set

of ST33051001 and ST33061000)

ST

PD350

Note

a Securely attach puller to bearing

inner race, utilizing two grooves

in

ddferential case

b Be careful not to confuse the left

and nght hand parts

PD-5

2 Remove ring gear by loosening

ring gear bolts

Note

Loosen bolts dlagonally

3 Punch off pinion mate shaft lock

pin from ring gear side using Sold

Punch KV3

1 100300

Note Lock pin is caulked at pin hole

mouth

on differential case Do not

punch it off forcibly without

checking

how it is caulked

4 Draw out pimon mate shaft and

remove thrust block, pimon mate

gears, side gears and thrust washers

Note Put marks on gear and thrust

washer

so that they can be re-

installed in theu oripnal positions

from which they were removed

INSPECTION

Thoroughly clean all disassembled

parts, and examine them to see that

they are worn, damaged

or otherwise

fdulty and how they are affected

Repdir or replace all faulty parts,

whichever is necessary

1 Check gear teeth for scoring,

cracking or chipping, and make sure

that tooth contact pattern indicates

correct

meslung depth If any damaged

part is endent, replace parts

as re-

quired

Note. Drive pinion and drive gear are

supphed for replacement as a set,

therefore, should either part be

damaged, replace

as a set

2 Check pmion mate shaft, thrust

block, and pmion gears for scores and

signs of wear, and replace as required

Follow the same procedure for side

gears and their seats

on differential

case

3 Inspect all bearing races and

rollers for scoring, clupping or

evldence of excessive wear They

should be in tiptop condition such as

not worn and with rmrror-lke sur-

faces Replace if there

is a shadow of

doubt

on their efficiency, as an incor-

rect beanng operation may result

in

noise and gear seuure