POWER STEERING GEAR AND LINKAGE

Disassembly and Assembly (Cont'd)

0 Refer to "Tie-rod inner socket installation",

"Tie-rod installation", and "Rack stroke"

-

ASSEMBLY

Before starting work, thoroughly clean all parts

in cleaning solvent or automatic transmission

fluid "Dexron Type" and blow dry with com-

pressed air,

if available

Do not reuse old oil seal, packing and O-ring

Always

install new ones

When installing oil

seals, use suitable tool

SST548

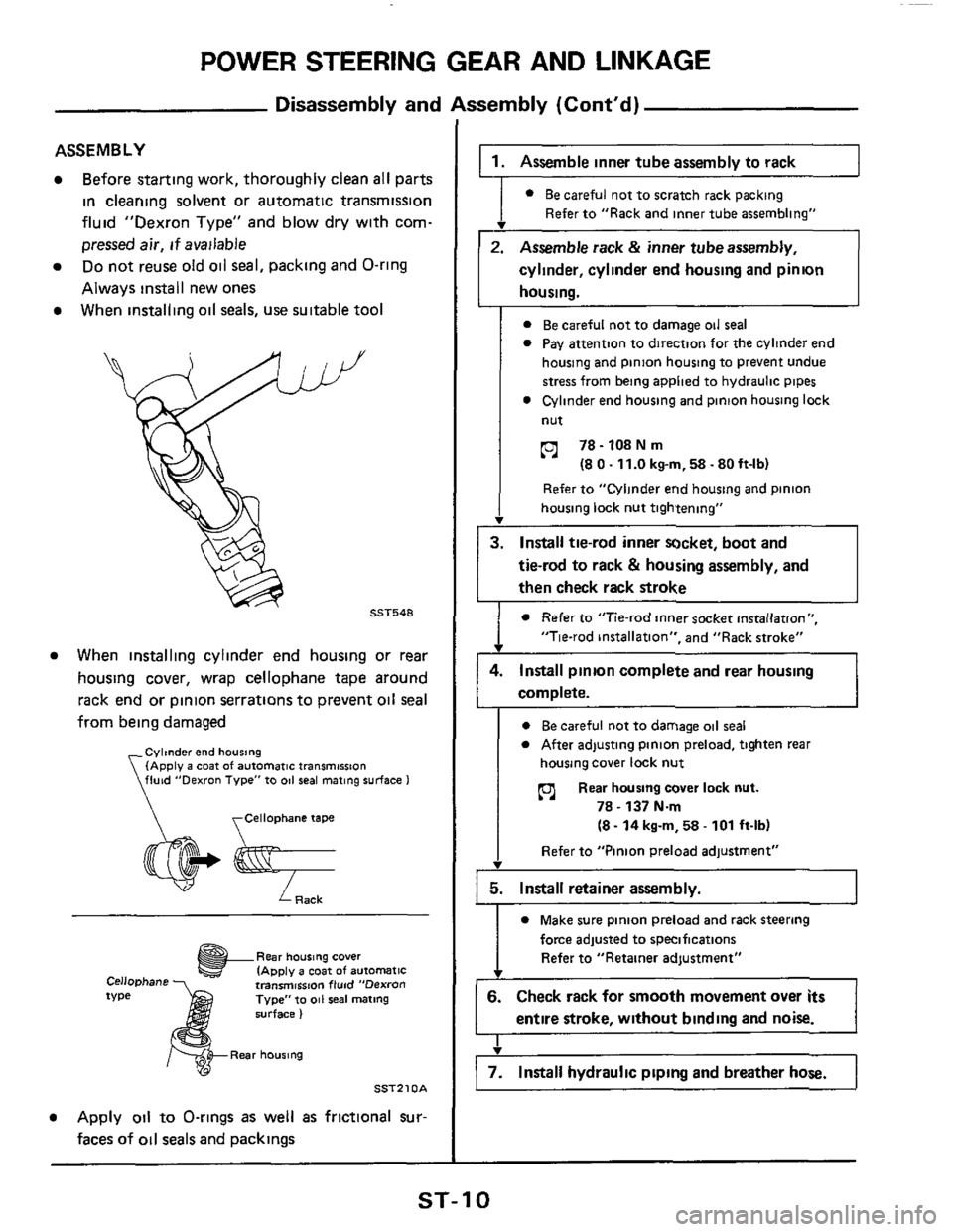

When installing cylinder end housing or rear

housing cover, wrap cellophane tape around

rack end

or pinion serrations to prevent oil seal

from being damaged

Cylmder end housing (Apply a coat of automatrc transmission fluid "Oexron Type" to 081 seal mating surface I

rCellophane tape

a- - Rack

Rear housng cover IA~ply a coat of automatic transmission fluid "Dexron Type" to 011 seal mating

SSTZlOA

Apply oil to O-rings as well as frictional sur.

faces of oil

seals and packings

Refer to "Rack and inner tube assembling" v

2. Assemble rack & inner tube assembly,

cylinder, cylinder end housing and pinion

housina.

I 0 Be careful not to damage oil seal

0 Pay attention to dlrection for the cylinder end

housing and pinion housing to prevent undue

stress from being applied to hydraulic pipes

0 Cylinder end housing and pinion housing lock

nut

p1 78-108Nm

(8 0 . 11.0 kg-m, 58 - 80 ft-lb)

Refer to "Cylinder end housing and pinion

housing lock nut tightening"

4. Install pinion complete and rear housing

complete.

I

0 Be careful not to damage oil seal

0 After adjusting pinion preload, tighten real

housing cover lock nut

p1 78 - 137 N.m

(8 - 14 kg-m, 58. 101 ft-lbl

Rear housing cover lock nut.

Refer to "Pinion preload adjustment"

5. Install retainer assembly.

force adjusted to specifications

Refer to "Retainer adjustment"

6. Check rack for smooth movement over its

entire stroke, without binding and noise. I

7. Install hydraulic piping and breather hose.

ST- 1 0