Engine NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2597 of 2898

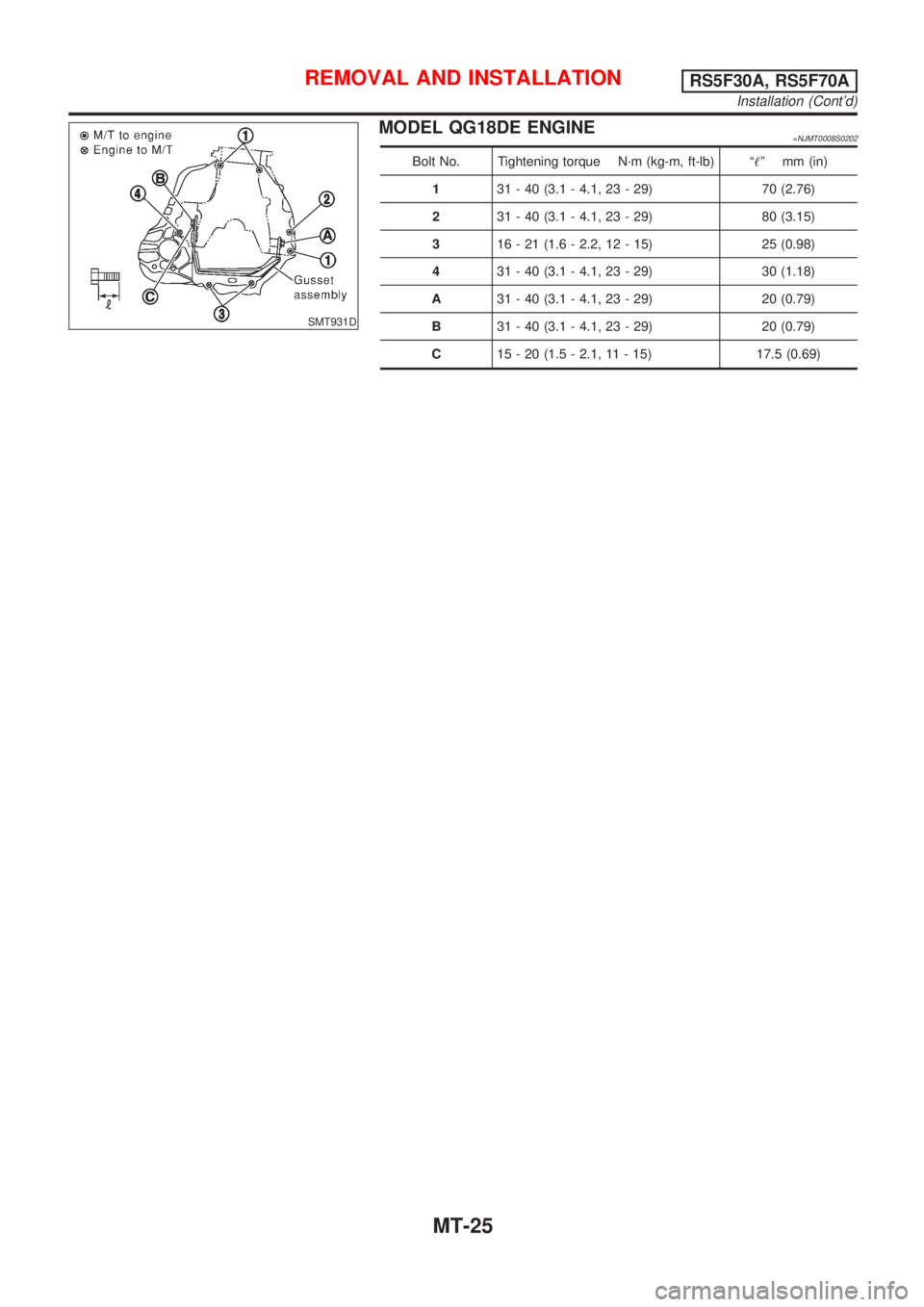

SMT931D

MODEL QG18DE ENGINE=NJMT0008S0202

Bolt No. Tightening torque N´m (kg-m, ft-lb) ª!º mm (in)

131 - 40 (3.1 - 4.1, 23 - 29) 70 (2.76)

231 - 40 (3.1 - 4.1, 23 - 29) 80 (3.15)

316 - 21 (1.6 - 2.2, 12 - 15) 25 (0.98)

431 - 40 (3.1 - 4.1, 23 - 29) 30 (1.18)

A31 - 40 (3.1 - 4.1, 23 - 29) 20 (0.79)

B31 - 40 (3.1 - 4.1, 23 - 29) 20 (0.79)

C15 - 20 (1.5 - 2.1, 11 - 15) 17.5 (0.69)

REMOVAL AND INSTALLATIONRS5F30A, RS5F70A

Installation (Cont'd)

MT-25

Page 2598 of 2898

NJMT0090

SMT928D

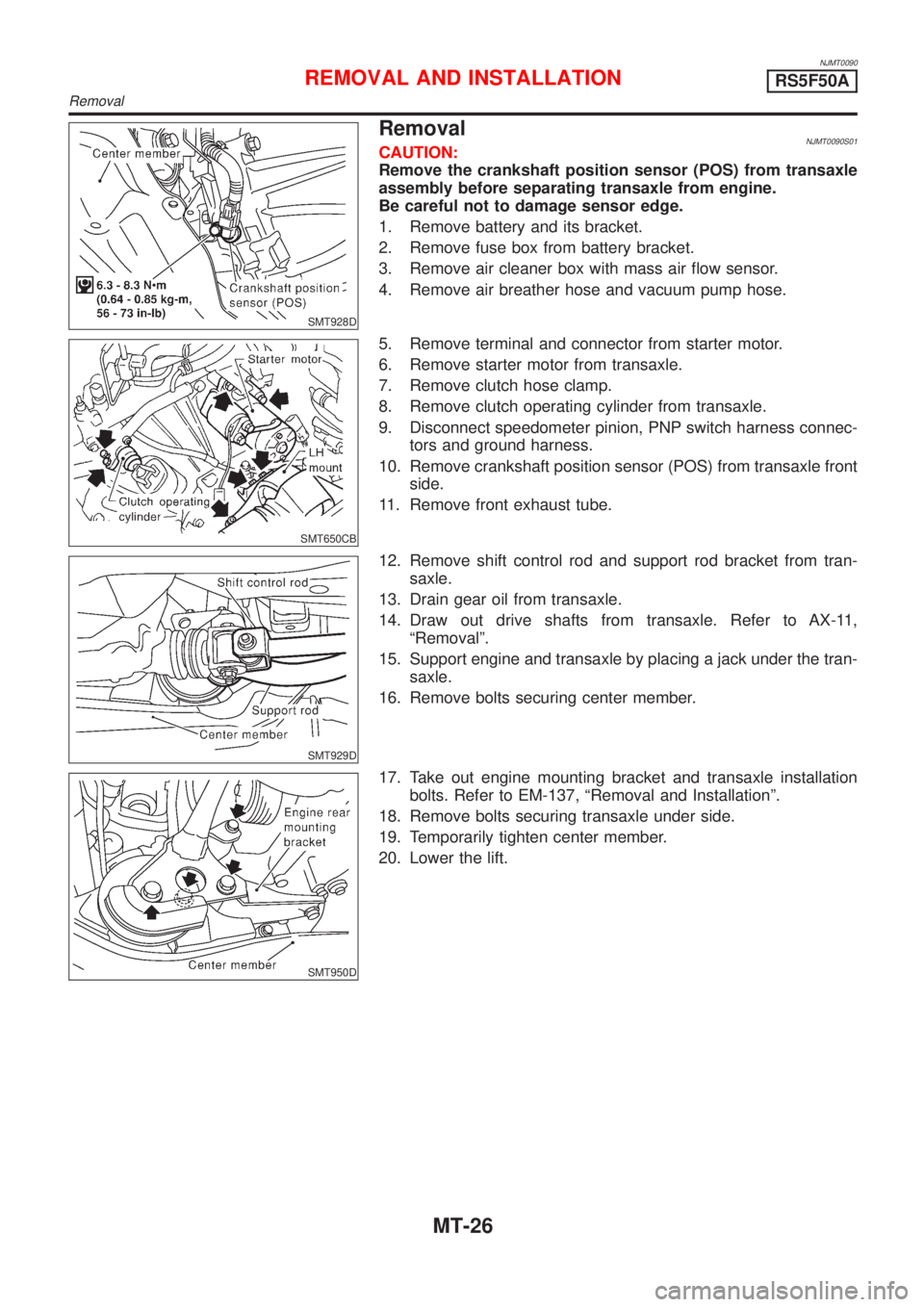

RemovalNJMT0090S01CAUTION:

Remove the crankshaft position sensor (POS) from transaxle

assembly before separating transaxle from engine.

Be careful not to damage sensor edge.

1. Remove battery and its bracket.

2. Remove fuse box from battery bracket.

3. Remove air cleaner box with mass air flow sensor.

4. Remove air breather hose and vacuum pump hose.

SMT650CB

5. Remove terminal and connector from starter motor.

6. Remove starter motor from transaxle.

7. Remove clutch hose clamp.

8. Remove clutch operating cylinder from transaxle.

9. Disconnect speedometer pinion, PNP switch harness connec-

tors and ground harness.

10. Remove crankshaft position sensor (POS) from transaxle front

side.

11. Remove front exhaust tube.

SMT929D

12. Remove shift control rod and support rod bracket from tran-

saxle.

13. Drain gear oil from transaxle.

14. Draw out drive shafts from transaxle. Refer to AX-11,

ªRemovalº.

15. Support engine and transaxle by placing a jack under the tran-

saxle.

16. Remove bolts securing center member.

SMT950D

17. Take out engine mounting bracket and transaxle installation

bolts. Refer to EM-137, ªRemoval and Installationº.

18. Remove bolts securing transaxle under side.

19. Temporarily tighten center member.

20. Lower the lift.

REMOVAL AND INSTALLATIONRS5F50A

Removal

MT-26

Page 2599 of 2898

SMT940D

SMT951D

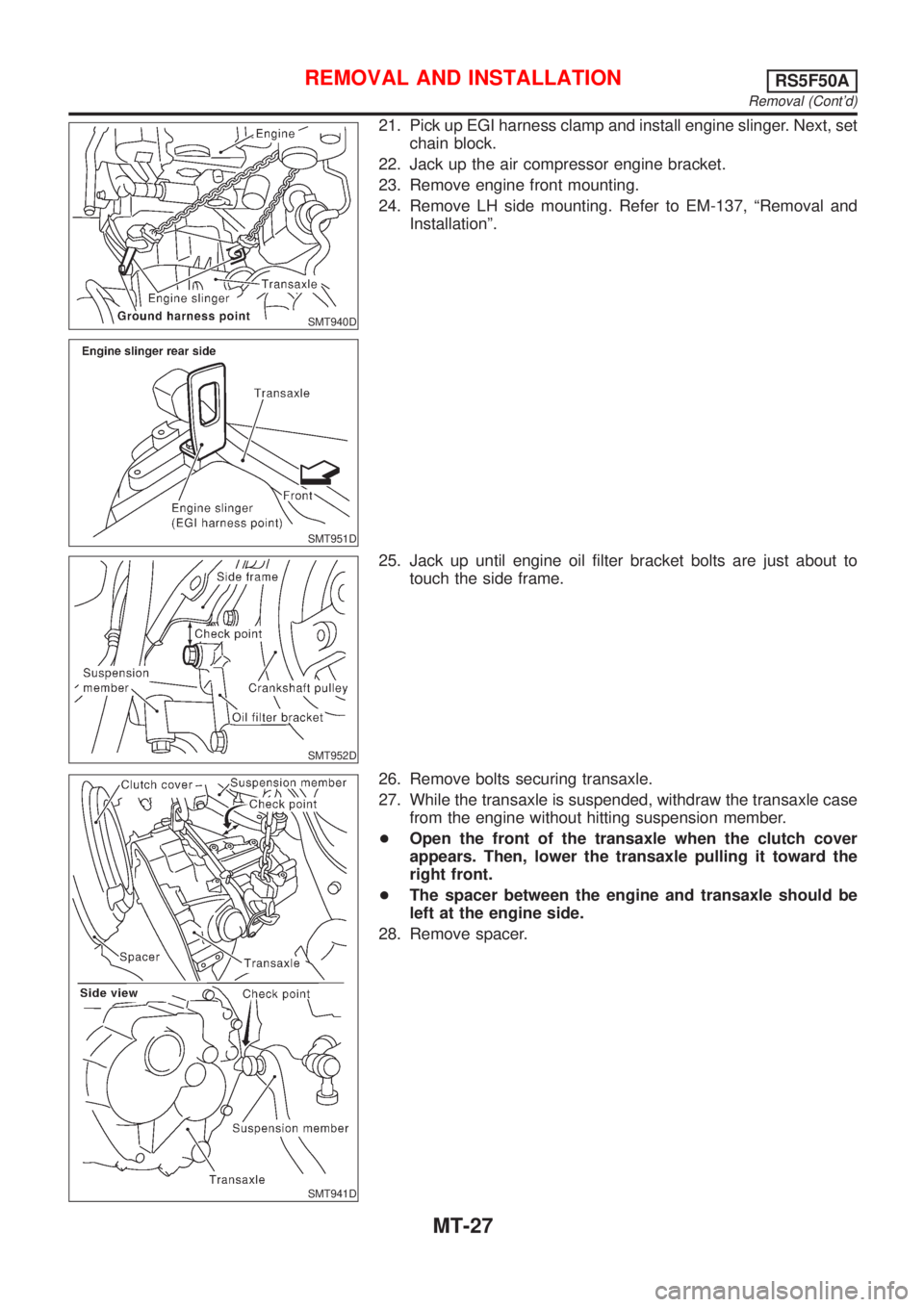

21. Pick up EGI harness clamp and install engine slinger. Next, set

chain block.

22. Jack up the air compressor engine bracket.

23. Remove engine front mounting.

24. Remove LH side mounting. Refer to EM-137, ªRemoval and

Installationº.

SMT952D

25. Jack up until engine oil filter bracket bolts are just about to

touch the side frame.

SMT941D

26. Remove bolts securing transaxle.

27. While the transaxle is suspended, withdraw the transaxle case

from the engine without hitting suspension member.

+Open the front of the transaxle when the clutch cover

appears. Then, lower the transaxle pulling it toward the

right front.

+The spacer between the engine and transaxle should be

left at the engine side.

28. Remove spacer.

REMOVAL AND INSTALLATIONRS5F50A

Removal (Cont'd)

MT-27

Page 2600 of 2898

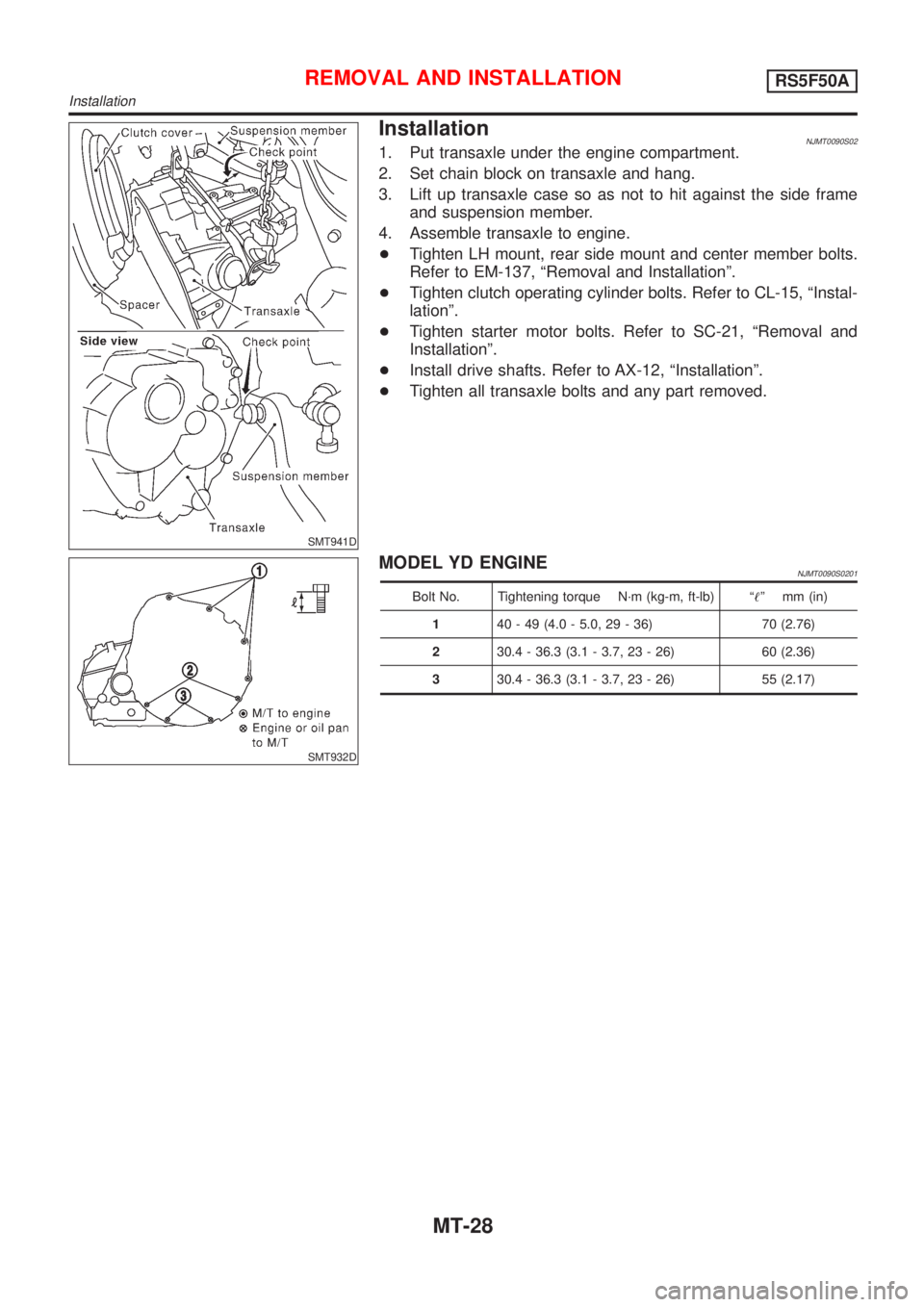

SMT941D

InstallationNJMT0090S021. Put transaxle under the engine compartment.

2. Set chain block on transaxle and hang.

3. Lift up transaxle case so as not to hit against the side frame

and suspension member.

4. Assemble transaxle to engine.

+Tighten LH mount, rear side mount and center member bolts.

Refer to EM-137, ªRemoval and Installationº.

+Tighten clutch operating cylinder bolts. Refer to CL-15, ªInstal-

lationº.

+Tighten starter motor bolts. Refer to SC-21, ªRemoval and

Installationº.

+Install drive shafts. Refer to AX-12, ªInstallationº.

+Tighten all transaxle bolts and any part removed.

SMT932D

MODEL YD ENGINENJMT0090S0201

Bolt No. Tightening torque N´m (kg-m, ft-lb) ª!º mm (in)

140 - 49 (4.0 - 5.0, 29 - 36) 70 (2.76)

230.4 - 36.3 (3.1 - 3.7, 23 - 26) 60 (2.36)

330.4 - 36.3 (3.1 - 3.7, 23 - 26) 55 (2.17)

REMOVAL AND INSTALLATIONRS5F50A

Installation

MT-28

Page 2690 of 2898

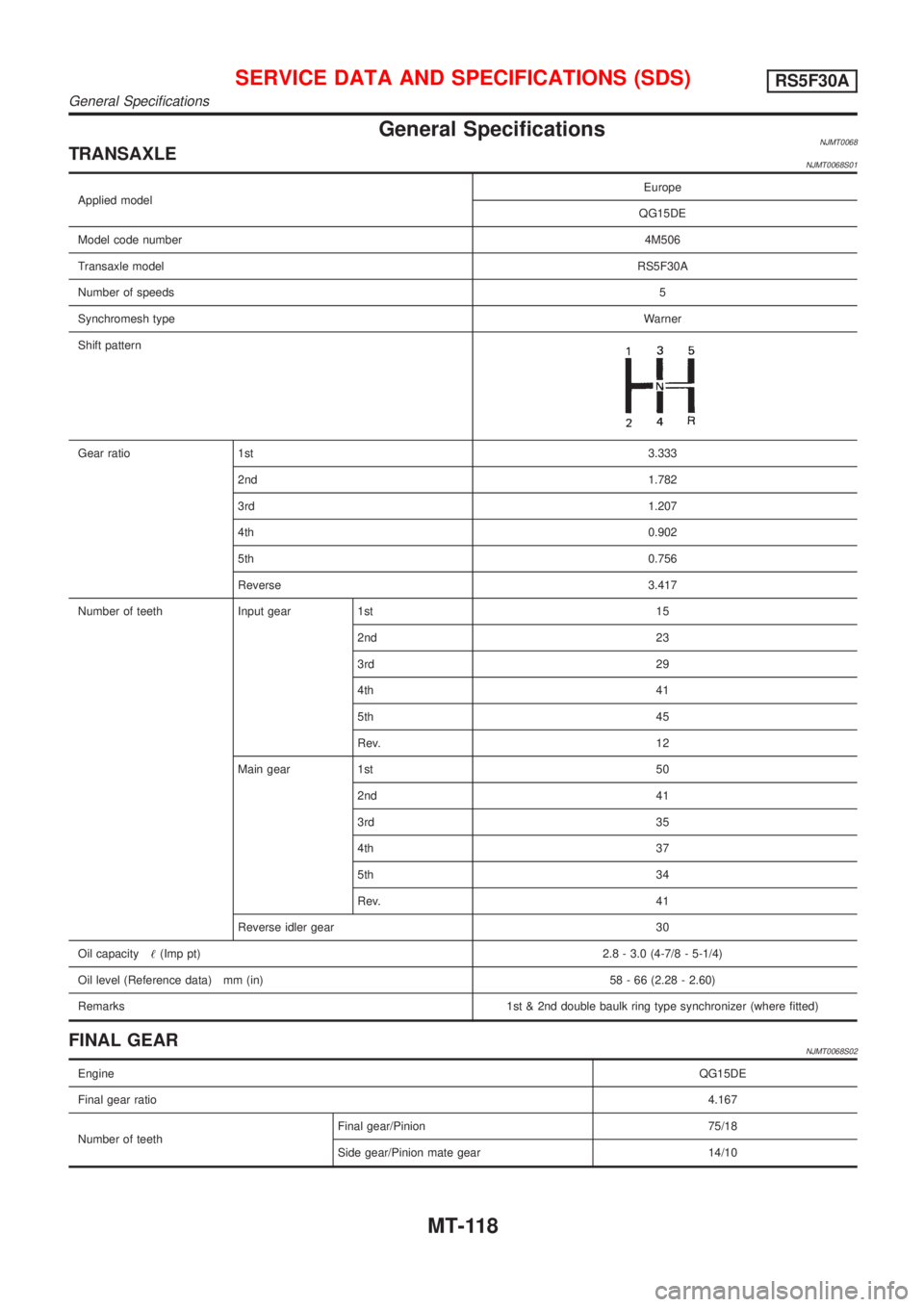

General SpecificationsNJMT0068TRANSAXLENJMT0068S01

Applied modelEurope

QG15DE

Model code number4M506

Transaxle modelRS5F30A

Number of speeds5

Synchromesh typeWarner

Shift pattern

Gear ratio 1st3.333

2nd1.782

3rd1.207

4th0.902

5th0.756

Reverse 3.417

Number of teeth Input gear 1st 15

2nd 23

3rd 29

4th 41

5th 45

Rev. 12

Main gear 1st 50

2nd 41

3rd 35

4th 37

5th 34

Rev. 41

Reverse idler gear 30

Oil capacity!(Imp pt)2.8 - 3.0 (4-7/8 - 5-1/4)

Oil level (Reference data) mm (in) 58 - 66 (2.28 - 2.60)

Remarks1st & 2nd double baulk ring type synchronizer (where fitted)

FINAL GEARNJMT0068S02

EngineQG15DE

Final gear ratio4.167

Number of teethFinal gear/Pinion 75/18

Side gear/Pinion mate gear 14/10

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F30A

General Specifications

MT-118

Page 2695 of 2898

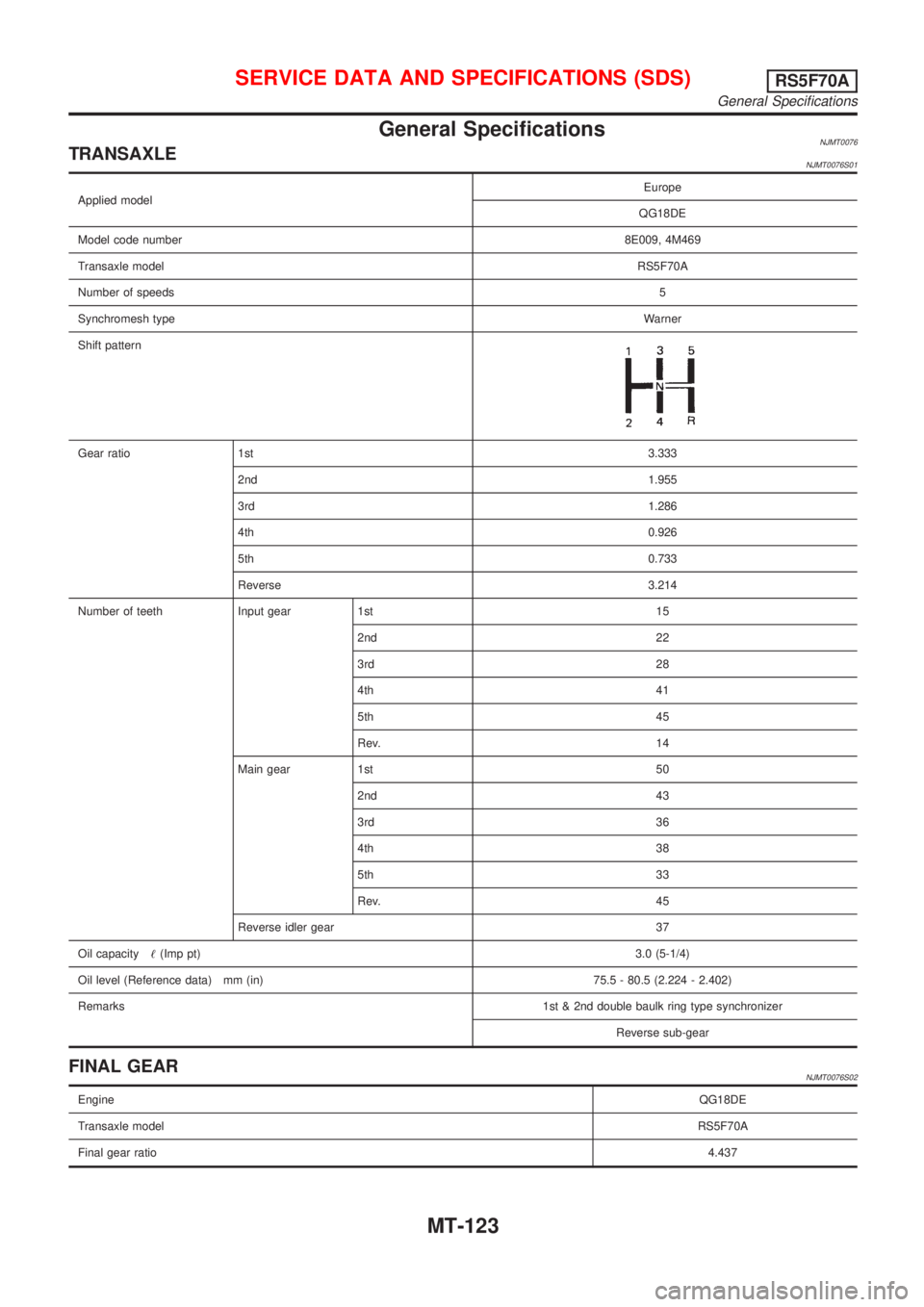

General SpecificationsNJMT0076TRANSAXLENJMT0076S01

Applied modelEurope

QG18DE

Model code number8E009, 4M469

Transaxle modelRS5F70A

Number of speeds5

Synchromesh typeWarner

Shift pattern

Gear ratio 1st3.333

2nd1.955

3rd1.286

4th0.926

5th0.733

Reverse 3.214

Number of teeth Input gear 1st 15

2nd 22

3rd 28

4th 41

5th 45

Rev. 14

Main gear 1st 50

2nd 43

3rd 36

4th 38

5th 33

Rev. 45

Reverse idler gear 37

Oil capacity!(Imp pt)3.0 (5-1/4)

Oil level (Reference data) mm (in) 75.5 - 80.5 (2.224 - 2.402)

Remarks1st & 2nd double baulk ring type synchronizer

Reverse sub-gear

FINAL GEARNJMT0076S02

EngineQG18DE

Transaxle modelRS5F70A

Final gear ratio4.437

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F70A

General Specifications

MT-123

Page 2703 of 2898

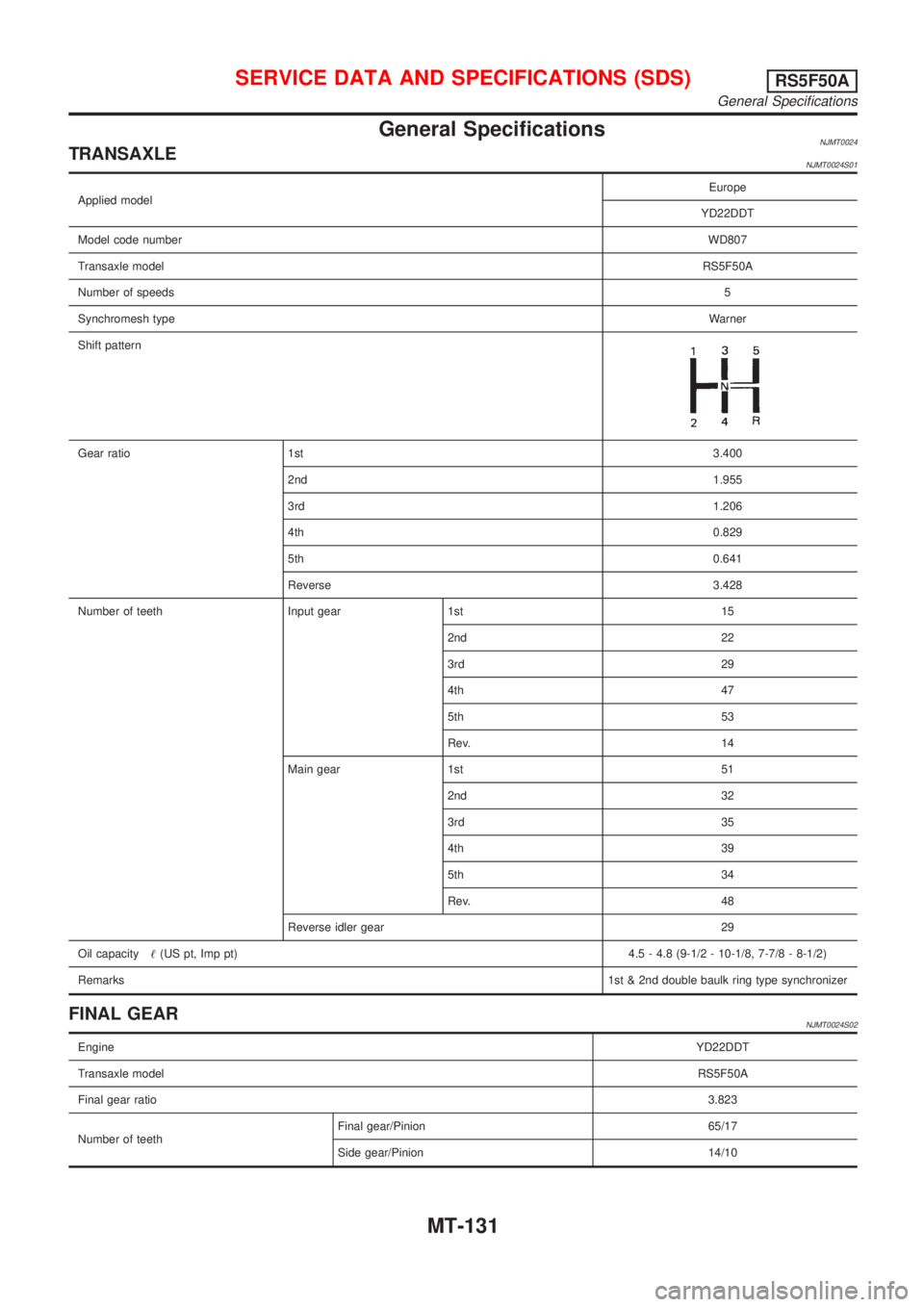

General SpecificationsNJMT0024TRANSAXLENJMT0024S01

Applied modelEurope

YD22DDT

Model code numberWD807

Transaxle modelRS5F50A

Number of speeds5

Synchromesh typeWarner

Shift pattern

Gear ratio 1st3.400

2nd1.955

3rd1.206

4th0.829

5th0.641

Reverse3.428

Number of teeth Input gear 1st 15

2nd 22

3rd 29

4th 47

5th 53

Rev. 14

Main gear 1st 51

2nd 32

3rd 35

4th 39

5th 34

Rev. 48

Reverse idler gear 29

Oil capacity!(US pt, Imp pt)4.5 - 4.8 (9-1/2 - 10-1/8, 7-7/8 - 8-1/2)

Remarks1st & 2nd double baulk ring type synchronizer

FINAL GEARNJMT0024S02

EngineYD22DDT

Transaxle modelRS5F50A

Final gear ratio3.823

Number of teethFinal gear/Pinion 65/17

Side gear/Pinion 14/10

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F50A

General Specifications

MT-131

Page 2797 of 2898

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

METHODS OF PREVENTING OVER-DISCHARGE......3

CHECKING ELECTROLYTE LEVEL............................3

SPECIFIC GRAVITY CHECK......................................4

Battery Test and Charging Chart .................................6

CHART I...................................................................6

CHART II..................................................................7

A: SLOW CHARGE....................................................8

B: STANDARD CHARGE..........................................10

C: QUICK CHARGE................................................. 11

STARTING SYSTEM.....................................................13

System Description ....................................................13

M/T MODELS..........................................................13

A/T MODELS...........................................................13

Wiring Diagram - START -/Sedan .............................14

M/T MODELS..........................................................14

A/T MODELS...........................................................15

Wiring Diagram - START -/Hatchback.......................16

Trouble Diagnoses.....................................................17

Construction ...............................................................18

Removal and Installation ...........................................21

REMOVAL...............................................................21

INSTALLATION........................................................21

Inspection...................................................................21

MAGNETIC SWITCH CHECK...................................21

PINION/CLUTCH CHECK.........................................21

BRUSH CHECK.......................................................22

YOKE CHECK.........................................................23

ARMATURE CHECK................................................23

Assembly ...................................................................24

PINION PROTRUSION LENGTH ADJUSTMENT........24

CHARGING SYSTEM....................................................26

System Description ....................................................26

SEDAN...................................................................26

HATCHBACK...........................................................26

Wiring Diagram - CHARGE -/Sedan .........................27

GASOLINE ENGINE MODELS..................................27

DIESEL ENGINE MODELS.......................................28

Wiring Diagram - CHARGE -/Hatchback...................29

Trouble Diagnoses.....................................................30

WITH IC REGULATOR.............................................30

MALFUNCTION INDICATOR....................................30

Construction ...............................................................31

Removal and Installation ...........................................34

REMOVAL (QG ENGINE).........................................34

REMOVAL (YD ENGINE)..........................................34

INSTALLATION........................................................35

Disassembly...............................................................35

REAR COVER.........................................................35

REAR BEARING......................................................35

Inspection...................................................................35

ROTOR CHECK......................................................35

BRUSH CHECK.......................................................36

STATOR CHECK.....................................................36

Assembly ...................................................................36

RING FITTING IN REAR BEARING...........................36

REAR COVER INSTALLATION.................................37

SERVICE DATA AND SPECIFICATIONS (SDS).........38

Battery........................................................................38

Starter ........................................................................38

Alternator ...................................................................39

Page 2799 of 2898

How to Handle BatteryNJSC0003CAUTION:

If it becomes necessary to start the engine with a booster

battery and jumper cables,

1) Use a 12-volt booster battery.

2) After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

MEL040F

METHODS OF PREVENTING OVER-DISCHARGENJSC0003S01The following precautions must be taken to prevent over-discharg-

ing a battery.

+The battery surface (particularly its top) should always be kept

clean and dry.

+The terminal connections should be clean and tight.

+At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

MEL041F

+When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

MEL042F

+Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVELNJSC0003S02WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

BATTERY

How to Handle Battery

SC-3

Page 2809 of 2898

System DescriptionNJSC0004M/T MODELSNJSC0004S01Power is supplied at all times

+through 40A fusible link (letterB, located in the fuse and fusible link box)

+to ignition switch terminal 1.

With the ignition switch in START position, power is supplied

+from ignition switch terminal 5

+to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

A/T MODELSNJSC0004S02Power is supplied at all times

+through 40A fusible link (letterB, located in the fuse and fusible link box)

+to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

+from ignition switch terminal 5

+to park/neutral position relay terminal 5.

With the ignition switch ON or START position, power is supplied

+through 10A fuse [No. 20, located in the fuse block (J/B)]

+to park/neutral position (PNP) relay terminal 1.

With the selector lever in the P or N position, ground is supplied

+to park/neutral position relay terminal 2 through the park/neutral position switch

+from body grounds, F9 and F10.

Then park/neutral position relay is energized and power is supplied

+from park/neutral position relay terminal 3

+to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

STARTING SYSTEM

System Description

SC-13